DC charging terminal automatic wire welder

A charging terminal, automatic welding technology, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of low degree of automation, high processing efficiency, and long wire transfer time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

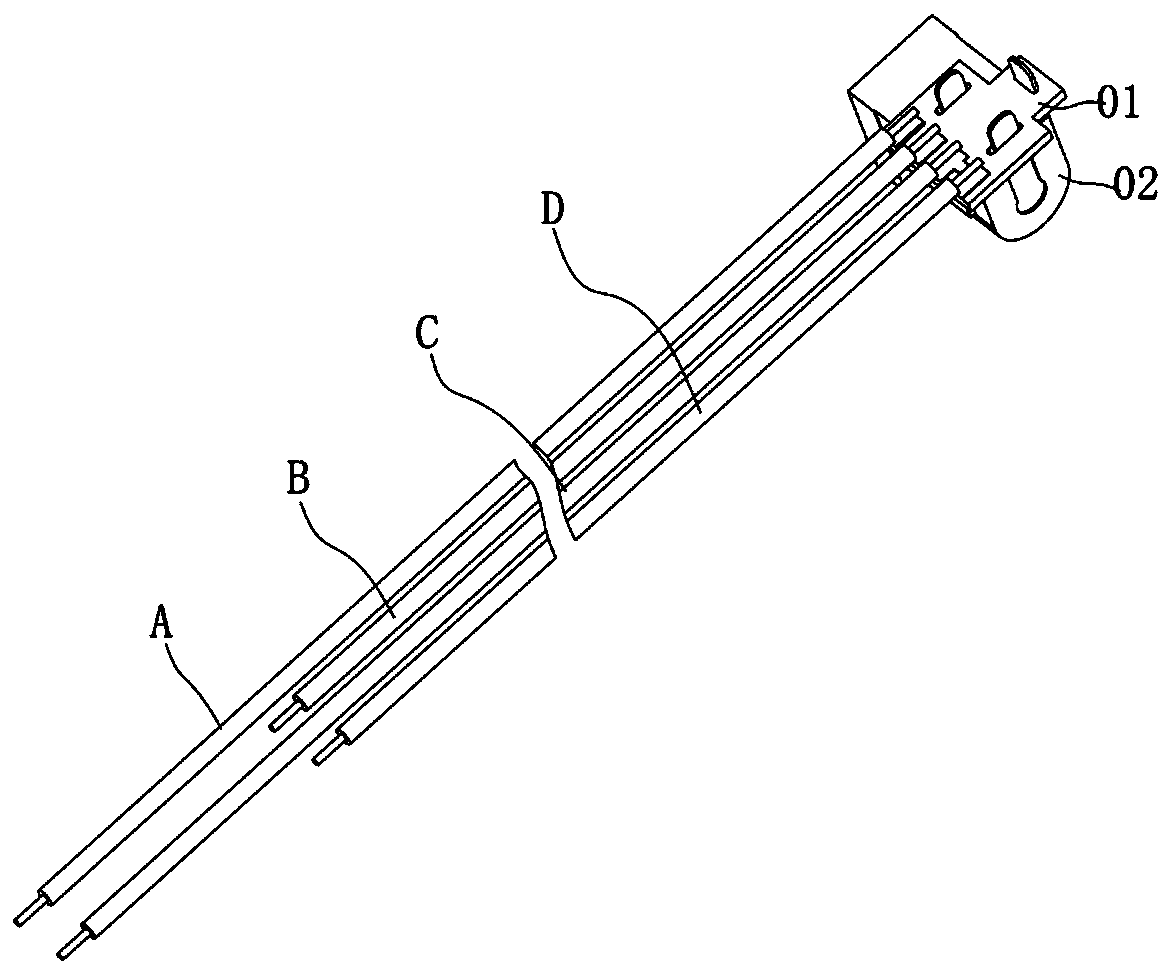

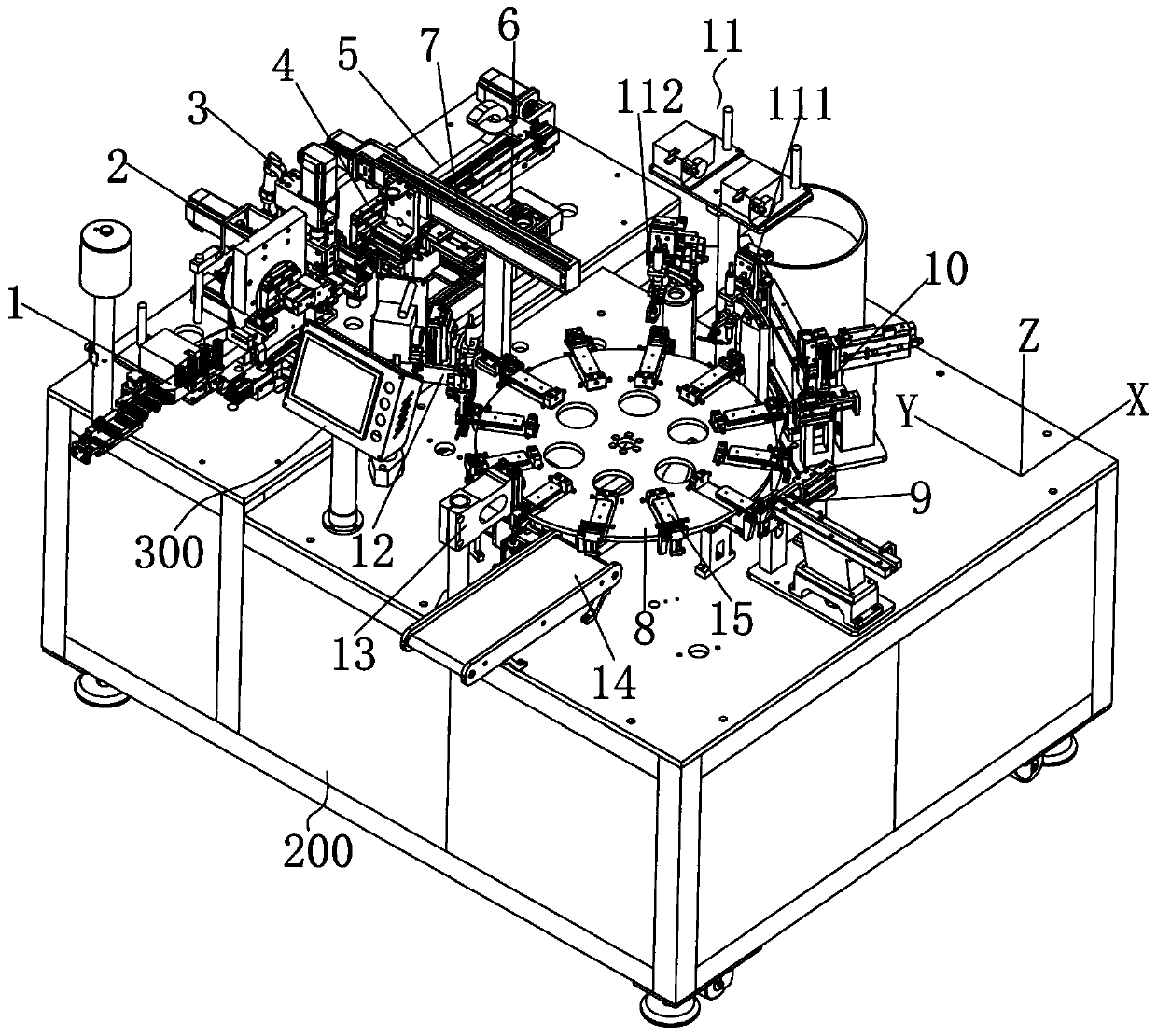

[0036] attached Figure 1-17 Embodiment A kind of embodiment of the present invention, refer to appended Figure 1-17 , an automatic DC charging terminal welding machine, which includes a frame 200 and a control system 300 (PLC controller), and also includes:

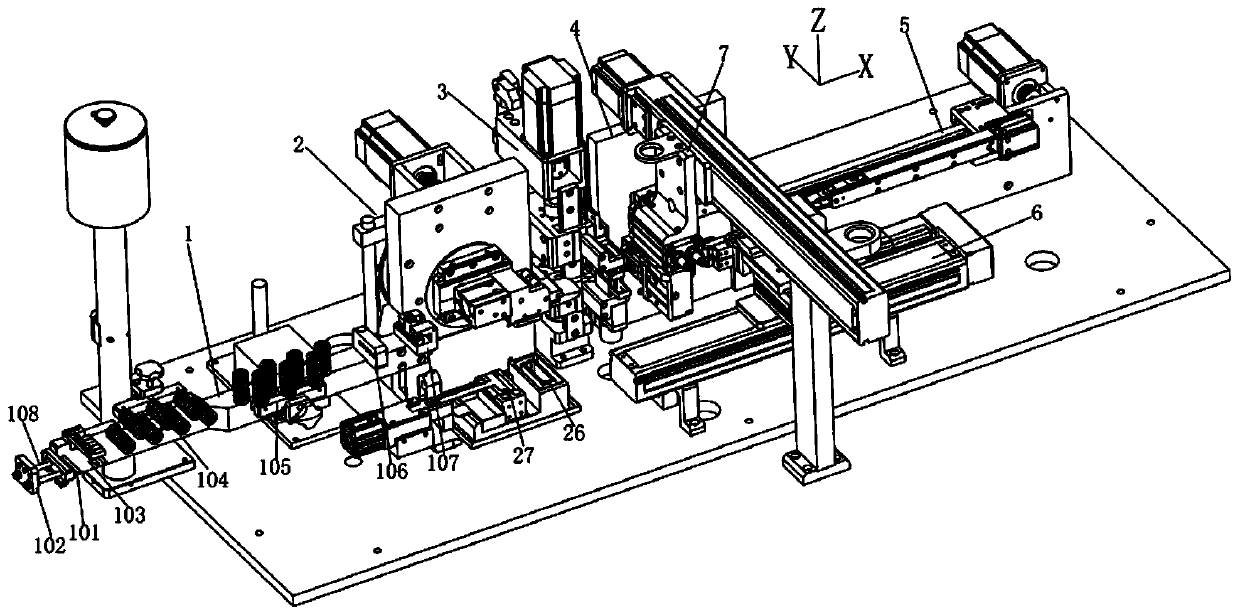

[0037] The wire processing mechanism 400 includes a wire passing frame assembly 1, a tinning assembly 2, a wire cutting and stripping assembly 3, a stripping assembly 4, a long pull wire assembly 5, and a pull wire assembly 6 arranged along the X direction of the frame 200 and arranged along the Y direction. The wire feeding assembly 7; the tinning assembly 2, the cutting and stripping assembly 3, the stripping assembly 4, the long pull wire assembly 5, the pull wire assembly 6 and the wire feeding assembly 7 are movable butt joints at the cutting station. Active docking means that the tinning compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com