A kind of flexible steel dam construction method

A construction method and technology for steel dams, applied in sea area engineering, water conservancy engineering, construction, etc., can solve many problems, achieve the effects of preventing displacement, safe and reliable operation, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

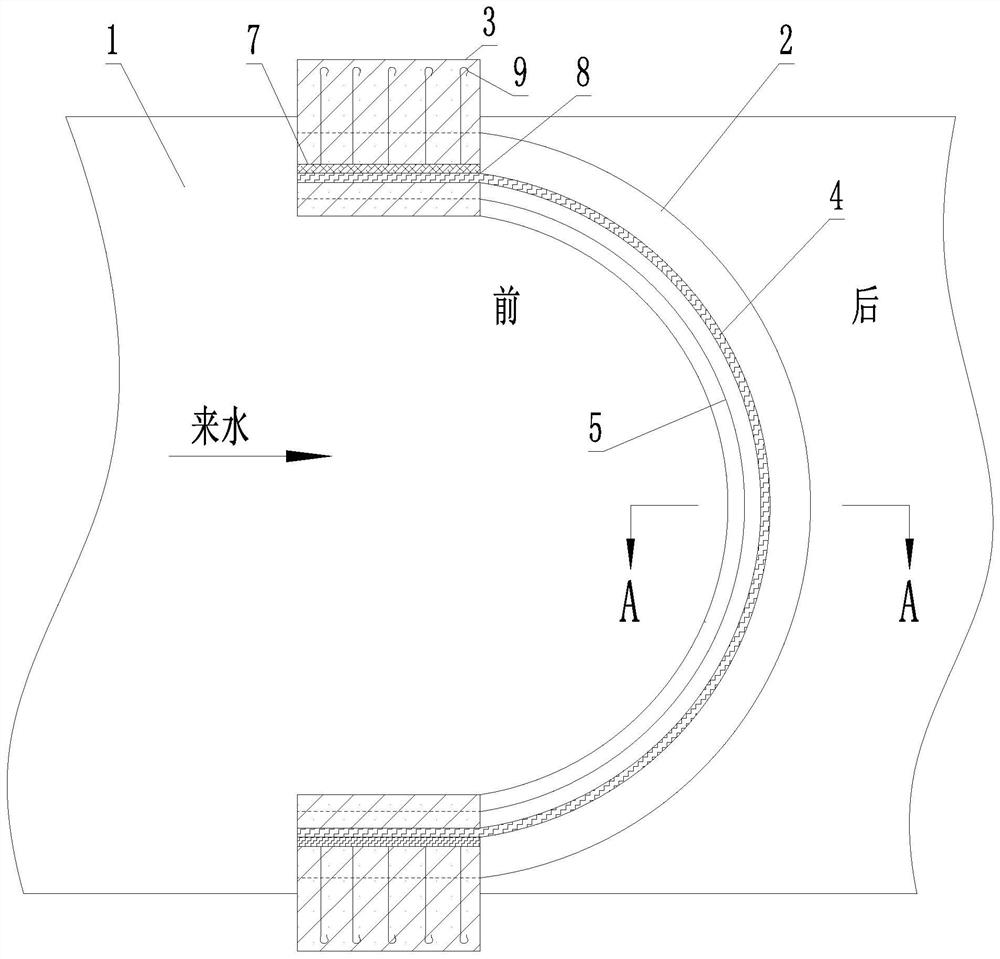

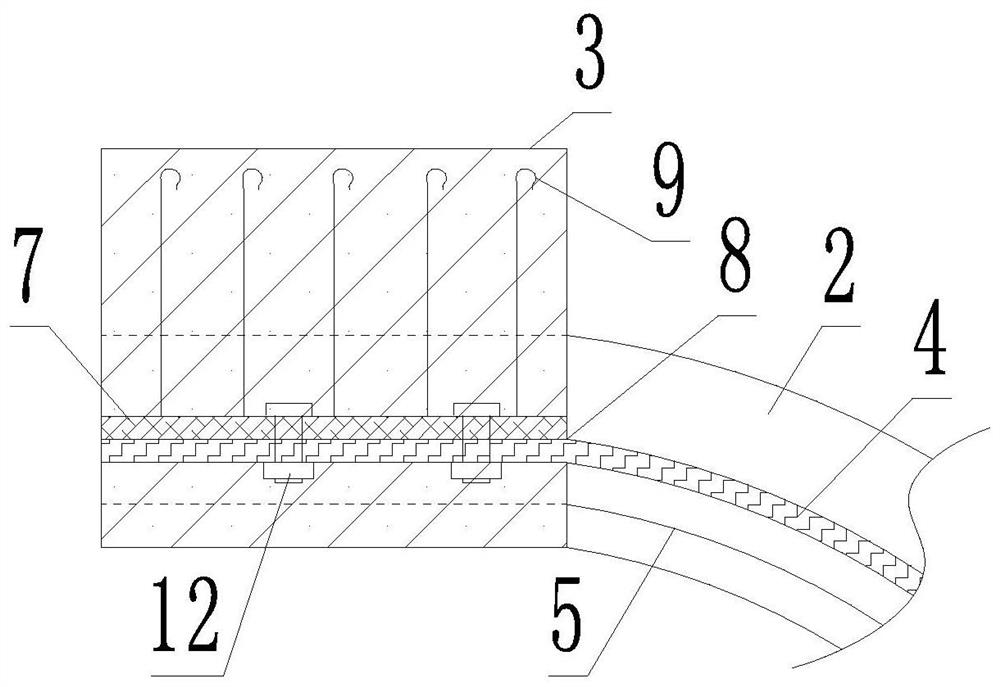

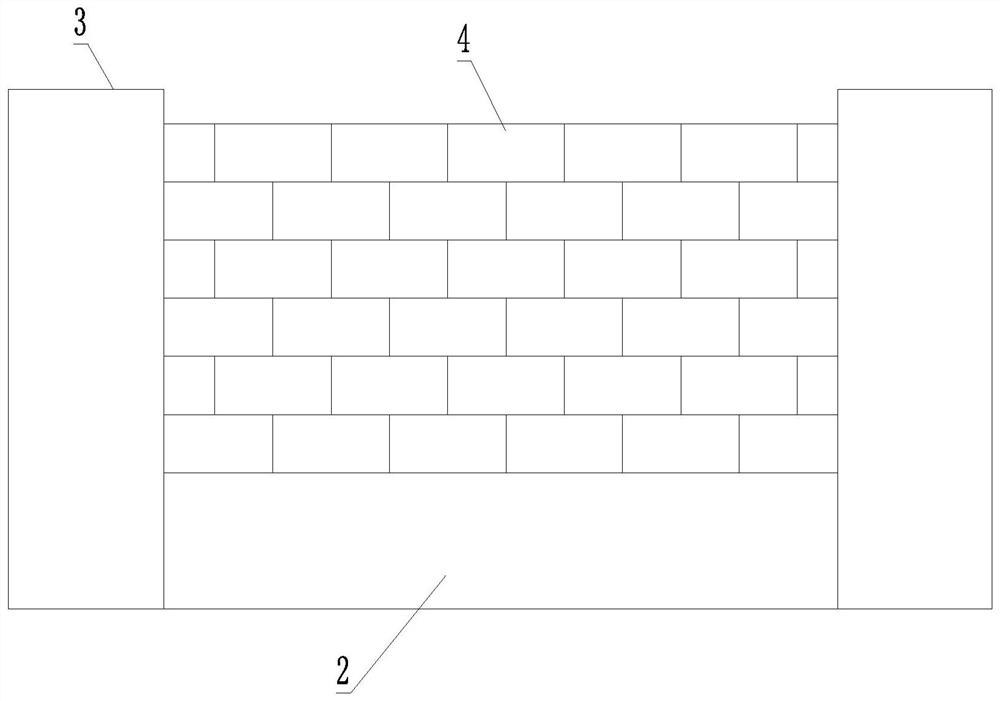

[0039] like Figure 1-9 As shown, this embodiment proposes a flexible steel dam, wherein the flexible steel dam includes a dam body 4, a concrete base 2, a concrete abutment 3, and a channel steel 5, wherein the concrete base 2 is along the width direction of the reservoir area 1 Construction; the concrete base 2 is provided with a channel steel 5, and the channel steel 5 can be a straight channel steel 5 or an arc-shaped channel steel 5, and is preferably an arc-shaped channel steel 5 in this embodiment; so the concrete base 2 is also The bottom of the dam body 4 is connected to the notch of the channel steel 5, and it is fixed by welding; A plurality of steel plate units welded to each other, the dam body layers are connected as a whole by welding, and the steel plate units in the dam body 4 are welded by staggered seam; The dam abutment 3 is built on the river bank, the bottom of the concrete abutment 3 is connected with the concrete base 2, and the dam body 4, the concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com