Intensive vehicle body drying system and drying method

A drying system, intensive technology, applied in conveyors, pretreatment surfaces, devices for coating liquids on surfaces, etc., can solve the problems of poor length of car body drying chambers, affecting automobile production rhythm, and low utilization rate of heat energy. , to achieve the effect of improving the production cycle, reducing the difficulty of smoke leakage protection, and high utilization of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

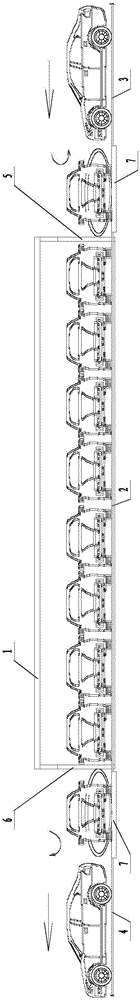

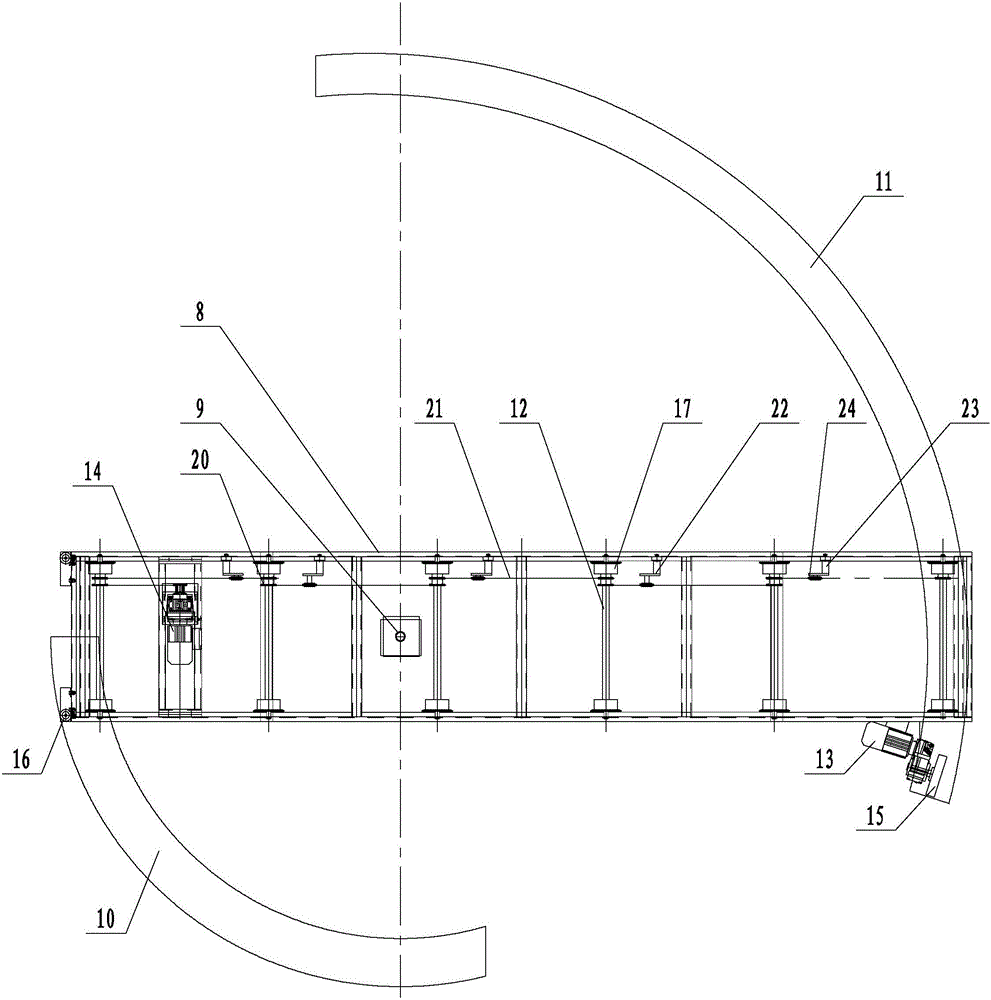

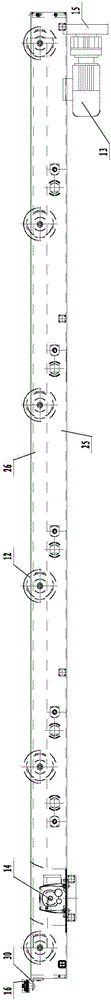

[0023] Embodiment: a kind of intensive body drying system (see attached Figures 1 to 4), including the drying room 1, the conveying ground chain 2 installed on the ground in the drying room, the input transmission mechanism 3 and the output transmission mechanism 4 arranged outside the drying room, and the drying room is equipped with the input transmission mechanism and the output transmission mechanism respectively Correspondingly provided input port 5 and output port 6, a type transfer mechanism 7 is installed between the input port outside the drying room and the input transmission mechanism and between the output port and the output transmission mechanism. The type transfer mechanism includes a type transfer frame 8, a steering column 9. The front slide rail 10, the rear slide rail 11, and the steering pillar are rotatably connected to the lower end of the shifting frame, on which a number of parallel wheel rollers 12 are rotatably connected, and the body conveying motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com