Mold detection method for electric injection molding machine

A detection method and injection molding machine technology, applied to computer parts, character and pattern recognition, instruments, etc., can solve problems such as plastic residue, mold damage, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

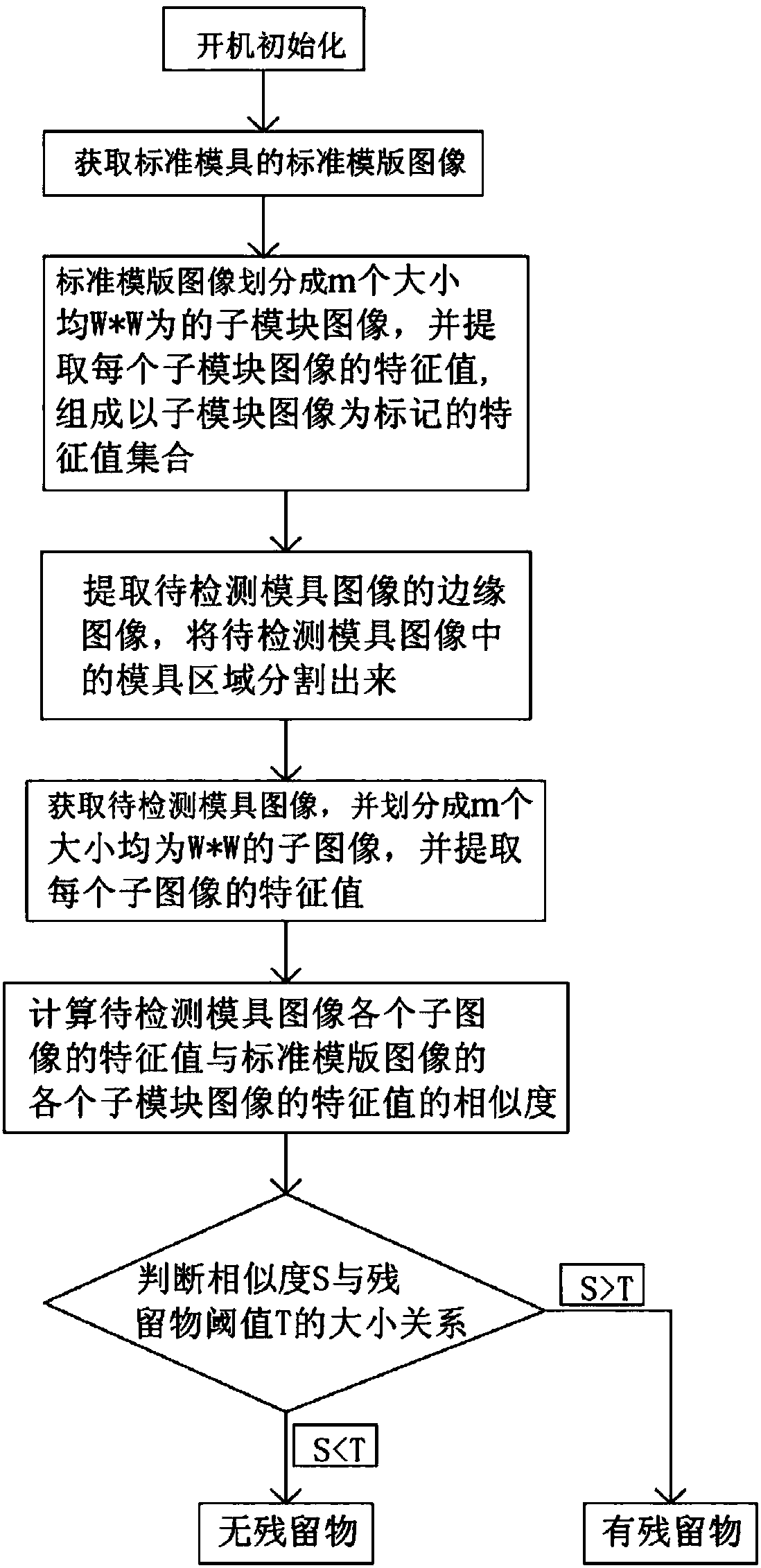

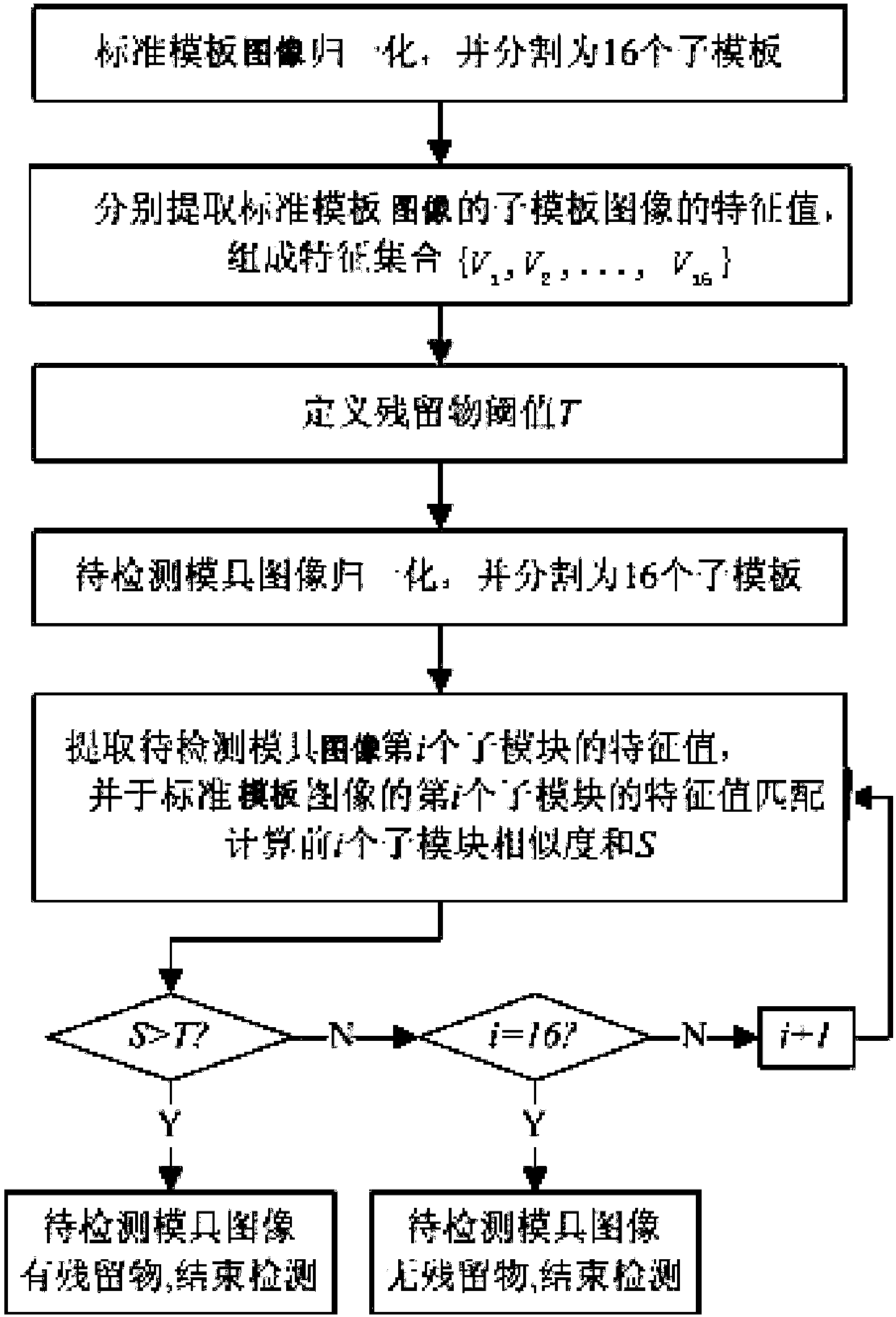

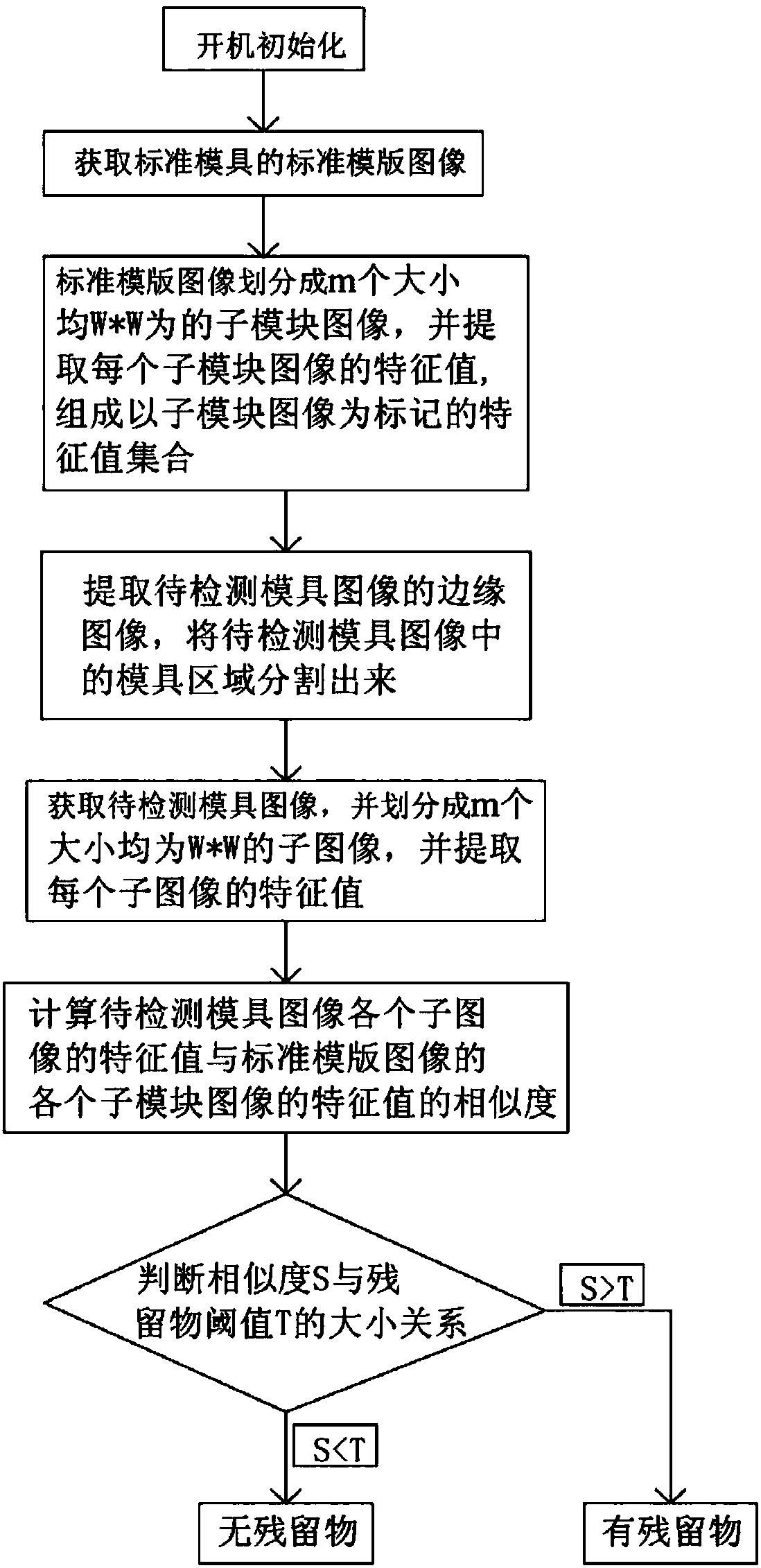

[0059] as attached figure 1 with 2 Shown, a kind of electric injection molding machine mold detection method of the present invention comprises the following steps:

[0060] S1, obtain a rectangular standard mold image without residue as a standard template image, extract the edge image of the standard template image, remove the background area of the standard template image to obtain the mold area, and normalize the size of the standardized template image to L× L size, divide the standard template image into m sub-module images with the size of W×W, extract the eigenvalues of each sub-module image, and form a eigenvalue set marked by the sub-module image:

[0061]

[0062] Let the residue threshold in the standard template image be T. The eigenvalues of sub-module images include energy m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com