Kitchen sewage treatment method

A sewage treatment method and kitchen technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc. Long and other problems, to achieve the effect of simple assembly, small footprint, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

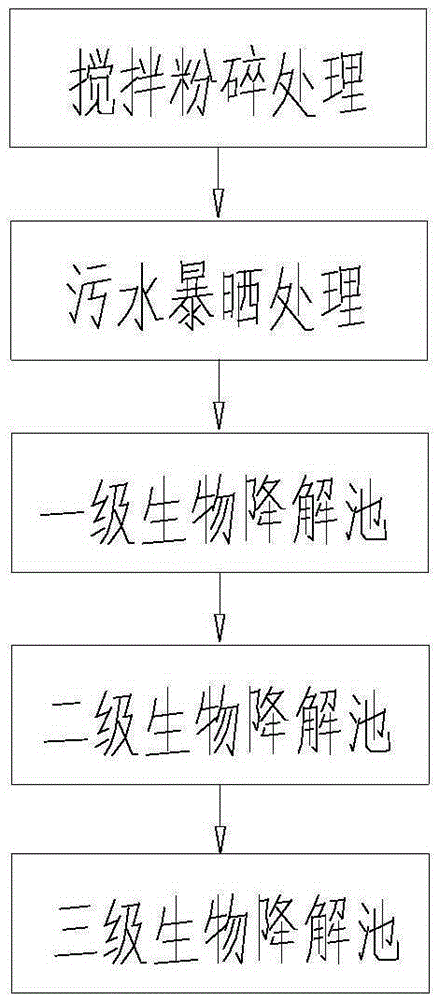

[0025] A kind of kitchen sewage treatment method, comprises the steps:

[0026] 1) Stirring and crushing treatment, the collected kitchen sewage is stirred and crushed;

[0027] 2) Sewage exposure treatment, the sewage obtained in step 1) is put into a barrel, and exposed to the sun for 5 days;

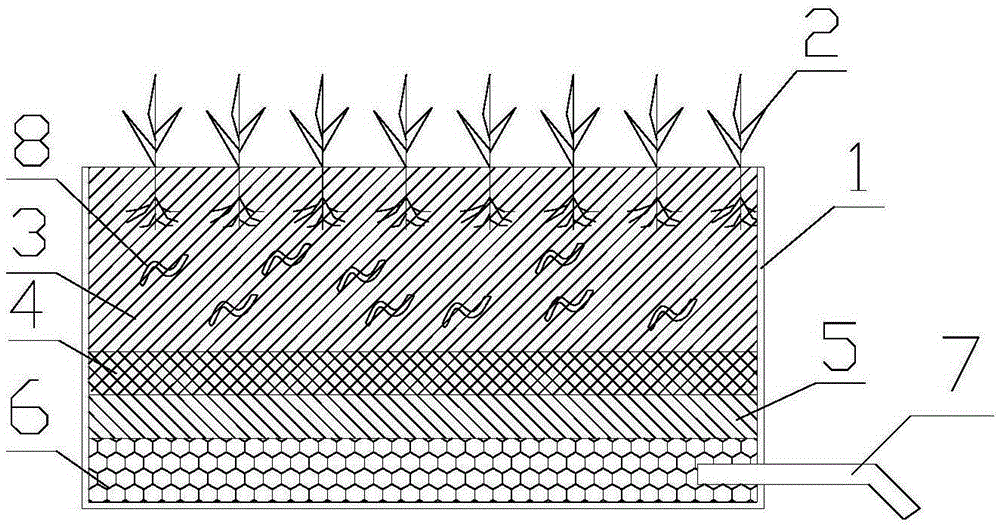

[0028] 3) First-level biodegradation treatment, the sewage obtained in step 2) is put into a first-level biodegradation treatment pool, and the first-level biodegradation treatment pool includes a pool body 1, a plurality of plants 2, a soil layer 3, and a plurality of earthworms 8. The sand layer 4, the first stone layer 5 and the second stone layer 6, the bottom of the pool body 1 has a through hole, and one end of the flexible pipe 7 is installed on the through hole, and the flexible pipe 7 The other end is provided with a clip; the second stone layer 6 is laid on the bottom of the pool body 1, and the first stone layer 5, sand layer 4, and soil layer 3 are successively laid on th...

Embodiment 2

[0038] A kind of kitchen sewage treatment method, comprises the steps:

[0039] 1) Stirring and crushing treatment, the collected kitchen sewage is stirred and crushed;

[0040] 2) sewage exposure treatment, the sewage obtained in step 1) is put into a barrel, and exposed to the sun for 7 days;

[0041] 3) First-level biodegradation treatment, the sewage obtained in step 2) is put into a first-level biodegradation treatment pool, and the first-level biodegradation treatment pool includes a pool body 1, a plurality of plants 2, a soil layer 3, and a plurality of earthworms 8. The sand layer 4, the first stone layer 5 and the second stone layer 6, the bottom of the pool body 1 has a through hole, and one end of the flexible pipe 7 is installed on the through hole, and the flexible pipe 7 The other end is provided with a clip; the second stone layer 6 is laid on the bottom of the pool body 1, and the first stone layer 5, sand layer 4, and soil layer 3 are successively laid on th...

Embodiment 3

[0051] A kind of kitchen sewage treatment method, comprises the steps:

[0052] 1) Stirring and crushing treatment, the collected kitchen sewage is stirred and crushed;

[0053] 2) sewage exposure treatment, the sewage obtained in step 1) is put into a barrel, and exposed to the sun for 9 days;

[0054] 3) First-level biodegradation treatment, the sewage obtained in step 2) is put into a first-level biodegradation treatment pool, and the first-level biodegradation treatment pool includes a pool body 1, a plurality of plants 2, a soil layer 3, and a plurality of earthworms 8. The sand layer 4, the first stone layer 5 and the second stone layer 6, the bottom of the pool body 1 has a through hole, and one end of the flexible pipe 7 is installed on the through hole, and the flexible pipe 7 The other end is provided with a clip; the second stone layer 6 is laid on the bottom of the pool body 1, and the first stone layer 5, sand layer 4, and soil layer 3 are successively laid on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com