Pretreatment method of cunninghamia lanceolata floor board material

A pretreatment and flooring technology, applied in wood treatment, wood treatment details, impregnated wood, etc., can solve problems such as unfavorable sustainable development of Chinese fir plantations, low fir prices, poor anti-deformation ability of fir, etc., and achieve scientific and reasonable process design. , good performance, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

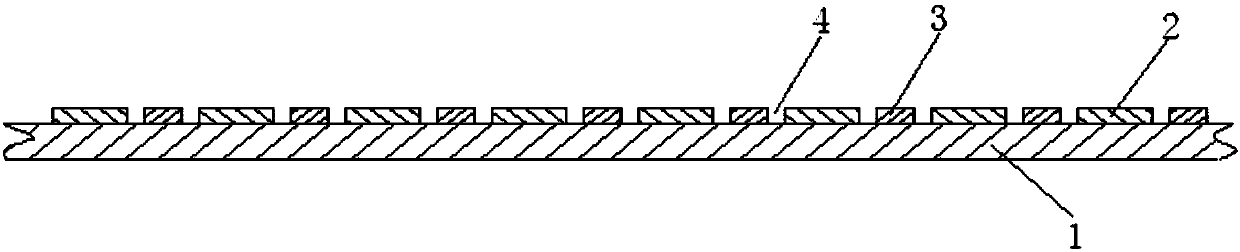

[0030] like Figure 1-2 Shown, a kind of pretreatment method of Chinese fir floor material, comprises the following steps:

[0031] S1: Treat the fir floor material with oil, soak the fir floor material in vegetable oil, heat the vegetable oil to 50°C, and soak for 2 hours;

[0032] S2: Take out the soaked fir floor material, and dry it at 60°C for 1 hour;

[0033] S3: The fir floor material dried in S2 is subjected to a second oil treatment, and the fir floor material treated in S2 is immersed in vegetable oil again, and the vegetable oil is heated to 60° C. for 1 hour;

[0034] S4: leave the fir floor material after S3 processing under vacuum condition, and the standing time is 2h;

[0035] S5: Place the bamboo slices obtained in S4 in ethanol, soak for 20 minutes, and take them out;

[0036] S6: Place the fir flooring material at 40°C and a pressure of 1.2MPa for 5 hours;

[0037] S7: drying the fir floor material treated in S6 to ensure a moisture content of 2%.

Embodiment 2

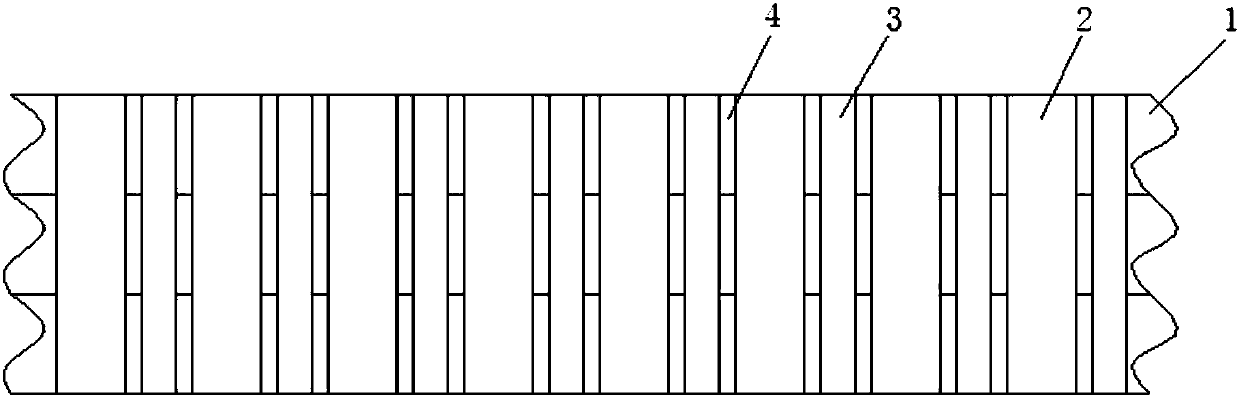

[0039] like Figure 3-4 Shown, a kind of pretreatment method of Chinese fir floor material, comprises the following steps:

[0040] S1: Treat the fir floor material with oil, soak the fir floor material in vegetable oil, heat the vegetable oil to 50°C, and soak for 2 hours;

[0041] S2: Take out the soaked fir floor material, and dry it at 60°C for 1 hour;

[0042] S3: The fir floor material dried in S2 is subjected to a second oil treatment, and the fir floor material treated in S2 is immersed in vegetable oil again, and the vegetable oil is heated to 60° C. for 1 hour;

[0043] S4: leave the fir floor material after S3 processing under vacuum condition, and the standing time is 2h;

[0044] S5: Place the bamboo slices obtained in S4 in ethanol, soak for 20 minutes, and take them out;

[0045] S6: Place fir flooring materials at 50°C and a pressure of 1.5MPa for 10 hours;

[0046] S7: drying the fir floor material treated in S6 to ensure a moisture content of 3%.

Embodiment 3

[0048] A kind of pretreatment method of Chinese fir floor material, comprises the following steps:

[0049] S1: Treat the fir floor material with oil, soak the fir floor material in vegetable oil, heat the vegetable oil to 50°C, and soak for 4 hours;

[0050] S2: Take out the soaked fir floor material, and dry it at 60°C for 2 hours;

[0051] S3: The fir floor material dried in S2 is subjected to a second oil treatment, and the fir floor material treated in S2 is immersed in vegetable oil again, and the vegetable oil is heated to 60° C. for 2 hours;

[0052] S4: leave the fir floor material after S3 processing under vacuum condition, and the standing time is 2h;

[0053] S5: Place the bamboo slices obtained in S4 in ethanol, soak for 40 minutes, and take them out;

[0054] S6: Place the fir floor material at 40°C and a pressure of 1.5MPa for 5 hours;

[0055] S7: drying the fir floor material treated in S6 to ensure a moisture content of 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com