Yinmi production process

A production process and a technology for yin rice, applied in the field of yin rice production technology, can solve the problems of insufficient guarantee of safety and sanitation, unstable product quality, and many manual operation parts, so as to ensure safety and sanitation. The effect of stability, less manual operation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

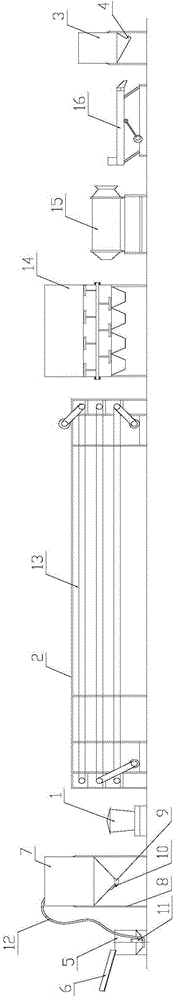

[0018] figure 1 It is the Yin rice production process schematic diagram of the present invention, as shown in the figure: the Yin rice production process of the present embodiment is characterized in that: specifically comprise the following steps:

[0019] A. Wash the glutinous rice and remove impurities;

[0020] B. Soak and ferment the cleaned glutinous rice;

[0021] C. Drain the water in the glutinous rice and cook it; soak the qualified glutinous rice and drain it and put it into the wooden box 1 and use steam to cook it. The cooked rice is overturned on the conveying airing device 2 with a forklift, and the cooking time is 10- 15 minutes;

[0022] D. Spread the steamed and cooked rice on the conveying airing device 2; Drying together, the dried glutinous rice is automatically sent out under the conveying of the conveyor belt, which can improve production efficiency, reduce production costs, less manual operation, low labor intensity of operators, small floor area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com