Patents

Literature

204results about How to "No mildew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paris polyphylla var. yunnanensis scale seedling culturing method

InactiveCN101822157AUnsleepImprove germination rateSeed and root treatmentHorticultureParis polyphylla var. yunnanensisHigh survival rate

The invention relates to a Paris polyphylla var. yunnanensis scale seedling culturing method. The method comprises the following steps of: selecting Paris polyphylla var. yunnanensis plants more than 10 years old and reserving seeds for planting; collecting mature seeds; washing the collected seeds to remove episperm; spreading and drying the seeds in a shade and ventilating place within 12 hours, wherein a temperature is maintained and an accumulation thickness is less than or equal to 6 cm; spreading the seeds uniformly and drying; filling the seeds into a ventilating container; storing the container in a shade environment with a suitable temperature, wherein the storage time is no more than 2 months; clearing impurities and residues in a seedling culturing field; fertilizing decayed farm manure and calcium superphosphate; plowing and raking soil; forming a furrow; spreading humus soil on the furrow surface; flatting the furrow surface; sowing in early June next year; taking the stored seeds, and after sterilizing, broadcasting the seeds uniformly according to the thickness of sowing; earthing after broadcasting; covering mantle on the furrow surface; irrigating sufficiently and performing seedling management. A method for drying the seeds of the Paris polyphylla var. yunnanensis in shade in an environment without direct sunlight is adopted, the dormancy of the seeds of the Paris polyphylla var. yunnanensis is broken, and the scale production of Paris polyphylla var. yunnanensis seedlings is realized, so that germchit guarantee is provided for large-area popularization and cultivation of the Paris polyphylla var. yunnanensis. The method has the characteristics of simple and easily-learned operation, high survival rate of germchit, low production cost, healthy and strong germchit, stable and reliable technology, high repeatability, and capacity of effectively solving the problem of scale seedling cultivation of the Paris polyphylla var. yunnanensis.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

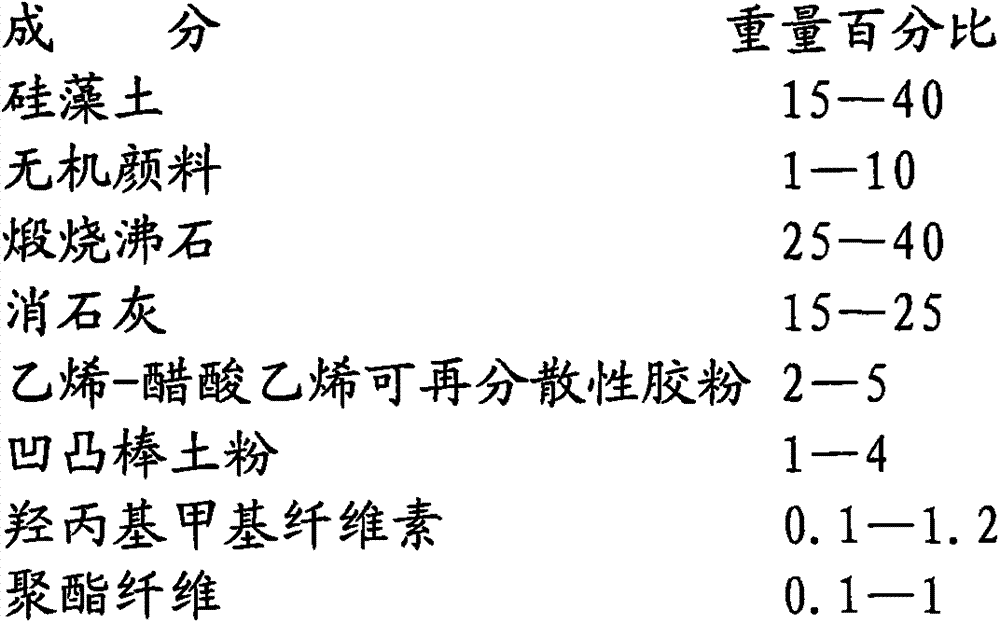

Ecological diatom ooze decorative wall material

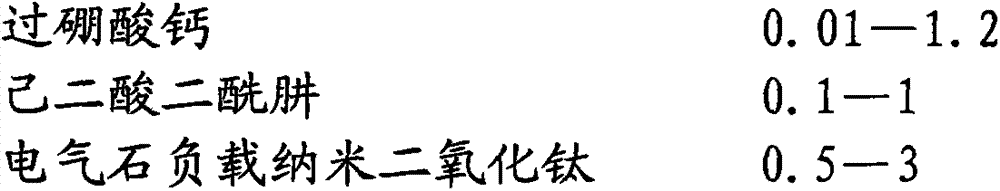

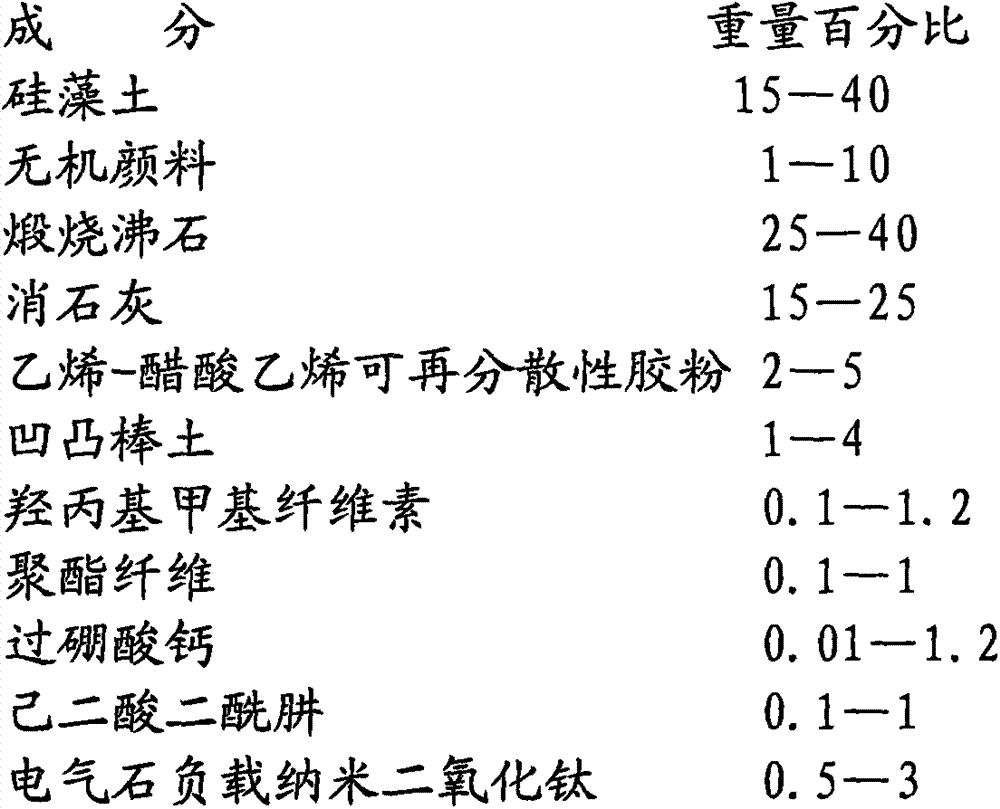

The invention relates to an ecological diatom ooze decorative wall material, which belongs to the technical field of the research and development of diatom ooze decorative wall materials. The ecological diatom ooze decorative wall material is formed by mixing diatomite, inorganic pigments, calcined zeolite, ethylene vinyl acetate re-dispersible rubber powder, attapulgite powder, tourmaline-loaded nanometer titanium dioxide, polyester fibers, adipic acid dihydrazide and the like. The main functional component of the wall material is the diatomite, and since the diatomite has a porous structure and a heat-insulation and heat-preserving function, the relative humidity of an indoor space can be automatically adjusted to 40 to 70 percent. Anion generated by utilizing the tourmaline-loaded nanometer titanium dioxide has a sterilizing function, so that the harmful gases can be adsorbed and decomposed; the calcined zeolite is used as aggregate and has a porous structure and large specific surface area, and the function for absorbing and releasing the moisture and purifying the air can be improved. The polyester fibers are used as anti-cracking fibers, so that the strength is enhanced, the anti-cracking capacity is improved, and the mildew can be avoided. The calcium perborate is used as a sterilizing agent and is long-acting and toxic-free. By adopting the ecological diatom ooze decorative wall material, the problems of an existing decorative wall material can be solved. A preparation method of the ecological diatom ooze decorative wall material is simple and easy to implement.

Owner:营口盼盼硅藻材料集团有限公司

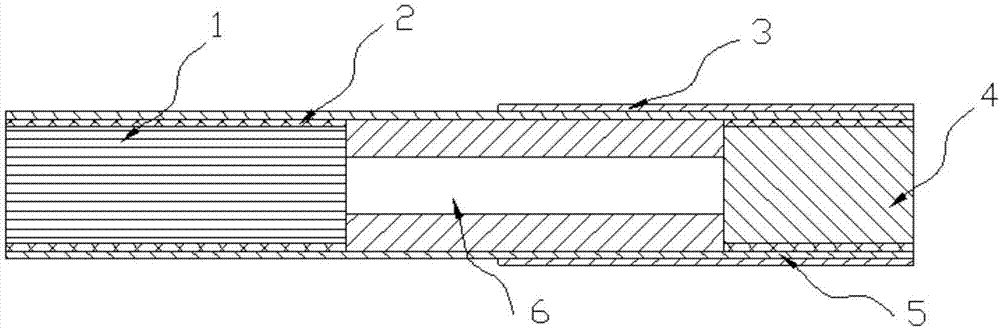

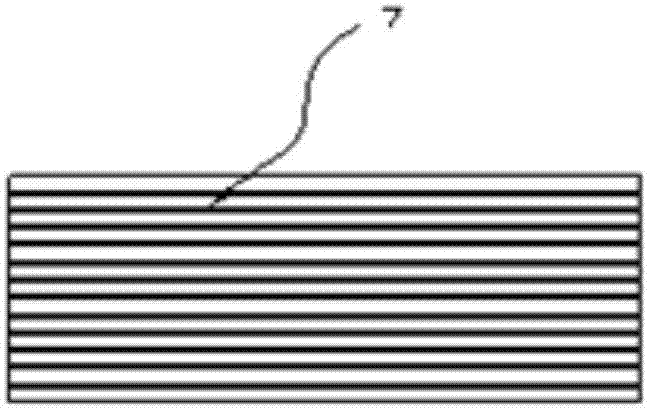

Smoking material-free heating incombustible cigarette

ActiveCN107536115ANo mildewLow environmental requirements for storage and storageCigar manufactureTobacco devicesEngineeringEnvironmentally friendly

The invention provides a smoking material-free heating incombustible cigarette. The cigarette does not contain a smoking material used for generating smoke, the cigarette comprises a tobacco section,a support part and an approaching lip section which are coaxially connected in sequence and an external package material limiting the tobacco section, the support part and the approaching lip section.The support part and / or the approaching lip section are / is provided with a unit increasing fragrance. Accordingly, due to the fact that the materials of the tobacco section do not contain the smokingmaterial, the phenomena that due to the fact the smoking material absorbs water, the external package material is polluted and deforms, and mildew is likely to be produced due to long time storage cannot be generated; the storage environment condition requirements are low, and the production cost is lowered. In addition, when the heating incombustible cigarette is used, lighting is not needed, harmful smoke components generated by cigarette burning are greatly reduced, and the cigarette is safer, healthier and more environmentally friendly. In addition, the cigarette has multiple fragrances and special functions, the fragrances are rich, and the mouthfeel is full.

Owner:NANTONG JIN YUAN NEW MATERIALS CO LTD

Bamboo fiber knitting fabric

The present invention relates to one kind of bamboo fiber knitting fabric with blended bamboo fiber yarn as facing layer and spandex or chinlon yarn covered with the bamboo fiber. It features that the blended bamboo fiber yarn consists of bamboo fiber in 50-70 wt% and cotton, Modal, Tencel, wool, cashmere or Dacron in 30-50 wt%, and has count of 20-60 s and twist multiplier of 330-345. The bamboo fiber knitting fabric has the excellent performance of bamboo, including moisture absorption, permeation, health care and antibiotic property, etc. as well as improved costume performance and size stability, and is one kind of high grade comfortable material for underwear.

Owner:北京铜牛集团有限公司

Formaldehyde-free animal specimen fixed liquid and preparation method thereof

The invention discloses a formaldehyde-free animal specimen fixed liquid and a preparation method thereof, the formaldehyde-free animal specimen fixed liquid includes the following components: a biocide mildewcide, a protein denaturant, a polyol moisturizing agent and balance of water, and if the biocide mildewcide is in solid state, the mass concentration of the biocide mildewcide is 5-20 g / L, if the biocide mildewcide is liquid, the volume concentration of the biocide mildewcide is 1-2%; the volume concentration of the protein denaturant is 5%-40%; and the volume concentration of the polyol moisturizing agent is 2% to 10%. The formaldehyde-free animal specimen fixed liquid does not contain formaldehyde, and is non-volatile, and harmless to the human body; a fresh animal organ is washed with normal saline, and stored in the fixed liquid, a year later, the organ is not corrupted, free of mildew spot, and free of obvious color and shape change, the fixed liquid color has no obvious change, and the storage effect is good.

Owner:QINGDAO AGRI UNIV

Degreasing and desugaring method of sympodial bamboo

Owner:中宇创业联合控股有限公司

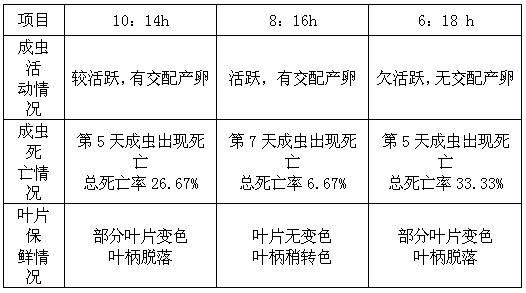

Insect breeding bottom and breeding method of gynaikothrips ficorum

The invention relates to an insect breeding bottom and a breeding method of gynaikothrips ficorum and belongs to the field of insect breeding and insect ecology. A bottom body is in a cone frustum shape with large top and small bottom and is in sealing match with a bottle cover, a magnifying glass is installed at the center of the bottle cover, a plurality of venting holes are evenly distributed on the bottle cover, and a filter screen is installed on the venting holes. The method utilizing the insect breeding bottom to breed the gynaikothrips ficorum comprises (1) collection of eggs, (2) hatching of the eggs, (3) breeding of nymphs and (4) breeding of imagoes. By using the breeding method, the hatching rate, survival rate and eclosion rate of the gynaikothrips ficorum are high, massive thrips of various insect states which are orderly in age and high in vigor can be obtained, and form changes and the whole life history of the gynaikothrips ficorum can be observed in real time.

Owner:INST OF PLANT PROTECTION FAAS

Preparation method of novel smokeless mosquito-repellent incense

InactiveCN105685114AConducive to environmental protectionSmooth appearanceBiocidePest repellentsIgnition pointFire retardant

The invention discloses a preparation method of novel smokeless mosquito-repellent incense, belonging to the technical field of preparation of the mosquito-repellent incense. The novel smokeless mosquito-repellent incense is prepared by the steps of preparing sludge carbon powder, preparing paste, molding the paste, drying the molded paste, spraying chemicals onto a dry mosquito-repellent incense blank, and the like. According to the preparation method, sludge carbon is taken as an incendiary agent, and an inorganic substance in the sludge carbon is taken as a flame retardant, so that not only is a new way provided for the resource utilization of the sludge carbon, but mass disafforestation caused by the mosquito-repellent incense industry is also avoided, and the preparation method of the novel smokeless mosquito-repellent incense is beneficial to environmental protection. The novel smokeless mosquito-repellent incense is non-toxic and harmless and can meet the requirement of environmental protection for the product; after the novel smokeless mosquito-repellent incense is burnt and absorbed by the human body, asthma, nerve poisoning and cancers are not caused; the novel smokeless mosquito-repellent incense has a smooth appearance, is free from fracture and mildew spots, and has the breaking-resistant strength of 425-456g and the ignition point time of 8.61-9.01h; in the burning process, smoke is not generated; the novel smokeless mosquito-repellent incense avoids a phenomenon of broken-end flameout when being burnt to an iron-tooth disk.

Owner:庞用

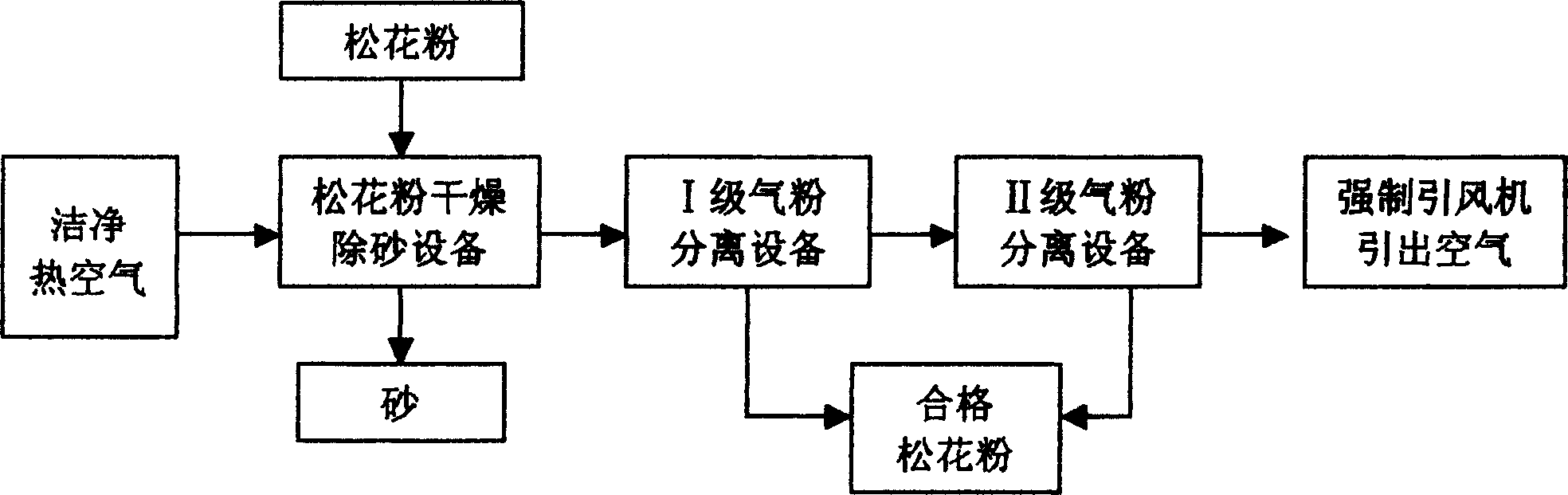

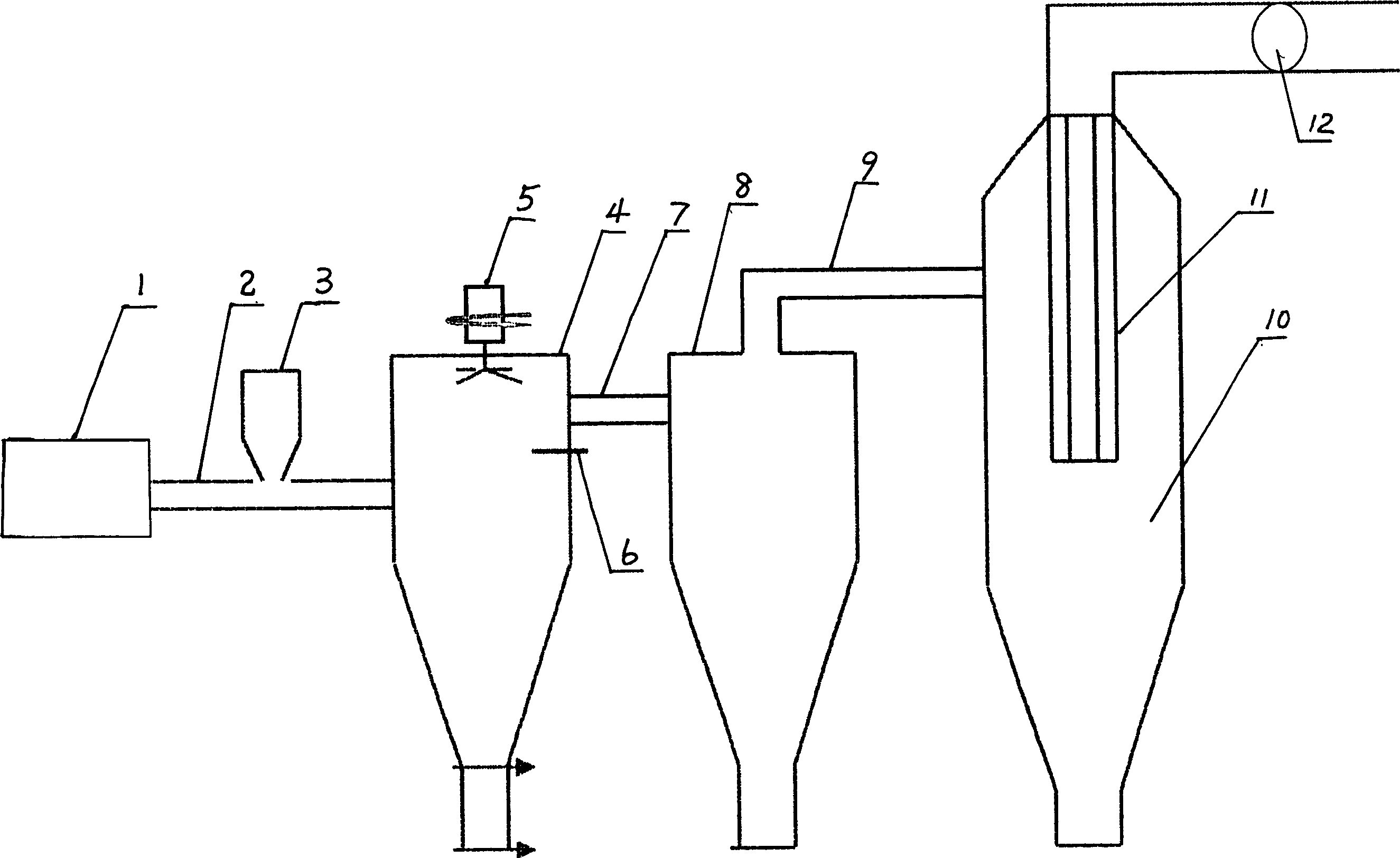

Pollen pini drying and sand-impurity-removing method

The present invention discloses a method for drying pollen pini and removing sand and impurity. Said method includes the following steps: (1) cleaning and heating air; (2). mixing hot air with pollen pini together and making the steps of drying and removing sand; (3). after the pollen pini is undergone through the processes of drying and removing sand and impurity making first air-powder separation to separate out most of pollen pini; and (4) making the air which contains small quantity of pollen pini and is discharged from first-slage separation tower undergo the process of secondary air-powder separation treatment so as to completely separate out pollen pini; and the air temp. in the drying process can be regulated.

Owner:NEW ERA HEALTH IND GRP

Toughened plastic tray and preparation method thereof

InactiveCN102952318AWide variety of sourcesLow costRigid containersTG - TriglycerideMechanical property

The invention discloses a toughened plastic tray prepared from the following raw materials in parts by weight: 50-60 parts of high density polyethylene, 20-30 parts of polyvinyl chloride, 20-30 parts of wood flour, 10-15 parts of silicon carbide, 10-20 parts of modified kaolin, 40-50 parts of recycled plastic polymer, 20-30 parts of active calcium, 1-2 parts of zinc stearate, 1-2 parts of calcium stearate, 2-3 parts of glycerol triglyceride, 0.3-0.5 part of polyethylene wax, 0.4-0.6 part of anilmomethyl triethoxy silane, 0.3-0.4 part of antioxidant 1680, 0.4-0.6 part of anti-aging agent ODA, 8-10 parts of foaming regulator, 4-8 parts of ACM, 4-8 parts of MBS, 25-30 parts of oxidized polyethlene wax, 0.2-0.3 part of foaming agent, 4-8 parts of ACR, 8-12 parts of chlorinated polyvinyl chloride, 5-8 parts of high silica glass fiber, 4-6 parts of mineral fiber and 3-4 parts of semi-reinforced carbon black. The toughened plastic tray produced by the invention has good mechanical properties, good durability, high repeated utilization rate, ageing resistance and corrosion resistance, the tray can be sawed, planed and nailed while needing no steaming or high temperature sterilization treatment, the tray can be flushed and has less possibility of absorbing water and deforming, and no mildew is generated, so that the toughened plastic tray is especially suitable for application at plum rain seasons in the south of the lower reaches of the Yangtze river.

Owner:芜湖太平洋塑胶有限公司

Processing method for bamboo strip

InactiveCN104400848AAvoid deformationImprove stabilityWood treatment detailsReed/straw treatmentDrugs solutionThermal treatment

A related processing method for a bamboo strip comprises the following steps: (1) bundling up bamboo strips; (2) preparing a processing solution; (3) putting the bamboo strip bundle prepared in the step (1) into the processing solution for processing, keeping the temperature of the processing solution to be 75-90 DEG C and processing for 1-2 h; and (4) performing heat treatment. The provided processing method for the bamboo strip prevents deformation in the processing process, improves the anticorrosion performance and mildew resistance of the bamboo strip by using a drug solution for processing, and improves the stability and the anticorrosion performance of the bamboo strip through heat treatment.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

Insect-killing method for tobacco leaves

The invention discloses an insect-killing method for tobacco leaves, which comprises the following steps of: 1, determining a pile location, placing a bottom membrane of a tent at the pile location; 2, piling a tobacco pile on the base membrane of the tent; 3, covering a cover membrane so that the whole tobacco pile is wrapped in the tent; 4, sealing the bottom membrane of the tent with the cover membrane together; and 5, discharging air in the tent, introducing dried nitrogen or inert gas in the tent, or introducing dried nitrogen or inert gas in the tent when discharging the air in the tent. By adopting the insect-killing method for the tobacco leaves, in a very short time range, concentration of oxygen in the sealed pile can be reduced to below 2 percent, the temperature is controlled to be 20-35 DEG C, and the humidity is controlled to be 55-75 percent. The state of the tobacco leaves is kept for above 8 days, the death rate of tobacco storage pests reaches above 99 percent, and the tobacco leaves are not mildewed.

Owner:湖南华望熏蒸消毒有限公司

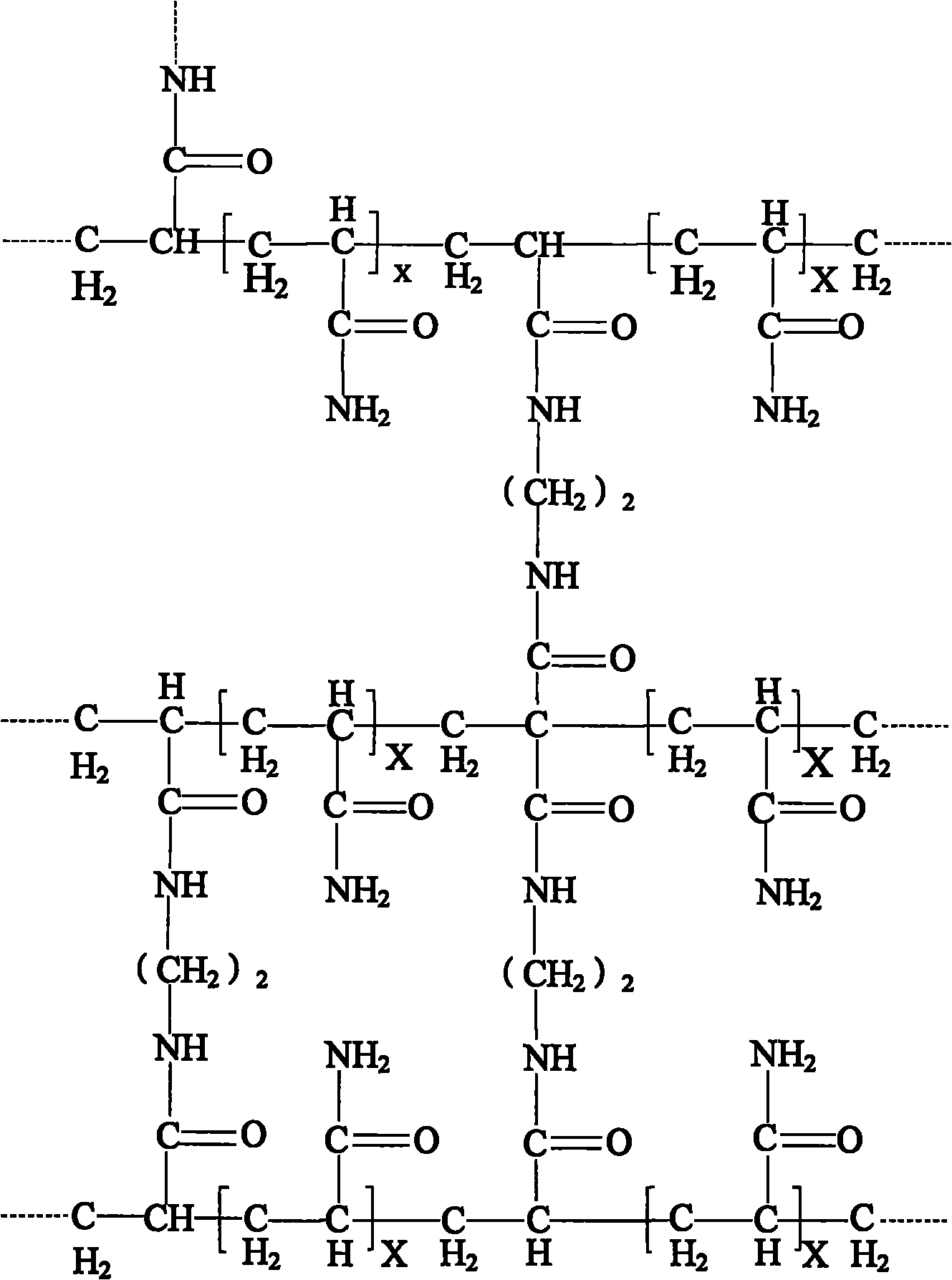

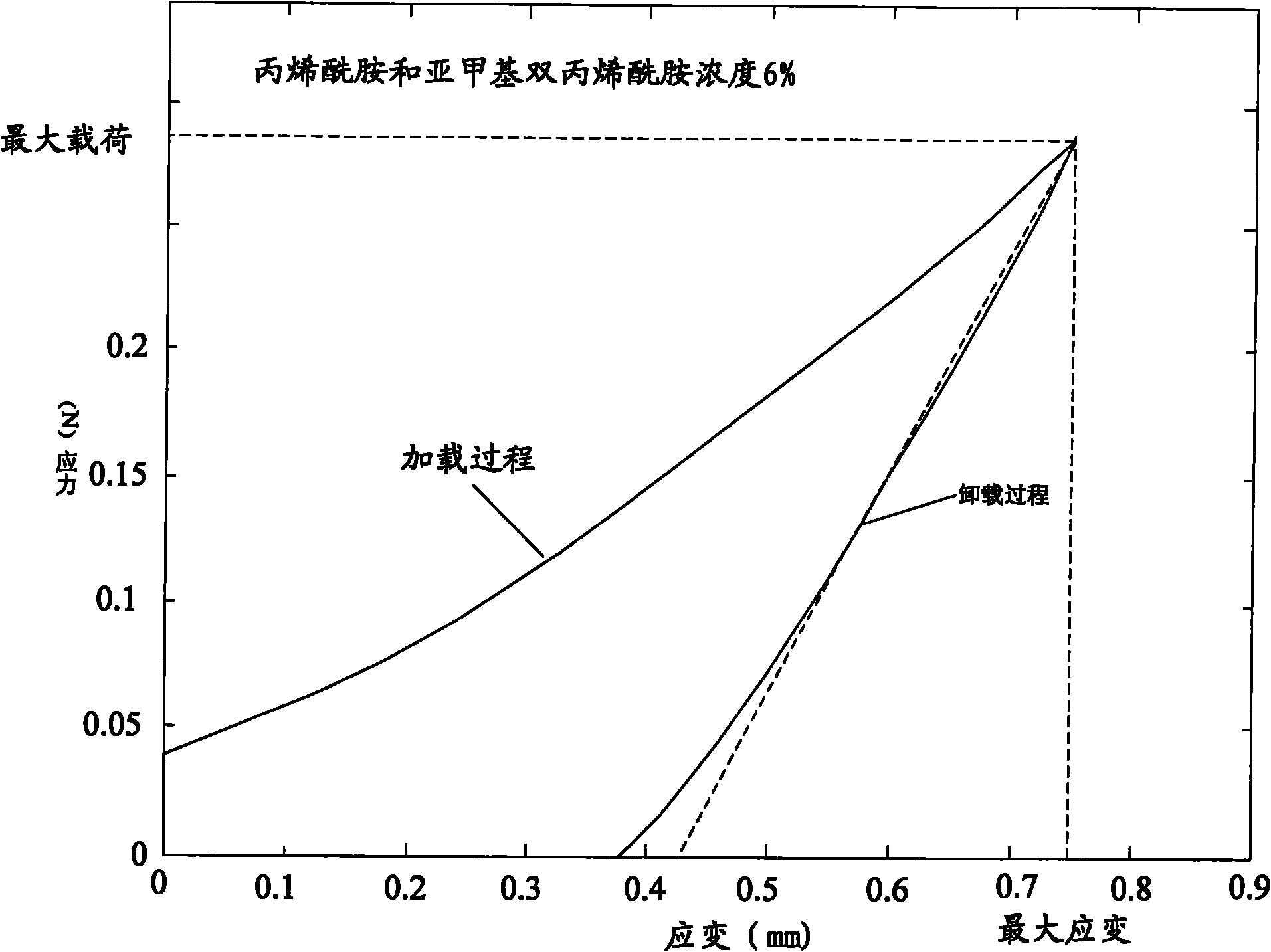

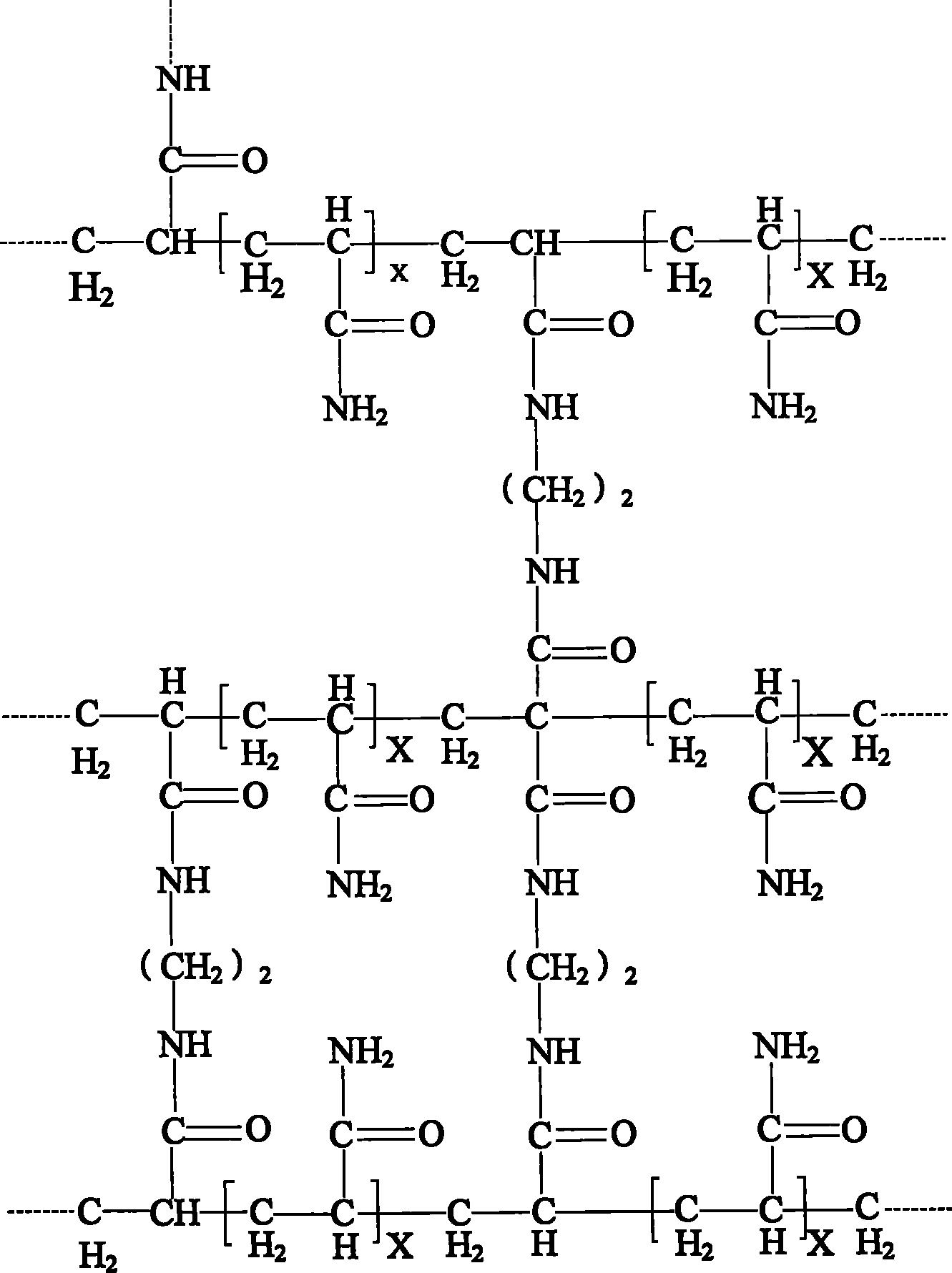

Ultraphonic elastic imaging body model and preparation method thereof

InactiveCN101864136AImprove stabilityNo mildewUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsAttenuation coefficientReticular formation

The invention relates to an ultraphonic elastic imaging body model comprising polyacrylamide hydrogel and a scatterer, wherein the polyacrylamide hydrogel forms a reticular structure to wrap the scatterer. The elasticity (or the rigidity) of the ultraphonic elastic imaging body model can be freely regulated within a larger range by regulating the concentration of an acrylamide monomer and the sound attenuation coefficient can be changed to accord with the standard of ultraphonic elastic imaging by regulating the proportion of the scatterer.

Owner:SHENZHEN HUIKANG PRECISION APP

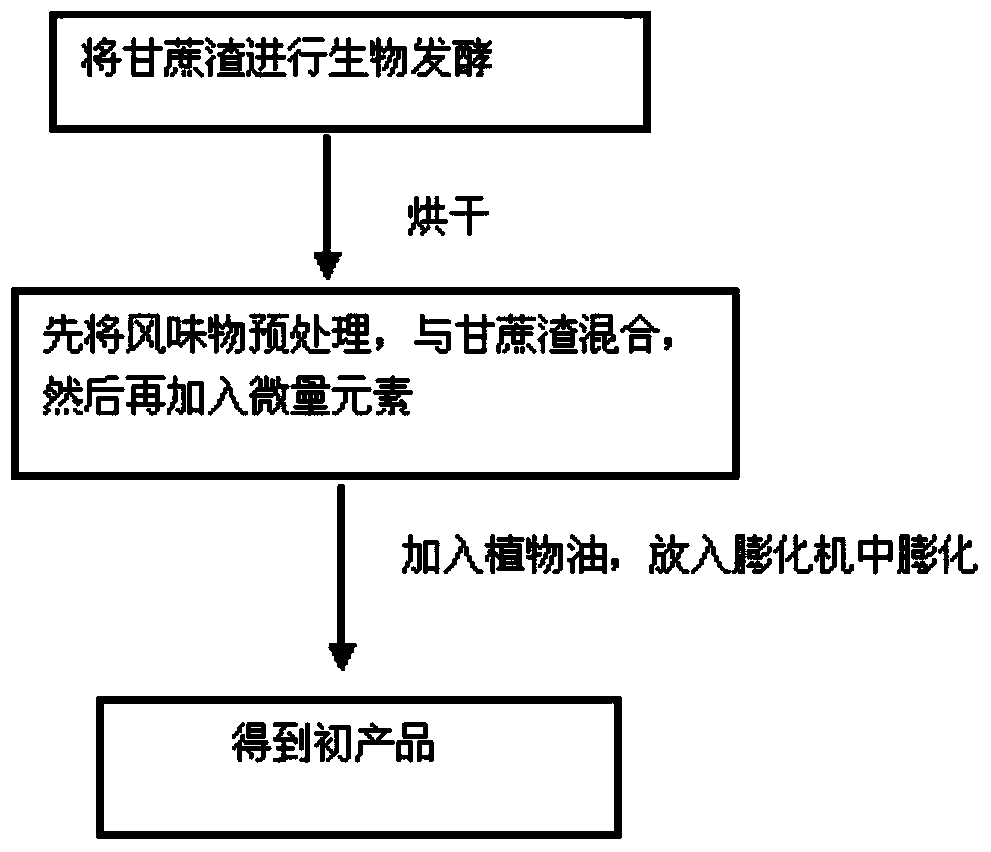

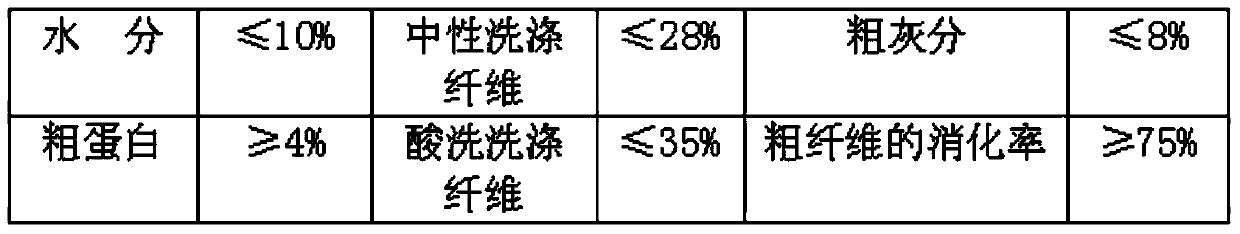

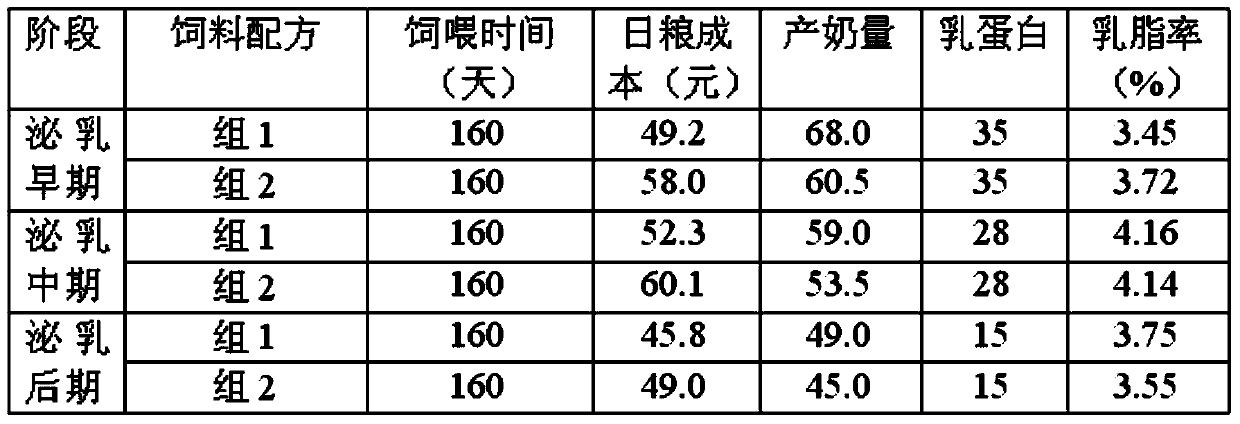

Ruminant animal feed and preparation method thereof

InactiveCN104186939AAvoid pollutionImprove immunityFood processingAnimal feeding stuffVegetable oilFermentation

The invention discloses a ruminant animal feed which is characterized by being prepared from the following raw materials in part by weight: 80-150Kg of bagasse, 30-50Kg of flavoring substances, 10-50Kg of vegetable oil, 1-3Kg of a microorganism preparation, 1-5Kg of bio-enzyme and 1-5Kg of trace elements, and is prepared by the steps of fermentation, pretreatment, puffing and the like. According to the ruminant animal feed, discarded honey, discarded fruit peels and the like are recycled to be used as the flavoring substances, so that the palatability of the animal feed is greatly improved, and the multi-flavor feed is supplied to the ruminant animals; furthermore, the feed is low in investment, safe and free from toxicity, can be stored for a long time and can be supplied all the year round; the problem of shortage of grass feeds in winter is solved.

Owner:卓礼仕

Mildew resistant treatment agent of wood

InactiveCN104522091ABacteriostaticHas anti-insect effectBiocideFungicidesSyzygiumPolygonatum sibiricum

The invention relates to a mildew resistant treatment agent of wood. The mildew resistant treatment agent comprises 5-8 parts of Polygonatum sibiricum, 12-15 parts of Syzygium aromaticum, 3-5 parts of Radix Aucklandiae, 3-5 parts of Trillium tschonoskii, 8-12 parts of Evodia lepta, 2-4 parts of whitetomentose ainsliaes herb, 1-2 parts of Ormosia henryi Prain, 2-4 parts of Rhizoma Arisaematis, 8-10 parts of bamboo leaf, 12-15 parts of quicklime and 100 parts of water. The mildew resistant treatment agent of wood has the advantages of simple use method and convenient treatment, wood treated by the agent has a long mildew resistant time, can be used in air with the relative humidity of 45% at 25DEG C for 2 years without molds, and can be used under normal conditions for 4 years without molds.

Owner:阜南佳利工艺品股份有限公司

Chinese chestnut rice wine and preparation method thereof

ActiveCN105296281ASweet and mellow tasteWith promoting blood circulation and removing blood stasisAlcoholic beverage preparationRed yeast riceDistillation

The invention relates to the technical field of nutritious and healthy wine processing, and especially relates to a Chinese chestnut rice wine and a preparation method thereof. The Chinese chestnut rice wine comprises the following raw materials in parts by weight: 30-50 parts of Chinese chestnut, 30-50 parts of glutinous rice, 8-14 parts of monocrystal rock sugar, 8-10 parts of red yeast rice, 1-5 parts of rice koji, and 1-5 parts of saccharomyces cerevisiae. The steps of crushing, saccharification, fermentation and distillation are carried out on raw materials of the provided Chinese chestnut rice wine, the Chinese chestnut rice wine is characterized in that the Chinese chestnut rice wine has crystal bright color, the color is orange red or bright red, nutrient composition is high, local flavor is unique, taste is sweet, obvious Chinese chestnut flavor and special ethyl caproate fragrance of the rice wine are provided; and the Chinese chestnut rice wine has the health caring functions of promoting blood circulation to remove blood stasis, invigorating spleen and promoting digestion, nourishing stomach and invigorating spleen, nourishing liver and tonifying kidney, delaying aging, treating beauty and skin, effectively adjusting human body, and reducing blood pressure and blood fat. The Chinese chestnut rice wine enables long-term preservation in a porcelain pot.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for manufacturing pickled dried vegetable

The invention discloses a method for manufacturing pickled dried vegetable, comprising the following steps: selecting raw materials, cleaning, draining, pickling for 7-15 days according to the weight ratio of salt to vegetable raw materials of 5-6:100, cleaning again, slitting, drying for the first time (the moisture content is required to be 18-22%), steaming for 15-18min for the first time, drying for the second time (the moisture content is required to be 13-16%), steaming for 15-25min for the second time in a thermal manner, and drying for the third time (the moisture content is required to be 8-12%), thus obtaining the finished product pickled dried vegetable; and packaging and warehousing. The invention has the advantages that the pickled dried vegetable manufactured by the method has good brittleness, easy poltophagy, moderate salty taste and good taste, has bluish yellow or faint yellow appearance, and has substantial uniform color, no impurities, no mildew and brittle and refreshing taste; and the moisture content thereof is less than 15% and the salty content is less than 10%, thus conforming to national related standard requirements.

Owner:宁海县城关翔鹰土特产加工厂

Production method of straw wood-like material and product thereof

The invention relates to a production method of a straw wood-like material, which comprises the following steps: preparing raw materials straw powder, coupling agent, polylactate or polyhydroxy fatty acid ester, modifier, plasticizer, paraffin, polyethylene wax, antioxidant, ultraviolet absorbent and fire retardant; mixing the straw powder in a double-speed mixer, sending the other raw materials into the double-speed mixer, and mixing; delivering the mixed raw materials into a double screw extruder, and granulating the raw materials by using the double screw extruder by extruding the raw materials from the output end of the double screw extruder; sending the granules extruded from the double screw extruder into a conical double screw extruder, drawing and cooling to water to form, therebyobtaining the required section; and printing on the section by using a printing machine. The straw wood-like material has the advantages of high mechanical strength, high toughness, water resistance,fire retardancy, corrosion resistance, termite bite resistance, no toxicity, no pollution and low production cost, is free of formaldehyde, and is degradable and recyclable.

Owner:BEIJING ZHONGNUO DERUI IND TECH

Imitation-rattan furniture and manufacturing method thereof

InactiveCN104287498AIncrease roughnessImprove sweat absorption and breathabilitySofasCouchesFiberWood flour

The invention discloses imitation-rattan furniture and a manufacturing method thereof. The imitation-rattan furniture is formed by weaving rattans, or is composed of a part made of rattans and a part made of other materials, wherein each rattan comprises one strand or multiple strands, and adopts imitation rattan made of fiber-containing bio-based composite material, the fiber-containing bio-based composite material is formed by compounding modified straw powder or modified wood flour and plastic at certain ratio. According to the invention, due to the adoption of the bio-based imitation rattan material, the use experience of the imitation-rattan furniture is improved, and the furniture is firm and durable, is convenient to manufacture, low in cost, and is environmentally friendly.

Owner:NANJING BIOFUNCTION CO LTD

Agent special for protecting color and making dried medlar

InactiveCN101322549AShorten drying timeRemove pesticide residuesFruit and vegetables preservationFood preparationSodium erythorbateDried fruit

The invention relates to a color retention drying agent specially used for wolfberry and is characterized in that the color retention drying agent is composed of edible sodium carbonate, sodium citrate, sodium erythorbate and potassium sorbate according to the mix ratio by weight of 1000: 2-10:1-8:0.5-6. The selected edible sodium carbonate of the wolfberry special color retention drying agent can resolve a waxy layer on the surface of a barbary wolfberry fruit and rapidly absorb the water, thus shortening the drying time, the sodium citrate can remove the pesticide residues, retain the original taste of the barbary wolfberry fruit and ensure the surface of the barbary wolfberry fruit to be round; the sodium erythorbate can prolong the guarantee period; the potassium sorbate can play the roles of color retention, color enhancement and fresh preservation, and the preparations can not damage the nutritious ingredients of the barbary wolfberry fruit. The color retention drying agent combines the chemical preparations, thereby shortening the drying time of the barbary wolfberry fruit, prolonging the fresh preservation time and the storage time and not damaging the nutritious ingredients of the barbary wolfberry dry fruit, and the barbary wolfberry dry fruit has good color, uniform color, no oily matters, no molds, no odor and no residues.

Owner:贺嘉利

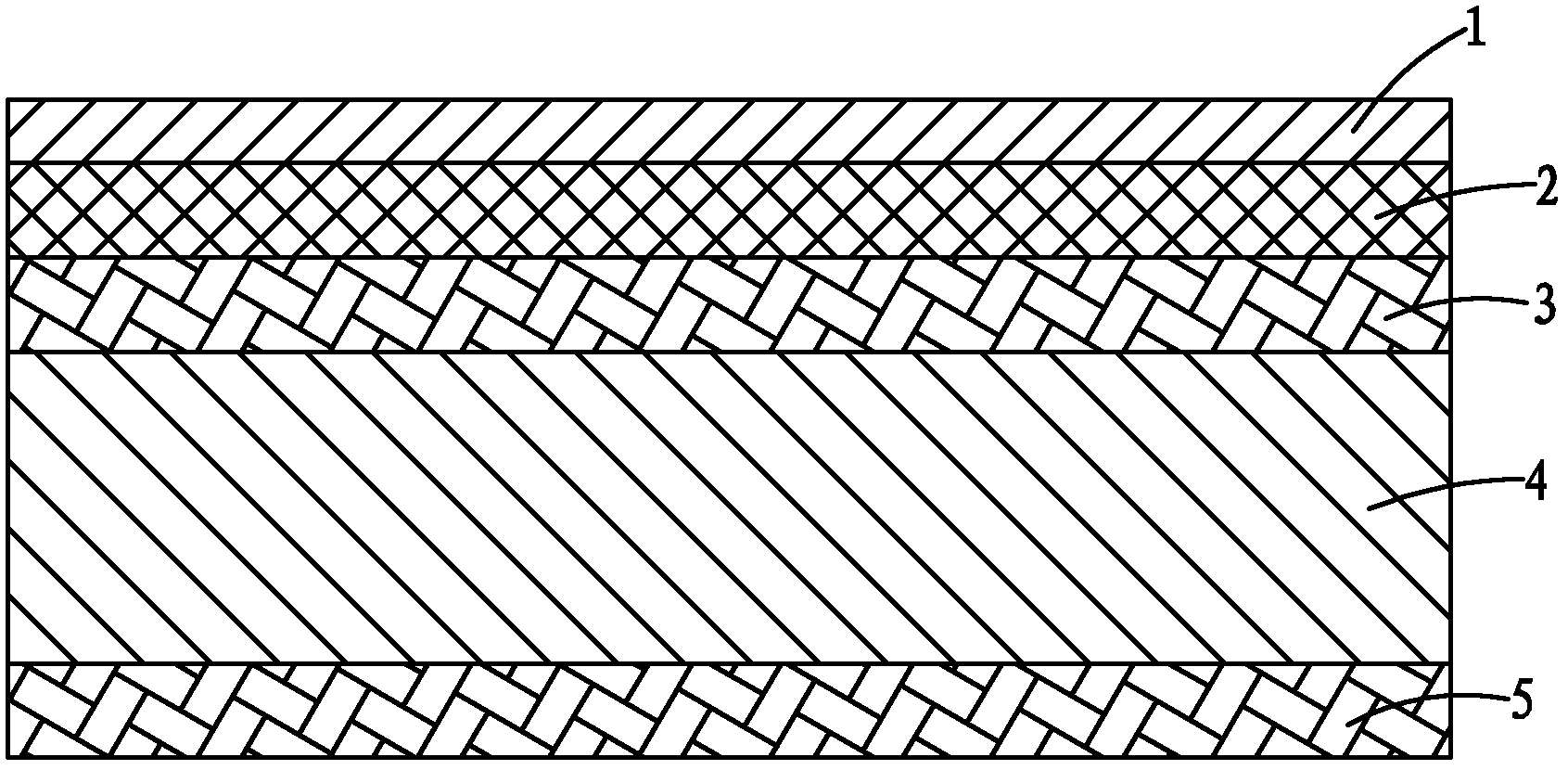

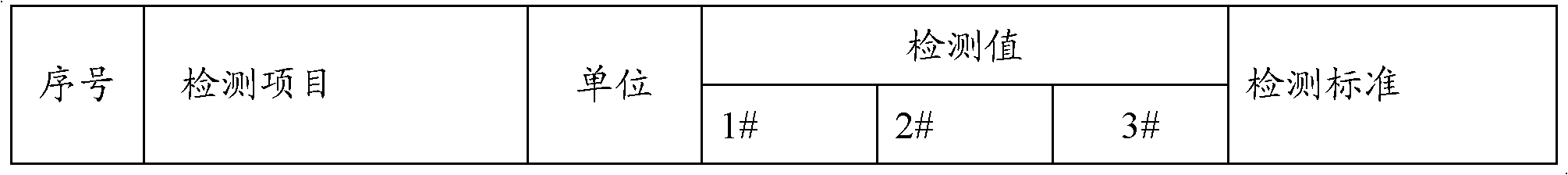

Raw bamboo fiber and polypropylene staple fiber composite molding interior panel and preparation process thereof

InactiveCN102582140AHigh tensile strengthImprove bending strengthLaminationLamination apparatusFiberSurface layer

The invention provides a raw bamboo fiber and polypropylene staple fiber composite molding interior panel and a preparation process thereof. The interior panel has a surface layer of a decorative fabric, a second layer of a hot melt adhesive film, a third layer of a first non-woven fabric, a fourth layer of a raw bamboo fiber and polypropylene staple fiber mixed needled felt and a fifth layer of a second non-woven fabric, wherein the raw bamboo fiber and polypropylene staple fiber mixed needled felt comprises the following components in percentage by weight: 53 to 56 percent of raw bamboo fiber and 44 to 47 percent of polypropylene staple fiber. The composite molding interior panel has excellent comprehensive performance and is high in environment friendliness.

Owner:福建建州竹业科技开发有限公司

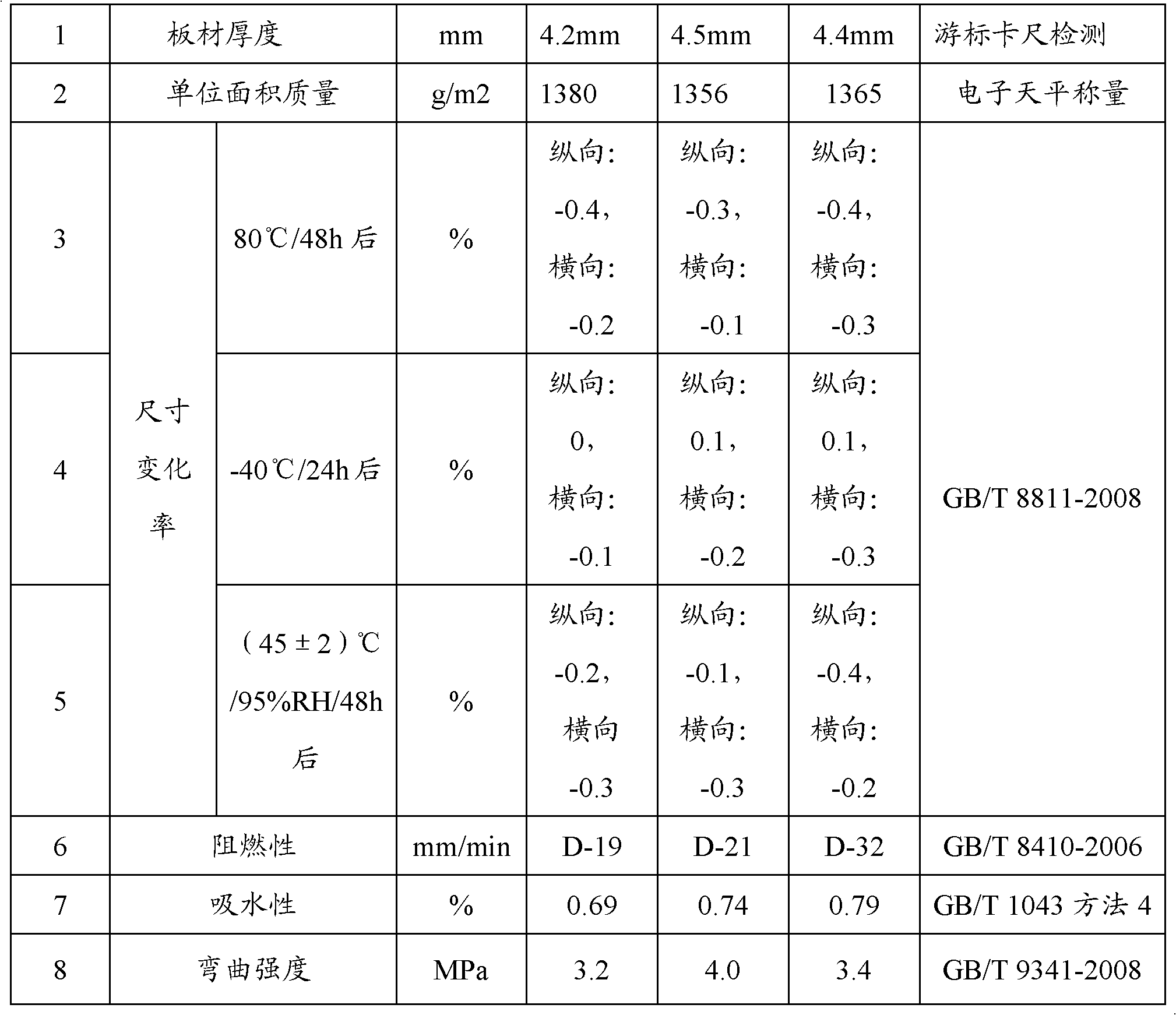

Freeze-dried truffle slice production method

ActiveCN102634458ALong shelf lifeEasy to transport and useMicroorganism based processesMicroorganism preservationBiologyBiological product

The invention discloses a freeze-dried truffle slice production method belonging to the field of novel biological products. Aiming at the technical problem, the invention provides a freeze-dried truffle slice production method, according to the method, the original flavor and the appearance can be stored. The method comprises the steps of conducting raw material processing, freezing, and carryingout vacuum drying: controlling the vacuum degree of a vacuum freeze drying machine to be 20-40Pa at drying temperature being minus 25-minus 18 DEG C, and controlling drying time within three to six hours; analytic drying: gradually reducing the vacuum degree of the vacuum freeze drying machine to be 5-10Pa, rising the drying temperature to be 35-50 DEG C, and then drying for 5-15 minutes to obtain freeze-dried truffle; and conducting aseptic packaging.

Owner:PANZHIHUA CHENFENG FORESTRY

Manufacturing method of loose-packed raw wet noodles

The invention discloses a manufacturing method of loose-packed raw wet noodles. The manufacturing method includes the following steps of 1, site preparation; 2, raw wet noodle formula making; 3, noodle manufacturing; 4, drying and moisture removal. The obtained wet noodles can be naturally stored for 7 days in freshness protection packages at normal temperature and can be stored for 20 days at the temperature of 0-4 DEG C, no foreign smell exists, no mould phenomenon exists, and the specification of DB43 / 338 is met. The process is simple, no expensive noodle dryer is needed, the manufacturing method is particularly suitable for production of breakfast loose-packed noodles or hotpot noodles, and adopted reagents all meet the requirements of the national safety standard GB2760.

Owner:HUNAN BIOLOGICAL & ELECTROMECHANICAL POLYTECHNIC

Far infrared interior wall painting

InactiveCN101709190AGood health effectPromote circulationAntifouling/underwater paintsPaints with biocidesCelluloseAdhesive

The invention discloses a far infrared interior wall painting, which comprises the following raw materials in part by weight: dispersant 15-25, thickener 8-12, defoamer 1.5-2.5, titanium oxide 100-150, nano silicon dioxide 1-3, neutralizer 1.5-2.5, zinc oxide 1-3, soybean cellulose 1.5-2.5, kaolin 40-60, polyacrylic emulsion 150-250, film-forming agent 8-12, titanium dioxide 2-6, silicon carbide 1-2, calcium carbonate 1-3, glycol 10-30, tourmaline 160-180, triple superphosphate 200-340 and water 100-140. The preparation method of the far infrared interior wall painting comprises the following steps: 1, putting the raw materials in a reaction kettle and stirring the raw materials till the raw materials are fully and uniformly mixed for later use; 2, crushing the tourmaline by nanometer for later use; and 3, putting the mixed raw materials obtained by the step 1 into the nanometer tourmaline raw material, adding water into the resulting mixture and stirring the resulting mixture by using a stirring machine to obtain the painting of the invention. The painting of the invention has a good health-care effect on human bodies and a bacteriostatic action, avoids generating mildews when applied on an interior wall and has good wall adhesive attraction and high stability.

Owner:吴尚泉

Box-type air-regulating storage fresh keeping method for fresh-taken brambie berry

InactiveCN102144658AExtend the market supply periodIncrease added valueFruits/vegetable preservation by freezing/coolingDiseaseInsect

The invention discloses a box-type air-regulating storage fresh-keeping method for a fresh-taken brambie berry, which is characterized by comprising the following steps of: harvesting fruits when the fruits are 80-90% ripe, selecting the fruits which have no mechanical injury, diseases and insect pests, rot and imperfect parts, loading the fruits in a plastic tray, pre-cooling the fruits for 18-24 hours at 0-3 DEG C within 12 hours after being harvested, and placing the plastic tray in a plastic box-type air-regulating case, placing holed brambie berry antistaling agent bags at two sides in the case, and then, tightly covering the opening of the case, and regulating the air in the plastic box-type air-regulating case through an air faucet to implement that the concentration of CO2 reaches 4%-7%; then, storing the plastic box-type air-regulating case at the temperature ranging from -0.5 DEG C to 0.5 DEG C, so that the storage period of the late-maturing brambie berry can be 40-45 days. The box-type air-regulating storage fresh-keeping method for the fresh-taken brambie berry has the positive effects that the brambie berry stored for 40-45 days is not rotted, so that market supply period of the fresh-taken brambie berry can be obviously prolonged, the fresh brambie berry is rich in special nutrition constituents, and the additional value of the fresh brambie berry can be increased by more than fivefold.

Owner:SHENYANG AGRI UNIV

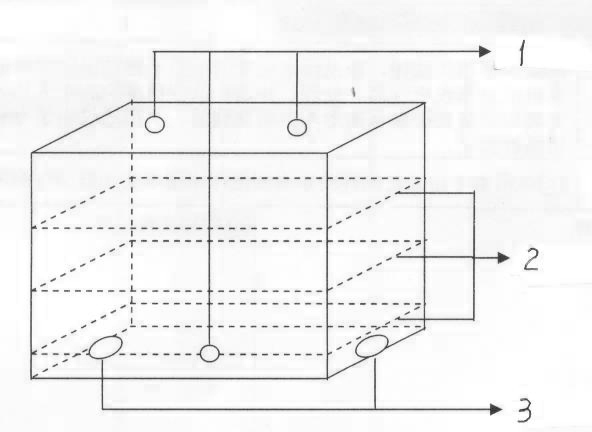

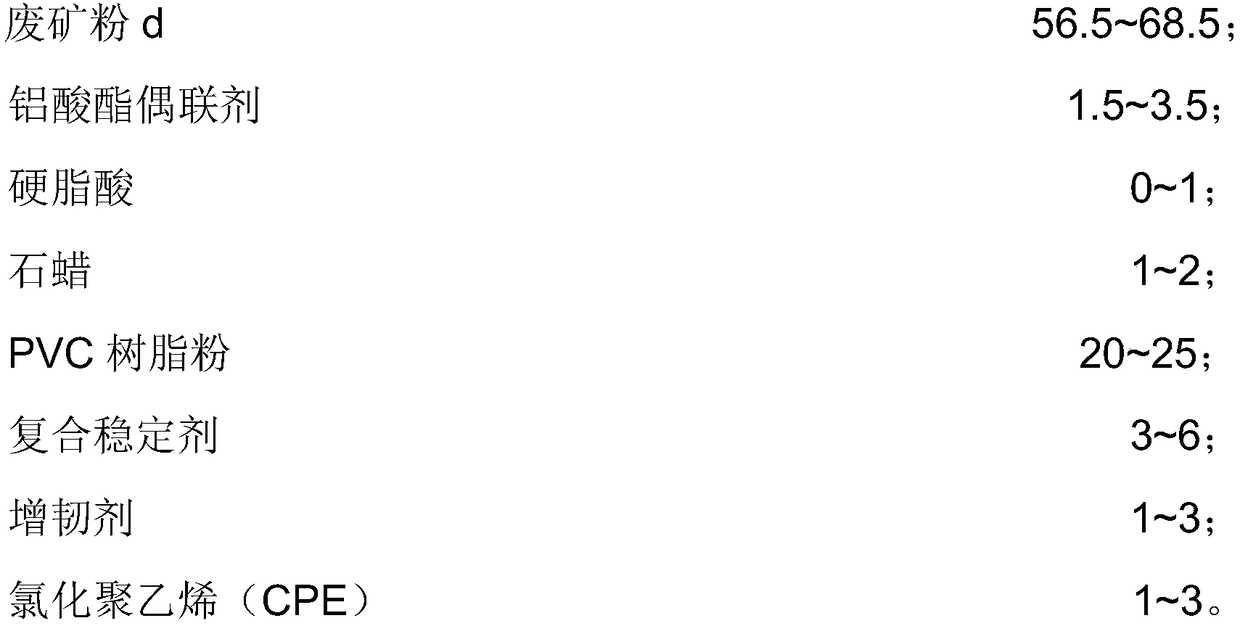

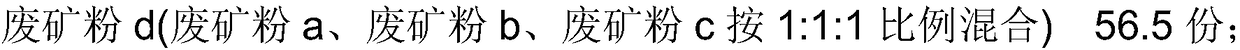

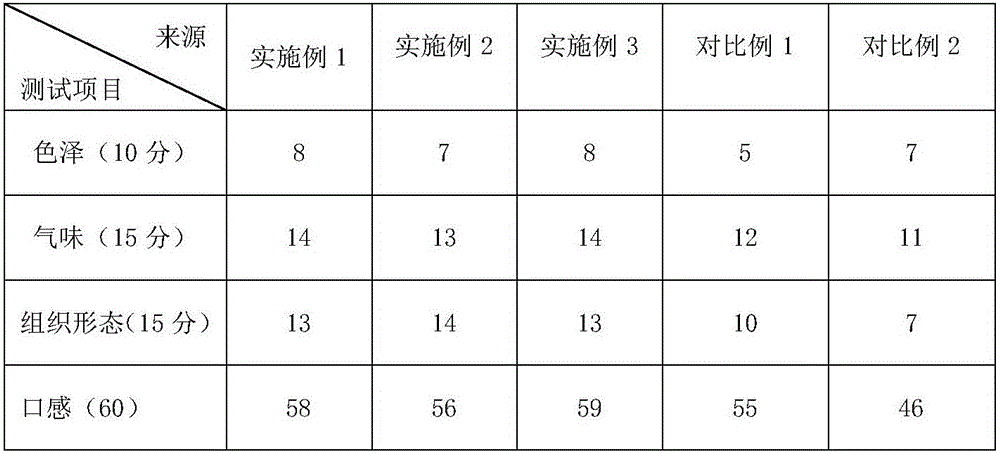

PVC composite material suitable for extrusion molding and preparation method

The invention relates to a PVC composite material suitable for extrusion molding and a preparation method. The preparation method comprises preparation of modified waste mineral powder, preparation ofa modified waste mineral powder premix and preparation of the PVC composite material. The modified waste mineral powder is obtained by performing grinding, screening and coupling activation treatmenton mixed waste mineral slag comprising tailings produced in mining of granites, wastes produced in marble processing and fired-coal coal ash produced in a smelting process; the modified waste mineralpowder premix is obtained by mixing the modified waste mineral powder with stearic acid and paraffin respectively; the PVC composite material is obtained by mixing the modified waste mineral powder premix with PVC resin, a composite stabilizer, a toughener and CPE under a heating condition. The composite material is suitable for extrusion molding, uniform in PVC plasticization and hard to decompose; the waste mineral powder is high in compatibility with PVC; no dust problem is caused; the defective rate is low; furthermore, a molded product is high in intensity, high in toughness and good inwater resistance and flame retardancy. The PVC composite material can replace a wood-plastic composite material and be widely applied to the field of buildings and home decoration.

Owner:SHAANXI SCI TECH UNIV +1

Method for making preserved white hyacinth bean

InactiveCN102550787ARetain colorPreserve the flavorConfectionerySweetmeatsAmylaseCryogenic treatment

The invention relates to a method for making a preserved white hyacinth bean. The cryogenic treatment, low-temperature saccharification and vacuum impregnation technologies are adopted. With cryogenic treatment, the histiocyte membrane of the white hyacinth bean is damaged so that the permeability of the histiocyte is increased to quicken the combination of starch contained in the white hyacinth bean with an enzyme. During the low-temperature storage period of the white hyacinth bean, starch and amylase change, the starch in the white hyacinth bean is converted into maltose and glucose, and the sugar content in the white hyacinth bean is promoted to be increased. The white hyacinth bean has the functions of tonifying the spleen, regulating the middle warmer, resolving summer heat and dissipating dampness. The preserved white hyacinth bean is made by using the cryogenic treatment, low-temperature saccharification and vacuum impregnation technologies, so that the preserved white hyacinth bean becomes a functional health-care food convenient to carry, easy to eat and beneficial to store, and the preserved white hyacinth bean has delicious taste, not only is nutritious but also can promote human health.

Owner:杨军

Preparation method of wild boar preserved meat

InactiveCN106819877ANo mildewNo mildew; no smellFood ingredient as colourFood ingredient as taste affecting agentFlavorForeign matter

The invention belongs to the technical field of food processing, and particularly relates to a preparation method of wild boar preserved meat. The preparation method comprises the following steps of A, selecting materials; B, treating at high pressure; C, preparing auxiliary materials; D, pickling; E, airing; F, fumigating; G, air drying. The wild boar preserved meat prepared by the preparation method has the advantages that the lean meat is bright red or dark red, and the fat meat is transparent or milky white, and the mucus and mildewing point are avoided; the foreign odor and rancid flavor are avoided; the meat body is dry, firm and elastic, the appearance is regular, the mildewing and mildew spot white membrane are avoided, and the foreign matter outside normal vision is avoided; after cooking, the taste is rich, the fat meat is not greasy, and the lean meat does not stick teeth.

Owner:巫溪县长贵养殖有限公司

Inorganic mineral environment-friendly fire-retardant coating and preparation method thereof

InactiveCN105925024AImprove waterproof performanceImprove scratch resistanceAlkali metal silicate coatingsFire retardantStain

The invention discloses an inorganic mineral environment-friendly fire-retardant coating and a preparation method thereof. The inorganic mineral environment-friendly fire-retardant coating is prepared from, by weight, 15-35 parts of a potassium silicate solution, 1-1.5 parts of a dispersing agent, 1-2.5 parts of a thickening agent, 1-3 parts of dimethyl silicone, 3-9 parts of emulsion, 1-10 parts of titanium dioxide, 1-9 parts of ferric oxide, 1-9 parts of sepiolite, 1-6 parts of zinc oxide, 1-8 parts of tourmaline, 1-4 parts of kaolin, 0.5-2.5 parts of silica sol and 10-50 parts of water. According to the inorganic mineral environment-friendly fire-retardant coating and the preparation method thereof, the variety and using amount of the thickening agent and the dispersing agent which are suitable for an exterior wall coating are preferably selected through the reasonable proportion, the water resistance, the scratch resistance, the stain resistance, the breathability and the weather resistance of a coating film are improved, peeling and color fading are avoided, and meanwhile the advantages of being resistant to fire and flame, capable of achieving sterilization without generating mildew stain and environmentally friendly are achieved; in addition, construction is easy and convenient, and the environmental adaptability is better.

Owner:上海嘉柏丽实业有限公司

Fermentation treatment method for beef feed

InactiveCN104336414AExtended storage timeReduce storage costsFood processingAnimal feeding stuffSaline waterEffective microorganism

The invention discloses a fermentation treatment method for beef feed. The fermentation treatment method comprises the following steps of using non-mildewing crop straws, and crushing into the length of 5-7cm; preparation of fermentation liquid, adding 1.5-2 parts of EM (effective microorganism) straw fermentation agent into 100 parts of hot brine with concentration of 1.5%, and stilling for 1.2-2 hours; setting the temperature of the hot brine as 35-45 DEG C; spreading the crushed straws on ground, uniformly spraying the fermentation liquid onto the straws, and controlling the water content of the straws to be less than 65%; putting the straws in a fermentation pool, and pressing and sealing for anaerobic fermentation; or, loading the straws into sacks, stacking, and sealing by non-poisonous plastic sheets for anaerobic fermentation, wherein when the environment temperature is higher than 5 DEG C, the fermentation time is not less than 25 days; when the environment temperature is lower than 5 DEG C, the fermentation time is not less than 35 days. The fermentation treatment method has the advantage that after the crop straws are fermented, the straws can be stored without airing, the mildewing is avoided, and the storage time of crude feed is greatly prolonged.

Owner:张汉桥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com