Ecological diatom ooze decorative wall material

A kind of diatom mud, ecological technology, applied in the field of research and development of diatom mud decorative wall materials, can solve the problems of diatom mud decorative wall materials are not very ideal, can not play a catalytic role, poor air purification performance, etc., to achieve Good conditioning treatment effect, prevention of mold growth, effect of relaxing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

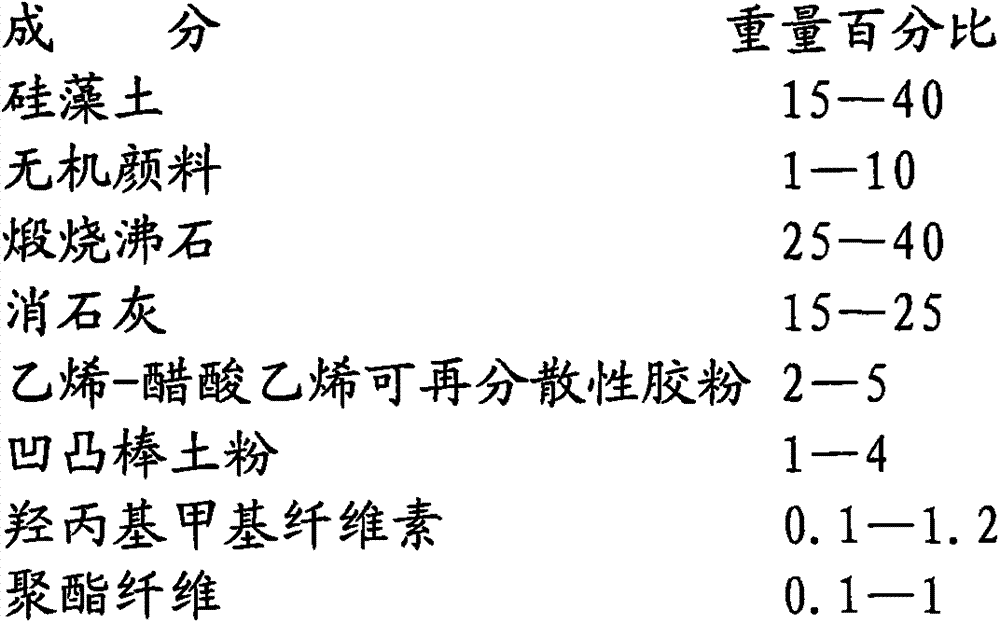

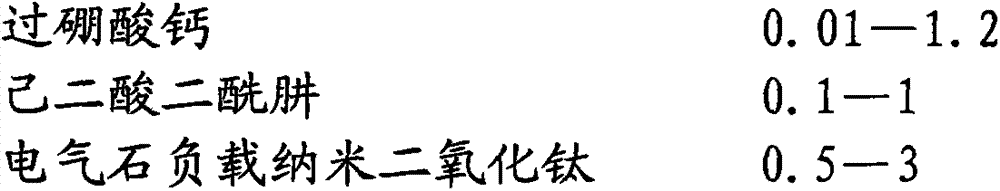

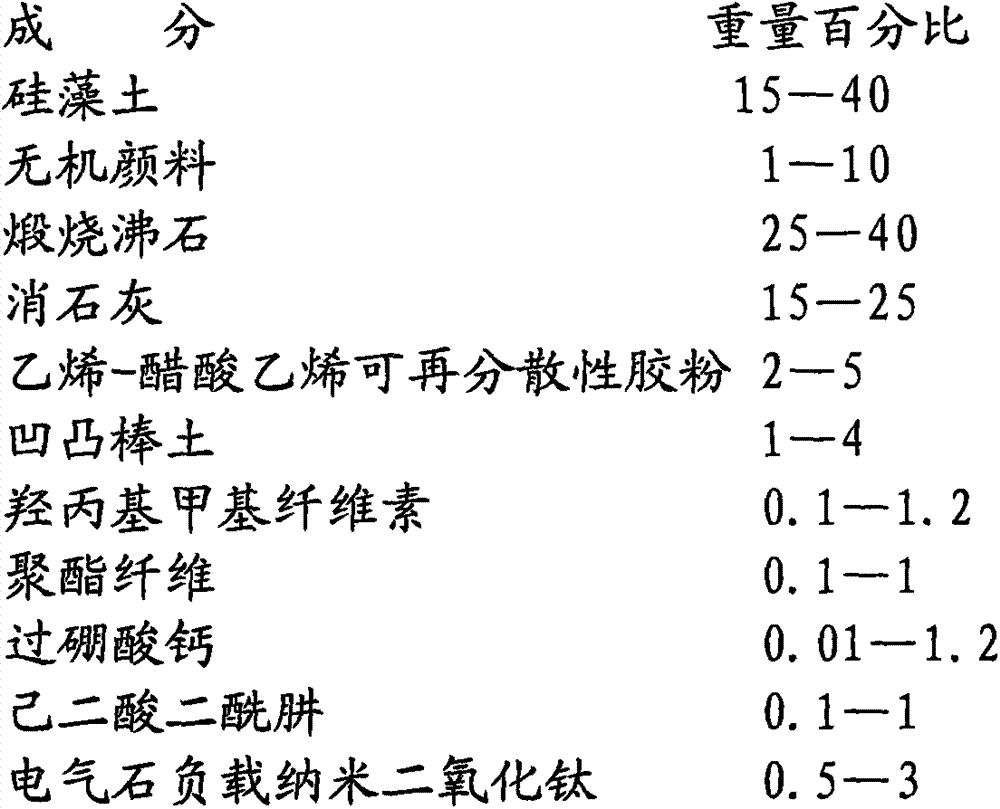

Method used

Image

Examples

Embodiment 1

[0022] Take 30kg of diatomaceous earth, with a silica content of more than 85%, and an average particle size of less than 0.074mm. Titanium dioxide 5kg, calcined zeolite 35kg, slaked lime 20kg, calcium hydroxide content is greater than 90%, and the average particle size is less than 0.074mm. Ethylene-vinyl acetate redispersible rubber powder 5kg, attapulgite powder 2kg, hydroxypropyl methylcellulose 0.6kg, polyester fiber 0.3kg, calcium perborate 1kg, adipic acid dihydrazide 0.5kg, tourmaline Load 1kg of nano titanium dioxide. The processing equipment is a general-purpose closed mixing equipment, and the above materials are put in proportionately, and the powder wall material can be obtained by mixing them fully.

Embodiment 2

[0024] Take 120kg of diatomaceous earth, 15kg of titanium dioxide, 100kg of calcined zeolite, 50kg of slaked lime, 15kg of ethylene-vinyl acetate redispersible rubber powder, 10kg of attapulgite powder, 2kg of hydroxypropyl methylcellulose, 2kg of polyester fiber, Calcium borate 2kg, adipic acid dihydrazide 2kg, tourmaline loaded nanometer titanium dioxide 5kg. The material specifications of each component are the same as in Example 1. Using the processing equipment and method of Example 1, the powder wall material was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com