Patents

Literature

424 results about "Off-flavour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Off-flavours or off-flavors (see spelling differences) are taints in food products caused by the presence of undesirable compounds. They can originate in raw materials, from chemical changes during food processing and storage, and from micro-organisms. Off-flavours are a recurring issue in drinking water supply and many food products.

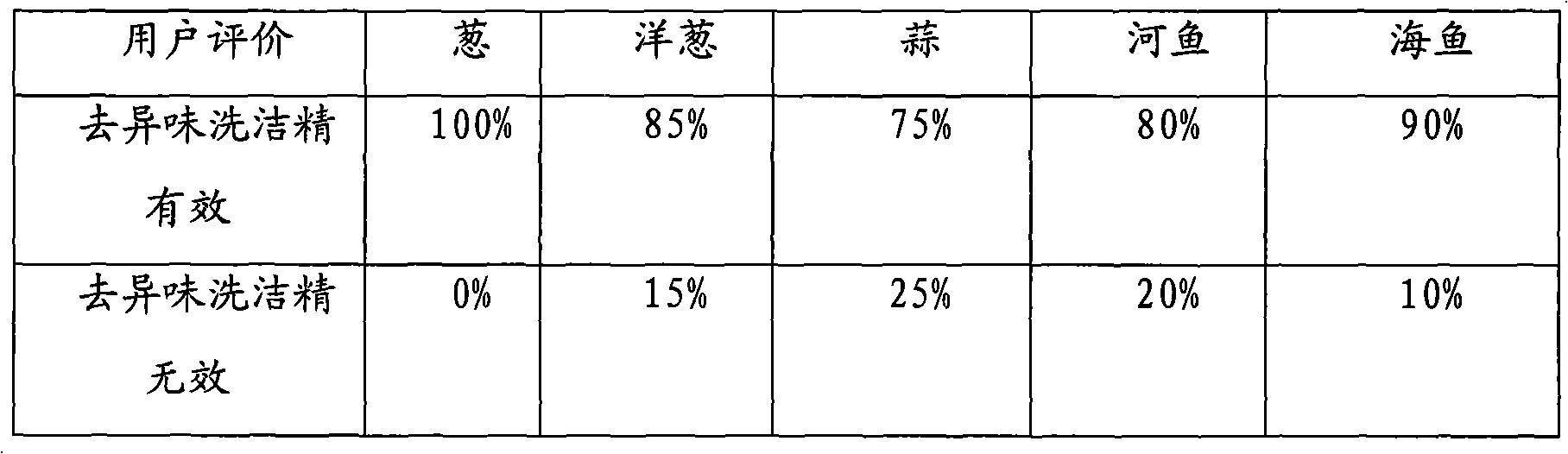

Cleanser essence capable of removing odors of kitchen utensils

InactiveCN101993786ANon-ionic surface-active compoundsAnionic surface-active compoundsFlavorCleansers skin

The invention relates to the field of chemicals for daily use, in particular to an odor removing cleanser essence containing one or more than one neutralization component, which has a rapid removal effect particularly specific to common odors in kitchens, such as fishlike smell, and stale flavors of onions, garlic, green onions and the like. The odor removing cleanser essence containing one or more than one neutralization component comprises the following components: 0.001-5 percent of neutralizer, 10-25 percent of surface active agent, 0.001-10 percent of solvent, 0.001-1.0 percent of synergist, 0.001-1.0 percent of antiseptic, 0.001-5 percent of essence and the balance of deionized water. The components are filled into a bottle after being evenly mixed and can be used for cleaning the utensils, such as bowls and dishes, chopsticks, chopping blocks, rags, table tops, bailers and the like, and the fishlike smell and the odors of the onions, the garlic, the green onions and the like can be rapidly removed. The cleanser essence is safe and is nontoxic for human bodies.

Owner:SHANGHAI BAIMAO

Low carbohydrate direct expanded snack and method for making

A method for making a low carbohydrate high protein puffed snack food product. Ingredients comprising soy isolate, soy concentrate, corn meal, and water are introduced into an extrudate. The ingredients are extruded through a die orifice at a high specific mechanical energy. The ingredient formula ranges have been determined that maximize volumetric expansion and the set operating conditions and keep texture, color, and flavor acceptable. The puffed snack is then dried and seasoned. There are minimal off-flavors in the product.

Owner:FRITO LAY NORTH AMERICA INC

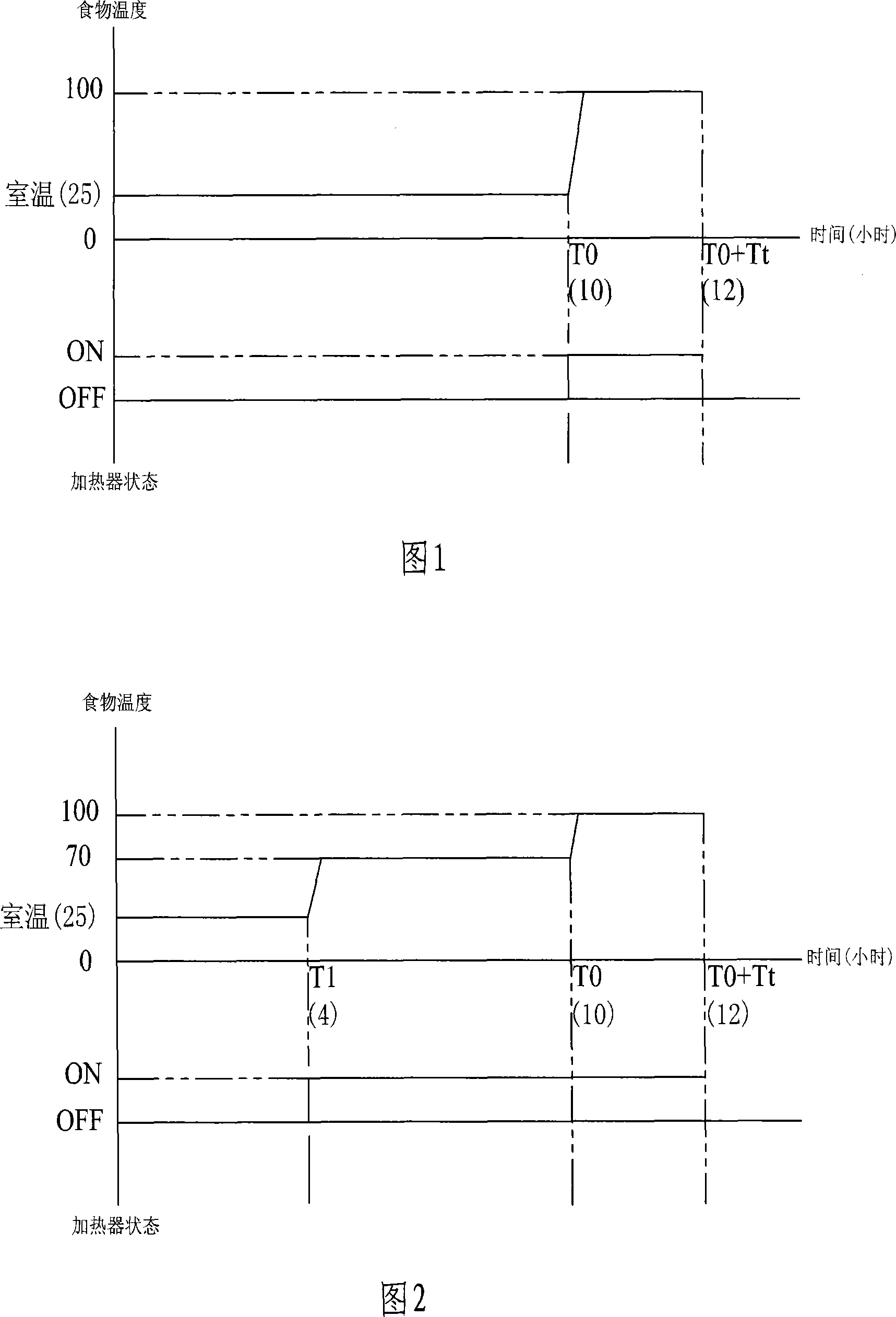

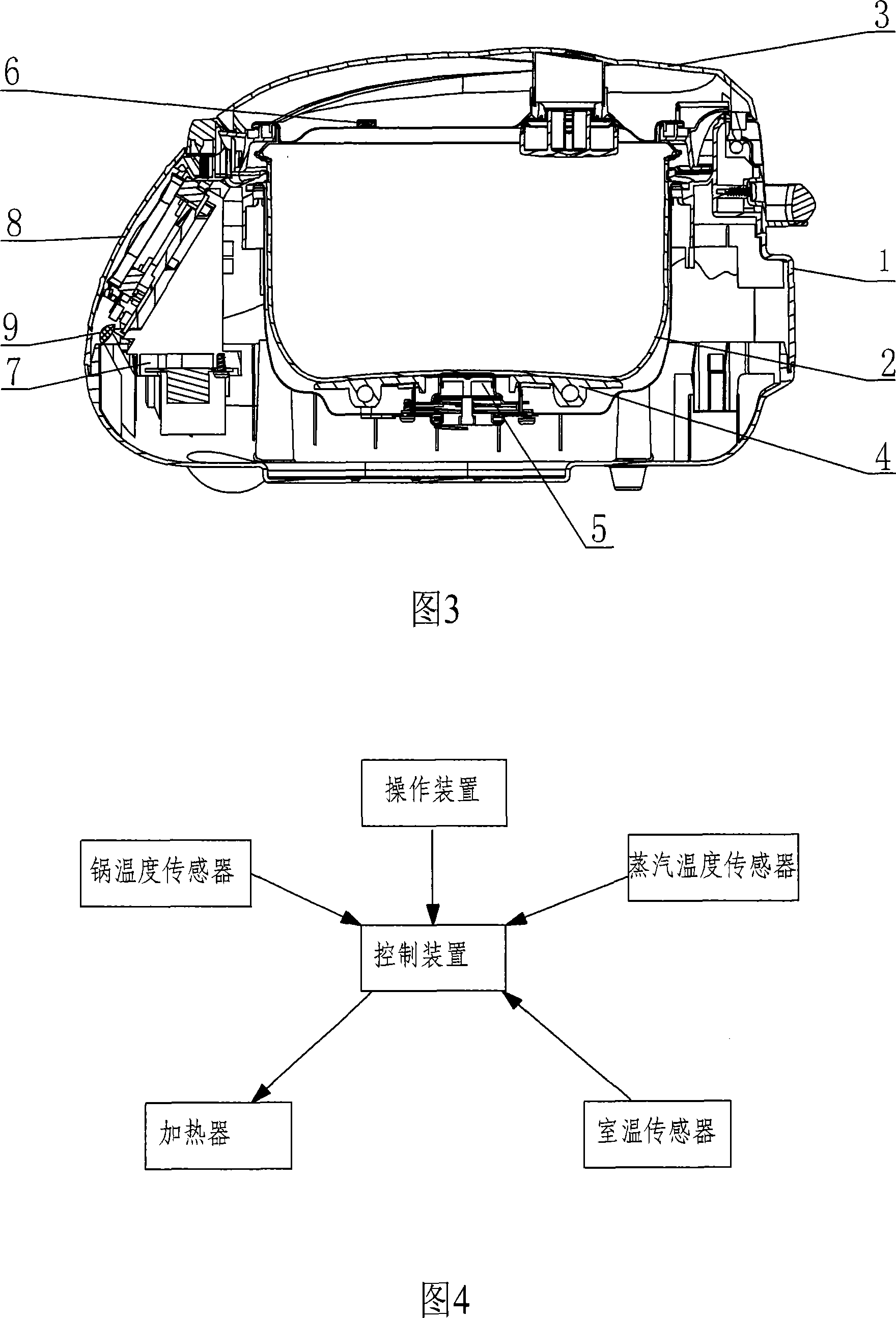

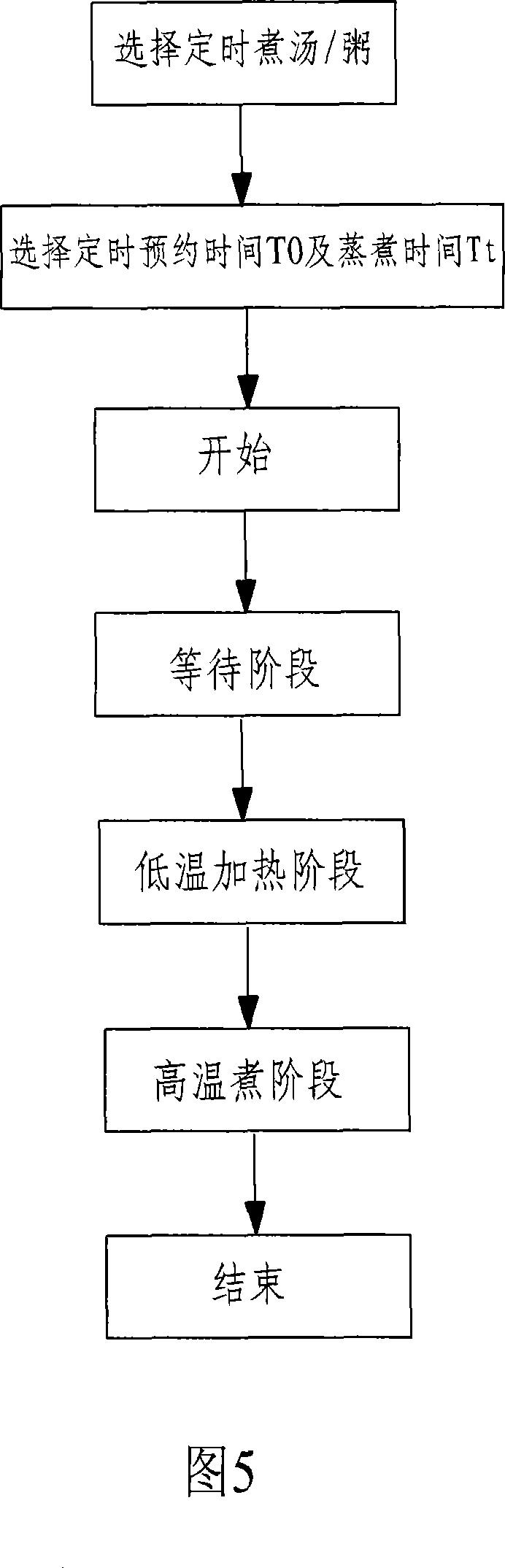

Timing cooking soup/porridge electric cooker and its cooking method

ActiveCN101099634AMeet needsIncrease autoscale wait timeCooking vesselsTemperature control using electric meansEngineeringCooking methods

The present invention discloses an electric rice cooker which can be used for boiling soup or porridge at fixed time. It includes the following several portions: main body, inner pot, heater, pot temperature sensor, control device with timer and operation device. Said invention also provides its cooking method and steps.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

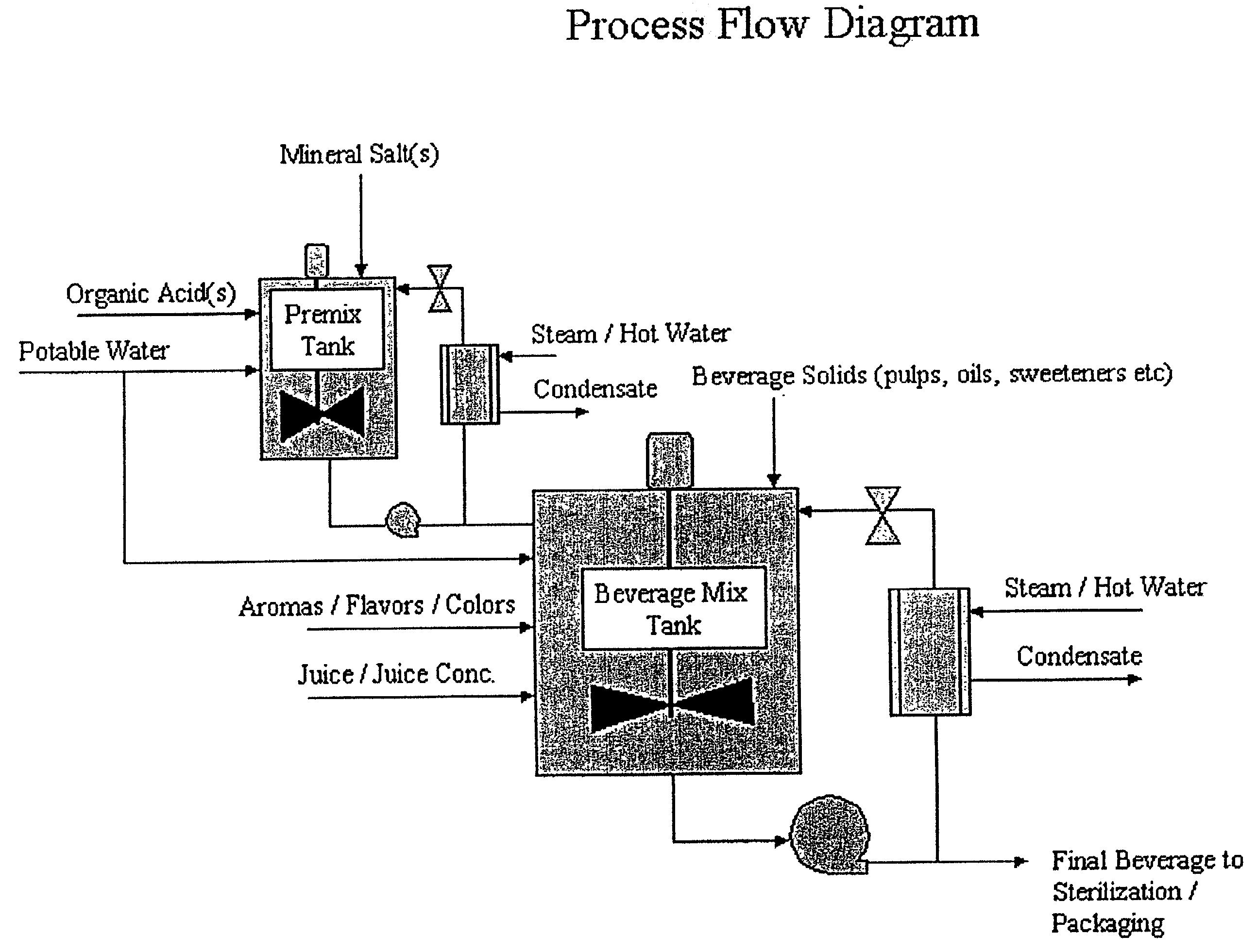

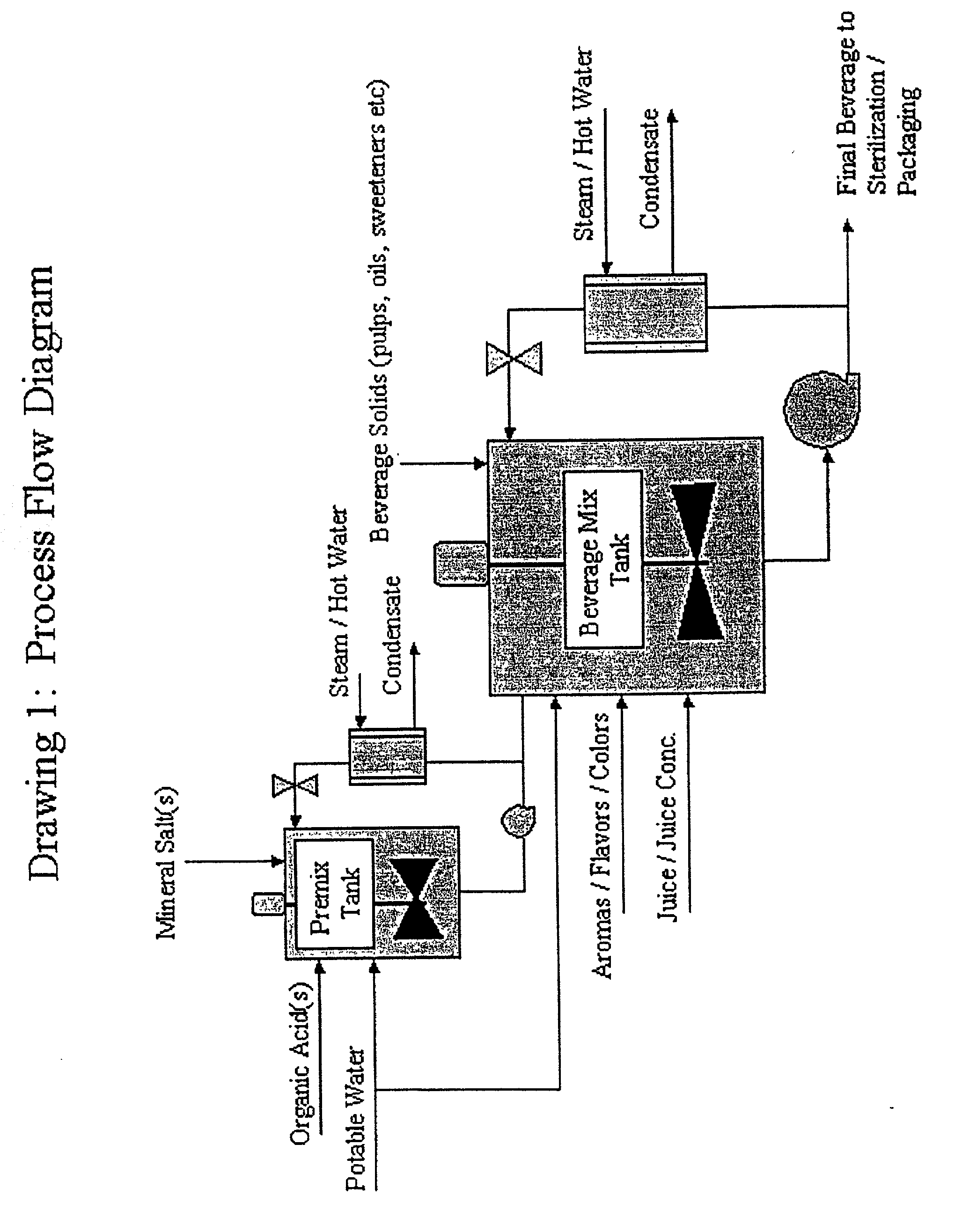

Method of preparing beverages and beverage concentrates nutritionally supplemented with minerals

InactiveUS20030211204A1Vitamin food ingredientsAnimal feeding stuffNutrition supplementationWater soluble

A method for preparing mineral fortified beverages and beverage concentrates involves forming a premix solution containing a highly soluble mineral salt, which is then combined with the final beverage or beverage concentrate product. This method provides beverages substantial levels of a solubilized mineral at a cost effective price without generating off flavors, tastes or mineral inter-actions currently resulting from most mineral fortification solutions.

Owner:FIELDS CHRISTINE C +1

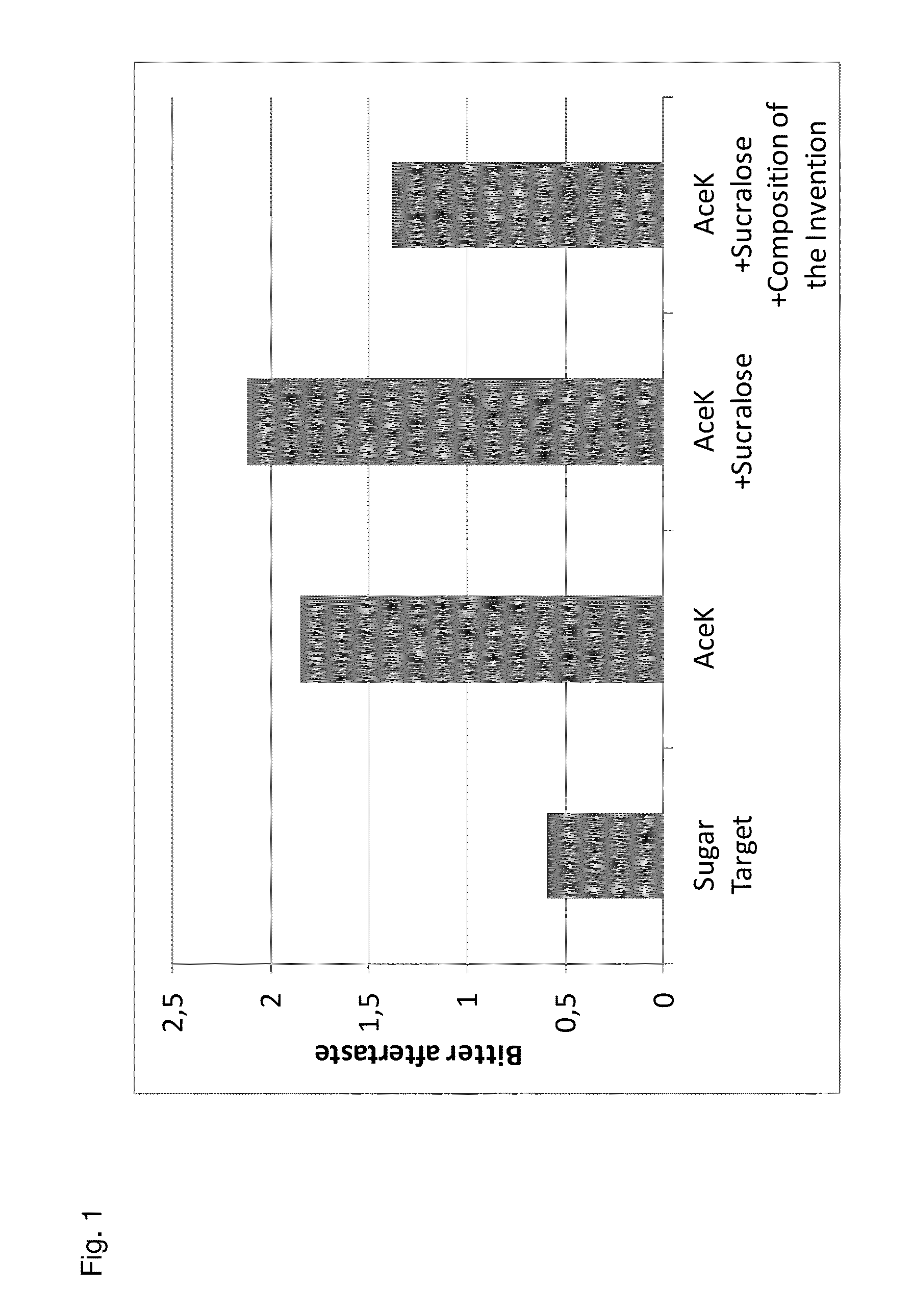

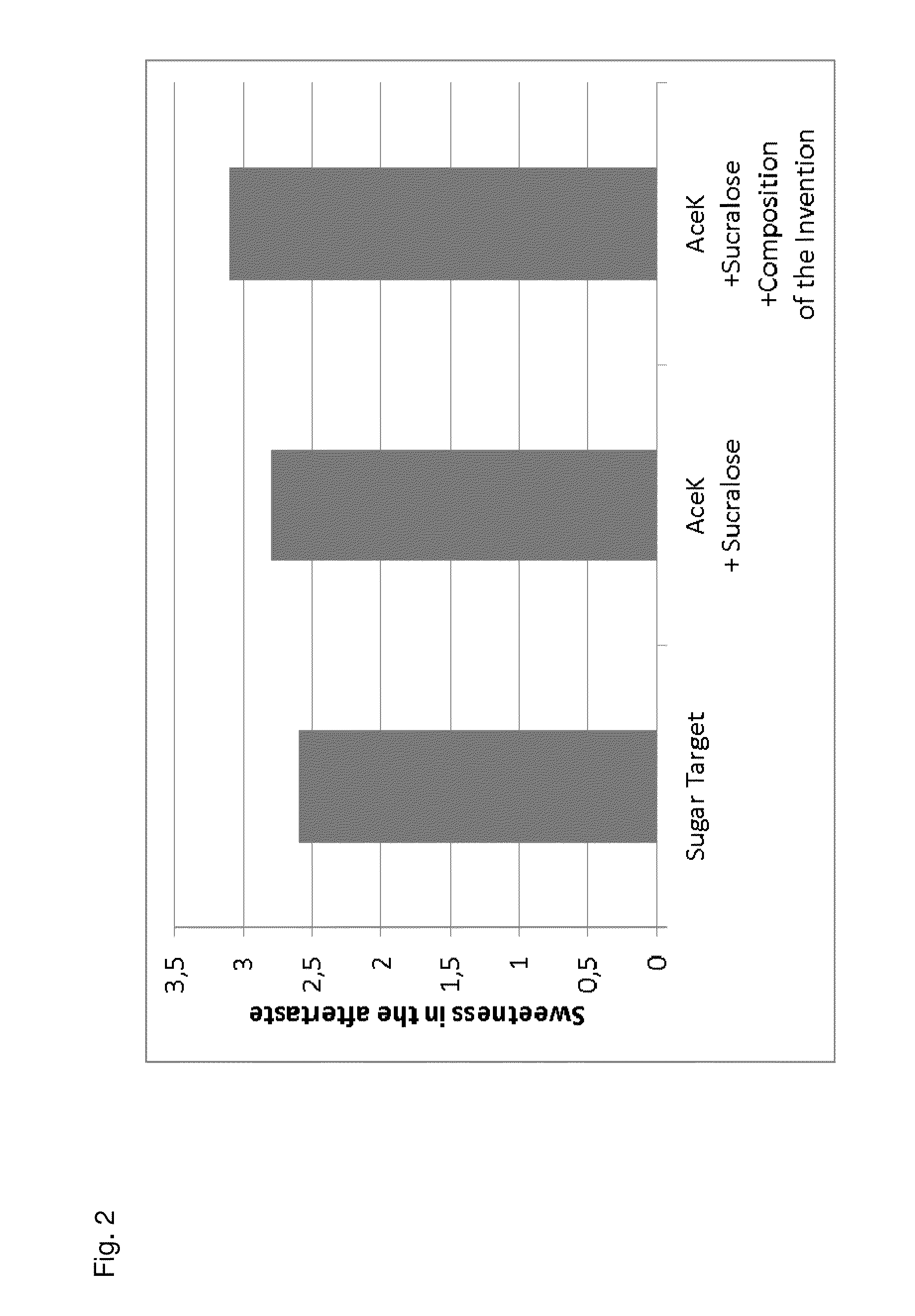

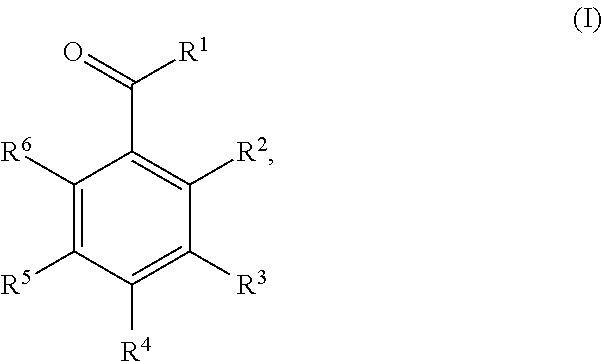

Taste-Masking Compositions, Sweetener Compositions and Consumable Product Compositions Containing the Same

In one embodiment, the present invention relates to a sweetener composition comprising: a sweetener and at least one flavoring. The at least one flavoring is suitable for modifying, masking, reducing and / or suppressing an unpleasant off-taste of the sweetener in a consumable product composition formed by adding the sweetener composition to a consumable product. A weight ratio of the at least one flavoring to the sweetener in the consumable product composition is such that the sweetness of the sweetener is detectable by taste in the consumable product composition and the flavor of the at least one flavoring is not detectable by taste in the consumable product composition.

Owner:CELANESE SALES GERMANY

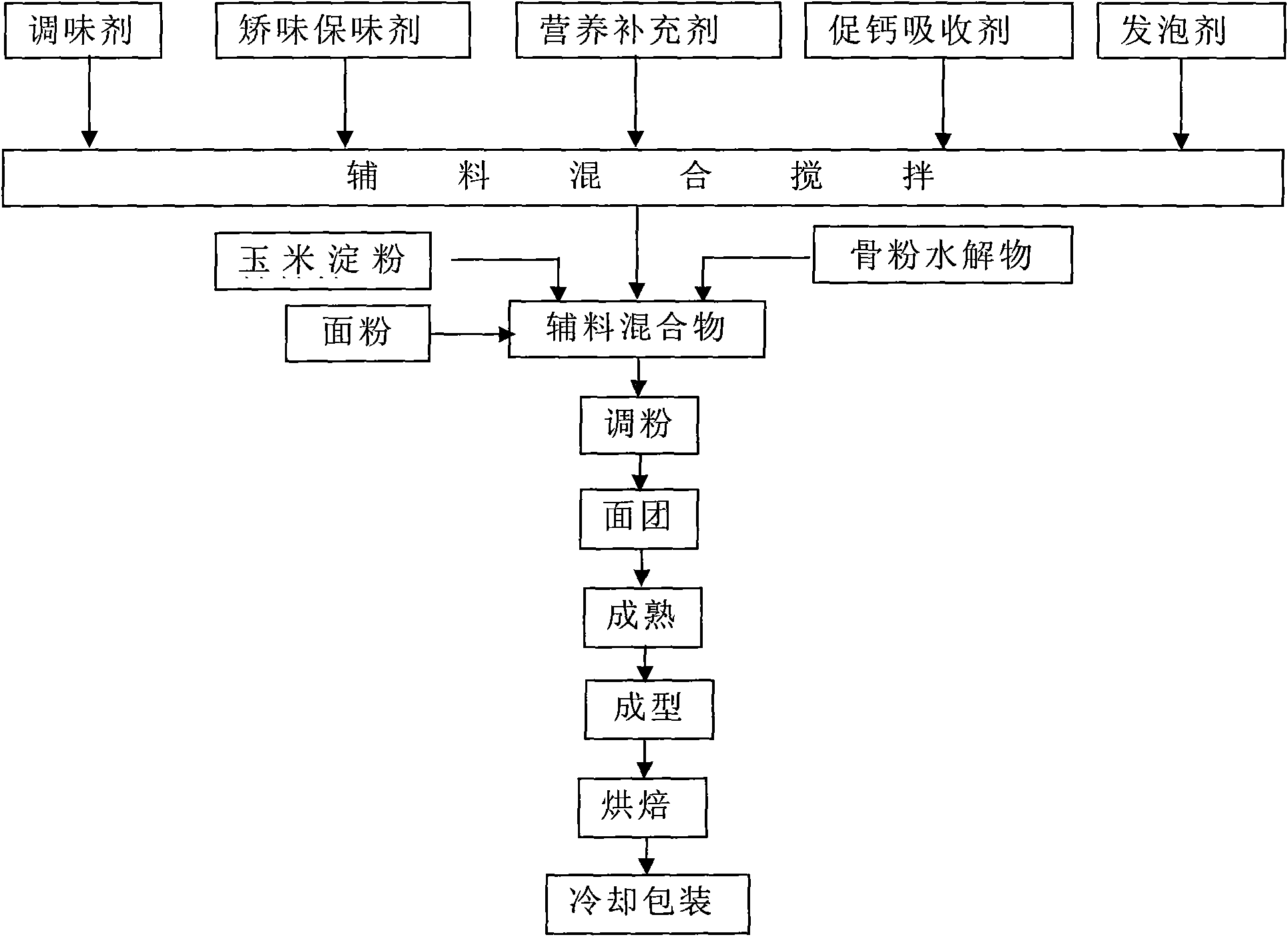

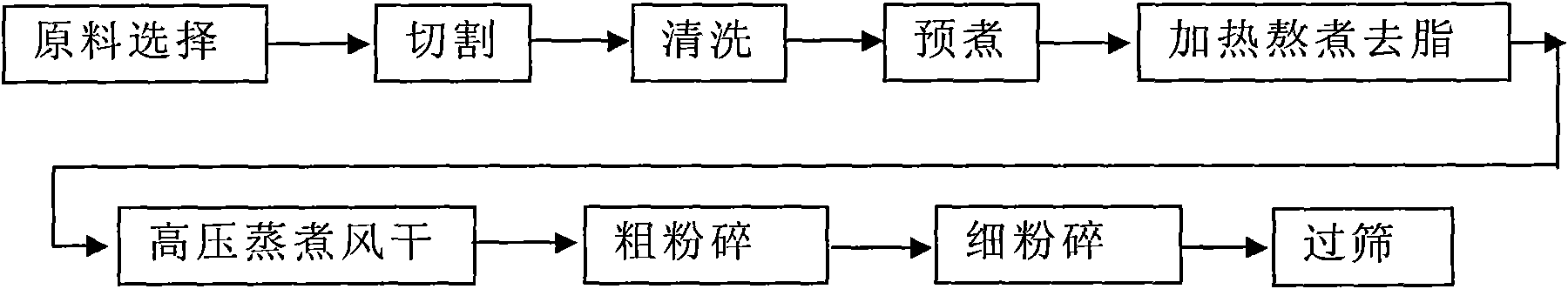

Nutritional biscuit with high bone calcium and making method thereof

InactiveCN101606545AIt has the effect of correcting and preserving flavorImprove and improve organizational structureDough treatmentBakery productsFlavorFoaming agent

The invention relates to a nutritional biscuit with high bone calcium and a making method thereof, belonging to a processing and making technique of foods required by the life of human beings. The nutritional biscuit is formed by preparing and processing the following raw materials according to a certain proportion formula and a certain production technology and comprises the following raw materials according to the formula and the mixture ratio: 950g of flour, 50g of corn starch, 350g to 450g of cattle bone powder hydrolyzing substance, 240g to 260g of flavoring agent, 140g to 160g of flavoring taste-retaining agent, 280g to 300g of nutritional extender, 80g to 100g of calcium absorption promoter, 6g to 8g of foaming agent and 1ml of butter essence. The product contains high effective calcium and abundant nutrition, the color of the surface of the biscuit is bright, and the biscuit has a deep red brown color, has the special flavor of bone, is soft, savory and crisp and has no peculiar odor. The processing procedure of the invention is shown as the attached drawing of the abstract.

Owner:GUIZHOU UNIV

Extraction of phenolic antioxidants

InactiveUS20050095332A1Increase pressureIncrease temperatureOrganic compound preparationCarboxylic acid esters preparationOff-flavourPhenolic antioxidant

Owner:STANLEY ROGER ANTHONY

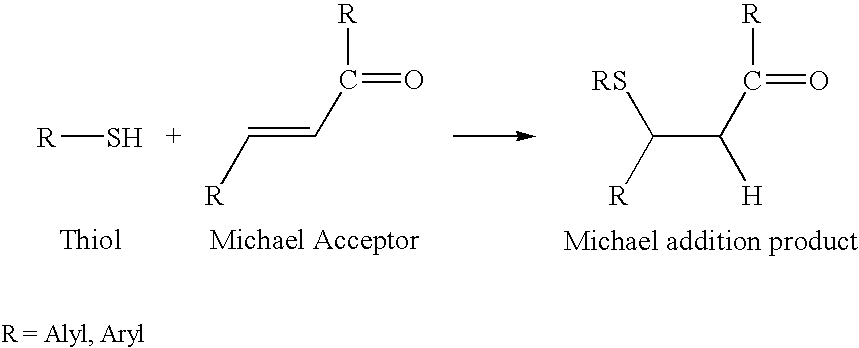

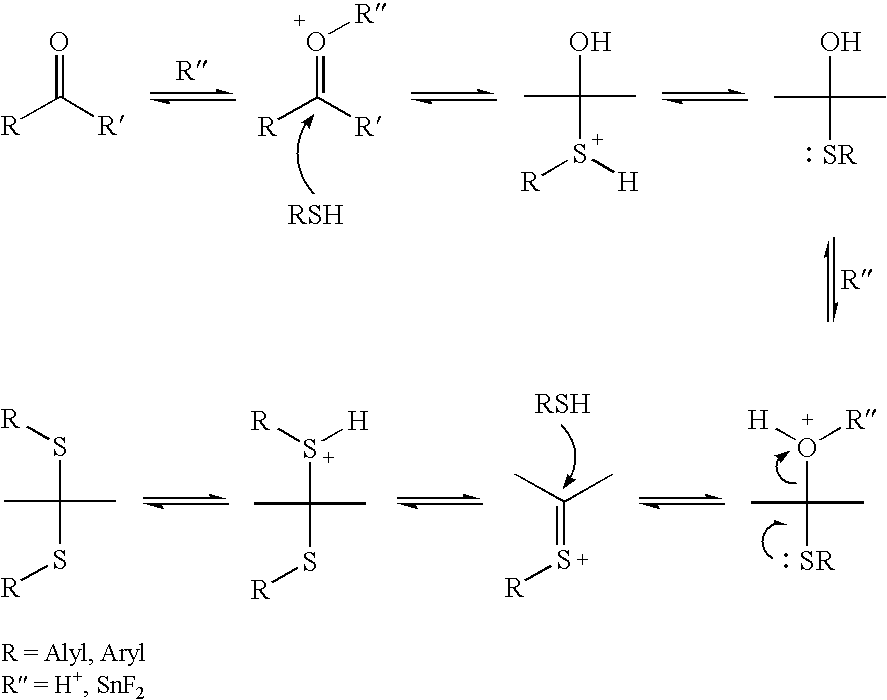

Flavors for oral compositions

ActiveUS20080008665A1Avoid generatingPrevents of off tasteBiocideCosmetic preparationsBenzaldehydePeppermints

The present invention relates to oral care compositions comprising stannous ions, a mint-type flavor oil, a protectant component that prevents generation of off odor and off taste in the composition, and orally acceptable carriers. The mint-type oils include peppermint, spearmint and corn mint. Suitable protectant components include copper salts and carbonyl compounds such as ascorbic acid; cis-jasmone; 2,5-dimethyl-4-hydroxy-3(2H)-furanone; 5-ethyl-3-hydroxy-4-methyl-2(5H)-furanone; vanillin; ethyl vanillin; anisaldehyde; 3,4-methylenedioxybenzaldehyde; 3,4-dimethoxybenzaldehyde; 4-hydroxybenzaldehyde; 2-methyoxybenzaldehyde; 4-methoxybenzaldehyde; benzaldehyde; cinnamaldehyde (3-phenyl-2-propenal); hexyl cinnamaldehyde; α-methyl cinnamaldehyde; ortho-methoxy cinnamaldehyde; α-amyl cinnamaldehyde; and combinations thereof. The oral care composition may be a dentifrice.

Owner:THE PROCTER & GAMBLE COMPANY

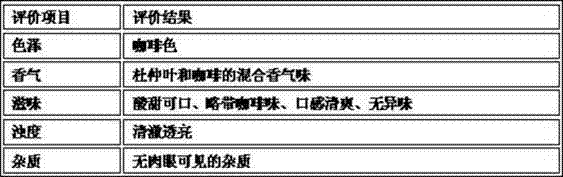

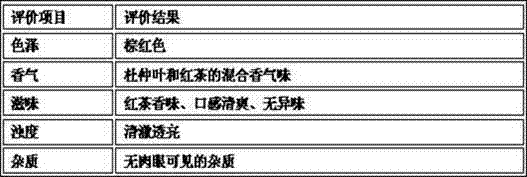

Method for preparing healthcare beverage by removing peculiar smell of eucommia ulmoides leaf extracting liquor

ActiveCN103689736AEliminate bitternessEliminate astringencyFood ingredient functionsBiotechnologyOff-flavour

The invention discloses a method for preparing healthcare beverage by removing peculiar smell of eucommia ulmoides leaf extracting liquor, which is a method for carrying out ozone treatment and biological embedding treatment on the eucommia ulmoides leaf extracting liquor, and overcomes grass smell, bitter taste and astringent taste of the eucommia ulmoides leaf extracting liquor. The prepared sugar-free type and common beverage has characteristics similar to those of coffee and black tea in color, appearance and mouthfeel, is adaptive to characteristics which are pursued by the young, and overcomes the defect that the coffee and the back tea affect the sleep, digestion, and the like; meanwhile, the healthcare beverage has healthcare functions of removing fatigue, refreshing and reinforcing intelligence, improving immunity, and the like.

Owner:陕西天承生物科技股份有限公司

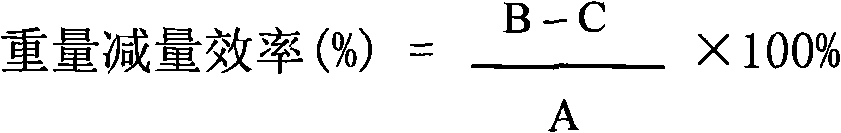

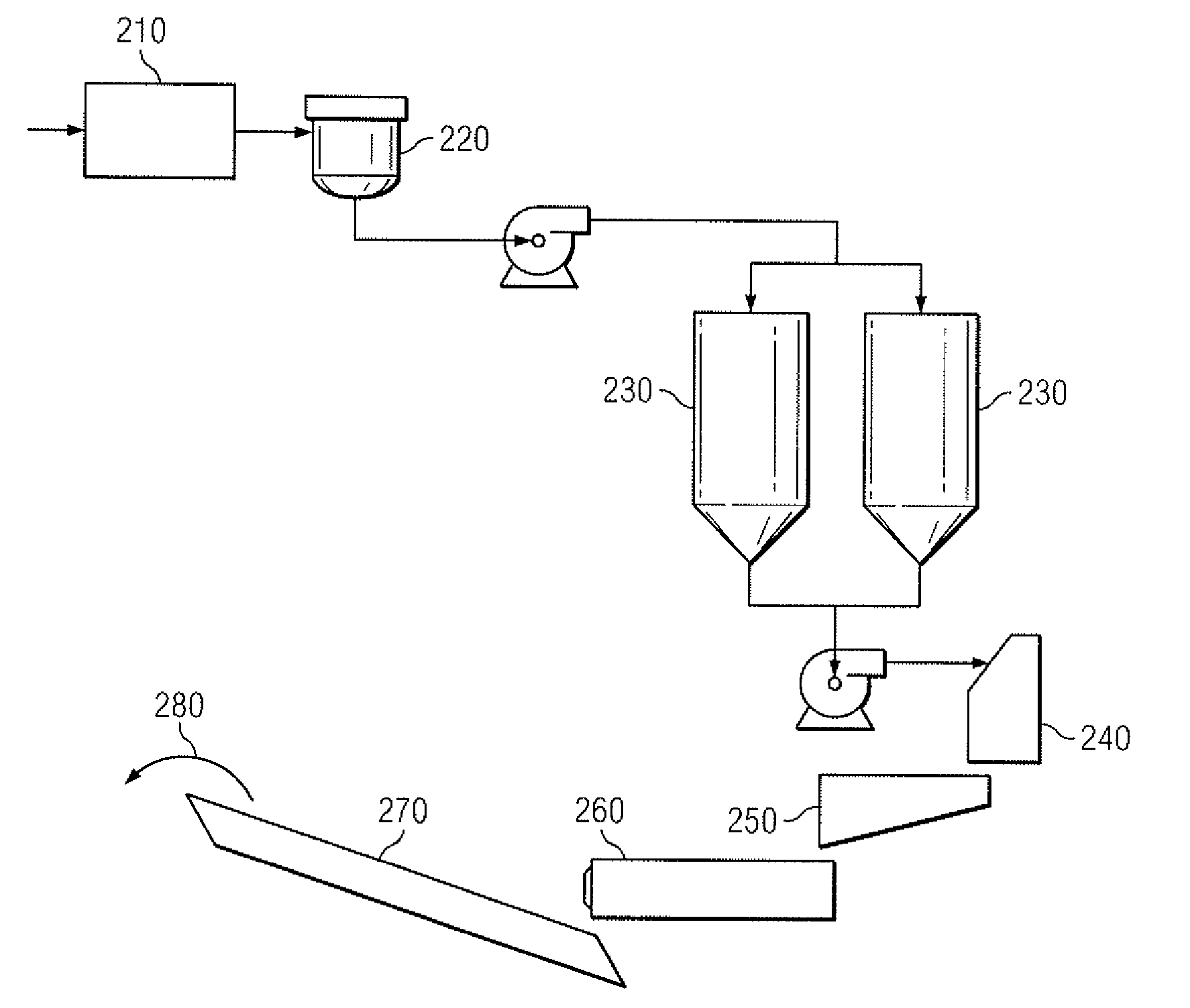

High-efficient restaurant-kitchen waste degrading microorganism bacterial agent and preparation method and application thereof

The invention discloses a high-efficient restaurant-kitchen waste degrading microorganism bacterial agent and a preparation method and application thereof. The microorganism bacterial agent is prepared by mixing microorganism compound thalli for degrading restaurant-kitchen wastes and carrier materials with high air permeability, and the compound thalli accounts for 5 to 20 percent based on the total mass of the carrier materials. The compound microorganism bacterial agent of the invention can achieve good effect when used in a waste grinder, and the average degradation rate is over 77 percent every day. The microorganism bacterial agent fundamentally solves the problems that the restaurant-kitchen wastes have high humidity and strong peculiar smell, and high-salt and high-oil components are difficultly degraded existing in the prior art. The microorganism bacterial agent has the advantages of stable treating effect, simple preparation method and no environmental pollution.

Owner:HANYU GRP CO LTD

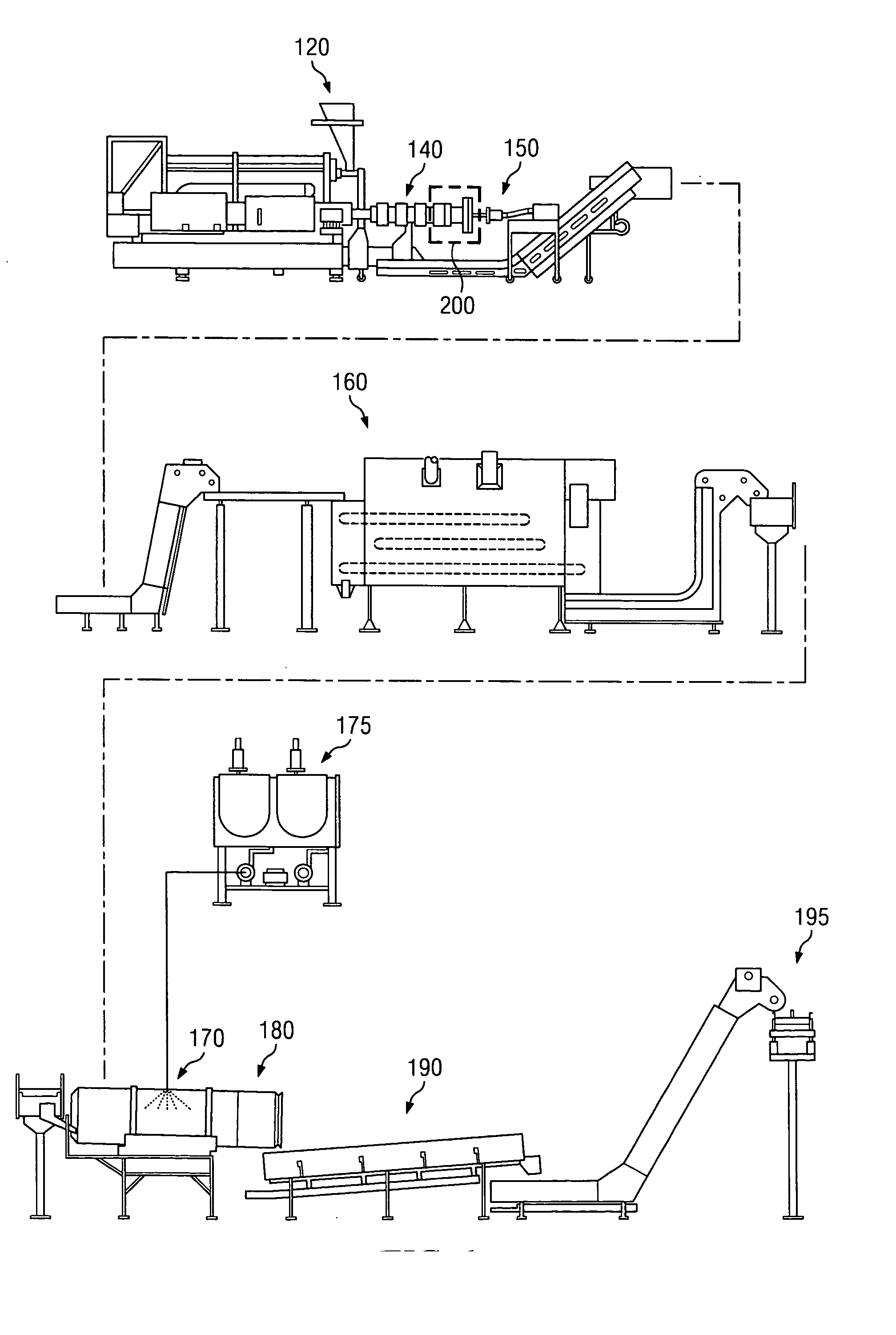

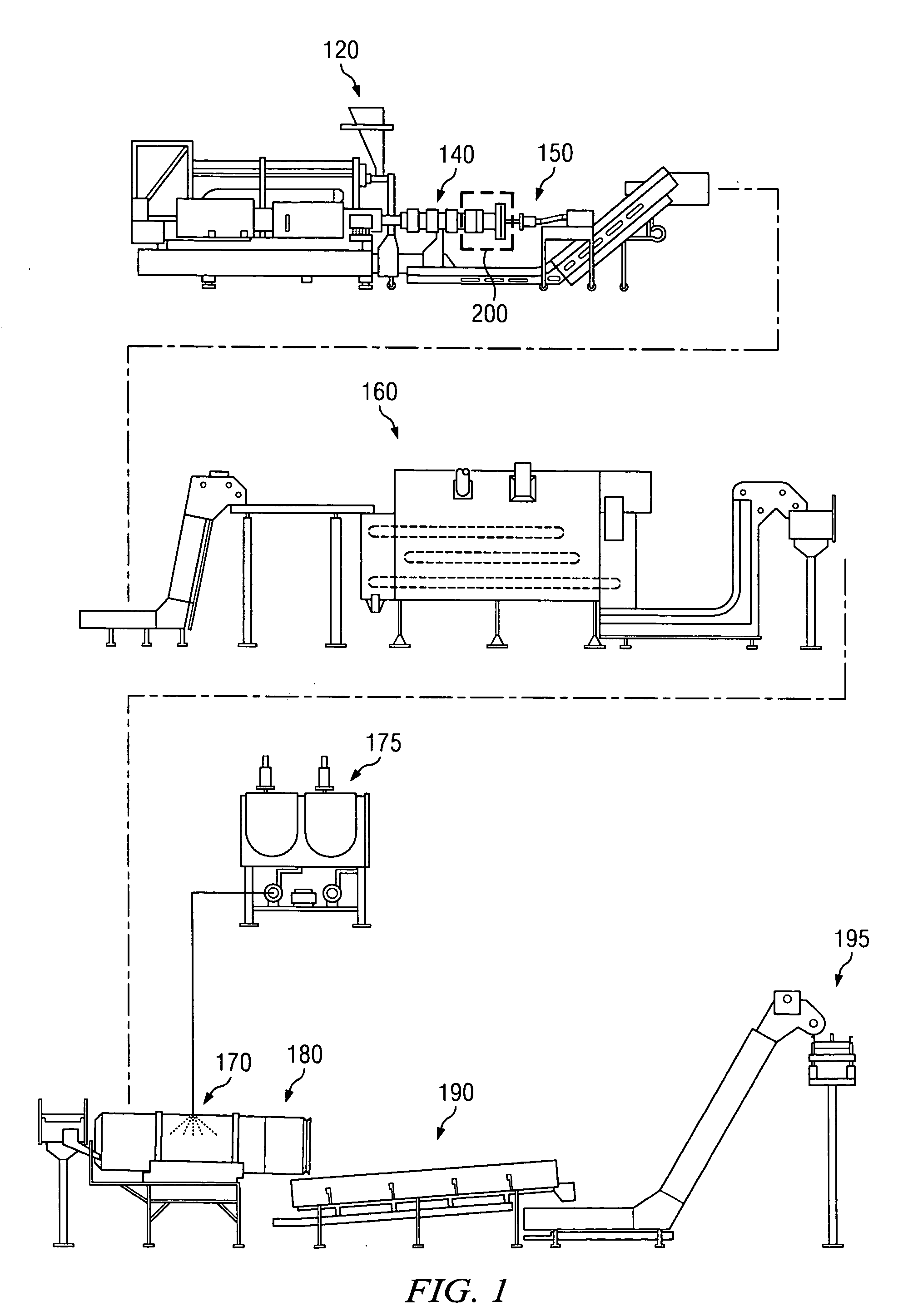

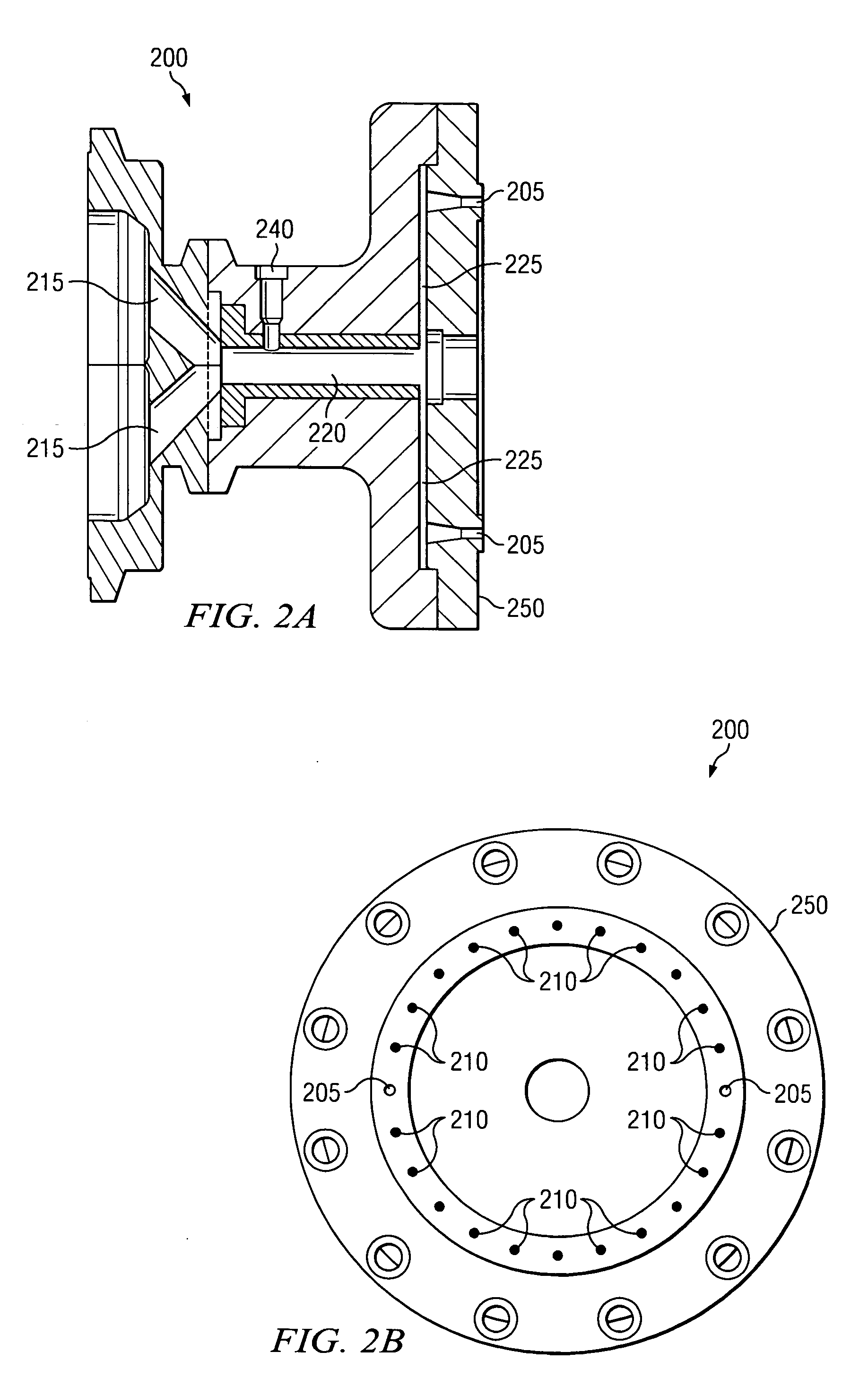

Process for Neutralizing Enzymes in Corn

A method of making an enhanced corn masa by roasting corn kernels to neutralize the corn seed prior to cooking and soaking the corn in lime. Roasting of the corn kernels provides numerous benefits including the ability to dial in a roasted flavor with the use of blends of roasted and unroasted kernels, a higher conversion of the corn kernel into a finished product, a reduced acrylamide content in finished product, and fewer off-flavors in baked products.

Owner:FRITO LAY NORTH AMERICA INC

Novel interlayer fine dried noodles and processing method thereof

InactiveCN105380103AHas a clear fragranceNot stickyFood coatingFood ingredient as mouthfeel improving agentOff-flavourInsect pest

The invention discloses novel interlayer fine dried noodles, comprising upper flour slices and lower flour slices, as well as sweet potato or solanum tuberdsm flour slices pressed between the upper flour slices and the lower flour slices. The cooked interlayer sweet potato fine dried noodles are slightly white in surface color and internal red and external white in section, have unique fresh scent of the sweet potato, and are not pasty, not thick in soup, not sticky in taste, not gritty, are soft and tasty and refreshing, a cooking noodle break ratio is smaller than or equal to 5%, the irregularity is smaller than or equal to 15%, wherein, the natural noodle break ratio is smaller than or equal to 8%, physicochemical indexes of the fine dried noodles have a water content being smaller than or equal to 13.5%, acidity being smaller than or equal to 4.0, and a bending noodle break ratio being smaller than or equal to 15%; hygienic indexes achieve no impurity, no mildewing, no extraneous odor, no insect attack and no pollution, and raw materials and auxiliaries accord with national standards.

Owner:李少卫

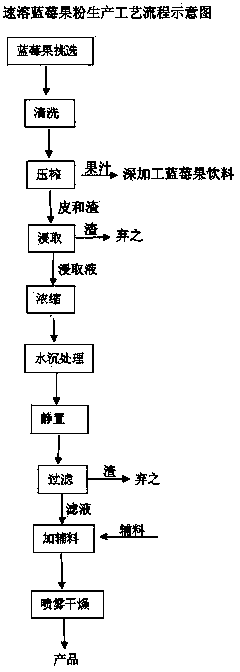

Method for preparing instant blueberry powder

InactiveCN103960615ARich varietyImprove comprehensiveFood dryingFood preparationOff-flavourSpray dried

The invention discloses instant blueberry powder and a preparation method thereof and belongs to the technical field of fruit processing. The preparation method comprises the following steps: extracting blueberry peels and residues, concentrating, performing water sedimentation, adding auxiliary materials, mixing, and processing by adopting a spray drying method. The prepared instant blueberry powder is bright red in color, fine and smooth in handfeel and odor-free, nutritional ingredients in fresh blueberries are completely preserved, the instant blueberry powder is enriched in blueberry anthocyanins, has the high nutrition and health care values and is high in brewing property, brewed liquid is pink in color, any insoluble substances are avoided after clarification, sugar, honey and the like can be added for flavoring and drinking according to the personal taste, and the instant blueberry powder is a product with good market prospects.

Owner:GUIYANG UNIV

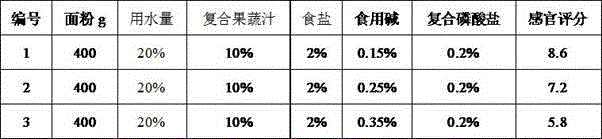

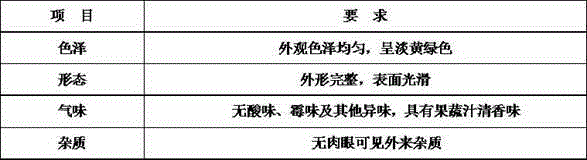

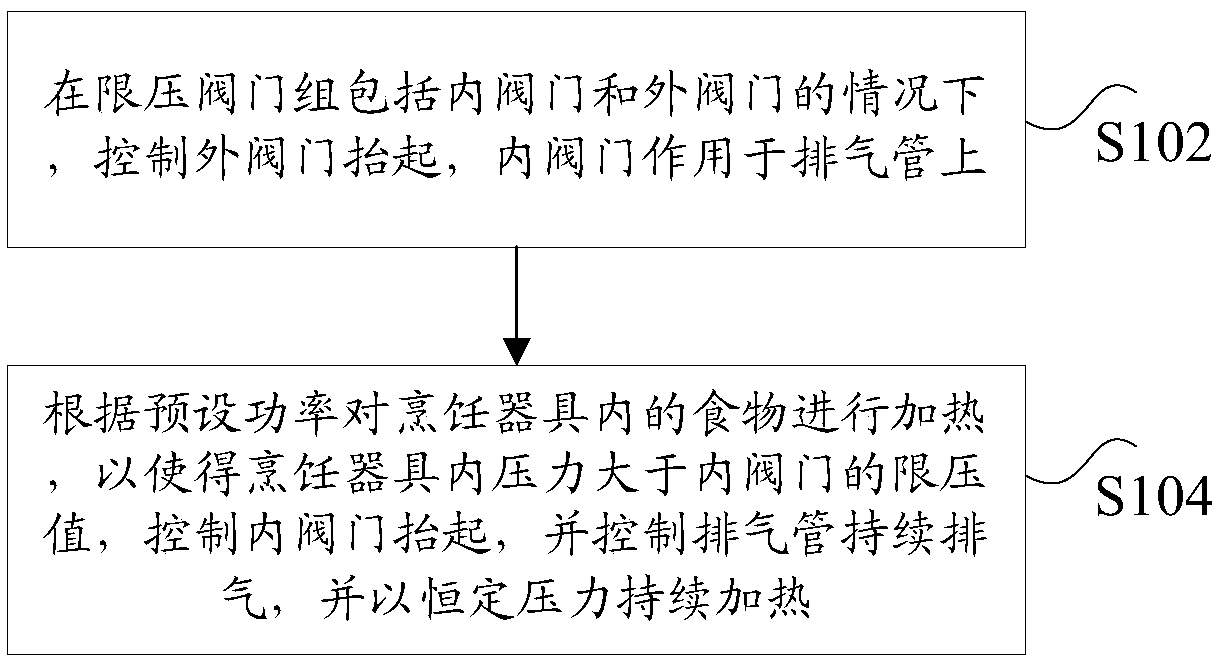

Composite fruit and vegetable juice fine dried noodles and preparation method thereof

The invention discloses composite fruit and vegetable juice fine dried noodles. The fruit and vegetable juice fine dried noodles are characterized by being prepared from the following components in parts by weight: 80-100 parts of wheat flour, 10-30 parts of water, 5-18 parts of composite fruit and vegetable juice, 1-5 parts of table salt, 0.1-0.5 part of dietary alkali and 0.1-0.5 part of composite phosphate. The composite fruit and vegetable juice fine dried noodles have uniform appearance color, are light yellow and green, complete in appearance and smooth in surface, have no sour and musty taste and other peculiar smell, and have scent fruit and vegetable flavor.

Owner:四川省苍溪漓山粮油有限公司

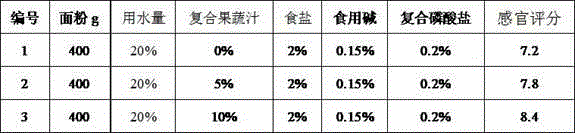

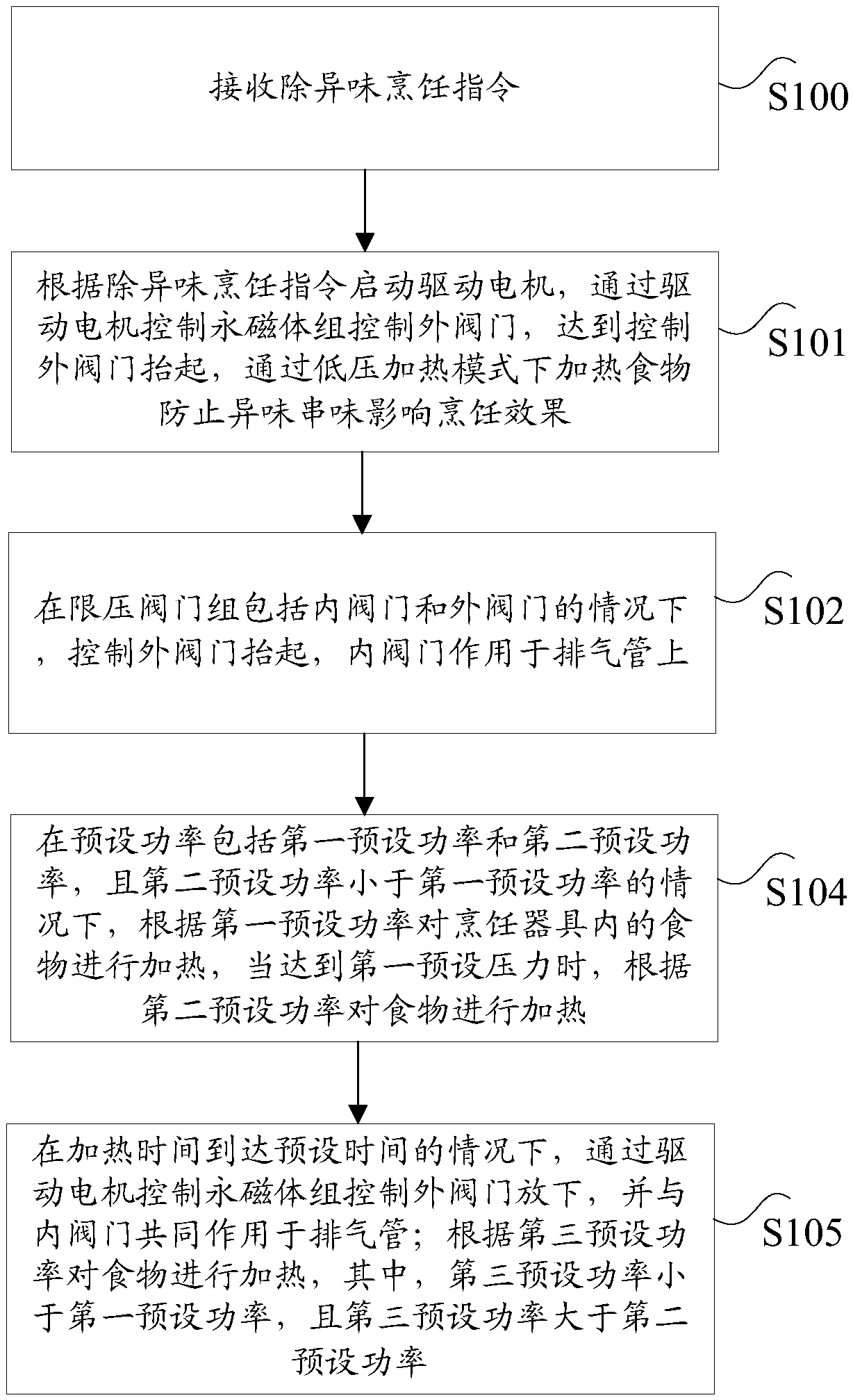

Cooking utensil, peculiar smell removal control method and peculiar smell removal control device

ActiveCN110801148AContinuous heatingEliminate odorPressure-cookersHome appliance efficiency improvementOff-flavourProcess engineering

The invention discloses a cooking utensil, a peculiar smell removal control method and a peculiar smell removal control device, wherein the peculiar smell removal control method and the peculiar smellremoval control device are applied to the cooking utensil. The peculiar smell removal control method comprises the following steps of under the condition that a pressure limiting valve group comprises an inner valve and an outer valve, controlling the outer valve to be lifted up and the inner valve to act on an exhaust pipe; heating food in the cooking utensil according to the preset power so that the pressure inside the cooking utensil can be greater than the pressure limiting value of the inner valve; controlling the inner valve to be lifted up; controlling the exhaust pipe to continuouslyexhaust air; and continuously performing heating at the constant pressure. The technical problem that peculiar smell of the food cannot be removed by a pressure cooker in the prior art is solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

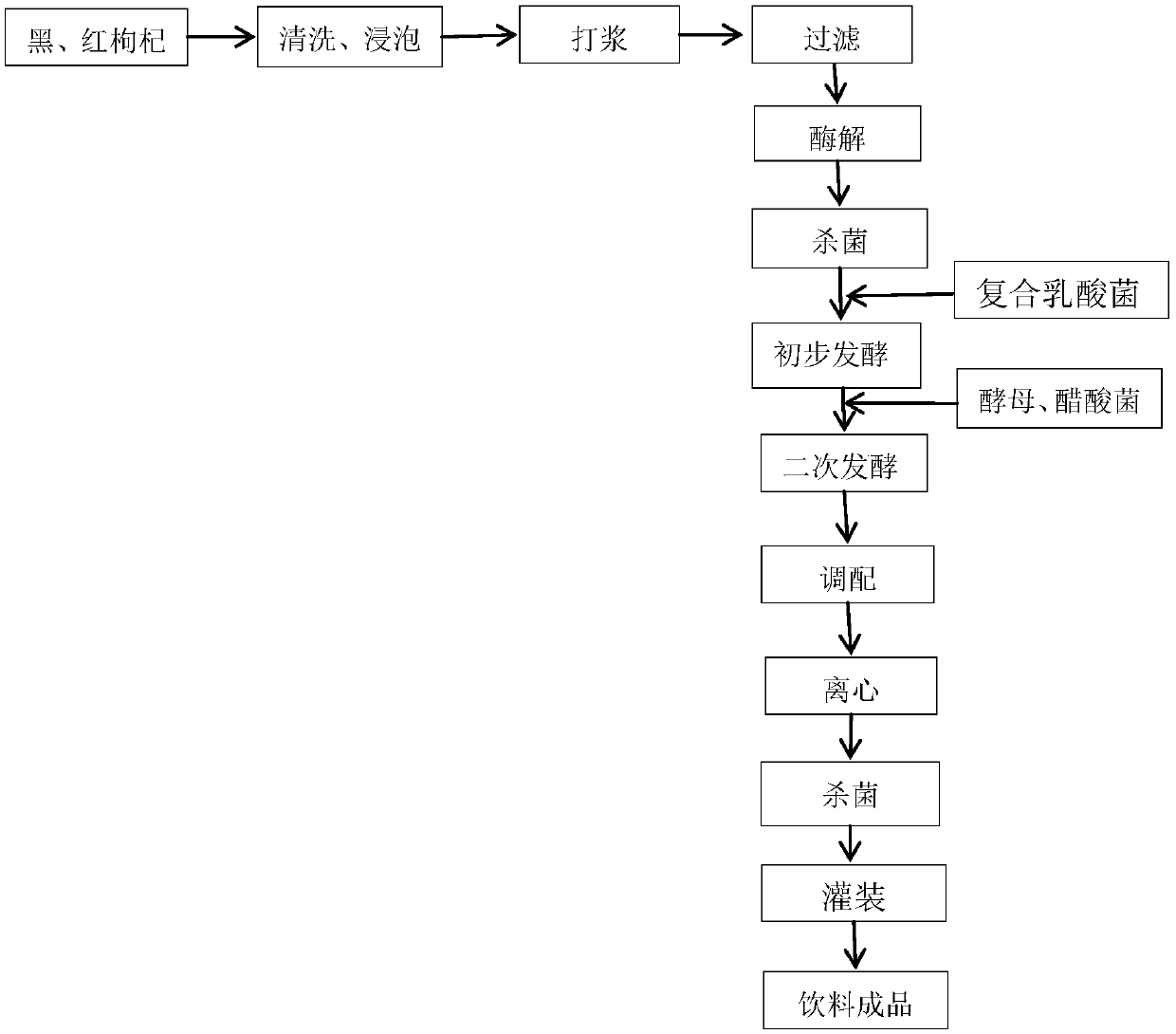

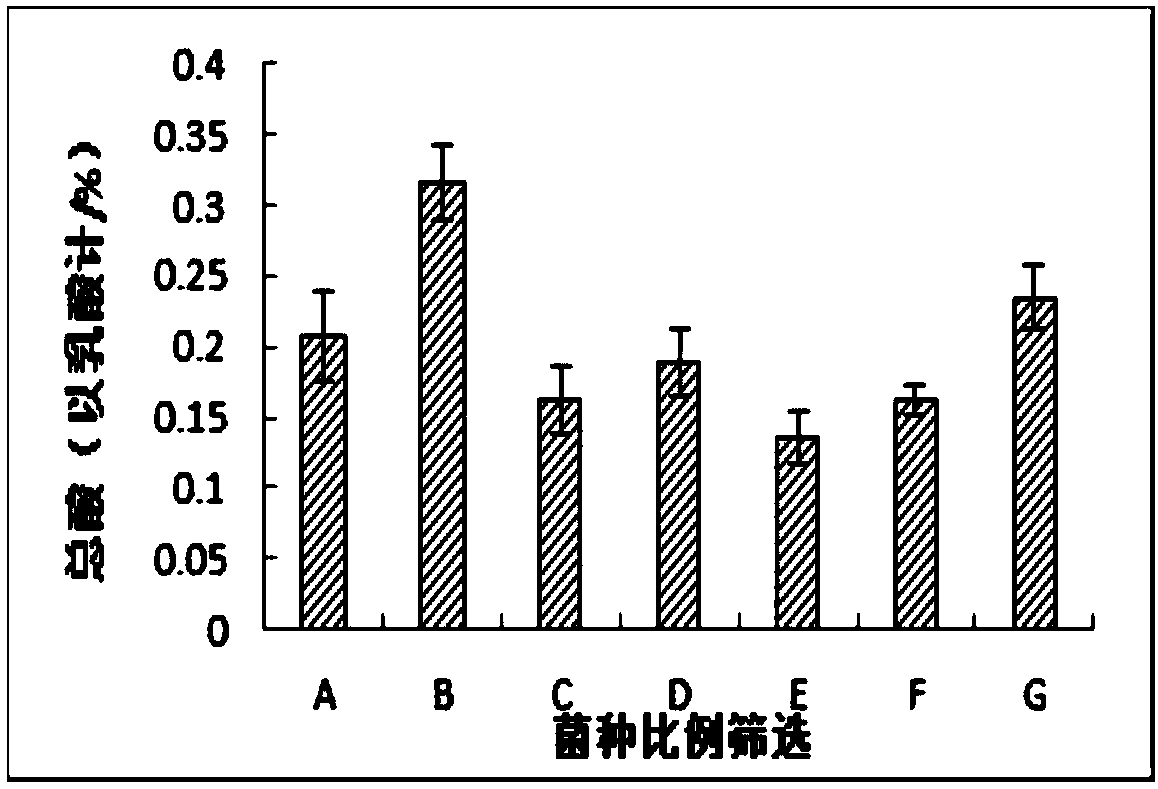

Black and red Chinese wolfberry fruit compound fermented beverage and preparation method thereof

InactiveCN109619352AImprove stabilitySolve difficult to recycleFood scienceEscherichia coliSaccharic acid

The invention discloses a novel black and red Chinese wolfberry fruit compound fermented beverage and a preparation method thereof and belongs to the processing field of microbial fermentation technologies of foods. The preparation method mainly comprises the steps of pretreatment of raw materials, juicing, ultrasonic assisted chitosan immobilized complex enzyme treatment, filtration, pasteurization, primary fermentation of a lactic acid bacterium composite leavening agent, secondary fermentation with active dry yeast and acetic acid bacteria, saccharic acid blending, centrifugation, pasteurization, filling and finished beverage. The preparation method is simple in process and low in processing cost, the prepared beverage has the flavor of Chinese wolfberry fruits and also has the smell produced through Chinese wolfberry fruit, a pleasant mellow aroma and soft sour, so that the beverage has more delicate taste, has no bad odor, homogeneous color and luster and good nutritional health-care functions; the total acid of the beverage is 2.83%, pH is 3.70, the aqueous protein of plants is 2.83g / L, the total phenol is 38.17mg / L, the carotenoid is 35.67ug / L, the alcoholic strength is 1% or below, and bacteria and escherichia coli are not detected out.

Owner:NINGXIA UNIVERSITY

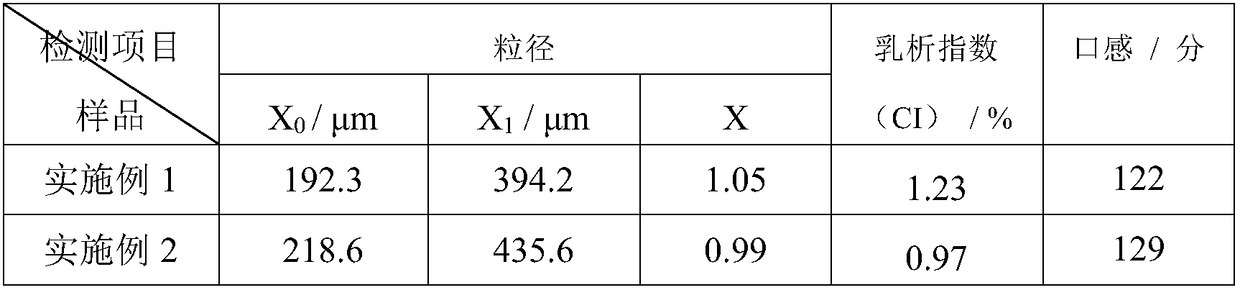

Microcapsule powder composition containing odor-free oil and preparation technology thereof

PendingCN108514117AComposite functionGreat tasteSugar food ingredientsFood homogenisationSolubilityOil phase

The present invention relates to a microcapsule powder composition containing odor-free oil and a preparation technology thereof, and relates to the fields of food, medicines and health-care products.The composition contains 10-100 parts by weight of an oil phase free of a special odor, 10-180 parts by weight of fat-soluble nutrients, 80-1,000 parts by weight of capsule materials, and 10-100 parts by weight of an oil-phase flavoring agent. The microcapsule powder composition has many advantages of good water solubility, high human body absorption rate, good mouthfeel, various taking ways, etc.

Owner:北京素维生物科技有限公司

Freshness and scent enhancing method for goat and fish bone combined soup stock

ActiveCN103349259AFull of nutritionUmami Extraction EfficiencyFood preparationFlavorAdditive ingredient

The invention discloses a freshness and scent enhancing method for goat and fish bone combined soup stock, which includes the steps of smell removing of raw materials, precooking, hot-pressing temperature-variable extraction, standing deslagging, scent generation thermal reaction, seasoning, homogenizing and emulsification, sterilization, filling and the like, and has the key points that precooking and frying pretreatment are performed before the bone extraction of raw materials to reduce fishy smell and peculiar smell of the soup stock; high temperature and low temperature are combined for temperature-variable extraction to enhance the content of nutritional ingredients and flavor materials in the soup stock and avoid quality damage caused by thermal treatment; thermal reaction is performed after vacuum concentration of the combined soup stock, so that the scent and freshness are improved; the freshness and scent enhancing method for the combined soup stock enables the soup stock to have satisfactory and strong sent, and solves the problems that soup stock with simple bone raw material is not rich in nutritional ingredients, is simple in flavor materials, poor in freshness and scent, and has strong peculiar smell, and the like.

Owner:翁牛特旗蒙源科技有限公司

Efficient foodstuff heat-emitting package

ActiveCN105038726AReduce manufacturing costSave materialHeat-exchange elementsOff-flavourSilicon dioxide

The invention provides an efficient foodstuff heat-emitting package. A heat-emitting composite of the package is mainly obtained by mixing several ingredients out of aluminium powder, calcium oxide, calcium hydrate, kieselguhr, silica dioxide, sodium chloride and calcium carbonate with sodium fluoride in a certain proportion, the materials are cheap and wide in source, and the cost is low. The sodium fluoride content is 3%-10%, the aluminium powder content is 15%-35%, the heat-emitting temperature is as high as 97 DEG C, the package has the advantages of being high in heat-emitting temperature, long in duration time, wide in material source and the like, the moisture absorbing effect before the reaction is not obvious, the spontaneous exothermic phenomenon does not exist fundamentally, no objectional odor is generated in the reaction process, and the appetite of a person is not affected; the product after water is added and the reaction is conducted is hardened into a block, and no pollution is caused to the environment. The package can be well applied to the field of fast foodstuff.

Owner:CHONGQING UNIV

Pre-forming process of vegetable protein meat and vegetable protein meat product thereof

ActiveCN111838398ASolve the smellSolve the problem of alkaline tasteProteins working-up by texturisingVegetable proteins working-upBiotechnologyMonosodium glutamate

The invention discloses a pre-forming process of vegetable protein meat and a vegetable protein meat product, and the pre-forming process comprises the following steps: adding plant structured proteininto water for soaking to obtain rehydrated plant structured protein; immersing the rehydrated plant structured protein in distilled water for washing until the washed water has no color, and dehydrating to obtain washed and dehydrated plant structured protein; washing dehydrated plant structured protein, removing shreds, chopping, adding alkaline water, konjac glucomannan, starch, salt, monosodium glutamate, a yeast extract and soy sauce, uniformly stirring, adding the prepared acid slow-release emulsion, and uniformly mixing; and adding essence to adjust the flavor of the meat, uniformly stirring, and carrying out steam heating molding to obtain the vegetable protein meat. According to the pre-forming process of the vegetable protein meat, the problem of alkaline taste caused by alkalidissolution of konjac gum and the problem of peculiar smell of vegetable protein are solved, and the finally prepared finished product is close to real meat in taste and good in flavor.

Owner:JIANGNAN UNIV

Masking Bitter Flavors

Mogrosides may be used as a flavor modifier in various foods, beverages, pharmaceutical compositions, and the like to block the perception of bitter and astringent flavors or other off flavors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Ultrahigh-pressure vegetable food processing method

The invention relates to an ultrahigh-pressure vegetable food processing method, which comprises the following steps: (1) washing vegetables; (2) soaking the vegetables; (3) reshaping the vegetables; (4) pre-boiling the vegetables; (5) cooling the vegetables; (6) filling the vegetables into bags for seasoning, and packaging under vacuum; (7) performing ultrahigh-pressure cold sterilization; and (8) storing and selling the finished products. In the invention, the physical properties, such as color, fragrance and flavor, of the vegetable food subjected to the ultrahigh pressure treatment are changed without generating peculiar smells, the pressured food still retains the original raw and fresh flavor and nutrients, and thus, food sterilization is uniform, instant and efficient. The protein denaturation and starch paste state of the vegetable food subjected to ultrahigh pressure treatment are different from those of vegetable food subjected to heat treatment, so food of new physical properties is obtained.

Owner:TIANJIN GUANGHUI FOOD

Processing method of special flavor spiced beef by vacuum freeze drying

The invention discloses a processing method of special flavor spiced beef by vacuum freeze drying. The specific processing method comprises the following steps of: a, preparing materials; b, preparing sauce; c, marinating; d, cooling and cutting; e, dipping; f, traying and quickly freezing; g, performing vacuum freeze drying; h, sorting; I, detecting metals; and j, packaging. In the processing method, beef is processed by firstly marinating and then dipping, and finally the processed beef is subjected to the vacuum freeze drying method which is well designed, so that the abundant nutrition ingredients of beef are maintained. The produced special flavor spiced beef is yellowish-brown granular or sheet in shape, has special flavor and taste of spiced beef without any other unwanted peculiar smell and can be directly eaten with a shelf life as long as 12 months.

Owner:HUBEI XINMEIXIANG FOODS

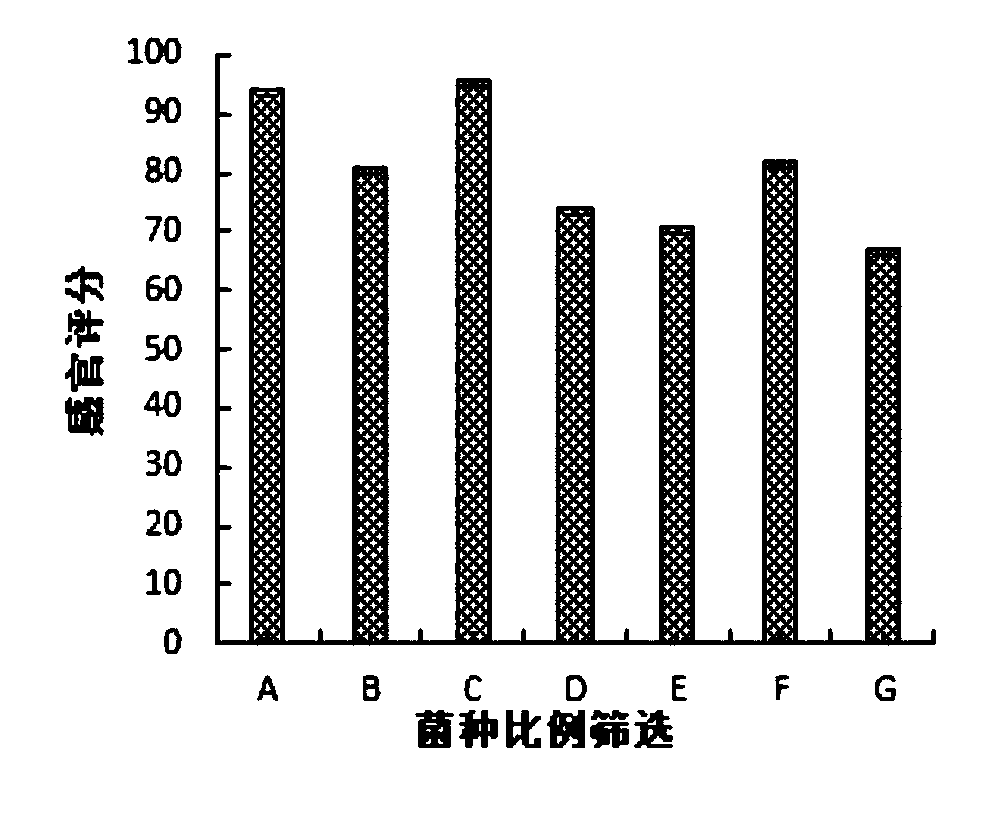

Raw material wine-brewing direct adding composite bacterium preparation and preparing method thereof

The invention relates to a compound bacteria preparation used in the field of liquor-making with raw meal and a preparation method thereof, particularly to a ready-to-use compound bacteria preparation used in liquor-making with the raw meal and a preparation method thereof. The ready-to-use compound bacteria preparation comprises the following ingredients: rice flour or bran culture of rhizopus Q303 2-5 weight parts, bran culture of Su-16 aspergillus flavus strain 30-50 weight parts, bran culture of hay bacillus BF7658 10 weight parts, rice flour or bran culture of active dry yeast used for bran liquor 5-10 weight parts, and maltogenic amylase with 50000 units per gram 25-30 weight parts. According to the technical proposal, the rhizopus Q303, Su-16 aspergillus flavus, hay bacillus, and active dry yeast used for bran liquor, which can make good use of raw starch, are selected as functional bacteria of ready-to-use compound bacteria preparation used in liquor-making with raw meal. The ready-to-use compound bacteria can improve the taste of raw meal liquor. The functional strains are combined in an optimal proportion so as to effectively inhibit mixed bacteria from growing, prevent high acidity, eliminate or obviously alleviate the bitter taste of liquor, and prevent mash from generating peculiar smell.

Owner:JIANGXI GANLIANG INDAL

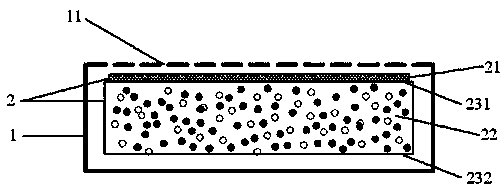

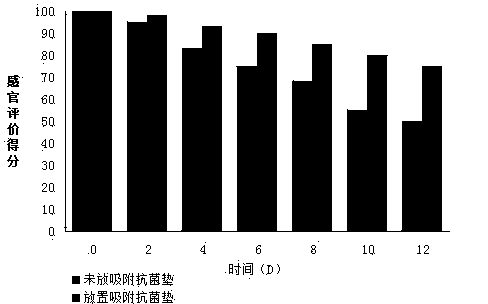

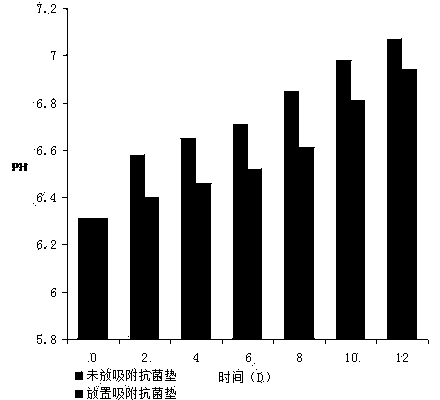

Food adsorption and antibacterial pad and preparation method thereof

ActiveCN104002528AIngenious designAdsorption hasSynthetic resin layered productsLow-density polyethyleneOff-flavour

The invention provides a food adsorption and antibacterial pad. The food adsorption and antibacterial pad is composed of a low-density polyethylene plastic film and an inner adsorption antibacterial layer, wherein fine holes are punched in the upper surface of the low-density polyethylene plastic film; the inner adsorption antibacterial layer is composed of an antibacterial coating and an adsorption layer; the antibacterial coating is fitted on the upper surface of a first non-woven fabric in a coating manner; the adsorption layer is uniformly sealed between the lower surface of the first non-woven fabric and the upper surface of a second non-woven fabric. The food adsorption and antibacterial pad has the advantages that the design is ingenious; the food adsorption and antibacterial pad has three functions of absorbing water, adsorbing objectionable odor and resisting bacteria, and can be used for absorbing liquid oozed by chilled fresh meat which is stored for a long time; the relative humidity in packages is reduced and the bacteria and the peculiar smell are reduced; the guarantee period of the chilled fresh meat on a tray is prolonged; the preparation method has a simple process and is convenient to operate.

Owner:SHANGHAI OCEAN UNIV

A processing method for preparing wheat germ polypeptide by a compound fermentation method

ActiveCN104996715ANo precipitationNo stratificationVegetable proteins working-upBiotechnologyOff-flavour

The present invention discloses a method for comprehensive utilization of the waste wheat germ resource so as to produce a wheat germ polypeptide, which has anti-oxidation, anti-fatigue, cholesterol activity-lowering, blood pressure-lowering and other functional activities, the applications of wheat germ in the healthy food and functional food are expanded, and the demands for healthy, nutritious and delicious drink are met on the basis of high-value utilization of wheat processing waste; according to the invention, ultrasound-assisted two-step enzymolysis and mixed fermentation are combined in the production process, such that the extraction rate, hydrolyzing degree and product functional activity of wheat germ polypeptide are improved; with the fermentation effect of microorganisms, bitter substances in the wheat germ polypeptide products are effectively removed, such that the product has no bitterness or other odors and with fermented flavor, and further has good application prospects.

Owner:广州萃取生物科技有限公司

Manufacturing method of loose-packed raw wet noodles

The invention discloses a manufacturing method of loose-packed raw wet noodles. The manufacturing method includes the following steps of 1, site preparation; 2, raw wet noodle formula making; 3, noodle manufacturing; 4, drying and moisture removal. The obtained wet noodles can be naturally stored for 7 days in freshness protection packages at normal temperature and can be stored for 20 days at the temperature of 0-4 DEG C, no foreign smell exists, no mould phenomenon exists, and the specification of DB43 / 338 is met. The process is simple, no expensive noodle dryer is needed, the manufacturing method is particularly suitable for production of breakfast loose-packed noodles or hotpot noodles, and adopted reagents all meet the requirements of the national safety standard GB2760.

Owner:HUNAN BIOLOGICAL & ELECTROMECHANICAL POLYTECHNIC

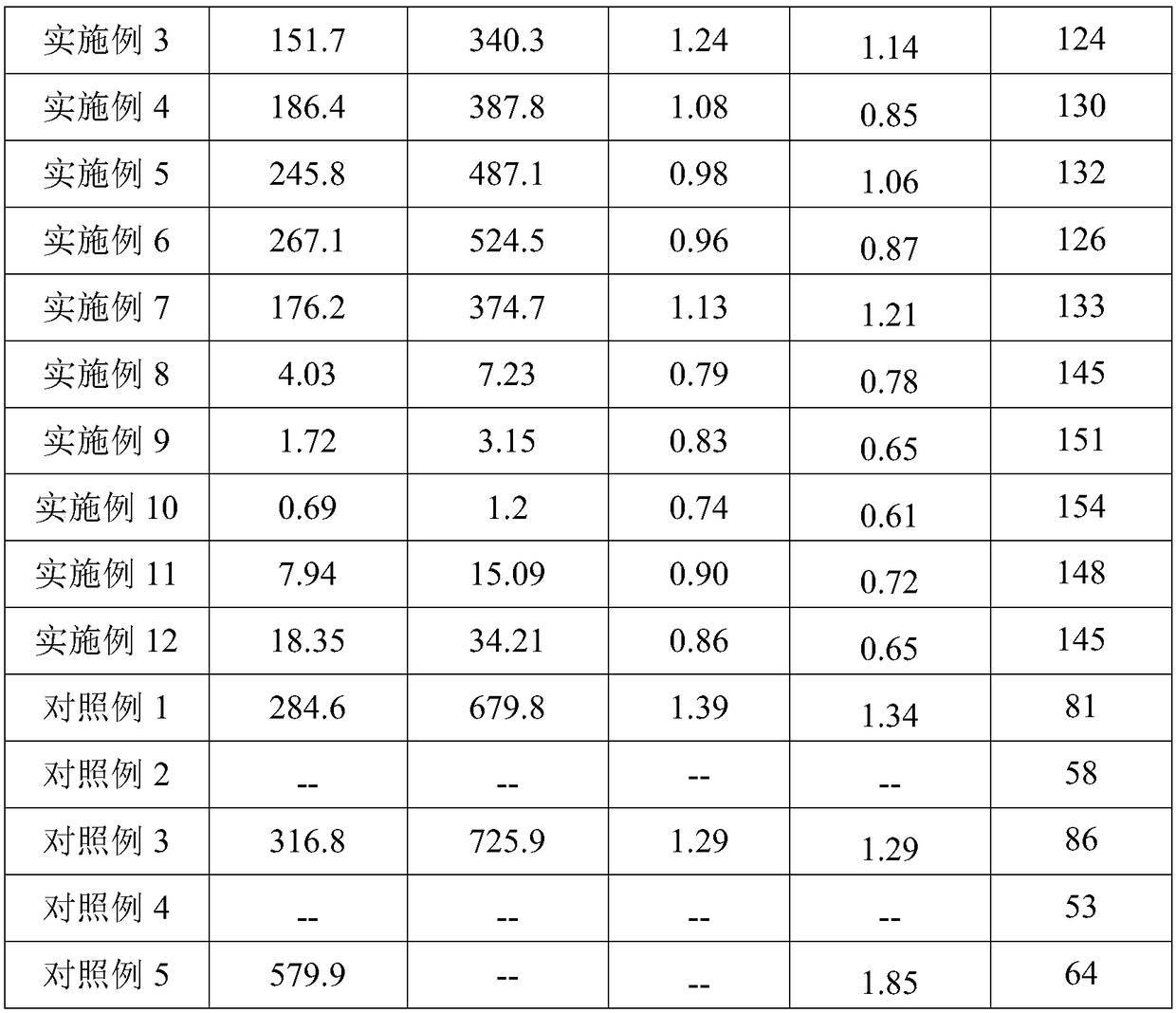

Enteromorpha fermented beverage and production technique thereof

InactiveCN103584247ANo precipitationNo stratificationMulti-step food processesFood ingredient functionsBiotechnologyOff-flavour

The invention discloses a novel algae fermented beverage based on comprehensive utilization of marine green tide algae enteromorpha suddenly gathered, satisfies the demands of people to a healthy, nutritious and delicious beverage, and develops an effective way for comprehensively using the enteromorpha resource. The enteromorpha fermented beverage is fine and smooth, uniform, has no precipitate and no layer, is light green in color, has full-bodied enteromorpha aroma and fermented aroma, is sour and sweet, palatable, has no fishy smell and other peculiar smell, total sugar content of products is not lower than 10% and total acid content is between 0.65% to 0.70%, the beverage has the following advantages: (1) the fermented beverage uses enteromorpha as a fermentation matrix; the enteromorpha is rich in nutritive substances such as carbohydrate, protein, crude fiber, mineral substances, fat, vitamin and the like, so that the trophism and the functionality of the fermented beverage are improved; (2) desalination, color protection and deodorization are performed on the enteromorpha, so that the active nutritive substances in the enteromorpha and the fresh algae smell of the enteromorpha are retained, and the product palatability is improved; (3) raw materials of products are added with cane sugar, honey and sodium benzoate, so that the fermented beverage is sour and sweet and palatable, has no fishy smell and other peculiar smell.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Snowflake flaky pastries mild in mouth feel and processing technology of snowflake flaky pastries mild in mouth feel

The invention provides snowflake flaky pastries mild in mouth feel and a processing technology of the snowflake flaky pastries mild in mouth feel, and relates to the technical field of foods. The snowflake flaky pastries mild in mouth feel comprise the following raw materials in percentage by weight of 7-10 parts of malt syrup of which the concentration is 75%, 1-4 parts of maltitol of which the concentration is 75%, 1-2 parts of trehalose, 0.8-1.2 parts of whole milk powder, 1-2 parts of butter, 0.01-0.04 part of maltol, 0.7-1.3 parts of anhydrous butter, 10-14 parts of biscuits, 0.1-0.4 partof egg white, 0.6-1 part of humid gelatin, 0.01-0.04 part of salt, 1-3 parts of white sugar and 0.4-0.6 part of water. The snowflake flaky pastries are crisp rather than hard, mild in mouth feel, sweet rather than greasy and free from peculiar smell, and do not stick to teeth; the malt syrup of which the concentration is 75% and the maltitol of which the concentration is 75% are used, so that thesnowflake flaky pastries are low in sugariness, mild, high in palatability and good in mouth feel; the processing technology is simple; and the made snowflake flaky pastries are better in mouth feel,and are easy in mass production and worth of promotion.

Owner:JIANGSU AISHINONG BIOLOGICAL TECH CO LTD

A fat-reducing food additive and application thereof

InactiveCN1994130ALower cholesterol levelsPromote conversionMetabolism disorderDigestive systemFood additiveDioscorea japonica

The invention relates to a food additive used to reduce fat and relative application, wherein said additive comprises that: dry lotus leaf, haw thorn, and Dioscorea japonica at 1:1. 2:1. 2 breaking materials into dry powder. The invention can be added into food at 10-13%. The inventive additive can reduce fat and protect stomach, with wide application.

Owner:田素勤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com