Microcapsule powder composition containing odor-free oil and preparation technology thereof

A technology of composition and microcapsule powder, which can be used in medical preparations with non-active ingredients, non-active ingredients of polymer compounds, food science, etc., and can solve the problems of not reaching the desired effect in taste and unable to cover up the taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

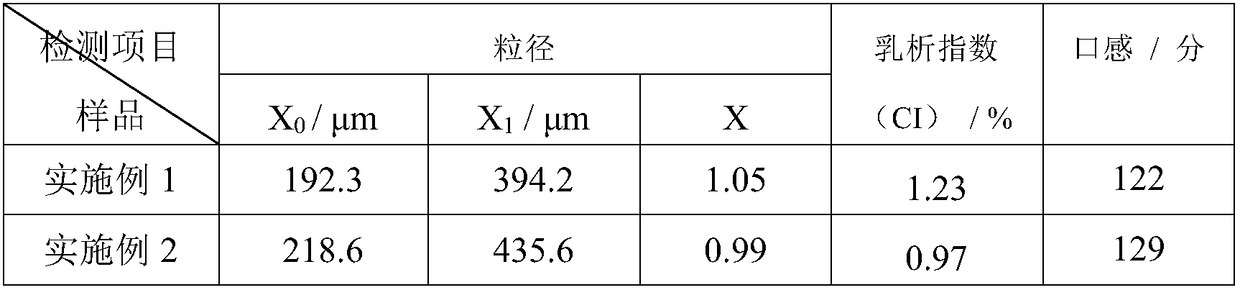

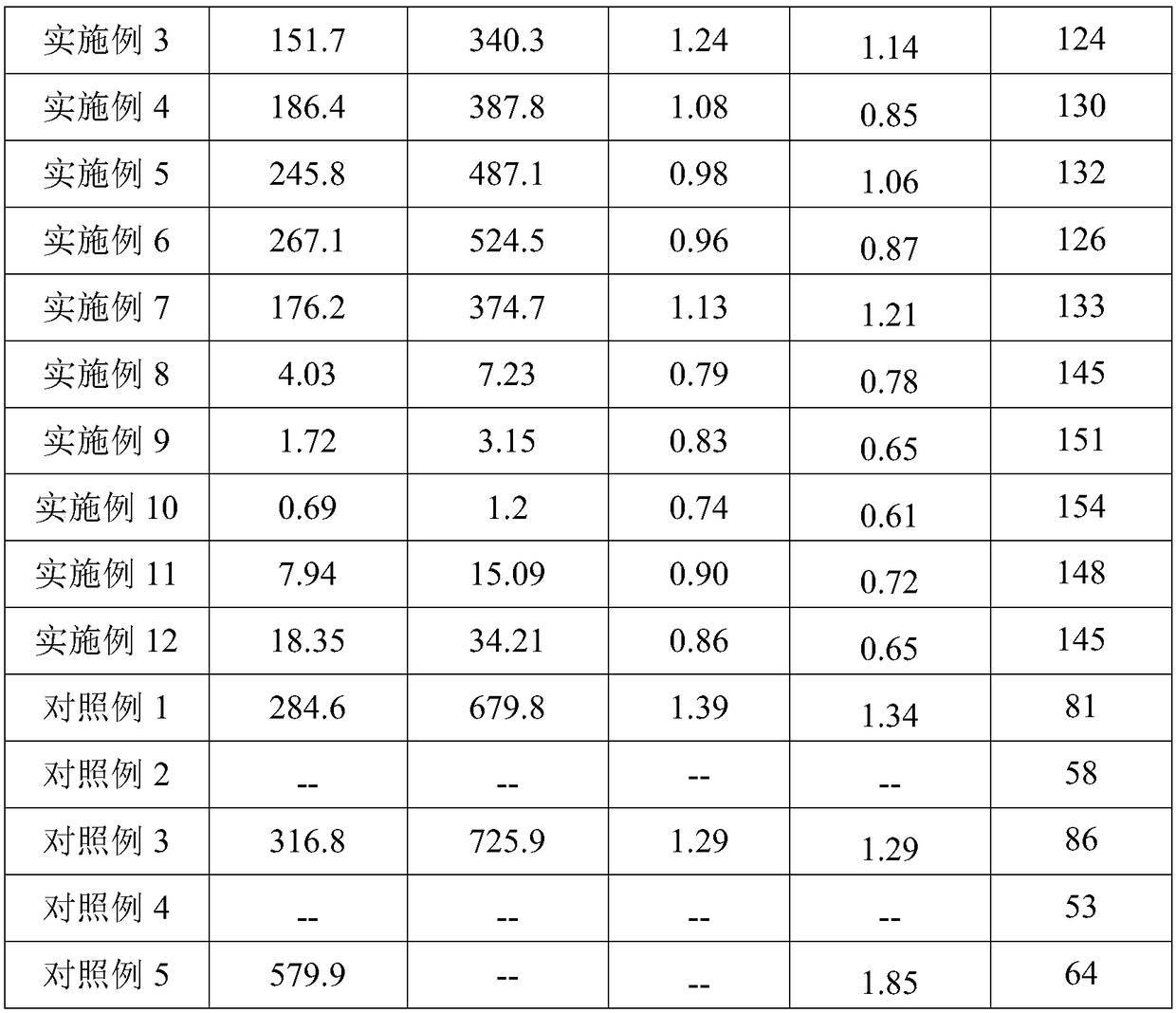

Examples

Embodiment 1

[0042] Recipe: 10g sunflower oil, 10g lutein, 80g sodium caseinate, 30g ginger oil

[0043] Process: at 60°C, mix and stir sunflower oil and ginger oil evenly to prepare an oil phase. At 70°C, mix sodium caseinate and lutein evenly, slowly add into water, stir while adding, until sodium caseinate and lutein are completely dissolved, and prepare into water phase. The mass ratio of water to dissolved raw material is 12:1. At 25°C with a stirring speed of 500 rpm, the oil phase and the water phase were mixed and emulsified for 2 hours to obtain an emulsion, and the emulsion was homogenized under a high pressure of 50 MPa to prepare a reprocessed emulsion. The reprocessed emulsion was spray-dried to obtain microcapsule powder. The inlet air temperature for spray drying is 170°C, and the outlet air temperature is 95°C.

Embodiment 2

[0045] Recipe: 30g corn germ oil, 180g astaxanthin, 1000g polyethylene, 80g lemon oil

[0046] Process: at 70°C, mix and stir corn germ oil, astaxanthin, and lemon oil evenly to prepare an oil phase. At 60°C, polyethylene was slowly added to water, and stirred while adding, until the polyethylene was completely dissolved, and an aqueous phase was prepared. The mass ratio of water to dissolved raw material was 19:1. At 25° C. with a stirring speed of 100 rpm, the oil phase and the water phase were mixed and emulsified for 1 hour to obtain an emulsion. The emulsion was spray-dried to obtain microcapsule powder. The inlet air temperature of the spray drying is 160°C, and the outlet air temperature is 90°C.

Embodiment 3

[0048] Formula: 100g soybean oil, 50g lutein, 800g gelatin, 30g ginger oil, 25g stevioside, 60g polysorbate 60

[0049] Process: Mix soybean oil, lutein and ginger oil evenly at 50°C to prepare an oil phase. At 60°C, mix gelatin, stevioside, and polysorbate 60 evenly, then slowly add to water, and stir while adding until the gelatin, stevioside, and polysorbate 60 are completely dissolved to prepare a water phase. The mass ratio of water to dissolved raw materials is 8:1. At 25°C, when the stirring speed is 400rpm, the oil phase and the water phase are mixed and emulsified for 2 hours to obtain an emulsion, and the emulsion is homogenized under a high pressure of 100MPa to prepare a high pressure homogeneous emulsion. The high-pressure homogeneous emulsion was spray-dried to obtain microcapsule powder. The inlet air temperature for spray drying is 150°C, and the outlet air temperature is 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com