Patents

Literature

979results about How to "No accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

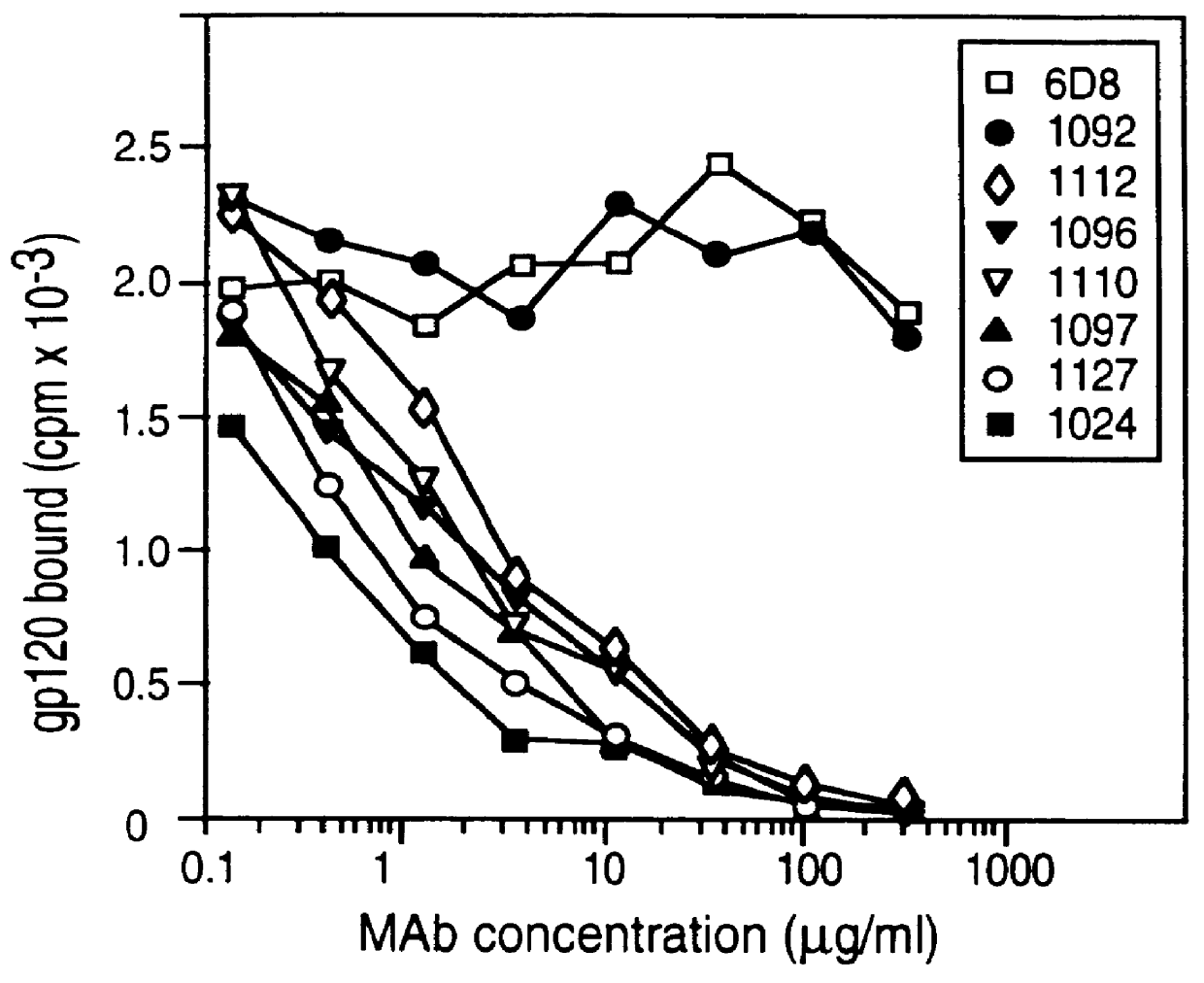

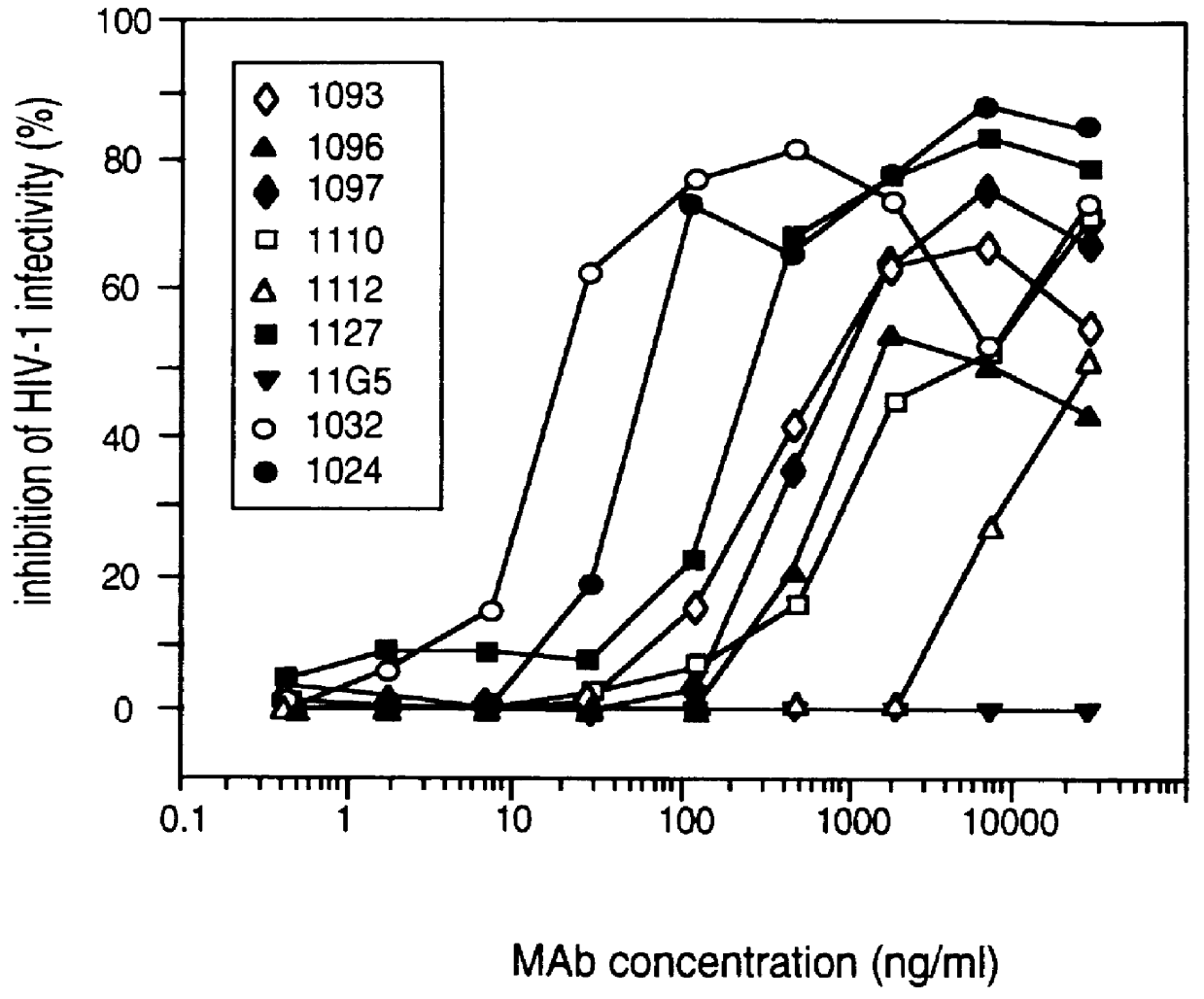

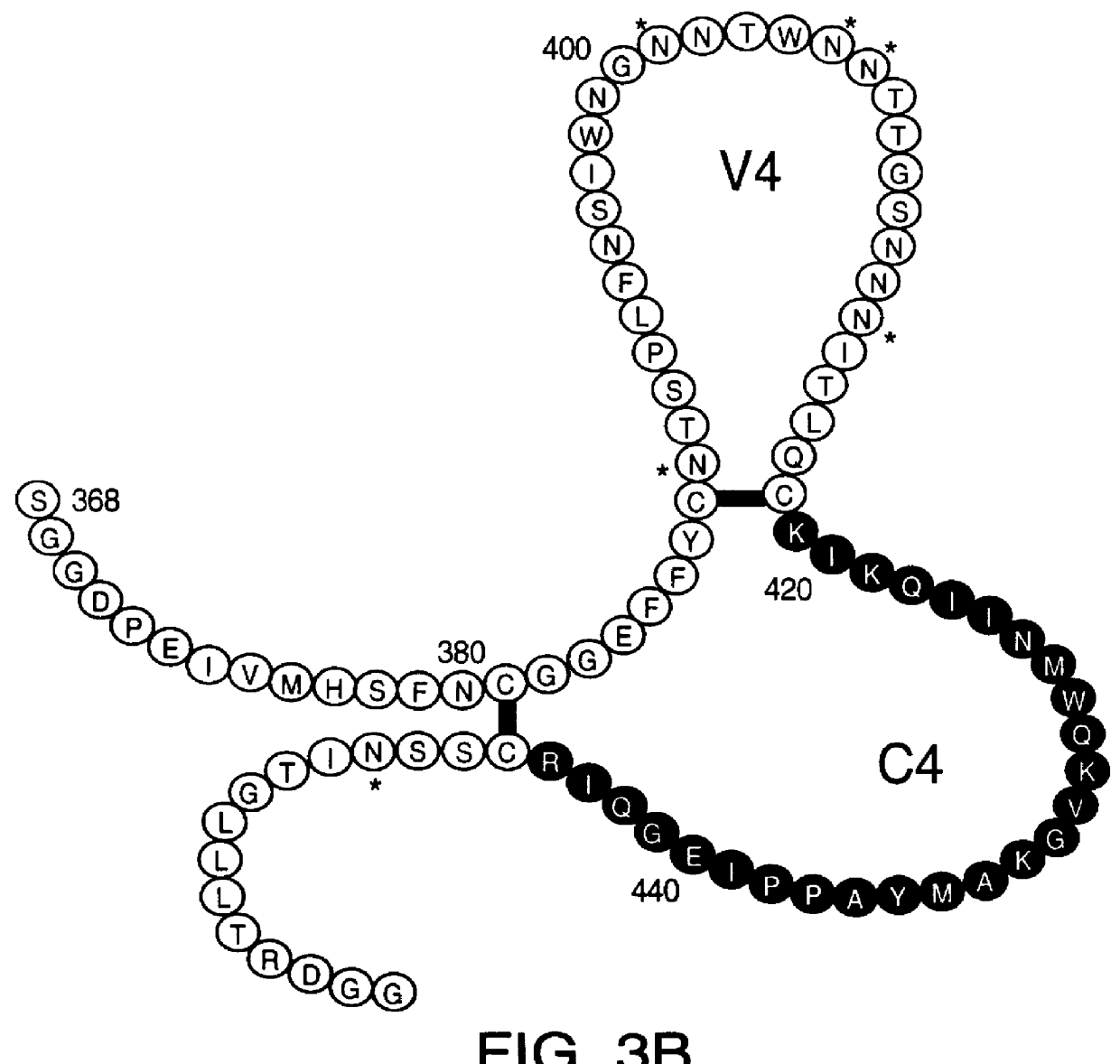

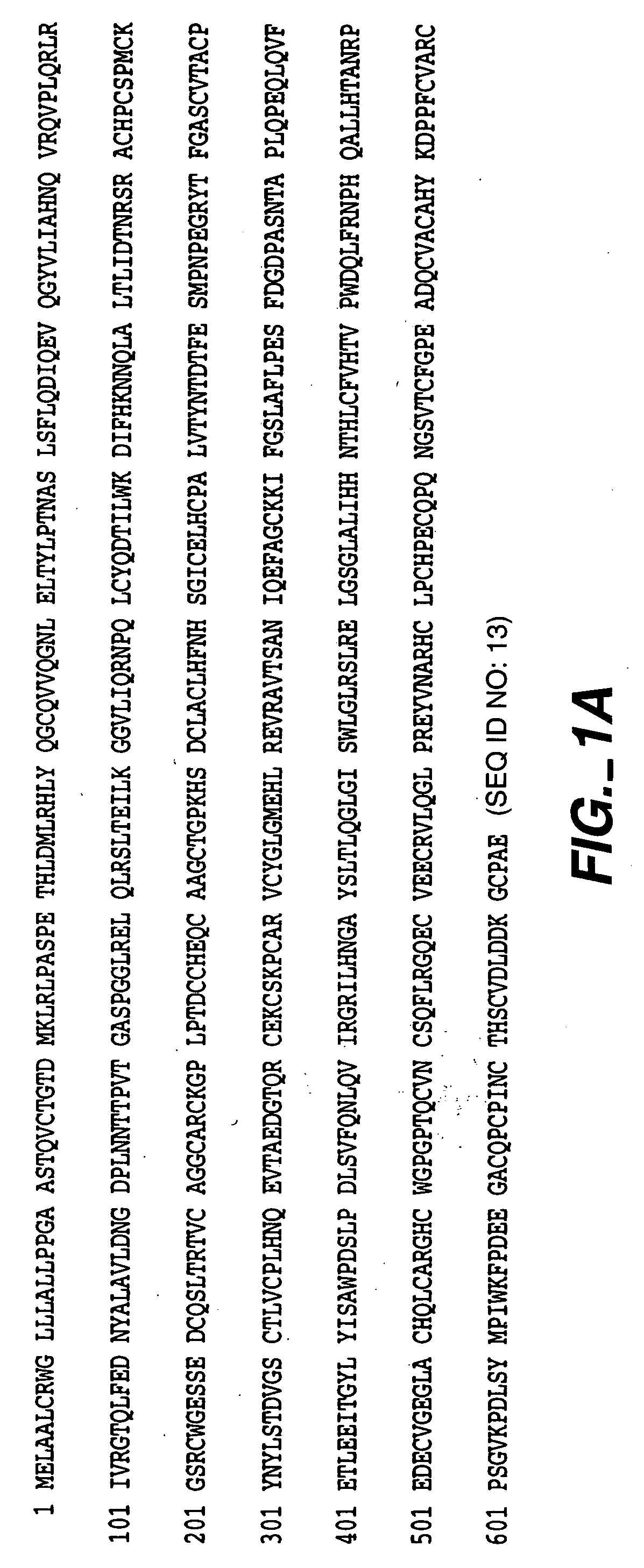

HIV envelope polypeptides

InactiveUS6042836ANo accumulationReduce capacitySugar derivativesViral antigen ingredientsGeographic regionsHiv envelope

Owner:GENENTECH INC

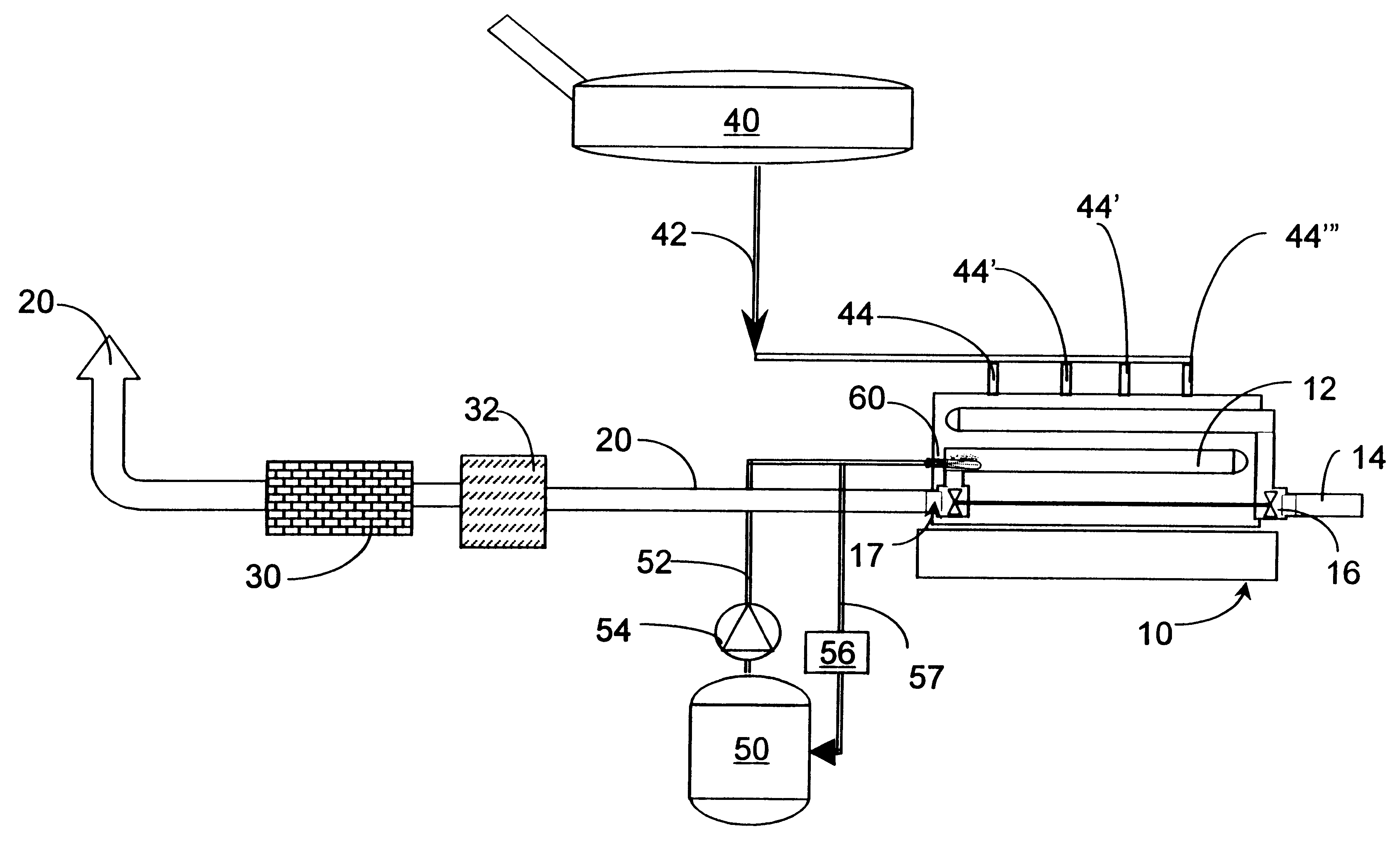

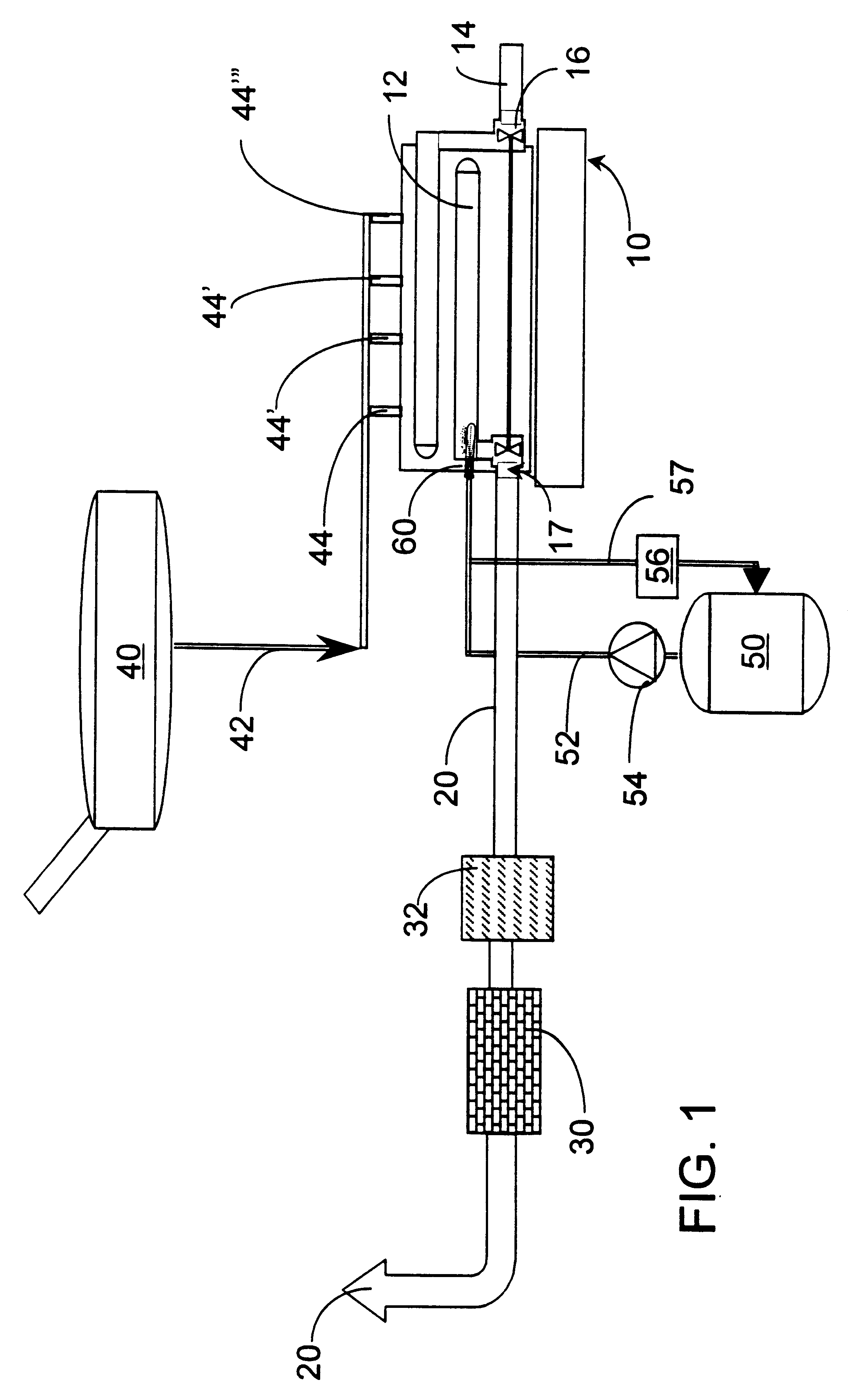

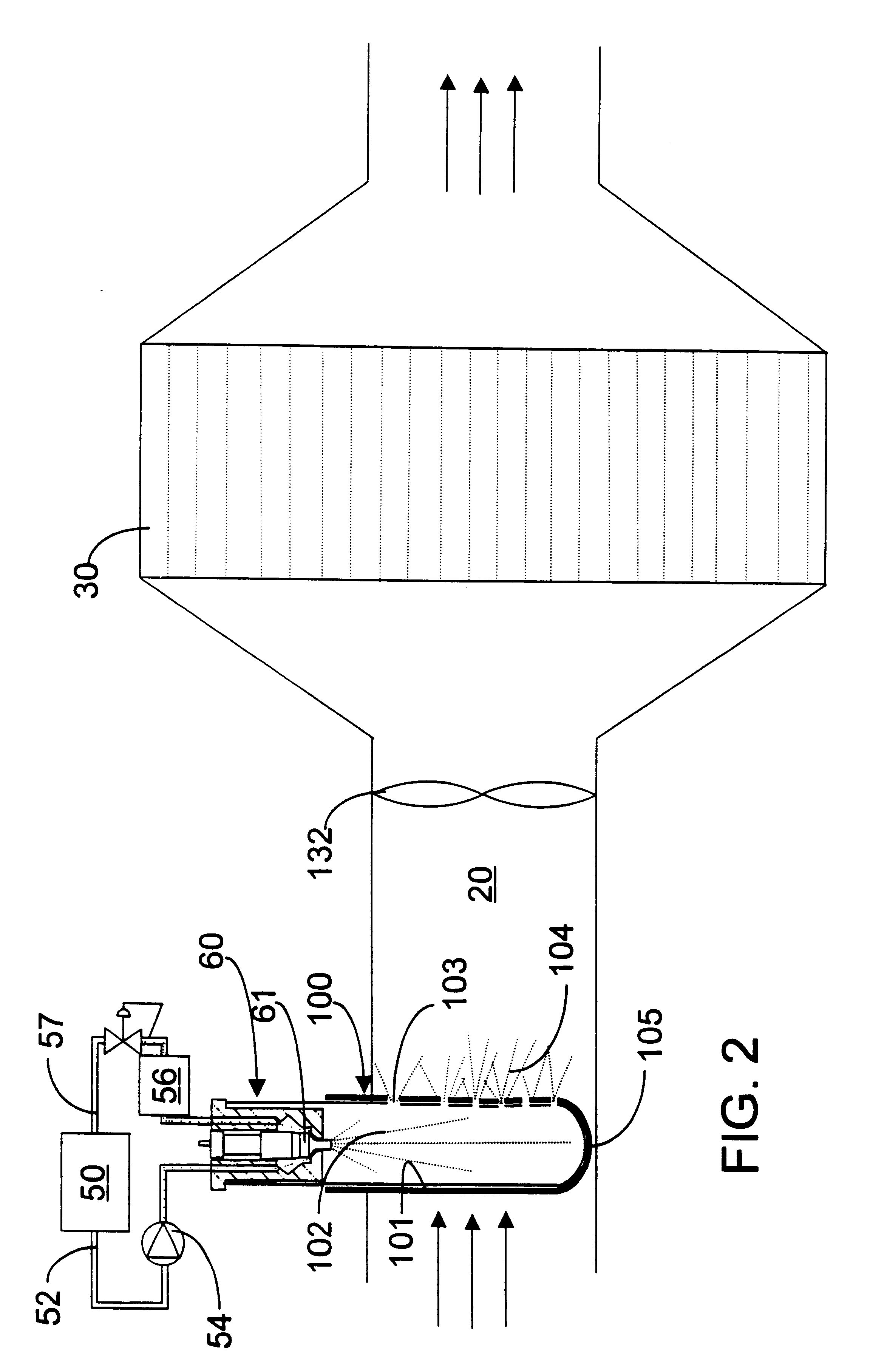

Urea pyrolysis chamber and process for reducing lean-burn engine NOx emissions by selective catalytic reduction

InactiveUS6203770B1No accumulationSafe and reliableNitrous oxide captureCombination devicesChamber designUrea

Urea is pyrolyzed in a chamber designed to facilitate gasification of the urea by pyrolysis with conversion of urea to ammonia and isocyanic acid (HNCO) with water vapor and carbon dioxide. The product gases are introduced into exhaust gases from a lean-burn engine, preferably upstream of a turbocharger. The exhaust gases are then contacted with an SCR catalyst.

Owner:CLEAN DIESEL TECHNOLOGIES

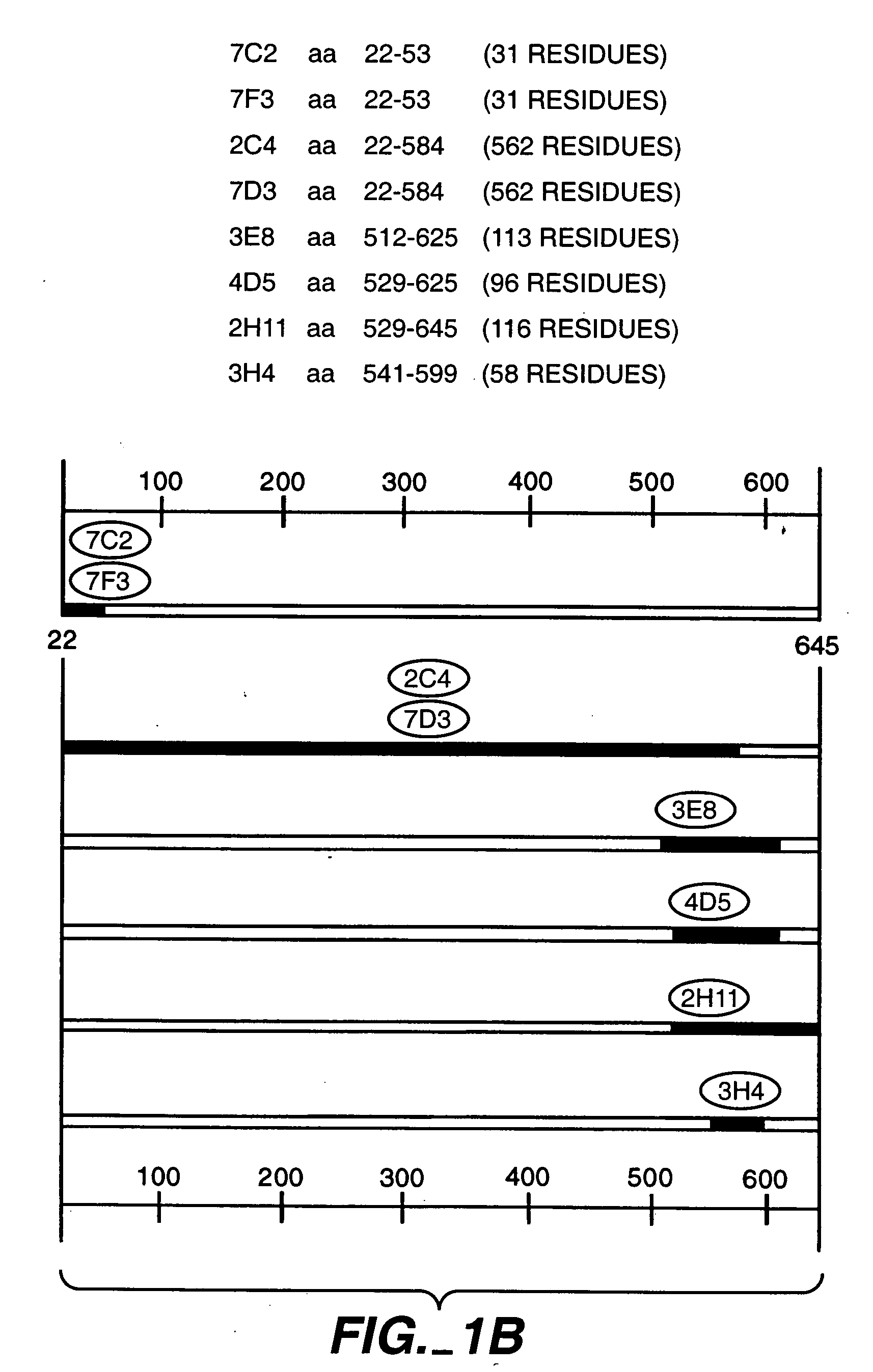

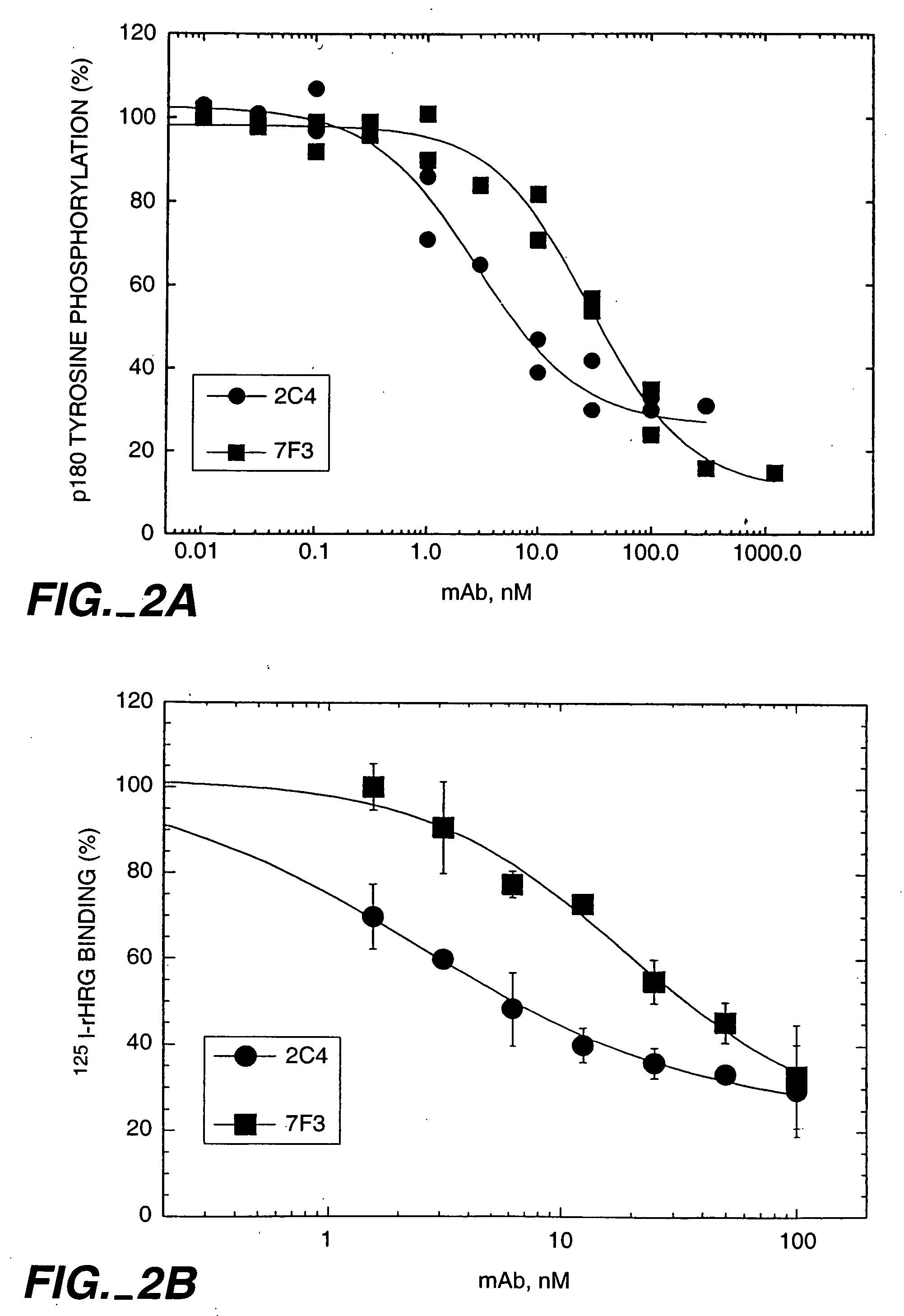

ErbB antagonists for pain therapy

The present application describes the use of ErbB antagonist, especially ErbB2 antibodies such as rhuMAb 2C4, for treating pain.

Owner:AGUS DAVID

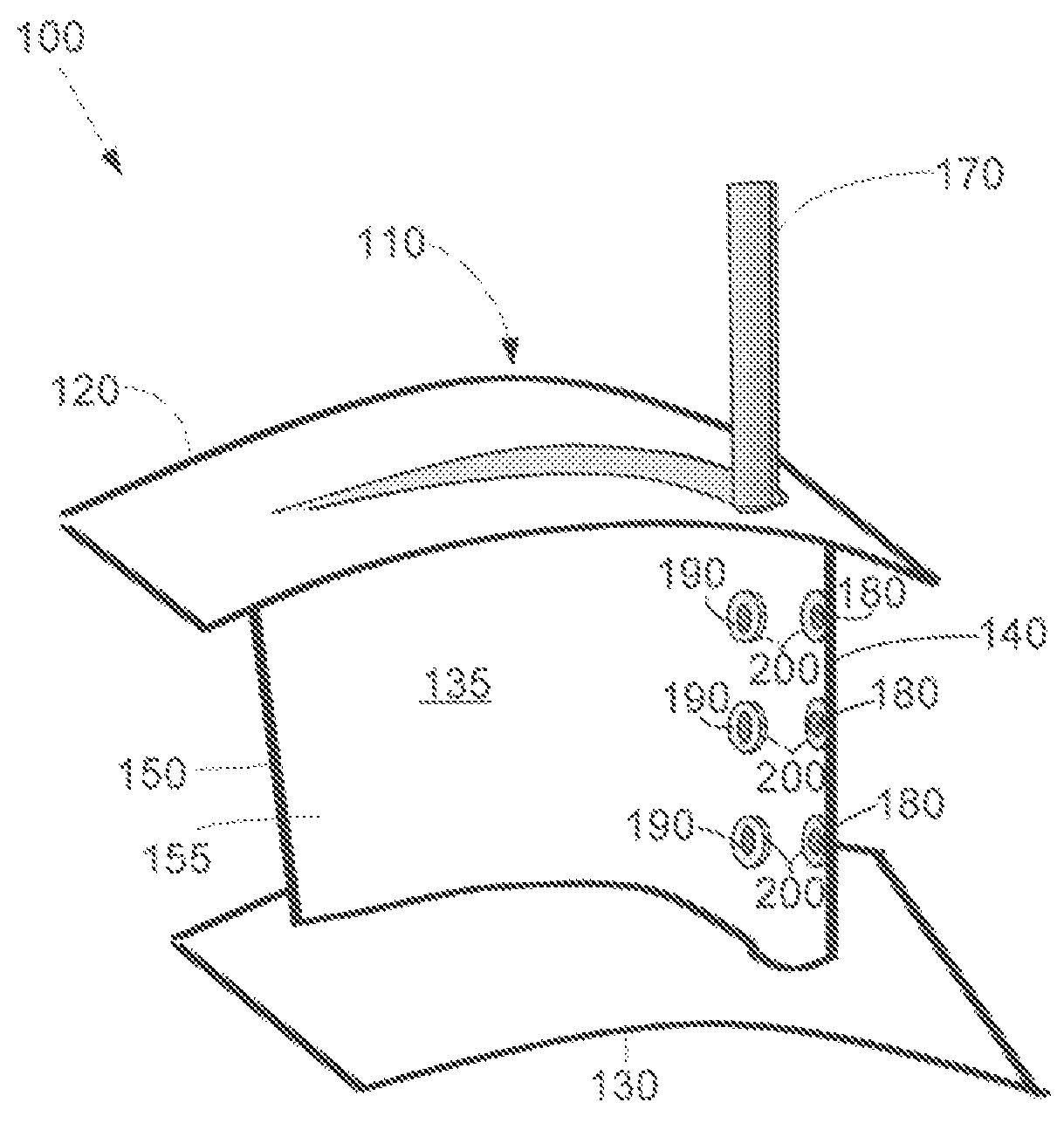

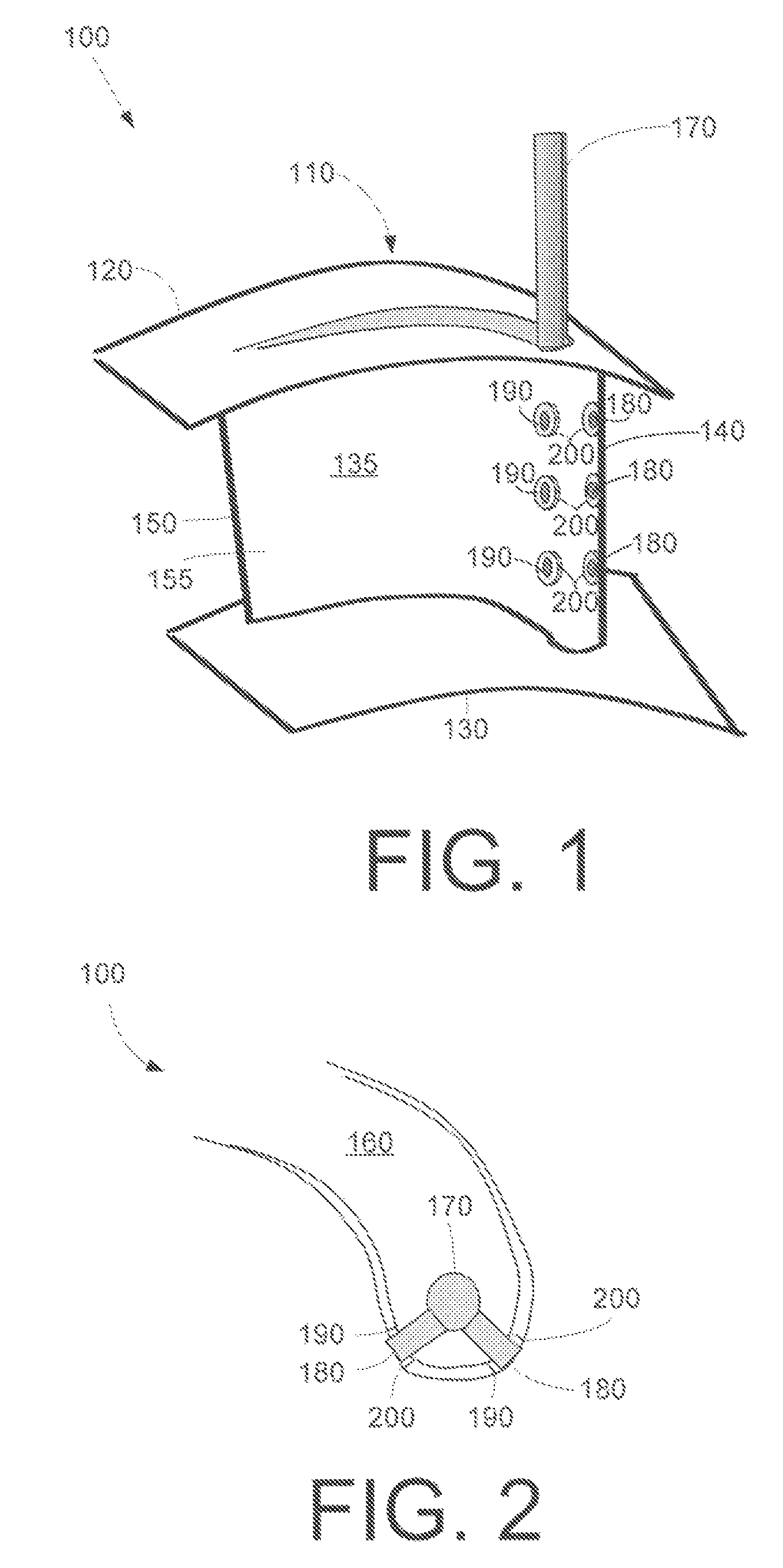

Secondary fuel injection from stage one nozzle

InactiveUS7603863B2Reduce NOx emissionLower temperatureTurbine/propulsion fuel supply systemsContinuous combustion chamberInjectorEngineering

A secondary combustion system for a stage one turbine nozzle. The secondary combustion system may include a supply tube extending into the stage one nozzle, a number of injectors extending from the supply tube to an outer surface of the stage one nozzle, and an air gap surrounding each of the number of injectors.

Owner:GENERAL ELECTRIC CO

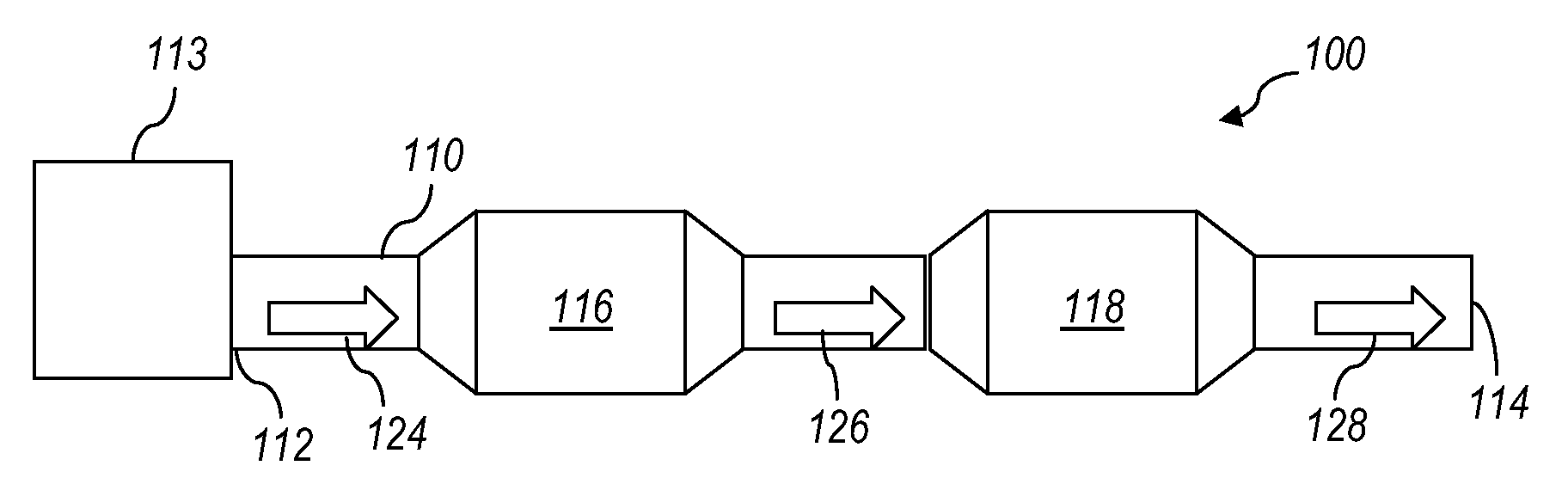

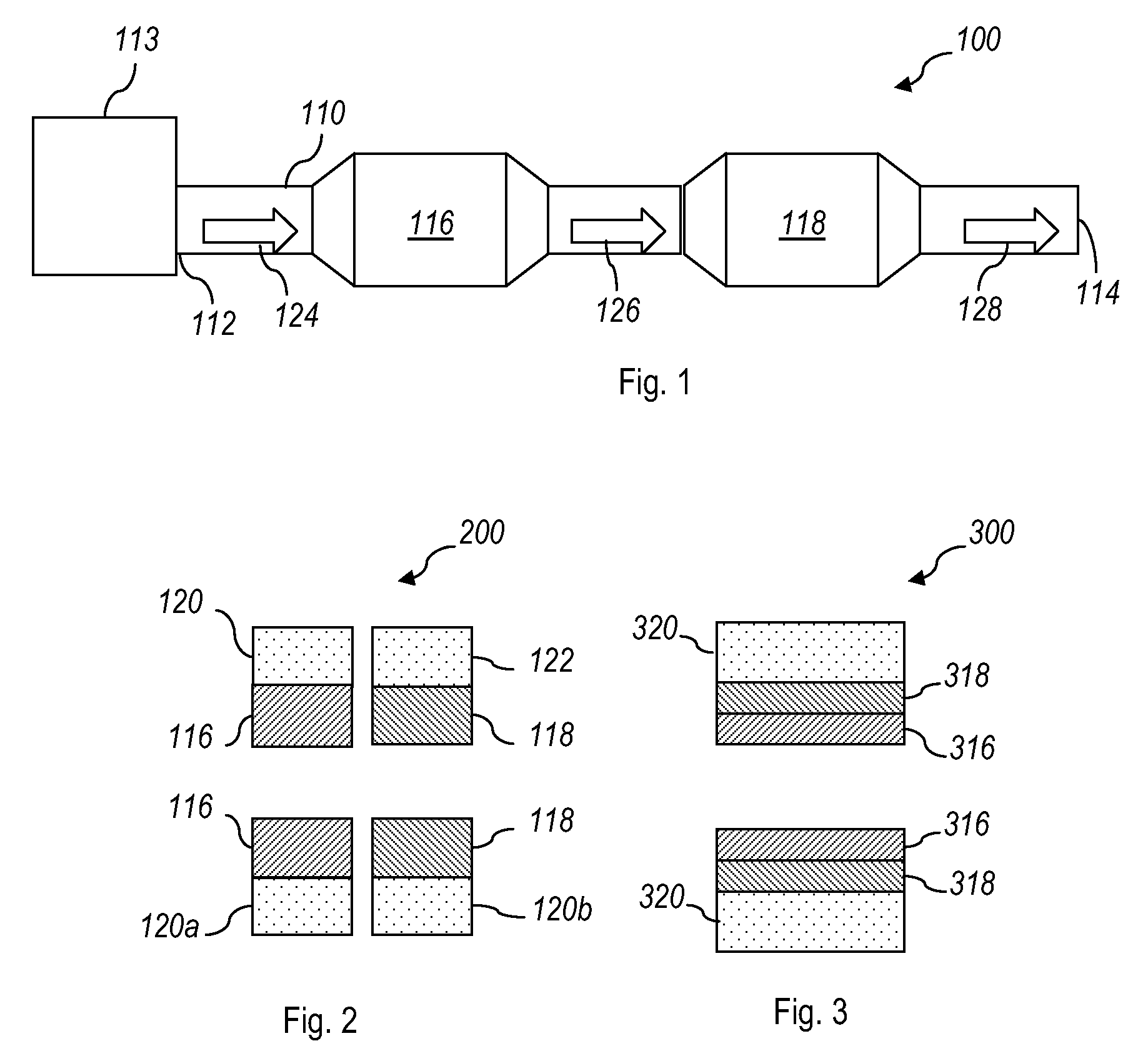

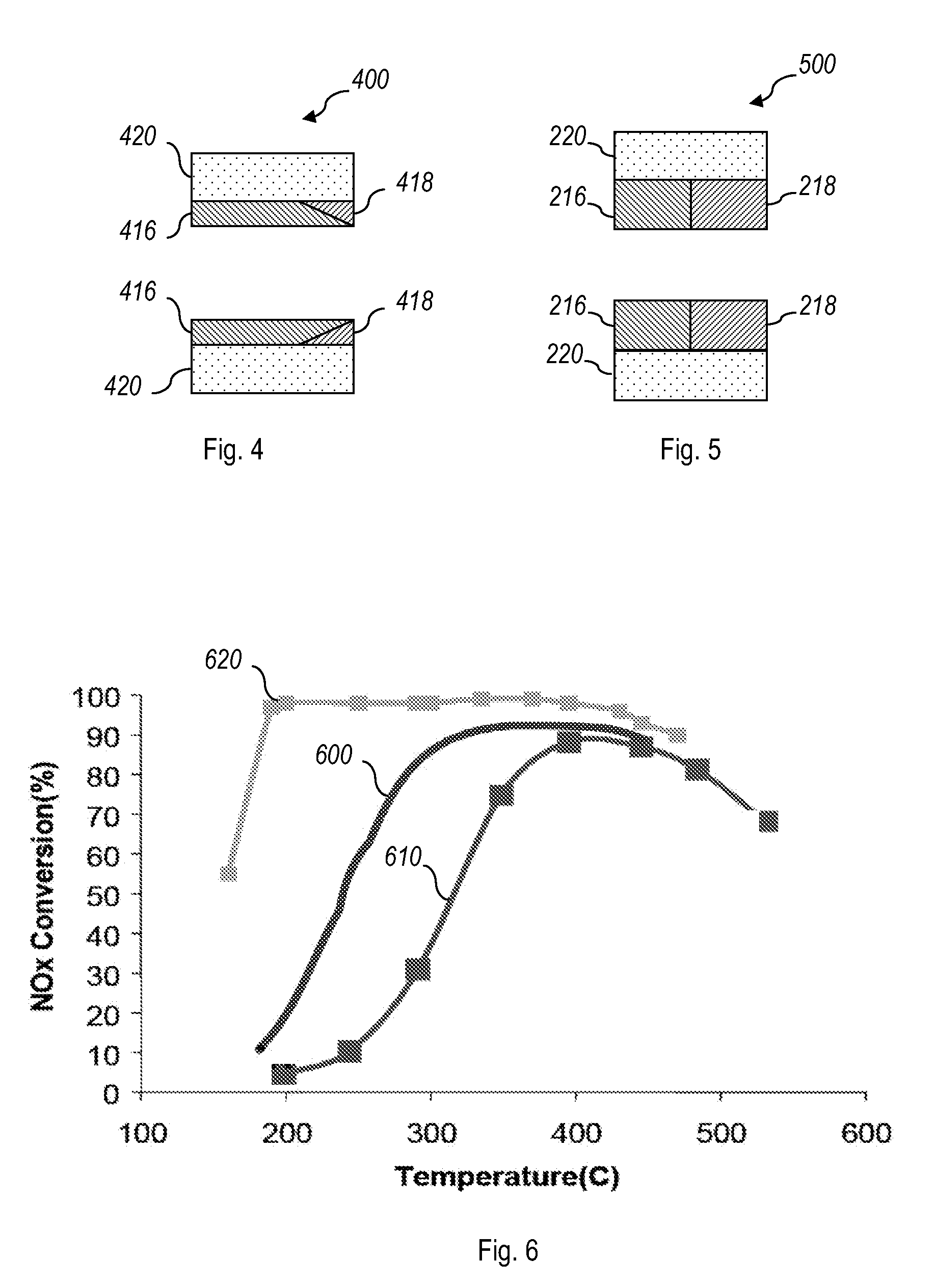

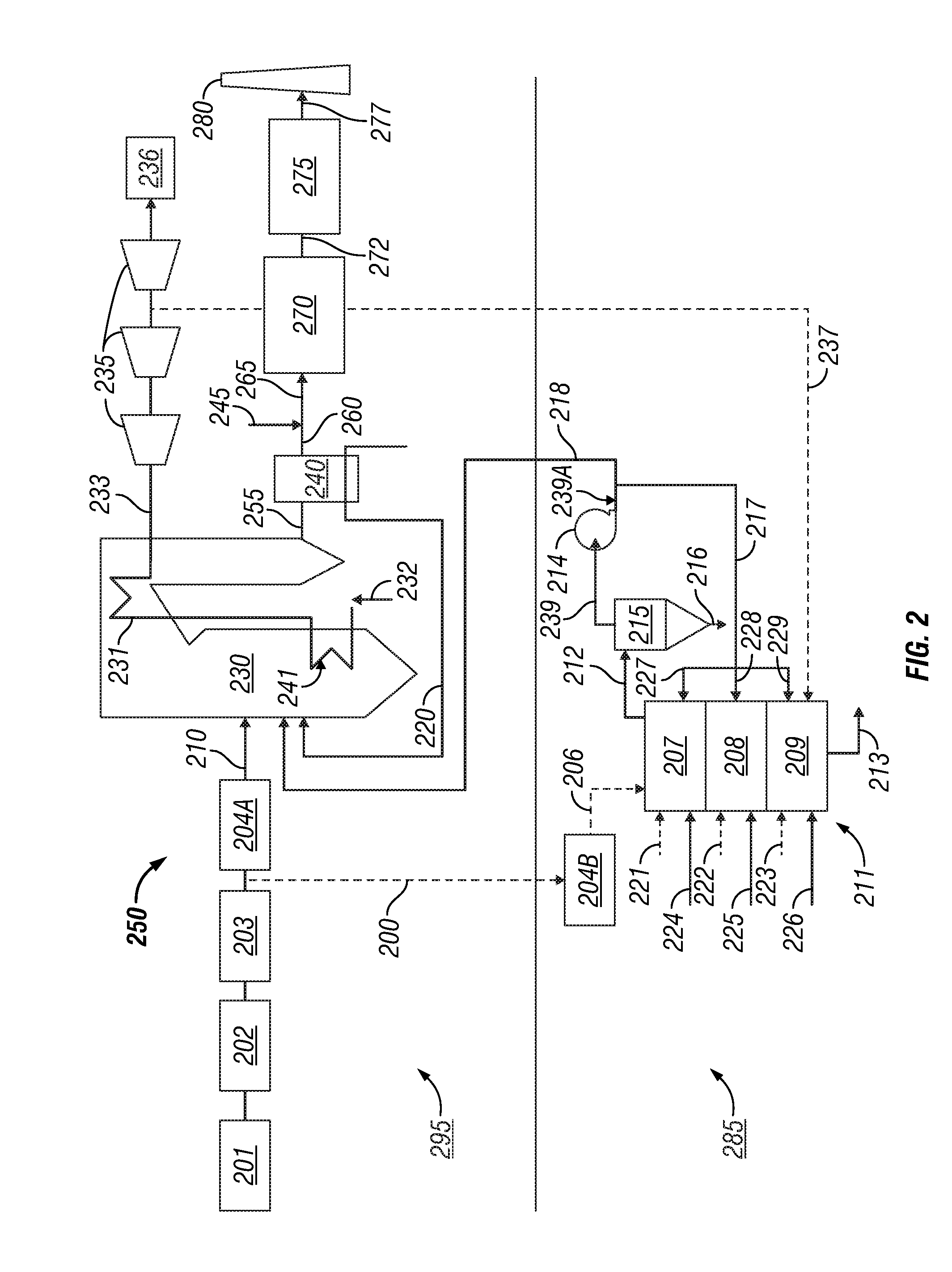

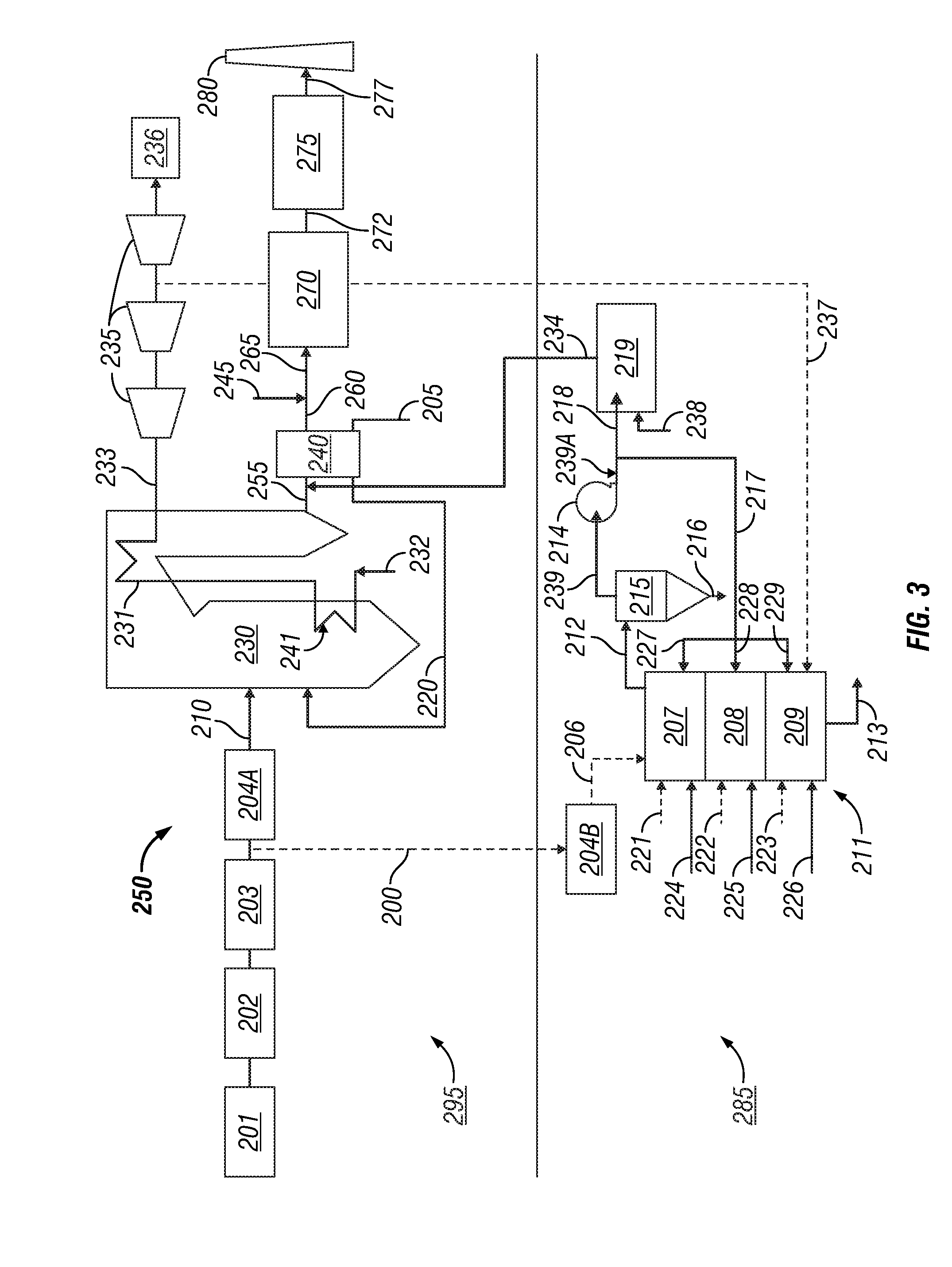

CATALYSTS, SYSTEMS, AND METHODS FOR REDUCING NOx IN AN EXHAUST GAS

InactiveUS20100101221A1Reduce nitrogen oxide emissionsReduce NOxGas treatmentMolecular sieve catalystsExhaust fumesAmmonia

Catalysts, systems, and methods disclosed herein provide for reduced NOx emissions in the exhaust stream of a lean burning engine. The catalysts include two different types of selective catalytic reduction (SCR) catalysts (i.e., two different types of catalysts that may catalytically reduce NOx using a reductant). The first SCR catalyst (116) is an SCR catalyst having a composition that produces a reductant (e.g., an HC-SCR catalyst that produces ammonia) and the second catalyst (118) is an SCR catalyst (e.g., NH3-SCR) having a composition that reduces NOx using the reductant produced by the first SCR catalyst (116).

Owner:CATERPILLAR INC

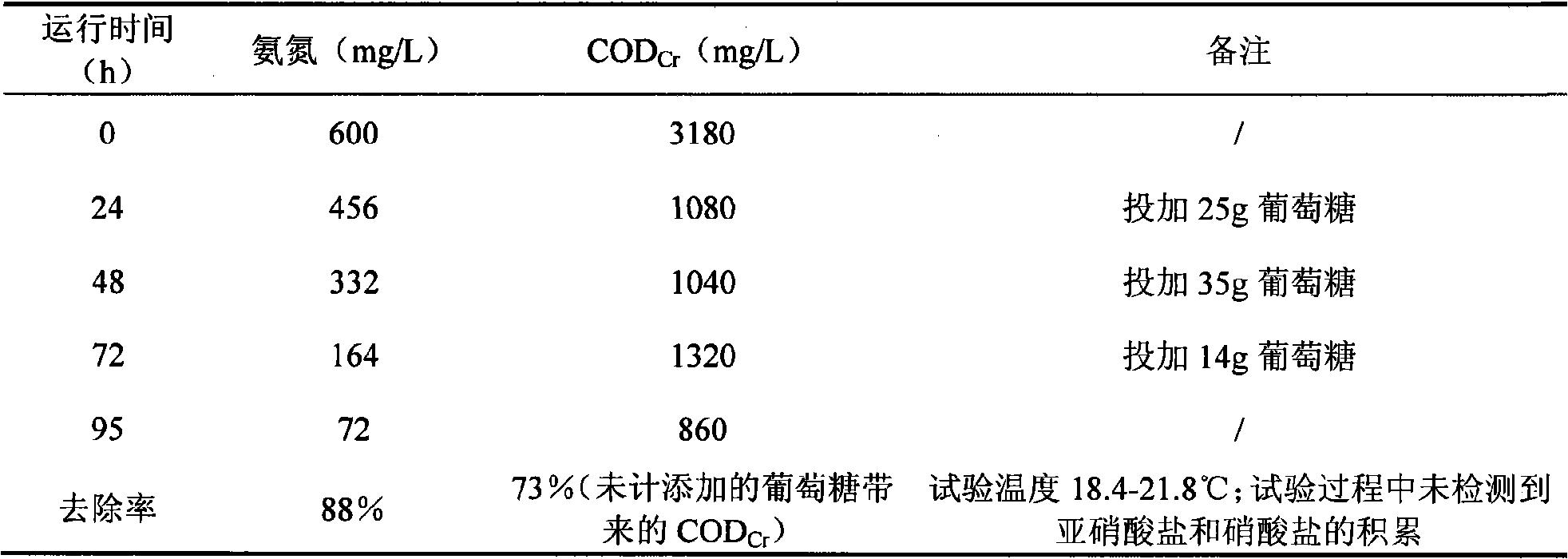

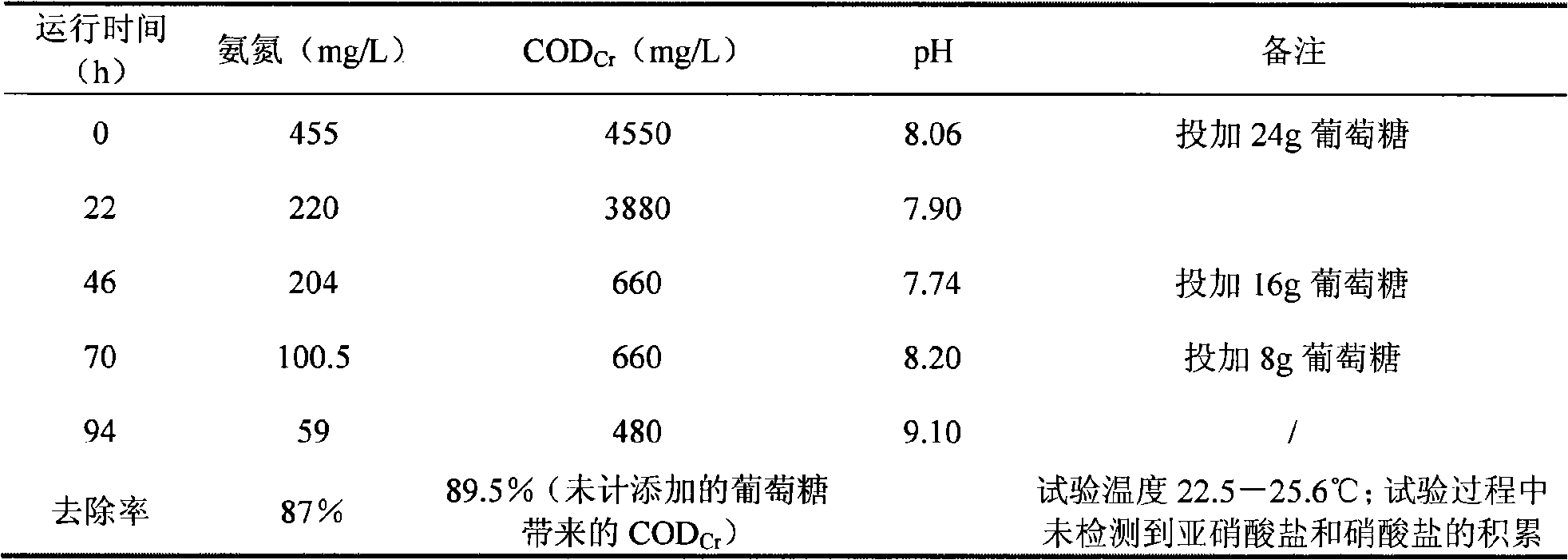

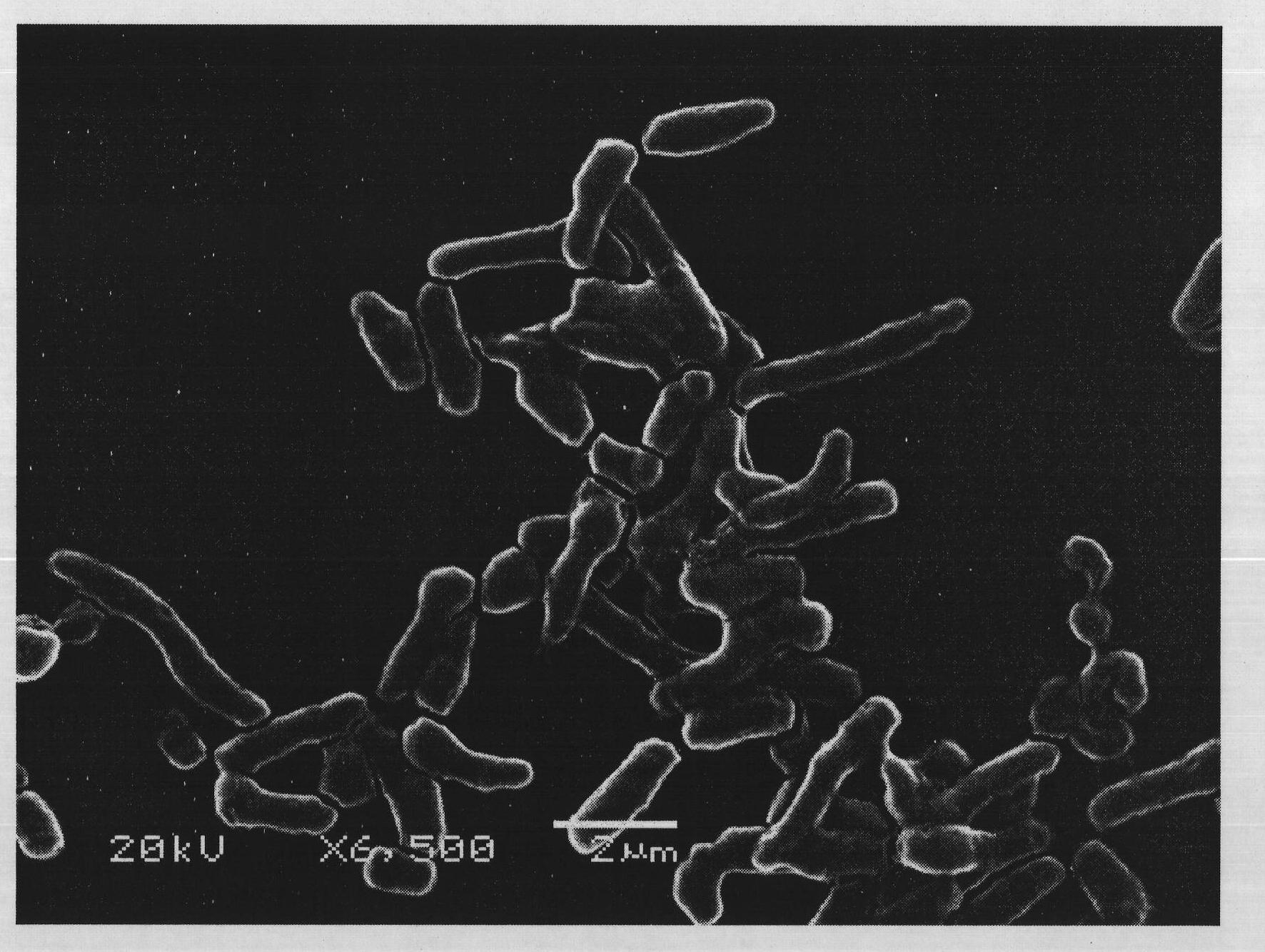

Heterotrophic nitrification microbial preparation, cultivation method and use thereof

ActiveCN101302485AWide range of substratesEasy to trainImmobilised enzymesBacteriaHigh concentrationMicroorganism

The invention belongs to the environmental microorganism field, and in particular relates to a heterotrophic nitrification microorganism agent, a method for cultivating the same, and a use of the same in culture wastewater treatment. The microorganism agent contains Stenotrophomonas maltophilias strain DN1.1 and Pseudomonas putida strain DN1.2 which have the preservation registration numbers respectively as CCTCC M 207074 and CCTCC M 207075. The microorganism agent can effectively remove ammonia nitrogen and total nitrogen in a water body, accumulates no nitrite or nitrate during denitrification, and can simultaneously remove CODCr in organic wastewater, which is applicable to the treatment of high-concentration culture wastewater. The use of the microorganism agent in treating culture wastewater is simple in process and stable in effect.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

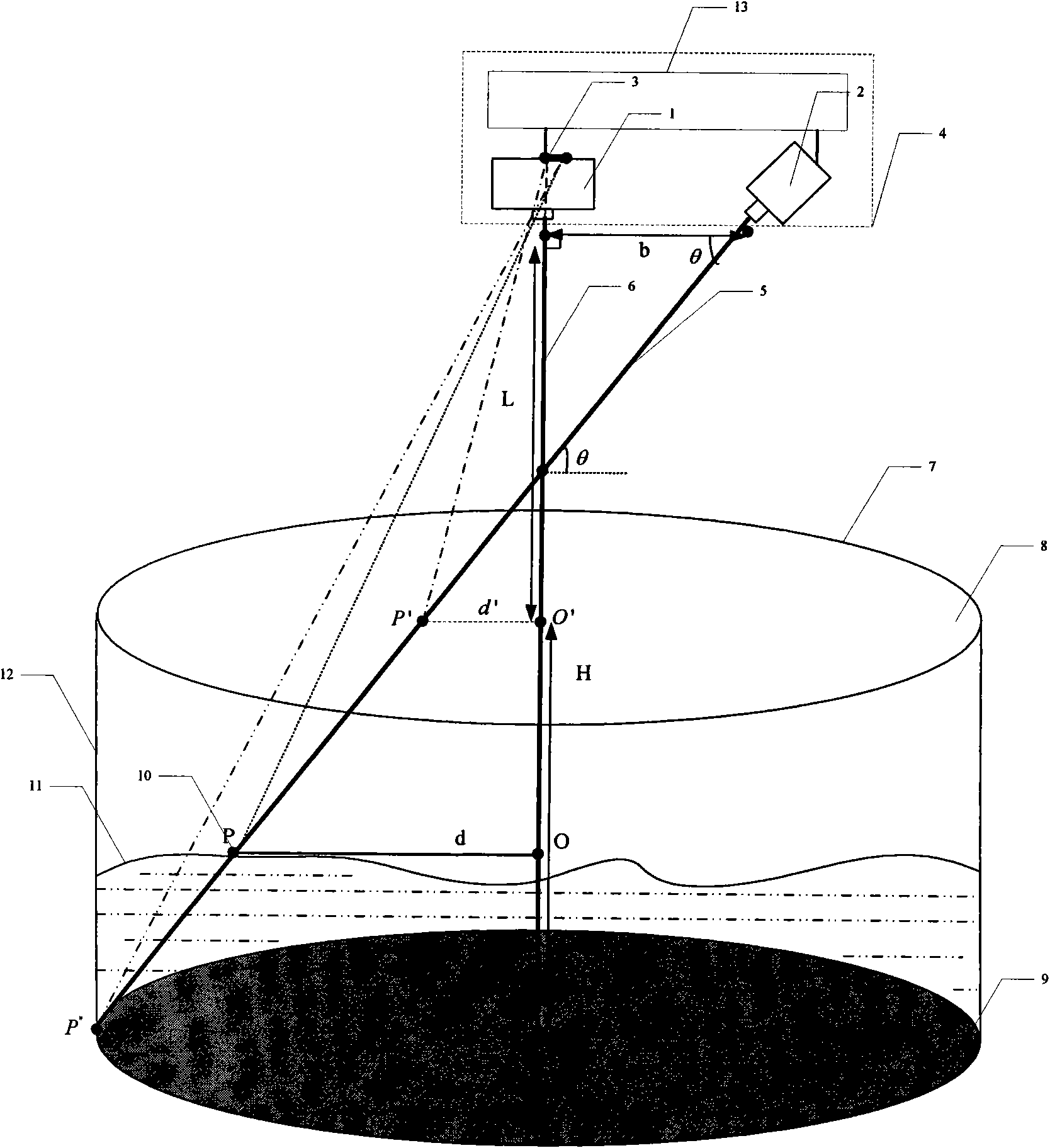

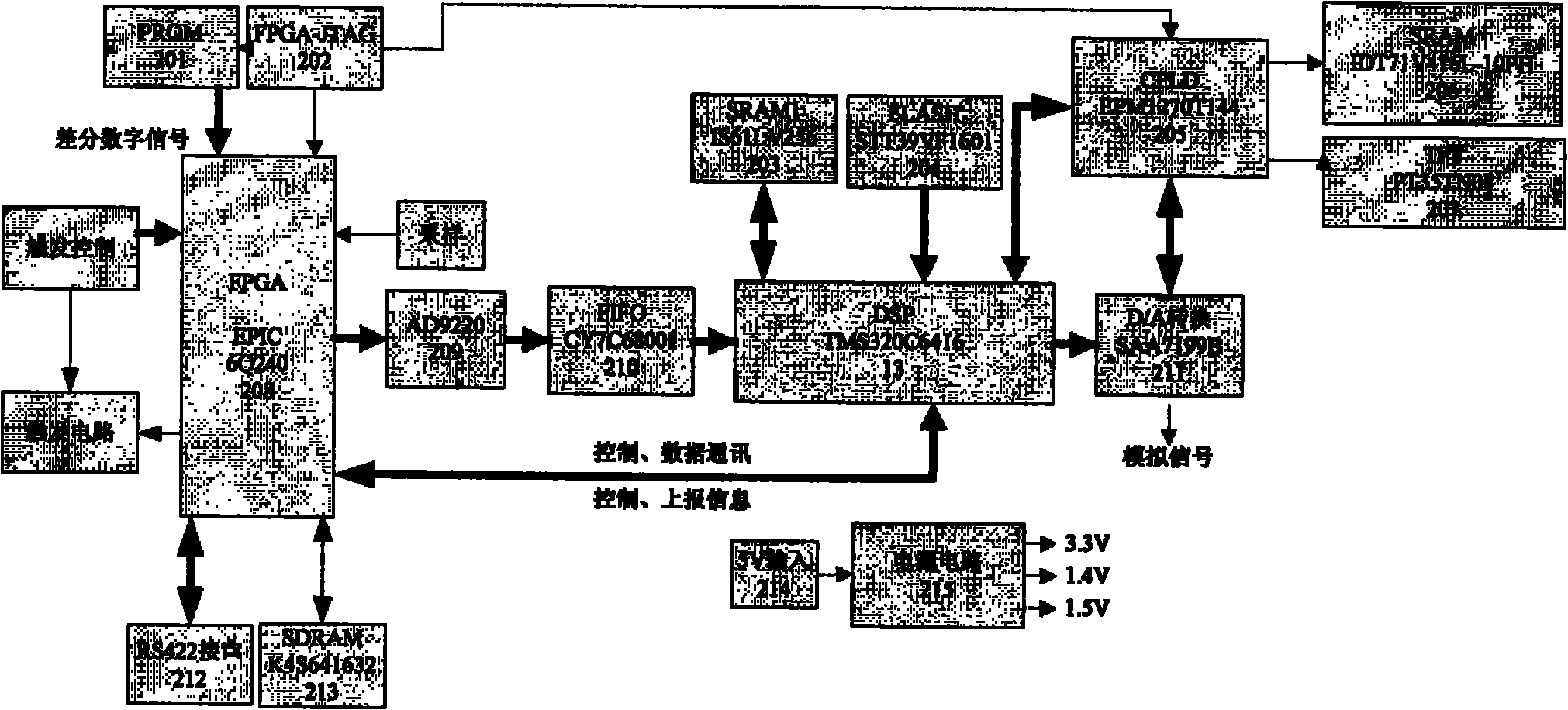

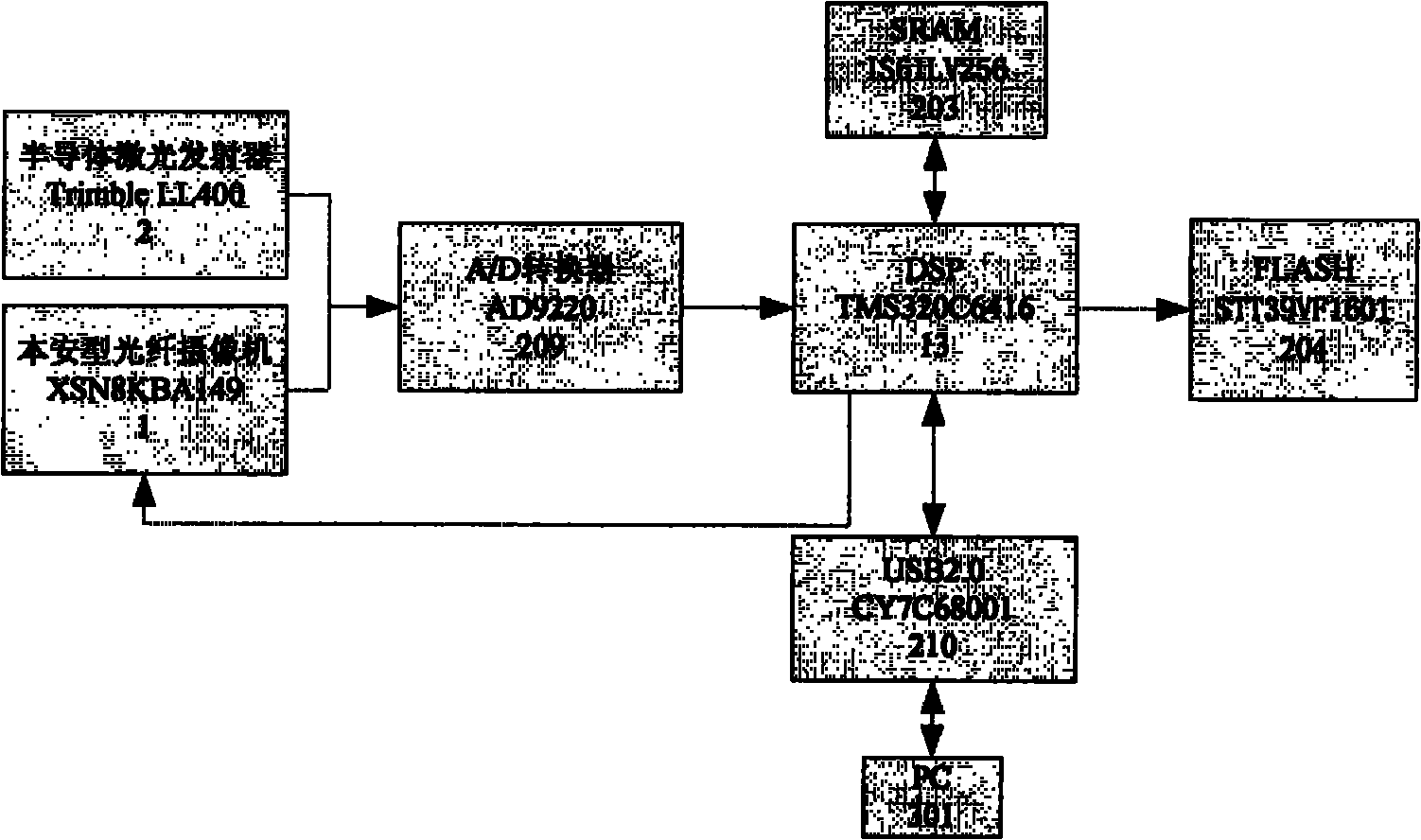

Non-contact photoelectric measurement method and device for bunker coal position

InactiveCN102023045ANo accumulationAccurate measurement dataMachines/enginesLevel indicatorsLaser transmitterMeasurement device

The invention provides a non-contact photoelectric measurement method and device, which obtains the depth value of materials in a bunker on the basis of the number of pixels between a laser facula imaging spot and an image center spot in an image, belonging to the technical field of material position measurement. The invention is especially suitable for measuring the depth of the bunker coal position. In the device of the invention, a digital camera and a laser emitter are fixed on the top of the principal axis of a barrel-shaped bunker, so that the light path of the camera is vertical to the surface of material. The laser emitter is arranged on the position at the angle theta with the horizontal direction so as to ensure that the imaging zone of the laser facula can be projected on the material surface within the field range of the camera. The camera focuses by N-gear segment so as to satisfy the situation that clear images can be shot on all different coal positions of the bunker. DSP (Digital Signal Processor) serves as the inner core of a processor. The number of pixels between the laser facula imaging spot and the image center spot is calculated, and a depth table which is calibrated in advance and corresponds to different pixel number mean values is inquired to finish depth detection. The measurement device is composed of the digital camera, the laser emitter, the image processor and a real-time display module.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

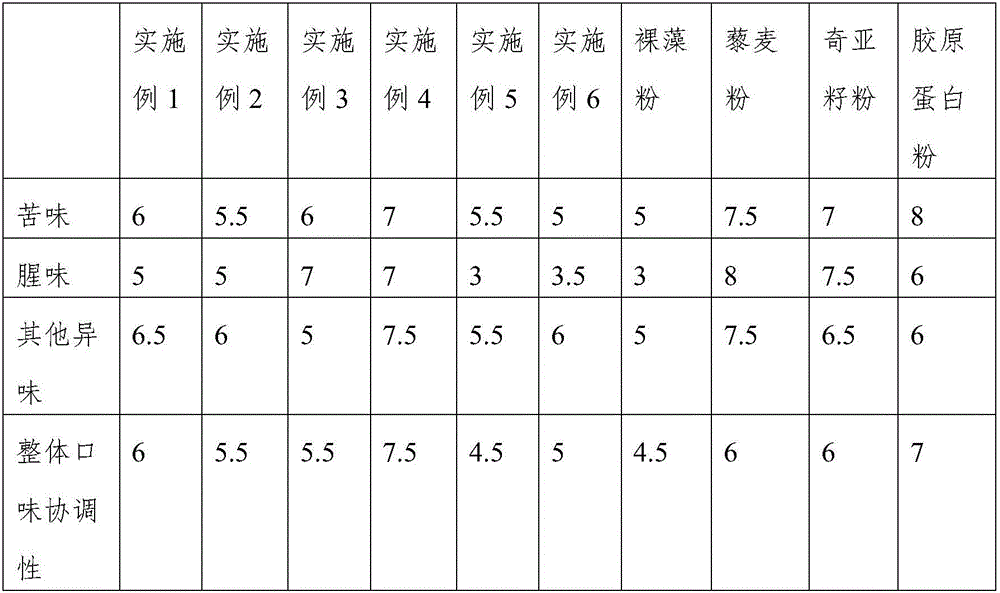

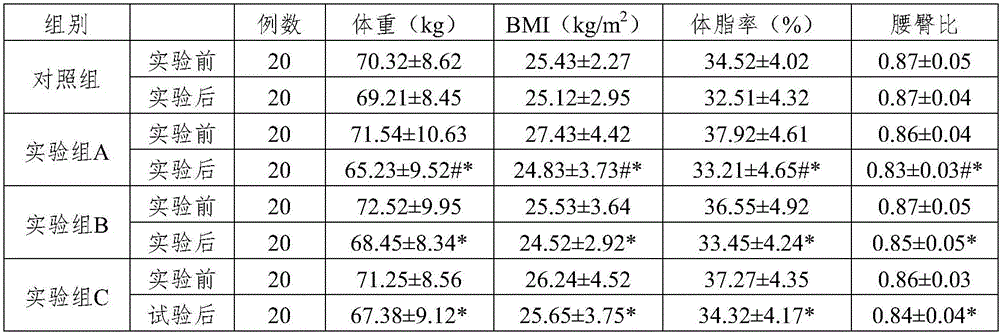

Nutrition meal replacement composition and application thereof

InactiveCN106616998AIncrease contentNo accumulationFood ingredient functionsFood additiveMeal replacement

The invention discloses a nutrition meal replacement composition, which is prepared from the following components in parts by weight: 10-300 parts of euglenophyta powder, 60-500 parts of quinoa powder, 100-400 parts of chia seed powder, 40-450 parts of collagen powder, 50-520 parts of a carbohydrate compound, 0-200 parts of vitamin and 0-500 parts of mineral substances. The invention further discloses a nutrition meal replacement refresher. The refresher is prepared from the nutrition meal replacement composition and a food additive. The nutrition meal replacement composition has the effects of regulating intestinal tracts, dual-directionally regulating blood glucose and providing abundant nutrient substances needed for a human body while losing weight and controlling the weight.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

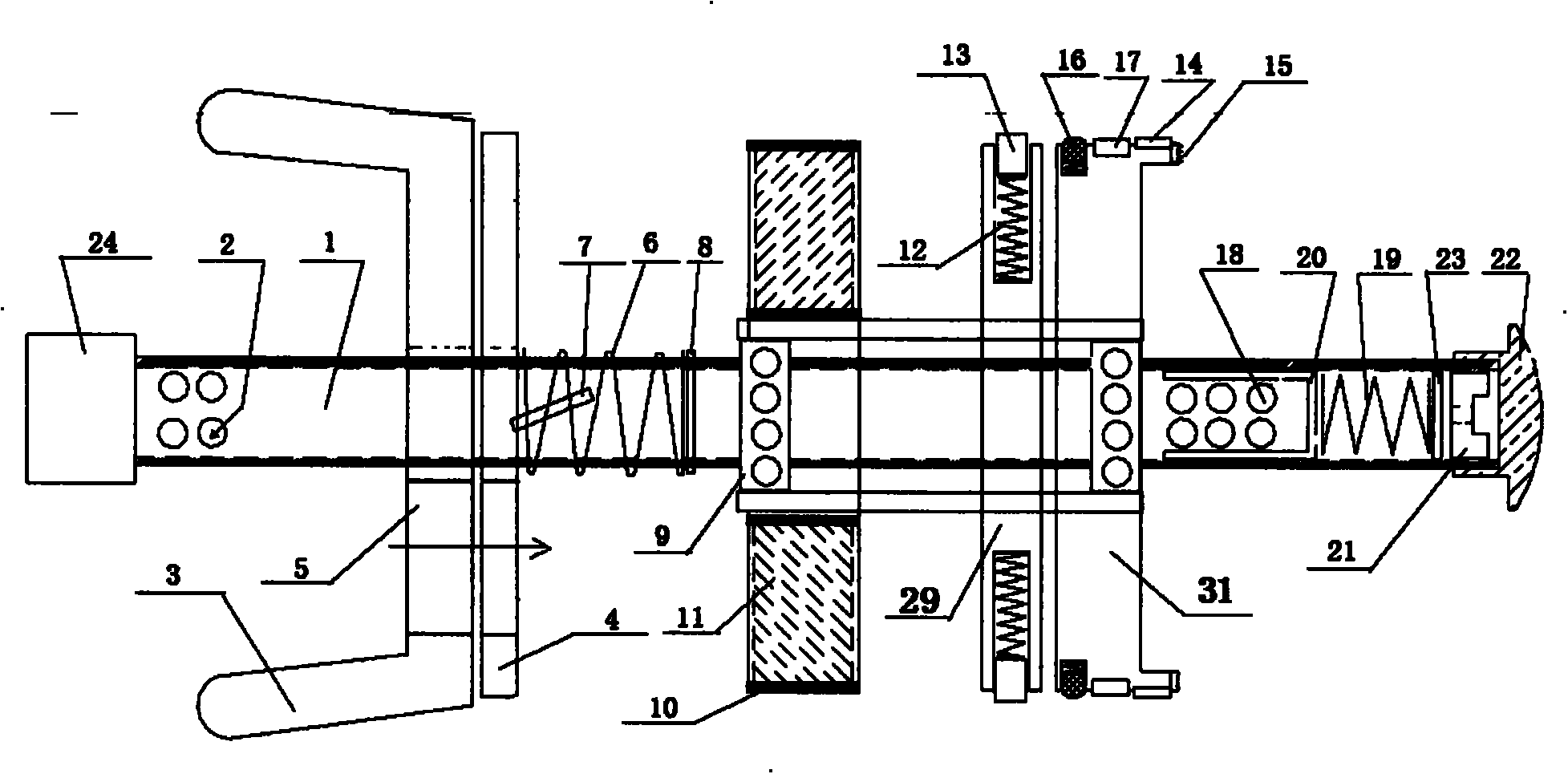

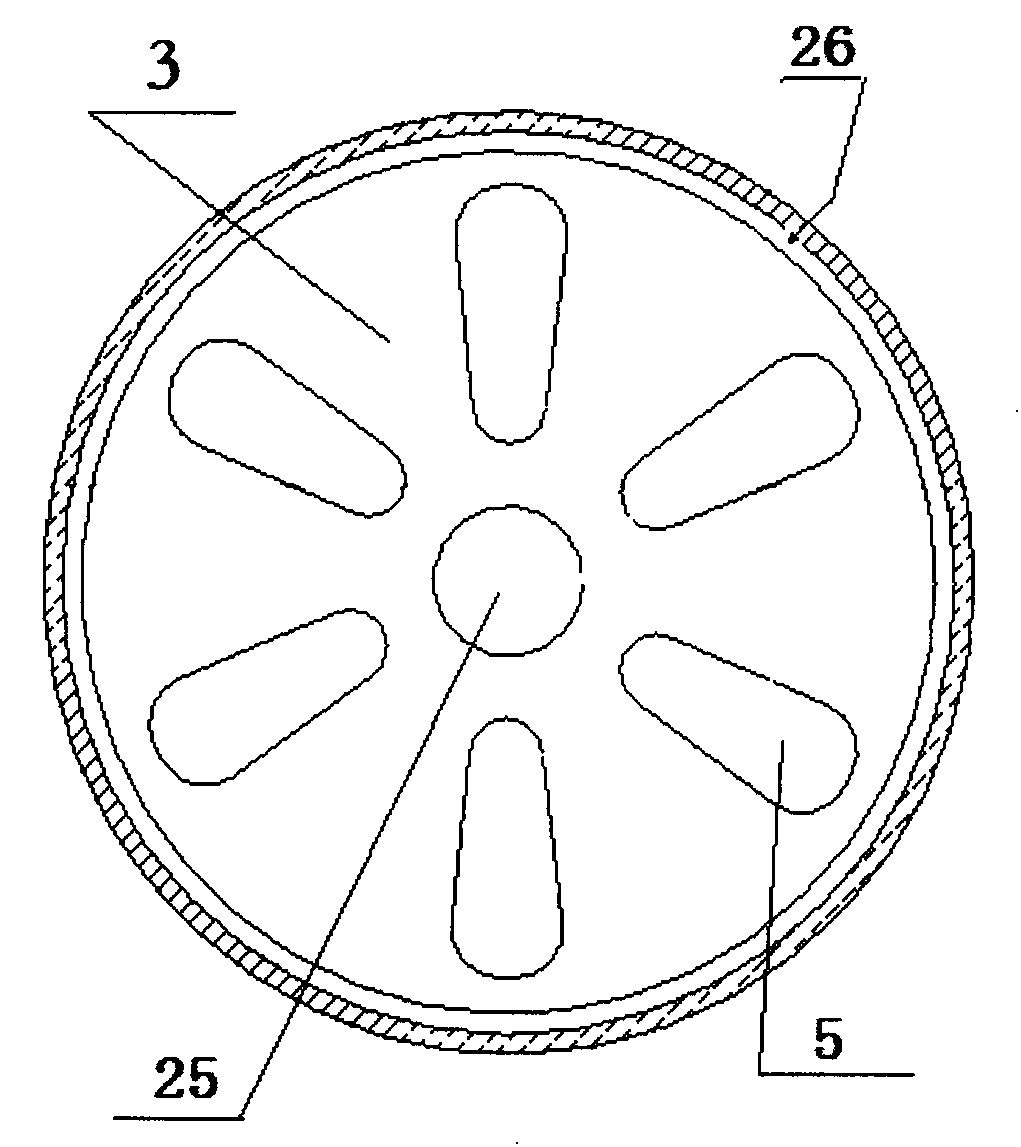

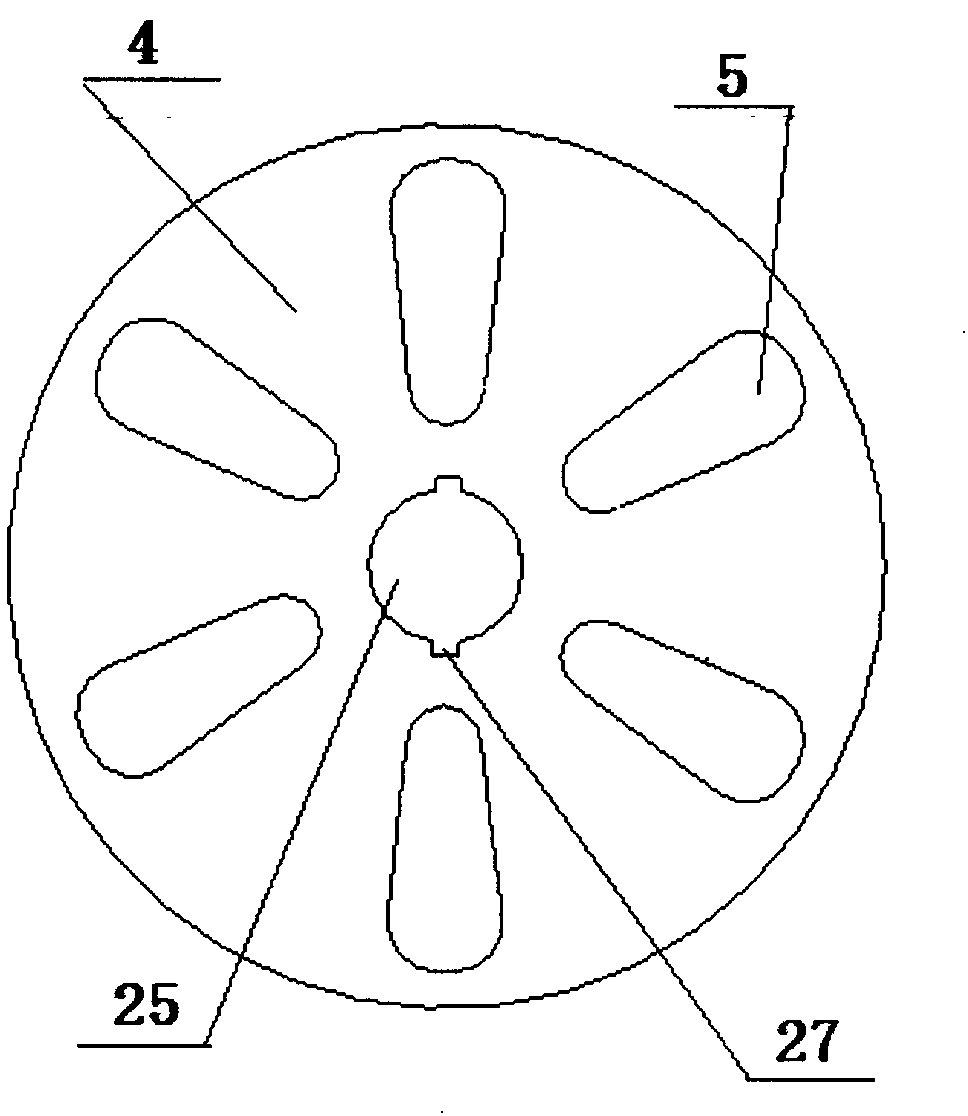

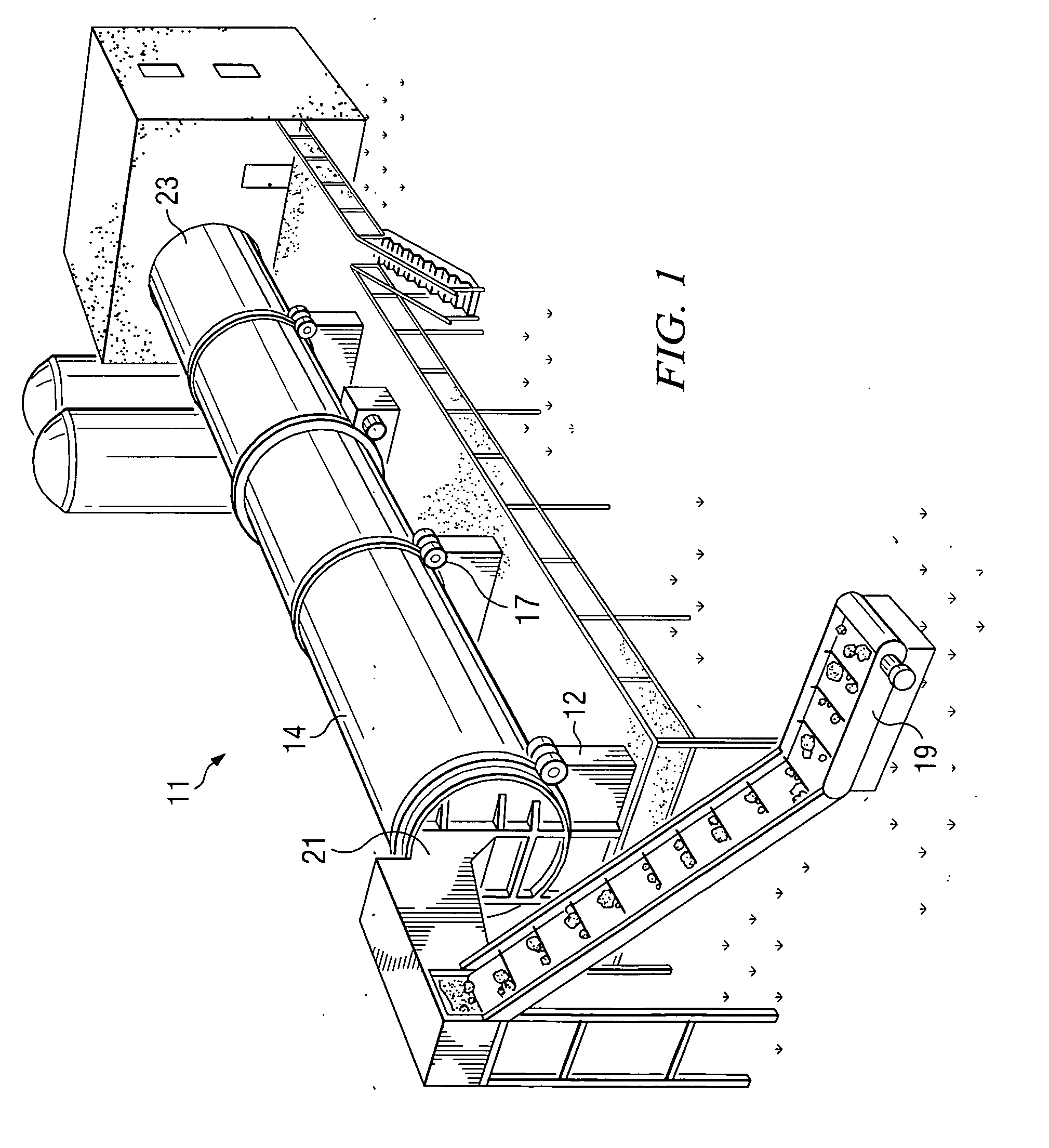

Hydraulic driven built-in rotation scraping type pipeline cleaning device

Disclosed is a hydraulic driven built-in rotation scraping type pipeline cleaning device. A main guide plate and an auxiliary guide plate are adopted to form a one-way pressure relief structure, the operating posture of a spindle on the inner central line of a pipeline is maintained through the guide plates, a sealed impeller and a positioning support frame, fluid kinetic energy is used for driving the impeller to drive a pipeline cleaning cutter to clean the pipeline circumferentially in the pipeline, meanwhile, a rim working portion of the composite pipeline cleaning cutter combining effective functions of various pipeline cleaners is further kept in the maximum and optimal contact with the inner wall of the pipeline, the axial portion adopts an alloy grinding head to remove large-particle dirt and metal scaling bonded on the inner wall of the pipeline, the kinetic energy of fluid is used for driving the pipeline cleaning cutter to work, the pipeline can still be in a normal operation state, cleaned dirt can be carried by the fluid quickly and cannot accumulate, and choking of the pipeline can be avoided. The pipeline cleaning device is compact in structure, convenient and flexible, safe and durable, high in popularity, simple to operate, convenient to implement, energy saving, high in cleaning speed, long in cleaning distance and free of damage to the pipeline wall.

Owner:钟平贵

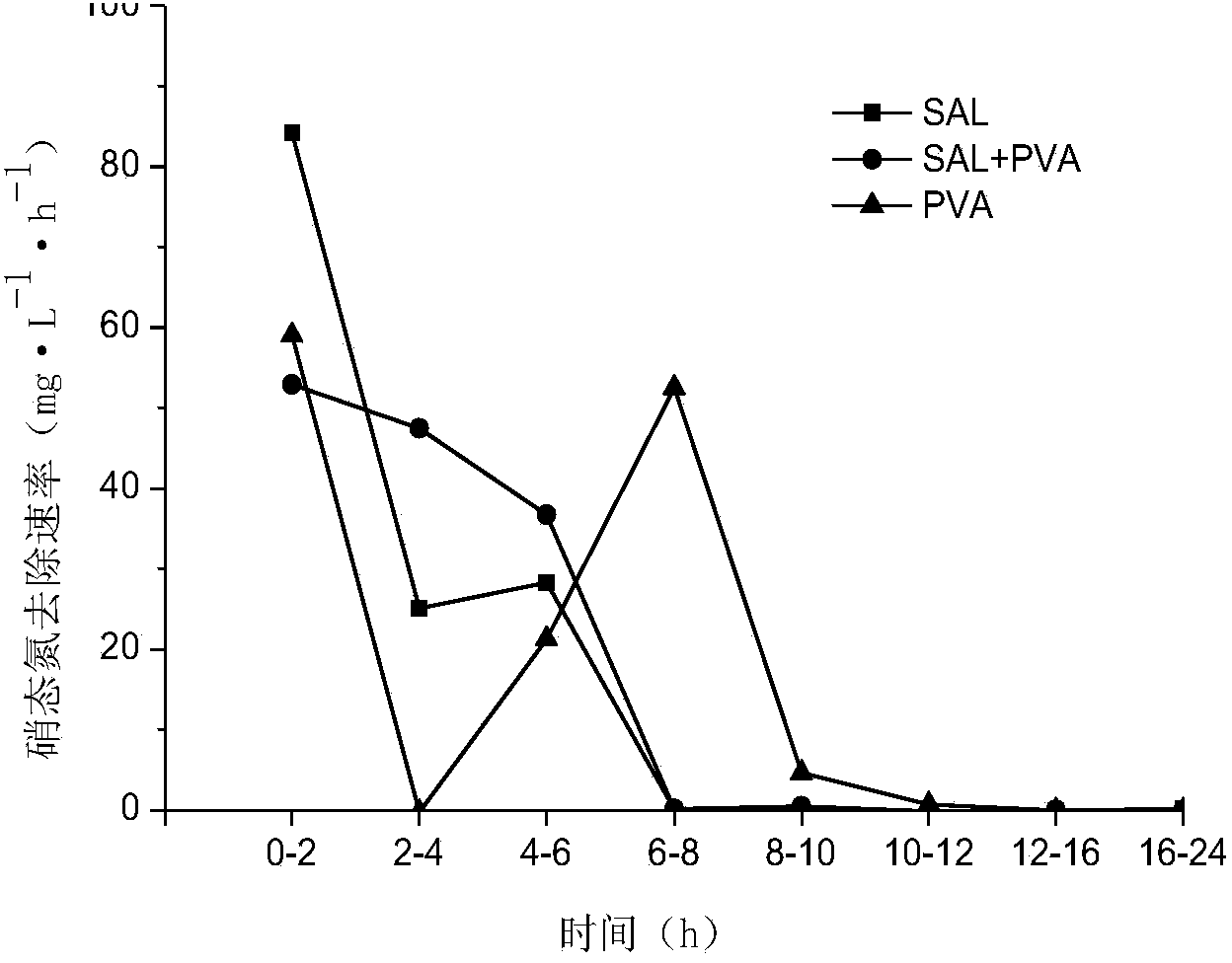

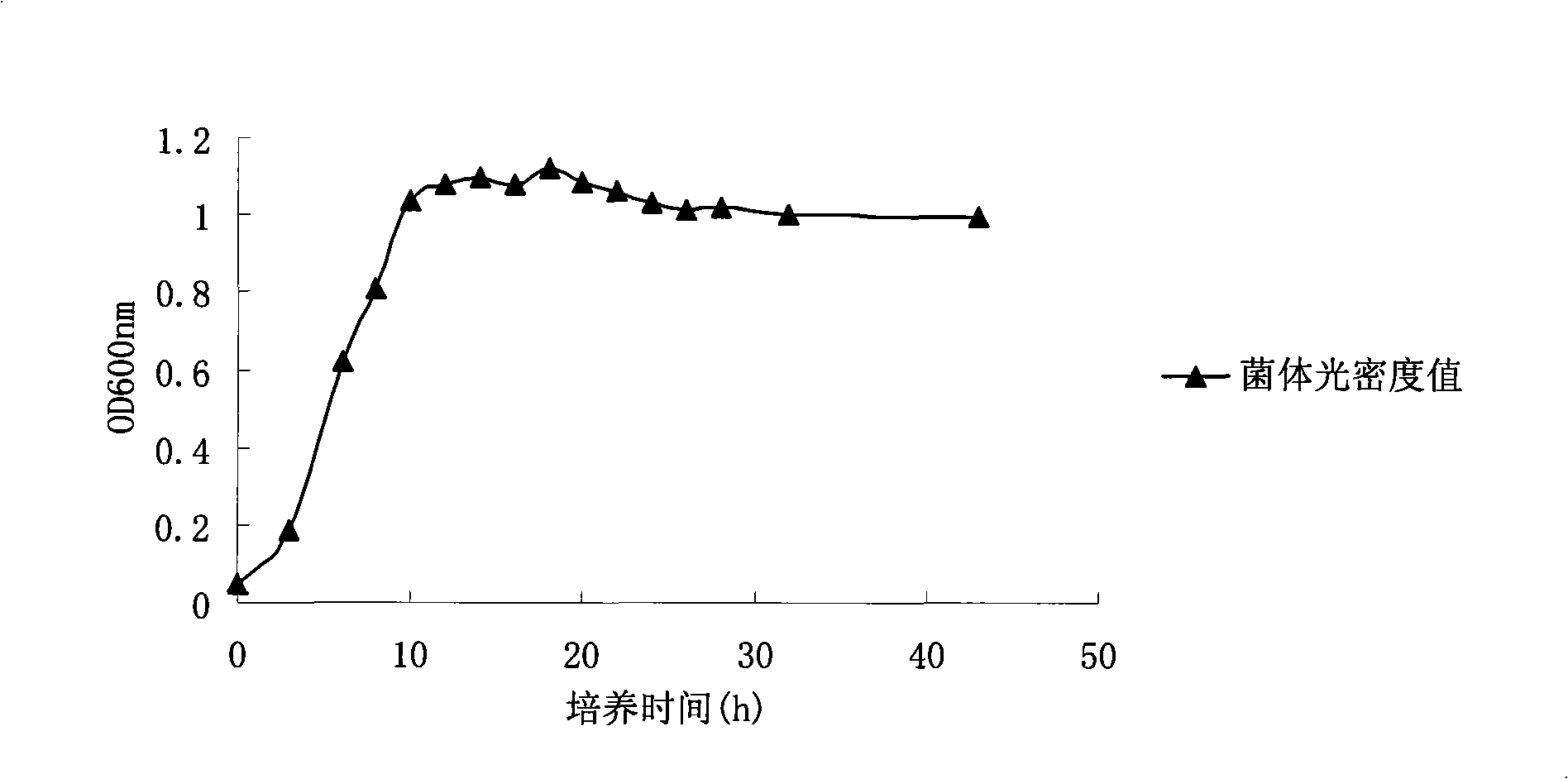

Aerobic denitrifying bacterium and application thereof in wastewater treatment

ActiveCN103667168AEasy to trainNo accumulationMicroorganism based processesOn/in organic carrierDenitrifying bacteriaWastewater

The invention discloses an aerobic denitrifying bacterium and application thereof in wastewater treatment. The applicant selects an aerobic denitrifying bacterium through enrichment, Pseudomonas stutzeri JH-1, CCTCC NO: M2013488 from a wet land. The bacterium can be used for treating wastewater with high NO3<->, reaches the highest removing rate of 99.6%, avoids the accumulation of nitrite nitrogen, meanwhile can remove COD in organic wastewater with the highest removing rate of 60%-80%; compared with other reported aerobic denitrifying bacteria for wastewater treatment, the bacterial strain provided by the invention can efficiently treating wastewater, achieves the removal rate of nitrate nitrogen of 99.6% after 24 h and the denitriding rate of 22.6 mg. L<-1>.h<-1>, which is 1.51-4.57 times of that of the reported bacterial strains, can be independently used or solidified for wastewater treatment, and is widely applied.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Heterotrophic nitrification aerobic denitrifying bacteria, culturing method thereof and uses

ActiveCN101338282AWide range of substratesEasy to trainBacteriaMicroorganism based processesBacteroidesHigh concentration

The invention belongs to the environmental microorganism field, relates to a high efficiency heterotrophic nitration aerobic denitrifying bacteria and the culture method and the purpose. The bacterium is Pseudomonas putida DN1.2 with the preservation and registration number of CCMCC M207075, which can effectively remove the ammonia nitrogen, nitrous acid and the mixture in water. At the same time, the bacterium also can remove the CODCr in the organic waste water. The bacterium is suitable for being used in the treatment of organic nitrogenous effluent with high concentration and inorganic nitrogenous effluent. The nitrite and nitrate can not be produced in the denitrification process. The waste water treatment process is simple by using the strain and the denitrification effect is stable.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

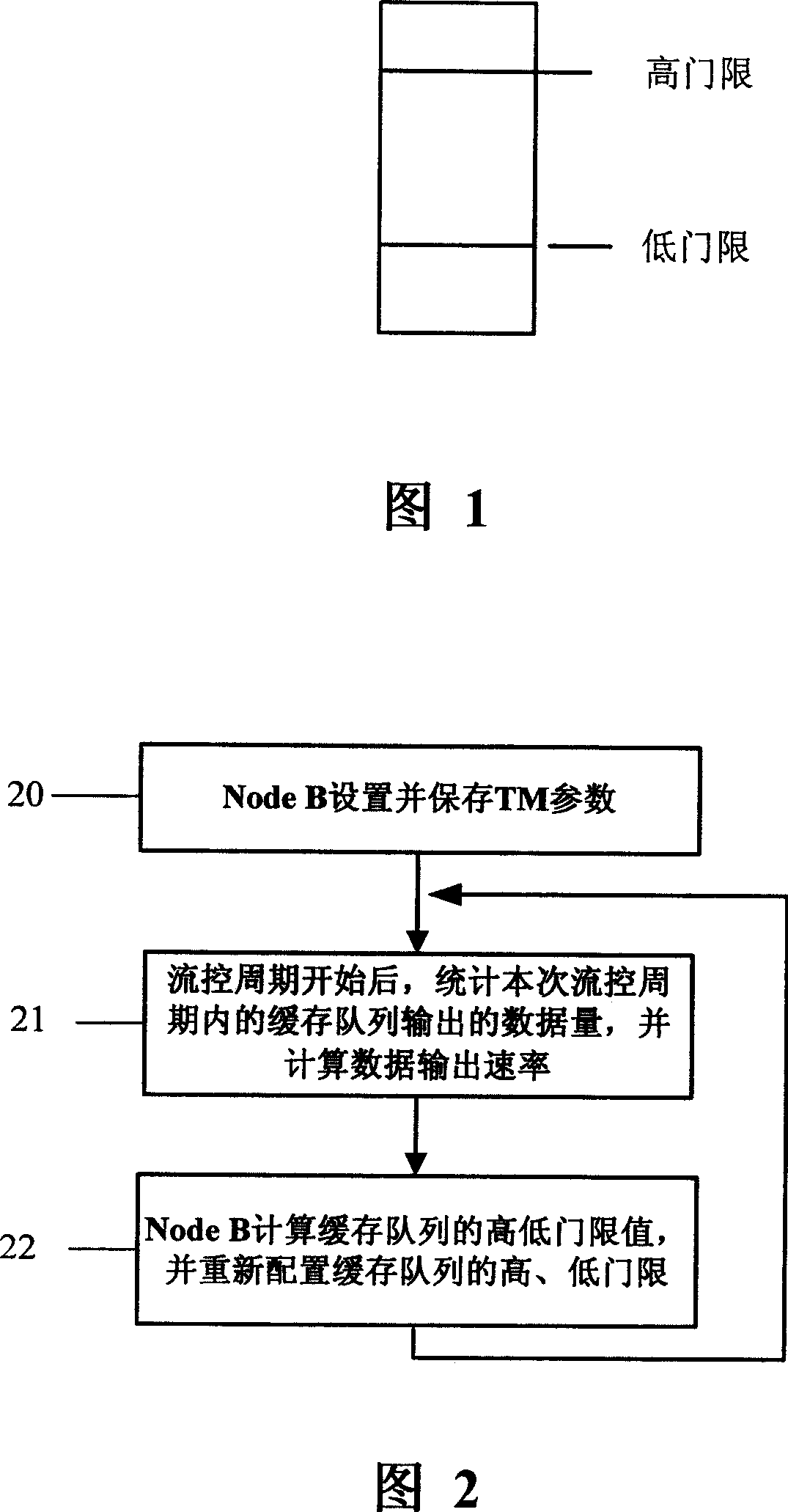

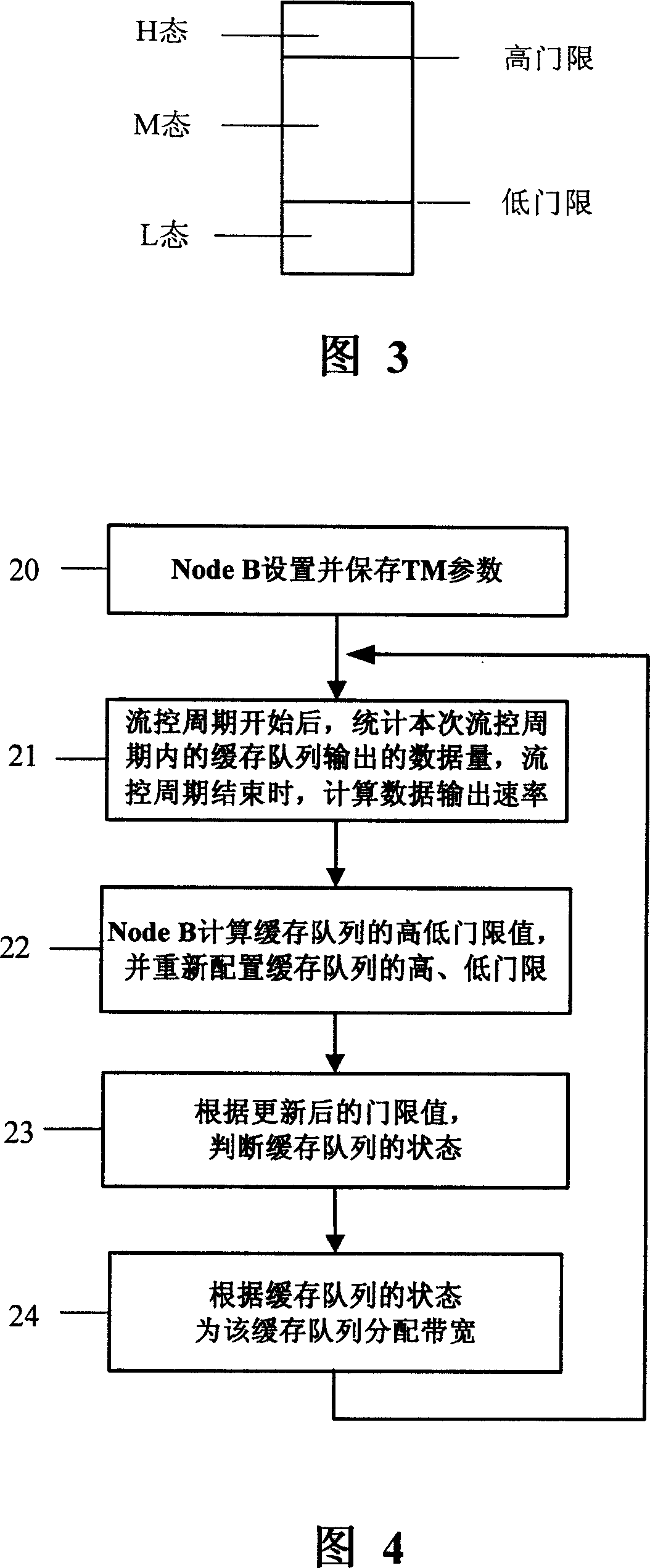

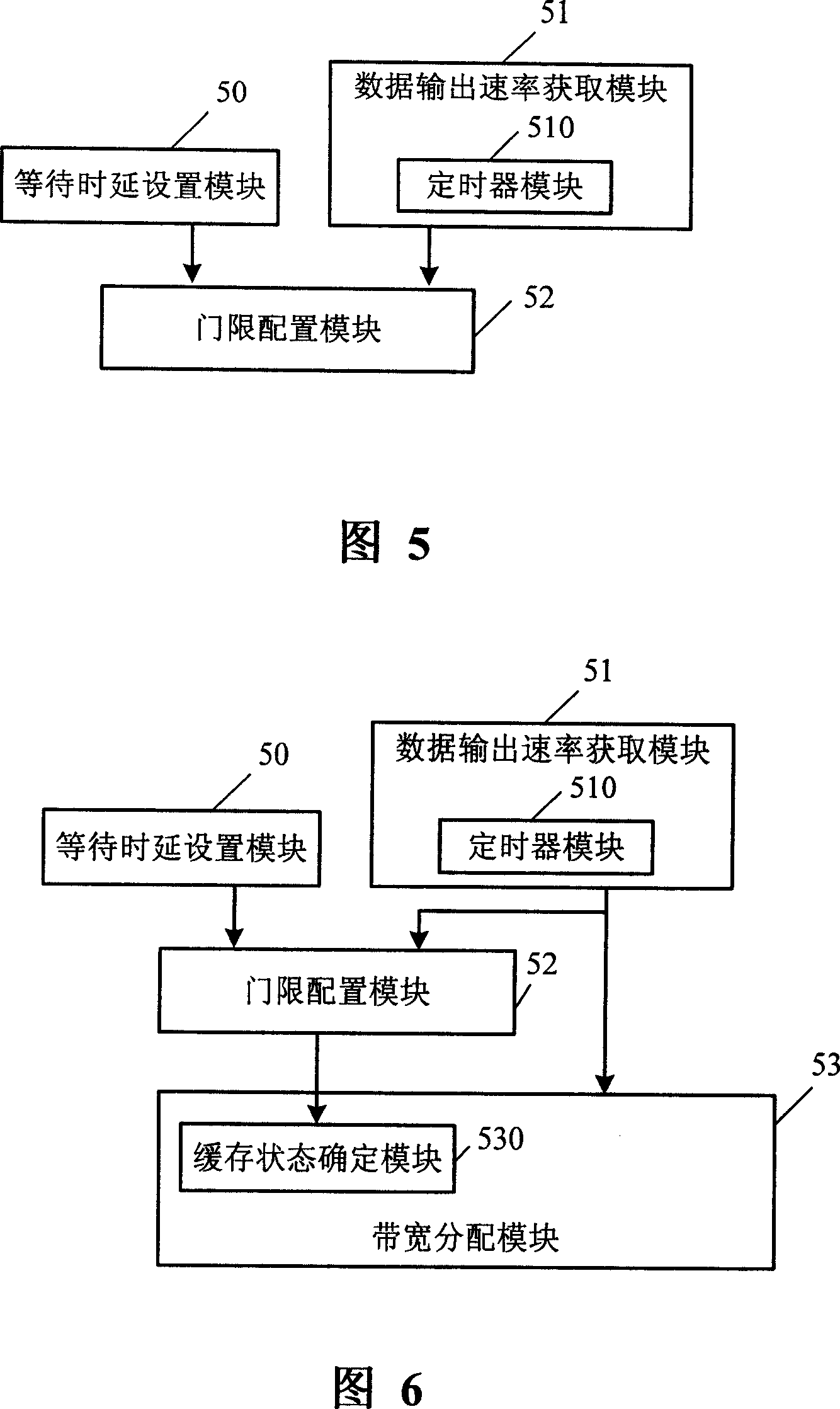

Method and device for allocating cache quene threshold, and its flow control method and device

ActiveCN1937594AImprove throughputNo accumulationRadio/inductive link selection arrangementsData switching networksCode division multiple accessAir interface

The invention discloses a buffer queue threshold configuring method and device, for dynamically configuring MAC-hs buffer queue threshold in wideband code division multiple access (WCDMA) system, and arranging at least two data waiting delay parameters in buffer queue; obtaining data output velocity V in the buffer queue; and using the product of each waiting delay parameter and data output velocity V to configure the threshold of the current buffer queue. And it also discloses a flow control method and device, after the above threshold is updated, regulating data input bandwidth of the buffer queue and making flow control. According to the data output velocity of the buffer queue, it correspondingly regulates the buffer queue threshold and controls the flow, thus making the data length in the buffer queue being in a proper range, and assuring the buffer queue can provide enough data for aerial interface to transmit, reducing data length in the buffer queue and data processing waiting time.

Owner:XFUSION DIGITAL TECH CO LTD

Biodegradable coated carbamide and preparation method thereof

InactiveCN101723751AReduce releaseReduce rateUrea compound fertilisersFertilizer mixturesCoated ureaNitrification inhibitors

The invention relates to coated carbamide, in particular to a totally biodegradable coated carbamide and a preparation method thereof. The coated carbamide consists of a coated layer and a carbamide core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, organic and / or inorganic conditioner, urease and / or nitrification inhibitor in the solution, spraying and coating the surfaces of the fluidized carbamide after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release of the nitrogen nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

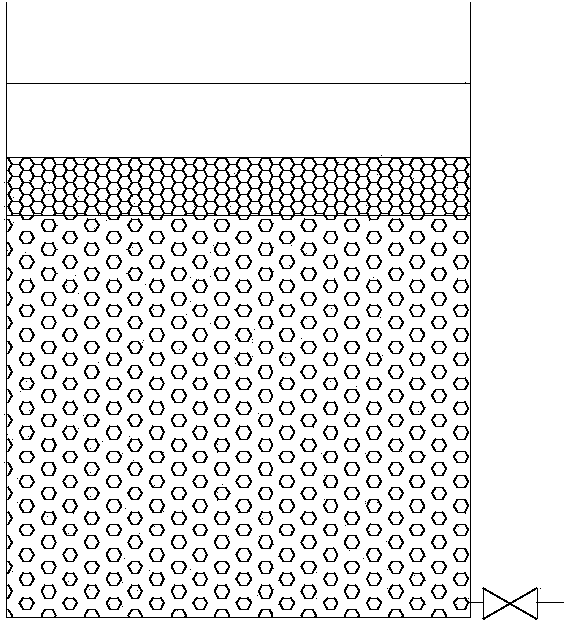

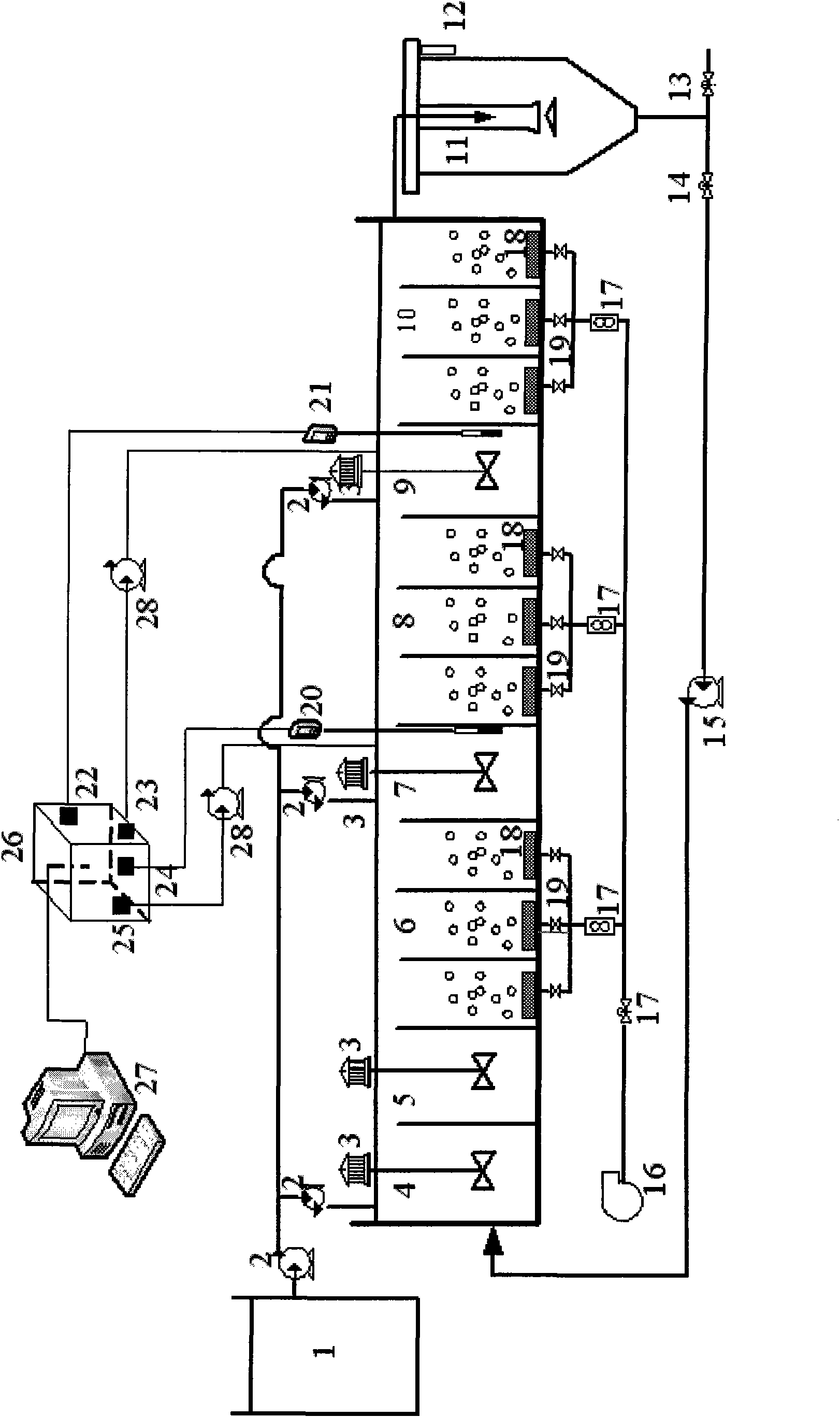

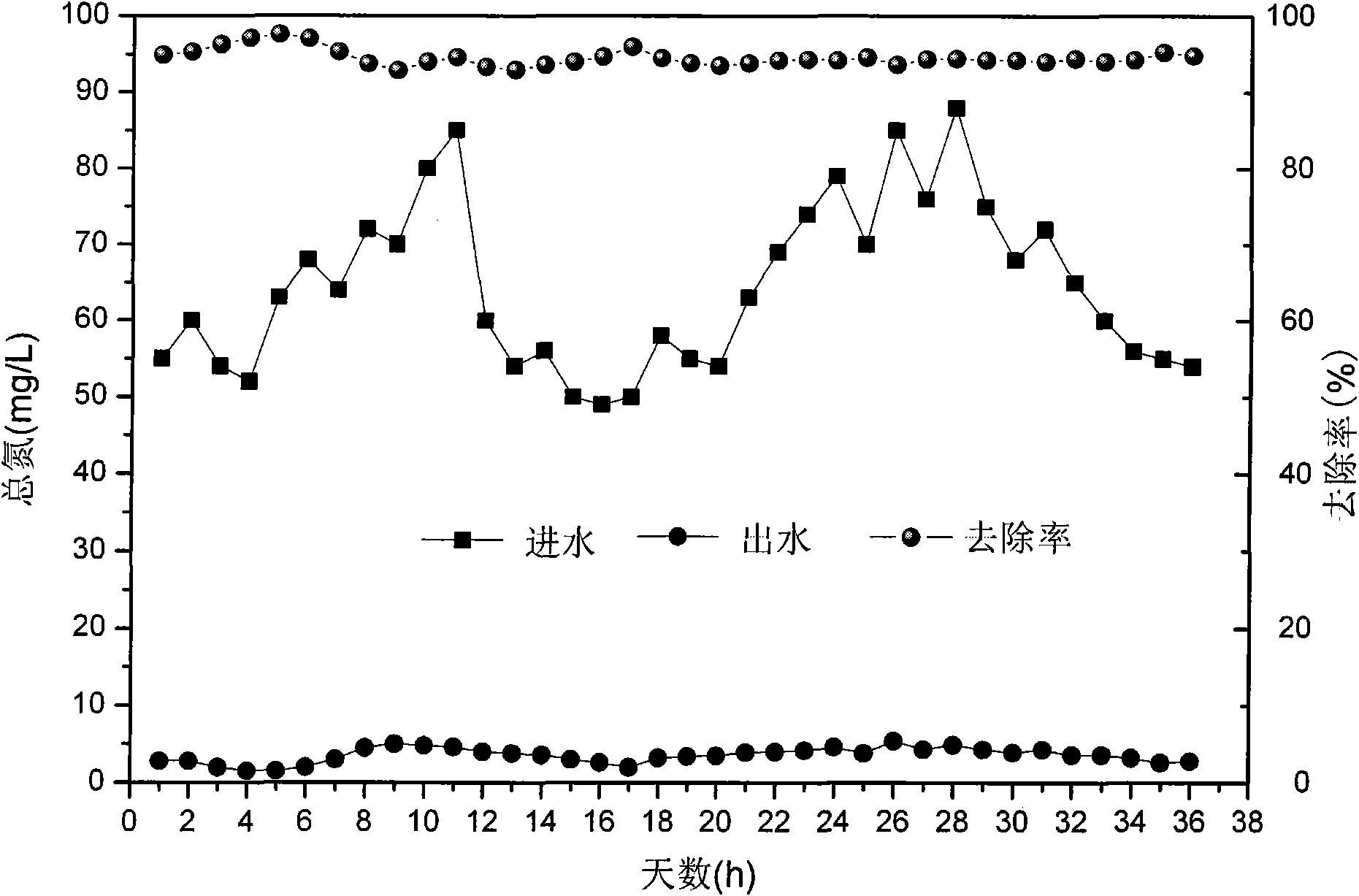

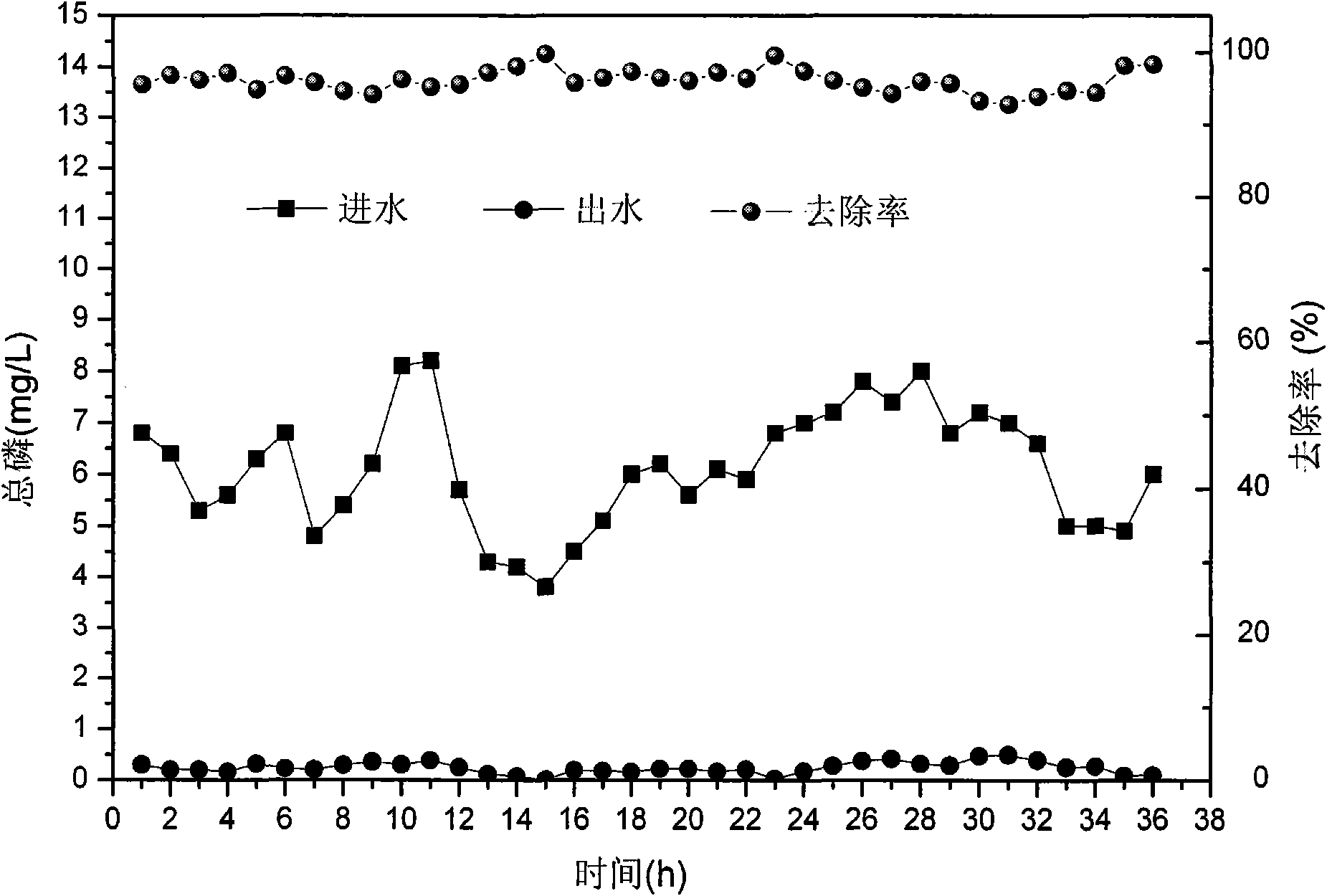

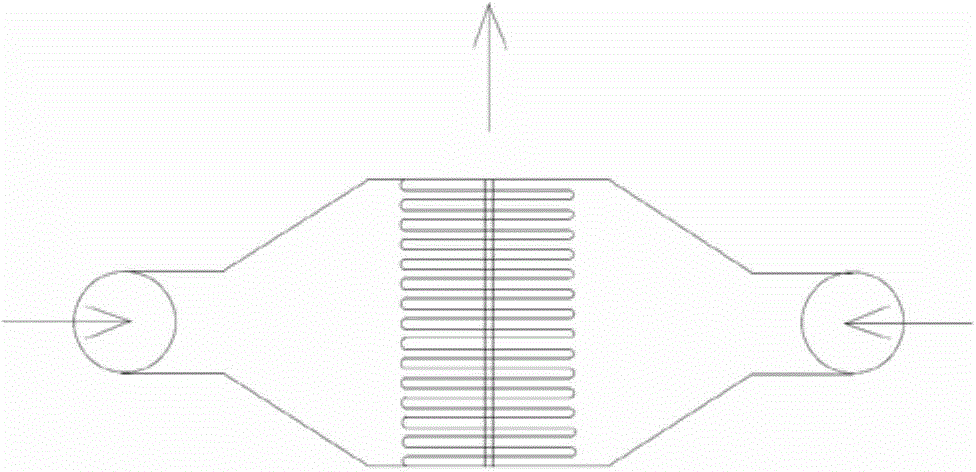

Advanced nitrogen and phosphorus removal device and process control method thereof

ActiveCN101570383ARealize denitrification and dephosphorizationBreaking through the bottleneck that is difficult to improve the efficiency of nitrogen and phosphorus removalTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentLine sensorWater quality

The invention relates to an advanced nitrogen and phosphorus removal device and a process control method thereof, belonging to the technical field of biological sewage treatment by using a biochemical method. Aiming at the defects that the existing A / O step feed technology can not synchronously have advanced biological phosphorus removal, reverse A / O technology is high in energy consumption and complicated in operation and the like, the invention combines the reverse A / O technology and the step feed technology, nitrification liquid internal reflux does not needed to be set, a first section is provided with an anaerobic reactor, anoxic reactors at a second section and a third section are respectively installed on an ORP on-line sensor and a nitrate on-line sensor, and data obtained by collecting ORP and nitrate in an on-line way can be taken as input of a process controller, is output by fuzzification treatment and can act on opening and closing a frequency converter of an actuating mechanism and an external carbon source dosing metering pump so as to save the external carbon dosage. The invention can greatly improve the denitrification effect of the step feed technology, utilizes carbon source of raw water to the utmost extent, realizes synchronous nitrogen and phosphorus removal, and has the advantages of simple control structure and stable quality of yielding water.

Owner:BEIJING UNIV OF TECH

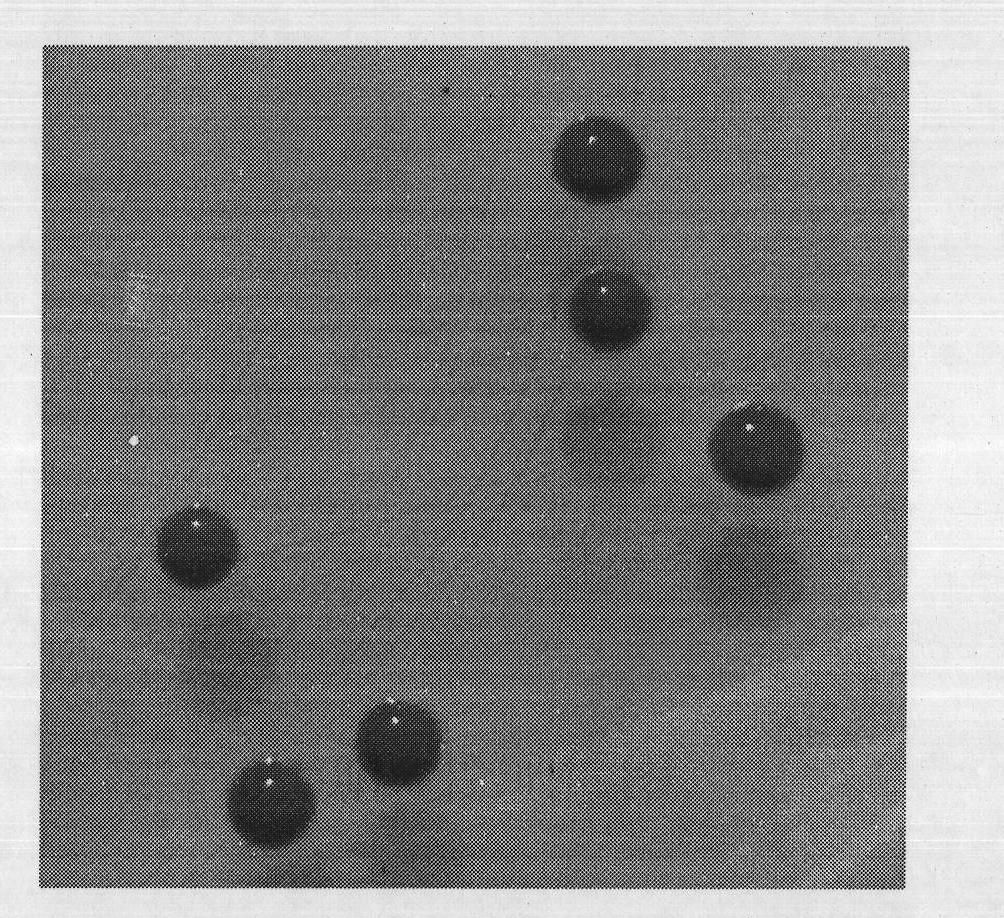

System and method for coproduction of activated carbon and steam/electricity

InactiveUS7981835B2Increase heat productionNo accumulationPigmenting treatmentSteam generation heating methodsCarbonizationBiological activation

A system and method for producing activated carbon comprising carbonizing a solid carbonaceous material in a carbonization zone of an activated carbon production apparatus (ACPA) to yield a carbonized product and carbonization product gases, the carbonization zone comprising carbonaceous material inlet, char outlet and carbonization gas outlet; activating the carbonized product via activation with steam in an activation zone of the ACPA to yield activated carbon and activation product gases, the activation zone comprising activated carbon outlet, activation gas outlet, and activation steam inlet; and utilizing process gas comprising at least a portion of the carbonization product gases or a combustion product thereof; at least a portion of the activation product gases or a combustion product thereof; or a combination thereof in a solid fuel boiler system that burns a solid fuel boiler feed with air to produce boiler-produced steam and flue gas, the boiler upstream of an air heater within a steam / electricity generation plant, said boiler comprising a combustion zone, a boiler-produced steam outlet and at least one flue gas outlet.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

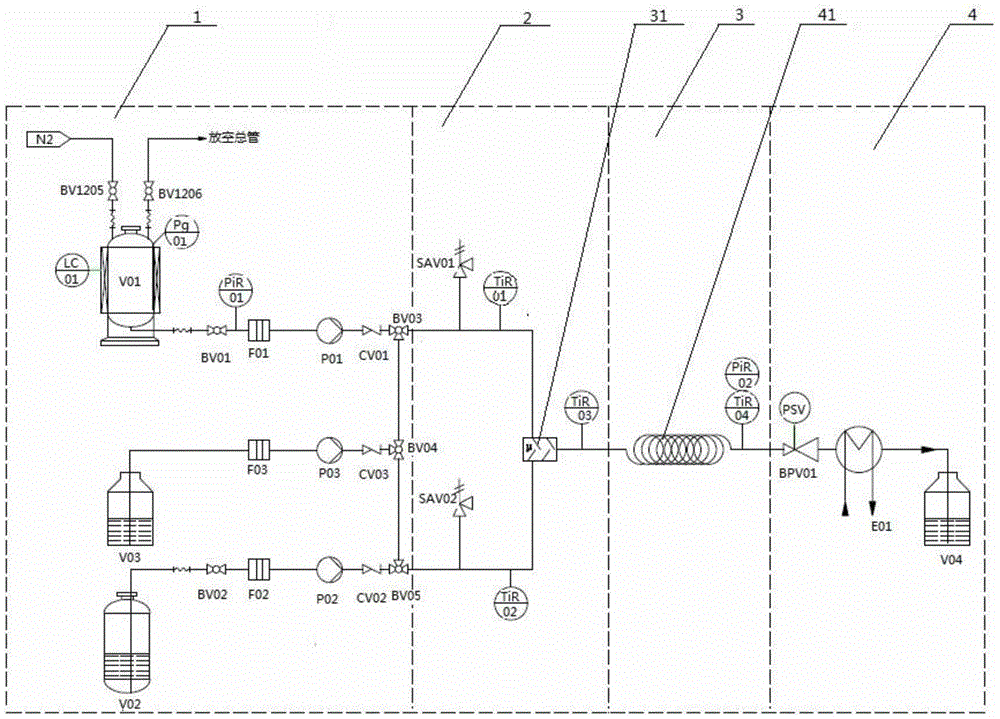

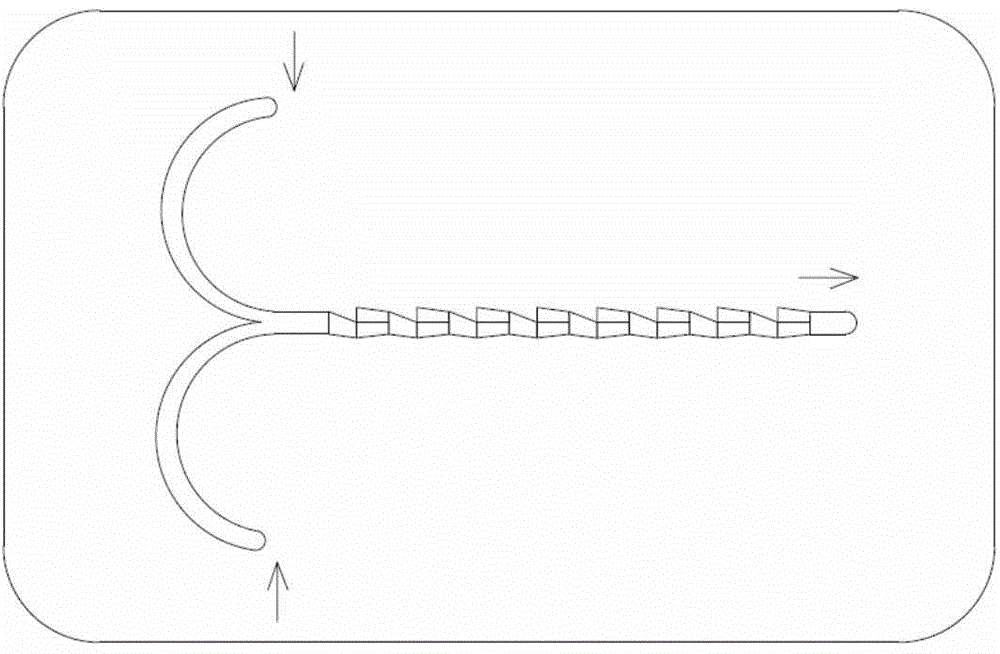

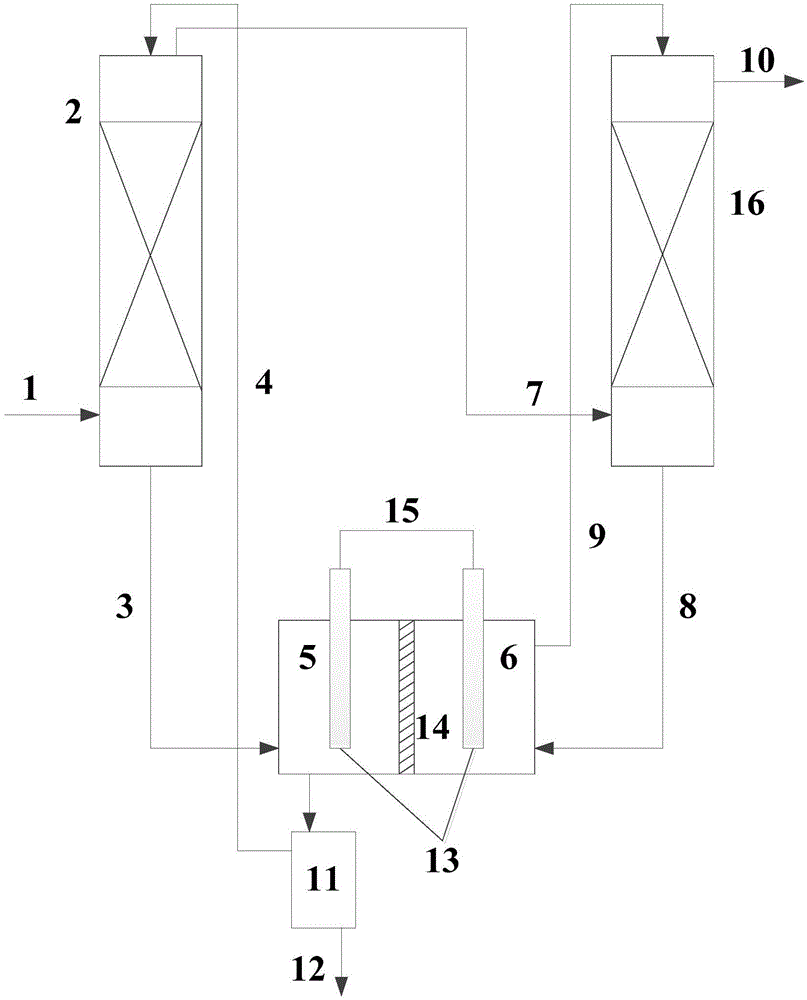

Microreactor device for producing 2-hydroxyethylhydrazine and preparation process

ActiveCN104876833AEthylene oxide accumulationNo accumulationHydrazine preparationMicroreactor2-hydroxyethylhydrazine

The invention discloses a microreactor device for producing 2-hydroxyethylhydrazine and preparation process. The device comprises a feeding system, a mixing system, a reaction system, a backpressure valve, a cooling receiving system, a washing system and an external circulating bathing system, wherein the feeding system comprises a hydrazine hydrate storing tank, an oxirane storing tank and a feeding pump; the mixing system comprises a CPMM or SIMM or Starlam serial micro mixer; the reaction system comprises a rimule reactor section; the pressure of the backpressure valve ranges from 0 to 15MPa; the cooling receiving system comprises a CRMH serial micro heat exchanger and a receiving storing tank; the washing system comprises a washing storing tank and a washing pump which are connected in series; the hydrazine hydrate storing tank or oxirane storing tank, the feeding pump, the micro mixer, the rimule reactor, the backpressure valve, the micro heat exchanger and the receiving storing tank are connected in series; the mixing system, the reaction system and the cooling receiving system are respectively arranged at the circulating bathing system.

Owner:大连微凯化学有限公司

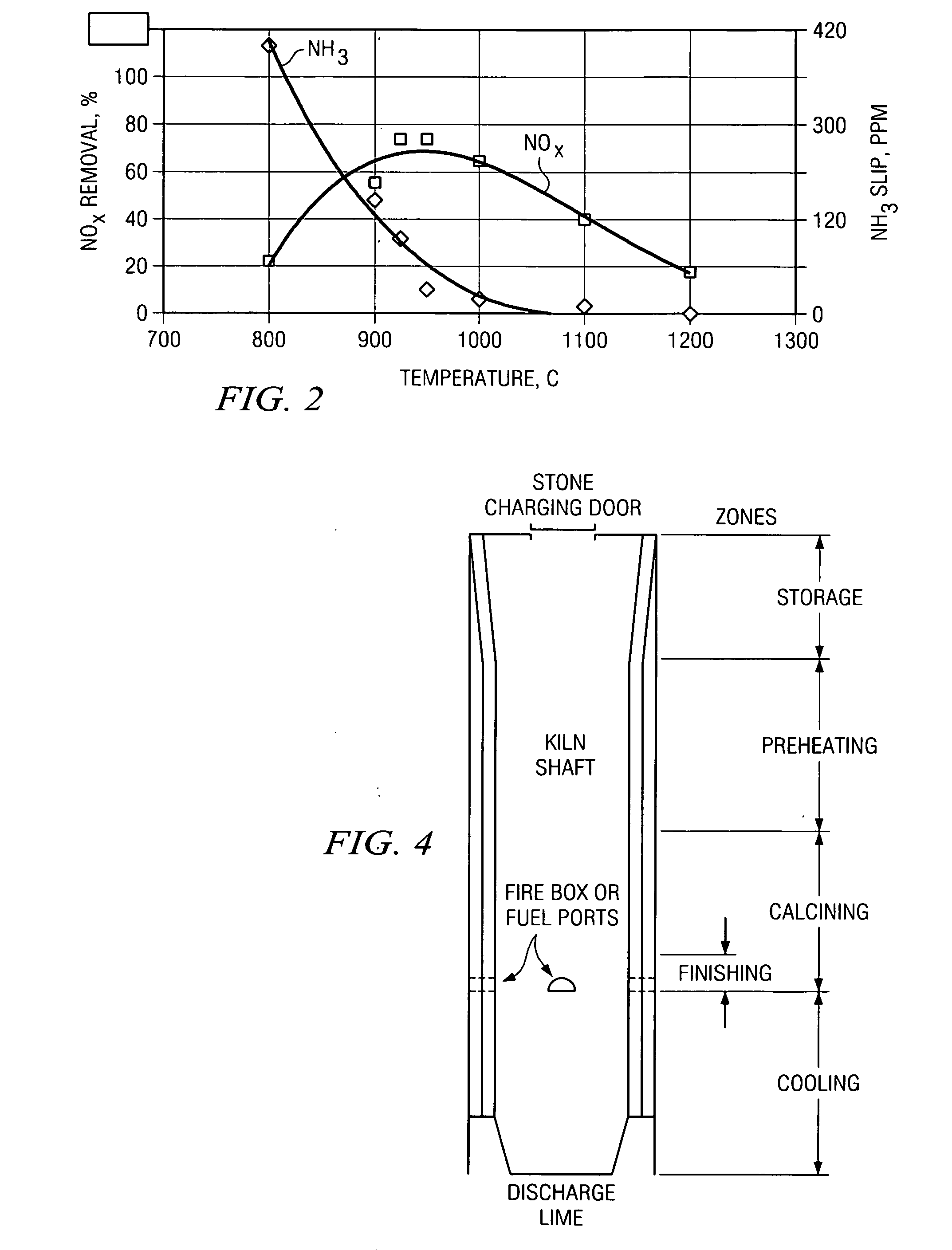

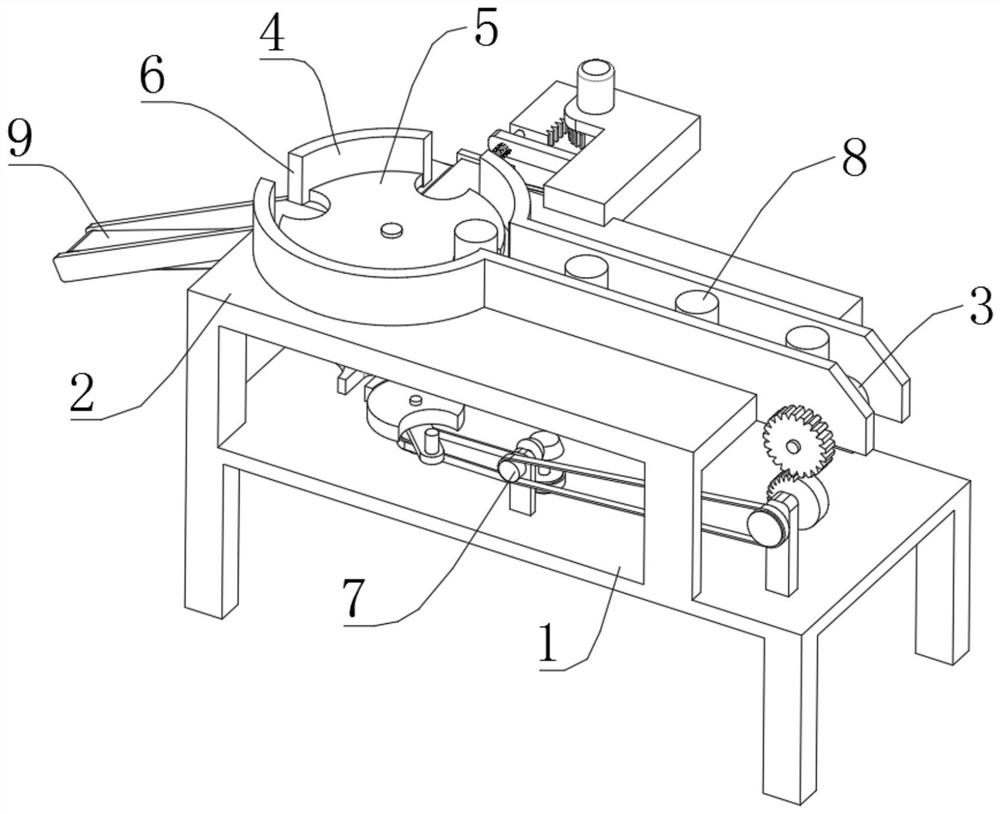

Method of improving NOx emissions control in rotary preheater mineral kilns

ActiveUS20080032247A1Reduce nitrogen oxide emissionsSimple methodRotary drum furnacesDispersed particle separationGas compositionMineralogy

This invention relates to a method to further enhance NOx reduction in rotary preheater mineral kilns by coupling the temperature control and gas composition uniformity afforded by the high temperature mixing with the use of chemical reducing agents. The chemical reducing agent or agents, generally chosen from ammonia or ammonia precursors, are introduced at a specific point in the rotary preheater kiln which has as an optimal temperature window to achieve the greatest reduction of NOx emissions.

Owner:LHOIST NORTH AMERICA INC

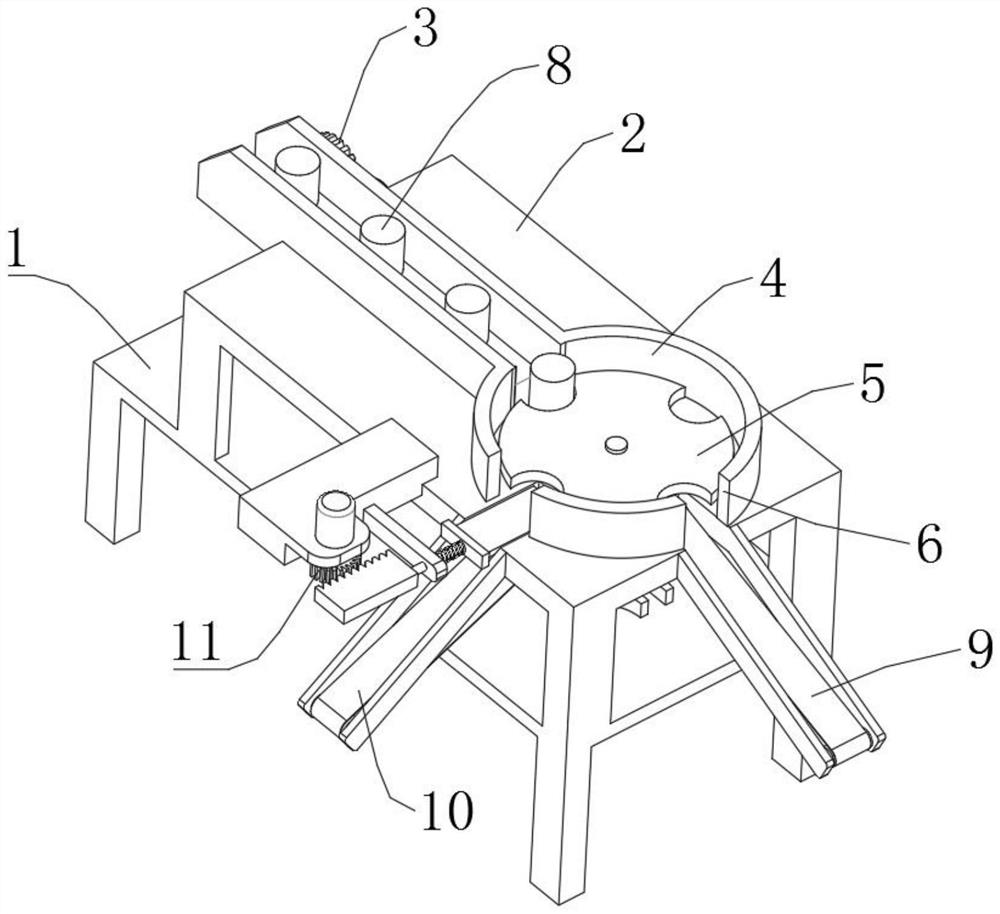

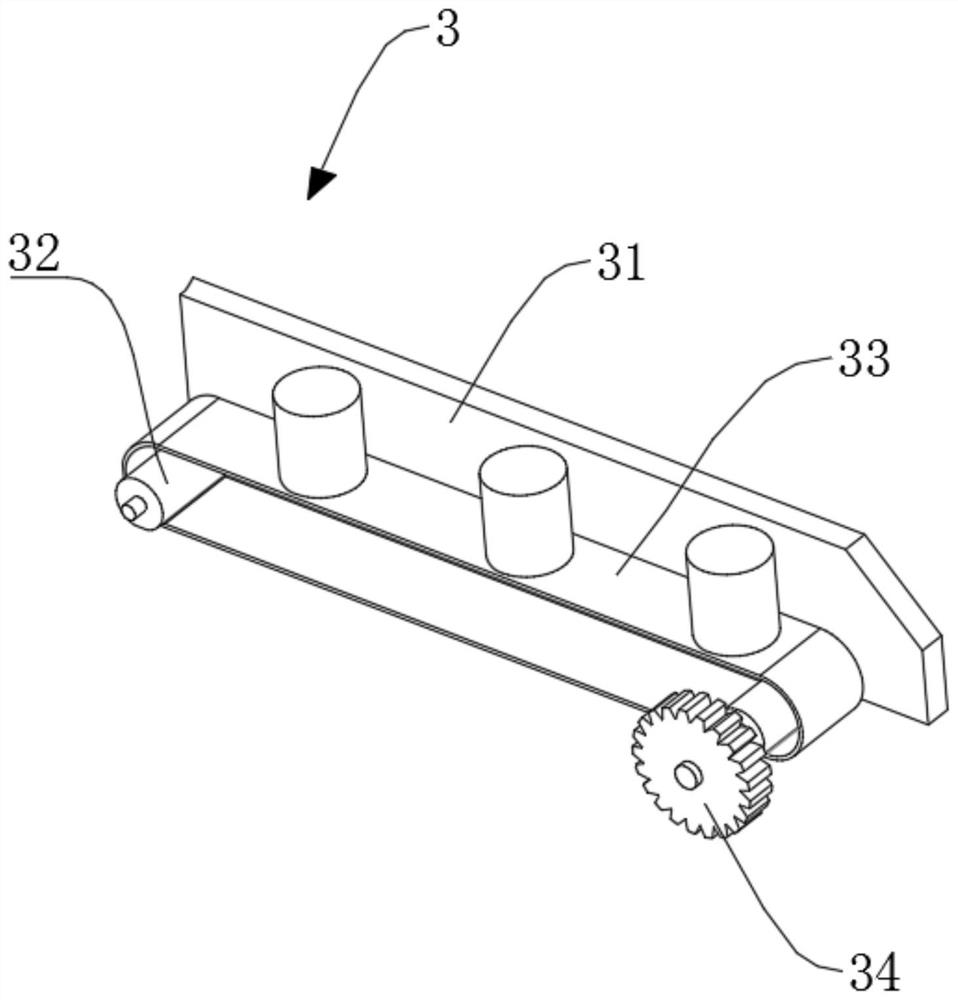

Casting carrying and separating equipment

PendingCN111776686ARealize automatic feeding processOrderly arrange the dischargeConveyor partsGear wheelWorkbench

The invention relates to the technical field of casting separation, in particular to casting carrying and separating equipment. The casting carrying and separating equipment comprises a supporting frame. A workbench is installed at the top of the supporting frame. A feeding mechanism is installed at one end of the workbench and comprises a fixed frame plate, two conveying rollers, a conveying beltand a transmission gear. An installation seat is installed at the output end of the conveying belt and is fixedly connected with the top of the workbench. A material separating mechanism is installedon the inner side of the installation seat and comprises a material separating disc. A rotary shaft is fixedly installed at the bottom of the material separating disc. A rotary seat is fixedly installed at the bottom end of the rotary shaft. A plurality of butt joint grooves are formed in the outer extending part of the rotary seat. A rotary disc is arranged on the outer extending part of the rotary seat. The bottom of the rotary disc is fixedly provided with a fixed plate. One end of the top of the fixed plate is fixedly provided with a lug. By means of the equipment, perfect cooperation ofautomatic feeding, automatic separating and automatic discharging of castings is achieved, the manual labor amount is greatly saved, the castings can be arranged and discharged in order, and accumulation is avoided.

Owner:林素芹

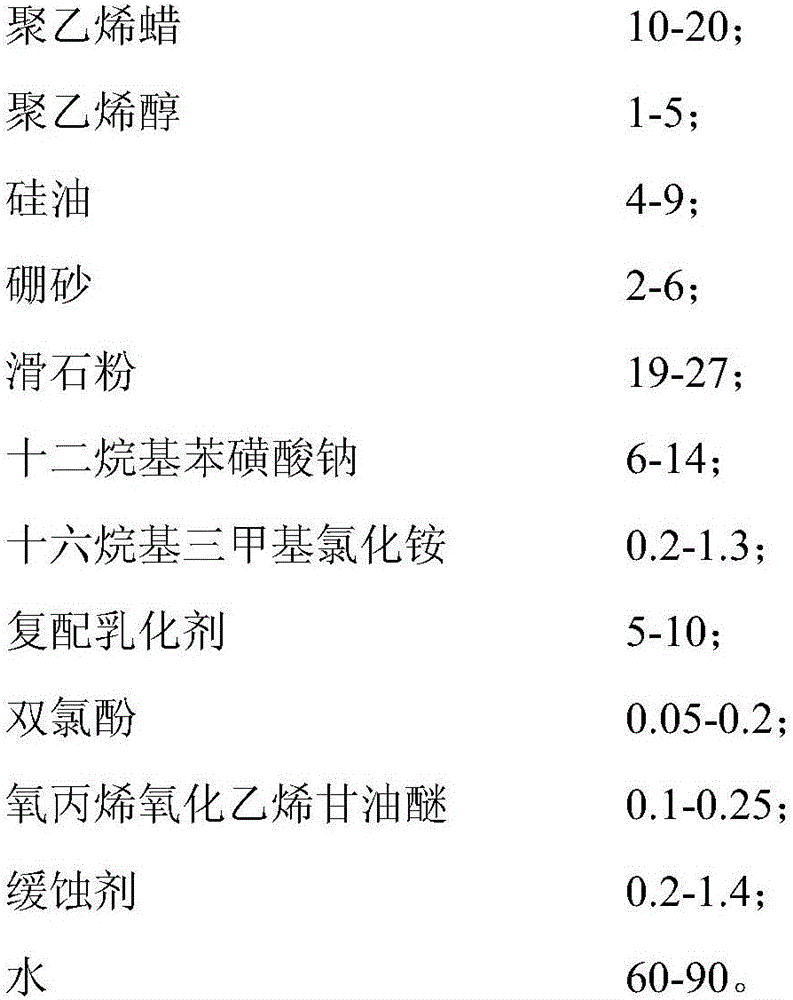

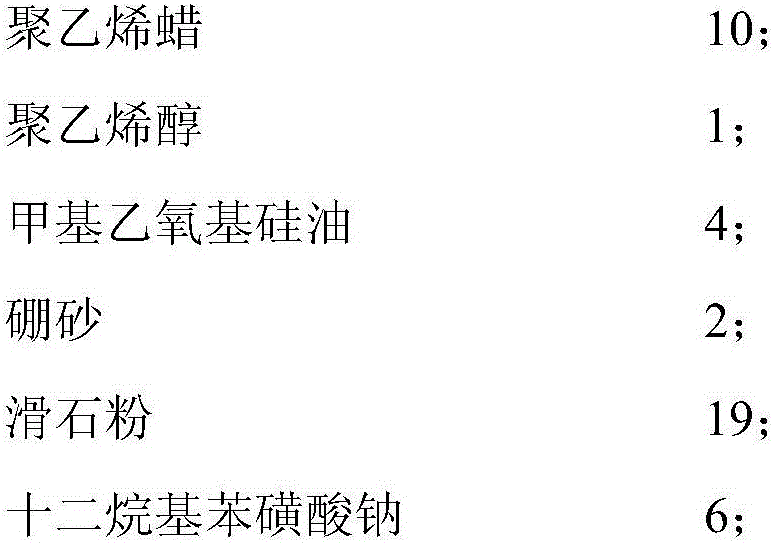

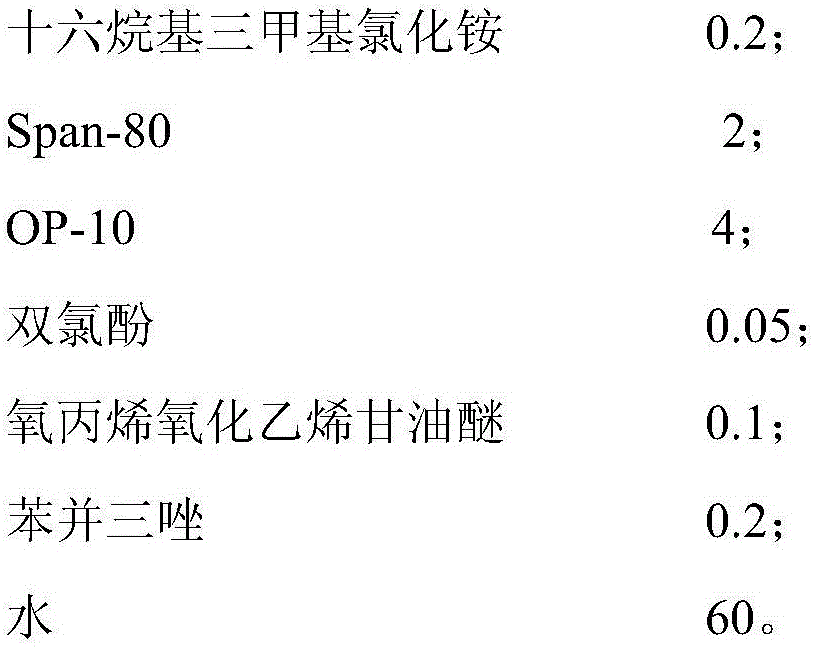

Release agent for aluminum alloy mold and preparation method of release agent

InactiveCN106311968AEasy to prepareNo pollution in the processFoundry mouldsFoundry coresCooling effectOxygen

The invention provides a release agent for an aluminum alloy mold and a preparation method of the release agent. The release agent comprises, by weight, 10-20 parts of polyethylene wax, 1-5 parts of polyving akohol, 4-9 parts of silicone oil, 2-6 parts of boraxes, 19-27 parts of talcum powder, 6-14 parts of sodium dodecyl benzene sulfonate, 0.2-1.3 parts of cetyltrimethylammonium chloride, 5-10 parts of compound emulsifiers, 0.05-0.2 part of dichlorophen, 0.1-0.25 part of oxygen propylene ethylene oxide glyceryl ether, 0.2-1.4 parts of inhibiters, and 60-90 parts of water. The preparation method of the release agent comprises the steps that the raw materials are weighed according to the formula, and then stirred and cooled, and thus the release agent for the aluminum alloy mold is obtained. The release agent prepared through the method is safer, clean and free of pollution; compared with a traditional oil-based release agent, the release agent has the advantages that the cooling effect is good, accumulation is avoided, and the surface quality of castings is good; and compared with a powdery release agent, the release agent has the advantage of being low in cost.

Owner:天津可喜涂料有限公司

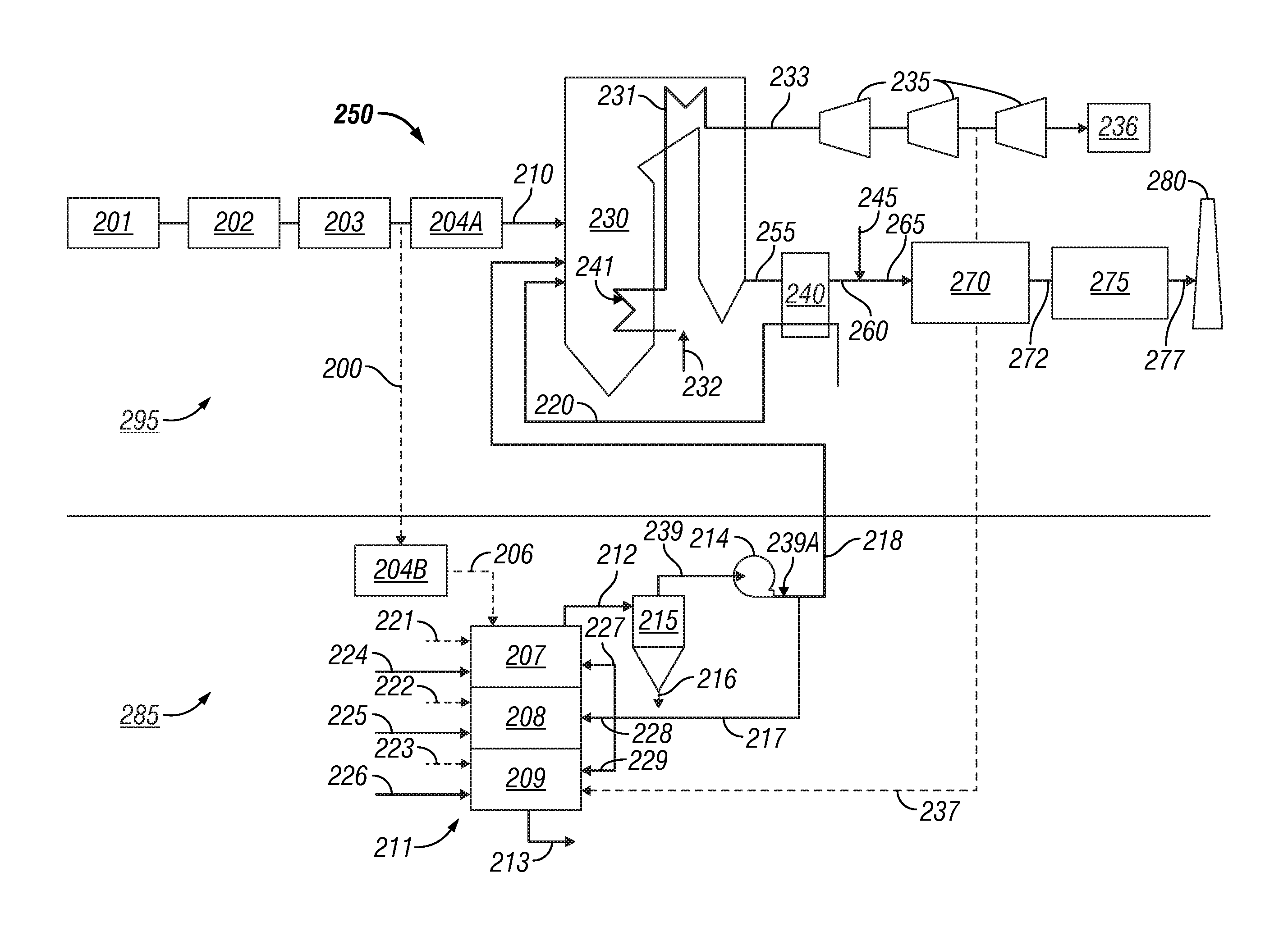

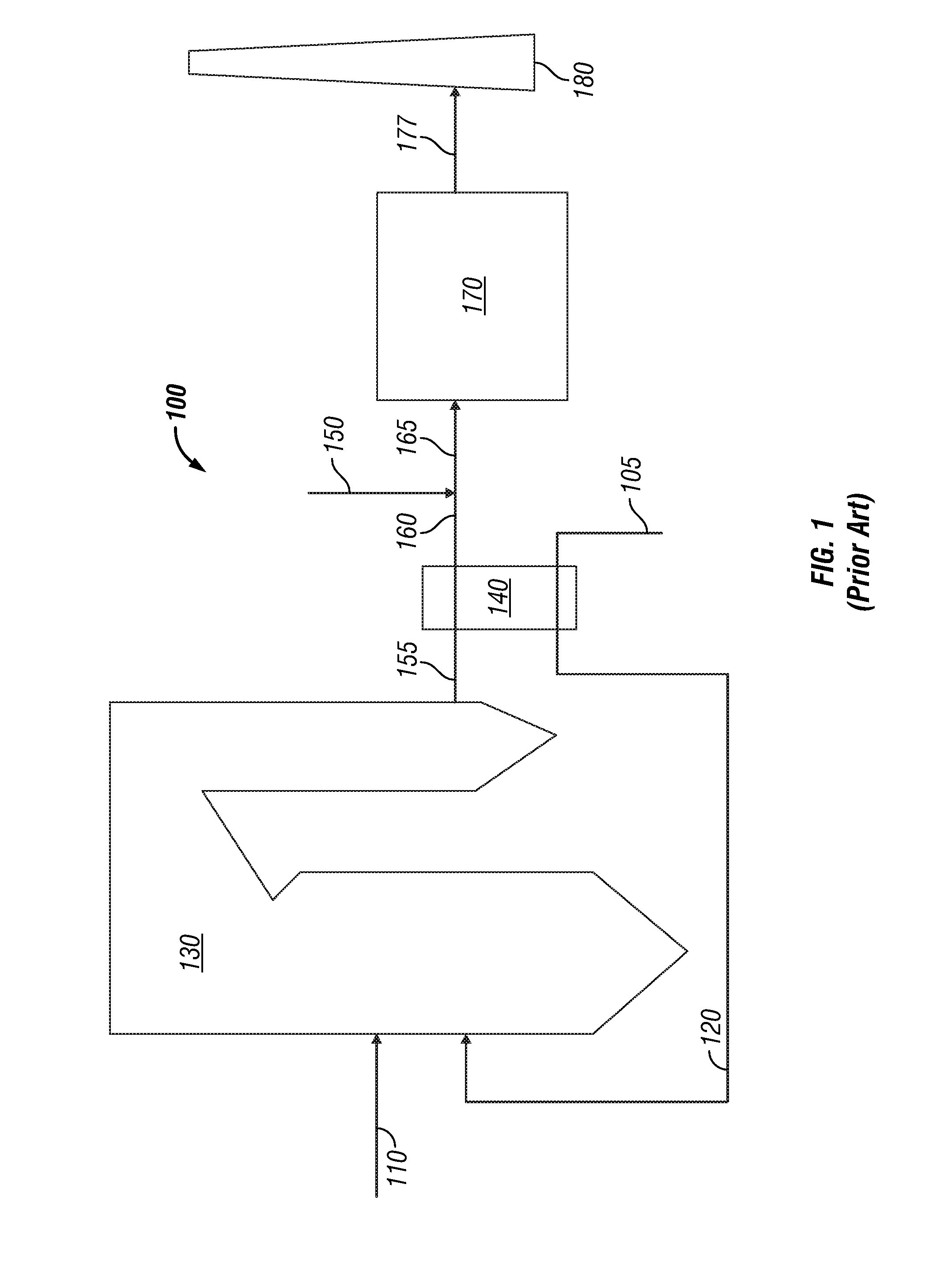

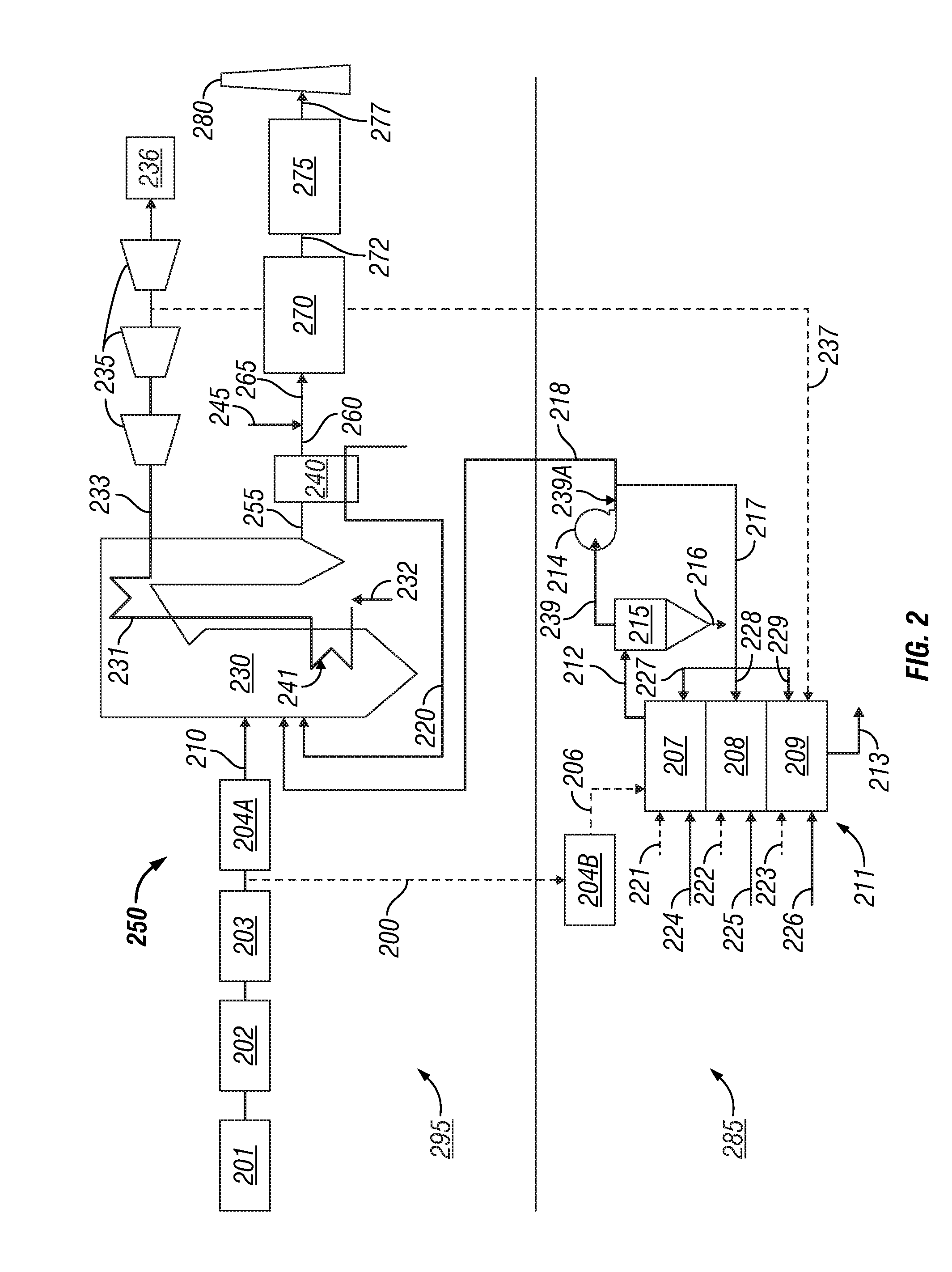

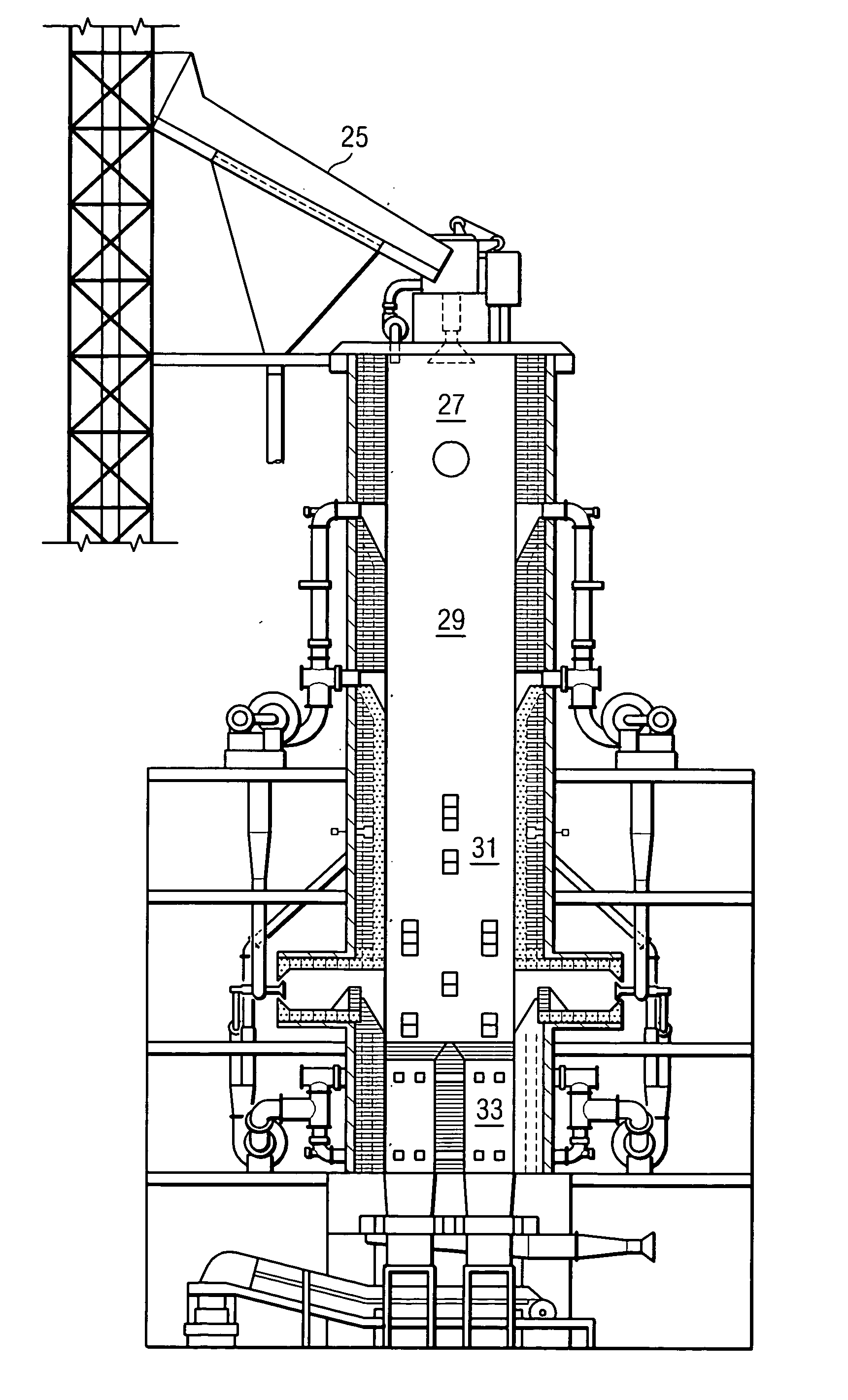

System and method for coproduction of activated carbon and steam/electricity

InactiveUS20090317320A1Increase heat productionReduce nitrogen oxide emissionsPigmenting treatmentSteam generation heating methodsCarbonizationBiological activation

A system and method for producing activated carbon comprising carbonizing a solid carbonaceous material in a carbonization zone of an activated carbon production apparatus (ACPA) to yield a carbonized product and carbonization product gases, the carbonization zone comprising carbonaceous material inlet, char outlet and carbonization gas outlet; activating the carbonized product via activation with steam in an activation zone of the ACPA to yield activated carbon and activation product gases, the activation zone comprising activated carbon outlet, activation gas outlet, and activation steam inlet; and utilizing process gas comprising at least a portion of the carbonization product gases or a combustion product thereof; at least a portion of the activation product gases or a combustion product thereof; or a combination thereof in a solid fuel boiler system that burns a solid fuel boiler feed with air to produce boiler-produced steam and flue gas, the boiler upstream of an air heater within a steam / electricity generation plant, said boiler comprising a combustion zone, a boiler-produced steam outlet and at least one flue gas outlet.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

Chemical absorption and microbial fuel cell combined synchronous flue gas desulfurization and denitration technology

ActiveCN105032152AAchieve recyclingAchieve regenerationNitrous oxide captureDispersed particle separationElectronBioconversion

The invention provides a chemical absorption and microbial fuel cell combined synchronous flue gas desulfurization and denitration technology, and belongs to the field of industrial flue gas treatment. According to the characteristics of a microbial fuel cell, the regeneration regularity of a complexing agent in the complexing absorption-biological reduction denitration process and conversion of sulfate in the biological flue gas desulfurization process, SO2 and NOx in flue gas are sequentially absorbed by an alkaline solution and a Fe(II) solution, then desulfurization and denitrification washing solutions enter an anode chamber and a cathode chamber of a built double-chamber MFC respectively, desulfuration is achieved to generate sulfate bioconversion and generate elemental sulfur in the anode chamber, electrons generated by an anode are fed into a cathode through an external circuit, and biological reduction of Fe(II)-NO and Fe(III) generated by complexing denitration and regeneration of Fe(II) are achieved in the cathode chamber. The washing agents absorbing SO2 and NOx in flue gas synchronously achieve biological sulfate reduction, biological sulfide oxidation to generate elemental sulfur and biological regeneration of a complexing denitrification solution through an MFC system.

Owner:DALIAN UNIV OF TECH

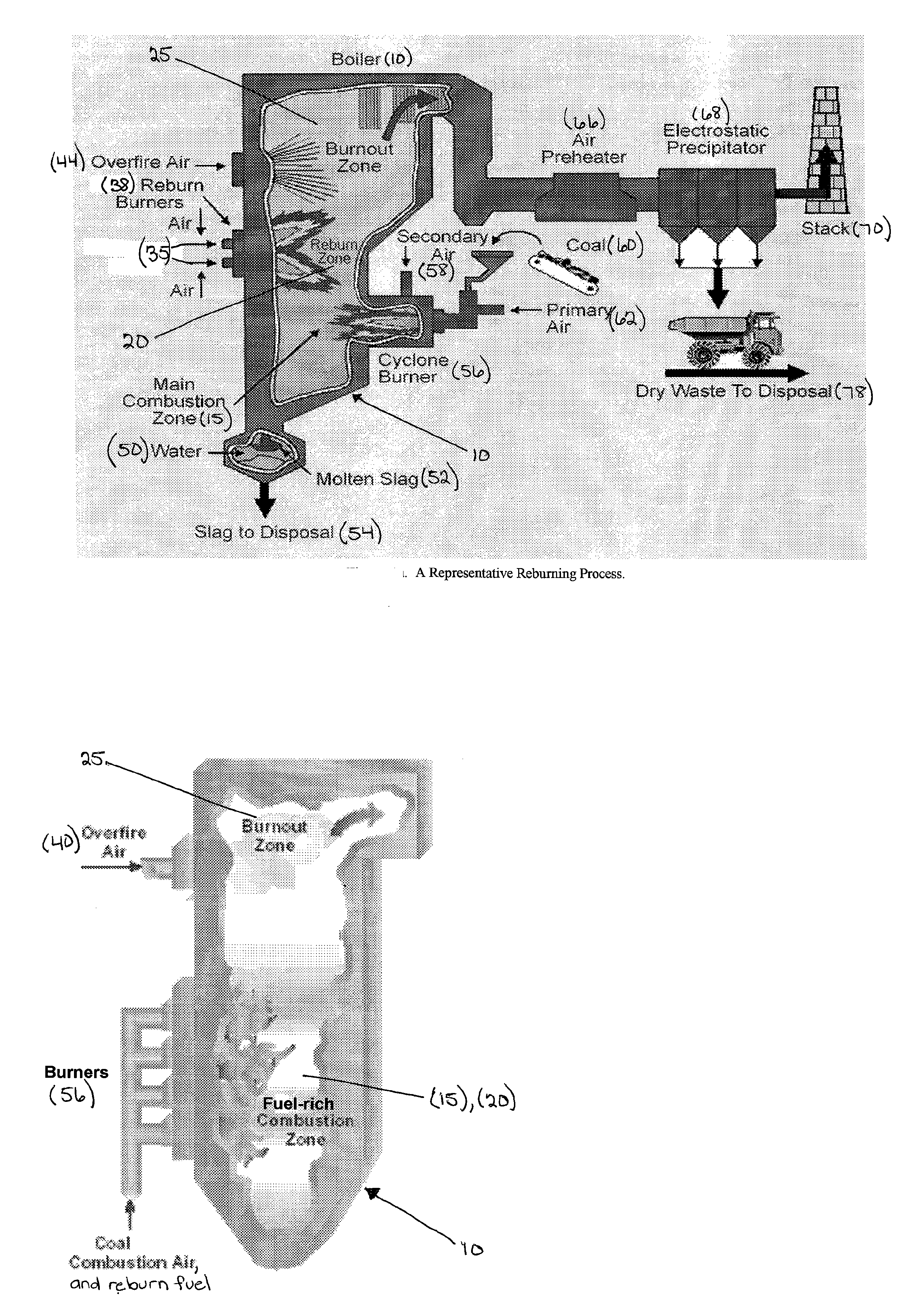

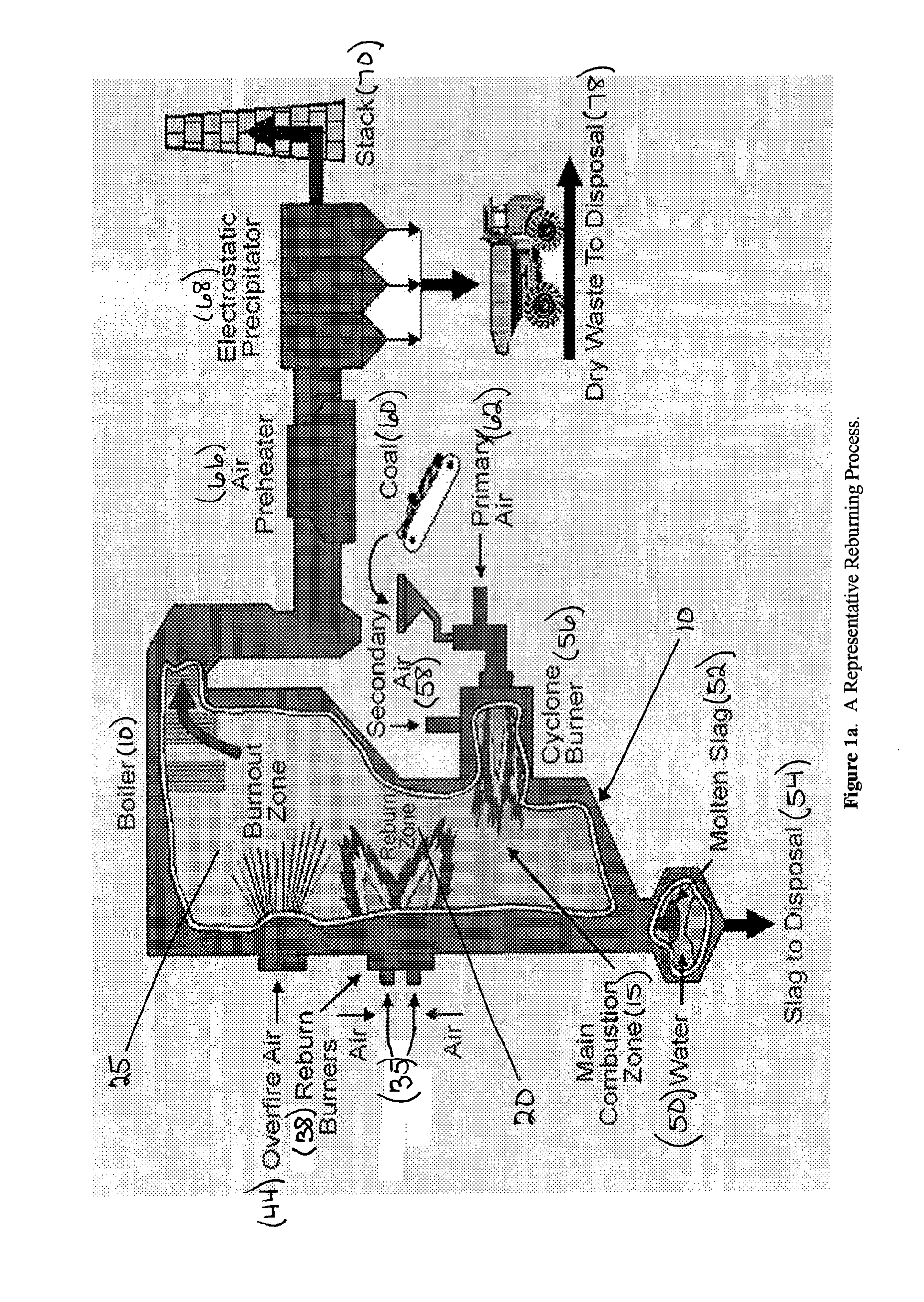

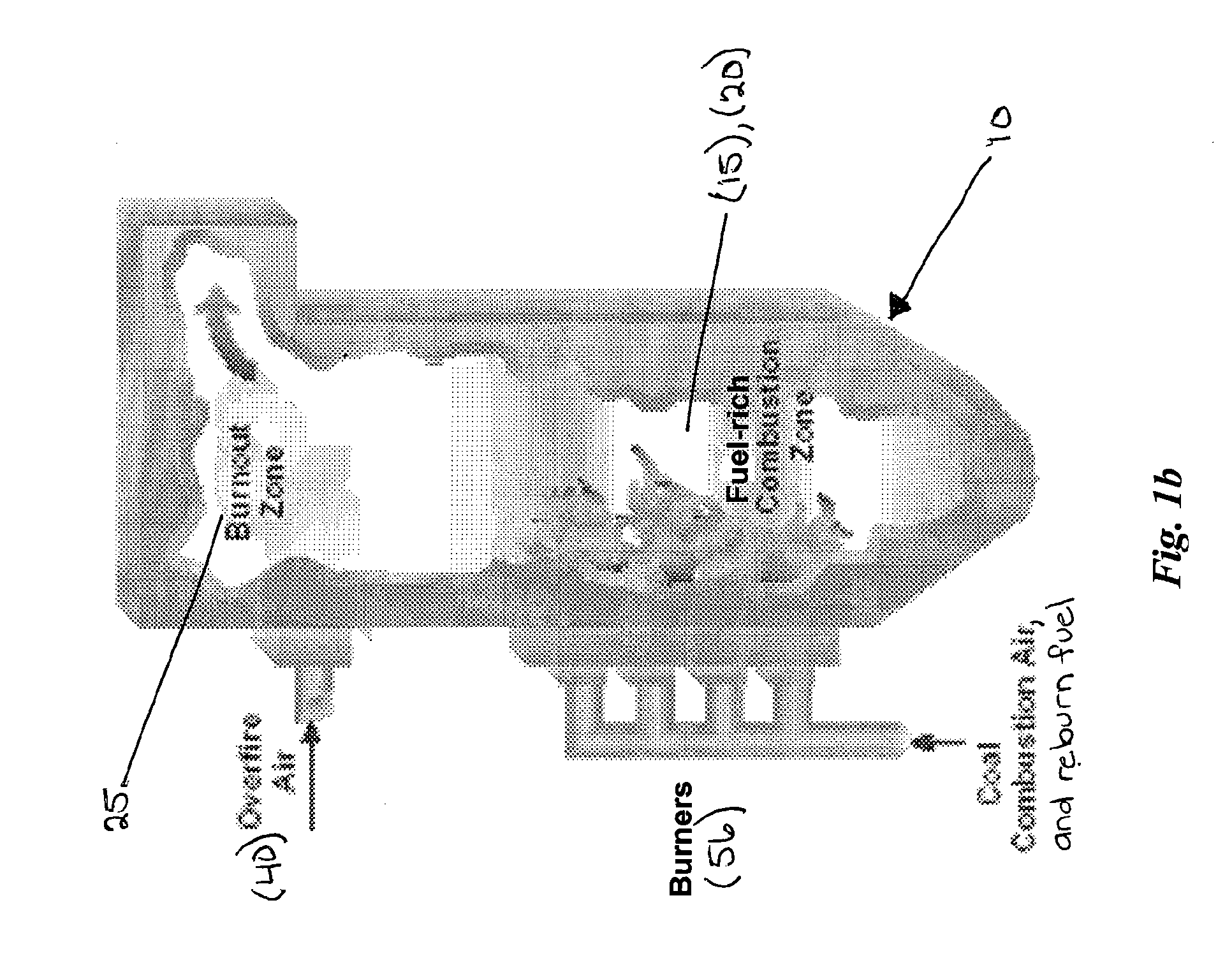

In-Furnace Reduction Of Nitrogen Oxide By Mixed Fuels Involving A Biomass Derivative

InactiveUS20070034126A1Maximize NO removal efficiency% reductionSolid fuel combustionChimneysCombustion chamberNitrogen oxide

A method of reducing nitrogen oxide emissions formed during fuel combustion by introducing biomass ash into a combustion chamber.

Owner:THE BABCOCK & WILCOX CO +1

Heterotrophic nitrification aerobic denitrifying bacteria and culture method and application thereof

ActiveCN101875909AEfficient removalWide range of substratesTreatment using aerobic processesBacteriaHigh concentrationBacteroides

The invention belongs to the technical field of environmental microbiology, and relates to high-efficiency heterotrophic nitrification aerobic denitrifying bacteria and a culture method and application thereof. The bacteria are Rhodococcus sp. DN2.3 with the preservation registration number of CCTCC M209300, can effectively remove ammonia nitrogen, nitrite nitrogen, nitric nitrogen and the mixture thereof from a water body, also can remove CODCr from organic wastewater, are suitable for treating high-concentration organic nitrogen-containing wastewater; the accumulation of nitrite and nitrate is avoided in the denitrifying process; and the process for treating wastewater by using the strain is simple and the denitrifying effect is stable.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

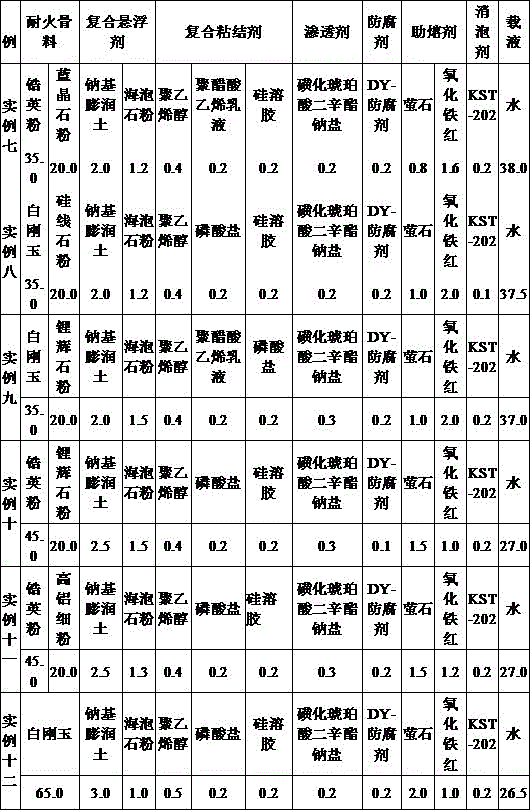

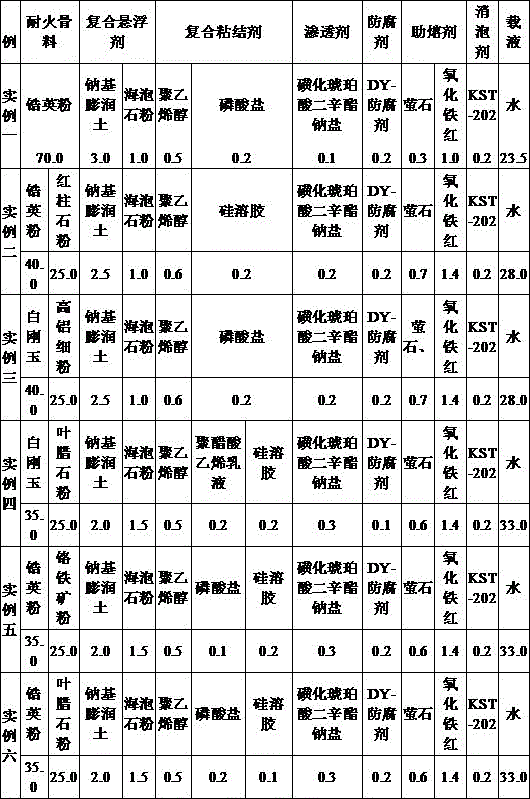

Preparation method of water based flow coating for 3D printing sand mold

ActiveCN105665620ANo pollution in the processImprove securityFoundry mouldsFoundry coresWater basedPyrophyllite

The invention relates to the technical field of 3D printing sand mold casting and in particular to a water based flow coating for a 3D printing sand mold and a preparation method of the water based flow coating. The water based flow coating is prepared from zircon powder, white corundum, high-aluminum fine powder, ferrochrome mineral powder, pyrophyllite powder, sillimanite powder, cyanite powder, andalusite powder, spodumene powder, sodium bentonite, sea-foam stone powder, polyvinyl alcohol, polyvinyl acetate emulsion, phosphate, silica sol, sulfonated dioctyl succinate sodium salt, preservative, a defoaming agent, fluorite, iron oxide red and water. The water based flow coating for the 3D printing sand mold has the advantages of excellent mobility, appropriate permeability, good leveling property, high-efficiency suspension stability, appropriate coating thickness, super strong anti-burn-on property, environment protection, no pollution and high efficiency.

Owner:NINGXIA KOCEL MOLD

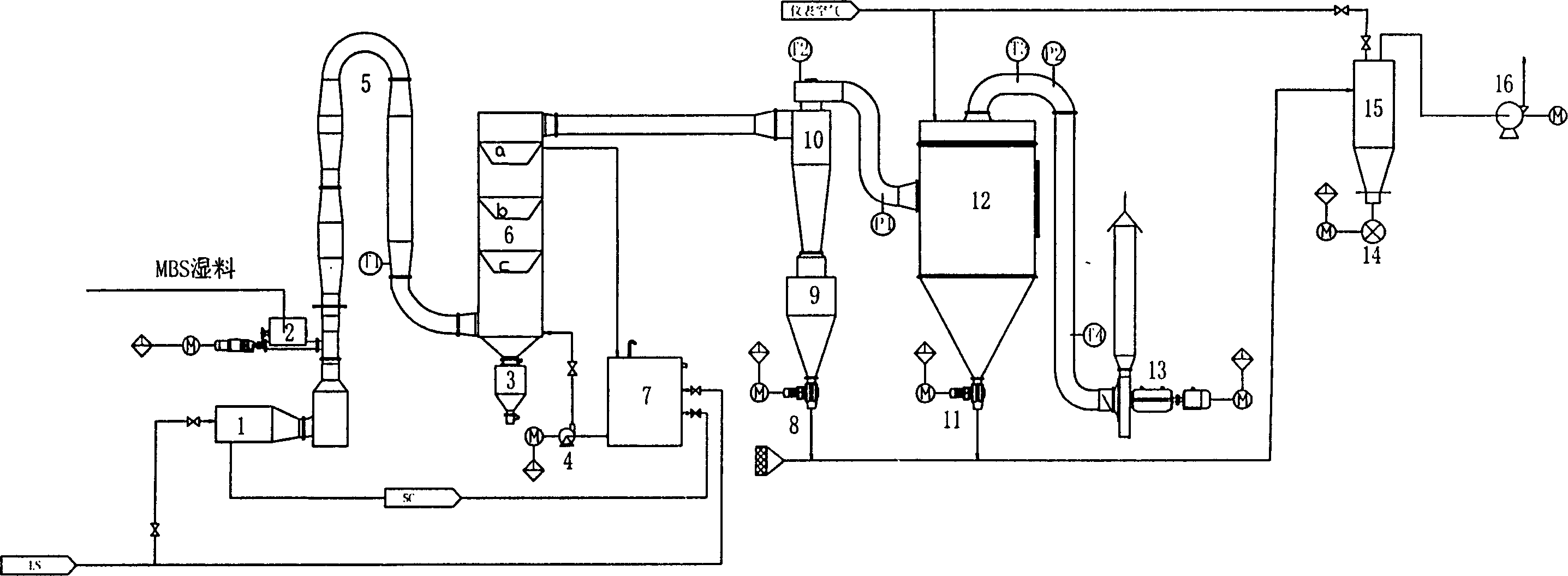

Method and apparatus for drying copolymer of methyl methacrylate-styrene-butadiene

InactiveCN1731057APrevent leakageReduce pollutionDrying solid materials with heatHearth type furnacesEngineeringMethacrylate methyl

The combined continuous airflow-cyclone MBS drying process includes drying wet MBS with hot air in a pulse drier to reduce water content to 10-15 %, making MBS enter to the cyclonic drier tangently in eddy flow mode to delay dry with hot water as heat source to water content of 0.5 %, and further processing in cyclonic separator and bag type dust collector. The operation conditions include air temperature of 125-130 deg.c, water temperature of 70-80 deg.c, average material residence time of 15-25 min, negative pressure operation and temperature in the cyclonic drier of 55-60 deg.c. The apparatus includes mainly screw conveyer, steam heat radiator to heat air, pulse drier, cyclonic drier, cyclonic separator, antistatic bag type dust collector, hot water tank, induced draft fan, etc. The present invention has high drying efficiency, low power consumption, and other advantages.

Owner:CNPC JILIN CHEM GROUP CORP

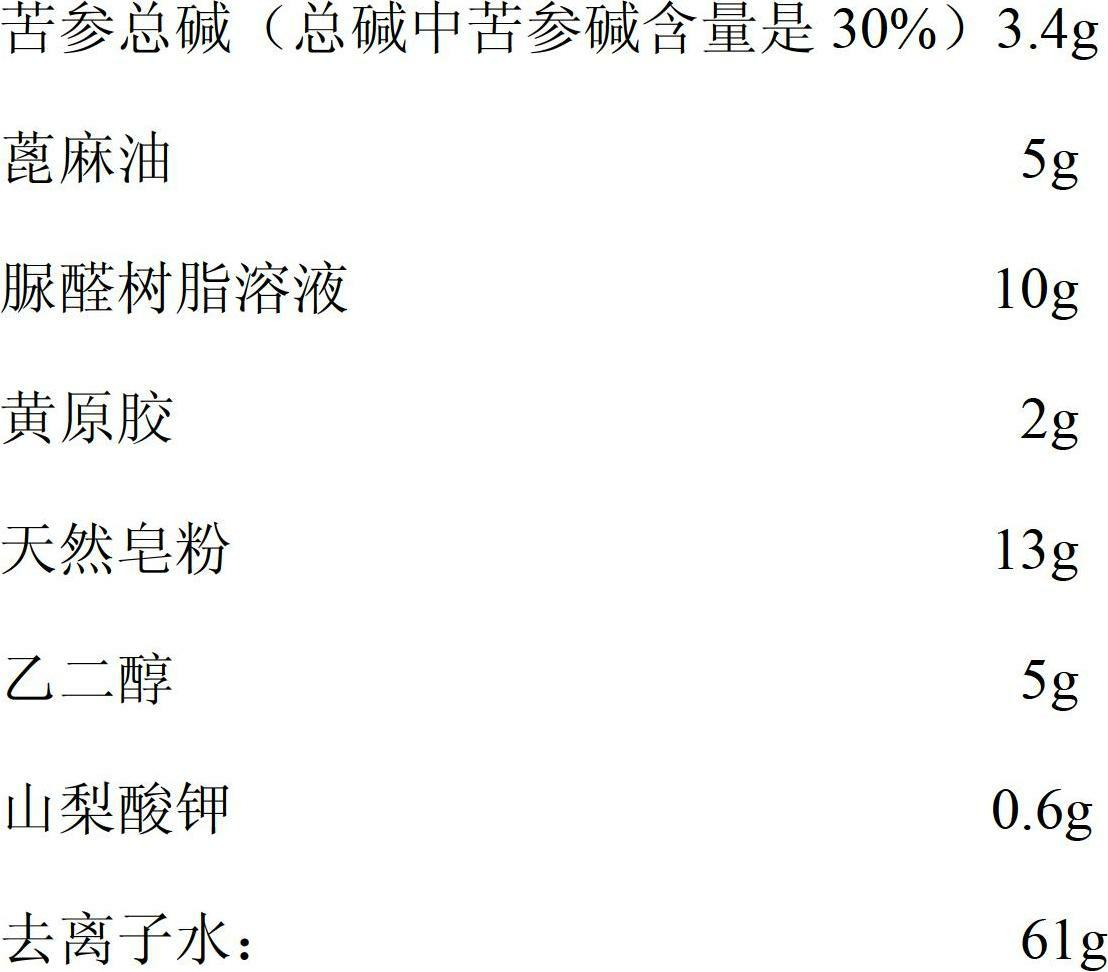

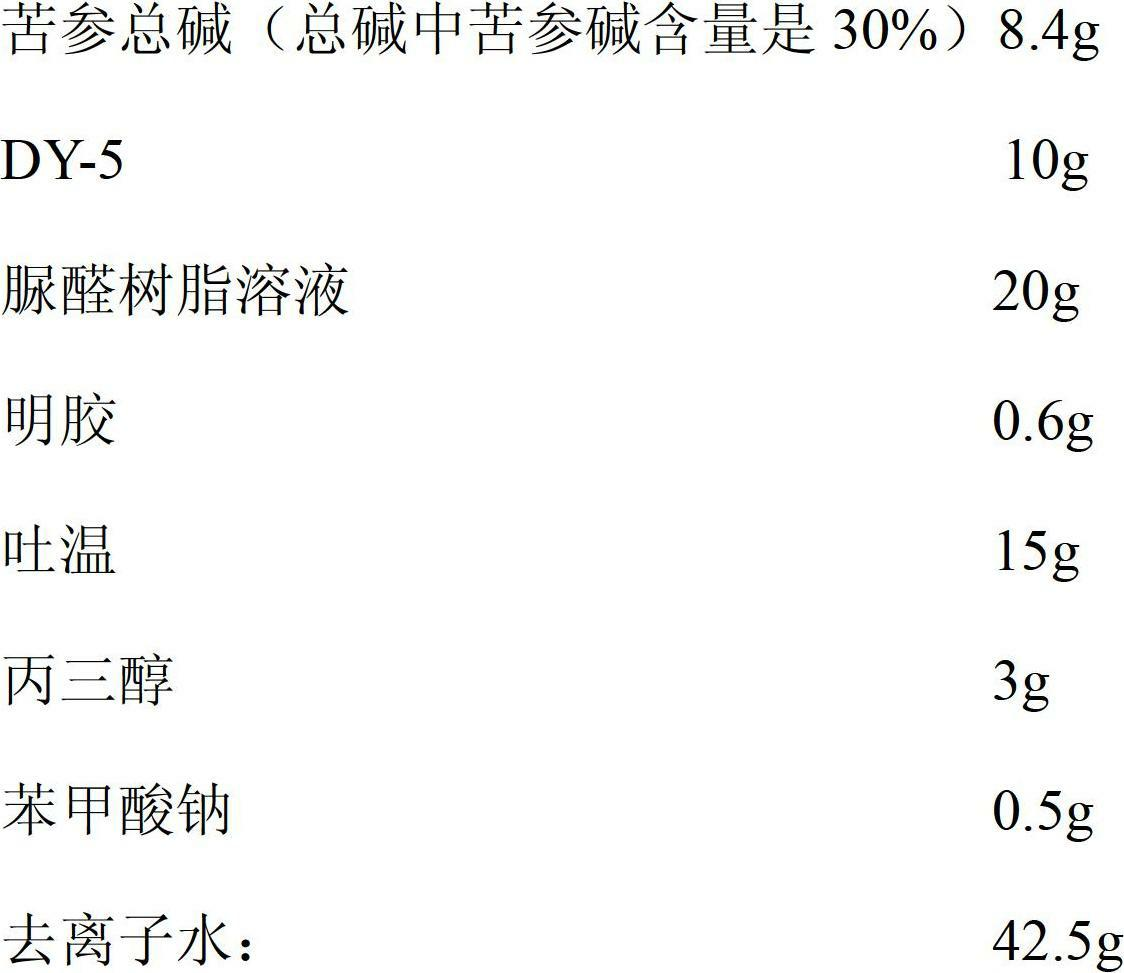

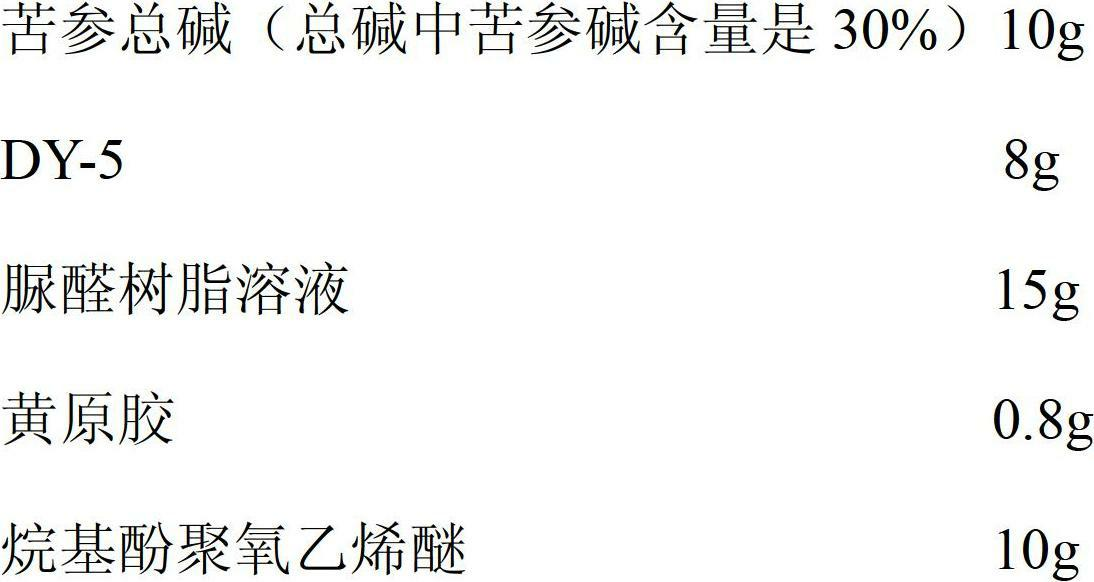

Matrine microcapsule suspension agent and preparation method thereof

InactiveCN102669192AImprove effective utilizationLong-lasting effectBiocideFungicidesAdditive ingredientSuspending Agents

The invention belongs to the technical field of biological pesticides, and more particularly relates to a matrine-containing pesticide and a preparation method thereof. The matrine-containing pesticide is characterized in that a suspension agent mainly comprises the following components in parts by weight: 1-25 parts of matrine, 5-20 parts of organic solvent, 1-25 parts of capsule wall material, 0.1-3 parts of colloid, 1-20 parts of emulsifier and the balance of de-ionized water to 100 parts. The matrine microcapsule suspension agent and the preparation method thereof aim to solve insufficient dosage form of biological pesticides in China, pollution to the environment and a poor control effect on insect pests. All active components in the scheme are naturally extracted from single-composition sophora flavescens plants, do not contain any chemical pesticides and are safe to natural enemies and the environment; and the novel matrine pesticide has the advantages of long duration of efficacy, anti-photolysis, improvement of utilization rate of pesticides and the like.

Owner:沈阳东大迪克化工药业有限公司

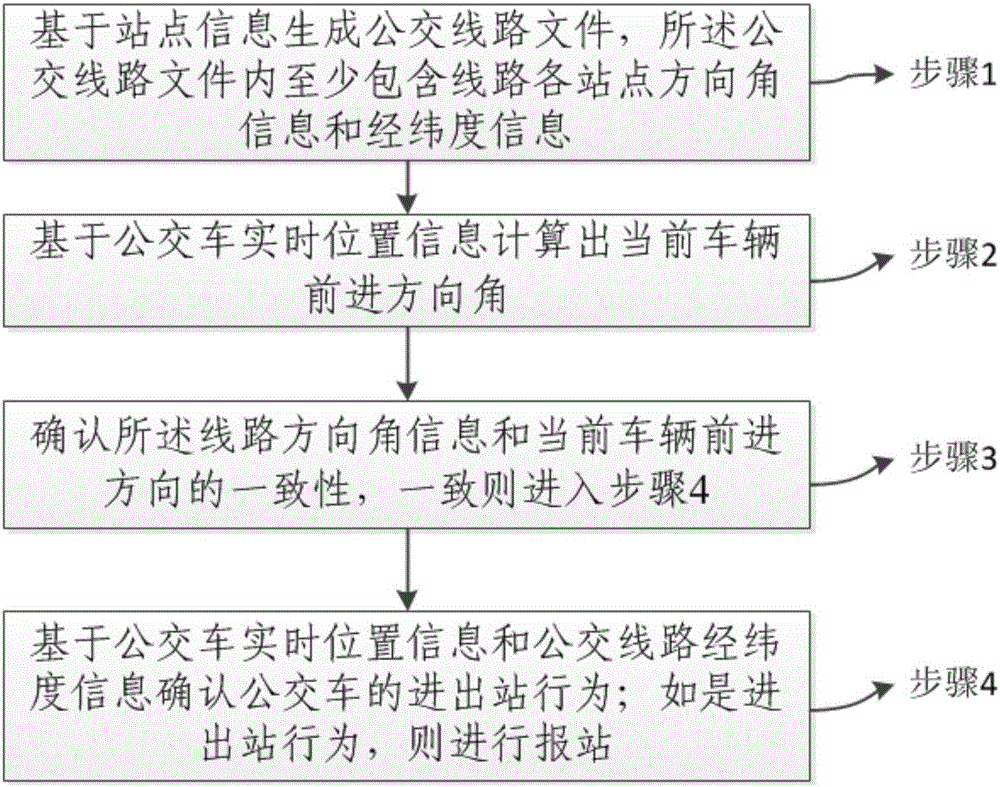

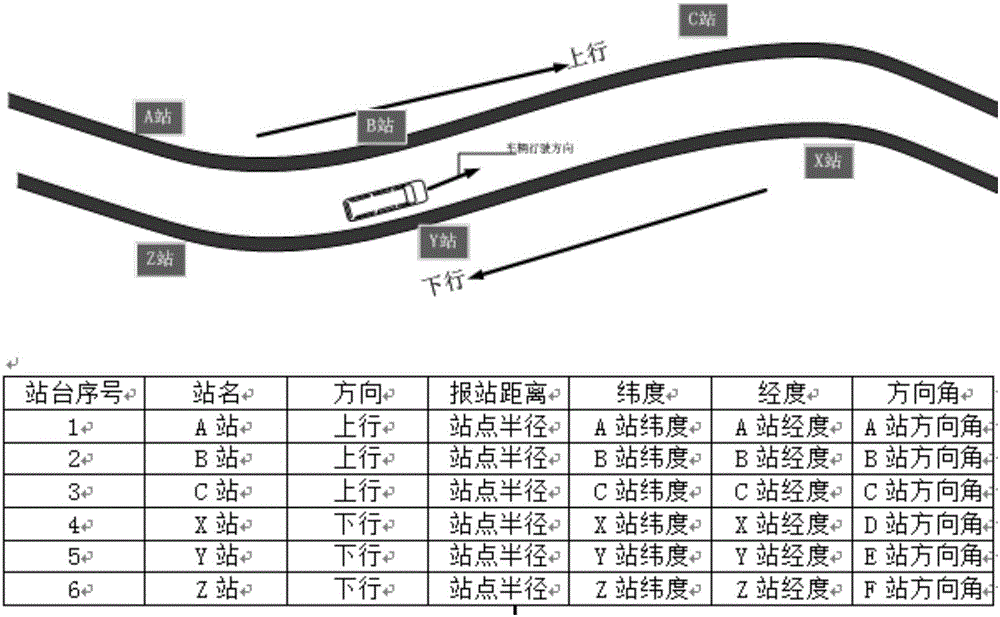

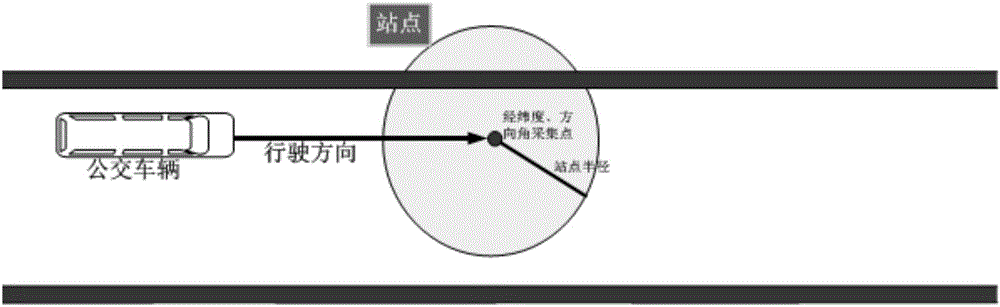

Automatic station reporting method of bus

InactiveCN106601013ASolve the problem of automatic station announcementReduce workloadRoad vehicles traffic controlReporting stateWorkload

Owner:WUHAN YANGTZE COMM ZHILIAN TECH

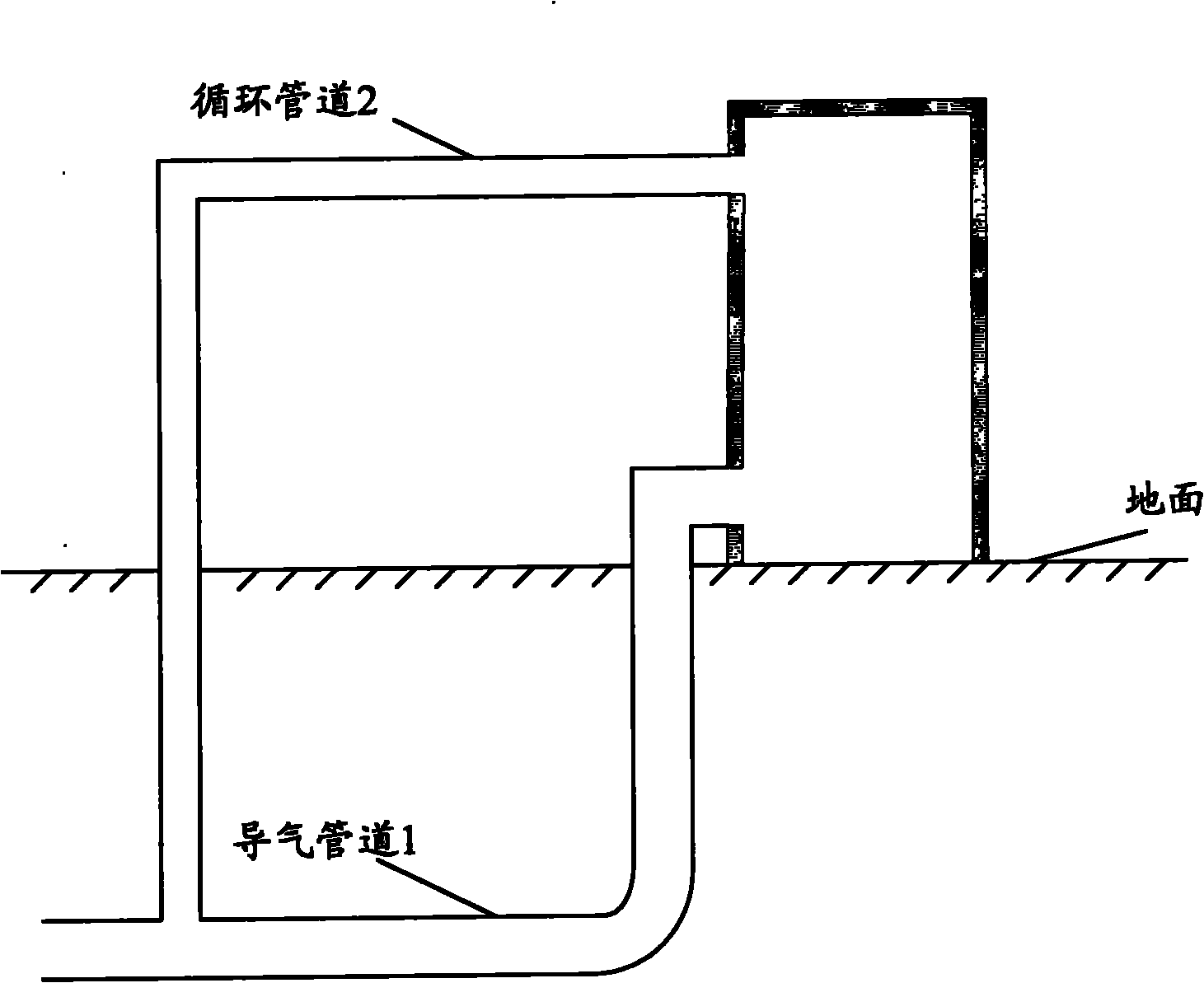

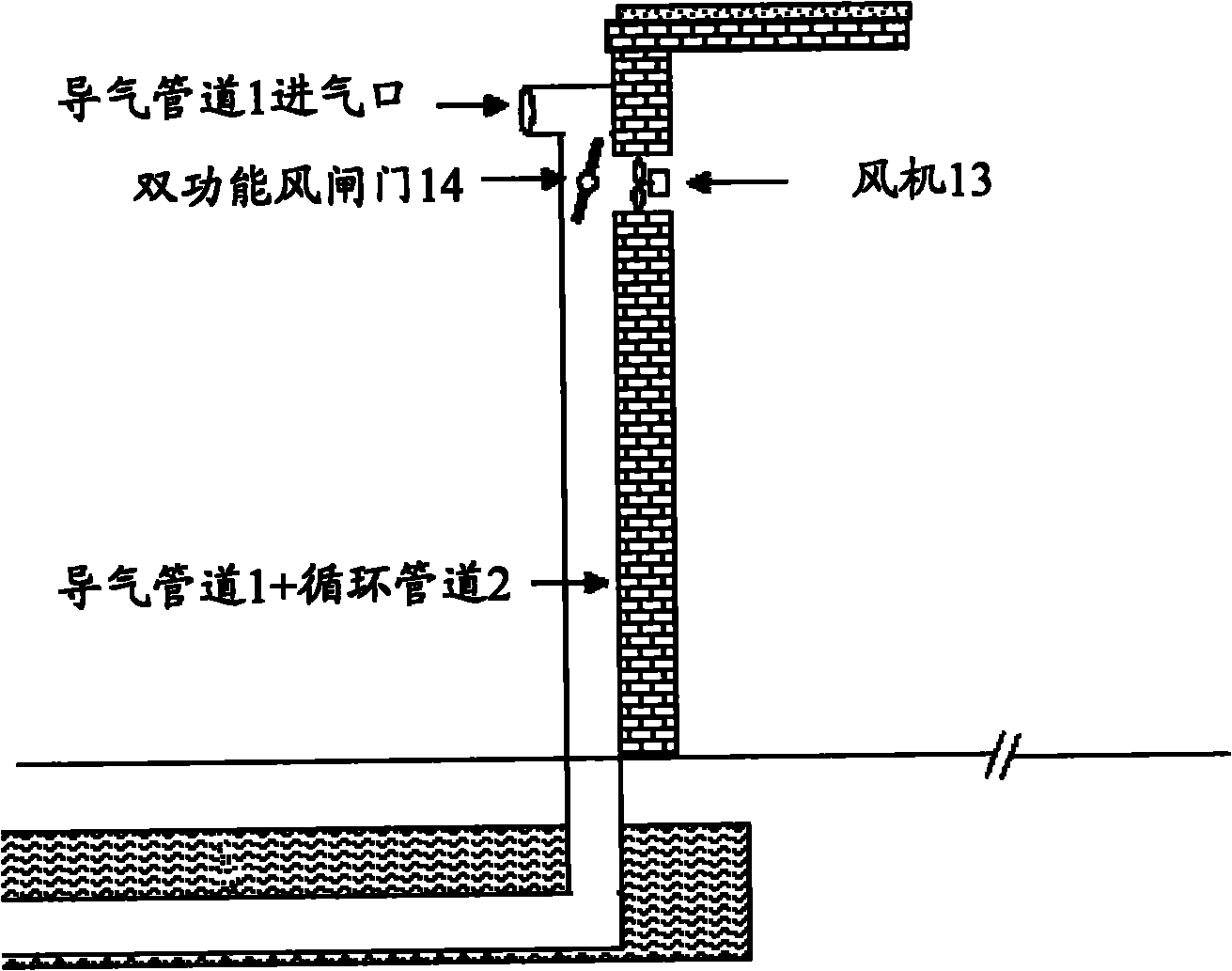

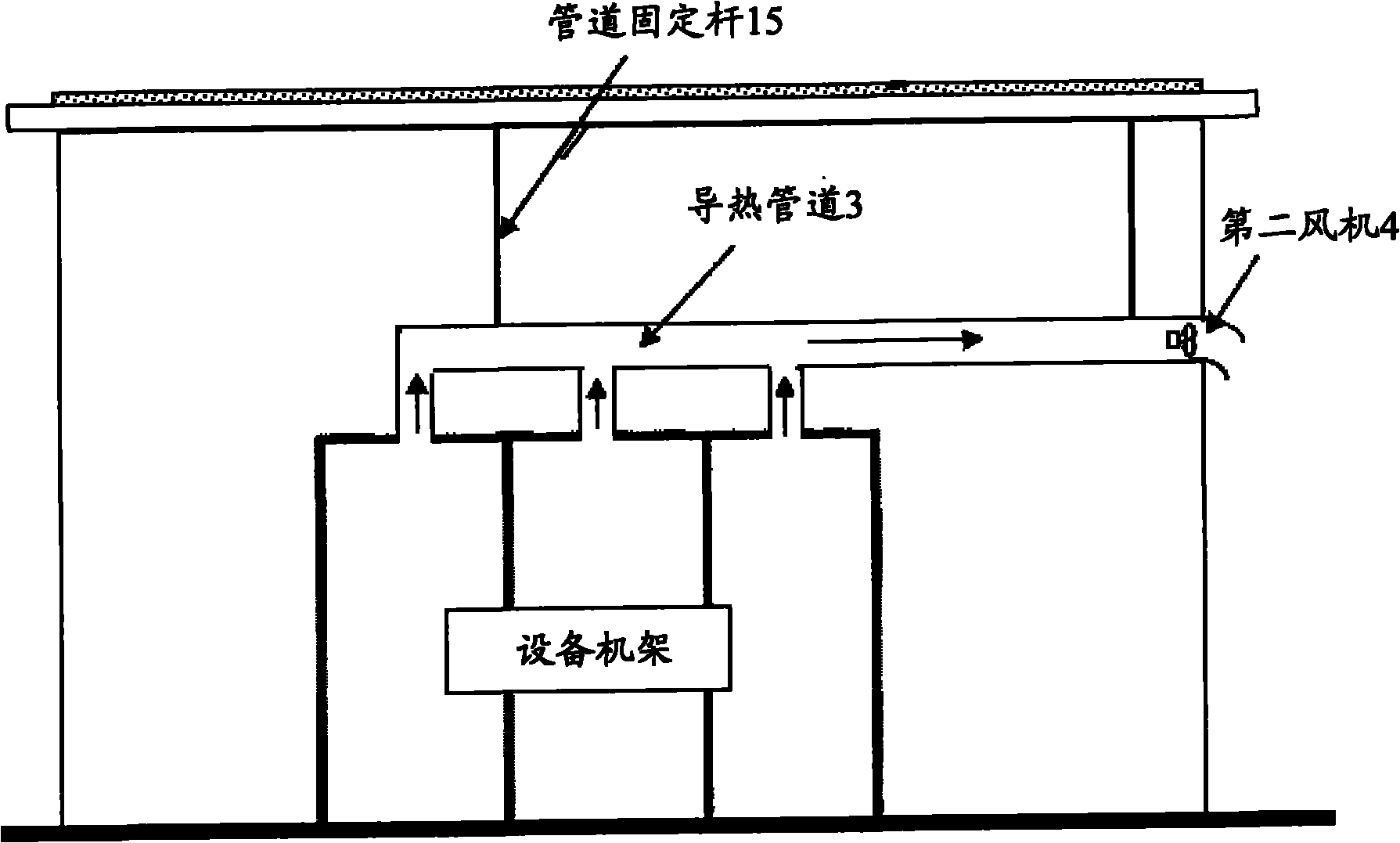

System and method for adjusting indoor temperature

ActiveCN102080857ACause a burdenNo accumulationDucting arrangementsLighting and heating apparatusTemperature conditioningEngineering

The invention discloses a system and method for adjusting the indoor temperature. The method is as follows: when the outdoor temperature is low, outdoor air is used as a heat exchange medium: the outdoor air is led into a gas guidance pipeline which is buried underground at a certain depth, the air temperature in the pipeline is adjusted by using the soil temperature around the gas guidance pipeline, and the cooled air in the pipeline is delivered to the interior, so that the cooled low-temperature air is utilized to directly cool the indoor high-temperature; and when the outdoor temperature is high, the outdoor air is not used as the heat exchange medium any longer, and cooling is carried out by an inner circulation mode, the indoor low-temperature air is fed back to the underground pipeline for cooling again, and later, the cooled low-temperature air is led into the interior. By using the inner circulation mode, outdoor air with a high temperature does not need to be led in all the time to serve as a heat exchange medium, thus, load can not be brought to the underground soil, excess heat accumulation is not generated, and the heat exchange efficiency of the system is improved inno need of utilizing underground water and surface water resources, thereby omitting air conditioners.

Owner:CHINA MOBILE GROUP SICHUAN

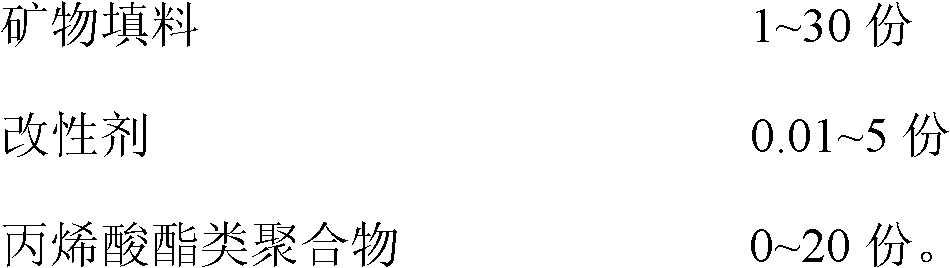

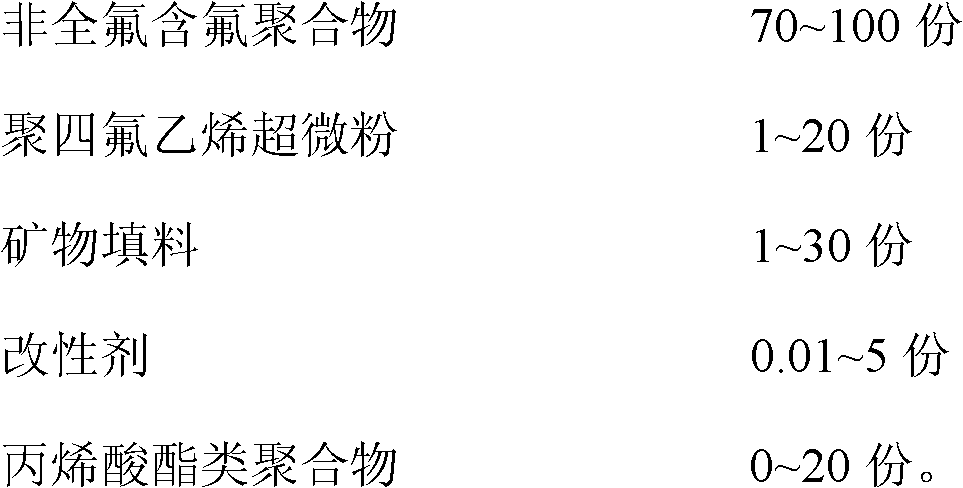

Fluorine-containing composition, and membrane thereof

The invention discloses a fluorine-containing composition, and a membrane thereof. The composition comprises components of, by weight: 70-100 parts of a non-perfluoro fluorine-containing polymer, 1-20 parts of polytetrafluoroethylene ultrafine powder, 1-30 parts of a mineral filling material, 0.01-5 parts of a modifying agent, and 0-20 parts of an acrylate polymer. The fluorine-containing composition provided by the invention has excellent alkali resistance and processing performance. The composition is subject to thermoplastic-process granulation under a temperature of 180-300 DEG C, and is extruded under a temperature of 200-320 DEG C by an extruder, such that a membrane with a thickness of 5-50mum and good flatness is obtained. During the processing procedure, no bonding with a die port occurs, and no material accumulation occurs. Therefore, a resin yield is improved, and a production cost is reduced.

Owner:ZHEJIANG GREEN NEW MATERIALS

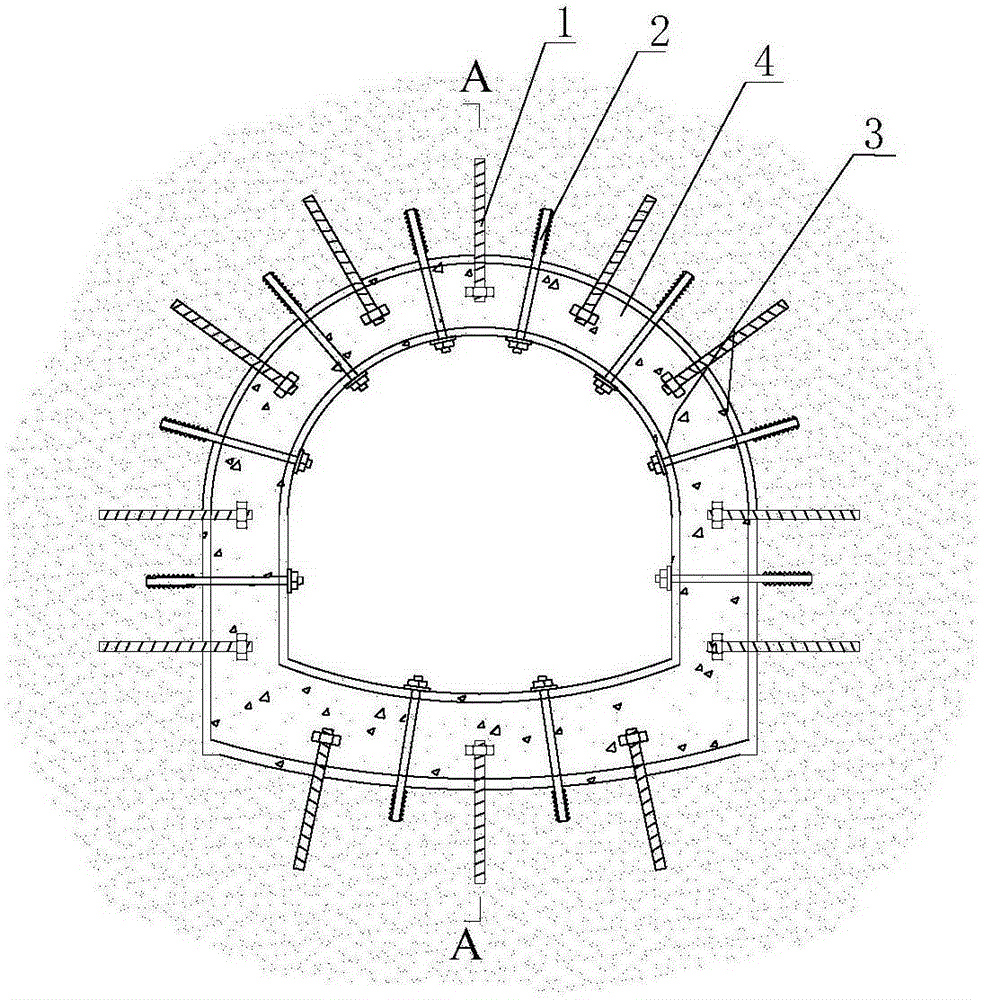

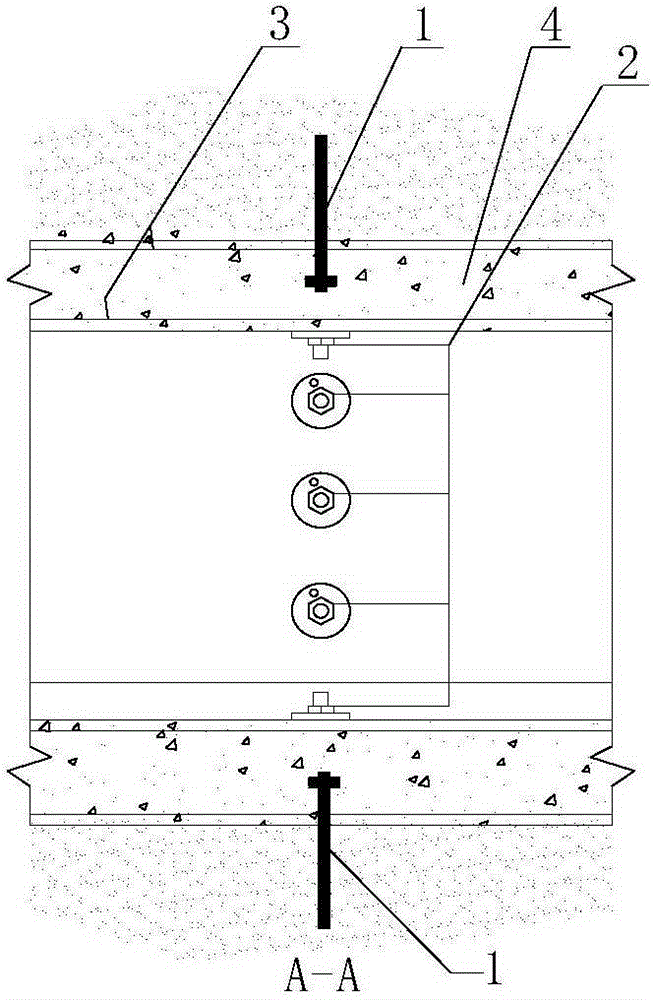

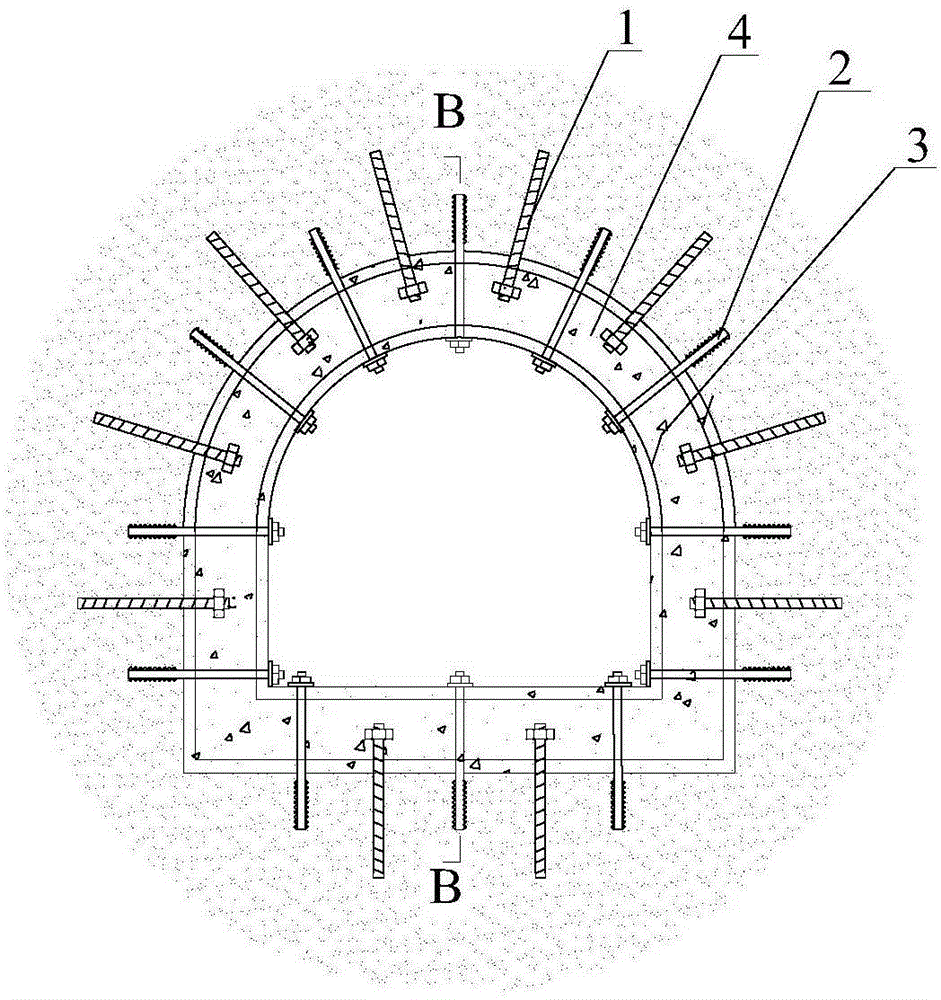

Water-bearing rock stratum borehole wall structure and construction method

ActiveCN105201514AImprove compactness and bond strengthHigh radial stiffness and bearing capacityShaft liningPre embeddingEnvironmental geology

The invention discloses a water-bearing rock stratum borehole wall structure and a construction method and belongs to a borehole wall structure and a construction method. The borehole wall is formed by an anchor pull rod I, an anchor pull rod II and a steel frame which are fixed on the surrounding rock, and concrete poured in a whole net frame to form a cylindrical borehole wall. The construction method comprises the following steps: manufacturing the anchor pull rod I and the anchor pull rod II on the surrounding rock body; then binding the borehole wall steel frame, connecting the anchor pull rod I and the anchor pull rod II with the steel frame, and connecting a pre-embedded grouting pipe; subsequently mounting a template and pouring the concrete; dismounting the template from the borehole wall and after the borehole wall reaches a certain strength, applying pre-tightening force to the anchor pull rod II by screwing an end nut; and finally grouting slurry via the pre-embedded grouting pipe in the anchor pull rod II, filling slurry liquid in holes in an interface between the borehole wall and the surrounding rock body through slurry transmission holes, and switching off a valve after finishing grouting the slurry. The water-bearing rock stratum borehole wall structure has the advantages that due to the fact that the borehole wall and the surrounding rock bear together, the radial stiffness of the borehole wall is improved, the accumulation of high-pressure water on the external surface of the borehole wall is avoided, and the structure has higher bearing force than that of a structure with the same section size and material, so the construction cost is greatly reduced, and the safety is improved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com