Release agent for aluminum alloy mold and preparation method of release agent

A technology of aluminum alloy template and mold release agent, which is applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of high cost of powder mold release agent, easy pollution of aluminum alloy surface, pollution of production environment, etc. Low cost, good cooling effect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

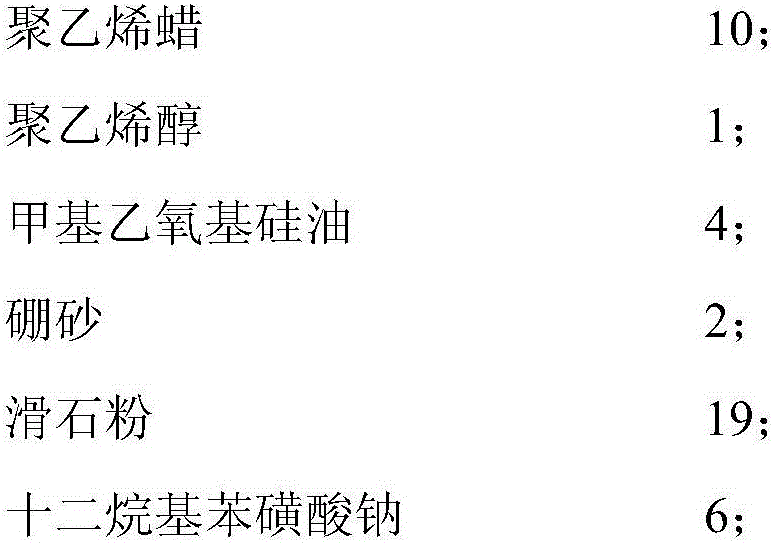

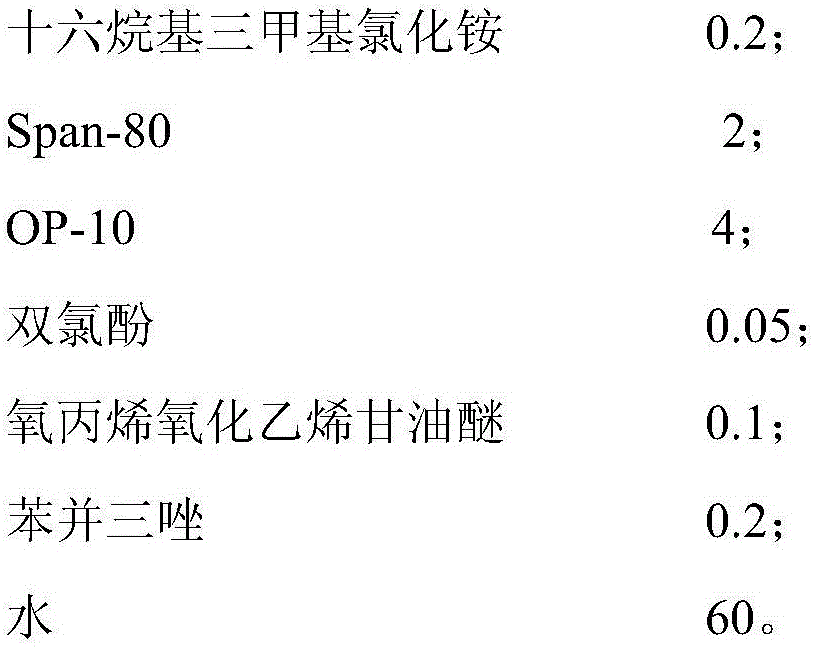

Embodiment 1

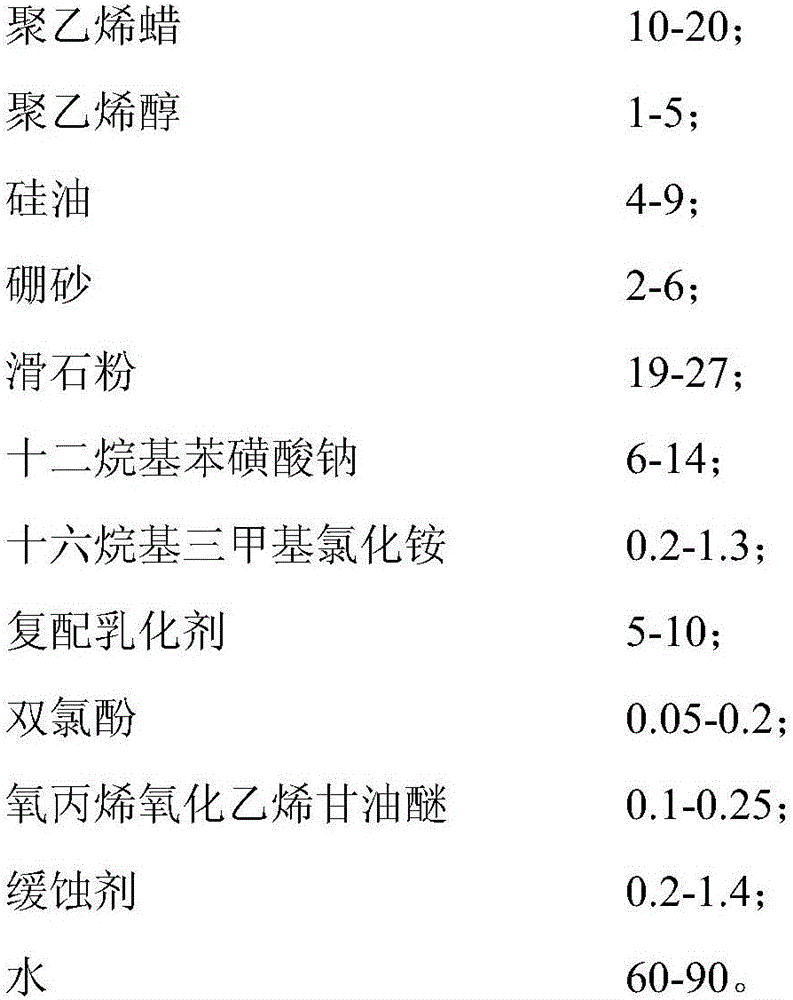

[0016] A kind of aluminum alloy mold release agent, is made up of the raw material of following parts by weight:

[0017]

[0018]

[0019] Preparation method: Taking the preparation of an aluminum alloy formwork release agent as an example, the preparation method of an aluminum alloy formwork release agent provided in this example is described as follows:

[0020] (1) Weigh polyethylene wax, polyvinyl alcohol, silicone oil, borax, talcum powder, sodium dodecylbenzenesulfonate, cetyltrimethylammonium chloride, oxypropylene oxide ethylene glyceryl ether, water , into the enamel cylinder;

[0021] (2) Then add Span-80 and OP-10 according to the formula, and slowly raise the temperature while stirring. After the material is completely melted and reaches a temperature of 120°C, slowly add dichlorophen and corrosion inhibitor into the enamel tank, and wait for 10 minutes. Added inside;

[0022] (3) Continue stirring at constant temperature for 40 minutes, cool to 30°C and d...

Embodiment 2

[0024] A kind of aluminum alloy mold release agent, is made up of the raw material of following parts by weight:

[0025]

[0026]

[0027] Preparation method: Taking the preparation of an aluminum alloy formwork release agent as an example, the preparation method of an aluminum alloy formwork release agent provided in this example is described as follows:

[0028] (1) Weigh polyethylene wax, polyvinyl alcohol, silicone oil, borax, talcum powder, sodium dodecylbenzenesulfonate, cetyltrimethylammonium chloride, oxypropylene oxide ethylene glyceryl ether, water , into the enamel cylinder;

[0029] (2) Then add Span-80 and OP-10 according to the formula, and slowly raise the temperature while stirring. After the material is completely melted and reaches a temperature of 120°C, slowly add dichlorophen and corrosion inhibitor into the enamel cylinder, and heat it for 13 minutes. Added inside;

[0030] (3) Continue stirring at constant temperature for 40 minutes, cool to 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com