Preparation method of water based flow coating for 3D printing sand mold

A 3D printing, sand molding technology, applied in casting molding equipment, coating, mold and other directions, to achieve the effect of no accumulation, superior fluidity, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

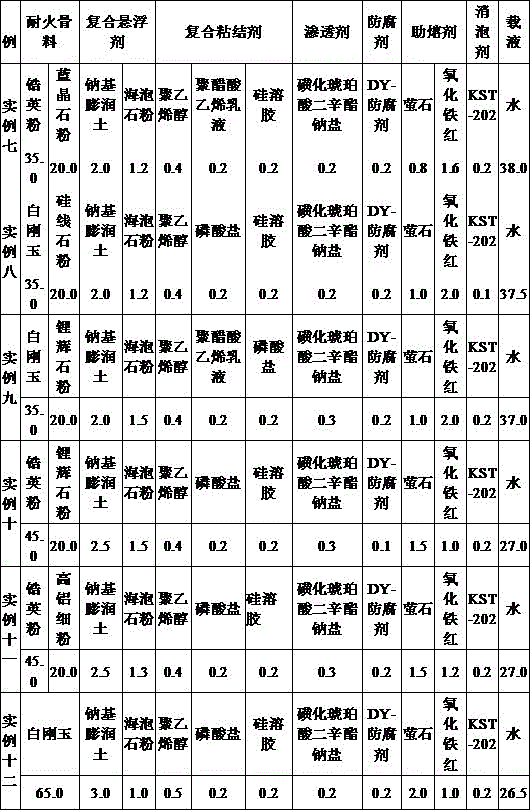

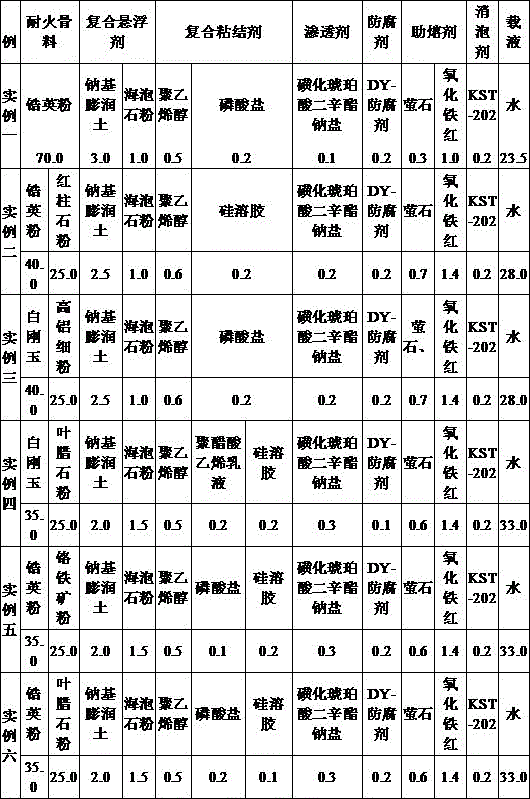

Examples

Embodiment 1

[0035] The production raw materials of a 3D printing sand mold water-based flow coating coating are: zircon powder refractory aggregate 70%, sodium bentonite 3%, sepiolite powder 1%, polyvinyl alcohol 0.5%, phosphate 0.2%, sulfonated amber Dioctyl acid sodium salt 0.1%, DY-preservative 0.2%, fluorite 0.3%, iron oxide red 1.0%, KST-202 defoamer 0.2%, water 23.5%.

[0036] A production process for 3D printing sand mold water-based flow coating, comprising the following steps:

[0037] a. Pretreatment of sodium bentonite and sepiolite powder: Mix 3% bentonite and 1% sepiolite with water at a ratio of 1:1 under stirring, completely disperse evenly, and let stand for 12-24 hours to obtain a pretreatment composite suspension slurry;

[0038] b. Pretreatment of polyvinyl alcohol: weigh 4 times the mass of polyvinyl alcohol in a bucket, slowly add 0.5% polyvinyl alcohol under stirring conditions, and then fully stir until it is completely dissolved, and filter it with a screen (to b...

Embodiment 2

[0043] The production raw materials of a 3D printing sand mold water-based flow coating coating are: zircon powder refractory aggregate 40.0%, andalusite powder refractory aggregate 25.0%, sodium bentonite 2.5%, sepiolite powder 1.0%, polyvinyl alcohol 0.6% , silica sol 0.2%, dioctyl sulfosuccinate sodium salt 0.2%, DY-preservative 0.2%, fluorite 0.7%, iron oxide red 1.4%, KST-202 defoamer 0.2%, water 28%.

[0044] A production process for 3D printing sand mold water-based flow coating, comprising the following steps:

[0045] a. Pretreatment of sodium bentonite and sepiolite powder: Mix 2.5% bentonite and 1% sepiolite with water at a ratio of 1:1 under stirring, completely disperse evenly, and let stand for 12-24 hours to obtain a pretreatment composite suspension slurry;

[0046] b. Pretreatment of polyvinyl alcohol: weigh 4 times the mass of polyvinyl alcohol in a bucket, slowly add 0.6% polyvinyl alcohol under stirring conditions, and then fully stir until it is complete...

Embodiment 3

[0051] The production raw materials of a 3D printing sand mold water-based flow coating coating are: white corundum refractory aggregate 40.0%, high alumina fine powder refractory aggregate 25.0%, sodium bentonite 2.5%, sepiolite powder 1.0%, polyvinyl alcohol 0.6% , phosphate 0.2%, dioctyl sulfosuccinate sodium salt 0.2%, DY-preservative 0.2%, fluorite 0.7%, iron oxide red 1.4%, KST-202 defoamer 0.2%, water 28%.

[0052] A production process for 3D printing sand mold water-based flow coating, comprising the following steps:

[0053] a. Pretreatment of sodium bentonite and sepiolite powder: Mix 2.5% bentonite and 1.0% sepiolite with water at a ratio of 1:1 under stirring, completely disperse evenly, and let stand for 12-24 hours to obtain a pretreatment composite suspension slurry;

[0054] b. Pretreatment of polyvinyl alcohol: weigh 4 times the mass of polyvinyl alcohol in a bucket, slowly add 0.6% polyvinyl alcohol under stirring conditions, and then fully stir until it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com