In-Furnace Reduction Of Nitrogen Oxide By Mixed Fuels Involving A Biomass Derivative

a biomass derivative and nitrogen oxide technology, applied in the field of nitrogen oxide emission reduction, can solve the problems of insufficient reburning technology on its own, insufficient to meet stringent regulations, and limited geographic distribution of lignite ashes to boilers in other parts of the united states, so as to achieve no reduction efficiency, no removal effect, and no reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental / examples

Experimental / Examples

[0053] The following describes examples or embodiments of the present invention. As such, the following should in no way be construed as limiting thereof.

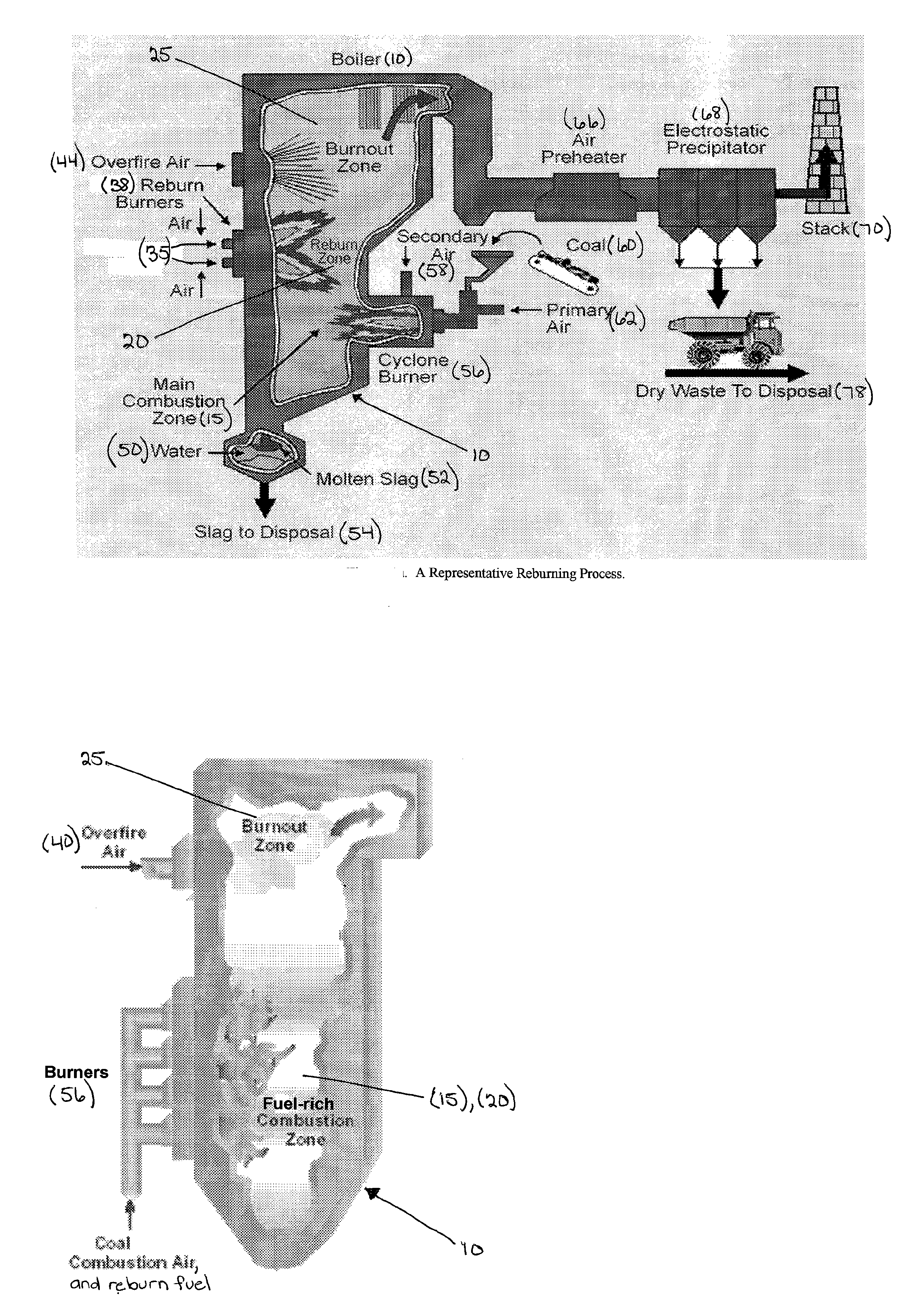

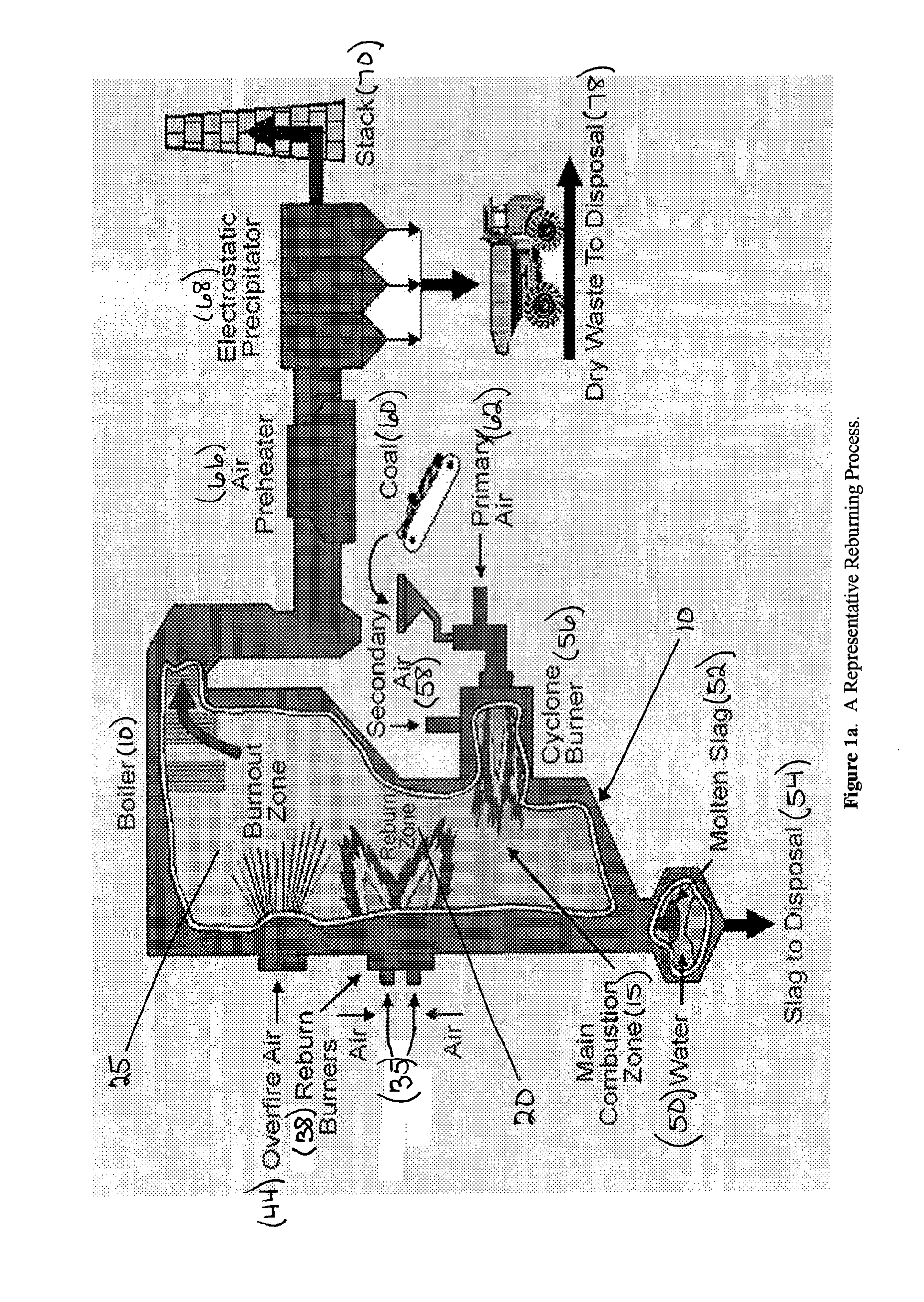

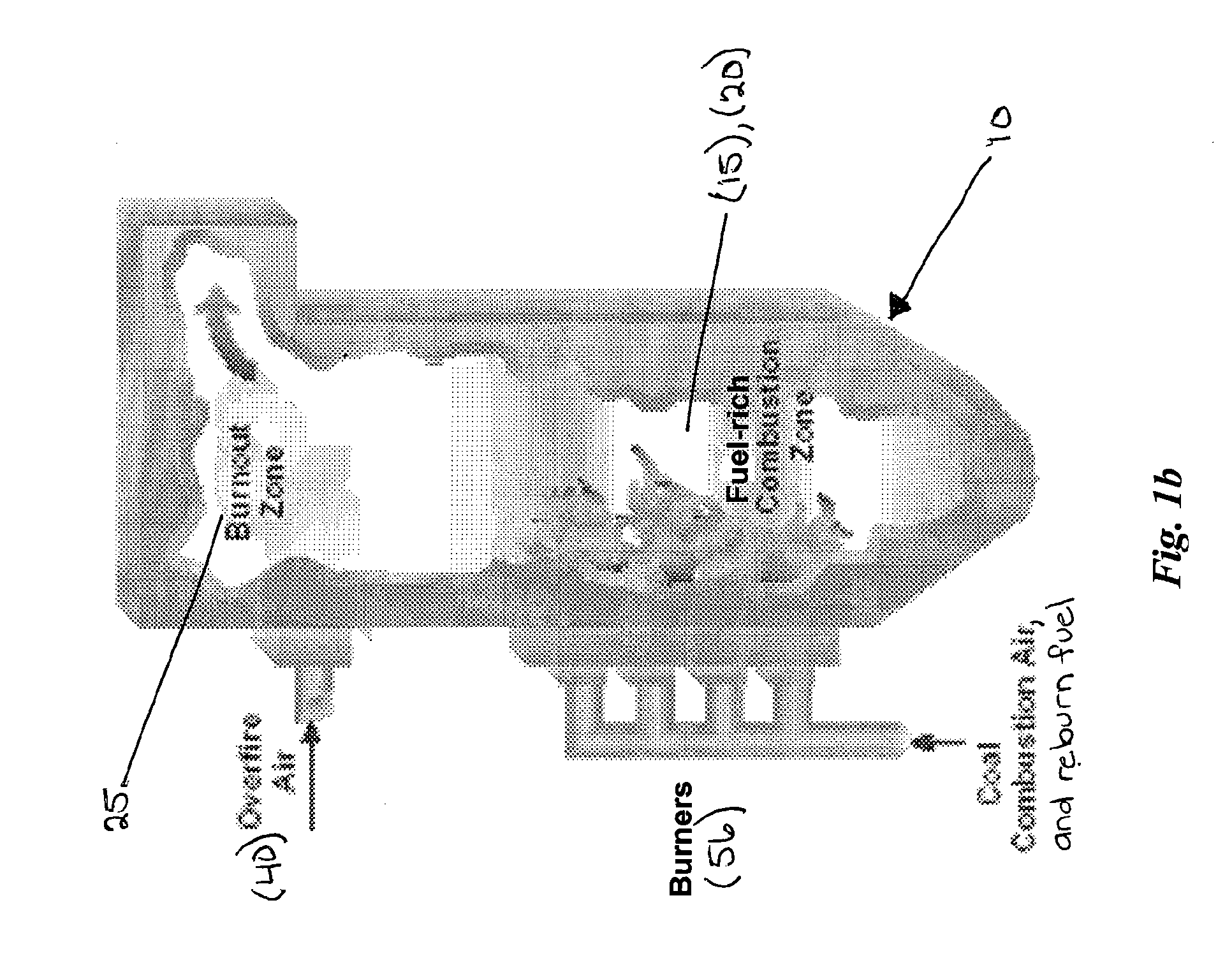

Apparatus for Simulated Reburning

[0054] Reburning experiments were carried out in a ceramic flow reactor (Burch et al., 1991; Burch et al., 1994; Chen and Ma, 1996; Chen and Tang, 2001) with a simulated flue gas comprising about 16.8% CO2, about 1.95% O2, and about 0.1% NO in a helium base. However, in other embodiments of the present invention the concentration of the ingredients of the flue gas can vary widely. The above concentrations of CO2, O2, and NO were chosen to be consistent with those of a coal primary flame operated at a stoichiometric ratio of 1.1. Helium, instead of nitrogen, was used as the base gas to minimize the heat-up time after the gas enters the reactor at room temperature. The flow reactor was an alumina tube (Bolt Technical Ceramics) with an inside diameter of 1.91 cm and an overall l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com