Patents

Literature

75 results about "No formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

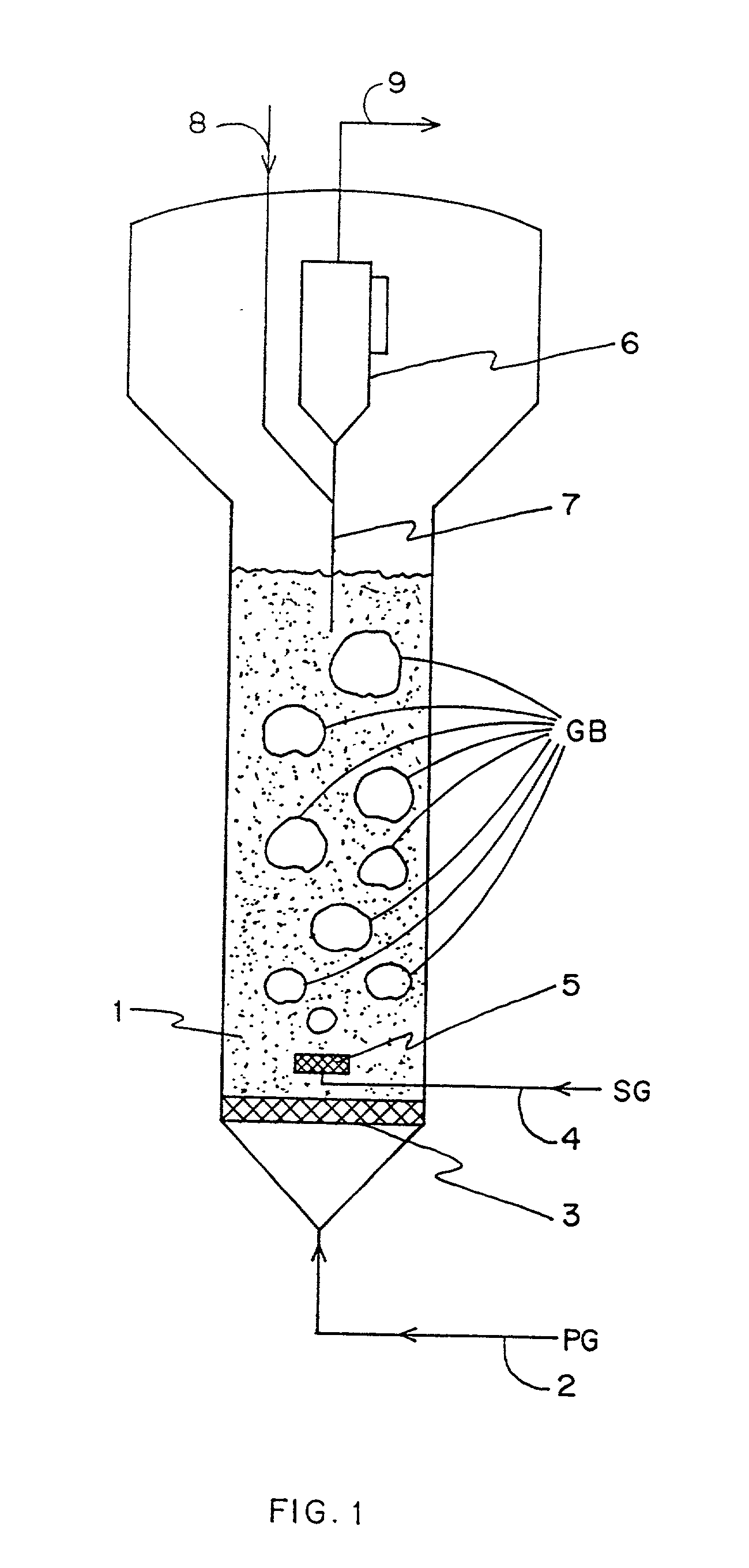

Method for gas-solid contacting in a bubbling fluidized bed reactor

InactiveUS6894183B2Eliminate and drastically reduce bypassEffective contactThermal non-catalytic crackingCatalytic crackingForming gasSolid particle

Owner:COUNCIL OF SCI & IND RES

Pegylated interleukin-10

InactiveUS7052686B2Minimize disruptionPeptide/protein ingredientsAntipyreticInterleukin 10White blood cell

Interleukin-10 (IL-10) conjugated via a linker to one or more polyethylene glycol (PEG) molecules at a single amino acid residue of the IL-10, and a method for preparing the same, are provided. The method produces a stable mono-pegylated IL-10, which retains IL-10 activity, where pegylation is selective for the N-terminus on one subunit of IL-10 with little or no formation of monomeric IL-10. The method also provides a substantially homogenous population of mono-PEG-IL-10.

Owner:MERCK SHARP & DOHME CORP

Pegylated interleukin-10

InactiveUS20060210534A1Minimize disruptionPeptide/protein ingredientsAntipyreticInterleukin 10White blood cell

Interleukin-10 (IL-10) conjugated via a linker to one or more polyethylene glycol (PEG) molecules at a single amino acid residue of the IL-10, and a method for preparing the same, are provided. The method produces a stable mono-pegylated IL-10, which retains IL-10 activity, where pegylation is selective for the N-terminus on one subunit of IL-10 with little or no formation of monomeric IL-10. The method also provides a substantially homogenous population of mono-PEG-IL-10.

Owner:SCHERING CORP

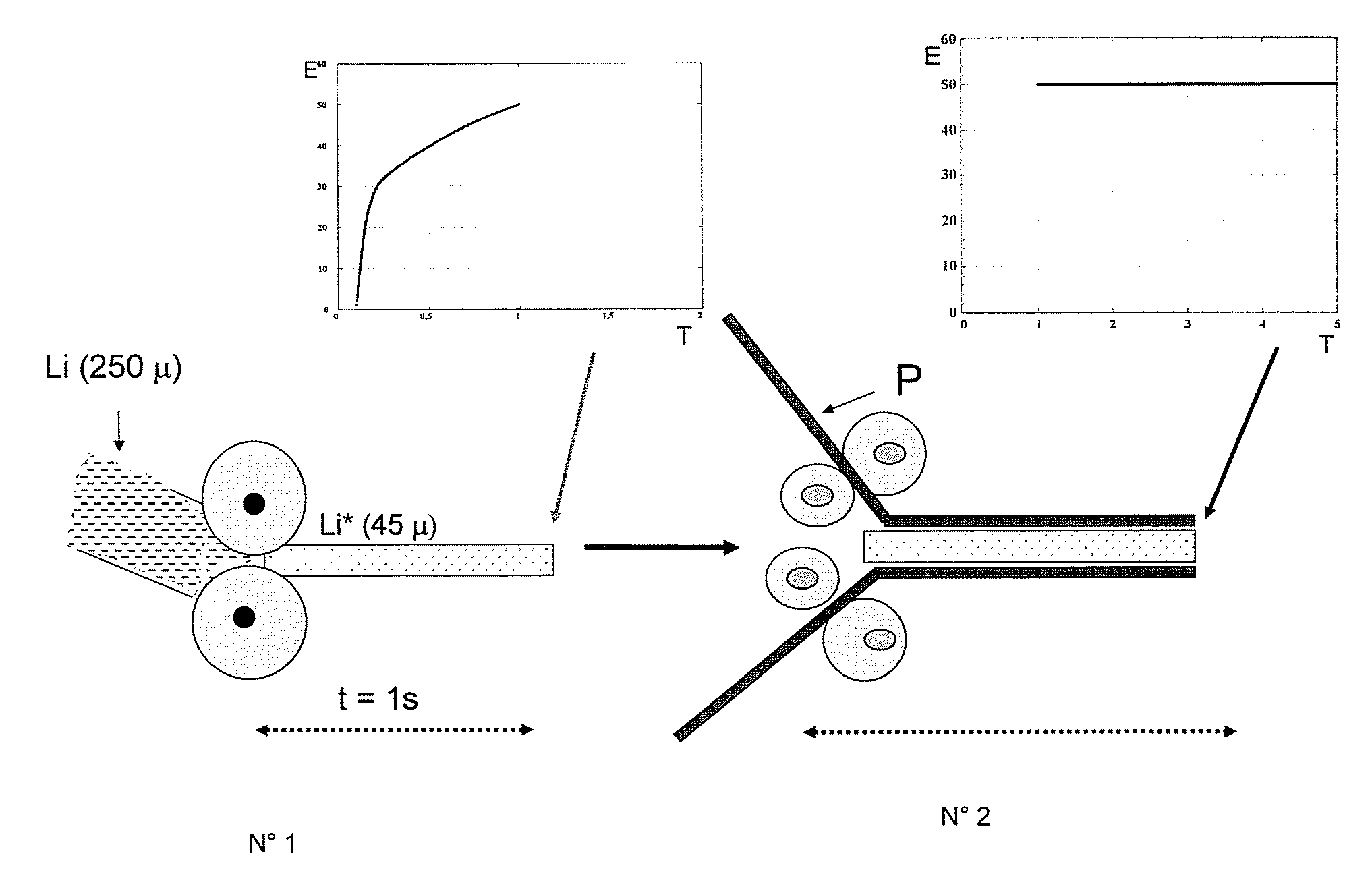

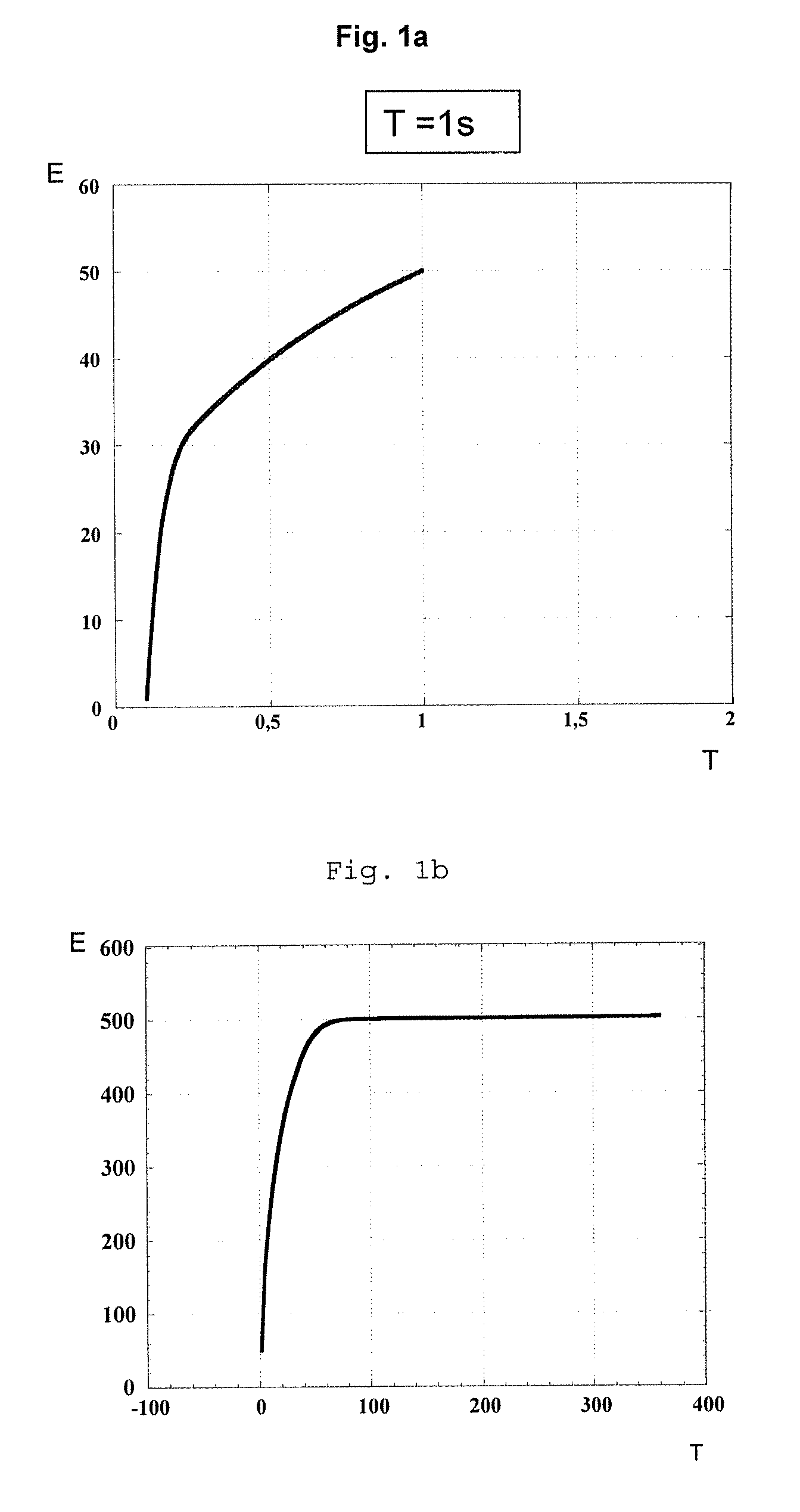

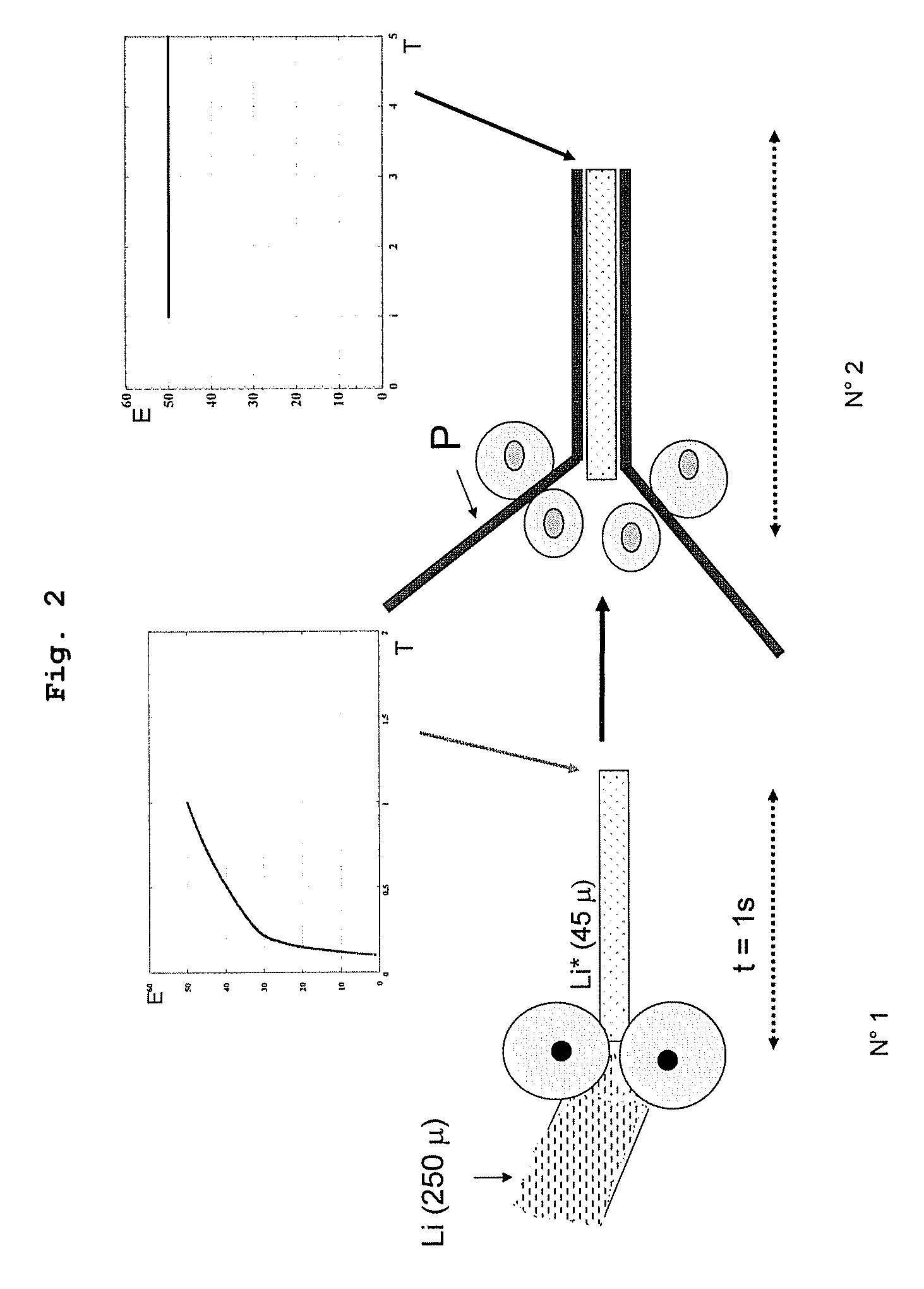

Multilayer material based on active lithium, method of preparation and applications in electrochemical generators

InactiveUS20090280410A1Improve adhesionExcellent impedance stabilityMolten spray coatingFinal product manufactureLithiumSufficient time

A method for preparing a multilayer material based on active lithium, by depositing a film of active lithium on a protective layer at a sufficient speed so that substantially no oxidation of the lithium occurs, and / or during a sufficient time for the adhesion of the lithium to develop after contact with the protective layer. The multilayer material, when incorporated in an electrochemical battery as an anode, has excellent impedance stability and no formation of dendrites during the cycling. Batteries where the anode is the multilayer material are particularly efficient in terms of their coulomb efficiency.

Owner:HYDRO QUEBEC CORP

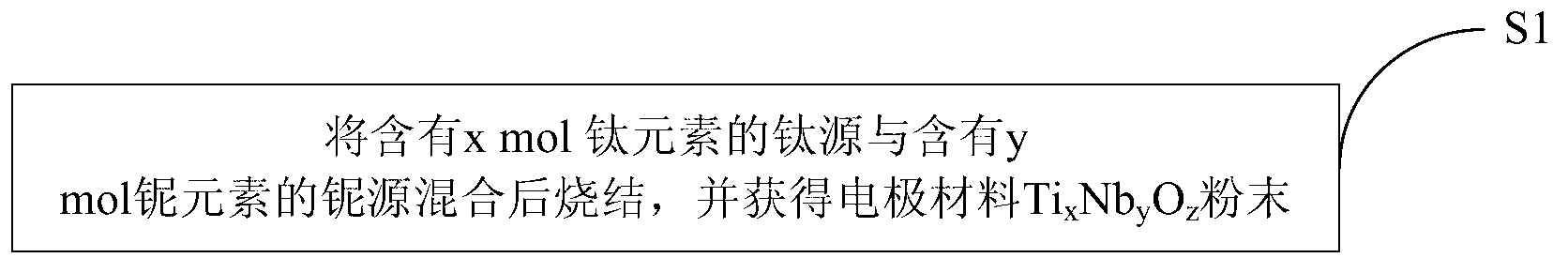

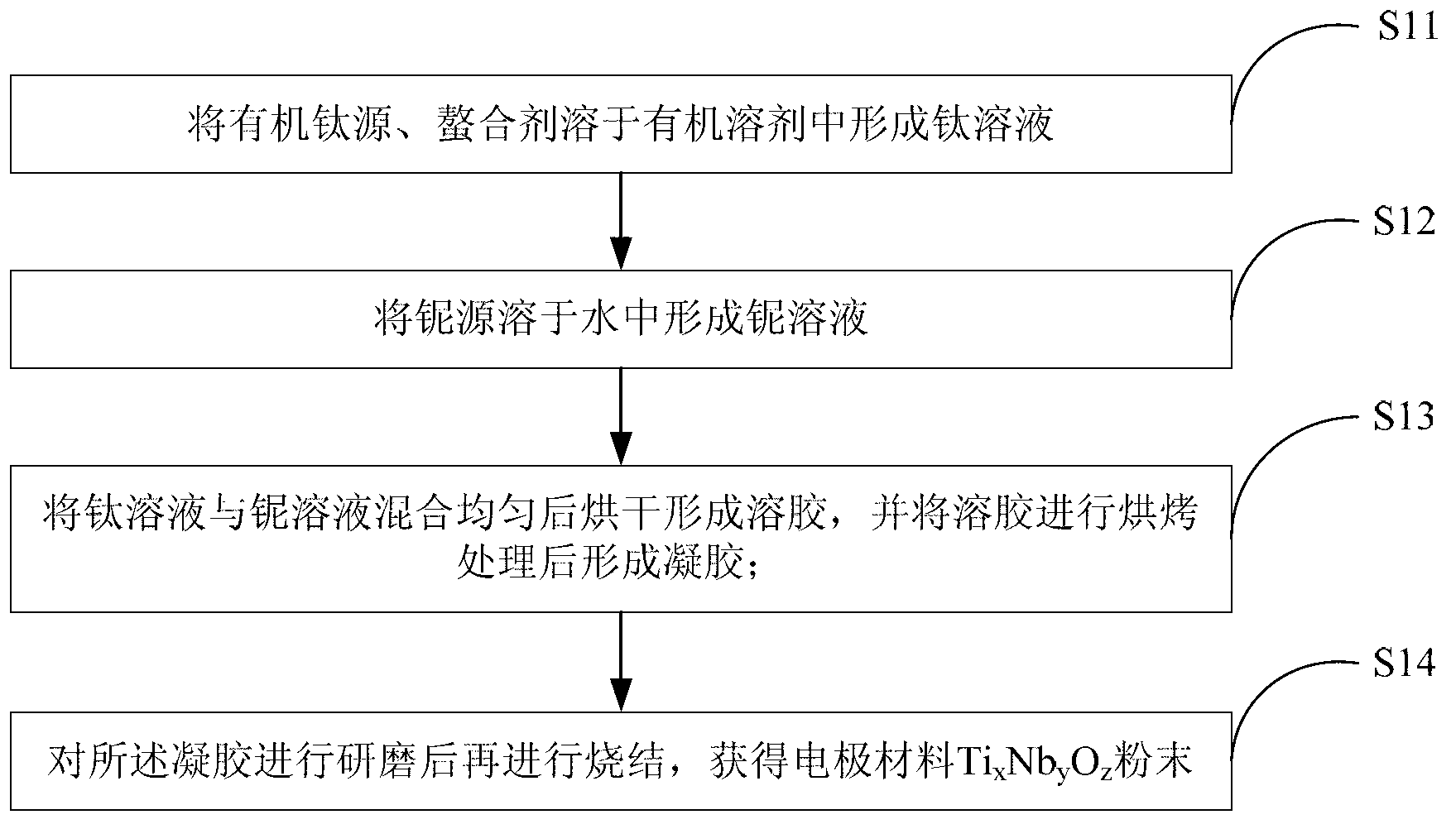

Electrode material of secondary lithium ion battery, and its preparation method

ActiveCN102983316AHigh theoretical specific capacityHigh reversible specific capacityCell electrodesNiobiumSodium-ion battery

The invention discloses an electrode material of a secondary lithium ion battery, and its preparation method. The chemical formula of the electrode material is TixNbyOz, wherein the value of x:y is not less than 1:24 and not more than 1:1. The preparation method comprises the following steps: mixing a titanium source containing x mol of a titanium element with a niobium source containing y mol of a niobium element to obtain a mixture, and sintering the mixture to obtain the powder of the electrode material TixNbyOz. The electrode material provided in the embodiment of the invention has a theoretic specific capacity as a cathode material of the lithium ion battery, and there is no formation of an SEI film in the working voltage rang of the cathode material of 3-1V; and the electrode material has the advantages of high reversible specific capacity, small voltage relaxation, high coulombic efficiency, excellent cycle performances, and good safety.

Owner:HUBEI HONGRUN HIGH-TECH NEW MATERIALS CO LTD

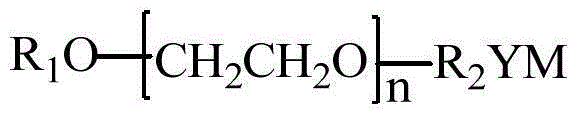

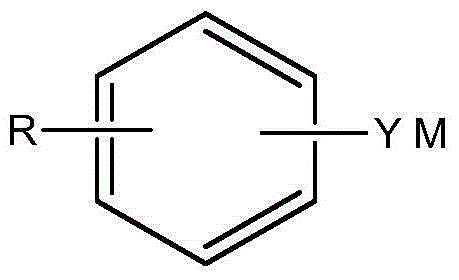

Method for synthesizing isomerous tridecanol polyoxyethylene ether

The invention relates to a synthetic method of isomeric tridecanol polyoxyethylene ether, belonging to the organic compound synthesis technical field, which uses the materials of isometric tridecanol and ethylene oxide. The synthetic method is characterized in that: firstly, the polymerization reaction is carried out with the boron trifluoride catalyst, and then the isomeric tridecanol polyoxyethylene ether is obtained by the polymerization reaction carried out with the strong alkali catalyst; wherein, the addition of the boron trifluoride adopted in the reaction is 0.1 to 0.6 percent of the weight of the isometric tridecanol, the strong alkali catalyst is one of or the mixture of solid sodium methylate, methanol solution of sodium methylate, KOH and NaOH, the addition of the strong alkali catalyst is 0.05 to 0.2 percent of the weight of isomeric tridecanol polyoxyethylene ether. The synthetic method of isomeric tridecanol polyoxyethylene ether has the advantages that: the synthetic method adopts a two-step reaction technical proposal that: the polymerization reaction is carried out with the boron trifluoride catalyst at first, and then the polymerization reaction is carried out with the strong alkali catalyst, so the isomeric tridecanol polyoxyethylene ether has mild reaction conditions, high yield, no formation of impurities and environment friendly performance.

Owner:ZHEJIANG HUANGMA TECH

Foam oil displacement agent with oil resistance, and its application

InactiveCN104152128AGood oil resistanceStrong foaming abilityDrilling compositionSURFACTANT BLENDNo formation

The invention relates to the technical field of tertiary recovery, and specifically relates to a foam oil displacement agent with oil resistance, and its application. The foam oil displacement agent with oil resistance is obtained by mixing and compounding an anionic surfactant with a cationic surfactant. The foam oil displacement agent with oil resistance has the characteristics of strong foaming capability and good oil resistance. The foam oil displacement agent with oil resistance enables the half life of foam to reach above 60min in the presence of crude oil, and can solve the problems of bad foam oil resistance, no formation of good plugging in present foam oil displacement and extraction processes; and the half life of foam having no oil resistance does not exceed 15min generally. The foam oil displacement agent with oil resistance can be used in the tertiary recovery of oilfields, and improves the recovery efficiency of the crude oil.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

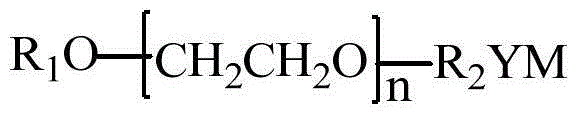

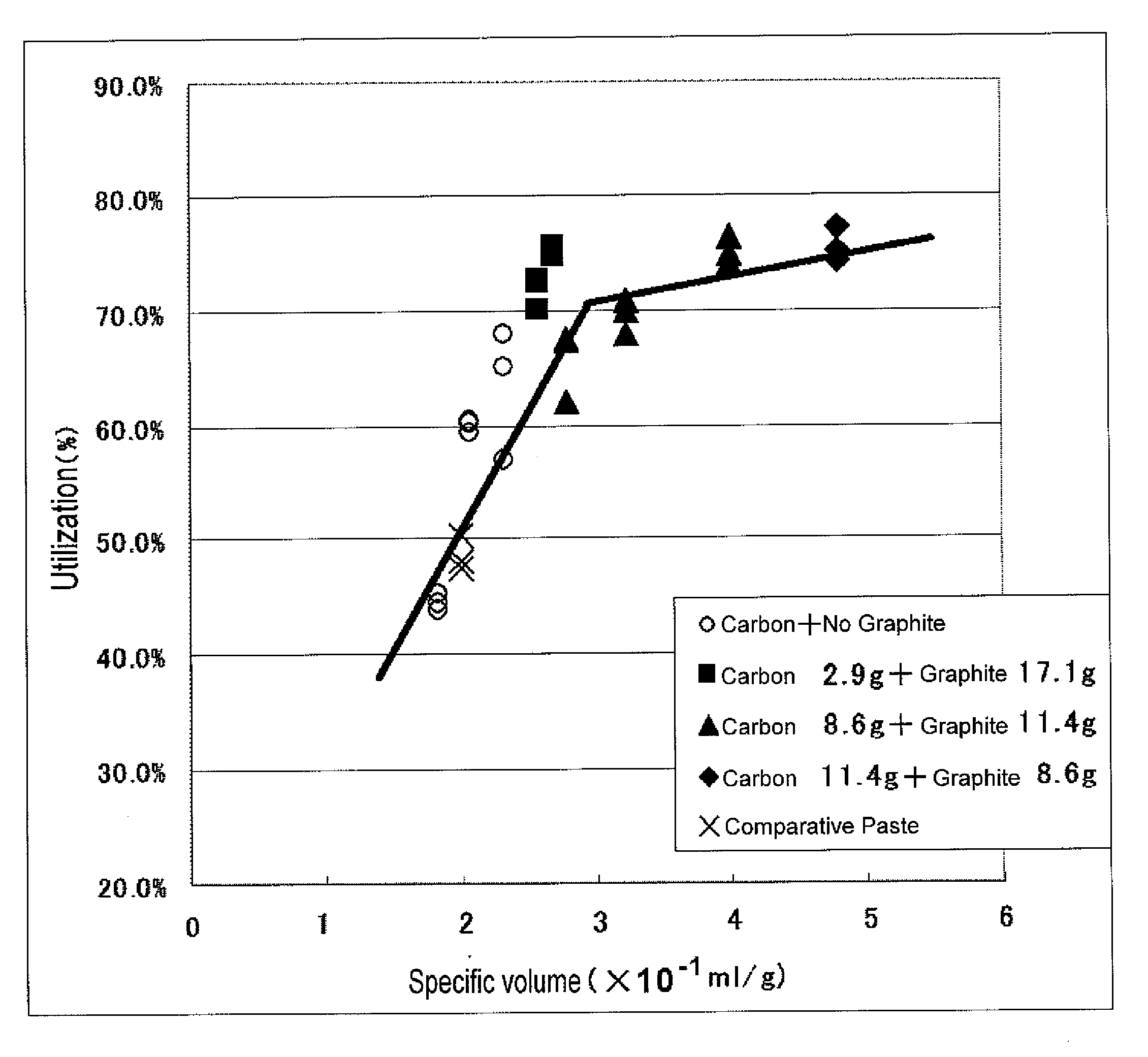

Negative-electrode active material for secondary battery

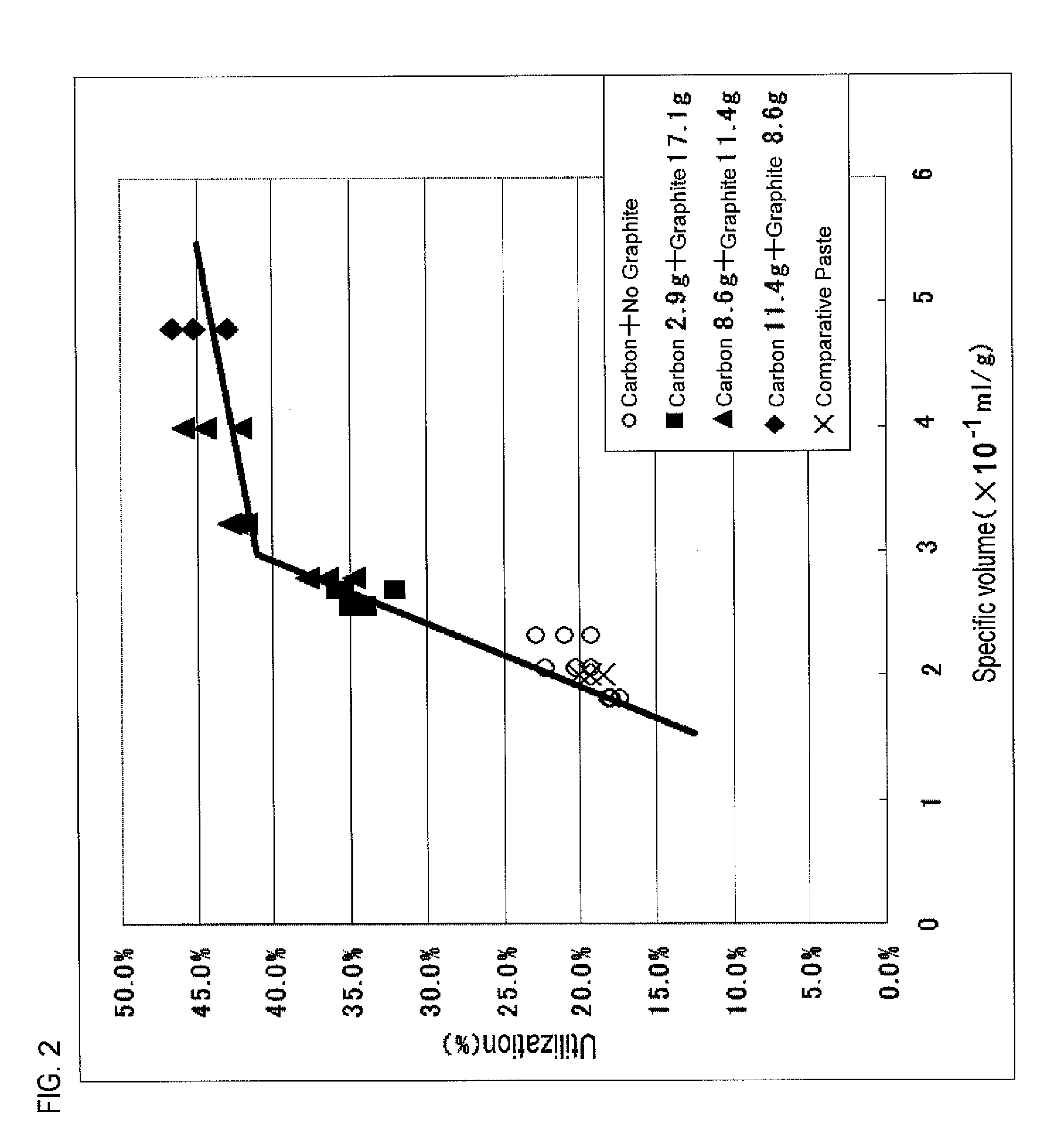

InactiveUS20100051857A1Improve overall utilizationGood dispersionLead-acid accumulator electrodesSulfateHigh energy

A storage battery or a secondary battery is capable of improving the utilization of an active material and obtaining a high energy density, using raw materials having costs substantially equal to those of a conventional lead storage battery especially as a negative-electrode plate of the secondary battery. The negative-electrode active material for the secondary battery is a kneaded mixture including: a raw active material having a metal and an oxide of the metal; and carbon in such an amount that the total absorption number thereof is at least 4.7 ml per mol of the raw active material, in which the kneaded mixture contains no sulfates or sulfates in an amount of 7×10−2 mol or smaller per mol of the raw active material. The negative-electrode active material has a specific volume of 2.2×10−1 to 5×10−1 ml / g with subjected to no formation. The carbon is acetylene black or furnace carbon.

Owner:NTT DATA INTELLILINK

Coated granular microbial agent and production method thereof

ActiveCN102925426ANo chemical reactionImprove liquidityOn/in inorganic carrierFertilizer mixturesChemical reactionMicrobial agent

The invention relates to a coated granular microbial agent and a production method thereof. The coated granular microbial agent is prepared by the following raw materials by weight percent in a mixing way: 7-20 percent of a microbial liquid, 50-85 percent of an adsorption carrier, 0-40 percent of a binding agent and 1-10 percent of a coating agent. The production method comprises the following steps: firstly weighing the raw materials with corresponding percent, mixing the adsorption carrier with the binding agent, adding the microbial liquid to adsorb and then crushing, performing granulation on the crushed material, drying the material after granulation and screening to obtain the finished product granular material through a screening machine, performing aeration-cooling on the finished product granular material and conveying the material after cooling to a coating machine and adding the coating agent for coating, and performing aeration-cooling and drying on the material after coating. The coated granular microbial agent has the benefits of no chemical reaction, no air slaking, no crushing for granules, no formation like sticky mud, good fluidity, high strength, soil adjustment, soil improvement and fertilizer effect enhancement when being mixed with chemical fertilizers such as urea, compound fertilizer and the like for use, and reduces the use cost.

Owner:北京世纪阿姆斯生物技术有限公司

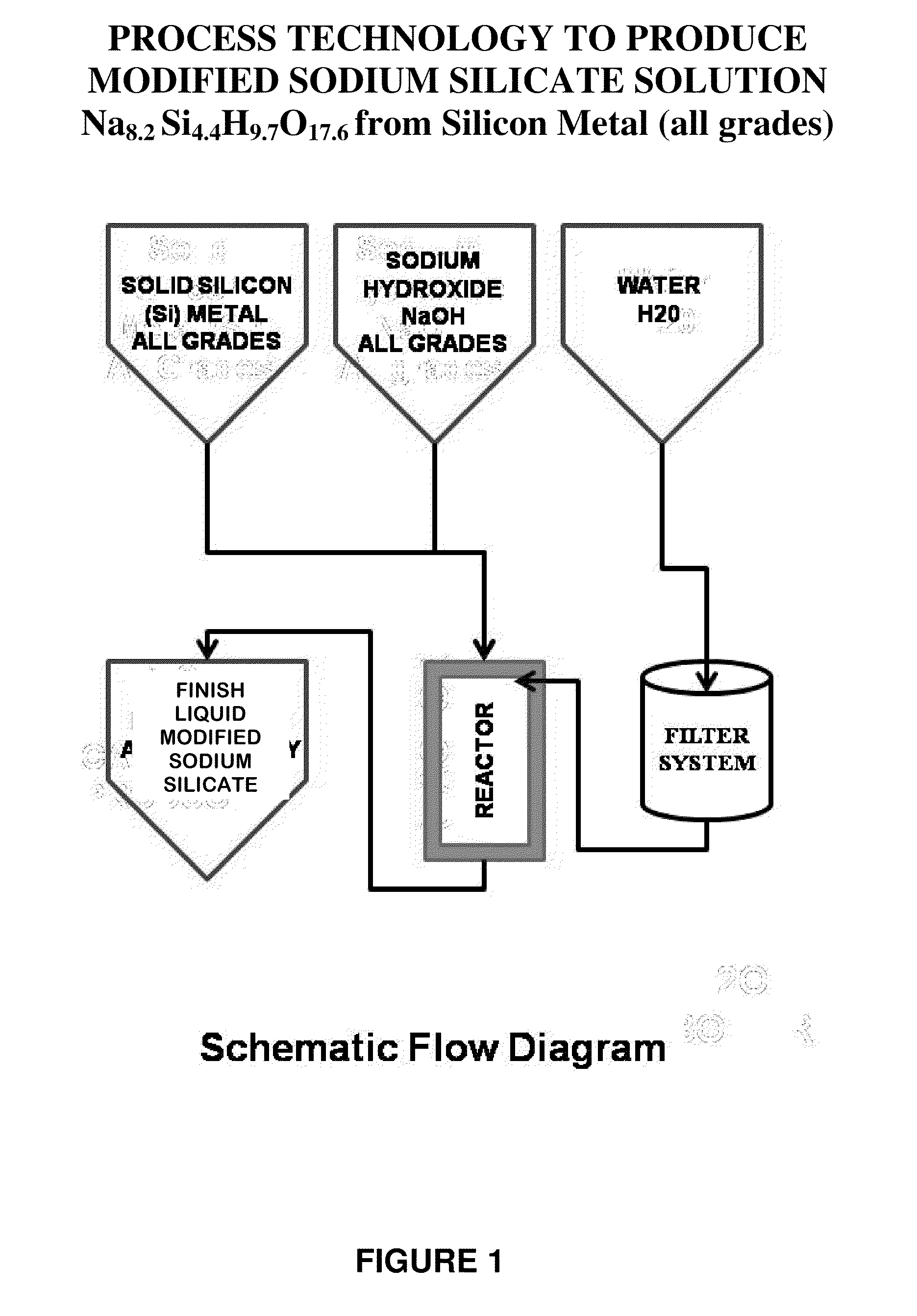

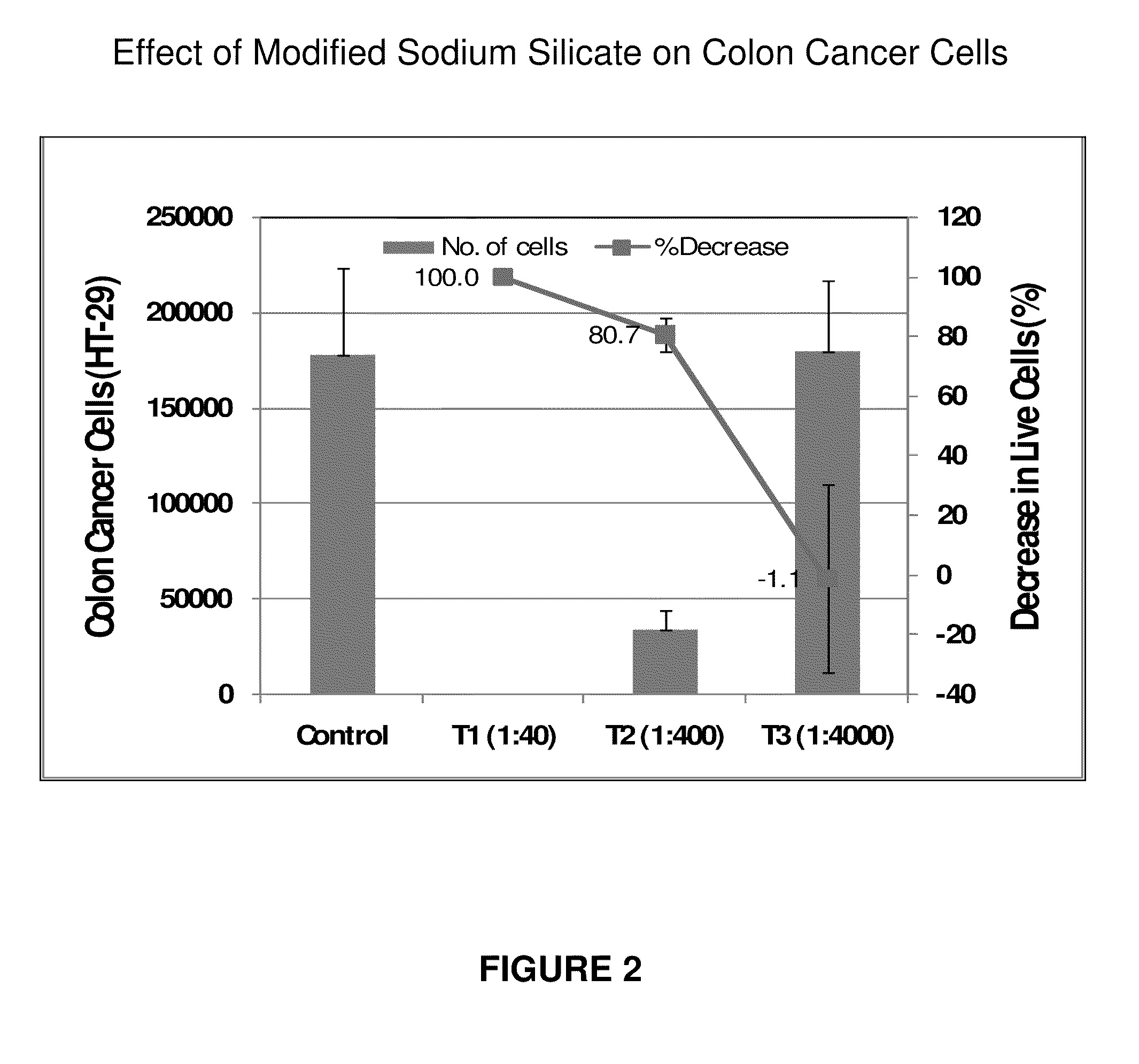

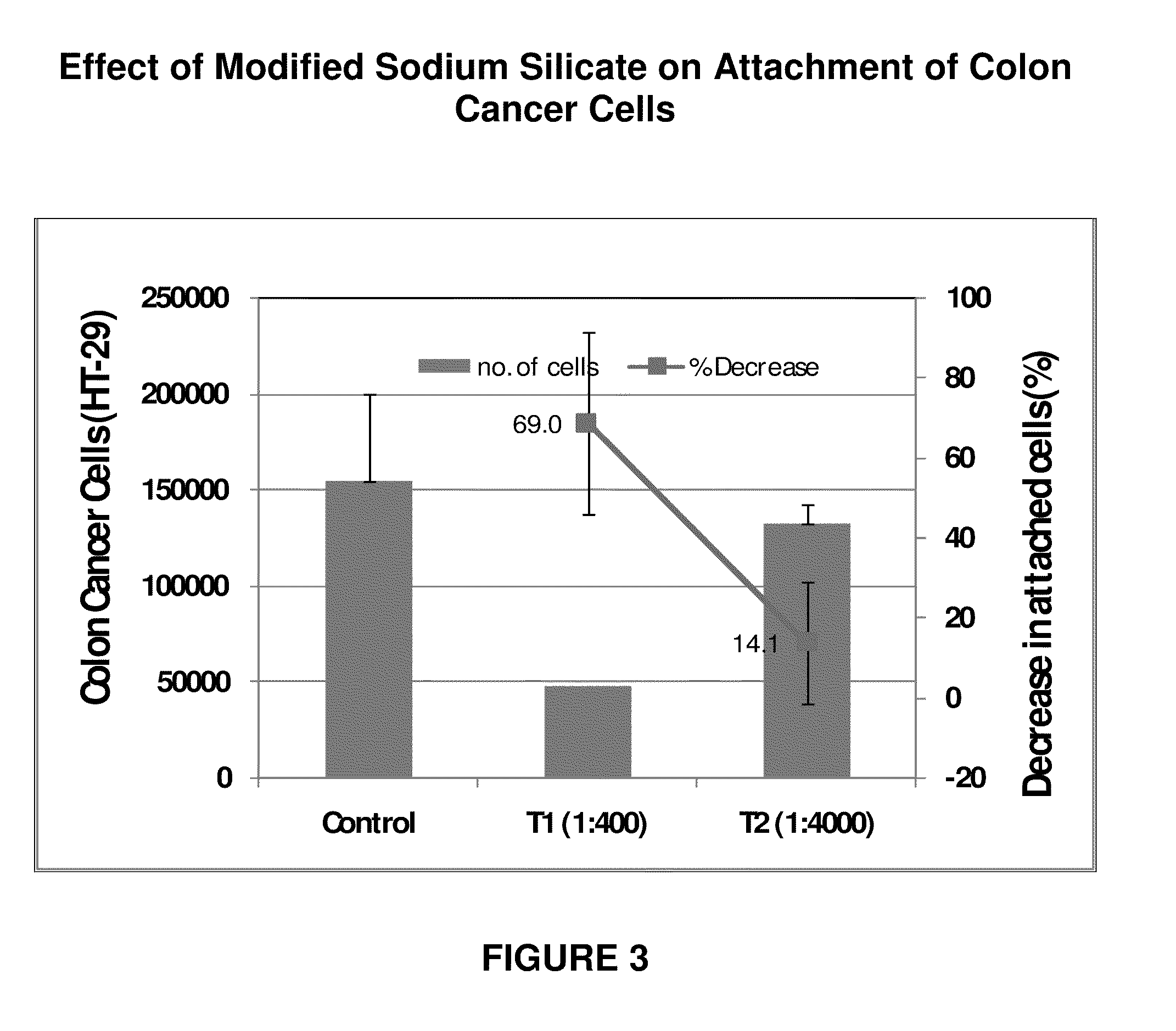

Method and composition for treating cancer, effecting apoptosis and treating retroviral infections

InactiveUS20110059189A1Prevent oxidationReduce concentrationBiocideInorganic active ingredientsOxidative stressRetroviral infection

A modified sodium silicate composition, and methods of treating cancer and viral infections utilizing the modified sodium silicate composition (Na8.2Si4.4H9.7O17.6). Na8.2Si4.4H9.7O17.6 can be administered to increase the nitric oxide concentration in the body, effect apoptosis, increase NO formation by neutrophils. Inhibit cell mutations, and inhibit oxidative stress.

Owner:CISNE ENTERPRISES

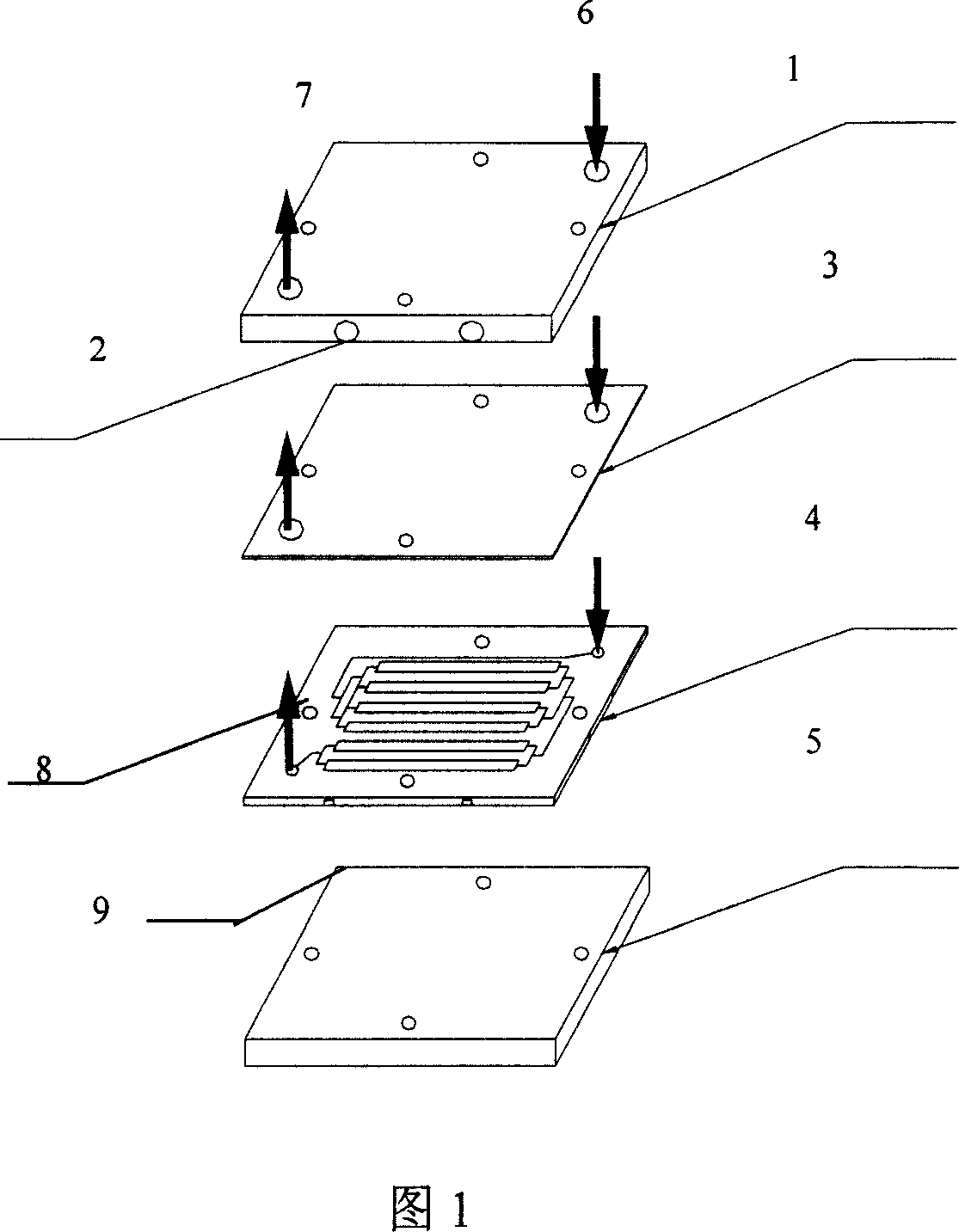

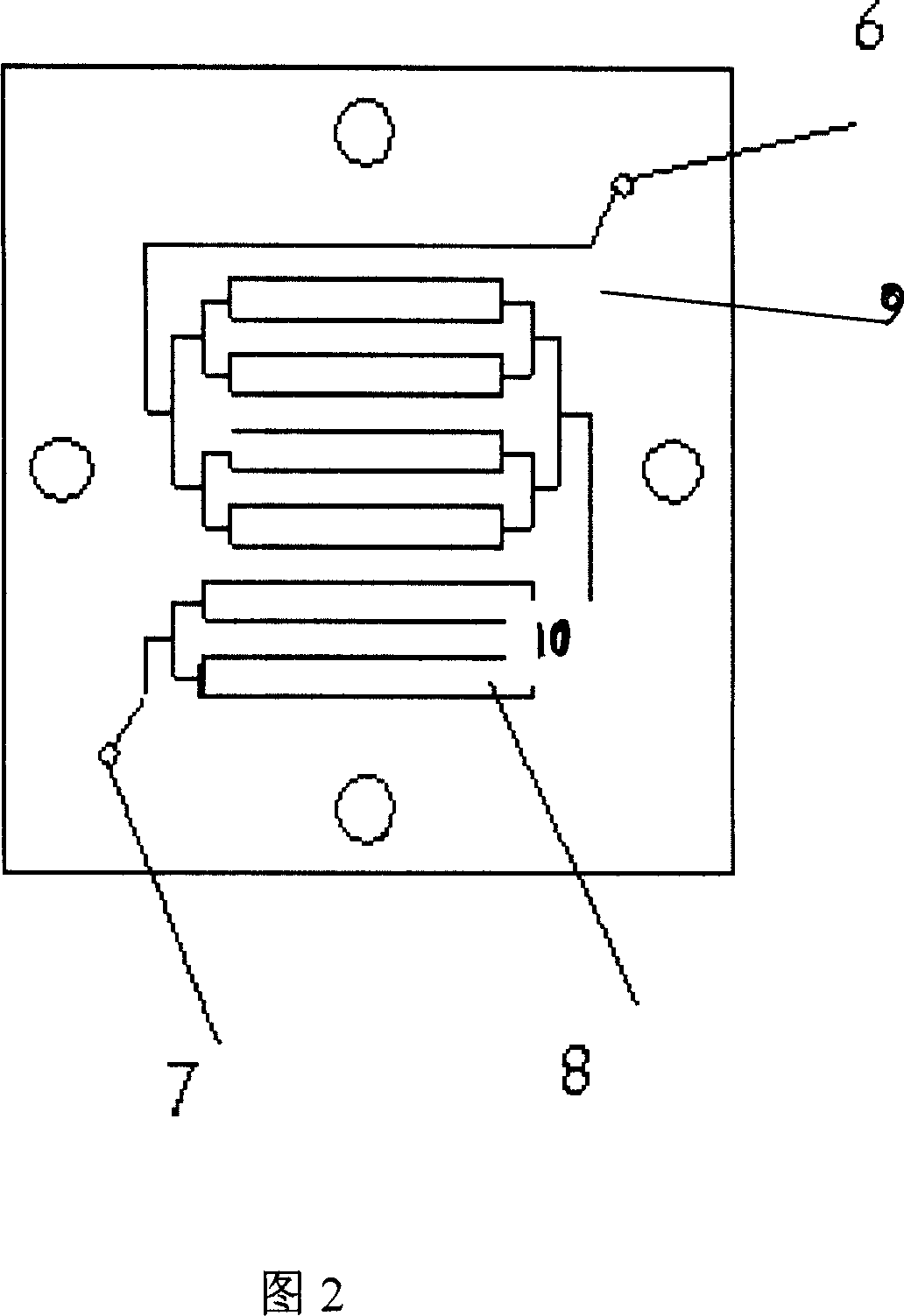

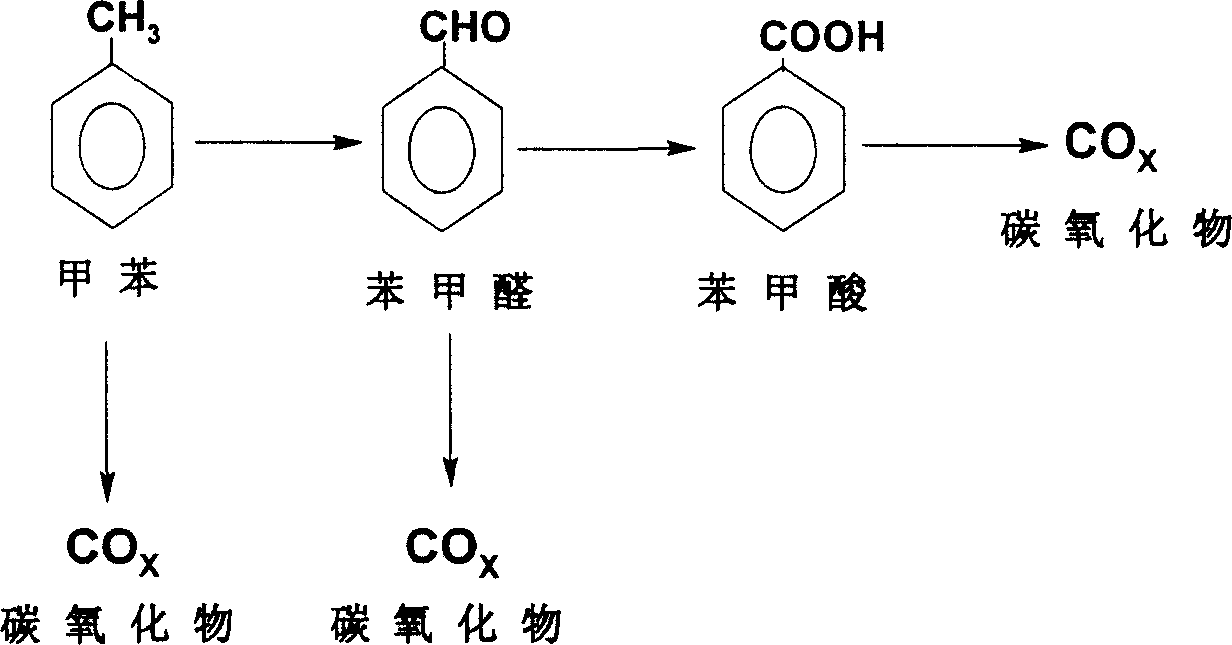

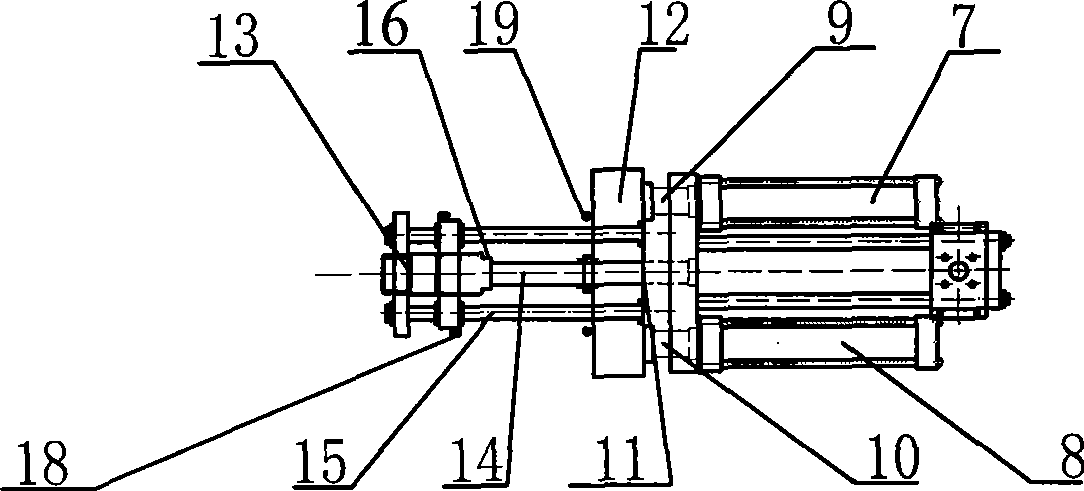

Process for preparing benzaldehyde and benzoic acid by methylbenzene gas-solid phase catalytic oxidation and micro reactor

InactiveCN1944362AReduce volumeHigh selectivityOxygen compounds preparation by hydrocarbon oxidationMetal/metal-oxides/metal-hydroxide catalystsBenzoic acidBenzaldehyde

The present invention discloses gas-solid phase catalysis process of toluene to prepare benzaladehyde (BA) and benzoic acid (BAc) and the micro rector therefor. The micro rector includes upper cover, heating rod, sealing graphite diaphragm, reaction plate, lower cover, inlet and outlet. Under the gas-solid phase catalysis of the Ag modified granular V / TiO2 catalyst filled inside the micro channel, toluene is oxidized selectively with pure oxygen as the oxidant to prepare BA and BAc in lowered mass transfer and heat transfer resistance, no formation of hot point, reduced deep oxidation and raised oxidation product selectivity. The present invention has high safety, capacity of operating within explosion range, high conversion rate, high material utilizing rate and other advantages.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

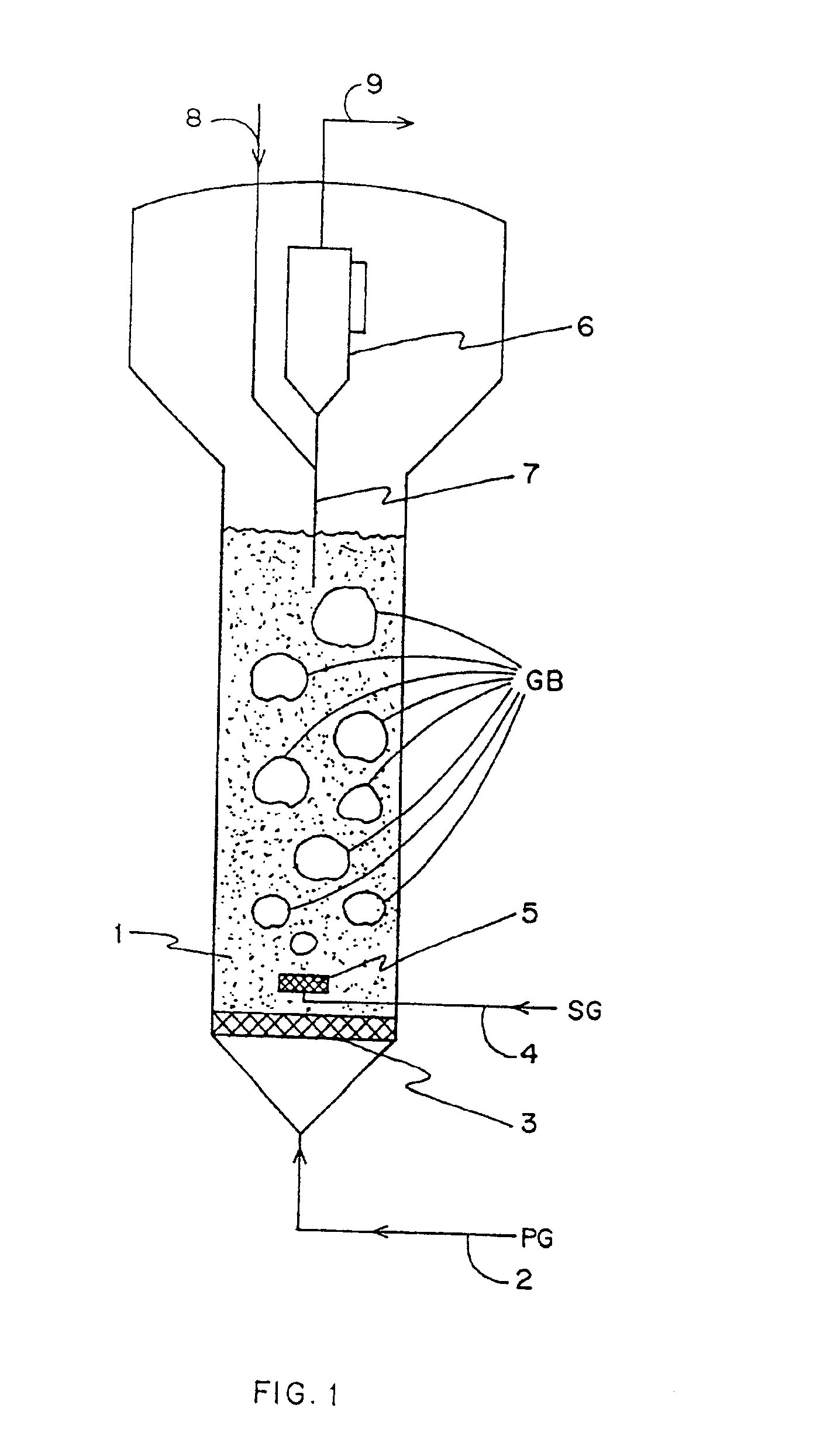

Method for gas - solid contacting in a bubbling fluidized bed reactor

InactiveUS20020179489A1Effective contactSpeed up the conversion processThermal non-catalytic crackingCatalytic crackingForming gasSurface velocity

The present invention relates to a method for gas-solid contacting in a bubbling fluidized bed reactor by: (a) introducing into a reactor with bed length to bed diameter ratio below about 5.0, a primary gas consisting essentially of reactant(s) of the reaction to be carried out in the bed of solid particles through a primary gas distributor located at the reactor bottom at a superficial gas velocity Up, which is very close or equivalent to the minimum fluidization velocity Umf, required for achieving the incipient fluidization of the solid particles in the bed to obtain an emulsion phase consisting essentially of the solid particles and the primary gas with little or no formation of gas bubbles to achieve incipient fluidization or liquid-like behavior of fluidizable solid particles; (b) forming gas bubbles in the incipiently fluidized bed by introducing through a secondary gas distributor located immediately above the primary gas distributor a secondary gas, selected from one of the reactants which is used in excess of that required for the reaction stoichiometry, steam, an inert or a mixture of two or more thereof at a superficial gas velocity, Us, which is related to the superficial velocity of the primary gas such that a ratio of the superficial velocity of the secondary gas to the superficial velocity of the primary gas Us / Up, is in the range from about 0.5 to about 10.0, preferably from about 1 to about 5.

Owner:COUNCIL OF SCI & IND RES

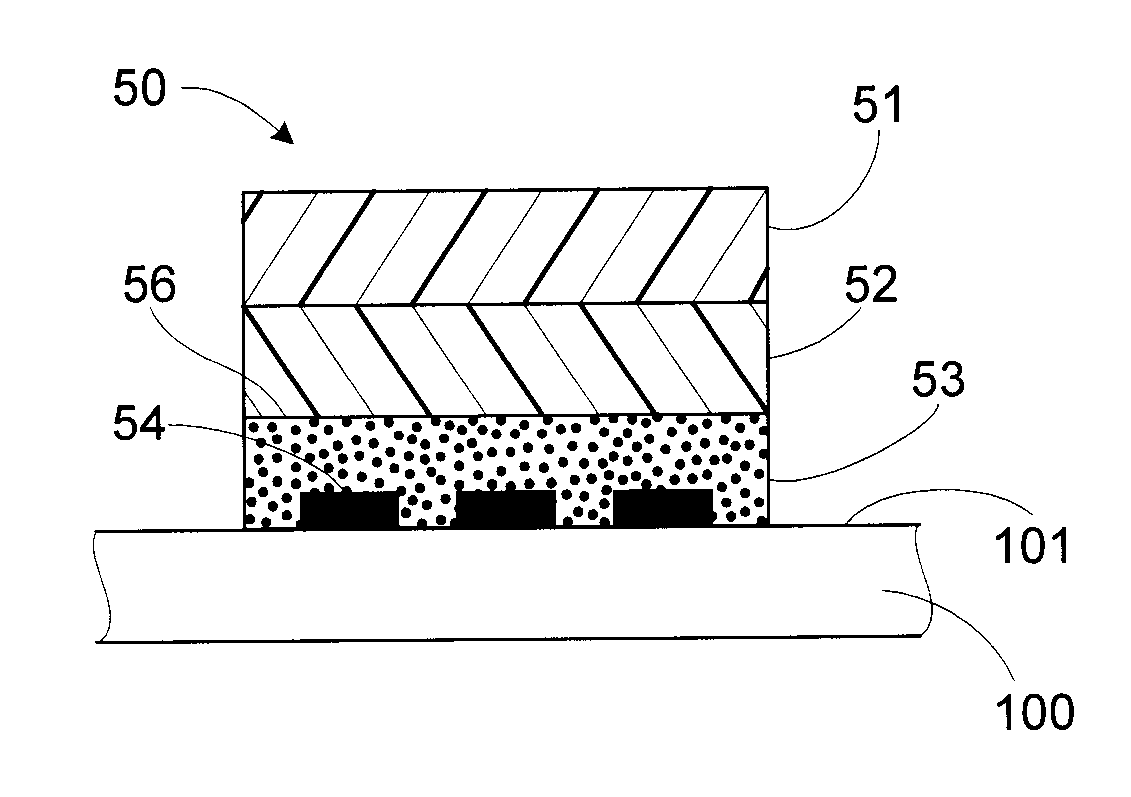

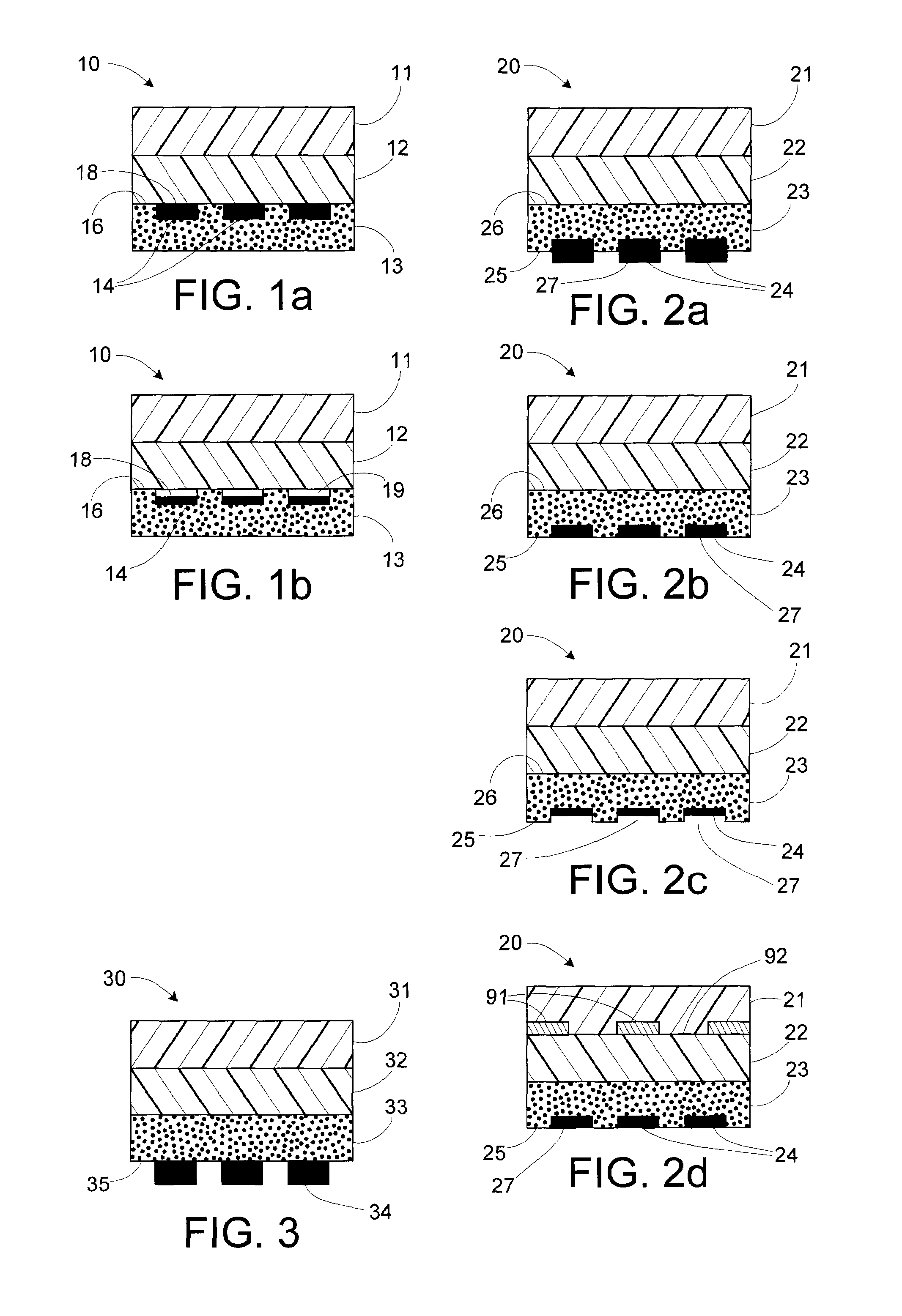

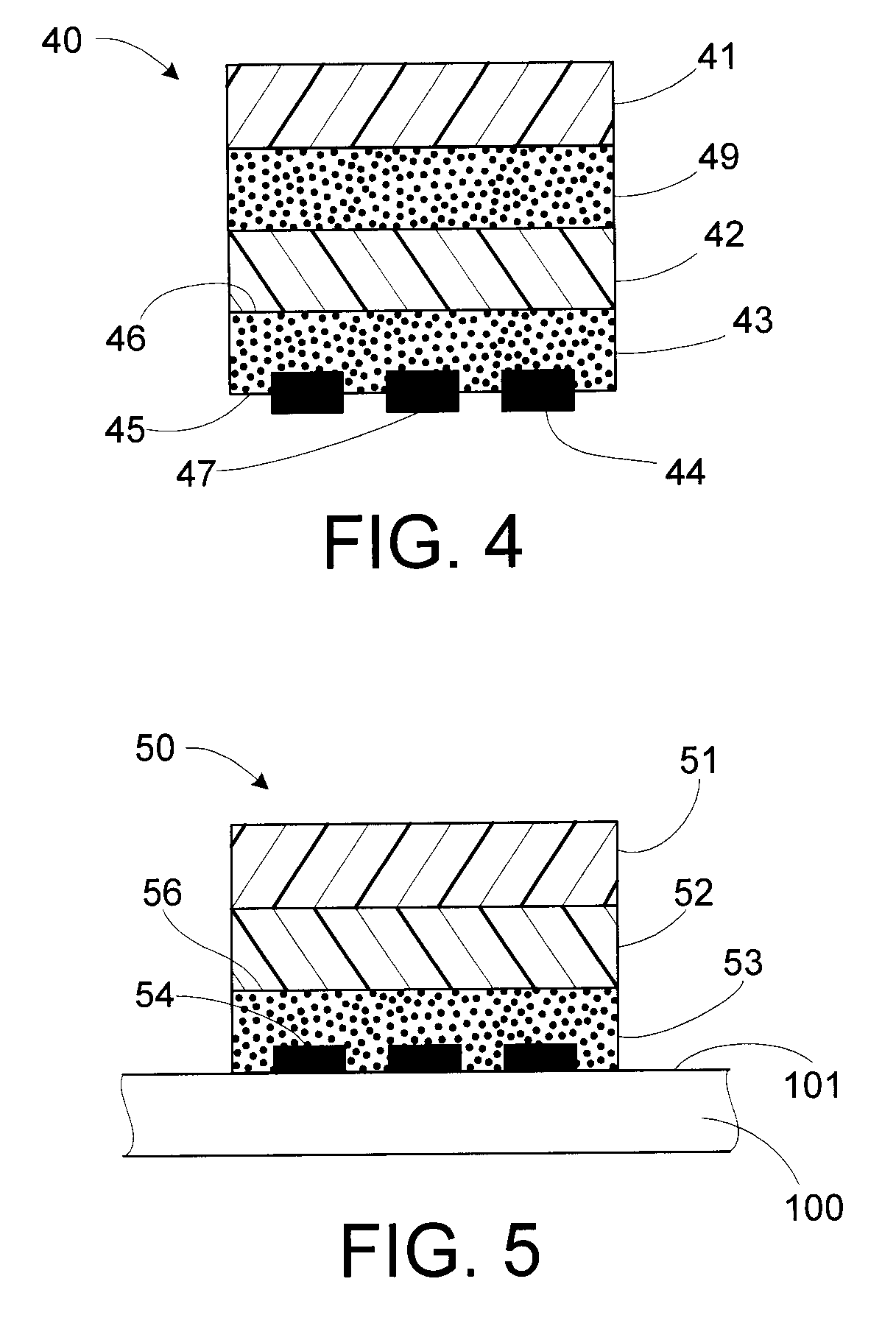

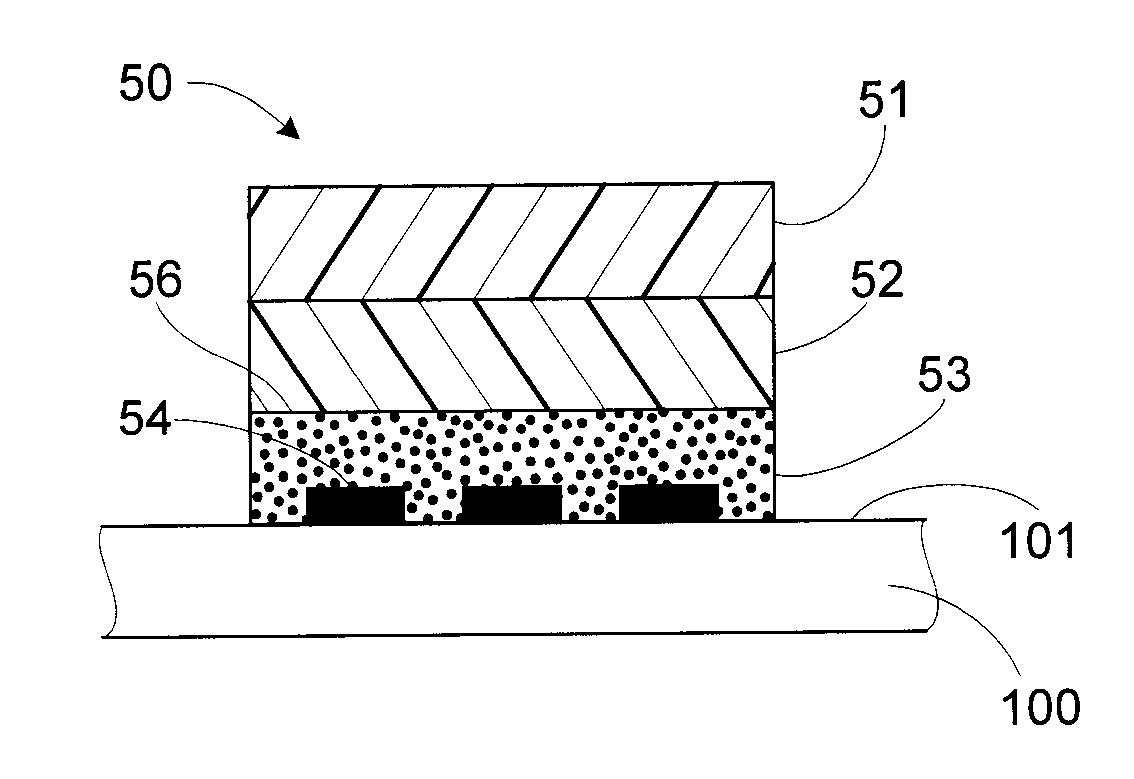

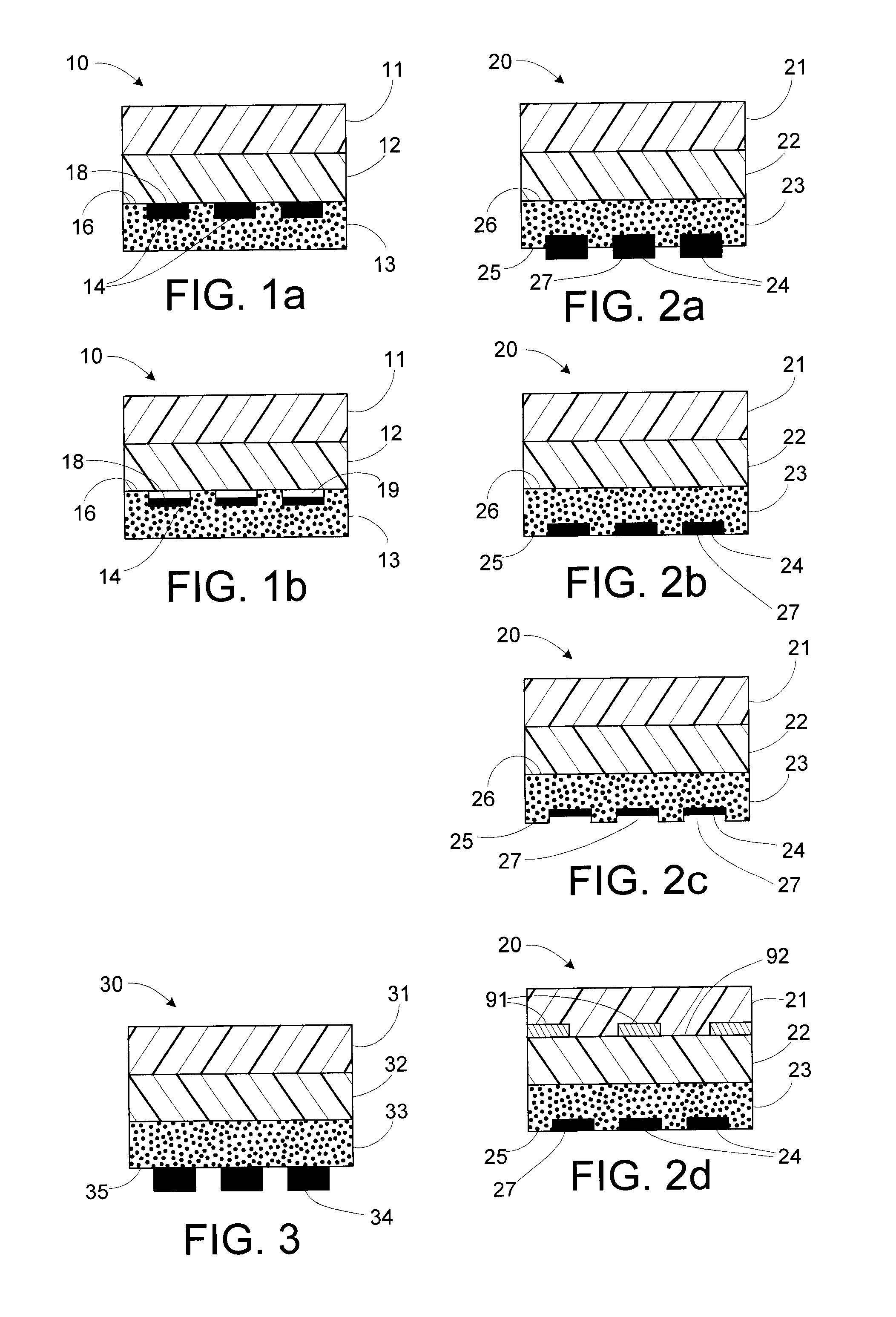

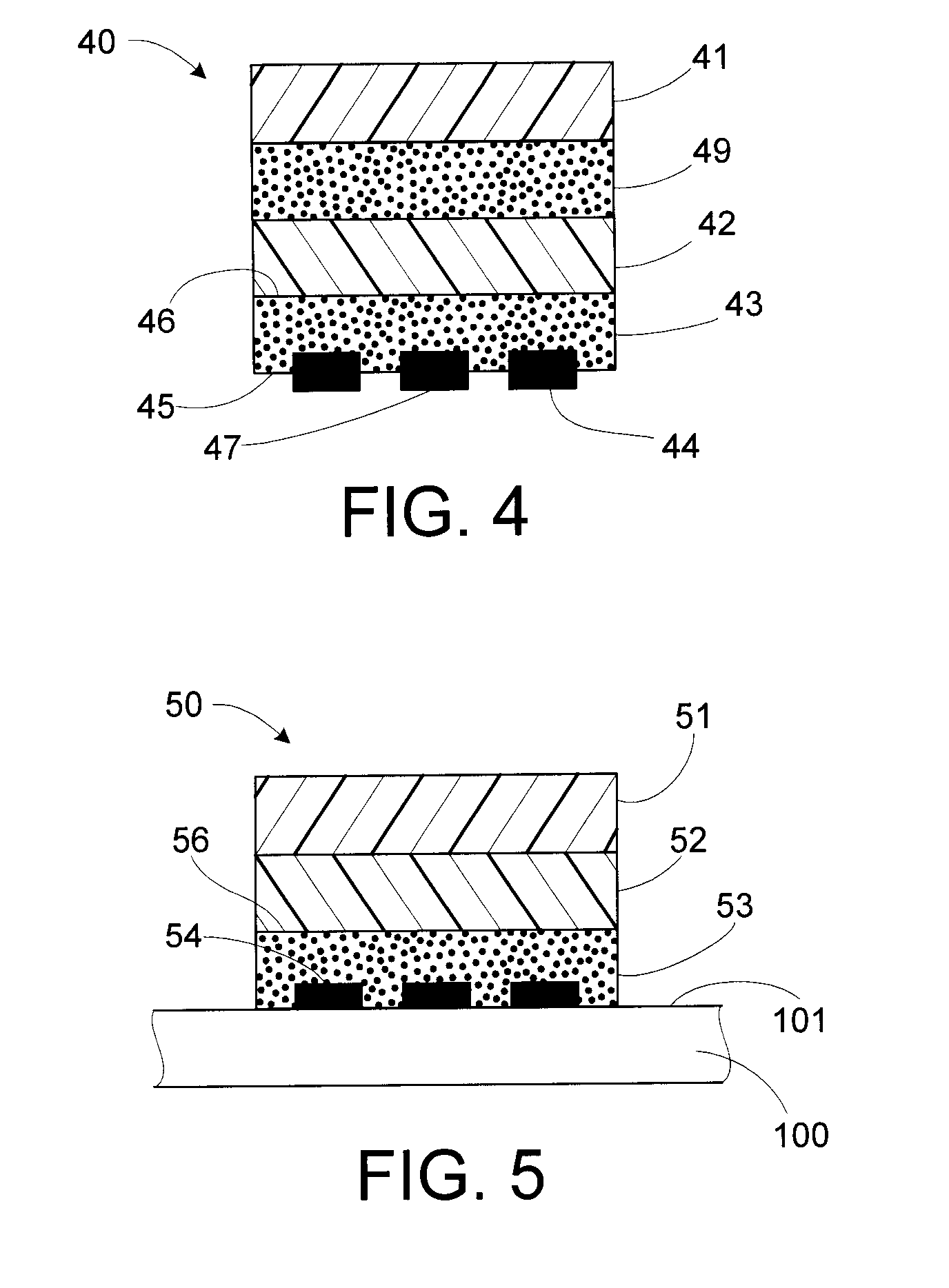

Dry erase writing board and method

This invention relates to a dry erase writing board. The dry erase writing board comprises a chalk or erase board having a face side, and a multilayer film which is adhered to the face side of the chalk or dry erase board. The outer or exposed surface of the multilayer film which is adhered to the chalk board or erase board is a clear dry erasable layer comprising at least one fluorocarbon polymer. The invention also relates to a method of preparing the dry erase writing boards of the invention which utilizes a multilayer film having an adhesive layer for adhering the multilayer film to the chalk or erase board and a pattern of non-adhesive material forms embedded into the upper or lower surface of the adhesive layer, or adhered to the lower surface of the adhesive layer. The dry erasable multilayer films described herein are easily applied to substrates such as a chalk or erase board with little or no formation of visible bubbles or wrinkles in the film.

Owner:AVERY DENNISON CORP

Process for incinerating nh3 and a nh3 incinerator

This invention relates to a process for incinerating NH3 in an NH3 incinerator comprising a first incineration step at controlled sub-stoichiometric incineration conditions and a second incineration step with at a greater than stoichiometric amount of oxygen, whereby a product stream is produced with reduced NO formation. The invention also relates to an NH3 incinerator.

Owner:DUIKER COMBUSTION ENGINEERS

Dry erase writing board and method

This invention relates to a dry erase writing board. The dry erase writing board comprises a chalk or erase board having a face side, and a multilayer film which is adhered to the face side of the chalk or dry erase board. The outer or exposed surface of the multilayer film which is adhered to the chalk board or erase board is a clear dry erasable layer comprising at least one fluorocarbon polymer. The invention also relates to a method of preparing the dry erase writing boards of the invention which utilizes a multilayer film having an adhesive layer for adhering the multilayer film to the chalk or erase board and a pattern of non-adhesive material forms embedded into the upper or lower surface of the adhesive layer, or adhered to the lower surface of the adhesive layer. The dry erasable multilayer films described herein are easily applied to substrates such as a chalk or erase board with little or no formation of visible bubbles or wrinkles in the film.

Owner:AVERY DENNISON CORP

Method for synthesizing isomerous tridecanol polyoxyethylene ether

The invention relates to a synthetic method of isomeric tridecanol polyoxyethylene ether, belonging to the organic compound synthesis technical field, which uses the materials of isometric tridecanol and ethylene oxide. The synthetic method is characterized in that: firstly, the polymerization reaction is carried out with the boron trifluoride catalyst, and then the isomeric tridecanol polyoxyethylene ether is obtained by the polymerization reaction carried out with the strong alkali catalyst; wherein, the addition of the boron trifluoride adopted in the reaction is 0.1 to 0.6 percent of the weight of the isometric tridecanol, the strong alkali catalyst is one of or the mixture of solid sodium methylate, methanol solution of sodium methylate, KOH and NaOH, the addition of the strong alkali catalyst is 0.05 to 0.2 percent of the weight of isomeric tridecanol polyoxyethylene ether. The synthetic method of isomeric tridecanol polyoxyethylene ether has the advantages that: the synthetic method adopts a two-step reaction technical proposal that: the polymerization reaction is carried out with the boron trifluoride catalyst at first, and then the polymerization reaction is carried out with the strong alkali catalyst, so the isomeric tridecanol polyoxyethylene ether has mild reaction conditions, high yield, no formation of impurities and environment friendly performance.

Owner:ZHEJIANG HUANGMA TECH

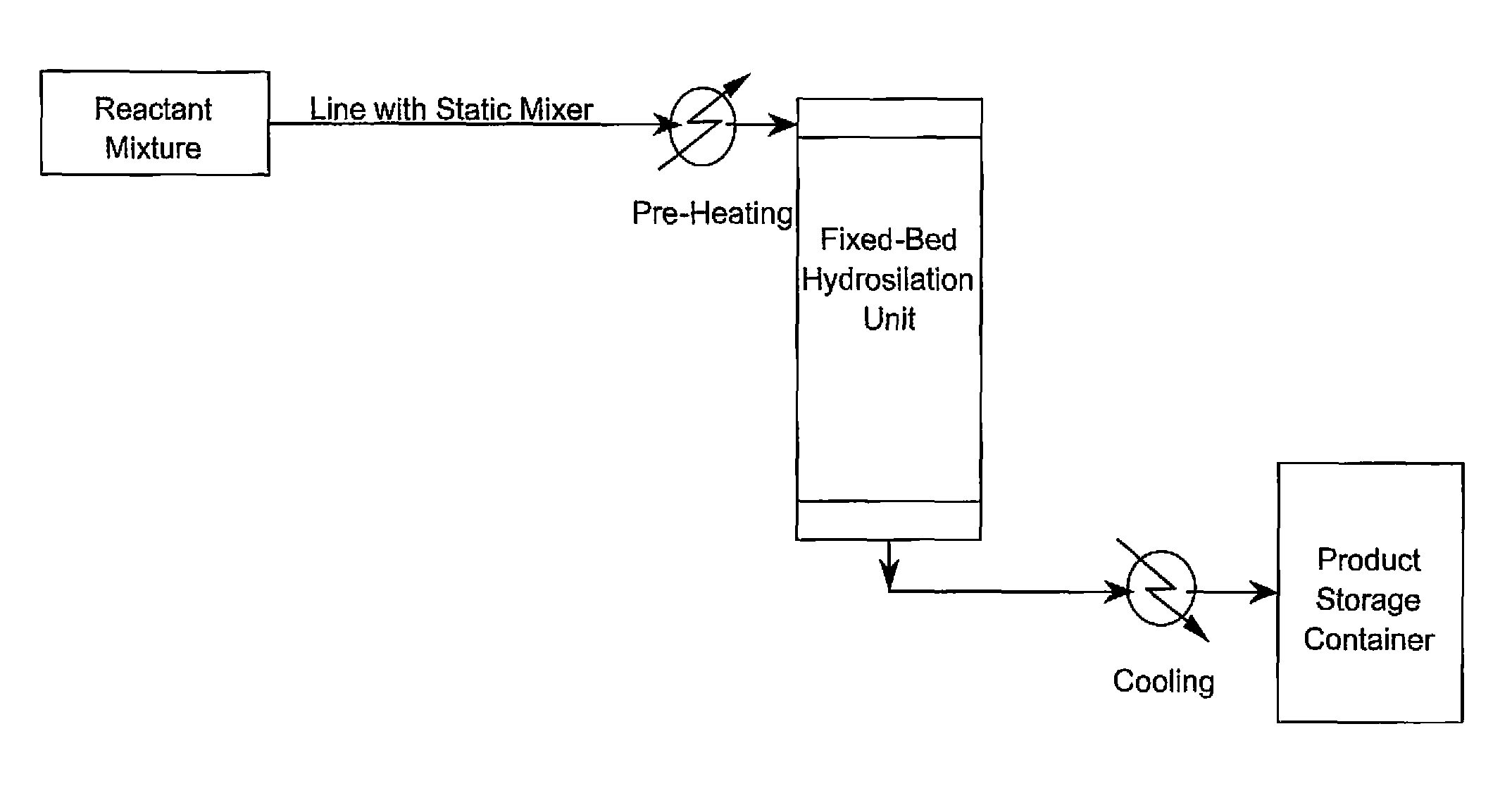

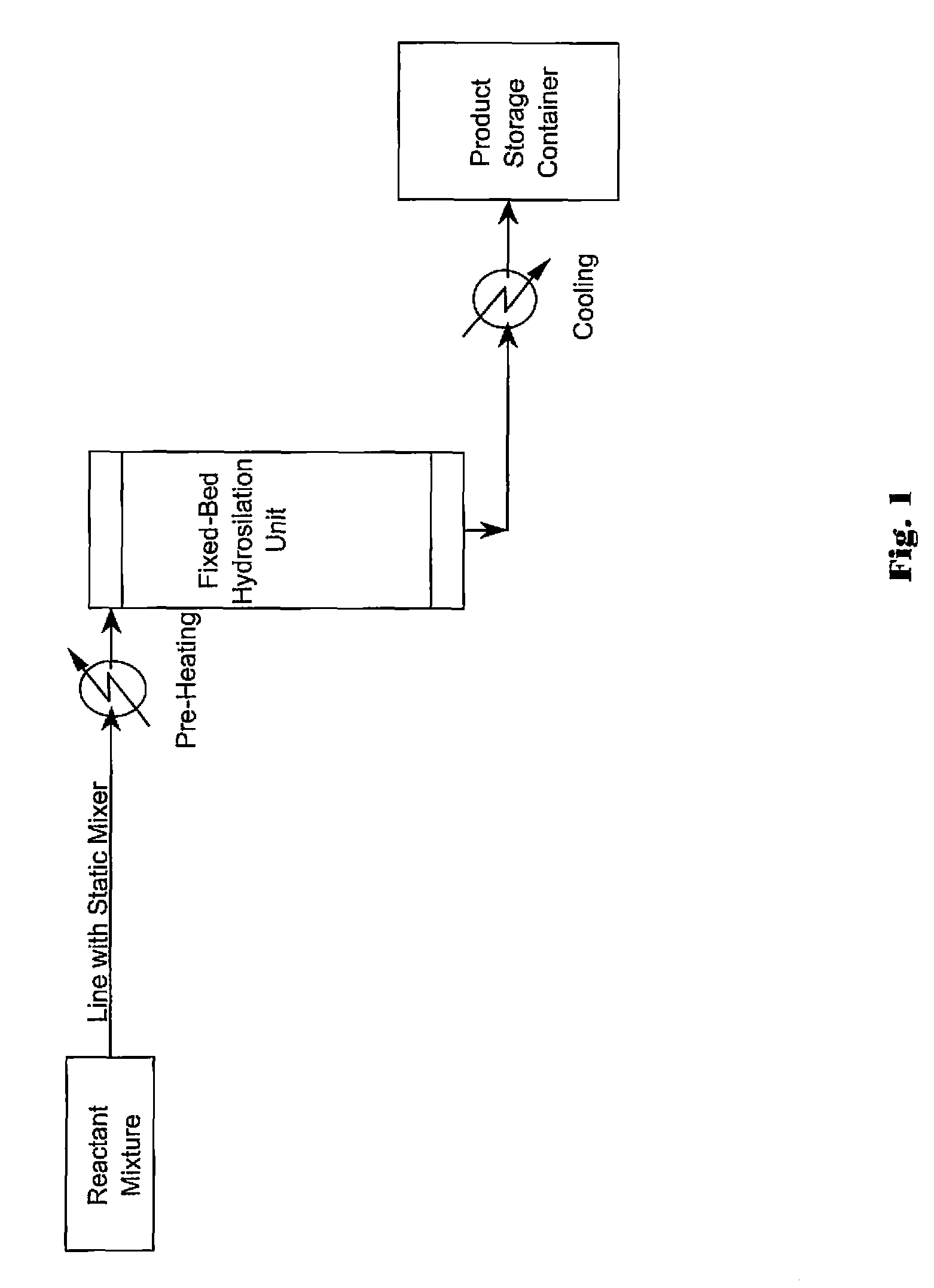

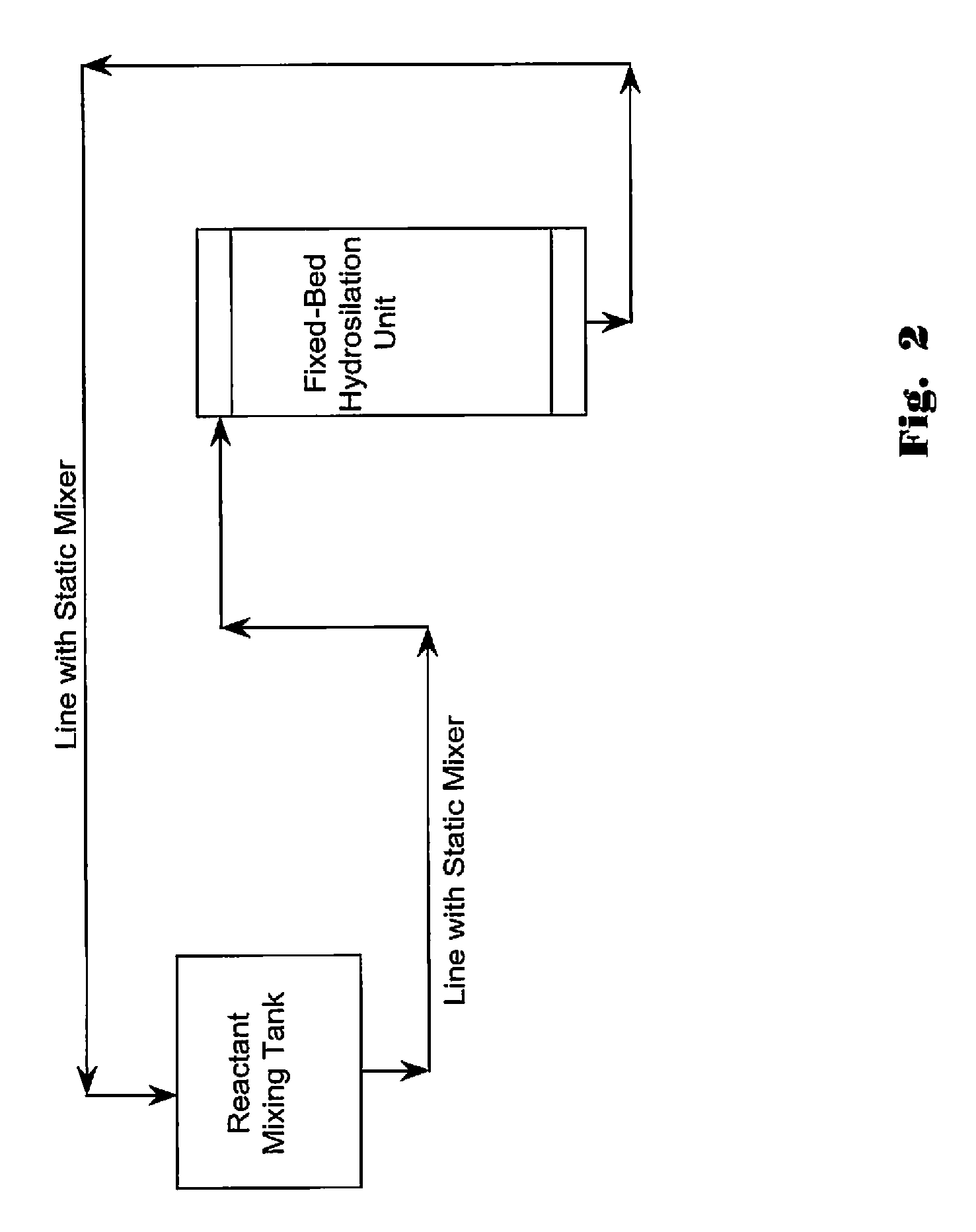

Process of manufacturing organosilicon products with improved quality using heterogeneous precious metal catalysts

ActiveUS8497338B2Easy to separateProduct quality issues caused by precious metal presence can be eliminatedSilicon organic compoundsChemical recyclingReaction zoneHydrosilylation

A process for manufacturing an organosilicon product having a stabilized low color and no formation of black particles during storage includes (a) reacting an unsaturated compound with a silicon compound having a reactive Si—H bond under hydrosilylation conditions in a reaction zone in the presence of a heterogeneous precious metal catalyst to provide an organosilicon product having a color of less than 40 pt / co; (b) separating the heterogeneous precious metal catalyst from the organosilicon product; and (c) recovering the heterogeneous precious metal catalyst.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

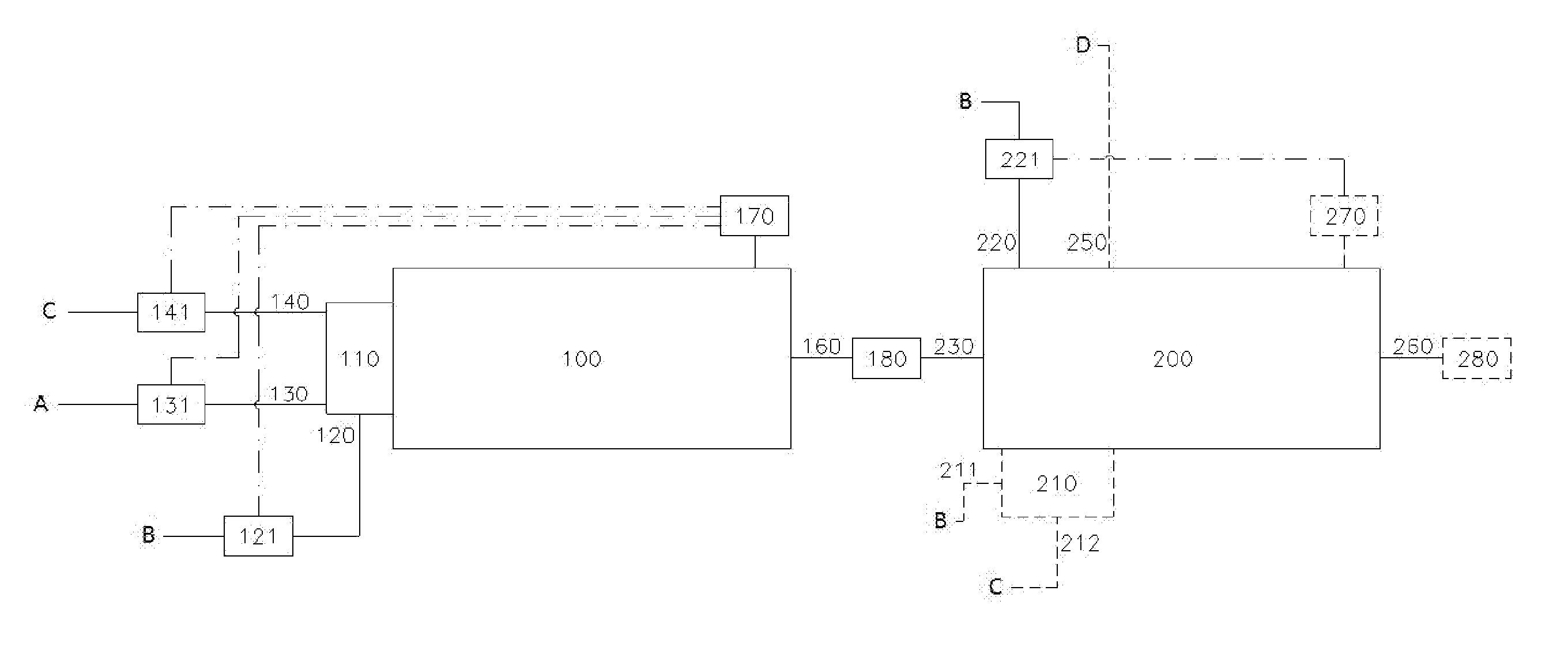

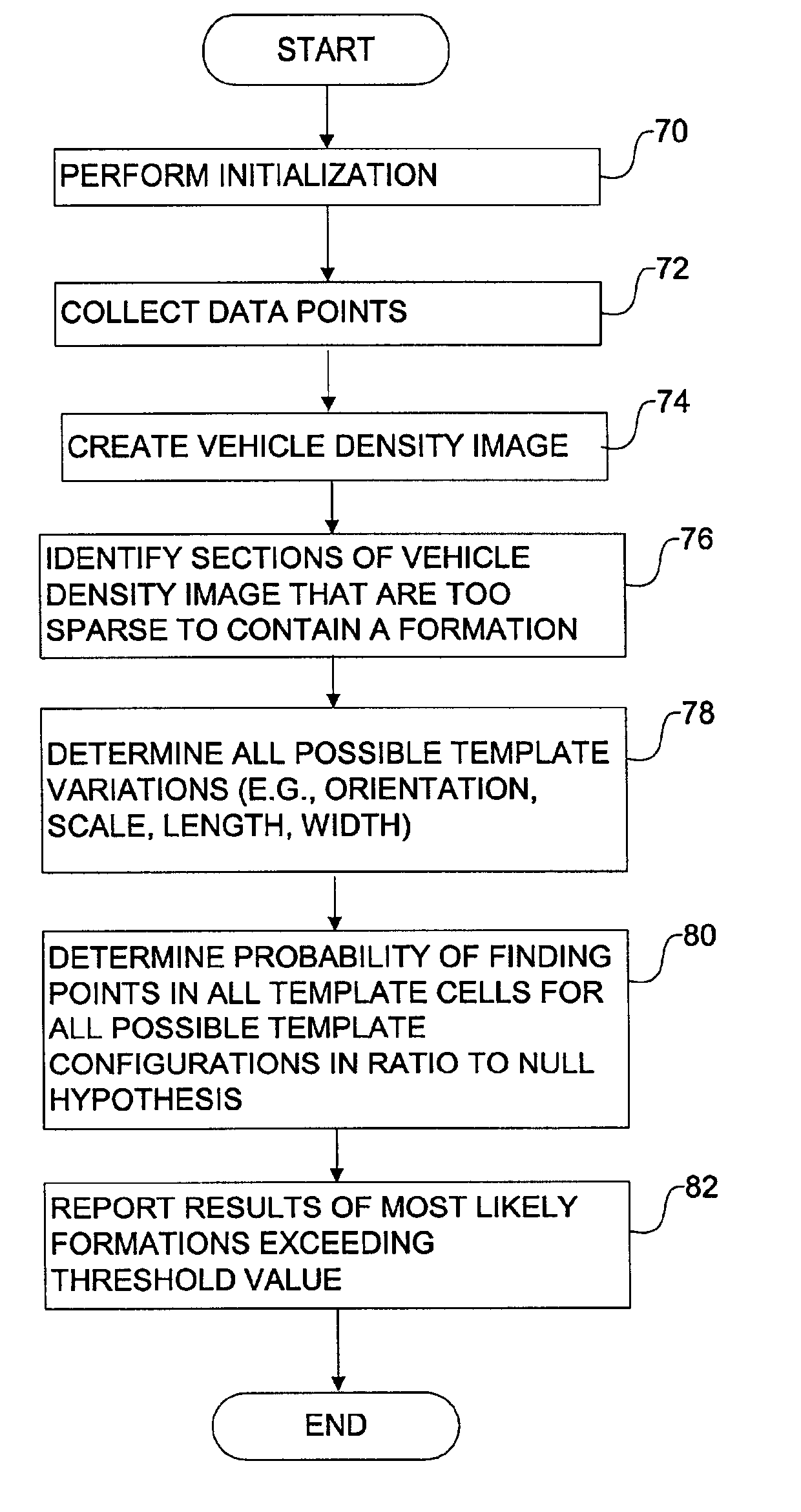

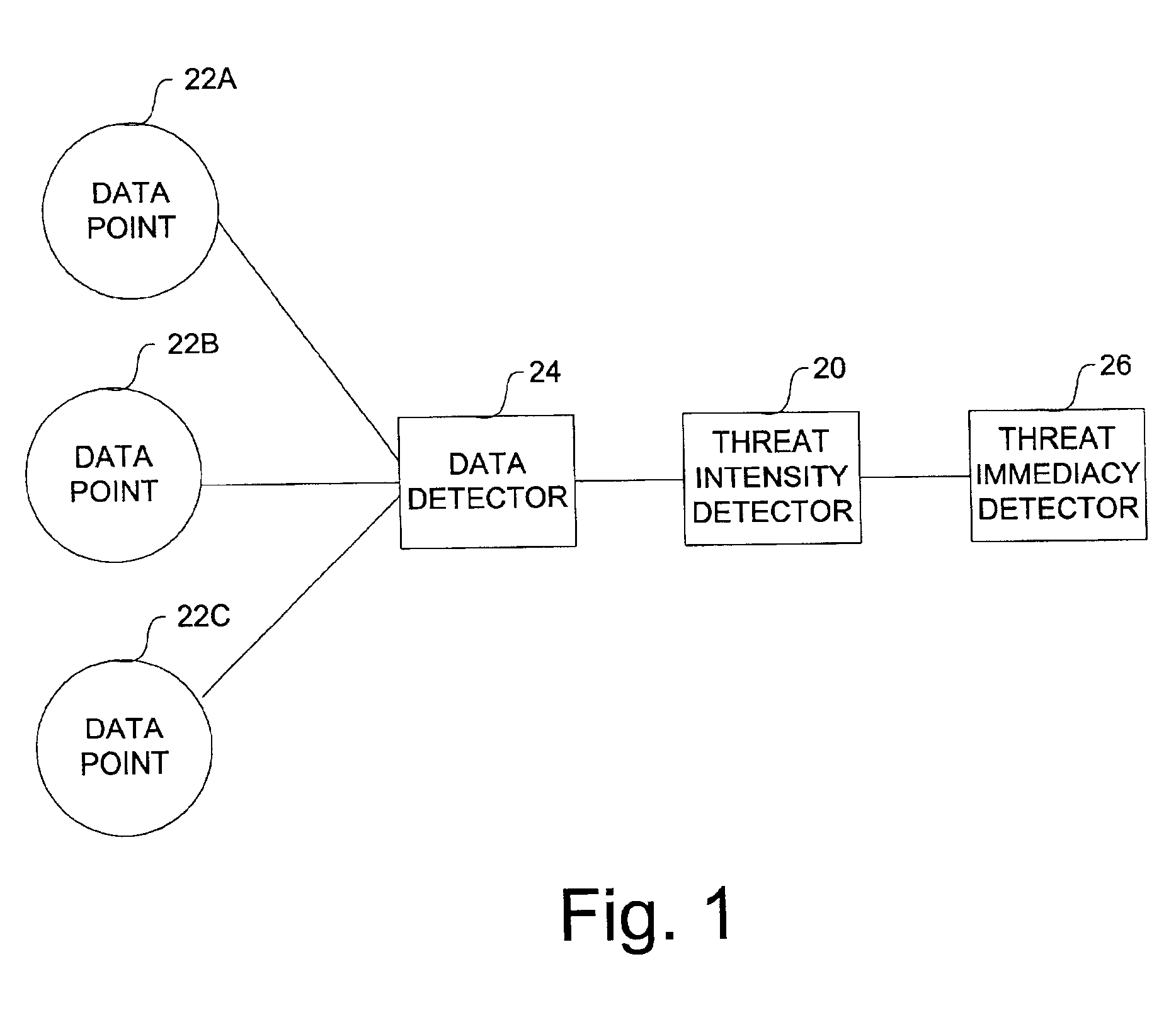

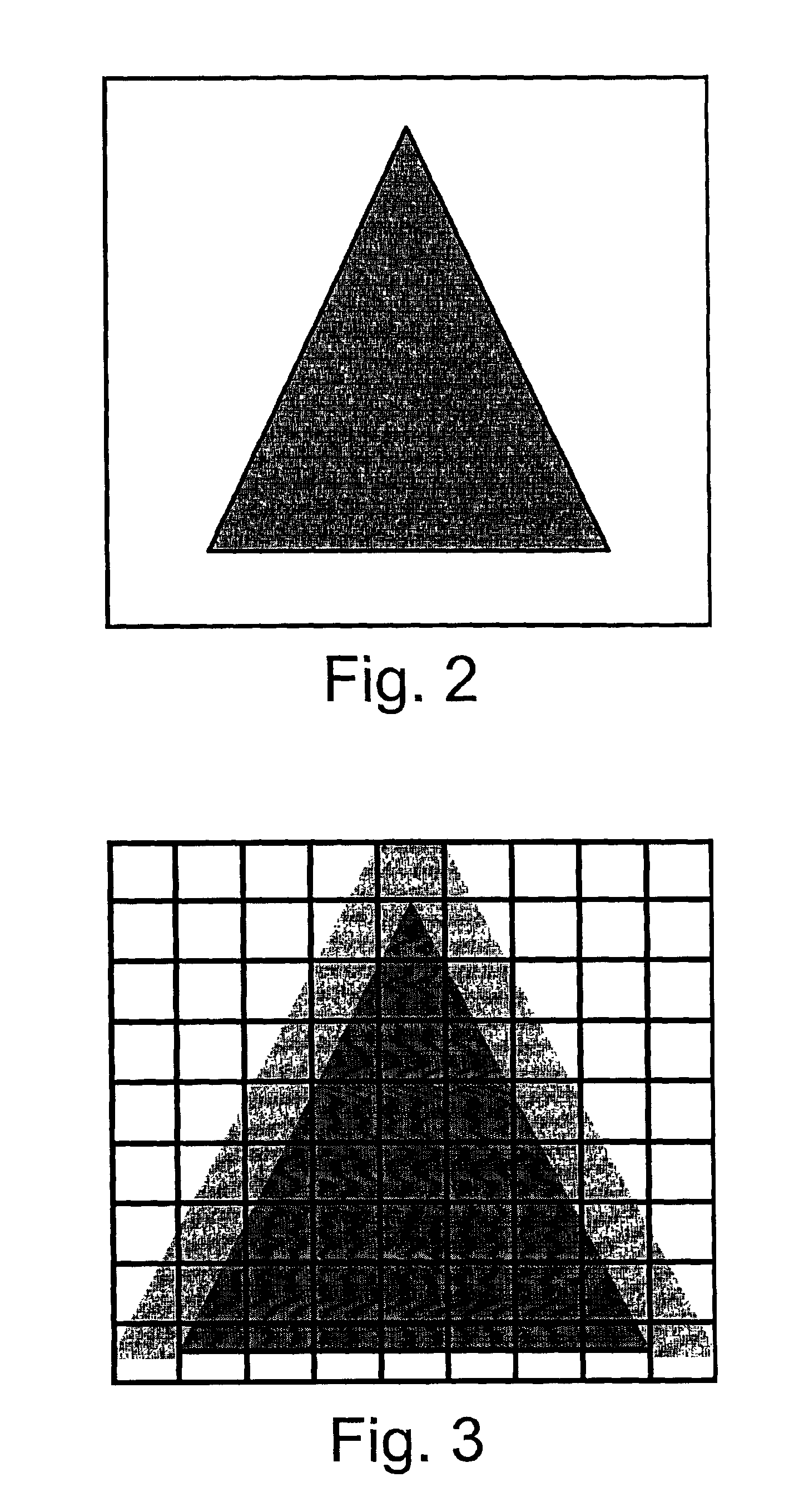

System and method for automatic recognition of formations in moving target indication data

InactiveUS6937746B2Wave based measurement systemsCharacter and pattern recognitionHypothesisAlgorithm

A system and method for determining a threat level associated with a collection of detected objects within a geographical area of interest are disclosed. A set of formation templates representative of organizational patterns are defined. Configurations for the templates are defined. Data is collected from objects detected in the area of interest. A density image is generated based on the geographic locations of the detected objects. Sections of the density image that are too sparse to contain a formation are determined and excluded from further analysis. The density image is compared to each of the template configurations. The probability of finding points in each of the template cells for each of the template configurations is determined. The probable formation(s), if any, based on the probability of finding points in each of the template cells for each of the possible configurations of each of the possible templates is determined. If this probability is greater than the null hypothesis (no formations), probable formation(s), if any, are reported.

Owner:NORTHROP GRUMMAN SYST CORP

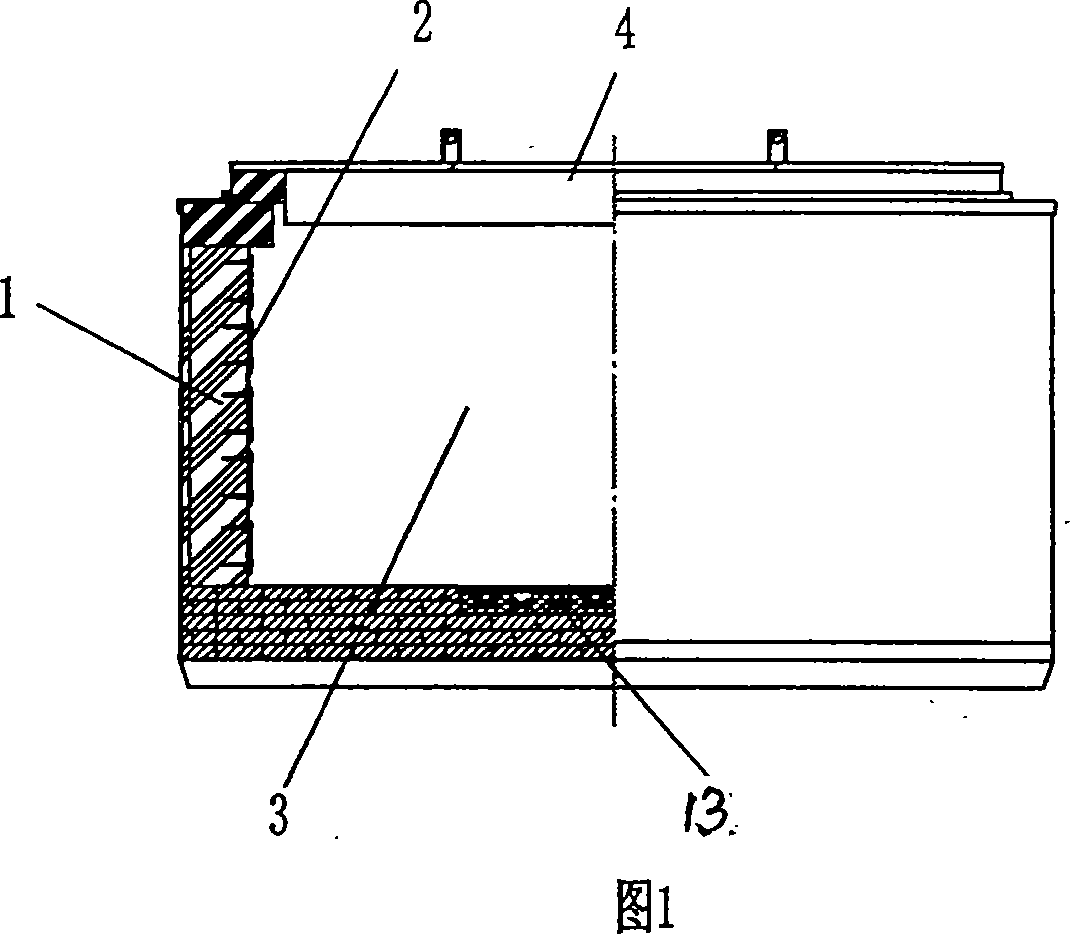

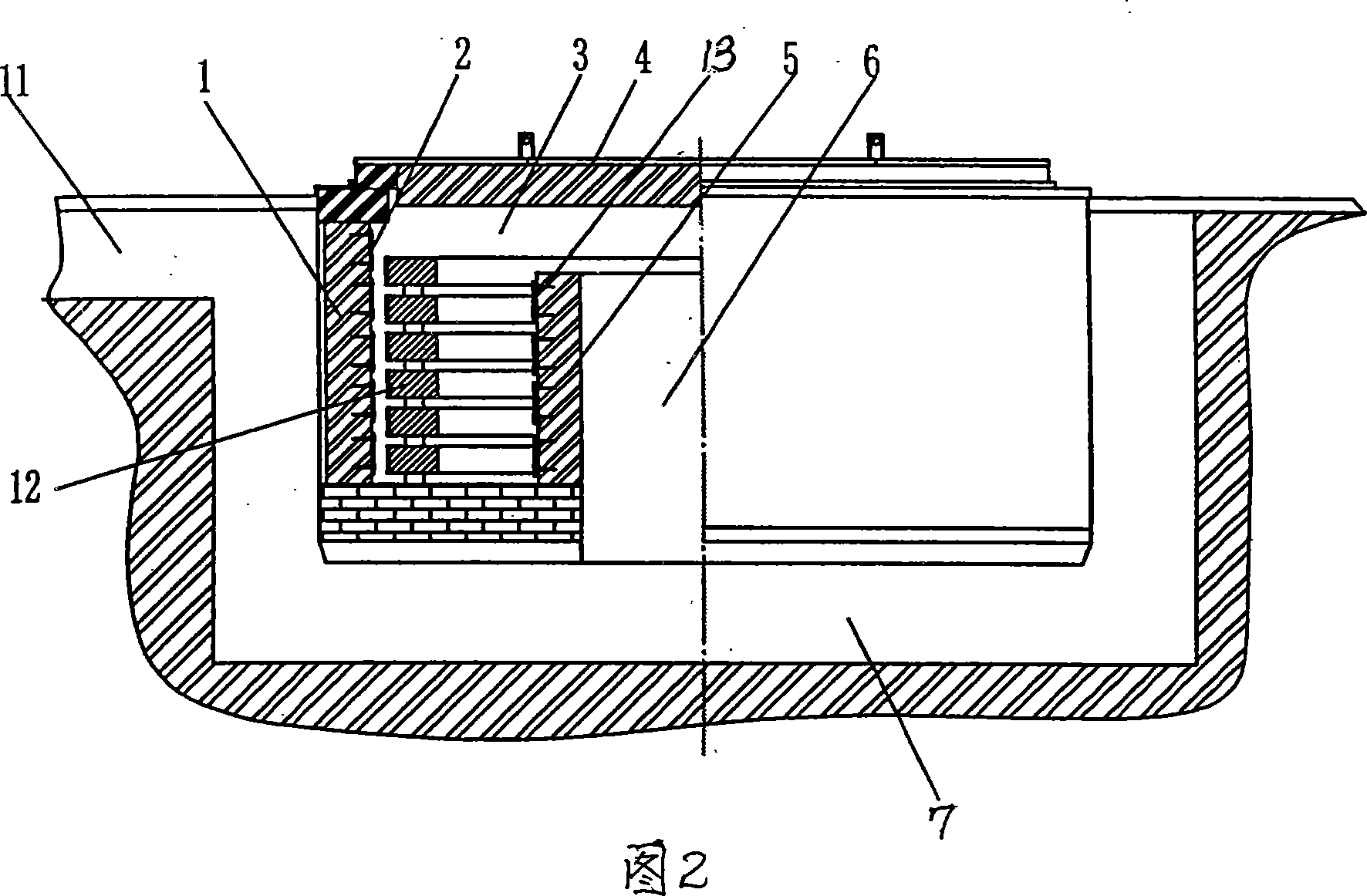

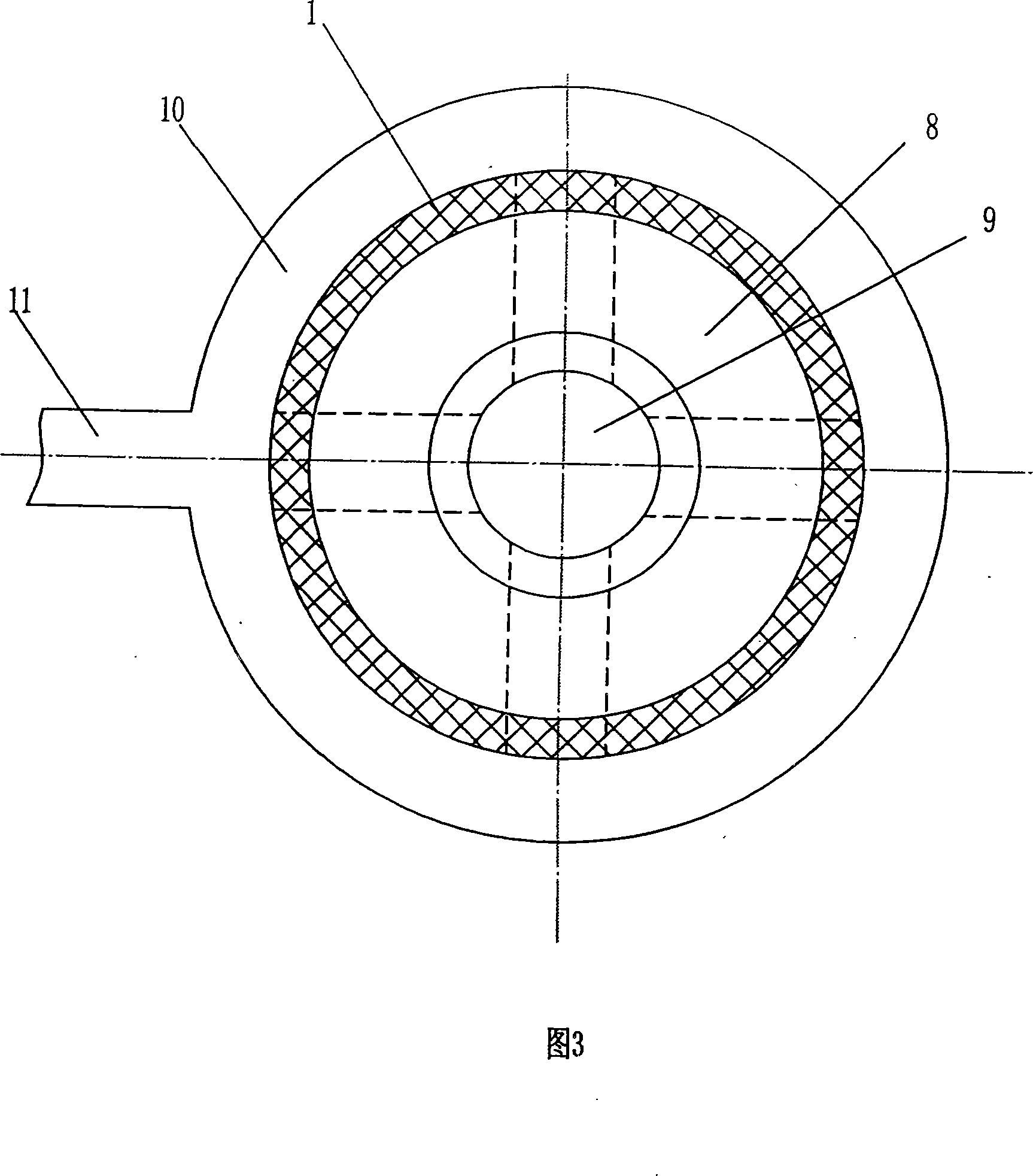

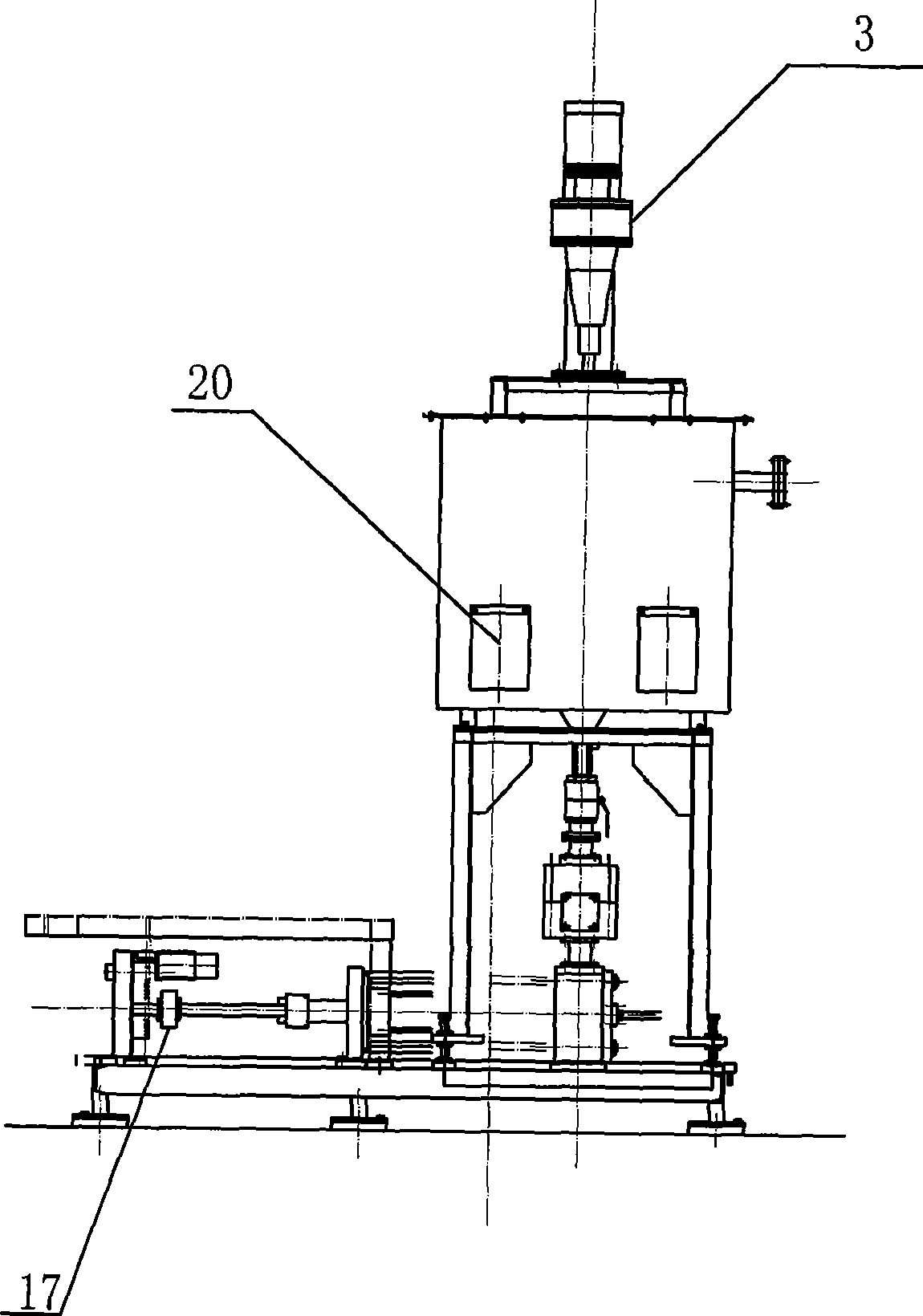

Heat treatment of large-circular piece welling heat-treating furnace and wind-forced generating tower drum flange

ActiveCN101074456AEvenly heatedPrecise temperature controlFurnace typesHeat treatment process controlHearthEngineering

A heat-treatment furnace and method for metal work pieces are disclosed. The heat-treatment furnace is a large circular well-shaped heat-treatment furnace, and process adopts wind-forced generating tower column flange; electric heater is placed inside original hearth. The process is carried out by heating to 600-650 degree for 2 hrs, reheating at 870-910 degree for 1 min, reheating to 920-930 degree for 20 mins, taking out of furnace, air cooling, tempering, heating to 540-560 degree for 2 mins, taking out of furnace and air cooling. Wind-forced generating tower column flange's raw material is Q345E: -40 degree, AKV is between 110-130J. It has homogeneous heating, less consumption, long life and no formation.

Owner:兰鹏光

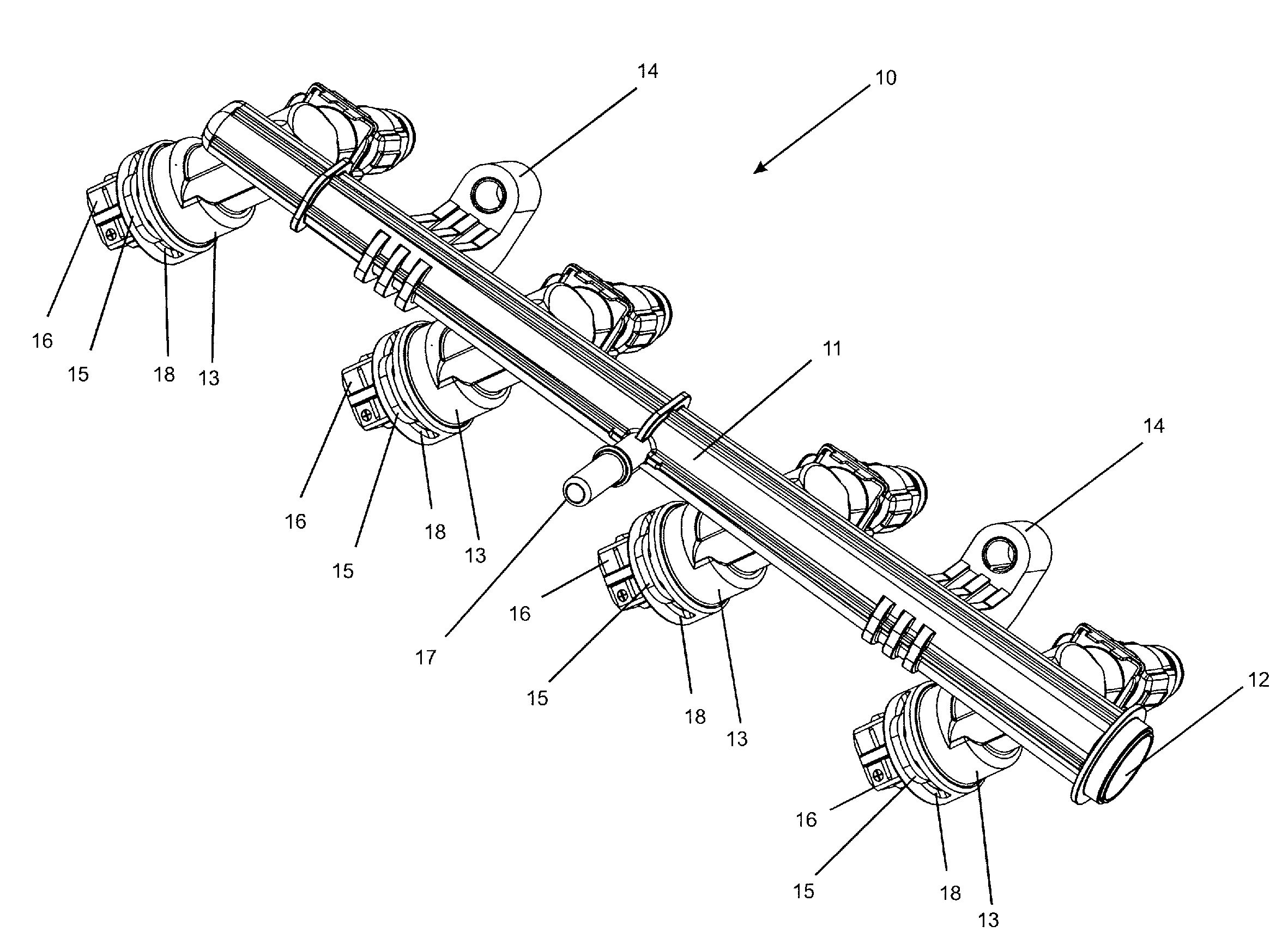

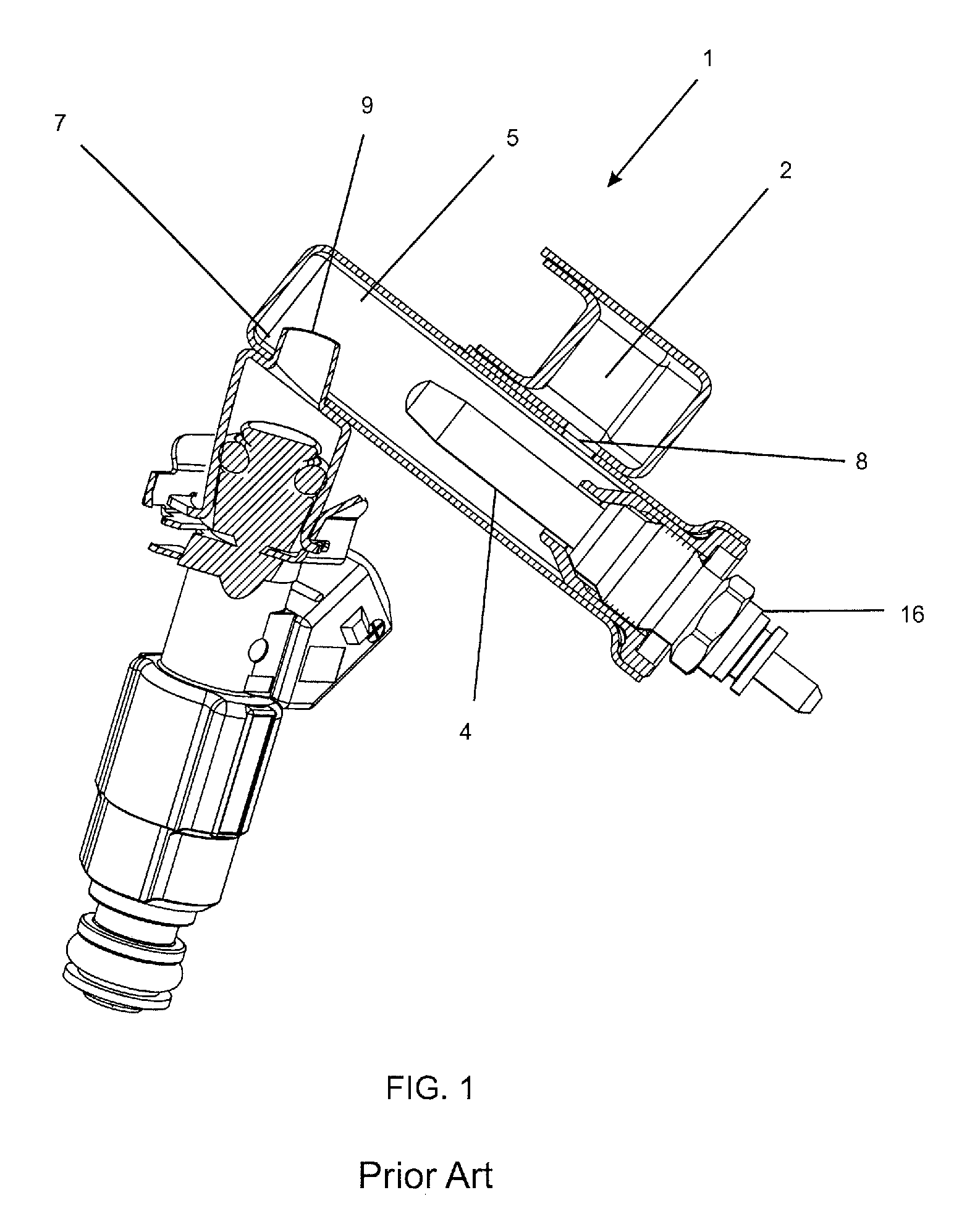

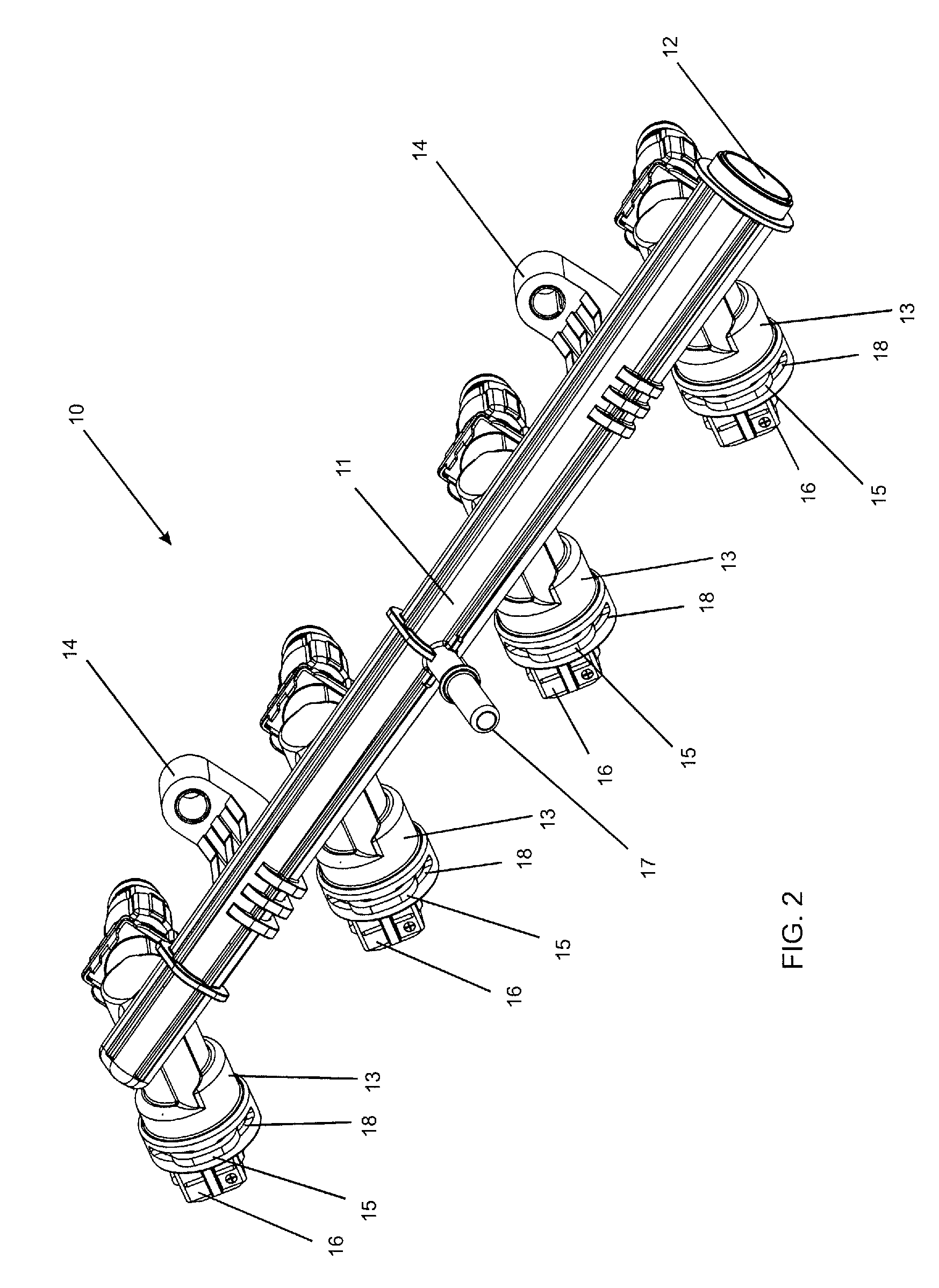

Fuel rail made of a plastic material with a heating system

ActiveUS9303606B2Low costSame functionElectrical controlLow-pressure fuel injectionAlcoholPlastic materials

The present invention refers to a fuel rail made of plastic material with a heating system (10,100). The said rail is applied, mainly, in the form of devices for aiding the cold start of engines which consume fuels whose specific vaporization heat is high, for example, alcohol. The fuel rail made of plastic material with a heating system presents reduced cost and weight and the same functional characteristics if compared to the fuel rails known by the state of the art, which are usually made of metal. Furthermore, the said fuel rail made of plastic material with a heating system presents internal compartments configured in such a manner that the sliders containing slide pins (51, 52, 53) of the injection mold can be easily removed, since there is no formation of negative faces.

Owner:ROBERTBOSCH LTDA

Tissue culture rapid propagation method of salvia miltiorrhiza bge

InactiveCN103798137AExpand and grow normallyImprove survival rateHorticulture methodsPlant tissue cultureAxillary budSalvia miltiorrhiza

The invention discloses a tissue culture rapid propagation method of salvia miltiorrhiza bge. The method comprises the steps of selecting explants, treating the explants, carrying out inoculation induction culture, carrying out rooting culture, carrying out bottle cap-opening hardening seedling for 3-5 days, and planting; after the method is used for inoculation, the explants are high in survival rate; plantlets germinated from axillary buds induced in a culture medium are robust, the nodes are obvious, new leaves are normal to spread and grow, the new leaves of the salvia miltiorrhiza bge are emerald green, have no formation of the callus, and have no generation of vitrification and browning; after the method is used for propagating the salvia miltiorrhiza bge, the salvia miltiorrhiza bge is high in survival rate, and the batch and rapid propagation can be realized.

Owner:WEIFANG VOCATIONAL COLLEGE

Normal-temperature air wet oxidation catalyst used for residuum processing wastewater deodorization reuse

InactiveCN103240092AEfficient removalReduce CODMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationElectrical conductorRare earth

The invention relates to a normal-temperature air wet oxidation catalyst used for residuum processing wastewater deodorization reuse. The catalyst is characterized in that the catalyst is obtained by treating active alumina as a carrier and a transition metal element as a main active component through a fractional deposition-immersion method, and the catalyst comprises 3.0-4.0wt% of a transition metal oxide, 1.0-2.0wt% of a rare earth metal oxide and 7.8-8.8wt% of a semiconductor metal oxide. The catalyst has the advantages of good deodorizing effect, effective removal of sulfides and ammonia nitrogen in wastewater, reduction of the COD of the wastewater, regeneration performance, reusability, no formation of new pollution, mild operation condition, and substantial reduction of the deodorization cost of the wastewater through utilizing air as an oxidant.

Owner:ZHEJIANG OCEAN UNIV

Copper alloy for drawing mould and preparation method thereof

Copper alloy for drawing mould is characterized by comprising following chemical components by weight: 10-12 parts of aluminum, 2.2-2.4 parts of magnesium, 4-5 parts of zinc, 1.2-1.4 parts of boron, 0.2-0.4 part of titanium, 1-1.3 parts of manganese, 2.1-2.3 parts of Be, 0.07-0.09 part of La, 0.06-0.09 part of Ho, 1.1-1.3 parts of Ni and the balance of copper. The copper alloy provided by the invention has advantages of good anti-sticking effect, no formation of a bonding tumor, no scratch of a drawing product, reduction on the mold repair time, small friction coefficient, low wear rate, great extension on the service cycle, no requirement on polishing or heat treatment, and easiness for mechanical processing.

Owner:SANLIAN PUMP IND CO LTD

Antifog thinned high-toughness heat shrinkable packaging color film

InactiveCN103935094ADoes not reduce impactHigh strengthSynthetic resin layered productsEngineeringThinning

The invention relates to an antifog thinned high-toughness heat shrinkable packaging color film. The antifog thinned high-toughness heat shrinkable packaging color film is composed of an upper layer, a middle layer and a lower layer. The upper layer and the lower layer are both made of a mixture containing metallocene MPE, LDPE, LLDPE and an additive; and the middle layer is made of a mixture containing LDPE, MDPE and HDPE. As the upper layer and the lower layer have a high metallocene content, the purpose of thinning by 20% has no influence to the mechanical properties of the film. The additive is a mixture of a lubricant, a plasticizer and an antifogging agent. The antifogging agent enables no formation of water mist after freezing of the product, thus increasing the optical properties and exhibition effect of the film. The middle layer employs about 40% medium density MDPE, and under the premise of ensuring the rigidity, the mechanical properties and optical properties of the film are increased. In general, under the premise of ensuring normal use, the raw material consumption is reduced, and consequently the production cost is reduced.

Owner:JIANGSU SHENQIAN PRINTING

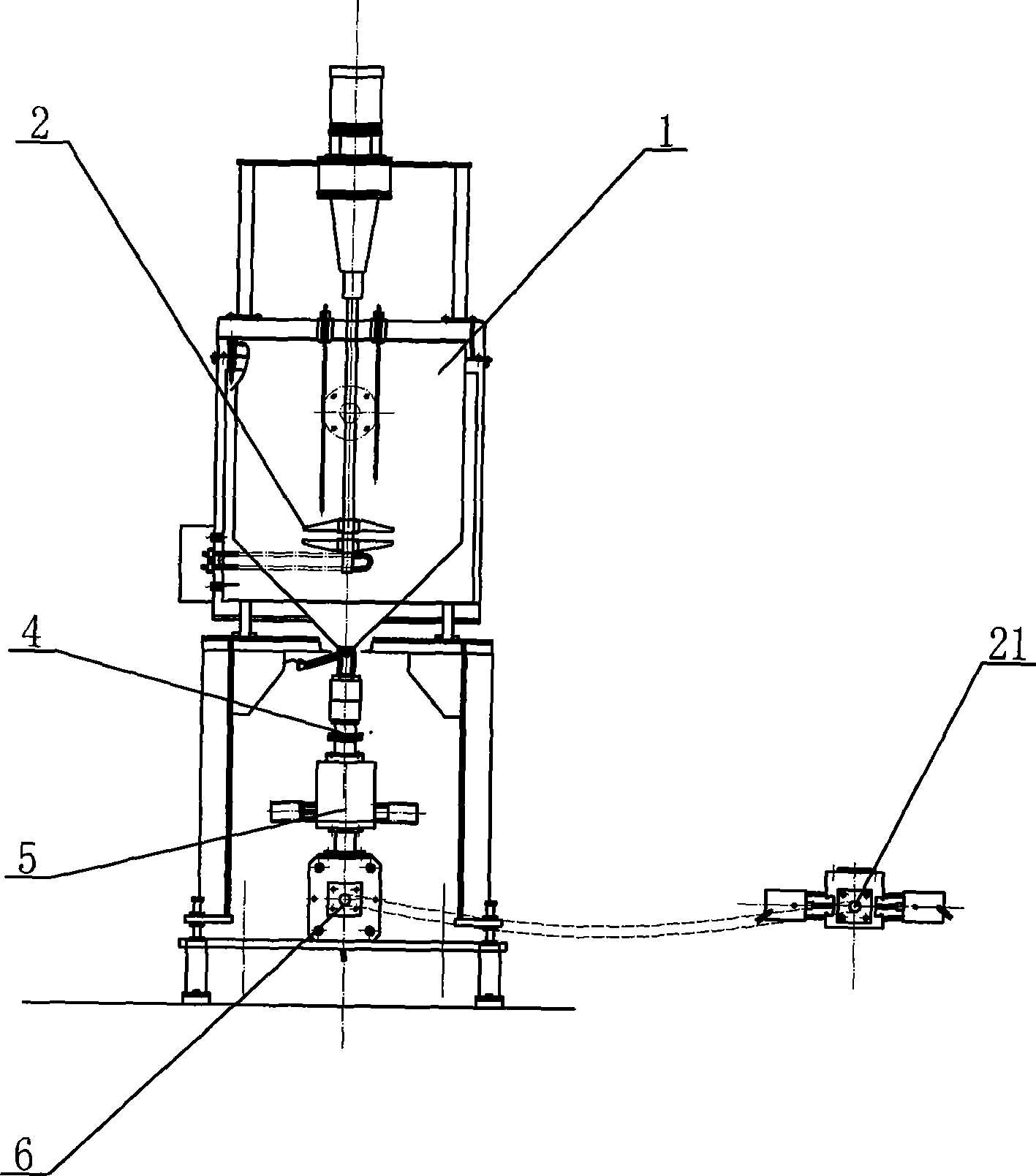

Material injecting device of magnetic material hydraulic press

The invention discloses a material injecting device of a magnetic material hydraulic press, which comprises a feed cylinder, an agitating device and a material injecting cylinder. An agitating device is arranged in the feed cylinder; the material injecting cylinder is connected with the feed cylinder; an automatic compensation and adjustment device for material injection amount is arranged on the material injecting cylinder and adopts the structure that a piston rod is arranged on two sides of the material injecting cylinder respectively; both the piston rod and the piston rod of the material injecting cylinder are fixedly connected with a slide block; and the slide block is also connected with an adjusting device. The material injection amount can be adjusted automatically by the automatic compensation and adjustment device for the material injection amount, so that the material amount required for the formation of finished products in a die cavity is satisfied; the integrative formation of products overflowed and damaged by excessive material amount and the no-formation of the products caused by lower material amount are prevented, and the production efficiency of the products is improved.

Owner:NANTONG GAOYE HEAVY IND CO LTD

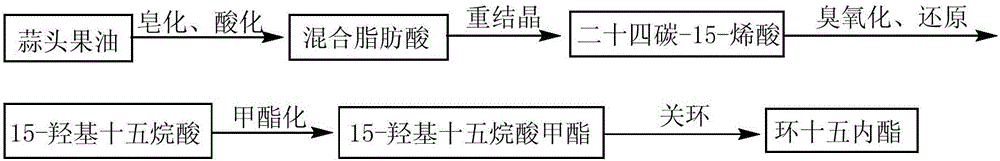

Method for synthesis of macrocyclic musk lactone

A method for synthesis of senior spice high-value musk spice cyclopentadecanolide (macrocyclic musk lactone) from malania oleifera oil is provided; the cyclopentadecanolide is prepared by taking the malania oleifera oil as raw material through saponification, acidification, recrystallization, ozonization, reduction, esterification and ring closing. The method has the advantages of high yield, good benefits and low cost, and overcomes the defects of complex production process, relatively low yield, relatively high cost and no formation of market advantages in the prior art. The malania oleifera oil contains 40%-60% of 15-tetracosenic acid, and is an ideal raw material for synthesis of the high-value musk spice. The 15-tetracosenic acid is an essential nutrient for brain development, has important roles in improving the cranial nerve activity and preventing encephalasthenia, has good curative effect on cardiovascular and human body autoimmune deficiency diseases, and can be used as medicines and health care products.

Owner:昆明酷特利生物科技有限公司

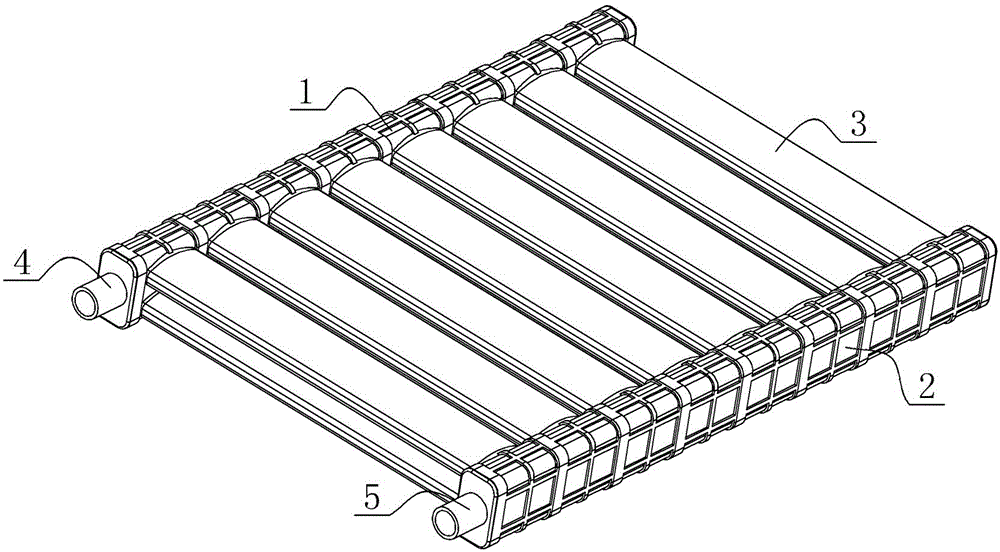

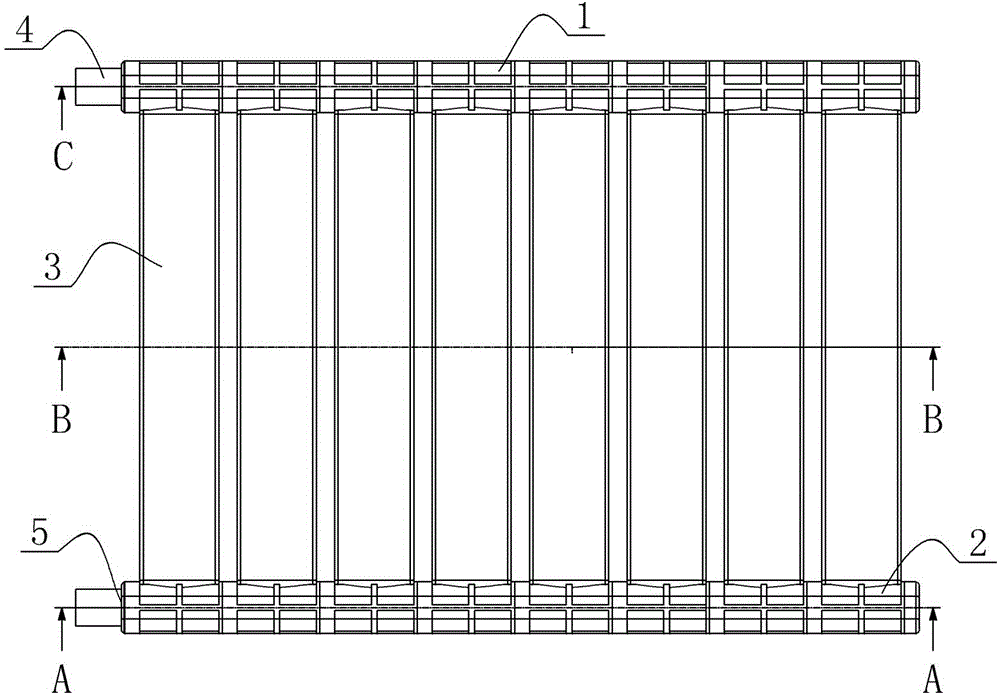

Full-plastic heat exchanger

ActiveCN104697382AInhibition formationForm noStationary conduit assembliesStationary tubular conduit assembliesLiquid mediumEngineering

The invention discloses a full-plastic heat exchanger. The full-plastic heat exchanger comprises an upper chamber and a lower chamber, each of the upper chamber and the lower chamber is provided with an interior storage cavity, a medium inlet convenient for entering of a heating or refrigerating liquid medium is formed in the upper chamber, and a medium outlet allowing the liquid medium to flow out after working is formed in the lower chamber. The full-plastic heat exchanger is characterized in that the upper chamber and the lower chamber are communicated with each other via a plurality of uniformly distributed heat exchange pipes, and the liquid medium flows along the heat exchange pipes to achieve heat exchanging. Compared with an existing metal heat exchanger, the full-plastic heat exchanger has the advantages the components such as the upper chamber, the lower chamber and the heat exchange pipes are made of plastic, so that scale formation prevention, no formation of heavy metal ions, corrosion resistance and no pollution to water are achieved; the full-plastic heat exchanger also has the advantages of low energy consumption in a production process, low in environment pollution and production cost, remarkable beneficial effect and convenience in application and promotion.

Owner:山东融合环保科技有限公司

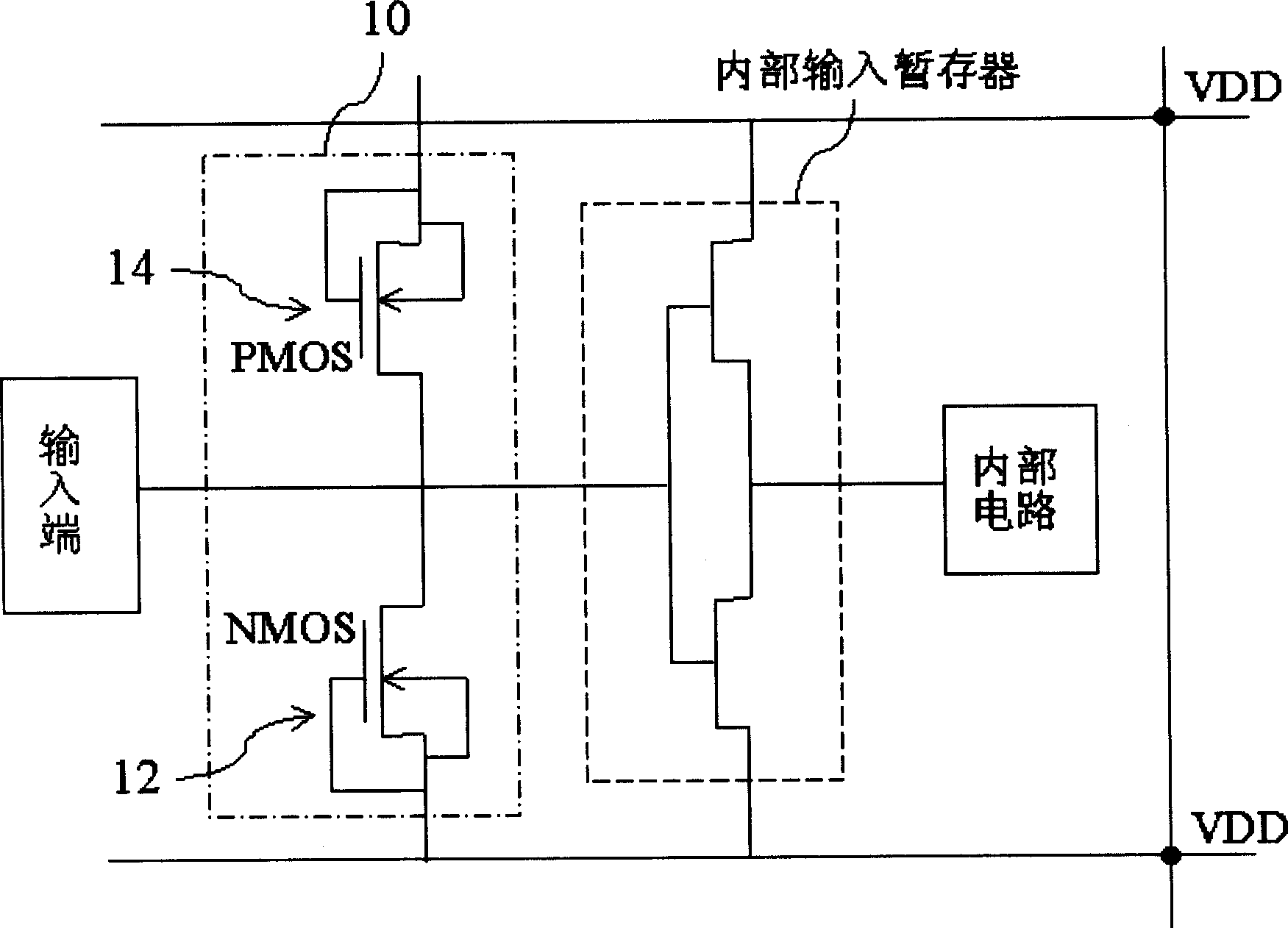

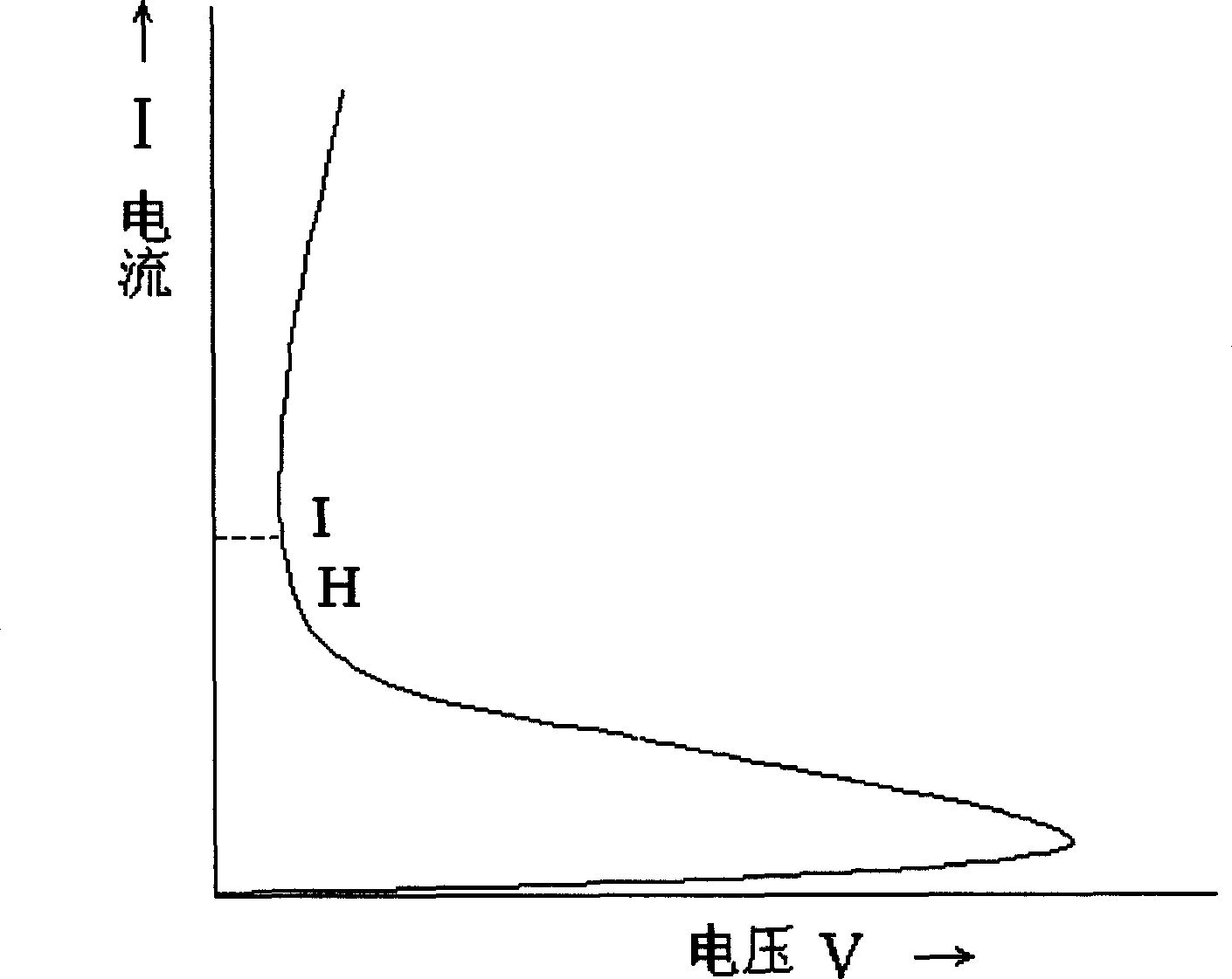

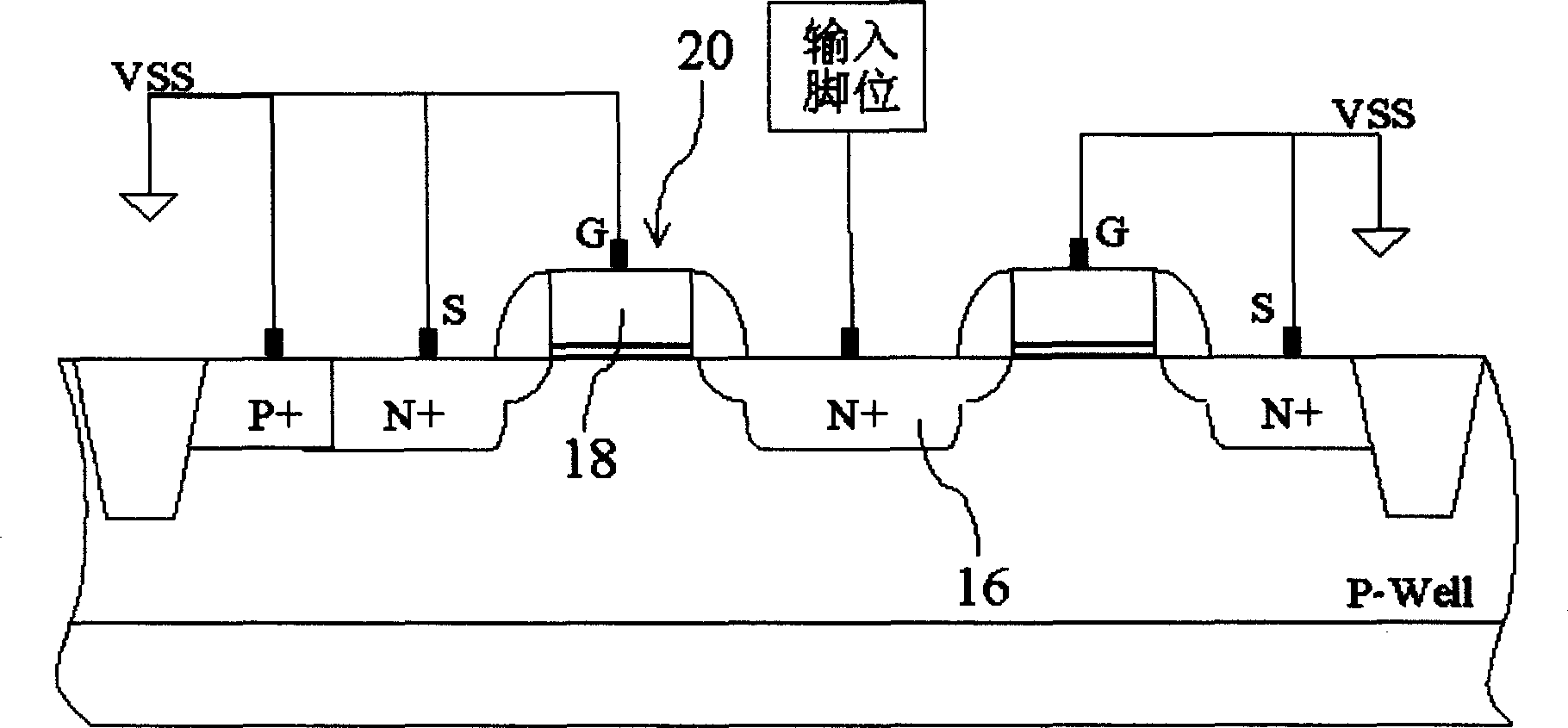

Method for mfg. electrostatic discharge protector by deep amicron process

InactiveCN1591860AAvoid heatingAvoid destructionSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceMetal silicide

The present invention provides a making method of electrostatic discharge protection device by using deep submicrometer process. Because of that in deep submicrometer process, when the automatic alignment metal silicide is used in transistor source / drain region including electrostatic discharge (ESD) protection component, the nonuniform high current can make the electrostatic protection component be broken, in order to improve said problem, said invention can adopt the automatic alignment metal silicide separation mode to make the electrostatic discharge protection component region have no formation of metal silicide, and make the drain be contacted to a resistance buffer region existed in polycrystalline silicon gate, and can make the high current produced by electrostatic discharge can be removed by utilizing an uniform mode so as to prevent the electrostatic discharge protection structure from being broken.

Owner:GRACE SEMICON MFG CORP

Yellowing-free polyurethane matte varnish

InactiveCN104356930AGood priceNot easy to producePolyurea/polyurethane coatingsMethyl carbonateTrimethylolpropane

The invention relates to yellowing-free polyurethane matte varnish. The yellowing-free polyurethane matte varnish is characterized in that a host of the yellowing-free polyurethane matte varnish comprises soybean oil modified alkyd resin, mixture of butyl acetate and propylene glycol monomethyl ether acetate, a defoaming agent, a levelling agent, an anti-settling agent, extinction powder and an anti-yellowing auxiliary, a curing agent comprises toluene diisocynate (TDI) tripolymer, a toluene diisocynate (TDI)-trimethylolpropane addition product and butyl acetate, and a diluent comprises butyl acetate, dimethyl carbonate, propylene glycol monomethyl ether acetate and dimethylbenzene. By adopting the technical scheme, the yellowing-free polyurethane matte varnish has the beneficial effects that the yellowing-free polyurethane matte varnish is applied to surface finishing of woodware; spraying mode is adopted during coating, the yellowing-free polyurethane matte varnish has the characteristics of high hardness, good fullness, strong adhesion and no formation of bubbles and pinholes and has the prominent characteristics that drying speed is high, especially low-temperature drying performance is good, cost is low, matting property is good and transparency is excellent as compared with the yellowing-free polyurethane matte varnish used in the current market.

Owner:上海展辰涂料有限公司 +4

Cushion-like shaped body and use thereof

A cushion-like shaped body (1) having an elastic, gel-like filling (2) in a thin-walled outer layer (3) are frequently used as seals, cushions, vibration dampers or shape compensation materials. This shaped body (1) is to be able to withstand severe strains, distortions, compressions and flexural forces, both in the event of brief severe stress and in the event of prolonged stress. For this purpose, the cushion-like shaped body (1) has a filling (2) of a polyurethane having Shore 000 hardness less than or equal to 80 and a compression set less than or equal to 14%, and this filling (2) is present within a shell having an outer layer (3) of a soft silicone material having a layer thickness of 0.075 to 1 mm and a Shore A hardness between 3A and 45A. Such a shaped body (1) is able to return to its original form without lasting elongation after tensile strain at room temperature up to 250%. There is no formation of cracks, detachment phenomena, bubbles, folds or other lasting damage. The elongation does not cause visible detachment between filling (2) and outer layer (3).

Owner:TECHNOGEL GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com