Heat treatment of large-circular piece welling heat-treating furnace and wind-forced generating tower drum flange

A technology of heat treatment furnace and piece well type, which is applied in the direction of heat treatment furnace, heat treatment equipment, heat treatment process control, etc., can solve the problems of uneven heating, unsafe and reliable, high energy consumption, etc., achieve safe and reliable service life, and improve production qualification rate , the effect of accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

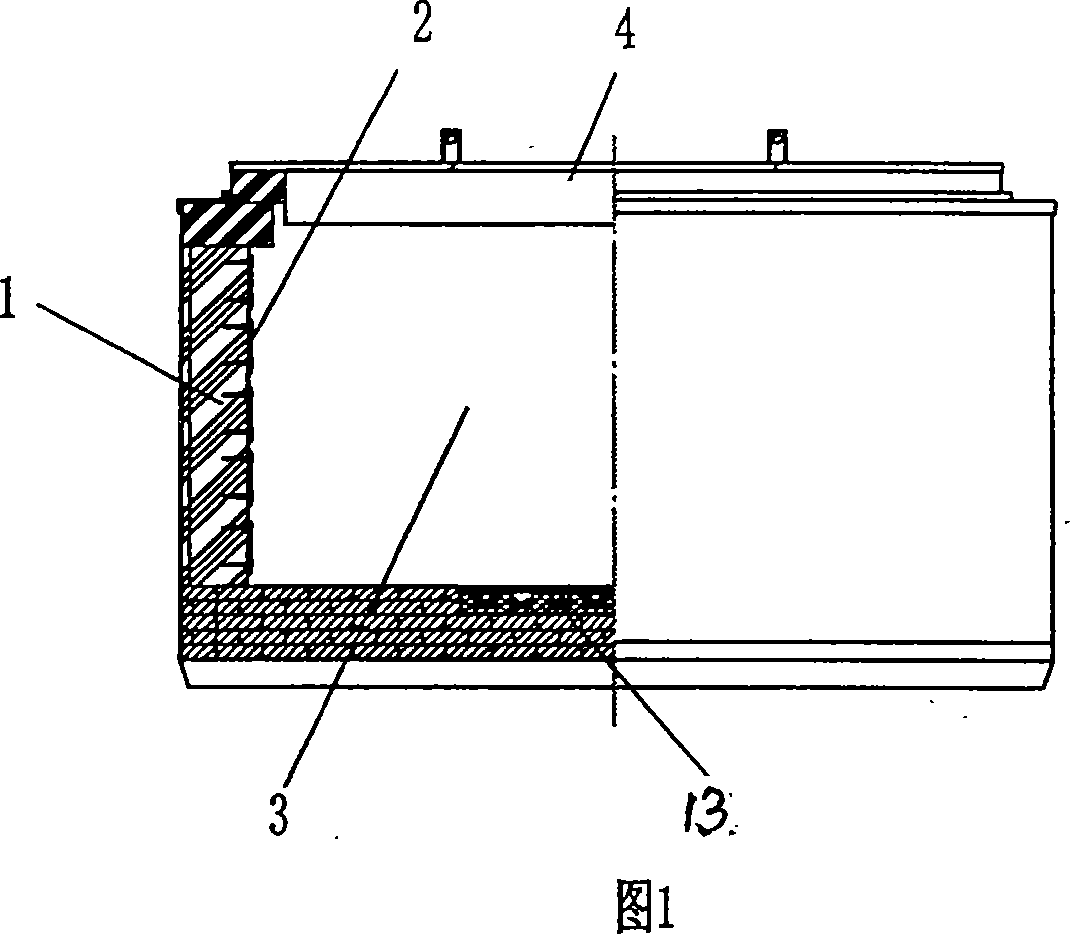

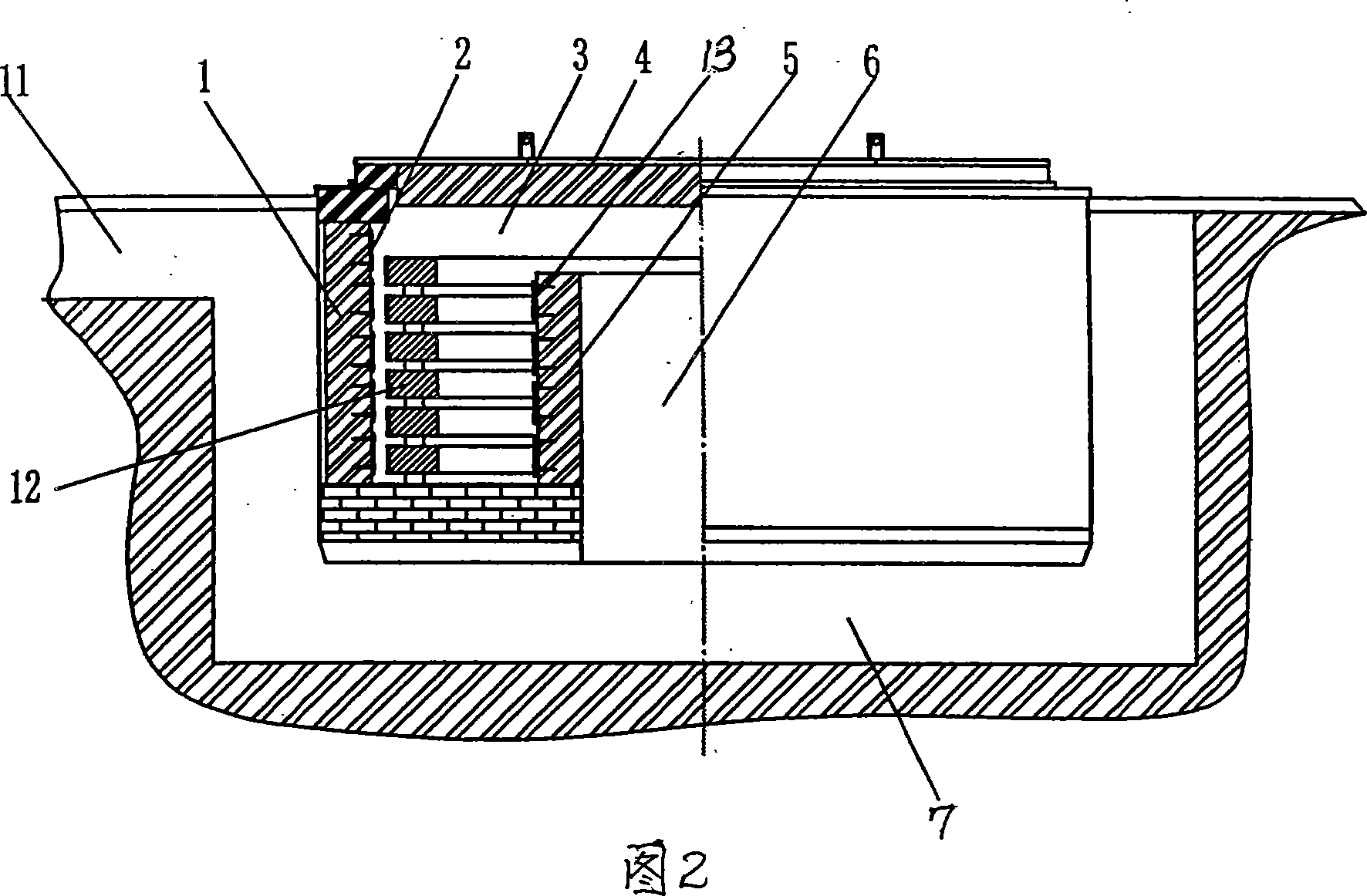

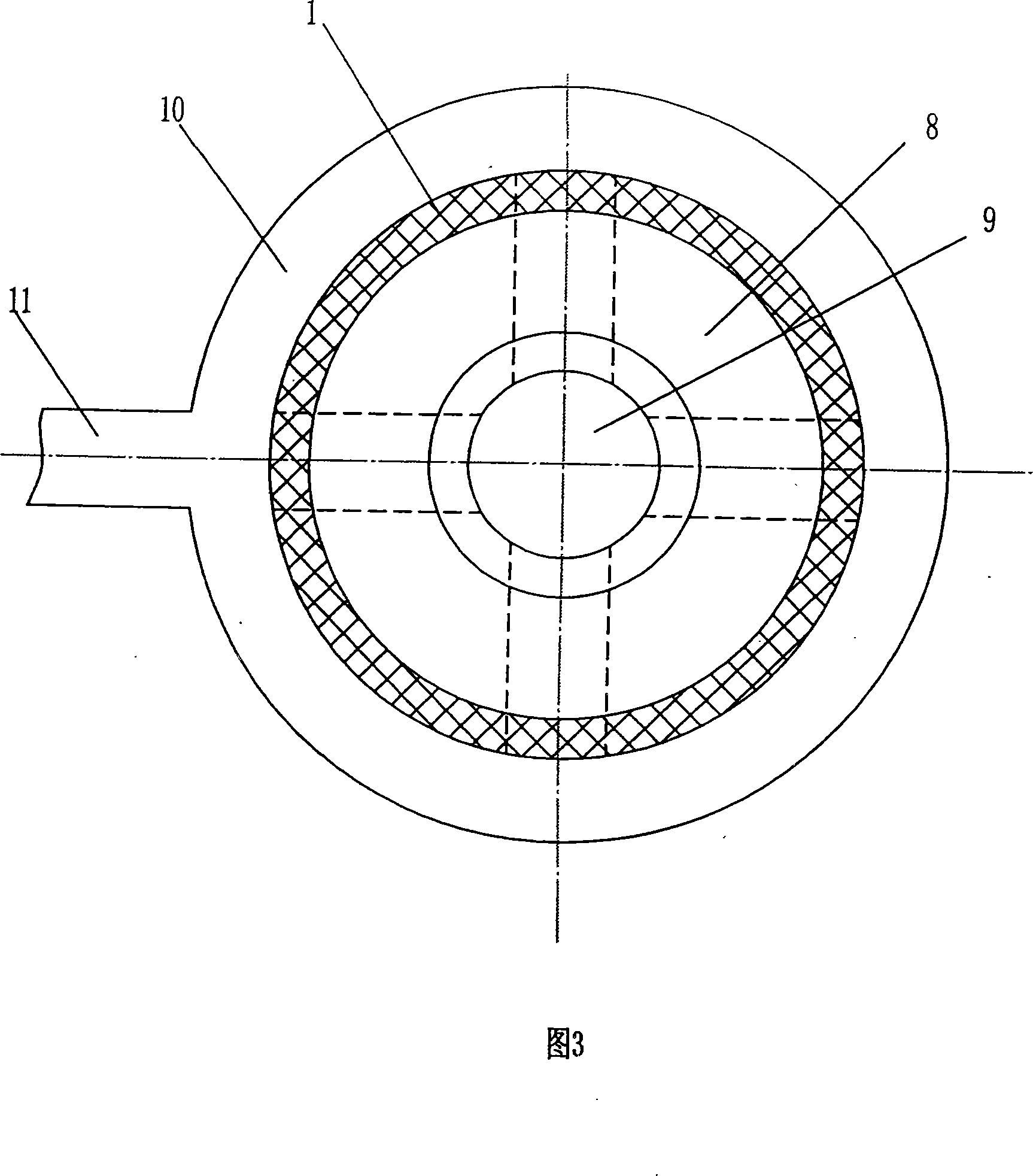

[0018] Large-scale annular well-type heat treatment furnace, including a cylindrical steel furnace body 1 made of refractory bricks as the furnace bottom and refractory fiber as the furnace lining, and an electric heater fixed on the refractory fiber lining on the inner wall of the furnace body with porcelain nails 2 (that is, resistance wire or electric heating rod), and a furnace cover 4 for closing the furnace 3 and being mounted on the top of the furnace body; an electric heater 13 is also provided in the furnace 3,

[0019] As shown in FIG. 1 , it is a schematic diagram of a large annular well-type heat treatment furnace with an electric heater installed at the bottom of the present invention. The electric heater 13 is installed in the bottom central area of the furnace 3 .

[0020] As shown in Figure 2, it is a large-scale ring-shaped well-type heat treatment furnace with an electric heater installed in the middle cylinder. Refractory fibers are also hung on the outer ...

Embodiment 1

[0025] Embodiment 1: The heat treatment process of the flange of the wind power generation tower, the specific process and steps are as follows:

[0026] (1) Furnace installation: It is required that the flanges should be placed horizontally between the flanges and supported at multiple points by support blocks, with a support height of 80-100mm, which is used to prevent flange heating deformation caused by improper furnace installation;

[0027] (2) Normalizing: First, heat the flange to 600°C in the furnace and keep it for 2 hours, then heat it to 910°C and keep it for h1 minute, and calculate the perimeter S dimension according to the average diameter d of the specific part , according to h1 = 1 ~ 1.4mm / min calculation, that is: S = πd, h1 = 1.4πd (minutes), wherein; Each piece of the flange is placed separately, so that a good cooling effect can be achieved;

[0028] (3) Tempering: heat the flange to 560°C in the furnace, hold it for h2 minutes, and calculate the circumfe...

Embodiment 2

[0030] Example 2, the specific steps are the same as Example 1, the difference is (2), normalizing: first, heat the flange to 650°C in the furnace and keep it for 2 hours, then heat it to 870°C, keep it for h1 minute, and then Heat to 930°C, keep for 20 minutes, take out the furnace and air cool; 3), tempering: heat the flange to 540°C in the furnace, and keep for h2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com