Patents

Literature

146results about How to "Good anti-sticking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

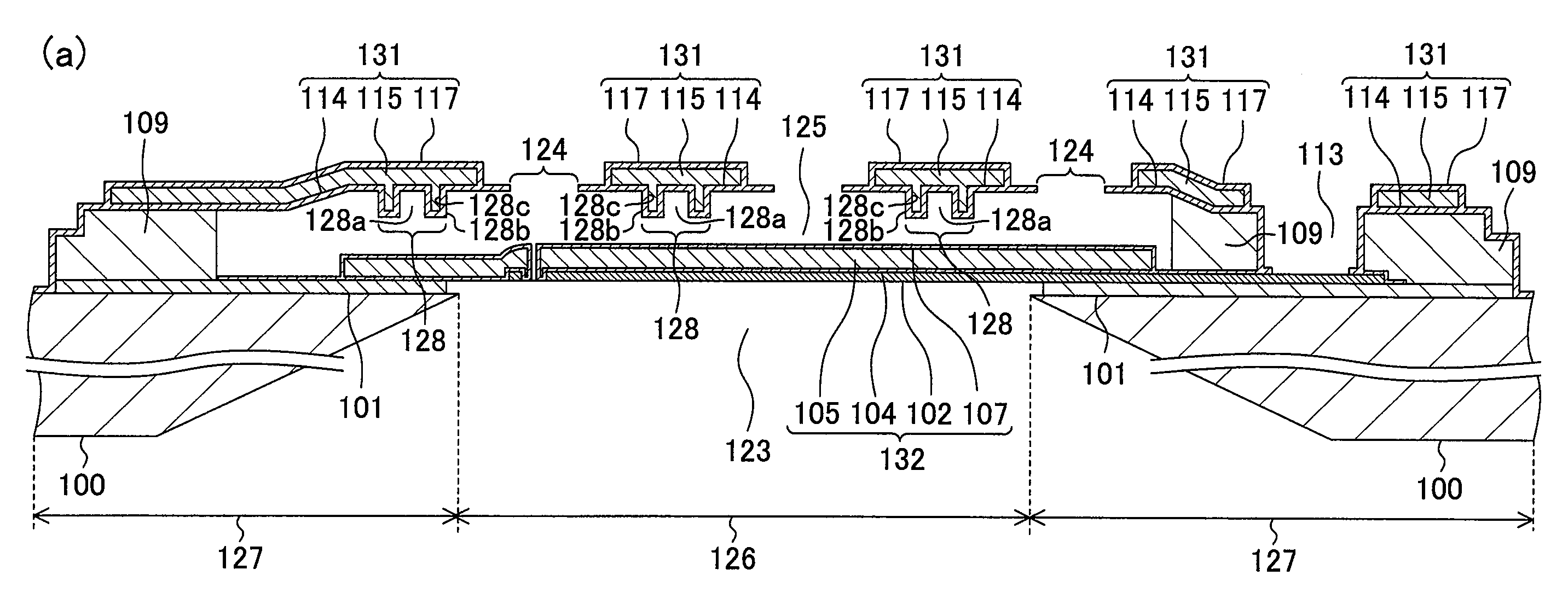

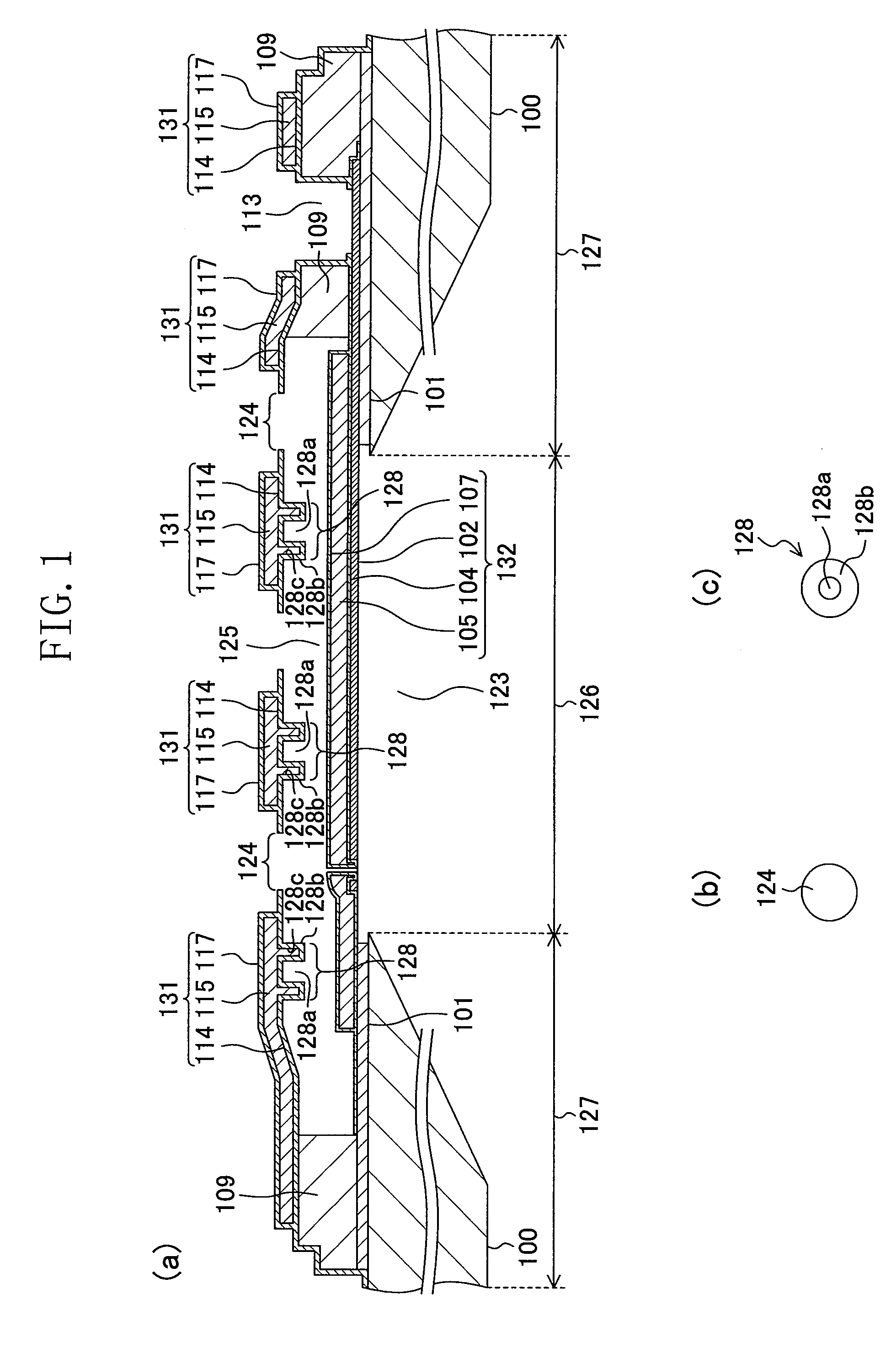

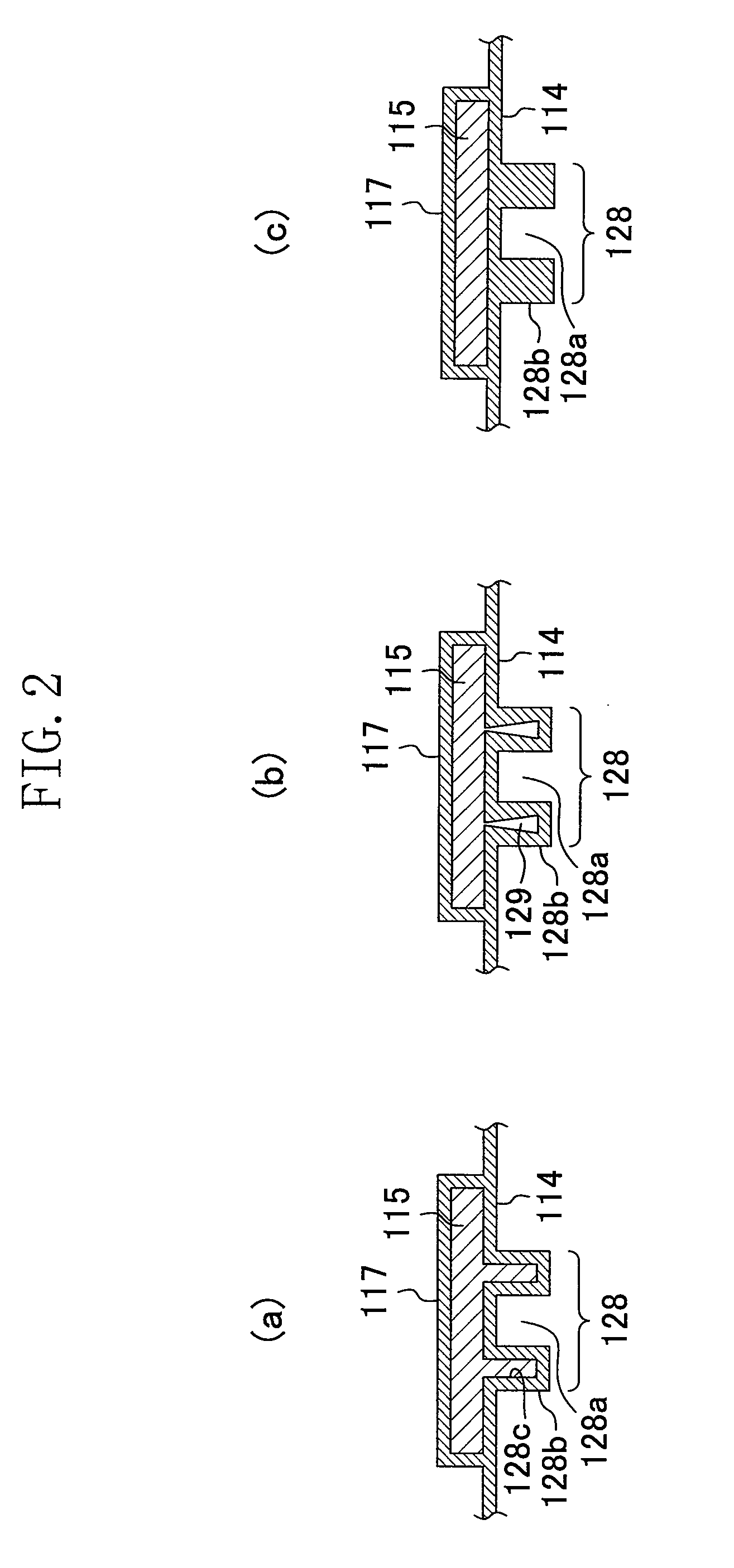

Condenser microphone and MEMS device

InactiveUS20100002895A1Excellent in sticking resistanceReduce contact areaElectretsElectrostatic transducersCondenser microphoneCapacitive microphone

Owner:PANASONIC CORP

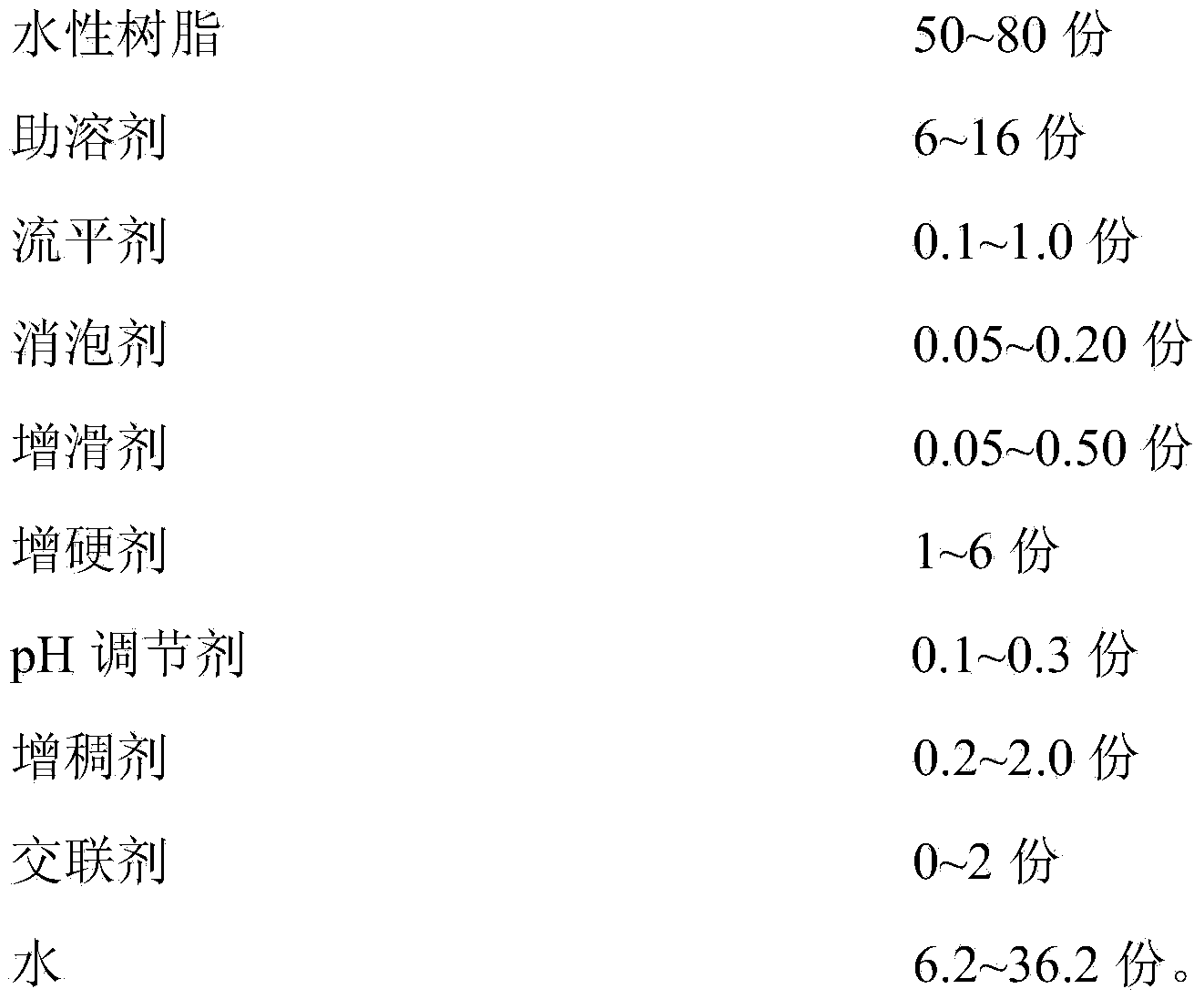

High-strength directly aluminizing water-based base coat and preparation method and application of high-strength directly aluminizing water-based base coat

ActiveCN103866607AGood sealingGood flexibilityNon-fibrous pulp additionPaper/cardboardWater basedWater vapor

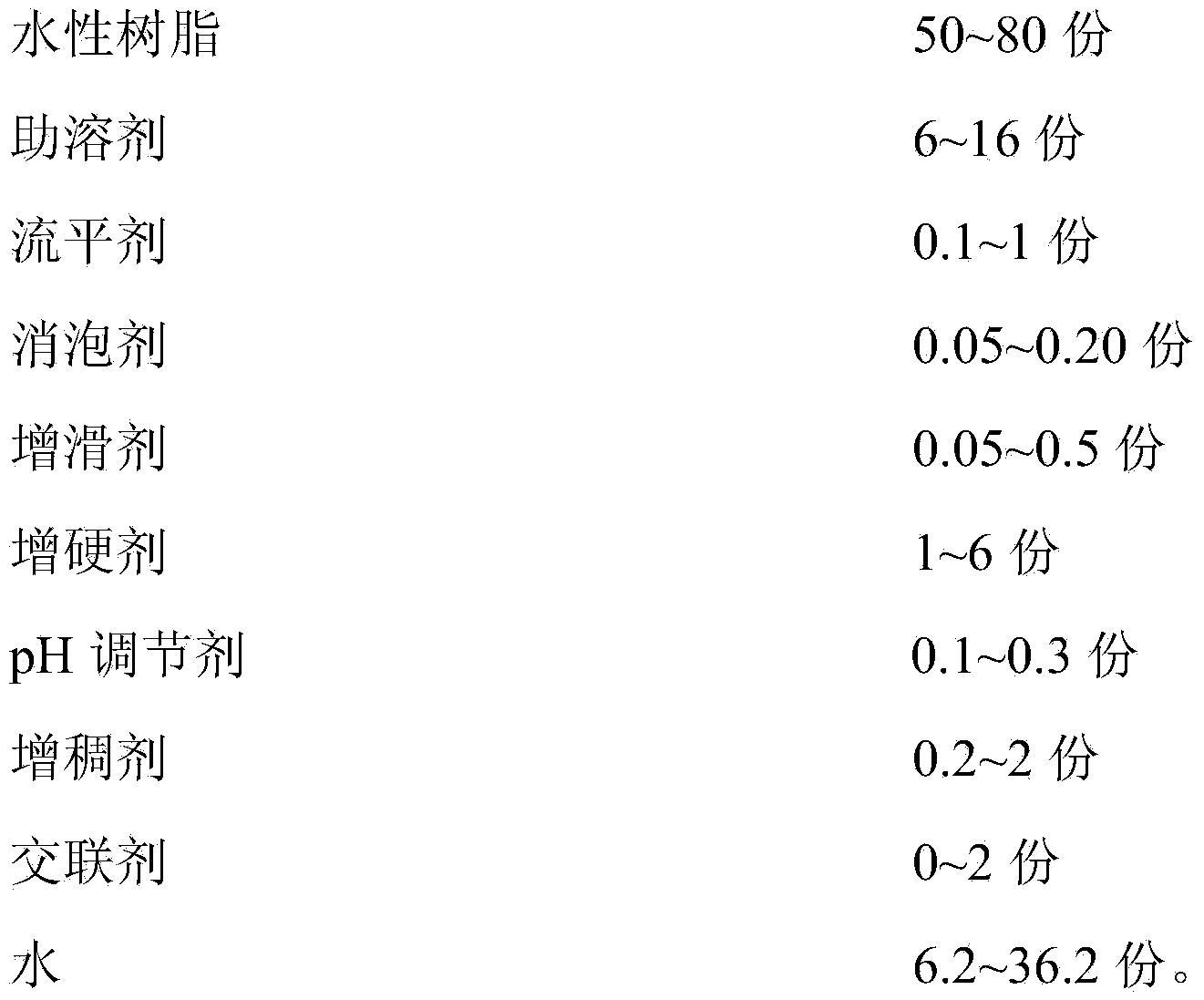

The invention discloses high-strength directly aluminizing water-based base coat and a preparation method and application of the high-strength directly aluminizing water-based base coat. The directly aluminizing water-based base coat comprises the following components in parts by mass: 50-80 parts of water-based resin, 6-16 parts of cosolvents, 0.1-1 part of flatting agents, 0.05-0.20 part of antifoaming agents, 0.05-0.5 part of slipping agents, 1-6 parts of hardening agents, 0.1-0.3 part of pH regulator, 0.2-2 parts of thickening agents, 0-2 parts of crosslinking agents and 6.2-36.2 parts of water. With good closure, the direct aluminizing water-based base coat disclosed by the invention guarantees the filling of micropores in the paper surface as well as the separation of water vapor; due to the characteristic of flexibility, the bending resistance of paper is realized; the viscosity resistance ensures that the film rolls are not bonded with each other after base coating on the aluminizing body paper; moreover, by adjusting the leveling property of the selected resin system and the coating, the base coat has high aluminizing metal texture.

Owner:GUANGZHOU HUMAN CHEM

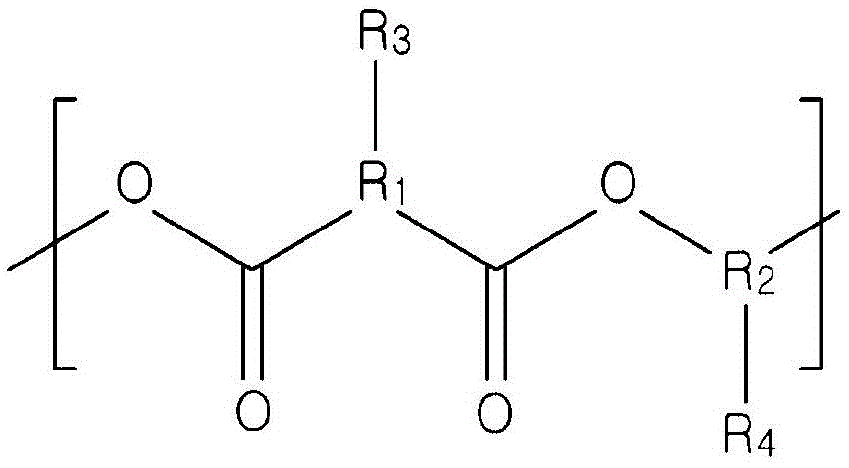

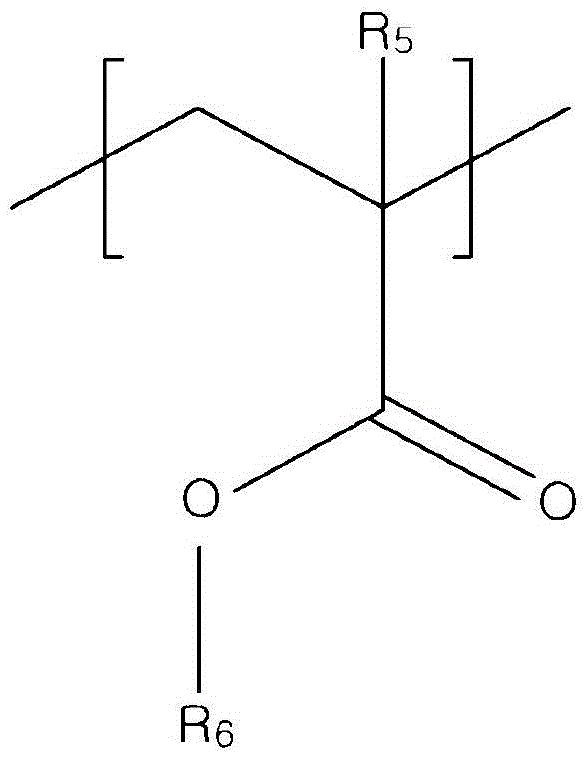

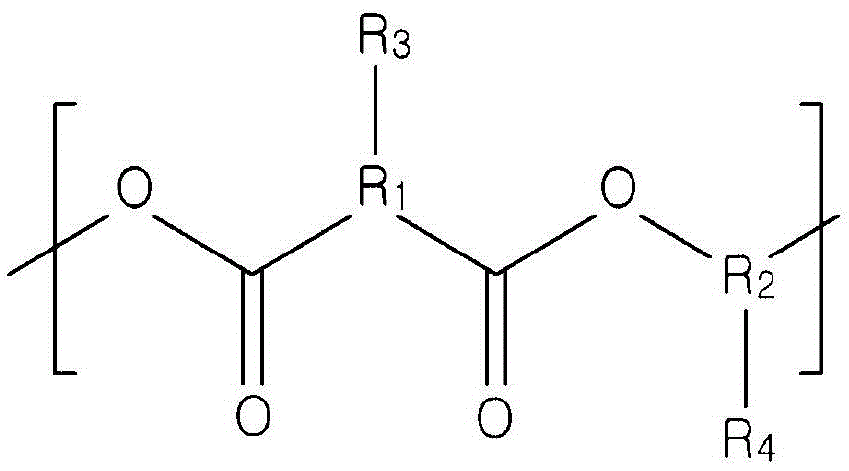

Non-yellowing polyurethane resin for mirror synthetic leather and preparation method of polyurethane resin

ActiveCN104387548AExcellent low temperature folding resistanceGood anti-sticking effectCoatingsTextiles and paperParticulatesIsobutanol

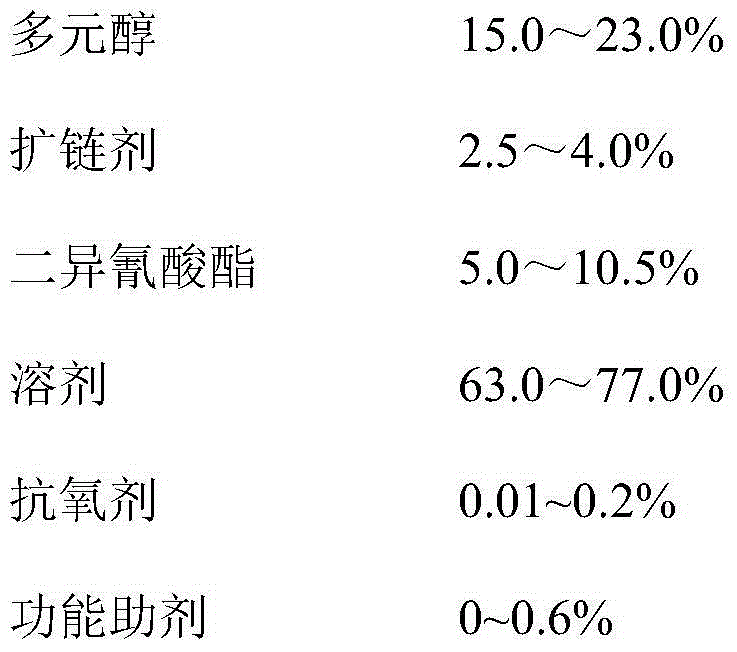

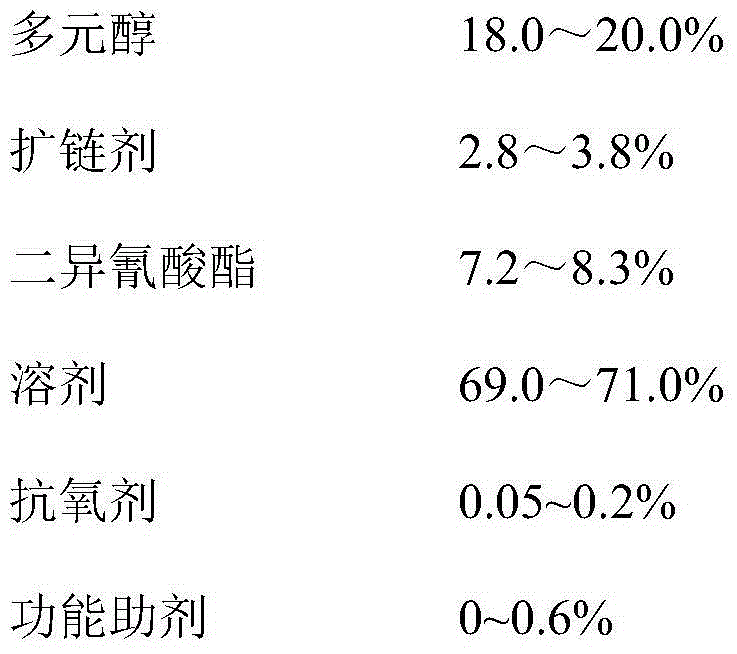

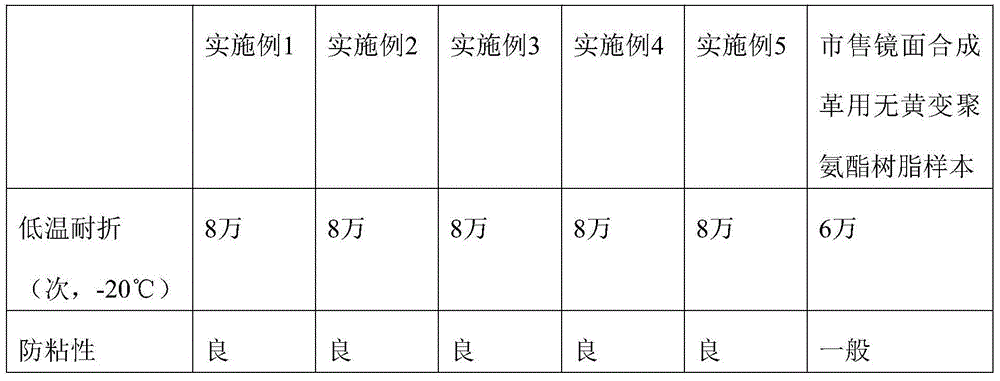

The invention discloses non-yellowing polyurethane resin for mirror synthetic leather and a preparation method of polyurethane resin. The non-yellowing polyurethane resin is prepared from following raw materials: polyol, a chain extender, diisocyanate, a solvent and an antioxidant, wherein polyol is a mixture of polytetramethylene ether glycol having a number average molecular weight of 2000, polytetramethylene ether glycol having a number average molecular weight of 3000, polydiol adipate having a number average molecular weight of 1000-3000; the chain extender is a mixture of C2-C6 aliphatic diol, piperazine and alicyclic diprimary amine; diisocyanate is aliphatic diisocyanate; the solvent comprises a solvent A, a solvent B and a solvent C, the solvent A is at least one selected from dimethylformamide and dimethylacetamide, the solvent B is at least one selected from toluene, butanone and ethyl acetate and the solvent C is at least one selected from isopropanol or isobutanol. By virtue of the non-yellowing polyurethane resin, the risk of generation of insoluble particulates and topical gel in the system is reduced and meanwhile, the non-yellowing polyurethane resin for synthetic leather has the characteristics of excellent low-temperature folding resistance and good anti-sticking performance.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

Separative film and its processing method

InactiveCN1821286AHigh tensile strengthGood anti-sticking effectLiquid surface applicatorsFilm/foil adhesivesPolyesterAlkane

The strippable film and its preparing process belong to making technology of antisticking material for pressure sensitive organosilicon adhesive tape. The strippable film includes one polyester film layer and at least one antisticking layer on one side of the polyester film and features the antisticking layer of fluoric polymethyl siloxane. Its preparation process includes: selecting polyester film; dissolving 2, 4-hexafluorovinyl methyl siloxane in organic solvent to obtain solution and adding organic Pt complex catalyst; treating the surface of polyester film; coating the solution to the surface of the polyester film and stoving in a stoving channel to form the antisticking 2, 4-hexafluorovinyl methyl siloxane film on the surface of the polyester film; winding and packing. The present invention has the advantages of high antisticking effect, high tensile strength, easy stripping, etc.

Owner:常熟市富邦胶带有限责任公司

Preparing method for pearlescent leather

ActiveCN104531920AImprove featuresChange chargePolyurea/polyurethane coatingsLeather surface finishingComposite materialPolymer chemistry

The invention relates to the technical field of leather processing, in particular to a preparing method for pearlescent leather. The method includes the processes of material selecting, foaming, plate pressing, ground color applying, pearlescent pigment spraying, manual color smearing, color fixing and drying. Traditional second-layer pig skin leather can only be applied to a lining and a rear cover of a material or be sold out as a waste material to be used as reclaimed leather. An inventor creatively starts to use second-layer pig skin, the feature of the second-layer pig skin is improved, the technology of foaming positive ion foaming resin is used for shielding rough pores of the second-layer pig skin, then plate pressing, ground color applying, pearlescent pigment spraying and manual color smearing are conducted, finally, the resin is used for color fixing, the obtained leather has the smoothness and the glossiness of the top-layer pig skin, pearlescent paint on a sprayed surface enables the product to become beautiful and colorful and have a very strong pearlescent three-dimensional effect, the added value of the leather is greatly improved, the prepared pearlescent leather can be used as the face layer of the leather, the application range is wide, and the economic benefits are high.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

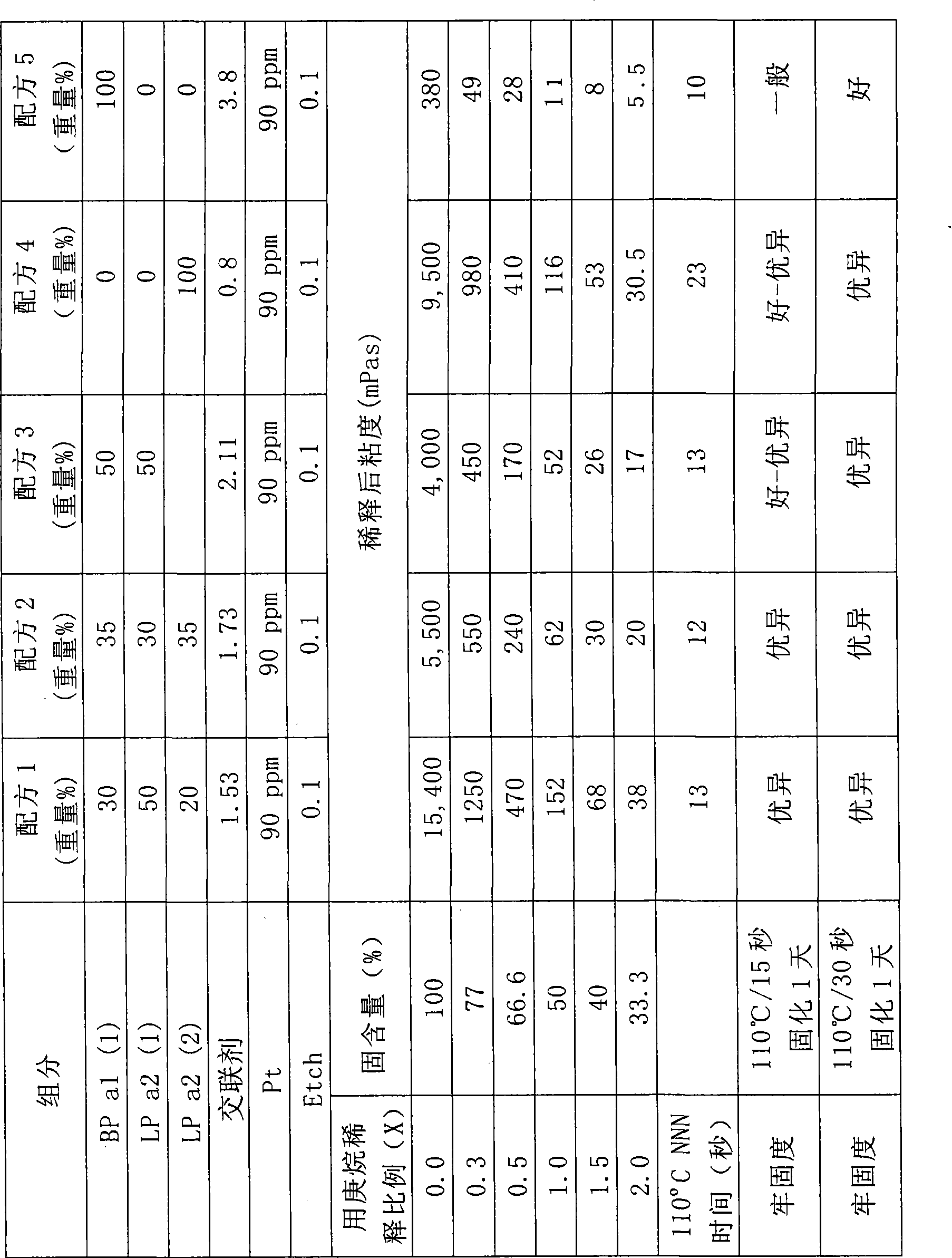

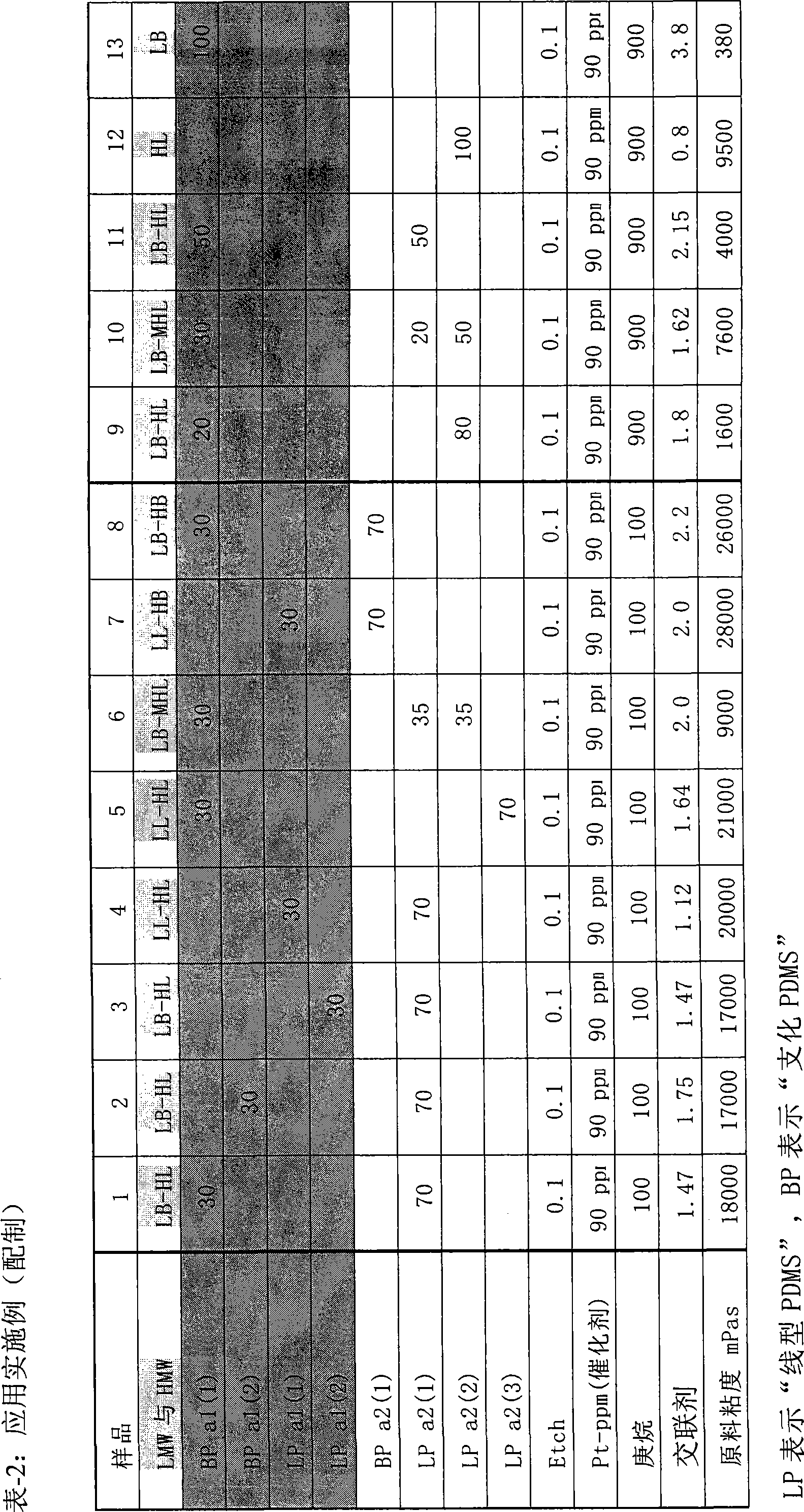

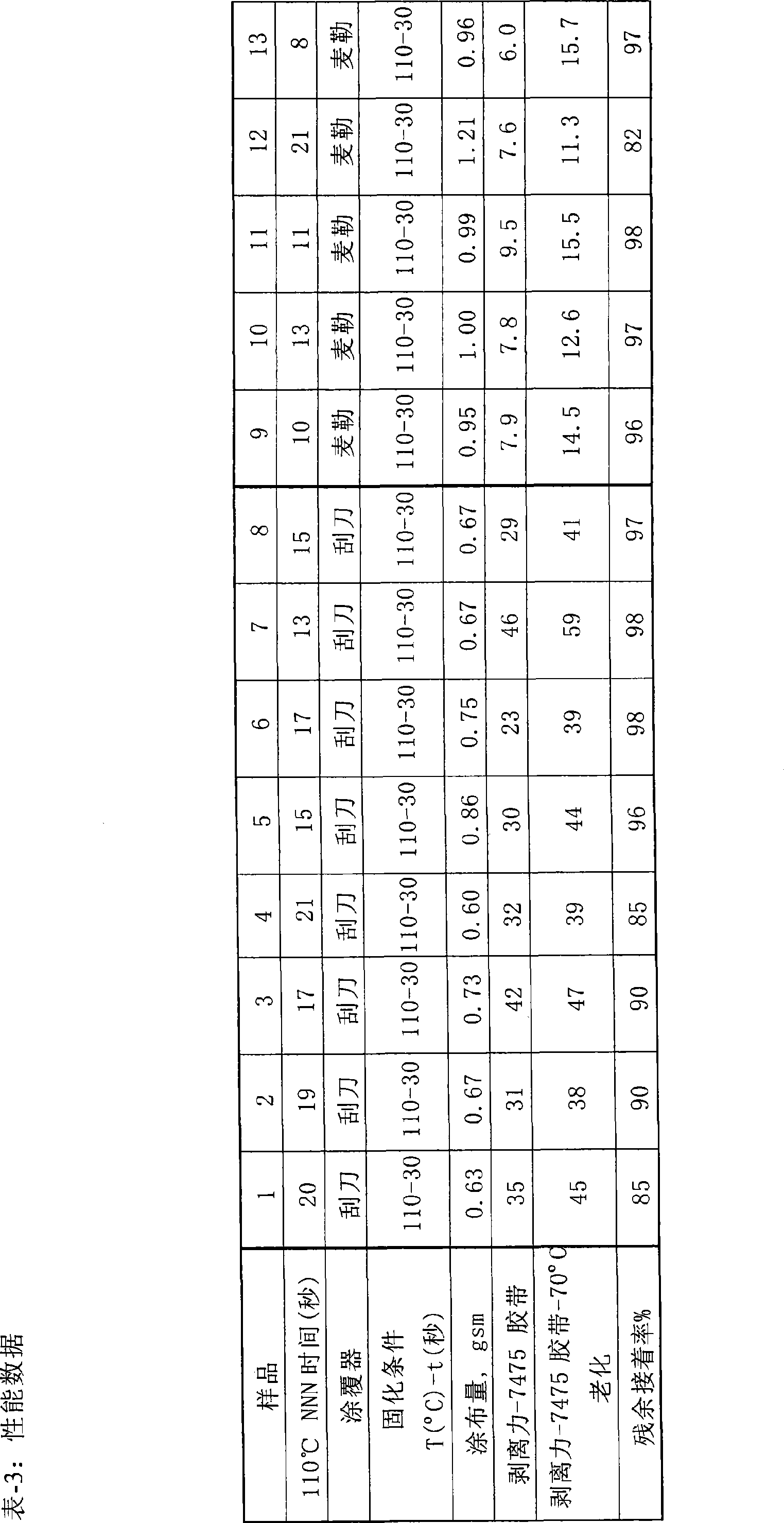

Organic silicon releasing coating mixture used in coating method with high solid content resolvent

ActiveCN101531868AImprove smoothnessGood anti-sticking effectSpecial surfacesCoatingsHydrogenHydrogen atom

The invention relates to an organic silicon releasing coating mixture, a releasing coating base material and a method for producing the releasing coating base material. The organic silicon releasing coating mixture comprises: (A) a mixture of poly di-organic-group siloxane (a1) and poly di-organic-group siloxane (a2) with a proportion of 10:90 to 70:30, (B) organic hydrogen polysiloxane of which each molecule has more than two hydrogen atoms connected with silicon on the average, (C) a catalyst in a hydrosilylation reaction and (D) an inhibitor with 0.001-2.0 parts by weight in the hydrosilylation reaction, wherein each molecule of the poly di-organic-group siloxane (a1) has at least two alkenyls on the average, and the viscosity of (a1) at the temperature of 25 DEG C is 100-500mPas; eachmolecule of the poly di-organic-group siloxane (a2) has at least two alkenyls on the average, and the viscosity of (a2) at the temperature of 25 DEG C is 5,000mPas; and the organic hydrogen polysiloxane has a content large enough to ensure that molar ratio of the hydrogen atoms connected with the silicon in the organic hydrogen polysiloxane and the alkenyls in the component (A) ranges from 0.8:1 to 5:1.

Owner:DOW CORNING CORP +2

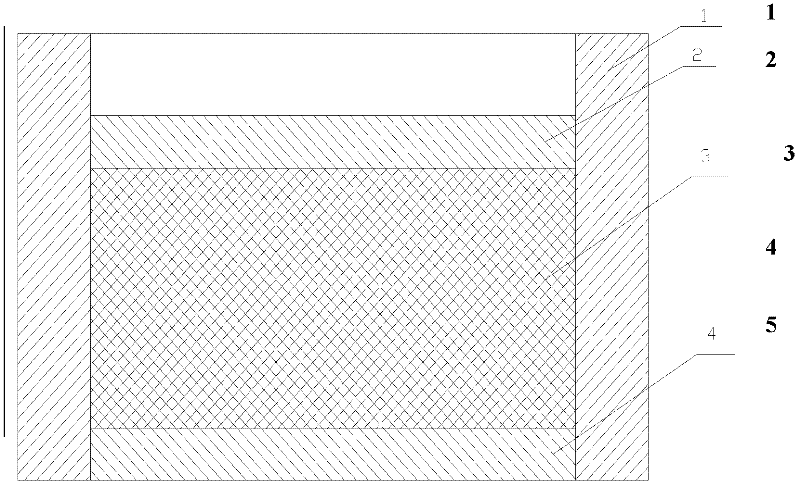

Color polytetrafluoroethylene release film and preparation method thereof

InactiveCN102532759AGood anti-sticking effectImprove flatnessFlat articlesTetrafluoroethyleneWeather resistance

The invention discloses a color polytetrafluoroethylene release film and a preparation method thereof. The color polytetrafluoroethylene release film is prepared through the following steps: blending polytetrafluoroethylene resin and a pigment according to a weight ratio of 100:1-10, and carrying out treatments of pre-forming, sintering, turning and rolling to prepare the color polytetrafluoroethylene release film. According to the present invention, the color polytetrafluoroethylene release film of the present invention has excellent anti-sticking property and surface smoothness of the polytetrafluoroethylene, and can provide light and stable release force during stripping; the color polytetrafluoroethylene release film of the present invention further has characteristics of weathering resistance, temperature resistance, chemical stability, and other excellent properties of the polytetrafluoroethylene, and has bright color, such that the application range is wide; the preparation method is simple, and is convenient to operate.

Owner:TIANJIN TIANSUBINHAI PTFE PLASTIC PROD

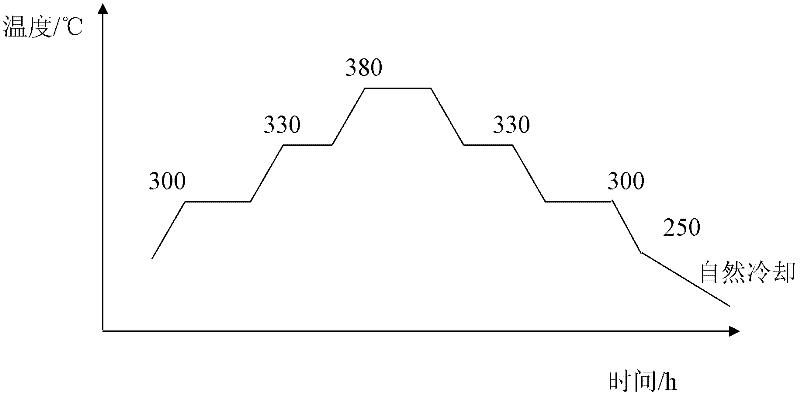

Meltability polytetrafluorethylene tubular film and method for preparing same

InactiveCN101254423AGood non-stickSmooth outer surfaceSemi-permeable membranesInorganic saltsSurface layer

The invention discloses a fusible polytetrafluoroethylene tubular film and the manufacturing method thereof. The tubular film is a seamless tubular piece consisting of a bottom layer and a surface layer, wherein the two layers are made mainly from fusible polytetrafluoroethylene, the bottom layer has a coating containing water-soluble inorganic salts that are dissolved out under ultrasonic water washing to form the micropores, and the surface layer is smooth and compact and has anti-sticking effect. The production method includes the following steps: coating the bottom and the surface layers respectively on the surface of an aluminum alloy tube, baking at a high temperature to form film, removing from the surface of the aluminum alloy tube, subjecting to ultrasonic washing to obtain the PFA tubular film with porous inner surface and smooth and compact outer surface. The outer surface of the product is smooth and compact and excellent in anti-fouling function. The inner surface of the product doesn't need subsequent treatment and has good effect of adhersion with silicone rubber after coating. The fusible polytetrafluoroethylene tubular film is particularly suitable for the production of silicone rubber hot rollers used in duplicators and laser printers.

Owner:陈贤斌

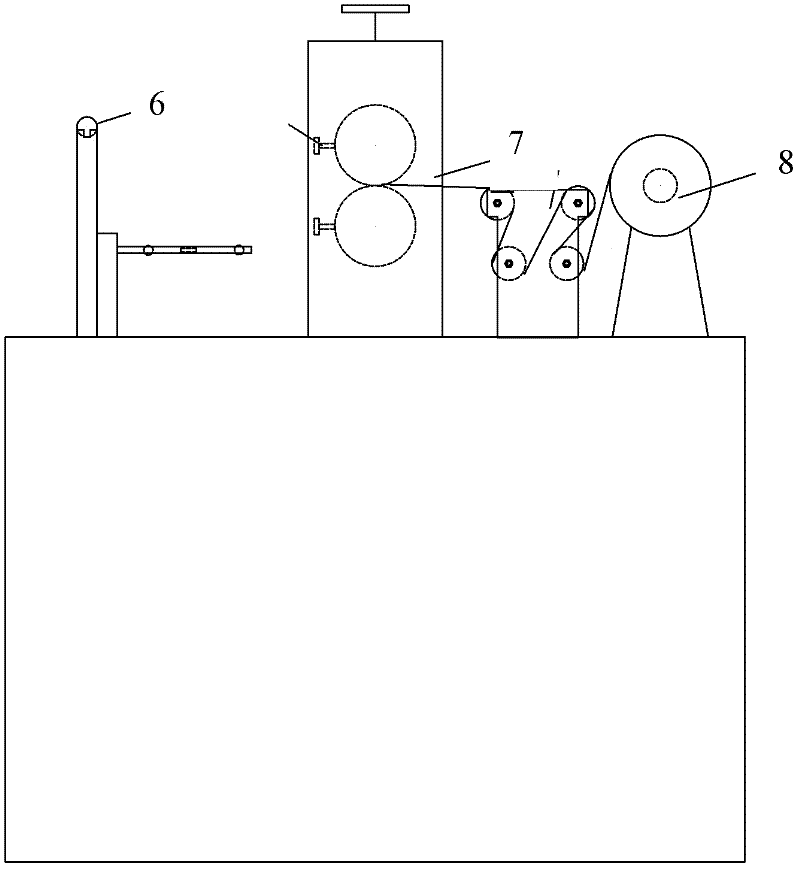

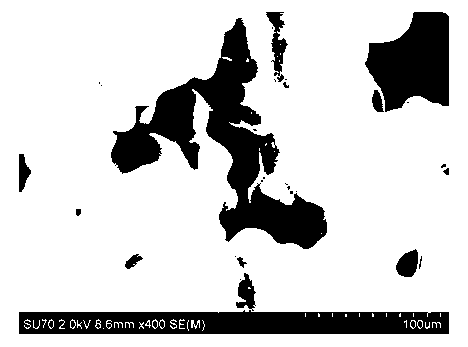

Method and catalyst for preparing high trans-polyisoprene by adopting gaseous phase polymerization

ActiveCN103265654AThe effect of preventing stickinessLow in NanoparticlesPolymer sciencePtru catalyst

The invention discloses a method and a catalyst for preparing high trans-polyisoprene by adopting gaseous phase polymerization. The catalyst comprises the following components: a first component, namely a compound of transition metal vanadium or titanium, a second component, namely a catalyst promoter, a third component, namely a carrier, and a fourth component, namely nano inorganic particles. In the catalyst, the mole ratio of the first component to the second component is 1:2-10, ratio of the molar weight of the first component to the mass of the third component is 1mol:2000-200000g, and the mass ratio of the fourth component to the third component is 1:0.125-200. The catalyst has high catalytic activity, the catalyst and gaseous phase polymerization are adopted for preparing polyisoprene, an inorganic-organic alloy containing the third component and the fourth component is generated in situ in a reactor, an anti-sticking effect which can not be realized by the existing method is still achieved under the condition that content of nano inorganic particles is as low as 0.1wt%, adhesion of rubber is effectively prevented, and perfect rubber particles are obtained.

Owner:ZHEJIANG UNIV

Silk fibroin based antibacterial nano-fibers and preparation method thereof

InactiveCN108385182AHigh antibacterial effect and antibacterial rateImprove stabilityMonocomponent protein artificial filamentArtifical filament manufactureChemistryAntibacterial effect

The invention provides silk fibroin based antibacterial nano-fibers. The silk fibroin based antibacterial nano-fibers are prepared from the following components in parts by weight: 100 to 150 parts ofsilk fibroin, 4 to 8 parts of titanium dioxide, 20 to 30 parts of chitosan, 10 to 15 parts of nano copper oxide and 10 to 15 parts of polyethylene oxide. The invention further provides a preparationmethod of the silk fibroin based antibacterial nano-fibers; the silk fibroin based antibacterial nano-fibers, prepared by the preparation method, have good biocompatibility, anti-sticking performance,good antibacterial effect and excellent color fixing effect.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

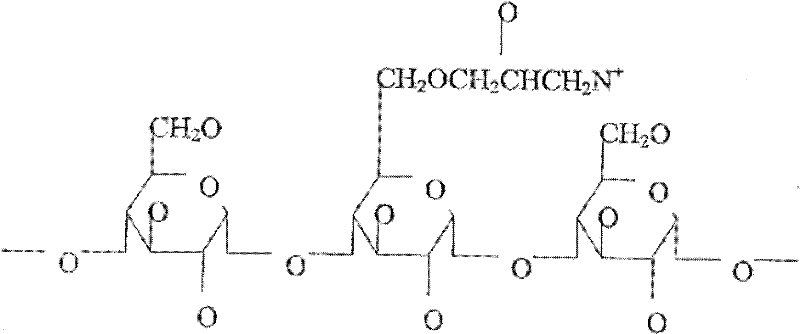

High performance low environmental impact detackifier

ActiveCN102459090AGood anti-sticking effectEasy to separatePaint waste treatmentWater/sewage treatment by neutralisationWater basedAluminium chlorohydrate

The current invention relates to a composition and a method for treating impurities in a circulating water system. The circulating water system impurities may be oversprayed paint in paint spray booth applications. The composition includes an aqueous solution of a cationized starch, a polybasic aluminum salt such as aluminum chlorohydrate or polyaluminum chloride and a solution of a medium to high MW aqueous flocculant. The composition is particularly useful when added to recirculating scrubber water in paint spray booths for effectively treating both water based and solvent based paints.

Owner:NALCO CO

Multi-layer composite filtering net for HEPA filter

ActiveCN104984600AStrong oxidation resistanceStrong acid and alkali corrosion resistanceDispersed particle filtrationHEPAPolyester

The invention provides a multi-layer composite filtering net for an HEPA filter. The multi-layer composite filtering net for the HEPA filter is characterized by sequentially comprising polytetrafluoroethylene membrane polyester non-woven cloth, an activated-carbon-supported formaldehyde scavenger filtering net, an HEPA filtering net and polytetrafluoroethylene membrane polyester non-woven cloth from the windward end to the downwind end. A single HEPA filtering net of an HEPA filter of the prior art is replaced by the multi-layer composite filtering net, not only conventional particles but also formaldehyde can be efficiently removed, the application range is wide, the filtering efficiency is high, and the service life of the HEPA filtering net is prolonged.

Owner:ZHEJIANG ZHIYUAN ENVIRONMENTAL TECH CO LTD

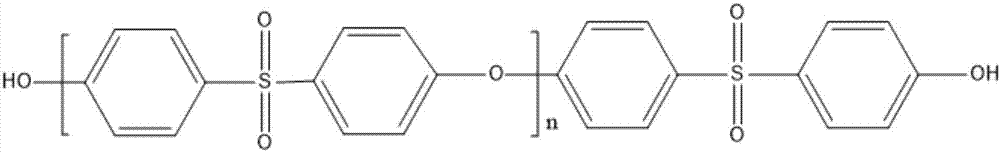

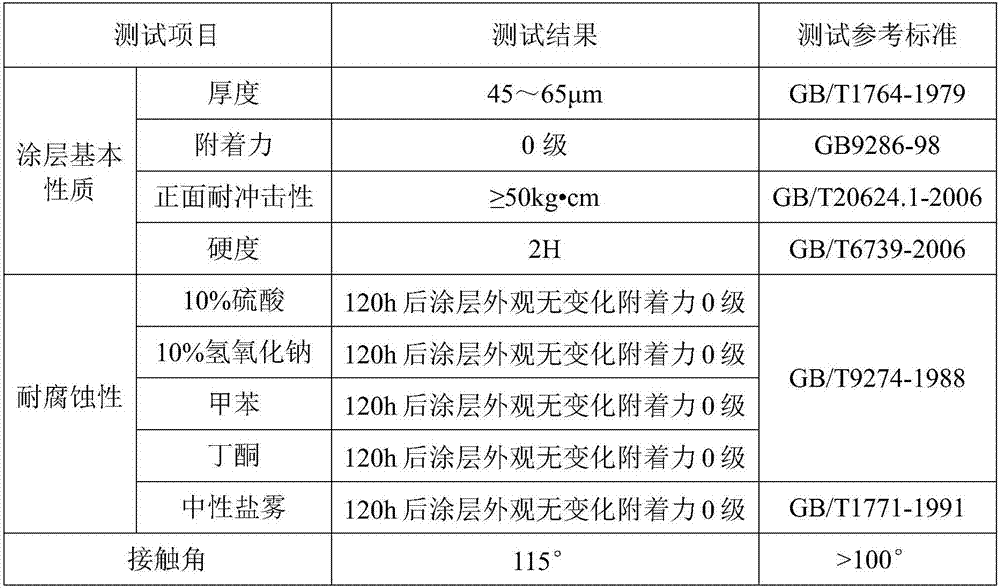

Low-temperature curing polyether sulfone coating composition and preparation method thereof, as well as coating process

ActiveCN106905841AImprove adhesionModerate thicknessPretreated surfacesAnti-corrosive paintsEpoxyLow temperature curing

The invention discloses a low-temperature curing polyether sulfone coating composition and a preparation method thereof, as well as a coating process, and belongs to the technical field of coatings. The low-temperature polyether sulfone coating composition is prepared from polyether sulfone resin, epoxy resin, polytetrafluoroethylene, a curing agent and a diluent. The preparation process comprises the following steps: dissolving the polyether sulfone resin in a composite solvent prepared from dimethylacetamide, methylbenzene and butanone at the stirring speed of 3,200 to 3,800 r / min, then adding the polytetrafluoroethylene and the epoxy resin in sequence, grinding the materials in a grinding machine for 2 to 6 hours, adding the curing agent before spraying, stirring for 0.2 to 0.5 hour for curing, spraying a sandblast metal base material with the cured coating through an air spraying gun and an air compressor, and drying at 150 to 170 DEG C for 2 to 6 hours. According to the preparation method disclosed by the invention, low-temperature curing of the polyether sulfone coating is realized; a prepared coating layer is high in adhesion force, impact resistance, wear resistance, hydrophobicity, corrosion resistance and the like; the preparation and coating process is easy to operate; production equipment is easy to realize and the application range is wide.

Owner:JILIN JITU GAOKE TECH CO LTD

Method for producing biaxially oriented multilayer co-extruded polyolefin shrink film by flat film process

ActiveCN102765190AAvoid compromising appearance qualityLow melting pointLow-density polyethylenePolymer science

The invention relates to a method for producing a biaxially oriented multilayer co-extruded polyolefin shrink film by a flat film process, which comprises the following steps: adding 95-97% of ternary-polymerized polypropylene (PP) and 3-5% of silicon dioxide using PP copolymer as a carrier into two surfaces of the co-extruded polyolefin shrink film, adding C6 linear low-density polyethylene (C6-LLDPE) into a core layer, sufficiently fusing and plastifying in an extruder at 220-250 DEG C, extruding by a hanger-type die, processing a thick piece into a film and then longitudinally / horizontally stretching, and then hauling and coiling. The method provided by the invention has advantages of high annual productivity and stable product shrinkage rate.

Owner:江苏恒创包装材料有限公司

Novel fluorine-containing siloxane fire retardant, and preparation method and application thereof

The invention relates to the technical field of plastic assistants, and concretely relates to a novel fluorine-containing siloxane fire retardant, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, uniformly mixing organosiloxane monomers, adding the obtained monomer mixture into a catalyst and emulsifier dissolved aqueous solution, and carrying out a reaction to obtain an organopolysiloxane emulsion; 2, adjusting the pH value of the organopolysiloxane emulsion by using an alkali liquid, adding a fluorine-containing styrene monomer and a copolymerization, adding an initiator, a crosslinking agent and a chain transfer agent, and carrying out a reaction to obtain an organosiloxane grafted fluorine-containing styrene polymer emulsion; and 3, diluting the polymer emulsion, adding a de-emulsifier to carry out demulsification, centrifuging the de-emulsified emulsion, and carrying out drying and crushing to prepare the novel fluorine-containing siloxane fire retardant. The novel fluorine-containing siloxane fire retardant prepared in the invention has excellent anti-dripping effect and fire-retardant property without affecting the mechanical properties of a high-molecular material polymer, and also can improve the mechanical properties and the heat resistance of matrix resin.

Owner:铨盛聚碳科技股份有限公司

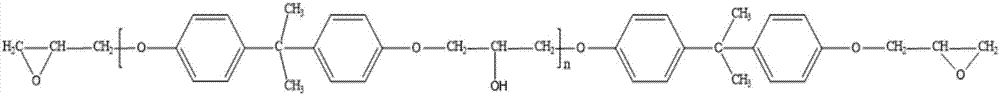

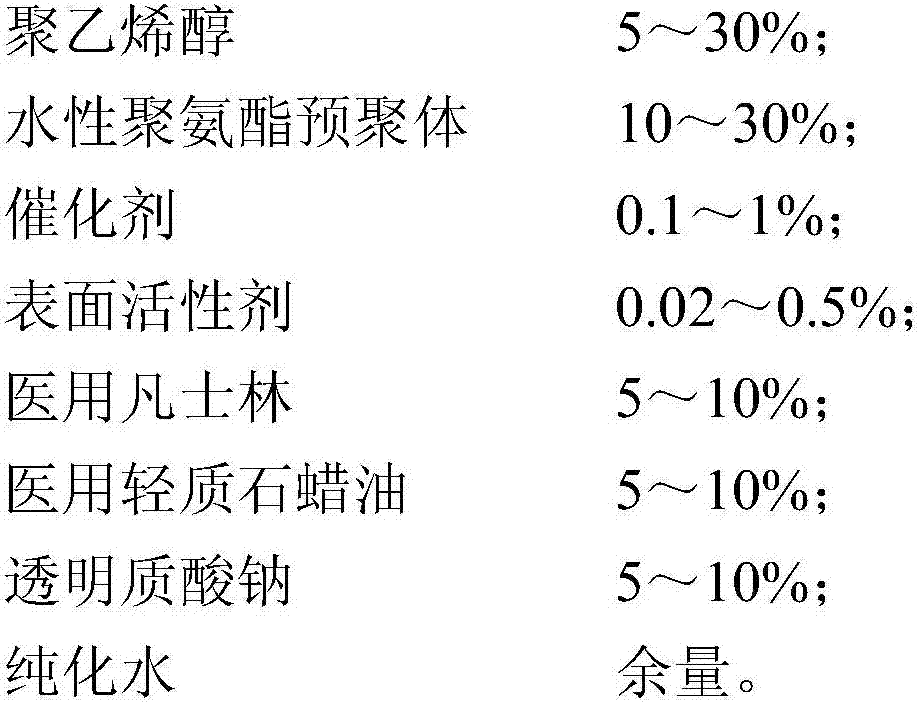

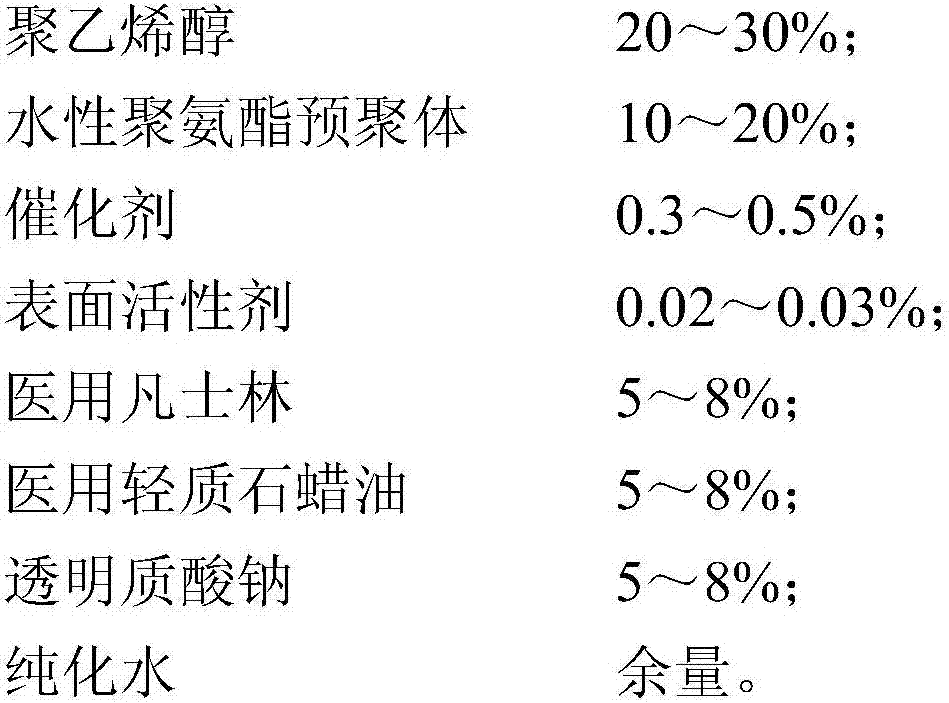

Environment-friendly multifunctional composite negative-pressure drain wound-protection sponge and preparation method thereof

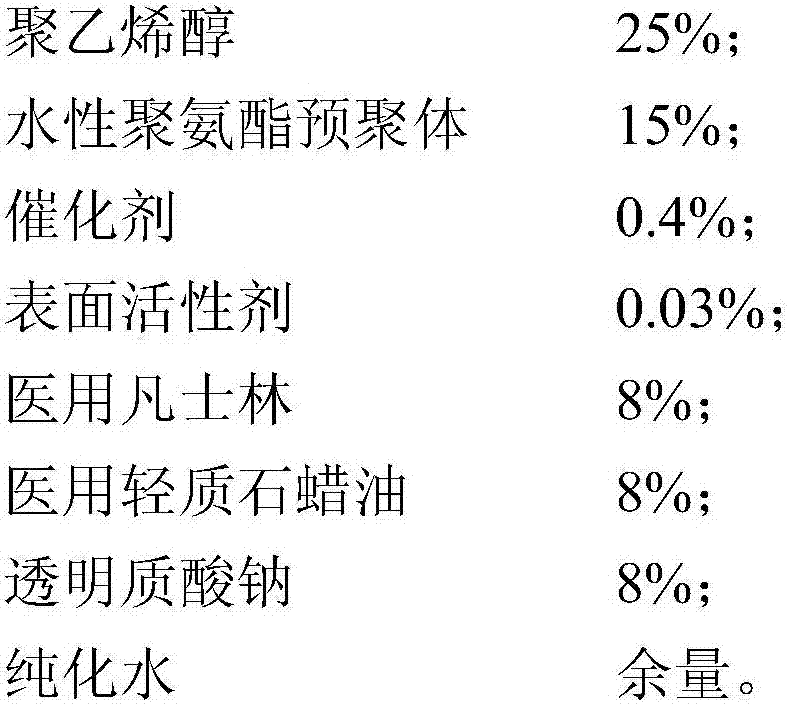

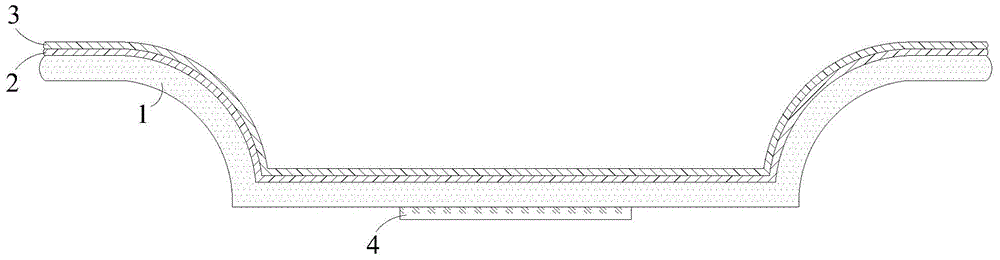

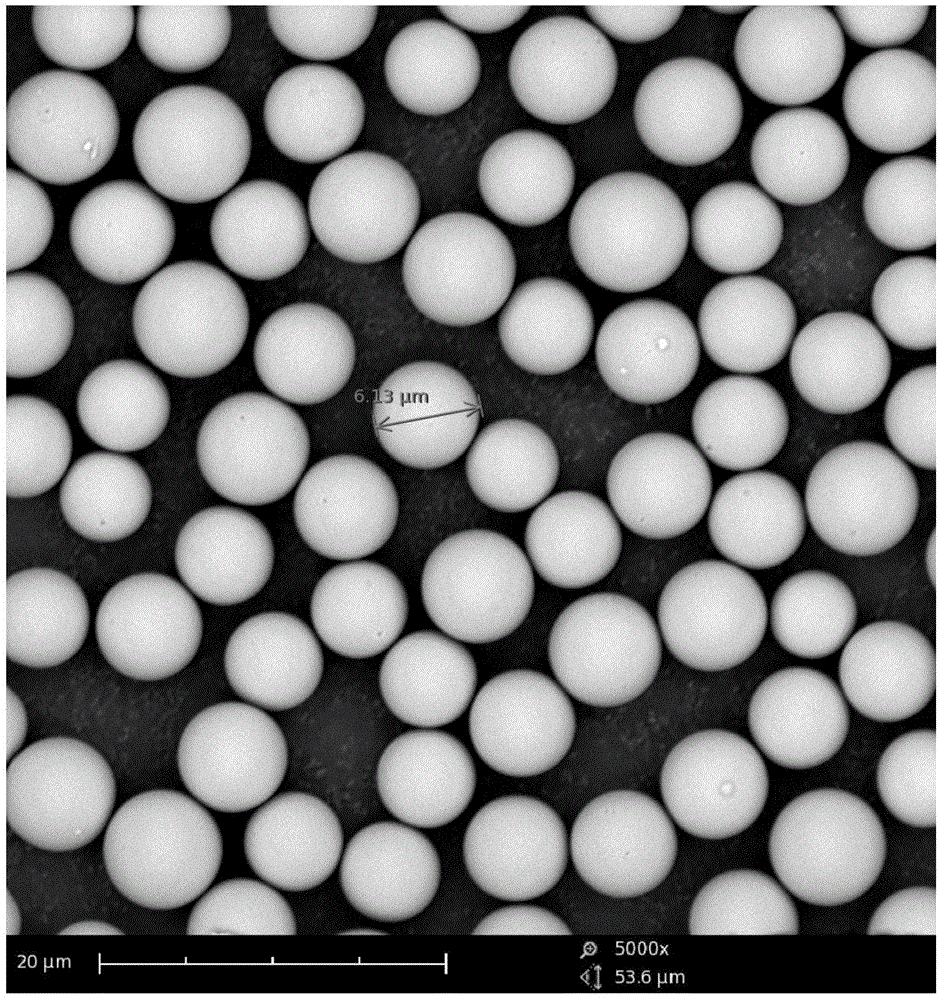

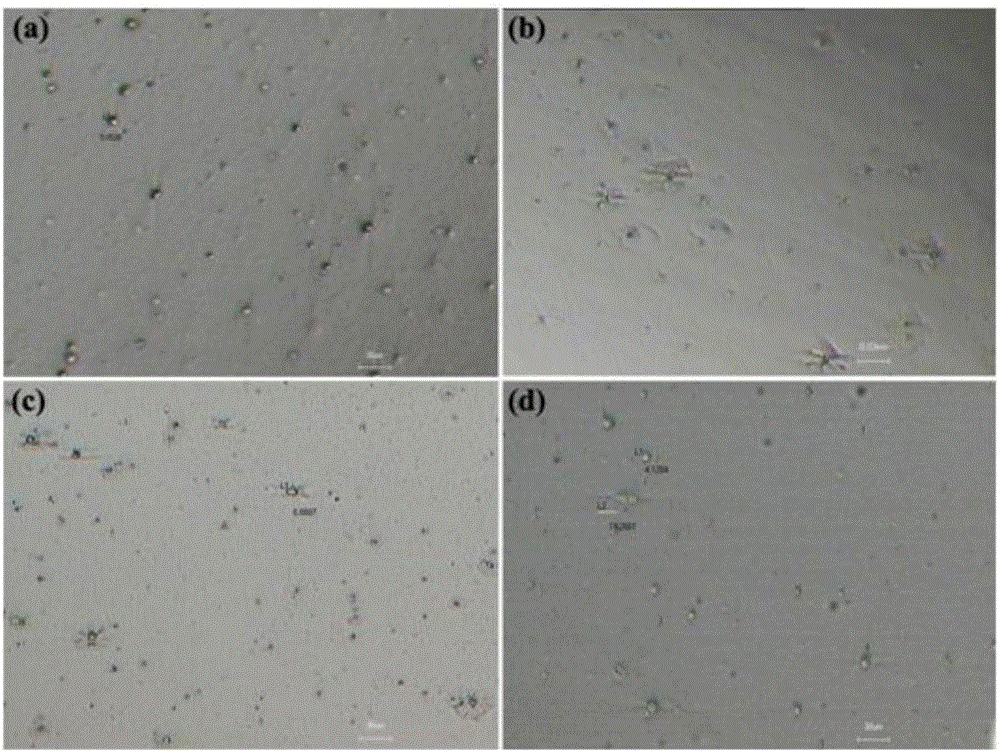

The invention discloses an environment-friendly multifunctional composite negative-pressure drain wound-protection sponge and a preparation method thereof. The sponge comprises the following components by mass percentage: 5-30% of polyvinyl alcohol, 10-30% of an aqueous polyurethane performed polymer, 0.1-1% of a catalyst, 0.02-0.5% of a surfactant, 5-10% of medical Vaseline, 5-10% of medical lightweight paraffin oil, 5-10% of sodium hyaluronate, and the balance of purifying water. The wound-protection sponge combines foaming technology general characteristics of PVA and PU, which organically combines the excellent performances of PVA and PU, by adding the sodium hyaluronate, sponge water absorption, water retention performance, water absorption rate of the sponge are increased, a supercritical CO2 foaming mode is used, and the chemical residue of the sponge is reduced, the sponge water absorption is increased by 22 times and more, the water retention performance is increased by 7-10 days, the water absorption rate of the sponge is increased by at least one time, which can reach 10-12 g / min.g, and the sponge has good antistick effect.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Imitation Zongye release paper and preparation method thereof

The invention discloses artificial steamed rice dumpling leaf release paper and its preparation method. The artificial steamed rice dumpling leaf release paper comprises greaseproof paper; the double faces of the greaseproof paper are both printed with steamed rice dumpling leaf patterns, the surface of which is covered with a silicone oil layer; the thickness of the greaseproof paper is 100-200g / m<2>. The preparation method of the artificial steamed rice dumpling leaf release paper comprises the following steps of: (1) printing of the steamed rice dumpling leaf patterns; (2) preparation of a release agent: the release agent contains, by weight, one part of silicone oil, 8 / 1000 parts of a noble metal catalyst and 3-10 parts of an organic solvent special for food; (3) coating of the release agent: the release agent is coated on the greaseproof paper printed with the steamed rice dumpling leaf patterns and the coating weight of the release agent is 0.3-0.6g / m<2>; (4) drying of the release paper: the oven tunnel temperature is 70-100 DEG C, the oven tunnel air volume is 7000-9000m<3> / h, and the drying time is 15s-30s. Then, the artificial steamed rice dumpling leaf release paper provided by the invention is obtained. The artificial steamed rice dumpling leaf release paper is suitable for industrial large-batch production, is easy to store and transport, can be preserved for a long time, has good stick resistance, and can be used as the steamed rice dumpling leaf substitute.

Owner:杭州广联复合材料有限公司

Ceramic coating and application thereof as well as non-stick tableware and preparation method thereof

InactiveCN104910655AStable in natureEnsure safetyTable equipmentsCoatingsCeramic coatingDistilled water

The invention belongs to the field of production for non-stick tableware, and specifically relates to a ceramic coating and an application thereof in non-stick tableware, and non-stick tableware and a preparation method thereof. The ceramic coating disclosed by the invention is mainly composed of the following ingredients in parts by weight: 4-6 parts of methyltrimethoxysilane, 35-40 parts of silica sol, 17-22 parts of isopropanol, 13-18 parts of distilled water and 18-22 parts of toner. The non-stick tableware disclosed by the invention is formed by spraying the ceramic coating disclosed by the invention on the surface of a glass base material. The ceramic coating and the non-stick tableware disclosed by the invention have the following beneficial effects that: the provided ceramic coating is suitable for the surface of the glass base material and achieving a high-temperature anti-stick effect; the provided non-stick tableware has a high-temperature anti-stick performance, a ceramic coating layer on the surface of the non-stick tableware is stable in property and not liable to fall off, and the non-stick tableware is capable of obtaining different appearance colour expressions in case of being observed from different perspectives, thus enriching the spiritual culture aesthetic demands of people.

Owner:高拓

Preparation method of anti-sticking asphalt isolation agent

Belonging to the technical field of preparation of asphalt isolation agents, the invention relates to a preparation method of an anti-sticking asphalt isolation agent. The method includes: firstly utilizing sodium dodecyl benzene sulfonate and span 80 to modify talcum powder under an oil bath condition to obtain modified talcum powder, then using waste engine oil as the raw material, conducting impurity removal treatment, then performing mixing with activated clay and a sodium carbonate solution, then conducting deacidification to obtain pretreated waste engine oil, then compounding span 60, Tween 60 and other emulsifiers to obtain a compound emulsifier, and finally mixing the compound emulsifier with the pretreated waste engine oil, illegal cooking oil, modified talcum powder and other substances, thus obtaining the anti-sticking asphalt isolation agent. The anti-sticking asphalt isolation agent prepared by the method provided by the invention has good stability performance, is free of oil-water separation phenomenon in 72h, and has good isolation and anti-sticking effects, when a road roller works for 1.5-2.0h, asphalt adhesion starts to appear on tire surfaces.

Owner:戴琪

Polyester release membrane for optical membrane

The invention discloses a polyester release membrane for an optical membrane, comprising a polyester thin membrane and non-adhesive separator layer applied to at least one lateral surface of the polyester thin membrane.The non-adhesive separator layer is made by mixing and baking the following components according to parts by weight: trifluoroethyl methacrylate, vinytrimethoxysilane, isooctyl methacrylate, long-chained alkane, glycol methyl ether, a photo-condensing initiator, an ultraviolet absorbent, acrylate carbamate, octadecanol methacrylate, and 2,4'-toluene diisocyanate.The polyester release membrane requires no expensive organosilicon light diffuser to be added, and the release membrane with light diffusing capacity can be made by adding the acrylate carbamate, the photo-condensing initiator and the ultraviolet absorbent.

Owner:苏州海晨塑胶有限公司

Copper alloy for drawing mould and preparation method thereof

Copper alloy for drawing mould is characterized by comprising following chemical components by weight: 10-12 parts of aluminum, 2.2-2.4 parts of magnesium, 4-5 parts of zinc, 1.2-1.4 parts of boron, 0.2-0.4 part of titanium, 1-1.3 parts of manganese, 2.1-2.3 parts of Be, 0.07-0.09 part of La, 0.06-0.09 part of Ho, 1.1-1.3 parts of Ni and the balance of copper. The copper alloy provided by the invention has advantages of good anti-sticking effect, no formation of a bonding tumor, no scratch of a drawing product, reduction on the mold repair time, small friction coefficient, low wear rate, great extension on the service cycle, no requirement on polishing or heat treatment, and easiness for mechanical processing.

Owner:SANLIAN PUMP IND CO LTD

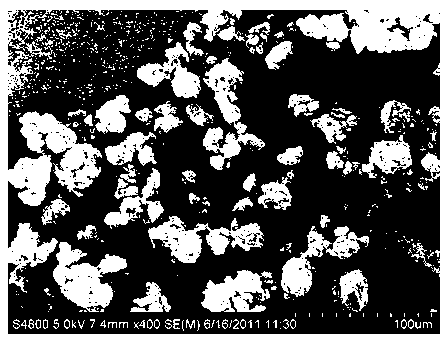

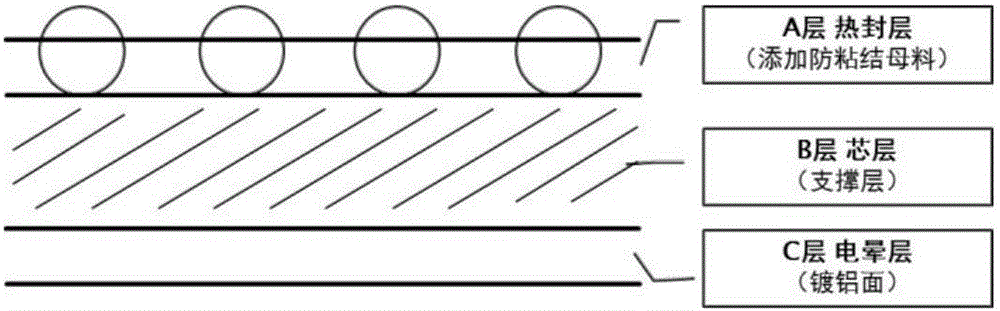

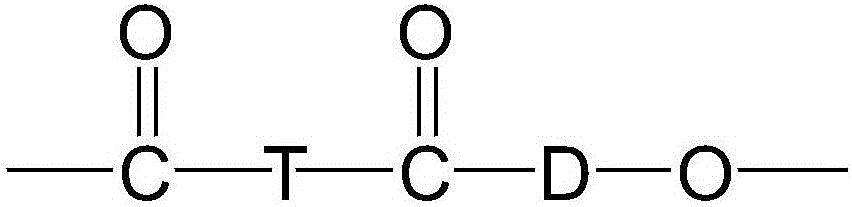

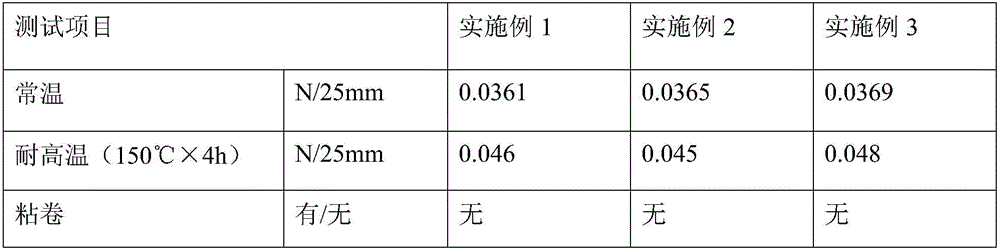

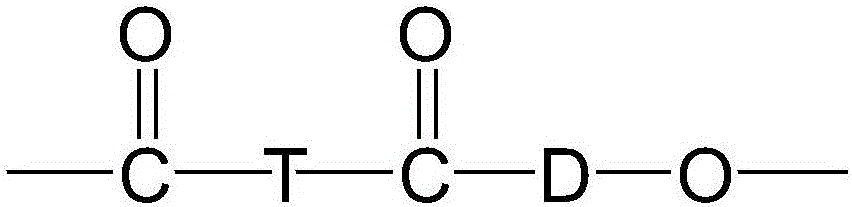

Low-friction coefficient anti-bonding master batch special for metallized base film and preparation method thereof

ActiveCN106519455ADoes not affect heat sealing temperatureDoes not affect heat sealing performanceMetallised filmPolypropylene

The invention relates to a low-friction coefficient anti-bonding master batch special for a metallized base film and a preparation method thereof. The low-friction coefficient anti-bonding master batch mainly comprises, by weight, 90-95 parts of polypropylene resin and 5-10 parts of polymethylsesquisiloxane-polyphenylsilsesquioxane. The polymethylsesquisiloxane-polyphenylsilsesquioxane is a ladder polymer with R3SiO terminated. The molecular formula of the polymethylsesquisiloxane-polyphenylsilsesquioxane is [CH3SiO1.5]n-[PhSiO1.5]m, wherein n is 5-8 and m is 2-5. According to the preparation method, an anti-sticking agent is added by means of side feeding through precision electronic weight loss scales, and pelleting is performed after melt blending by means of the special double-screw process. By the adoption of the method, the problem that no slipping agent (master batch) can be added into the metallized film and thus the friction coefficient is high and the problem that the low friction coefficient is required under the condition that no migration slipping agent can be added into an aluminum laminated film are effectively solved. The friction coefficient of the obtained metallized base film is lowered to 0.4 or below from 0.8 or above, the slipping property is good, no migration happens, and the product surface is not greasy, high in glossiness, resistant to abrasion, lasting and effective.

Owner:SHANTOU BEST SCI & TECH

High-temperature-resistant composite release film

InactiveCN106166863ACompact structureEasy to peelSynthetic resin layered productsIsolation effectElastomer

The invention discloses a high-temperature-resistant composite release film, which comprises a release film layer, an adhesive layer and a high-temperature-resistant resin film layer, wherein the release film layer is obtained by co-extrusion process of two thermoplastic resin materials; the adhesive layer is formed by coating one surface of the release film layer with an adhesive; and the high-temperature-resistant resin film layer is glued on the adhesive layer. The three-layer high-temperature-resistant composite release film has a compact structure and is easy to peel off. On the basis of not influencing characteristics of rubber surface, release force is low. A fluorine-containing material is selected for the high-temperature-resistant resin film layer. At the high temperature of 200 DEG C, the high-temperature-resistant resin film layer can never be decomposed or react with the release layer or the adhesive layer. The release film has excellent anti-sticking and isolation effects, and has dimensional stability at high temperature. The release layer adopts an organosilicon elastomer adhesive and the thickness is controlled. Then, there is no residue on the release layer.

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

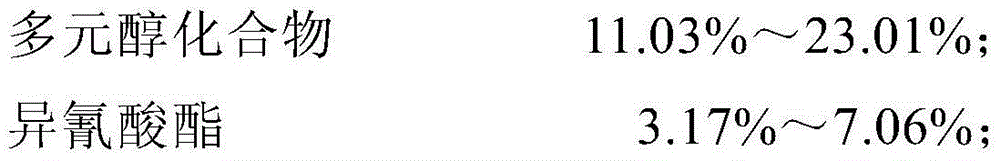

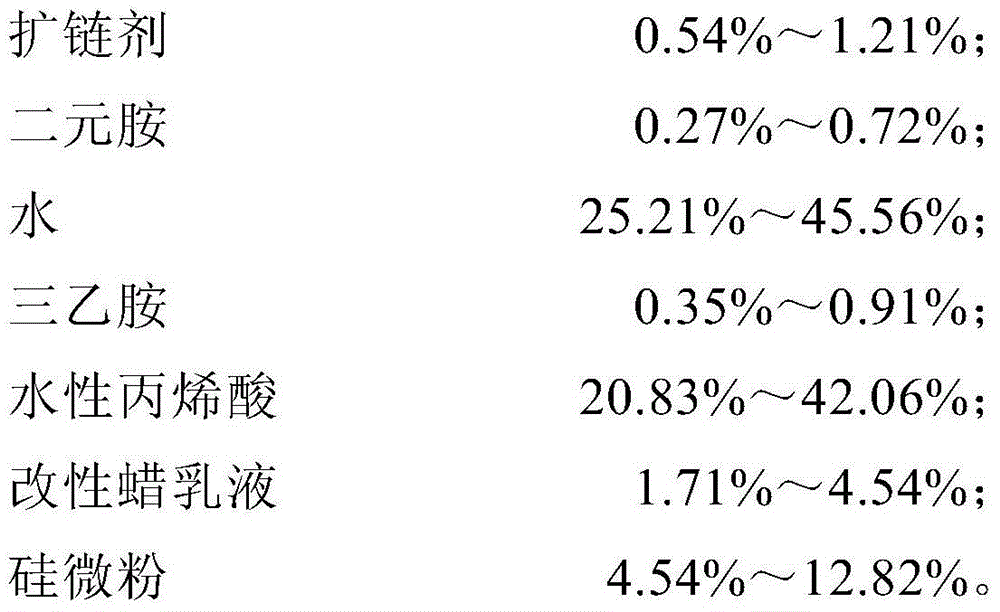

Modified waterborne polyurethane resin for safety gloves, as well as preparation method thereof

The invention provides modified waterborne polyurethane resin for safety gloves, as well as a preparation method thereof. The preparation method of the modified waterborne polyurethane comprises the following steps: polyester polyol, isophorone diisocyanate, and 2,2-dimethylol propionic acid serve as raw materials to prepare a prepolymer, triethylamine is added for salification through neutral reaction, water is then added for emulsification, and ethanediamine is then added to react with residual isocyanato in the system, so as to obtain waterborne polyurethane emulsion; waterborne acrylic acid, spherical silica powders and modified wax emulsion are then added to the obtained waterborne polyurethane emulsion which serves as a matrix, and uniform mixing is carried out, so as to obtain the modified waterborne polyurethane resin for the safety gloves. The safety gloves made from the obtained modified waterborne polyurethane have the characteristics of good handfeel, as well as high comfort, abrasion resistance, stick resistance and environmental friendliness.

Owner:SHANGHAI HUIDE TECH CO LTD

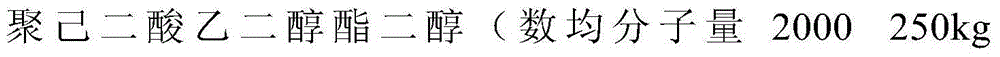

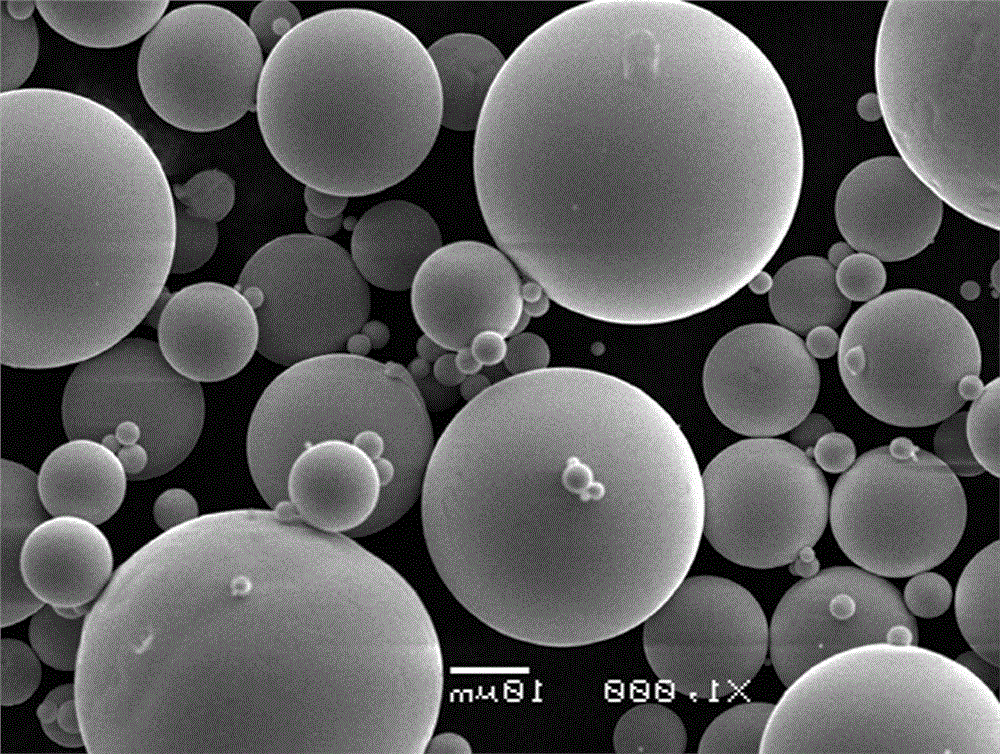

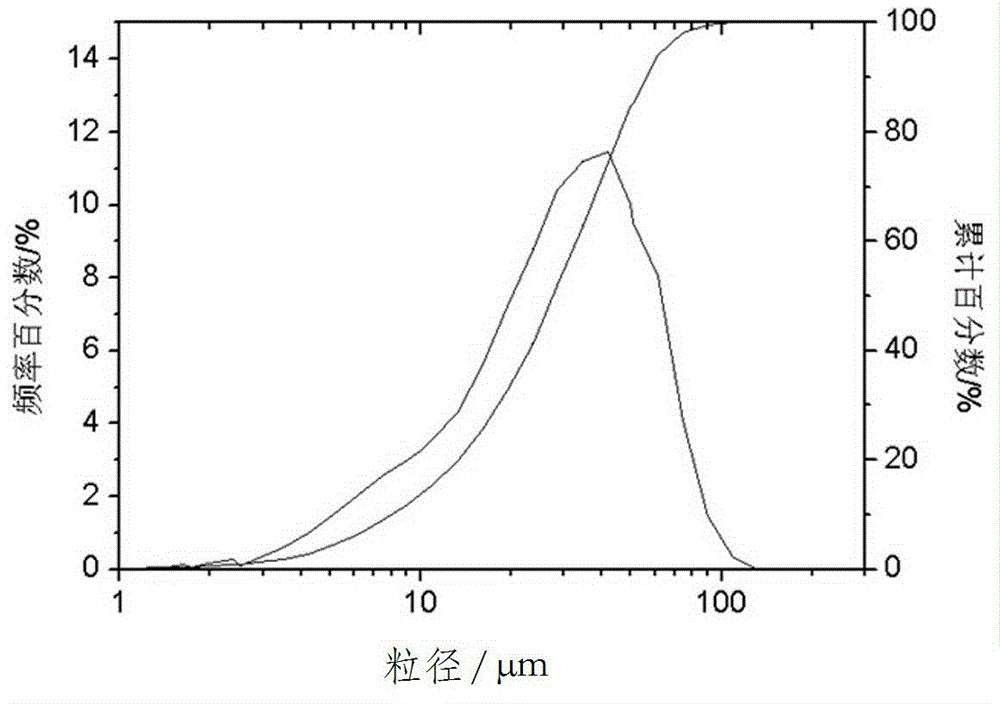

Blocking-preventing nozzle device used for preparing metal powder through gas atomization method

The invention relates to a blocking-preventing nozzle device used for preparing metal powder through a gas atomization method. The blocking-preventing nozzle device comprises a flow guiding pipe and a gas cavity located around the flow guiding pipe. The gas cavity is connected with a gas inlet pipe, and a nozzle circular seam communicated with the gas cavity is formed in the periphery of the lower end of the flow guiding pipe; a gas guiding seam surrounding the flow guiding pipe is formed between the gas cavity and the flow guiding pipe, and an opening of the gas guiding seam is located between the flow guiding pipe and the nozzle circular seam; a gas guiding hole communicated with the gas guiding seam is formed in the wall of the gas cavity. The blocking-preventing nozzle device can reduce nodulation of molten metal at a nozzle and prevent the flow guiding pipe from being blocked.

Owner:HUNAN METALLURGY MATERIAL RES INST

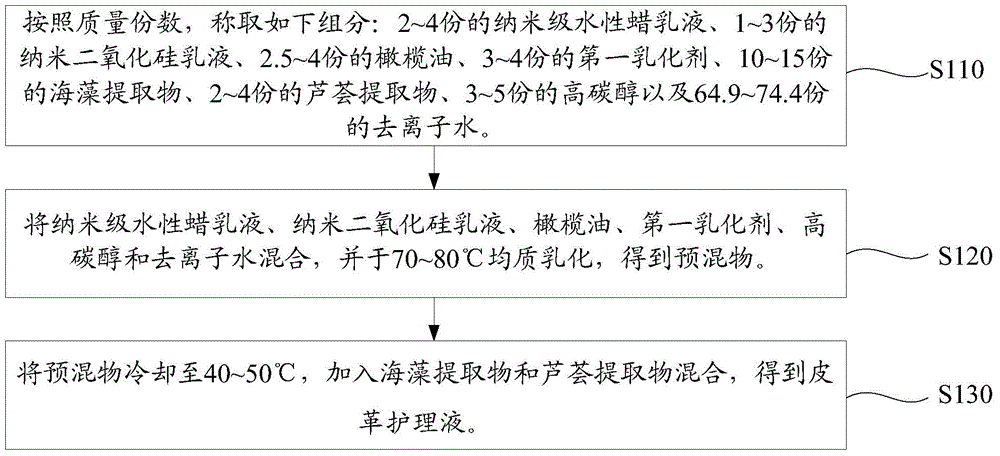

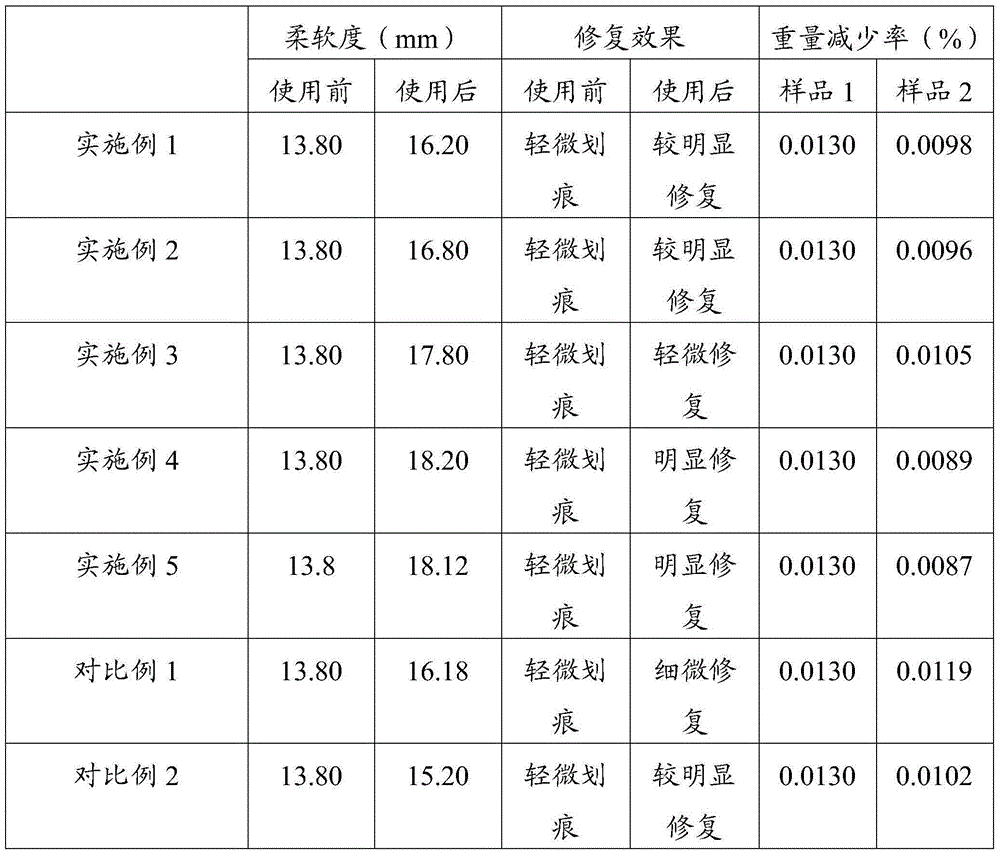

Leather care solution and preparation method thereof

The invention relates to a leather care solution and a preparation method thereof. The leather care solution comprises the following components in parts by mass: 2 to 4 parts of nanoscale water-based wax emulsion, 1 to 3 parts of nano silicon dioxide emulsion, 2.5 to 4 parts of olive oil, 3 to 4 parts of an emulgator, 10 to 15 parts of a seaweed extract, 2 to 4 parts of an aloe extract, 3 to 5 parts of high alcohols and 64.9 to 74.4 parts of deionized water, wherein the solid content of the nanoscale water-based wax emulsion is 20 to 25 wt.%, and the solid content of the nano silicon dioxide emulsion is 20 to 25 wt.%. The leather care solution can effectively moisten and soften leather, prevents the ageing of the leather, and increases the wear-resisting property and the gloss of the leather, thus prolonging the service life of the leather.

Owner:深圳市艾思生物技术有限公司

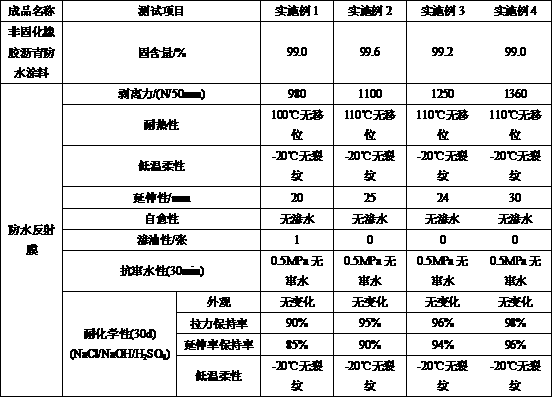

Uncured rubber asphalt waterproof coating, preparation method thereof and waterproof reflecting film

InactiveCN109439199AIncreased degree of chemical cross-linkingHigh chemical stabilityBituminous coatingsBituminous waterproofingPetroleum

The invention discloses an uncured rubber asphalt waterproof coating, a preparation method thereof and a waterproof reflecting film. The uncured rubber asphalt waterproof coating comprises the following raw materials in parts by mass: 30-70 parts of petroleum asphalt, 3-10 parts of a tackifier, 10-20 parts of a softening agent, 10-15 parts of rubber powder, 0.5-2 parts of an anionic dispersant, 10-20 parts of a thickening agent and 0.1-2 parts of a catalyst. The waterproof reflecting film is prepared from the coating. The petroleum asphalt is used as the main material of the uncured rubber asphalt waterproof coating, and is added with other additives which are in cross-linking reaction with the petroleum asphalt, thus, the coating has high chemical stability, has certain creep property, seals cracks and capillary pores of a base layer, can adapt to a complicated construction operation surface, and has good weather fastness, the characters of sticky rubber are always maintained, the capillary pores and the cracks of the base layer can be sealed well, the problems that cracking stress of the base layer is transmitted to a waterproof layer, thus, the waterproof layer is broken and isfatigue under flexing or is aged ahead of time due to the fact that the waterproof layer is in a high-stress state are solved, and the construction difficulty is simplified.

Owner:广东圣帕新材料股份有限公司

Acrylic optical film, and polarizing plate comprising same

ActiveCN105658708AImprove adhesion strengthGood solvent resistanceSynthetic resin layered productsOptical articlesWater dispersibleAcrylic resin

The present invention relates to a polarizing plate comprising an acrylic optical film, in which a first primer layer comprising a water-dispersible polyurethane resin is formed on one surface of the acrylic optical film, and a second primer layer comprising at least one of a water-dispersible polyester resin and a water-dispersible acrylic resin is formed on the other surface of the acrylic optical film.

Owner:ANHUI HEMEI MATERIALS TECH CO LTD

Polyurethane resin preparation method

The invention relates to the technical field of materials for synthetic leather, in particular to a polyurethane resin preparation method. The method includes the steps: 1) increasing the temperature of 145 parts of polyneopentanediol adipate with the molecular weight of 2000 to 100 DEG C, performing vacuum dehydration for about 1h and cooling to 50 DEG C; 2) adding 150 parts of methylbenzene, 251 parts of IPDI (isophorone diisocyanate) and 5 parts of organic bismuth catalysts into a reactor with stirring uniformly, increasing the temperature to 90 DEG C and reacting for 2h; 3) adding 46 parts of 1,6-hexanediol to continue reaction for 2h at the temperature of 90 DEG C; 4) cooling to 50 DEG C, adding 100 parts of methylbenzene, 100 parts of normal butanol and 100 parts of isopropyl alcohol with stirring uniformly, slowly tackifying with 53 parts of isophorone diamine, and stopping adding the isophorone diamine when the viscosity is increased to 150000cps; and 5) continuing to stir for 30 minutes and cooling to 30 DEG C to discharge so that weak-solvent aliphatic polyurethane resin with 50% of solid content and 220kgf / cm<2> of modulus is obtained.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com