Separative film and its processing method

A processing method and technology of release film, applied in the direction of film/sheet adhesive, device for coating liquid on the surface, coating, etc., can solve the problem that users of release film products are difficult to accept and the future is not discussed And the specific content of fluorine, the migration of liquid surfactants, etc., to achieve excellent anti-adhesive isolation effect, good adhesion effect, and easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

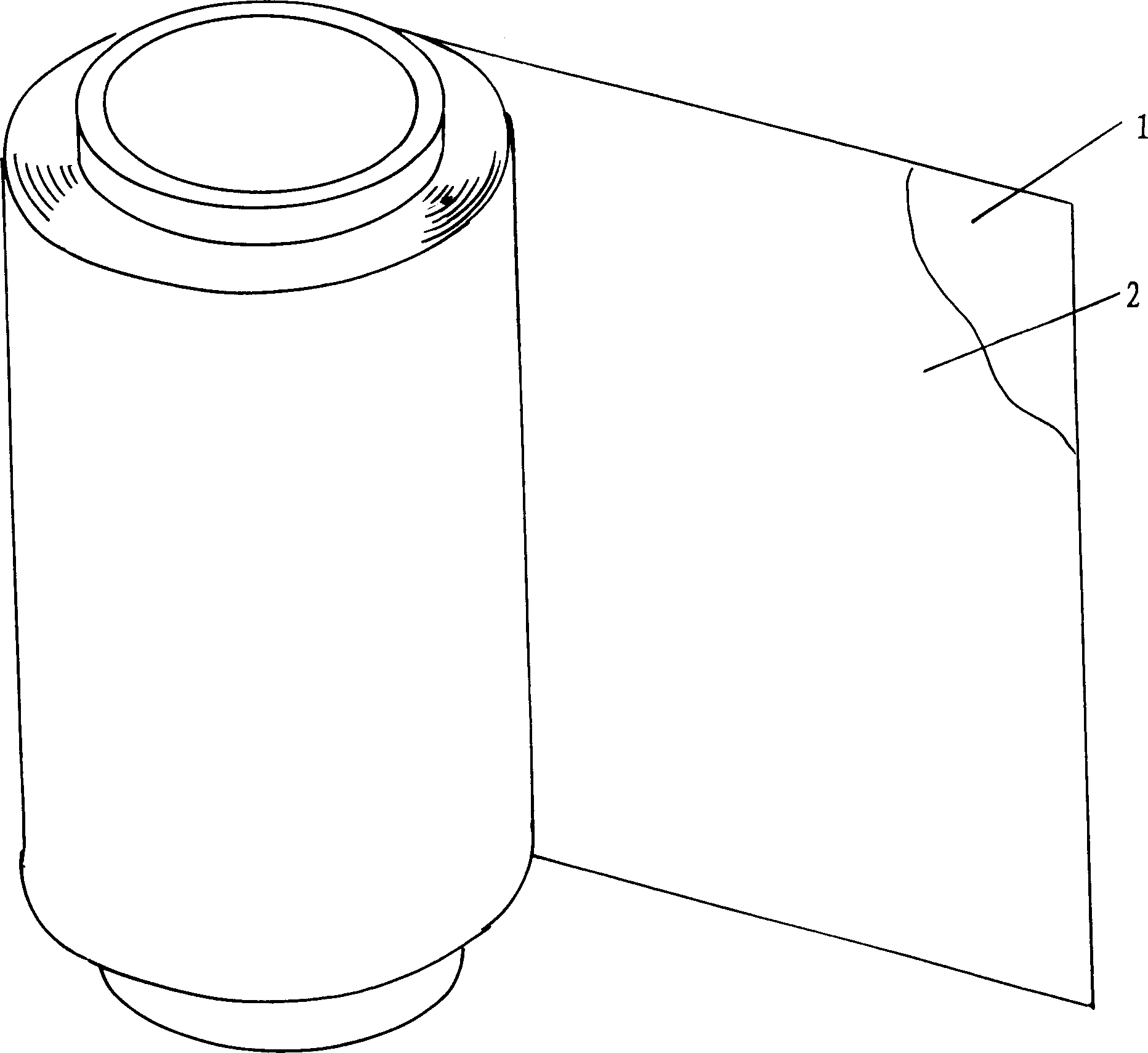

[0024] (a) selecting a polyester film 1 with a thickness of 0.025 mm that is resistant to high temperatures, good transparency, and has no defects such as pinholes and bubbles;

[0025] (b) Dissolve purchased or homemade 2,4-hexafluorovinylmethylsiloxane in heptane at a concentration of 5%, and the resulting 2,4-hexafluorovinylmethylsiloxane solution , add platinum (Pt) as the organoplatinum complex of catalytic main body, stand-by;

[0026] (c) release high voltage to the surface of polyester film 1 with a corona treatment machine, thereby increasing the tension force of polyester film 1, if only one side of polyester film 1 is given anti-adhesive release layer 2, so as long as single-sided Corona treatment is enough, but if it is coated on both sides, both sides need to be treated with corona;

[0027] (d) 2,4-hexafluorovinylmethylsiloxane solution is applied to the surface of the polyester film 1 with a coating machine (if both sides need to be coated, then both sides are ...

Embodiment 2

[0030] Only change the thickness of polyester film 1 in step (a) to 0.050mm; change the concentration in step (b) to 10%; change the temperature in step (d) to 56°C, 80°C, 100°C , 88 ℃, 73 ℃, the advancing speed of polyester film is changed into 65m / min, and all the other are the same as embodiment 1.

Embodiment 3

[0032] Only change the thickness of the polyester film in step (a) to 0.070mm; change the concentration in step (b) to 15%; change the temperature in step (d) to 60°C, 80°C, 100°C, 90 DEG C, 70 DEG C, the advancing speed of polyester film is changed into 45m / min, all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com