Patents

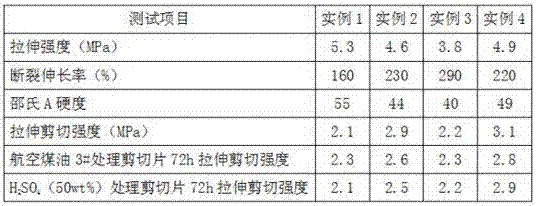

Literature

72 results about "Liquid fluorine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

At room temperature, fluorine is a gas of diatomic molecules, pale yellow when pure (sometimes described as yellow-green). It has a characteristic pungent odor detectable at 20 ppb. Fluorine condenses into a bright yellow liquid at −188 °C (−306 °F), a transition temperature similar to those of oxygen and nitrogen.

Multi-mode multi-propellant liquid rocket engine

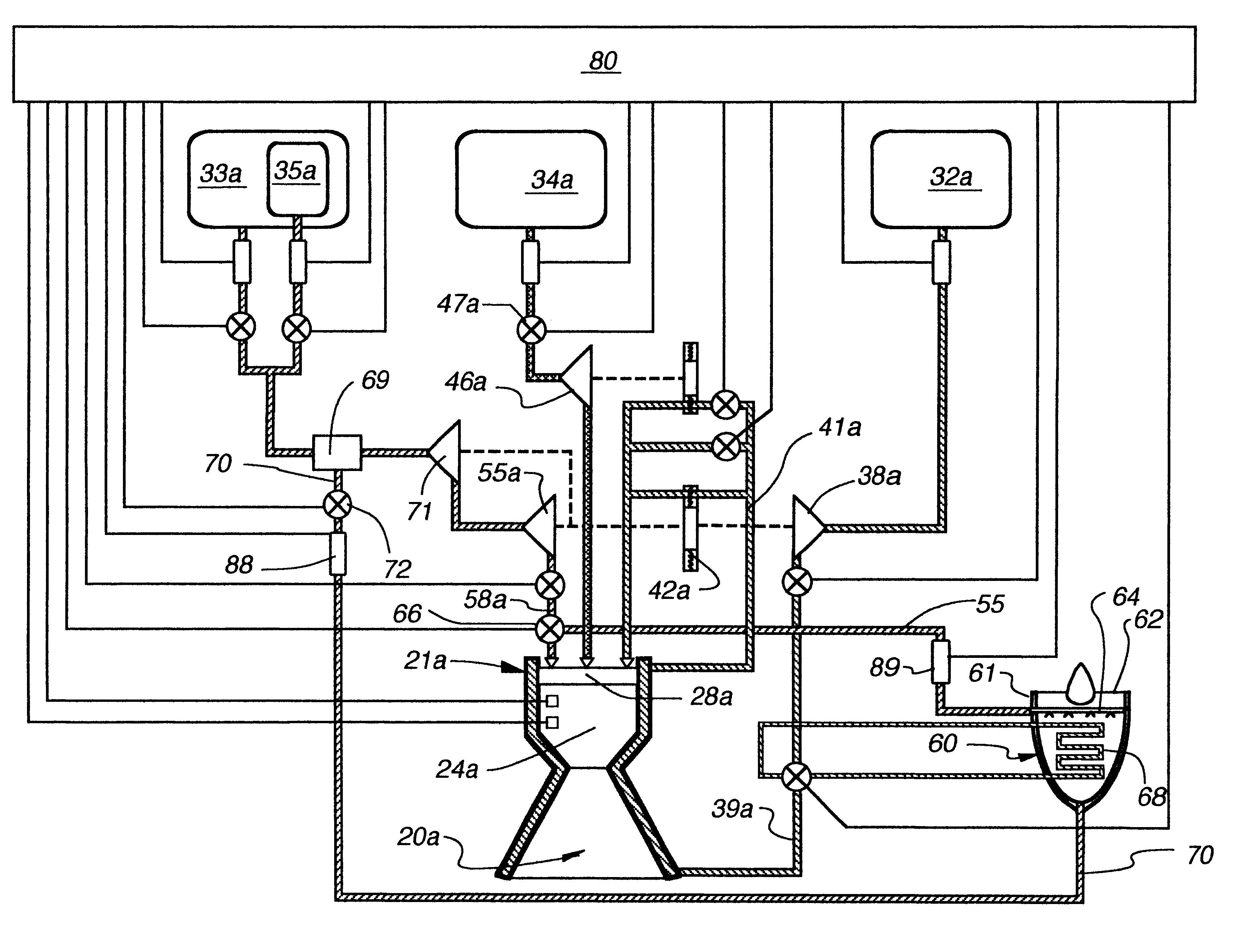

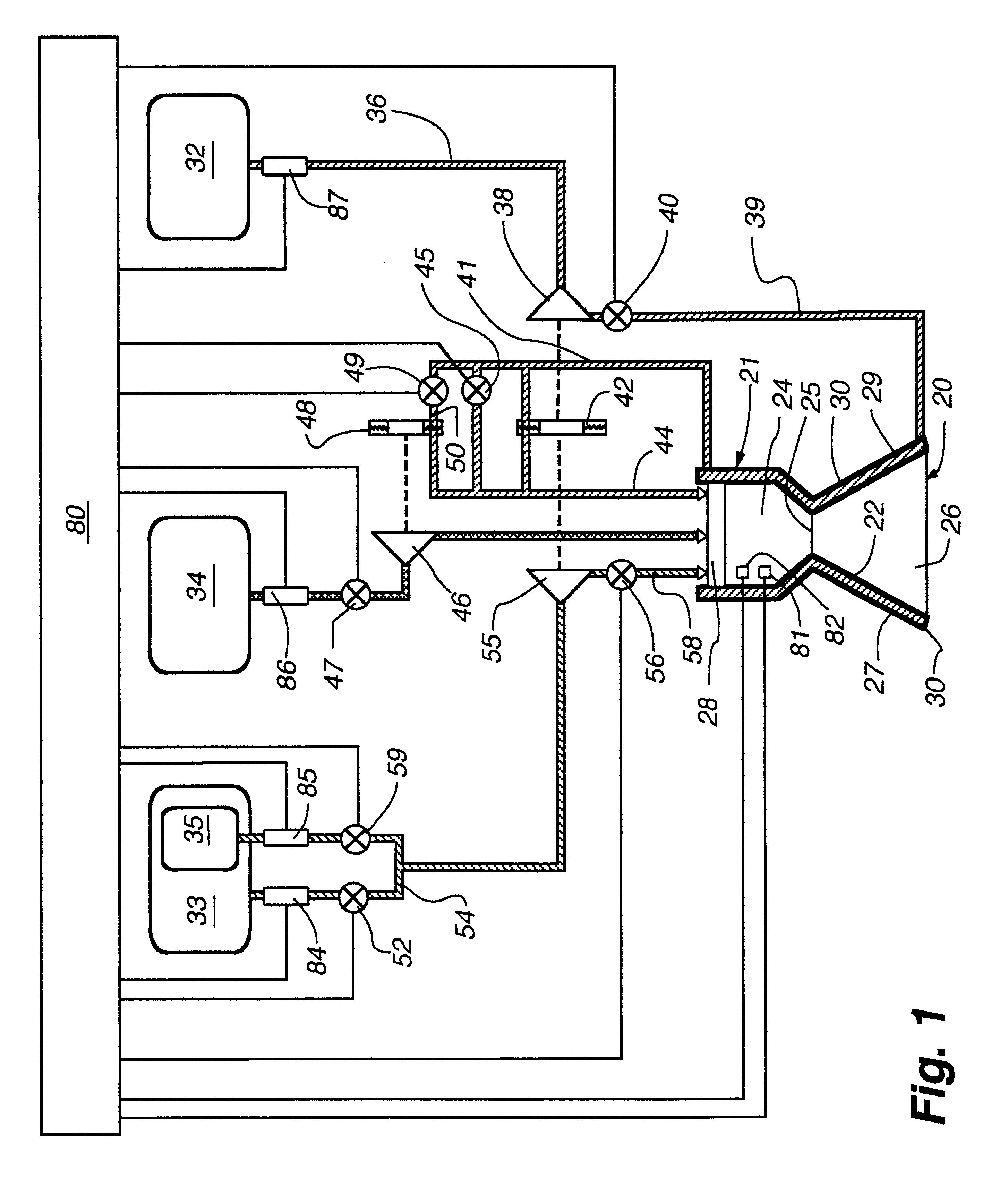

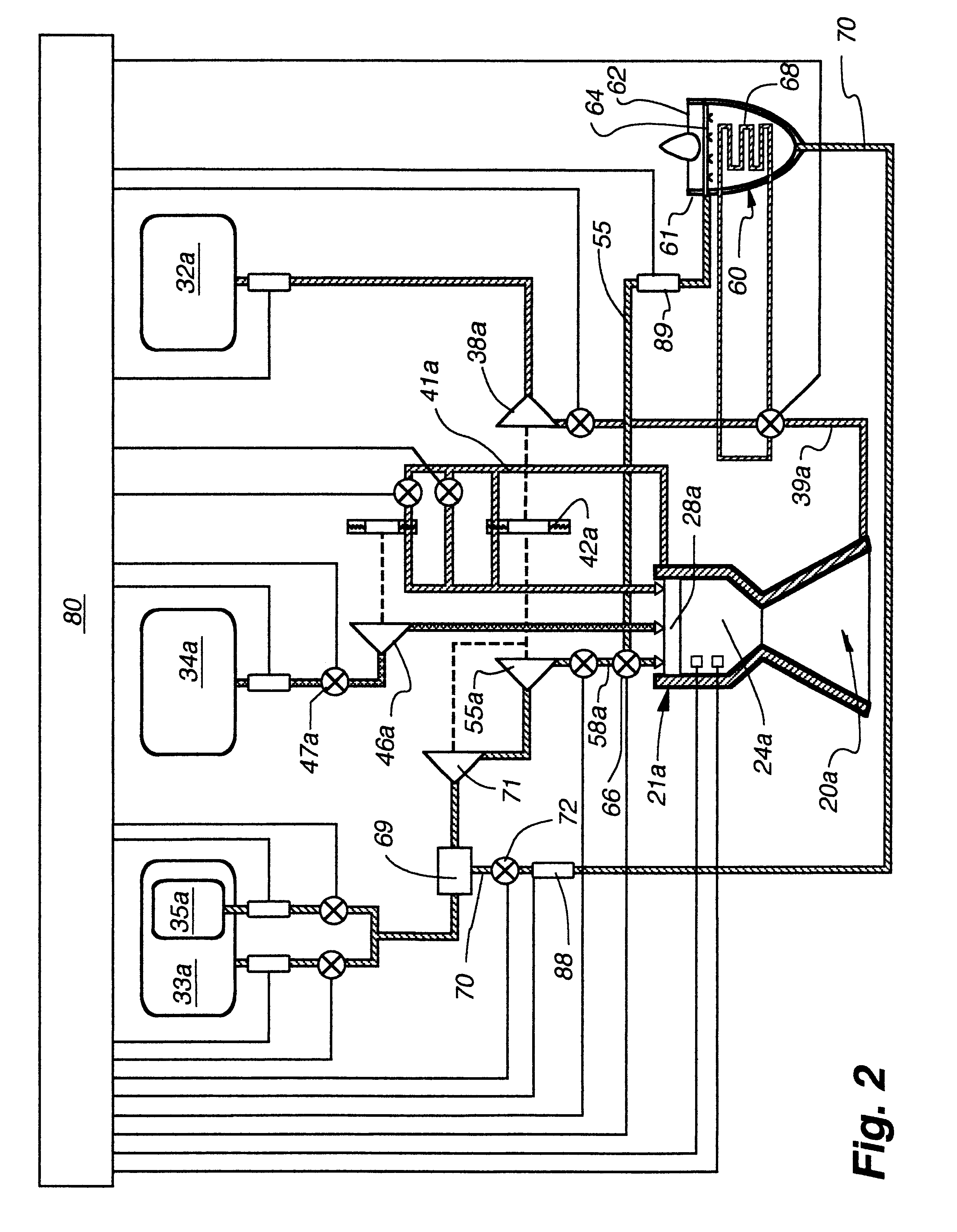

InactiveUS6619031B1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberLiquid fluorine

A multi-mode multi-propellant rocket engine capable of operating in a plurality of selected modes.Propellant components may include liquid hydrogen, liquid hydrocarbon, liquid oxygen, liquid fluorine, and liquid air. The liquid oxygen and the liquid air are stored in separate tanks are mixed in a dedicated mixer prior to their injection into the combustion chamber.

Owner:MSE TECH APPL

Preparation method of carboxyl-terminated liquid fluorine polymer

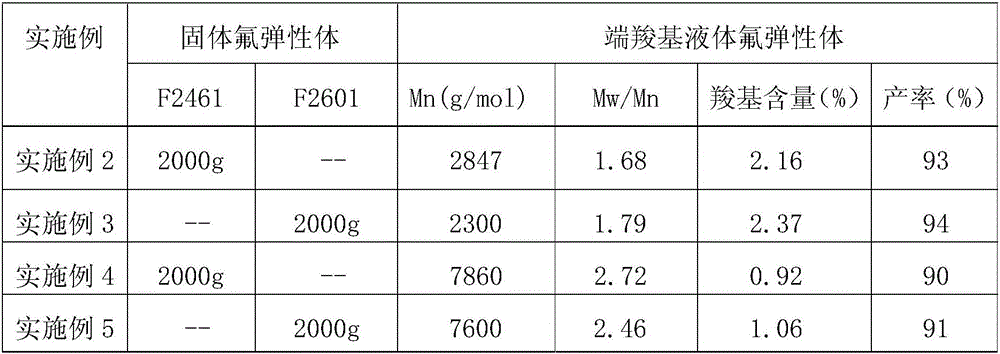

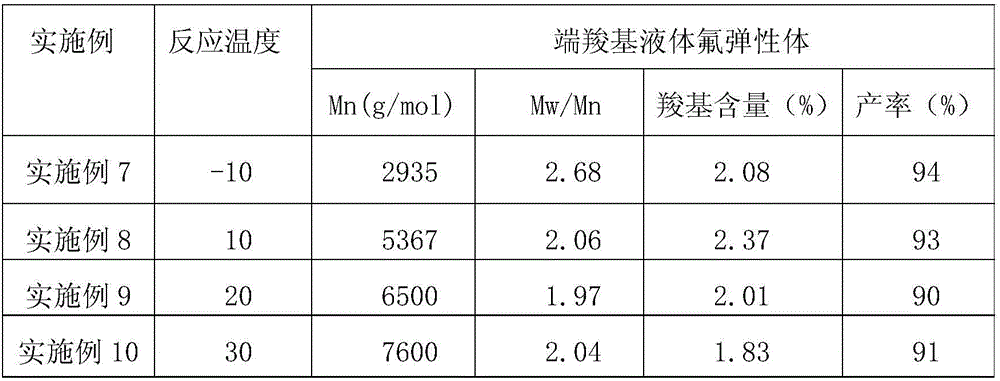

The invention discloses a preparation method of a carboxyl-terminated liquid fluorine polymer, comprising the following steps of: dissolving a solid fluorine elastomer in an organic solvent, adding oxidant and alkali, and stirring to react for 5 to 20 hours, wherein the reaction temperature is controlled within 10 to 70 DEG C, and the reaction pressure is self-generated pressure of a system; standing for 8 to 12 hours after reaction stops, and then recovering the carboxyl-terminated liquid fluorine polymer. The preparation method has the advantages of simple and easy process, less side reactions, high production ratio and low cost. The invention also discloses a solidification method of the carboxyl-terminated liquid fluorine polymer, and the carboxyl-terminated liquid fluorine polymer is reacted with an organic compound containing two or more than two epoxide groups or polyvalent metal oxides and solidified.

Owner:BEIJING UNIV OF CHEM TECH

Liquid fluorine-containing and two-component compositions for the surface treatment of mineral and non-mineral substrates

Fluorine-containing and two-component compositions exhibit improved surface properties for the permanent oil- and water-repellent surface treatment or modification of mineral and non-mineral substrates for various fields of application. At a simultaneously reduced fluorine content, these compositions have considerably improved application properties and, in combination with suitable stabilizing components and hydrophilic silane components, they exhibit excellent hydrophobic, oleophobic and soil-repellent properties, having overall excellent storage stability.

Owner:EVONIK DEGUSSA GMBH

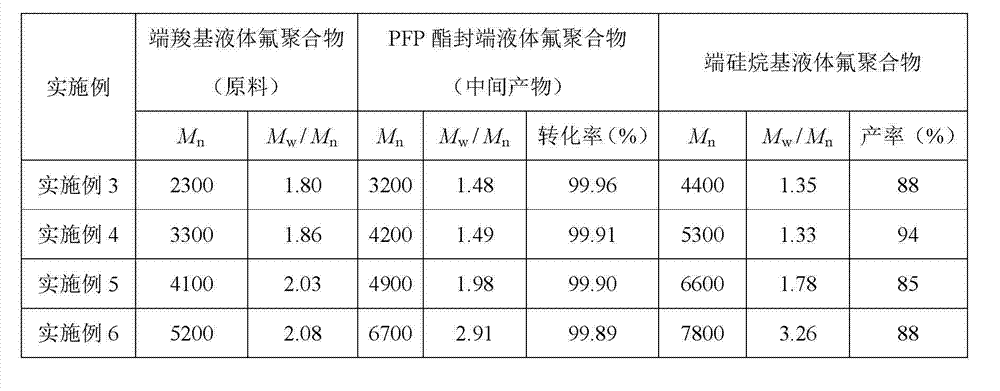

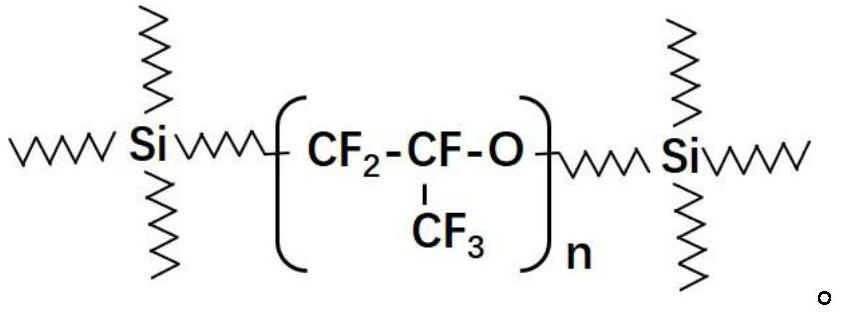

Preparation method and solidification method of silicyl-terminated liquid fluorine polymer

InactiveCN103193919AGood chemical resistanceGood high temperature fuel resistanceLiquid fluorineAdhesive

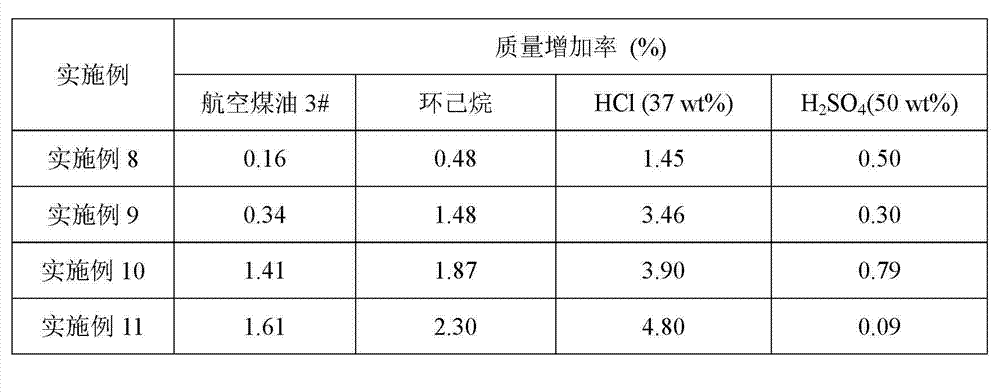

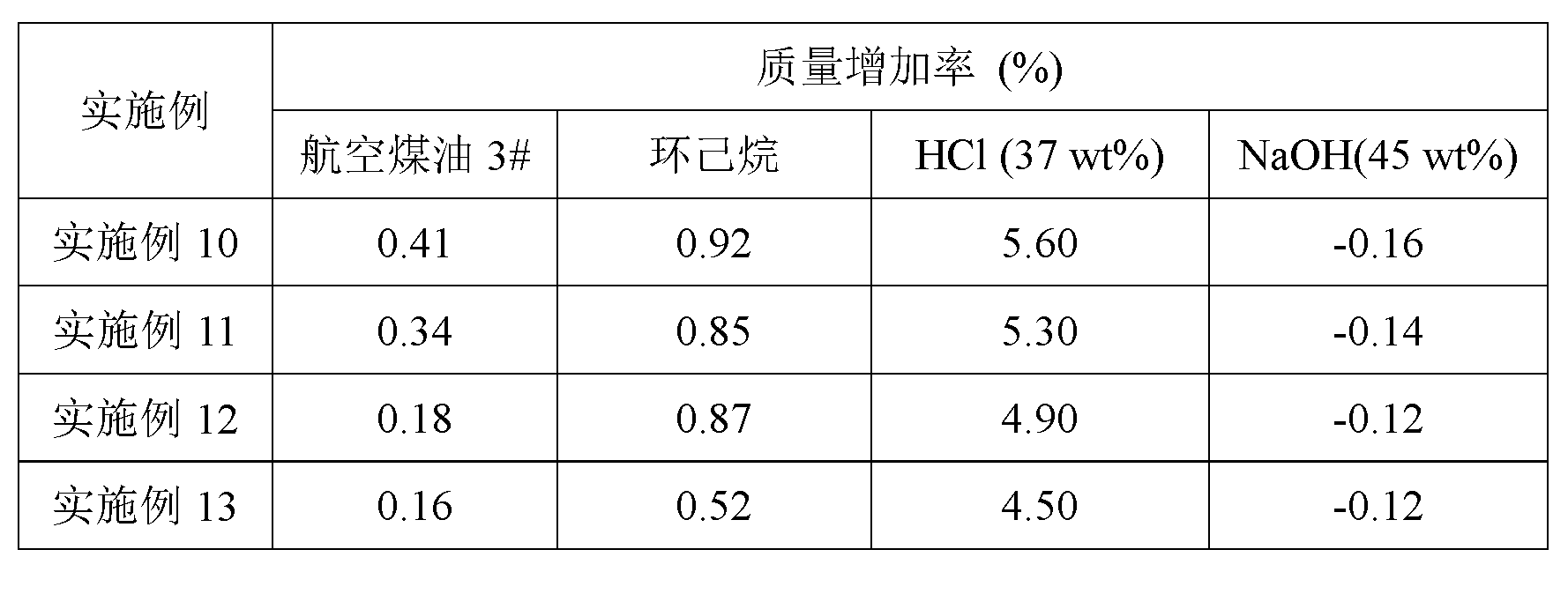

The invention discloses a preparation method of a silicyl-terminated liquid fluorine polymer. The silicyl-terminated liquid fluorine polymer is synthesized by a two-step method. The method comprises the following steps: (1) preparing a pentafluorophenol ester-terminated liquid fluorine polymer via a Steglich reaction by taking a carboxyl-terminated liquid fluorine elastomer and pentafluorophenol as raw materials; and (2) carrying out substitution reaction on the pentafluorophenol ester-terminated liquid fluorine polymer and silane, thereby preparing the silicyl-terminated liquid fluorine polymer. The humid solidification of the silicyl-terminated liquid fluorine polymer can be carried out at the room temperature, wherein the Tg of a solidified film is decreased along with the increasing of the relative molecular mass of the silicyl-terminated liquid fluorine polymer before being solidified. The solidified film has good resistance to acid, aviation kerosene, nonpolar solvents and other chemicals. The resisting performance of the solidified film with high molecular weight to the aviation kerosene, cyclohexane and hydrochloric acid is superior to that of the solidified film with low molecular weight. The method is simple and low in cost. The yield of the silicyl-terminated liquid fluorine polymer reaches more than 85%; and the strict pollution control measures are not required. The silicyl-terminated liquid fluorine polymer can be served as a raw material for preparing a sealant, an adhesive, a coating material and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

Drug-loaded silicone grease ultrasonic contrast agent and its preparation method and use

InactiveCN104826140AThe synthesis process is simpleStable in vivo and in vitroEnergy modified materialsEchographic/ultrasound-imaging preparationsUltrasound contrast mediaLiquid fluorine

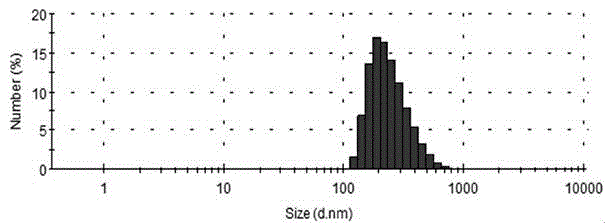

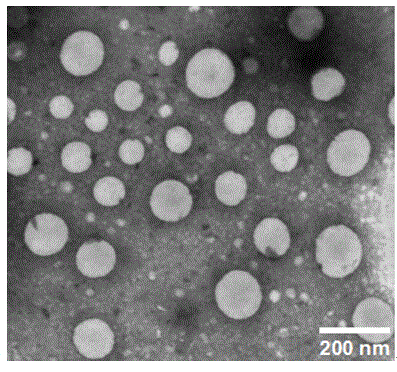

The invention provides a preparation method of a drug-loaded silicone grease ultrasonic contrast agent. The preparation method comprises fully dissolving silicone grease, polyethylene glycol phosphate derivatives and a fat-soluble anticancer drug in an organic solvent, adding water into the solution, carrying out whirling, removing the organic solvent, supplying water with a volume 3 times that of the solution into the solution, carrying out ultrasonic disintegration by an ultrasonic disintegrator, simultaneously and fast adding liquid fluorocarbon into the solution to obtain a pre-emulsion, and carrying out dialysis on the pre-emulsion in PBS for 1h to obtain a product. The preparation method has simple processes. The product has the average particle size of about 100nm and is conducive to aggregation at a tumor position by internal EPR effects. Siloxane silicone grease network distribution substantially improves structure stability and prolongs internal blood circulation time. Through HIFU, the drug-loaded silicone grease ultrasonic contrast agent release drugs at a local part of tumor tissue, drug treatment targeting is improved, HIFU treatment effects are substantially improved and HIFU-chemotherapy combined treatment is realized.

Owner:SUN YAT SEN UNIV

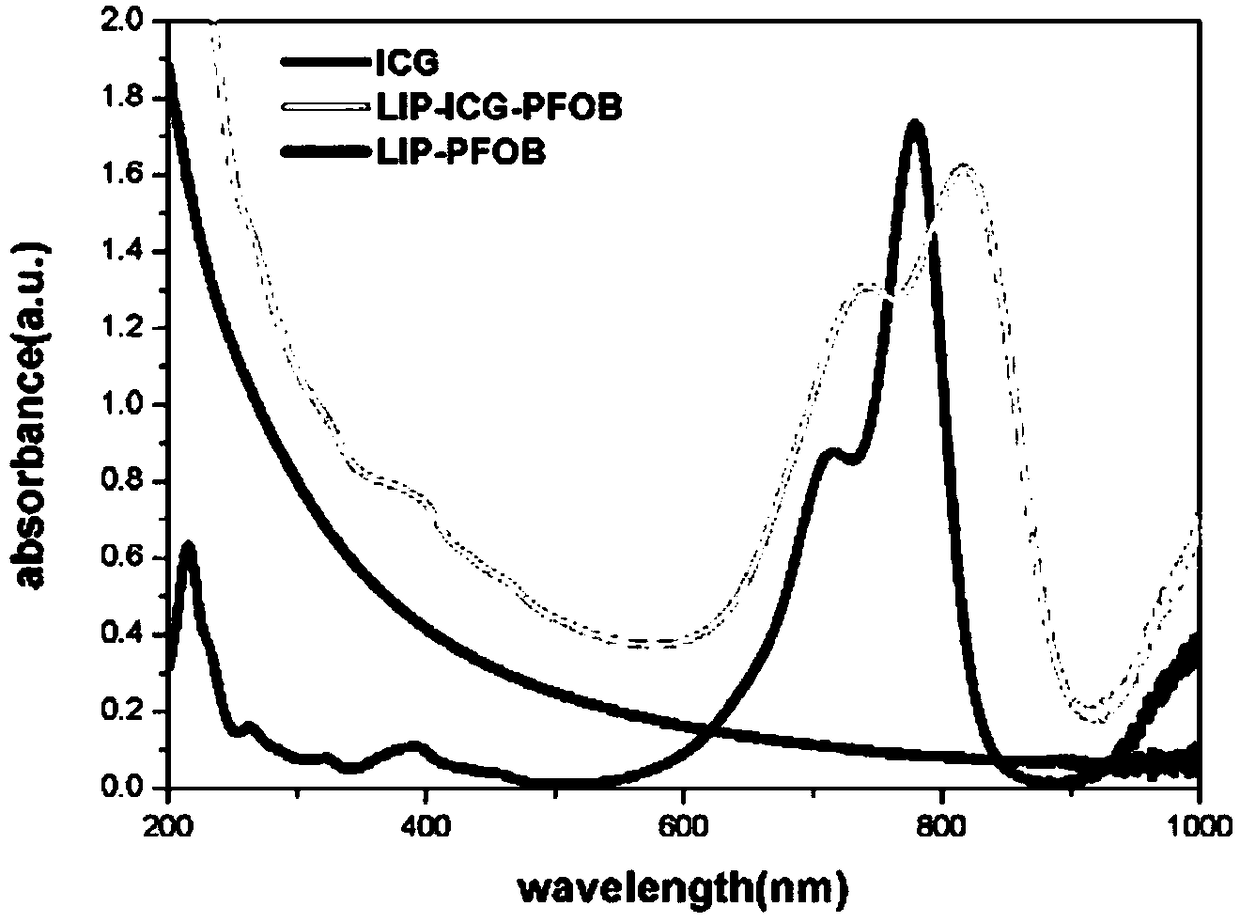

Multifunctional contrast agent of oxygen carrying liquid fluorocarbon and preparation method thereof

InactiveCN108379600AImprove the effect of photodynamic therapyDown-regulated expressionPhotodynamic therapyGeneral/multifunctional contrast agentsLight treatmentFluorocarbon

The invention discloses a multifunctional contrast agent of oxygen carrying liquid fluorocarbon. The multifunctional contrast agent is of a spherical shell-core structure; the core is prepared from liquid fluorocarbon and indocyanine green. The invention aims at solving the technical problems to provide the multifunctional contrast agent of oxygen carrying liquid fluorocarbon and the preparation method. The multifunctional contrast agent has high biological safety and stability, and is used for the multi-mode nanometer contrast agent guided breast cancer light treatment.

Owner:CHONGQING MEDICAL UNIVERSITY

Thermomechanical generating technique using low-temperature liquid as working medium

InactiveCN101832157AThe principle is simpleIncrease power generationSteam engine plantsLiquid fluorinePetroleum

The invention discloses a technique using low-temperature liquid of which the boiling temperature is below zero under a standard pressure as a generating working medium. Generally, the technique adopts fluorine R22 of 40.8 DEG C below zero, R410a of 51.6 DEG C below zero and the like, usually used in an air conditioner, as the generating working medium. When the liquid fluorine R22 is contacted with high-temperature hot water of +99 DEG C, the liquid fluorine R22 is vaporized sharply and generates high-pressure gas. The fluorine R22 can generate a pressure of MPa at a normal temperature and can generate a very high pressure if contacting the high-temperature hot water of +99 DEG C, wherein the pressure is high enough to propel an improved turbo machine and an improved compressor to rotate and drive a generator to generate electricity. The technique can absorb the heat energy of water or air of which the temperature is within +100 DEG C and converts the absorbed heat energy into electric energy to output. The technique can fully use the hot water generated in steel factories, power plants, brick, tile and ceramics plants and the like to generate electricity. The equipment needs no coal, fuel oil or oxygen and only needs hot water, hot air or normal-temperature water or normal-temperature air to generate electricity. Air or water exists in most areas in the earth and can be continuously recycled; the air or water does not need to be searched, exploited, refined and subjected to other steps as the coal, oil and uranium ore; the air or water does not need to be conveyed by vehicles, trains and steamships back and forth, which are built for conveying the coal, the oil and the uranium ore; and the air or water does not need a large amount of warehouses and gas stations, so the device of the invention can be used for a long time. Because the device can work without oxygen, the device can normally work undersea and can be used on a submarine.

Owner:翁志远

High-corrosion-resistance aluminum alloy composite material and preparation method thereof

ActiveCN107164661AImprove high temperature resistanceGood chemical stabilityFireproof paintsAnti-corrosive paintsLiquid fluorineCorrosion resistant

The invention belongs to the technical field of high-performance aluminum alloy composite materials and particularly relates to a high-corrosion-resistance aluminum alloy composite material and a preparation method thereof. The high-corrosion-resistance aluminum alloy composite material comprises an aluminum alloy composite material body and a corrosion-resistant coating. The corrosion-resistant coating is a carborane-liquid fluorine polymer coating. The high-corrosion-resistance aluminum alloy composite material has the excellent and high corrosion resistance.

Owner:山东创新精密科技有限公司

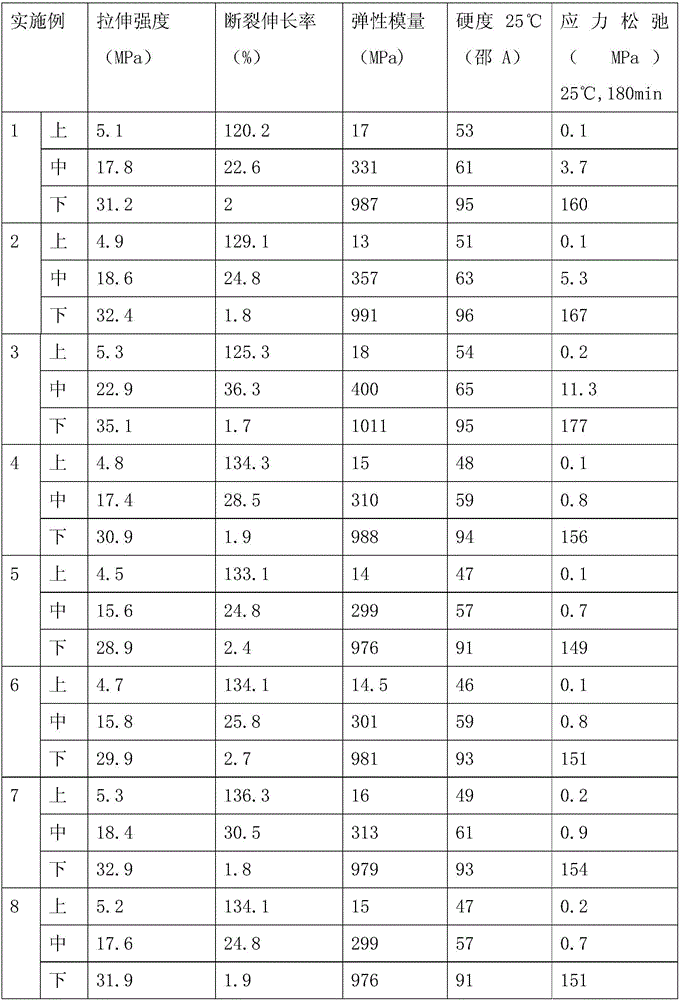

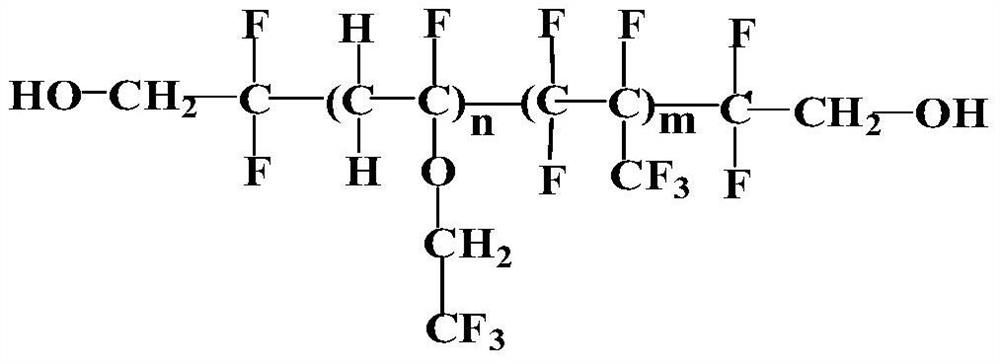

Synthesizing method of hydroxyl-terminated liquid fluorine rubber modified polyurethane material with gradient modulus

The invention provides a synthesizing method of a hydroxyl-terminated liquid fluorine rubber modified polyurethane material with gradient modulus. The method comprises the steps that 1, polyether diol with a low molecular weight, hydroxyl-terminated liquid fluorine rubber and aromatic diisocyanate serve as the raw materials to synthesize an isocyanate-terminated modified polyurethane prepolymer; 2, the product in the first step is mixed with different mole ratios of aromatic diisocyanate, a cyclotrimerization reaction is conducted in a solvent in the ontological status, and the hydroxyl-terminated liquid fluorine rubber modified polyurethane material with the gradient modulus is obtained finally. The synthesizing method has the advantages that the reaction system is low in viscosity, and synthesis of the isocyanate-terminated polyurethane prepolymer is promoted; the method is novel, the reaction is easy to control, and the product is good and stable in quality. The obtained polyurethane material with the gradient modulus is good in toughness, temperature resistance and chemical medium resistance, and the elasticity modulus has gradualness along with changes of temperature.

Owner:BEIJING UNIV OF CHEM TECH

Laboratory-scale synthesizing and curing method of terminal carboxyl liquid fluorine elastomer

The invention discloses a laboratory-scale synthesizing and curing method of a terminal carboxyl liquid fluorine elastomer. The method comprises the following steps: dissolving a fluorine elastomer in an organic solvent; carrying out oxidative degradation reaction in the presence of oxidant and alkali, in which the reaction time lasts for 8-24 hours, and the reaction temperature changes in a range of 10-40 DEG C; and controlling the dripping speed of the oxidant and the alkali via a peristaltic pump to obtain the terminal carboxyl liquid fluorine elastomer. The synthesizing method has the characteristics of few by-products, simplicity and controllability, and high yield. The terminal carboxyl liquid fluorine elastomer can be cured by reacting with carbodiimide-containing compounds under the normal temperature; the cured product has the characteristics of high mechanical performance, high resistance to high temperature and low temperature and high resistance to chemical media; the terminal carboxyl liquid fluorine elastomer can be used for preparing sealants and adhesives with resistance to chemical media and can also be used for preparing terminal-sealed liquid fluorine elastomers such as hydroxyl, silane, epoxy and amino and the like through terminal group transformation reaction.

Owner:BEIJING UNIV OF CHEM TECH

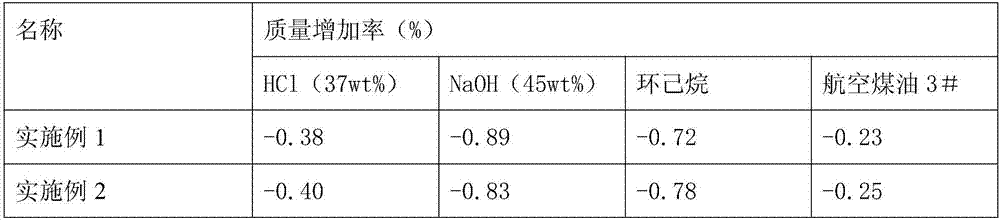

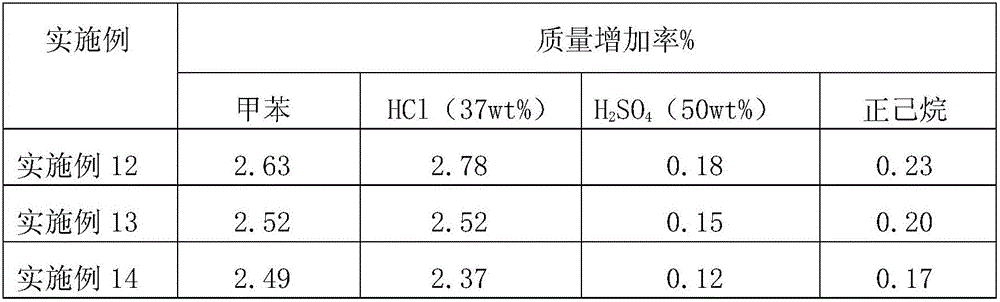

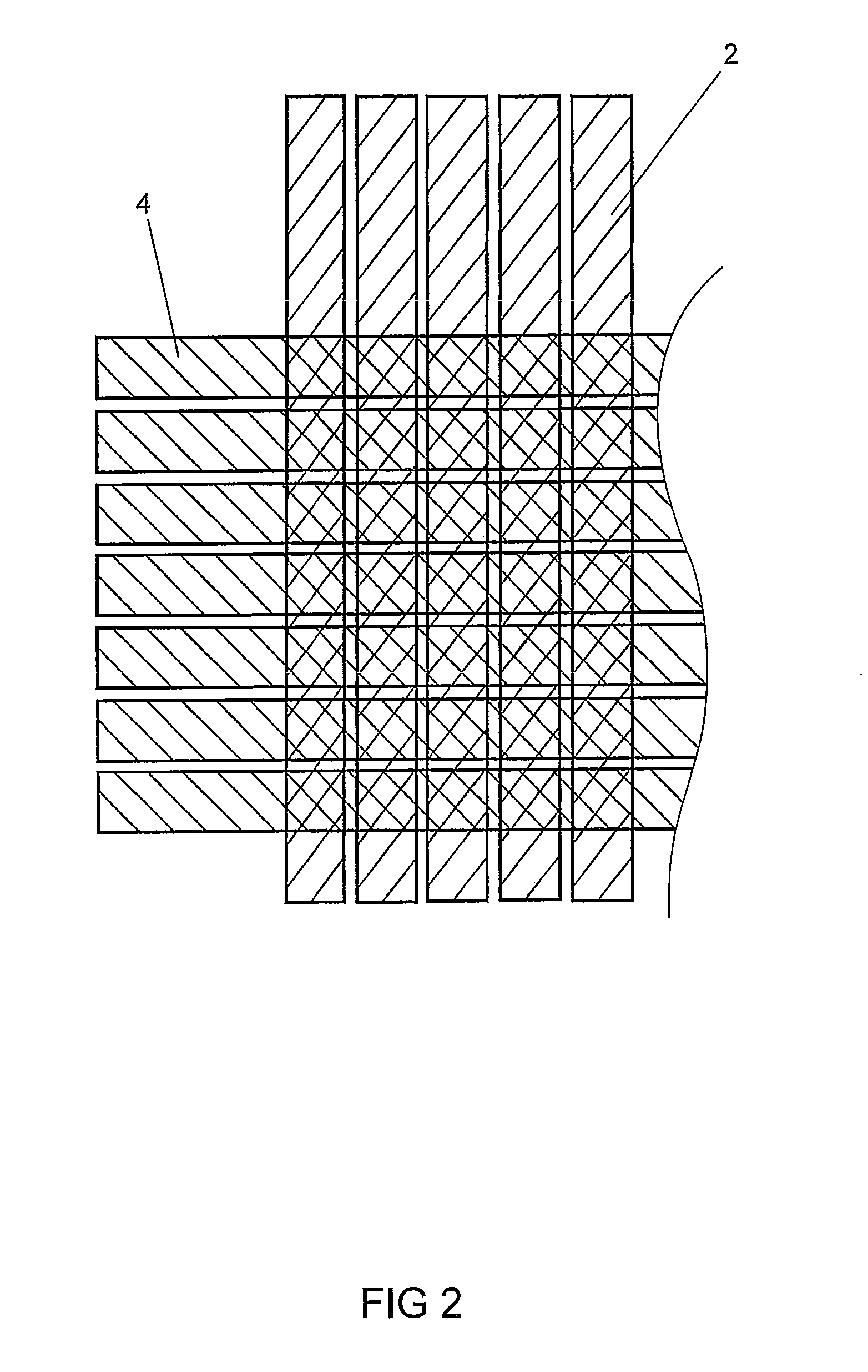

Preparation and solidification methods for carborane-liquid fluorine polymer

InactiveCN103183763AImprove heat resistanceImprove mechanical propertiesPolymer scienceLiquid fluorine

The invention discloses preparation and solidification methods for a carborane-liquid fluorine polymer. The preparation method takes a carboran diols and carboxyl-terminated liquid fluorine polymer as a raw material, prepares the carborane-liquid fluorine polymer through steglich reaction, and has the characteristics of simple and easy process, little side reaction and the like. The carborane-liquid fluorine polymer prepared by the preparation method has the characteristics of excellent heat resistance, chemical resistance, mechanical properties and the like. The invention further discloses a solidification method for the carborane-liquid fluorine polymer. The carborane-liquid fluorine polymer is solidified through reaction with an organic compound containing more than two isocyanate groups. The solidification product has the characteristics of excellent heat resistance, resistance to aviation kerosene, resistance to cyclohexane, resistance to hydrochloric acid, alkaline resistance, mechanical properties and the like. The carborane-liquid fluorine polymer can be used for preparing sealing agents, adhesives and coatings, which can be used in harsh working environments.

Owner:BEIJING UNIV OF CHEM TECH +1

Ultrasonoscopy nanocapsules and preparation method thereof

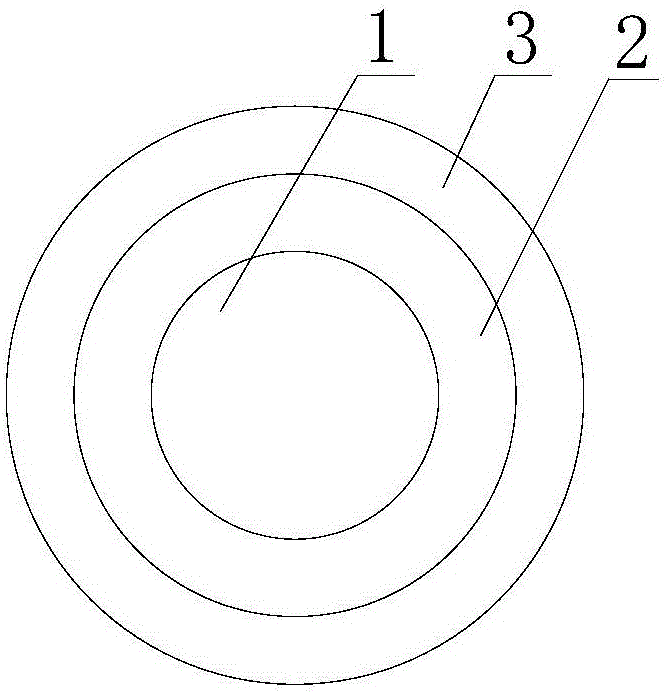

ActiveCN110604824AImprove stabilityExtend development timeEchographic/ultrasound-imaging preparationsMicrocapsulesPolymer scienceLiquid fluorine

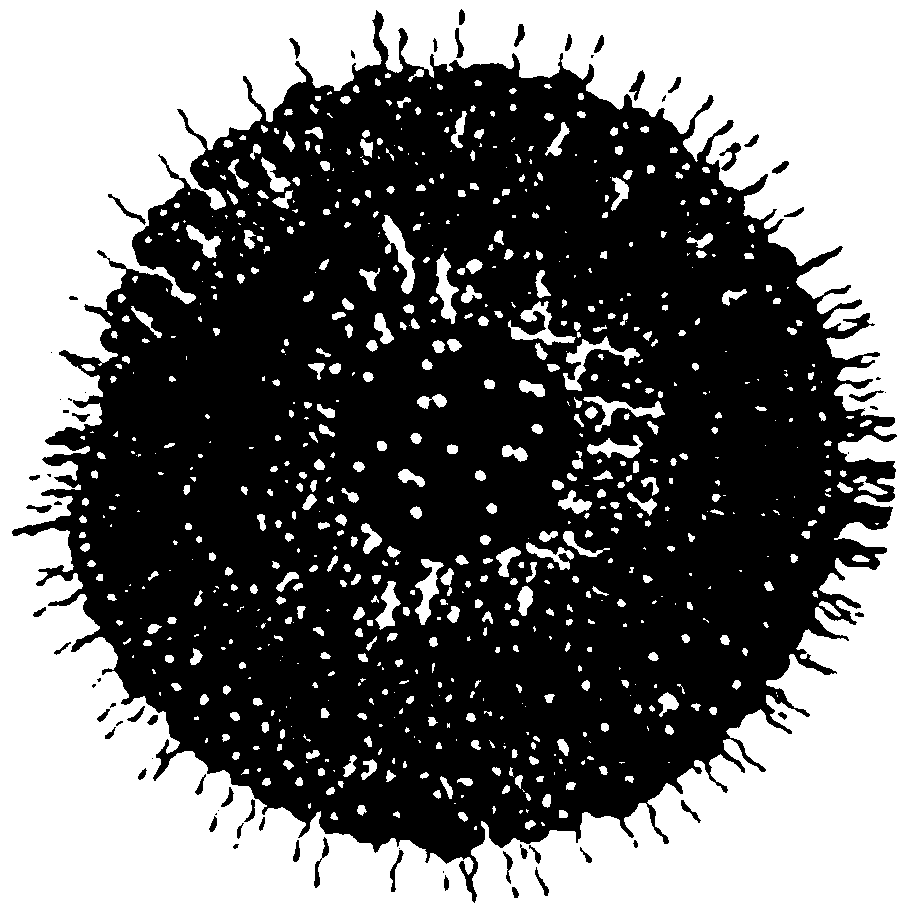

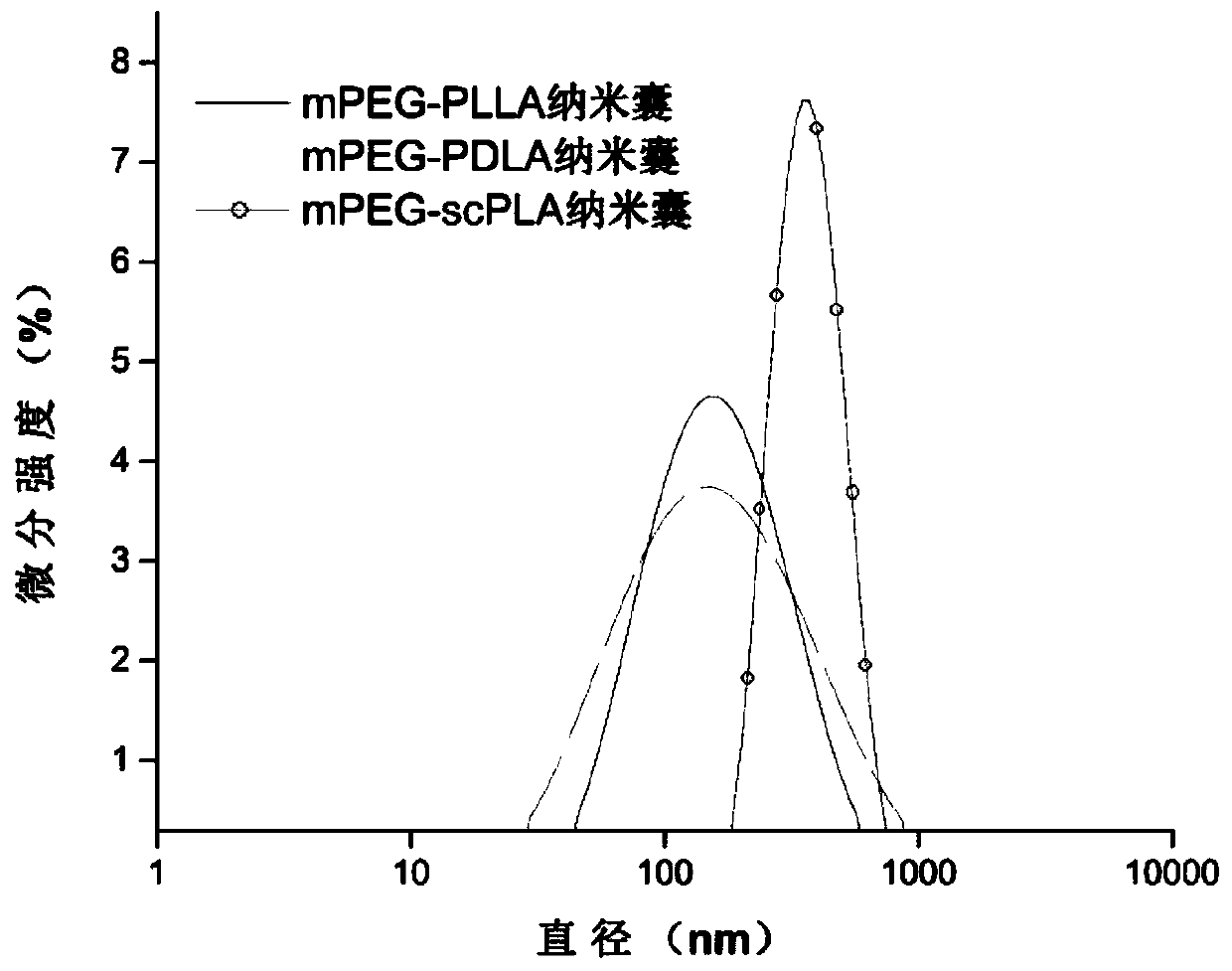

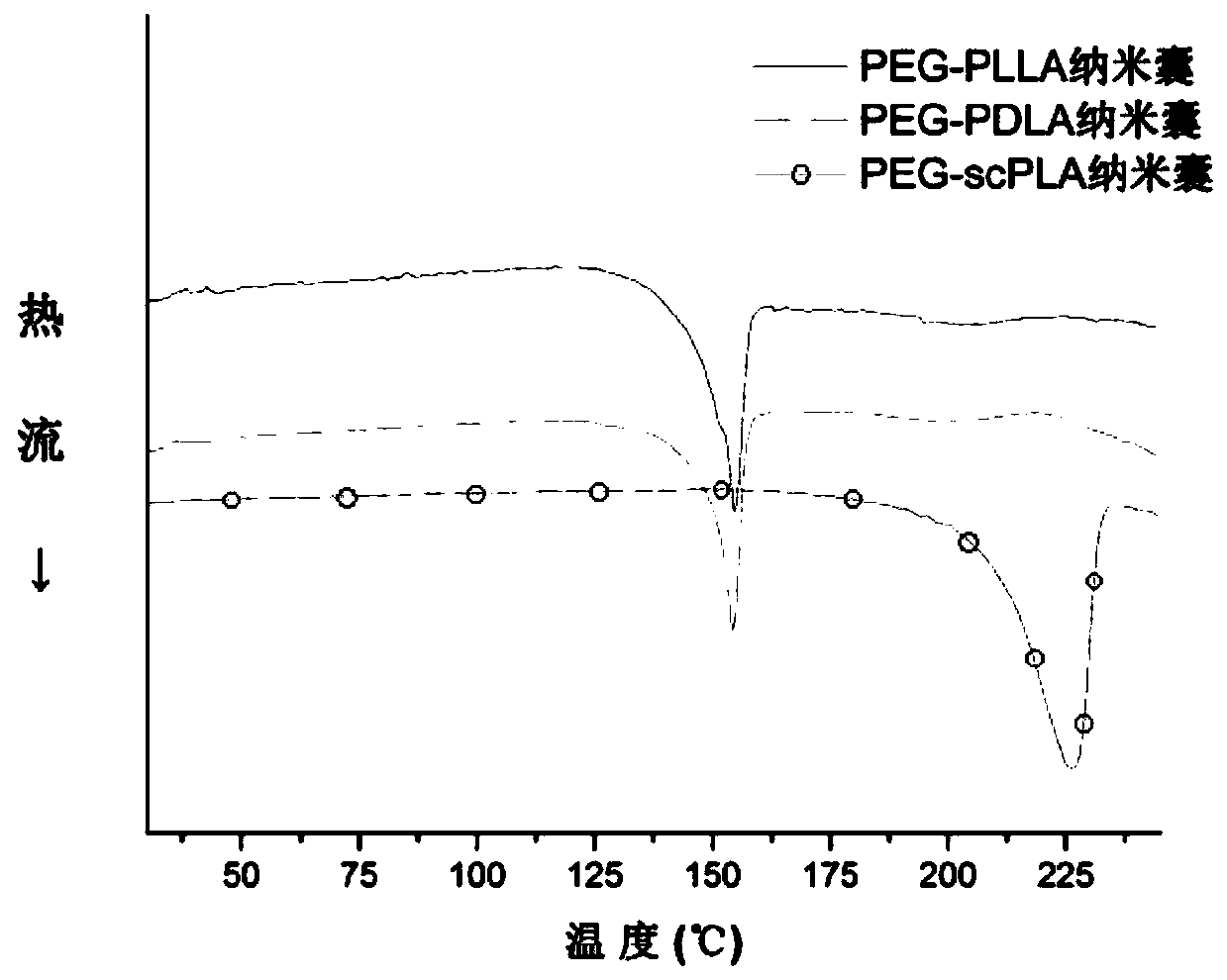

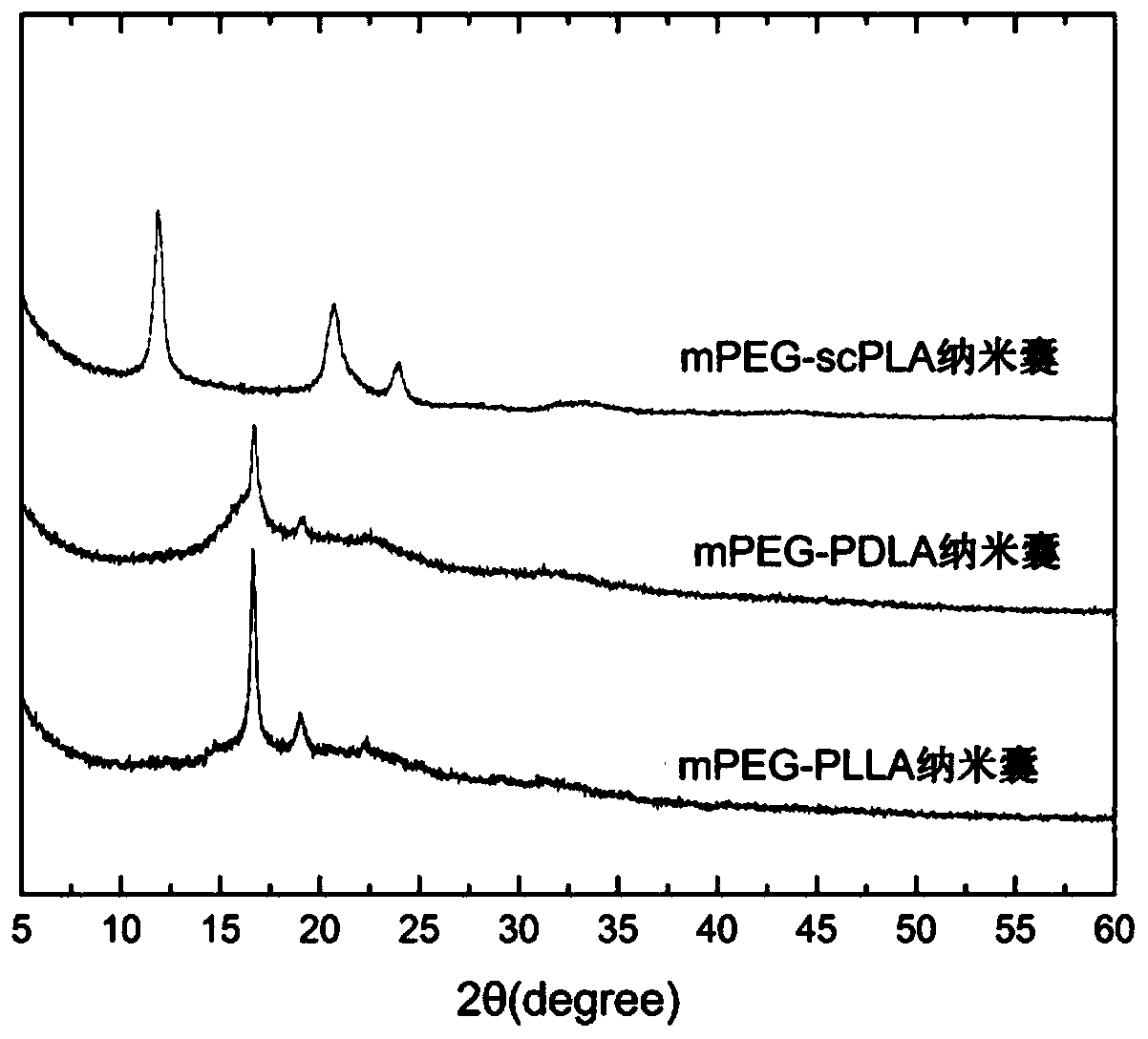

The invention discloses ultrasonoscopy nanocapsules and a preparation method thereof. The ultrasonoscopy nanocapsules present a core / shell structure, shell-layer materials are amphipathic block copolymers, and kernel materials are liquid fluorine-carbon type ultrasonoscopy reagents; the amphipathic block copolymers include hydrophilic chain segments and hydrophobic chain segments, the hydrophilicchain segments are selected from non-ion type water-soluble polymers, the hydrophobic chain segments are polylactic acid, and the polylactic acid includes levorotary polylactic acid and dextrorotatorypolylactic acid. In the manner, the ultrasonoscopy nanocapsules are nanometer-level, and are narrow in particle size distribution, excellent in thermology properties and high in stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

Method for fluorination modification of electrode material

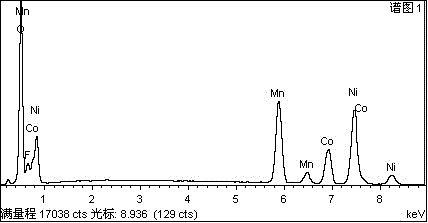

InactiveCN106067539AWell mixedSolve solidElectrode manufacturing processesSecondary cellsDecompositionLiquid fluorine

The invention relates to a method for fluorination modification of an electrode material. The method is characterized in that the electrode material or a precursor thereof is mixed with a liquid fluorine-containing material, and the mixture is subjected to treatment at a certain temperature to obtain a product; as the liquid fluorine-containing material reacts with the electrode material or the precursor thereof, the electrode material or the precursor thereof can be effectively mixed with the liquid fluorine-containing material uniformly, the reaction temperature is lowered, the problem that uniform mixing of raw materials in an electrode material fluorination process and the reaction process cannot be controlled effectively is solved, the explosion risk caused by fluorine gas is eliminated, the surface and interfacial properties of an electrode can be improved, the structural stability of an electrode structure and ordering of ions arranged in crystal lattices can be improved, the destruction of hydrofluoric acid generated in decomposition of an electrolyte can be inhibited, and the safety characteristic, the electrode reaction kinetic feature and the cycling stability of the electrode material are improved. The method has the advantages that the reaction condition is mild; the reaction is easy to control; the granularity and the morphology of the obtained product are easy to control; the energy consumption is low; the preparation method process is simple; the cost and the investment are low; the benefit is good; energy conservation, emission reduction, cleanness and environmental protection are realized.

Owner:SICHUAN UNIV

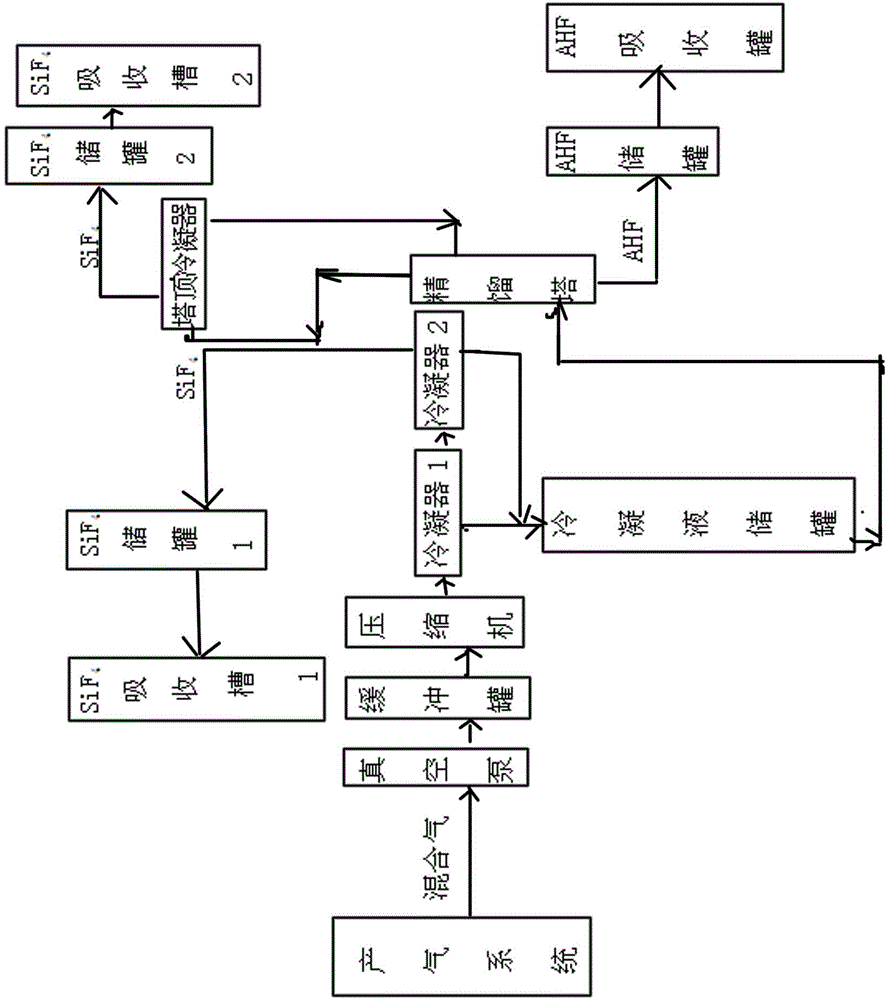

Direct separation method of silicon tetrafluoride and anhydrous hydrogen fluoride mixed gas

ActiveCN104671210AEasy to separateImprove controllabilityHydrogen fluorideHalogenated silanesChemical industryLiquid fluorine

The invention relates to the technical field of fluorine chemical industry, and in particular relates to a direct separation method of a silicon tetrafluoride and anhydrous hydrogen fluoride mixed gas. The method comprises the following process steps: a, collecting a silicon tetrafluoride and hydrogen fluoride mixed gas, which is obtained by pyrolysis of fluosilicic acid, compressing through a compressor, entering a condenser 1, cooling, and entering obtained liquefied hydrogen fluoride to a condensate storage tank; b, feeding the cooled silicon tetrafluoride gas to a condenser 2, further cooling with an ethylene glycol-water solution, removing residual hydrogen fluoride to obtain a silicon tetrafluoride gas and entering a silicon tetrafluoride storage tank 1 to store; and c, carrying out rectification and purification on liquid phases in the step a and the step b, and controlling the operation pressure and the overhead condensation temperature of a rectifying tower to obtain the refined liquid hydrogen fluoride product. The method has the advantages of being feasible to operate, low in investment, low in energy consumption, and free of difficult-to-treat waste, and is an economical, efficient and environment-friendly separation method; and equipment is not corroded.

Owner:YUNNAN TIANAN CHEM CO LTD +1

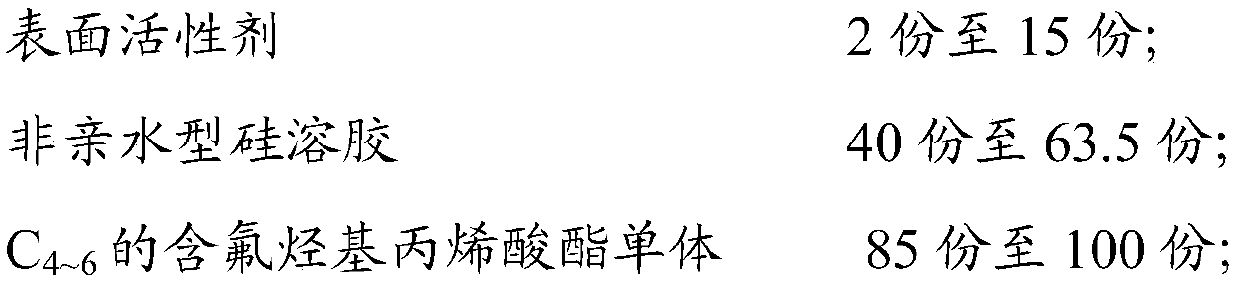

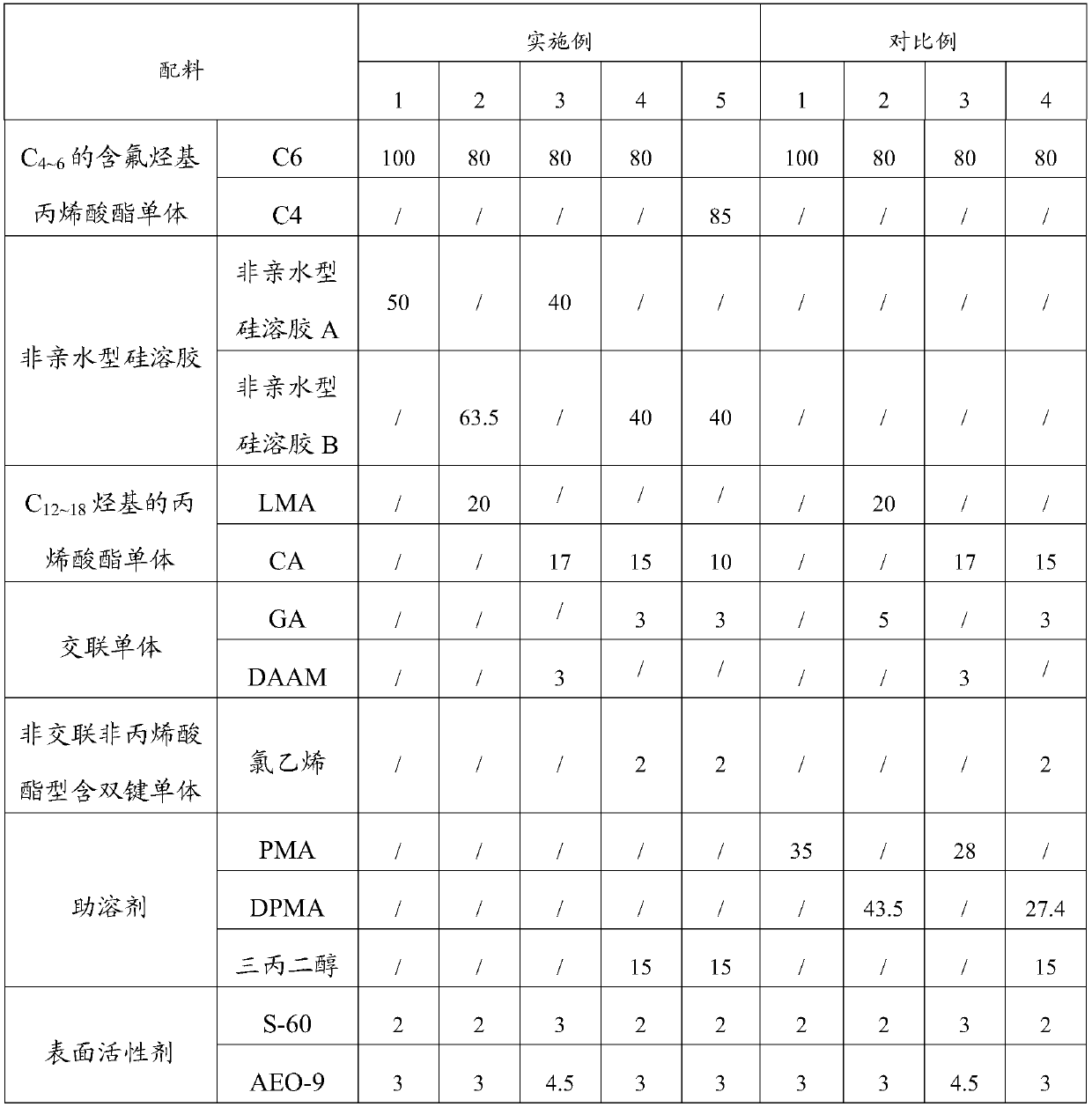

Fluorine-silicon hybrid polyacrylate dispersion liquid

Fluorine-silicon hybrid polyacrylate dispersion liquid comprises, by mass, 2-15 parts of surfactant, 215-263 parts of water and fluorine-silicon hybrid polyacrylate. Fluorine-silicon hybrid polyacrylate contains fluorine-containing alkyl acrylate monomer unit of C4-6 and is obtained by polymerizing 40-63.5 parts of hydrophobic silica sol and 85-100 parts of fluorine-containing alkyl acrylate monomer of C4-6 after co-emulsification. The fluorine-silicon hybrid polyacrylate dispersion liquid has good and lasting waterproof performance; testing shows that oilproof effect of textiles after the fluorine-silicon hybrid polyacrylate dispersion liquid acts on the textiles can reach Grade 6, and the dispersion liquid has good oilproof effect.

Owner:XIAMEN UNIPROS LEISURE PROD

Preparation method of single-component silane-terminated liquid fluorine sealing rubber

InactiveCN107325208AImprove high temperature resistanceGood chemical resistanceNon-macromolecular adhesive additivesOther chemical processesCross-linkSilane compounds

The invention discloses a preparation method of a single-component liquid fluorine sealing rubber based on silane-terminated liquid fluororubber. According to the preparation method, carboxyl-terminated liquid fluorubber is taken as an initial raw material, reaction with an epoxy silane compound is carried out at base catalysis so as to obtain silane-terminated liquid fluororubber; the obtained silane-terminated liquid fluororubber is taken as a basic polymer, and a diluent, a cross-linking agent, and a filling material are added so as to obtain the single-component silane-terminated liquid fluorine sealing rubber. The advantages of the preparation method are that: the production technology is simple; the resources of the basic polymer are widely available; requirements of different application fields can be satisfied; and when liquid fluorubber containing ether bonds is taken as the basic polymer, the low temperature resistance is better, the cost performance is higher, no volatile component is contained, and no environment pollution is caused.

Owner:吉林氟瑞恩新材料科技有限公司

High-temperature-resistant antibacterial cable

InactiveCN105733266AImprove microstructureMake up for the defects of low strengthRubber insulatorsEpoxyInsulation layer

The invention discloses a high-temperature-resistant antibacterial cable which comprises a conductor, wherein a fluoroplastic insulation layer is coated outside the conductor; a sheath is coated outside the fluoroplastic insulation layer; and the sheath is prepared from a silicon rubber composite material. The silicon rubber composite material is prepared from silicon rubber, fluororubber 23, ethylene propylene diene monomer rubber, an ethylene-methacrylic acid copolymer, an epoxy resin, zinc oxide, stearic acid, 2,5-dimethyl-2,5-bis(peroxyl-tert-butyl)hexane, fumed silica, aluminum oxide, talcum powder, quartz powder, wollastonite, nano copper, nano cerium oxide, modified nano silicon dioxide, hexamethyldisilazane, an accelerator, an anti-aging agent, phosphorus tetrahydroxymethyl sulfurate and liquid fluorine rubber. The high-temperature-resistant antibacterial cable disclosed by the invention has the advantages of high strength, favorable high temperature resistance and excellent mold resistance, and can satisfy operating requirements in many fields.

Owner:ANHUI FUYUEDA ELECTRONICS CO LTD

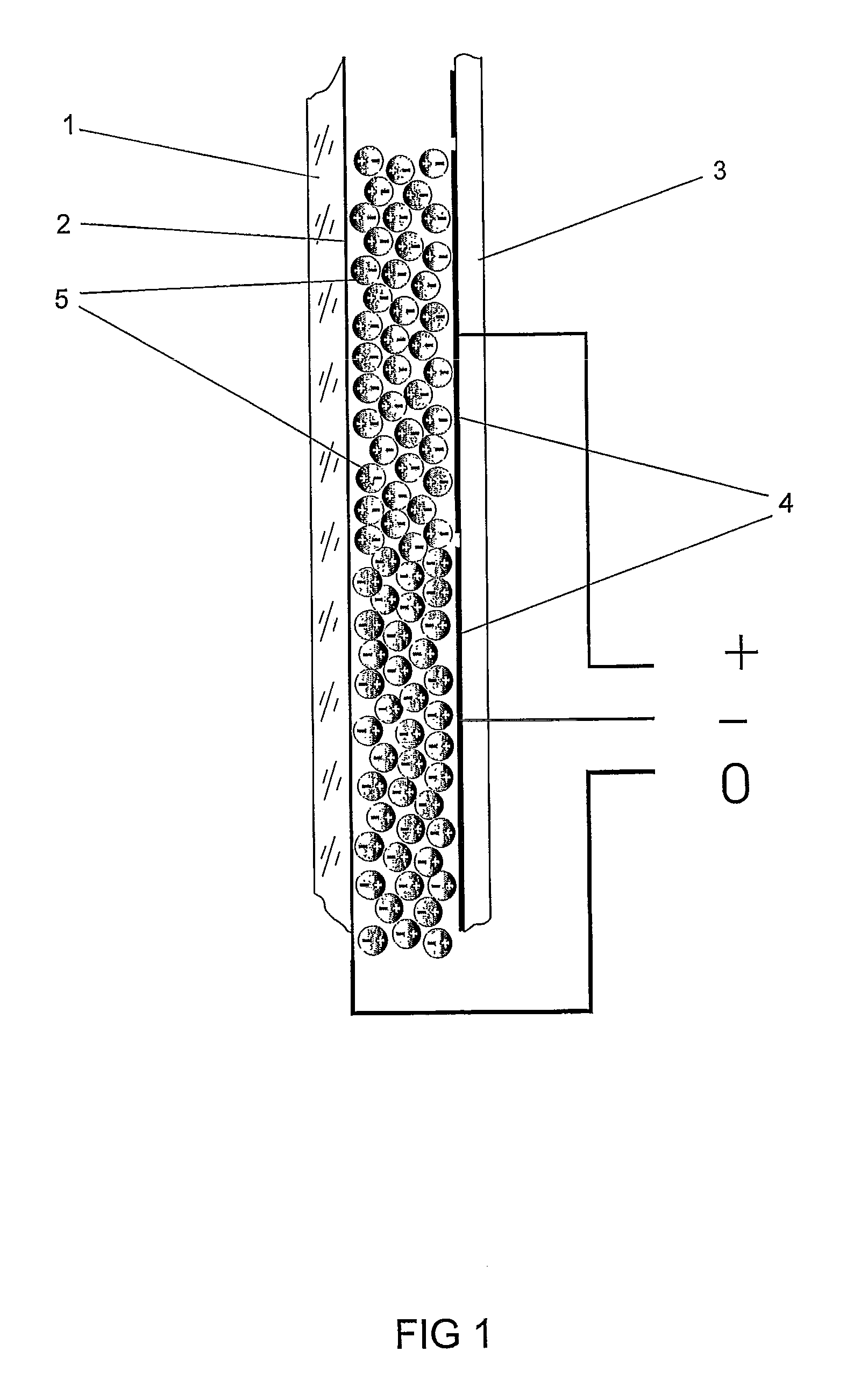

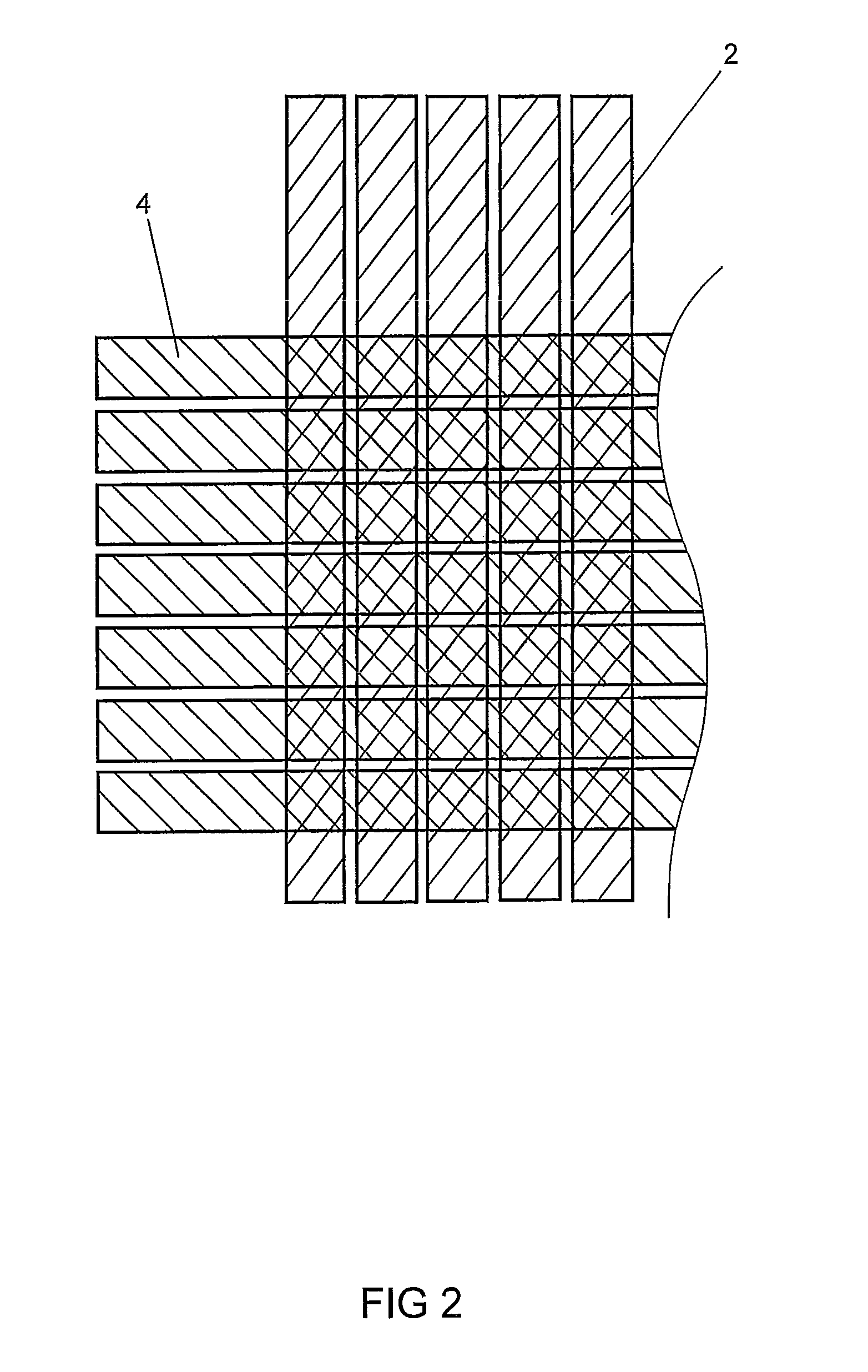

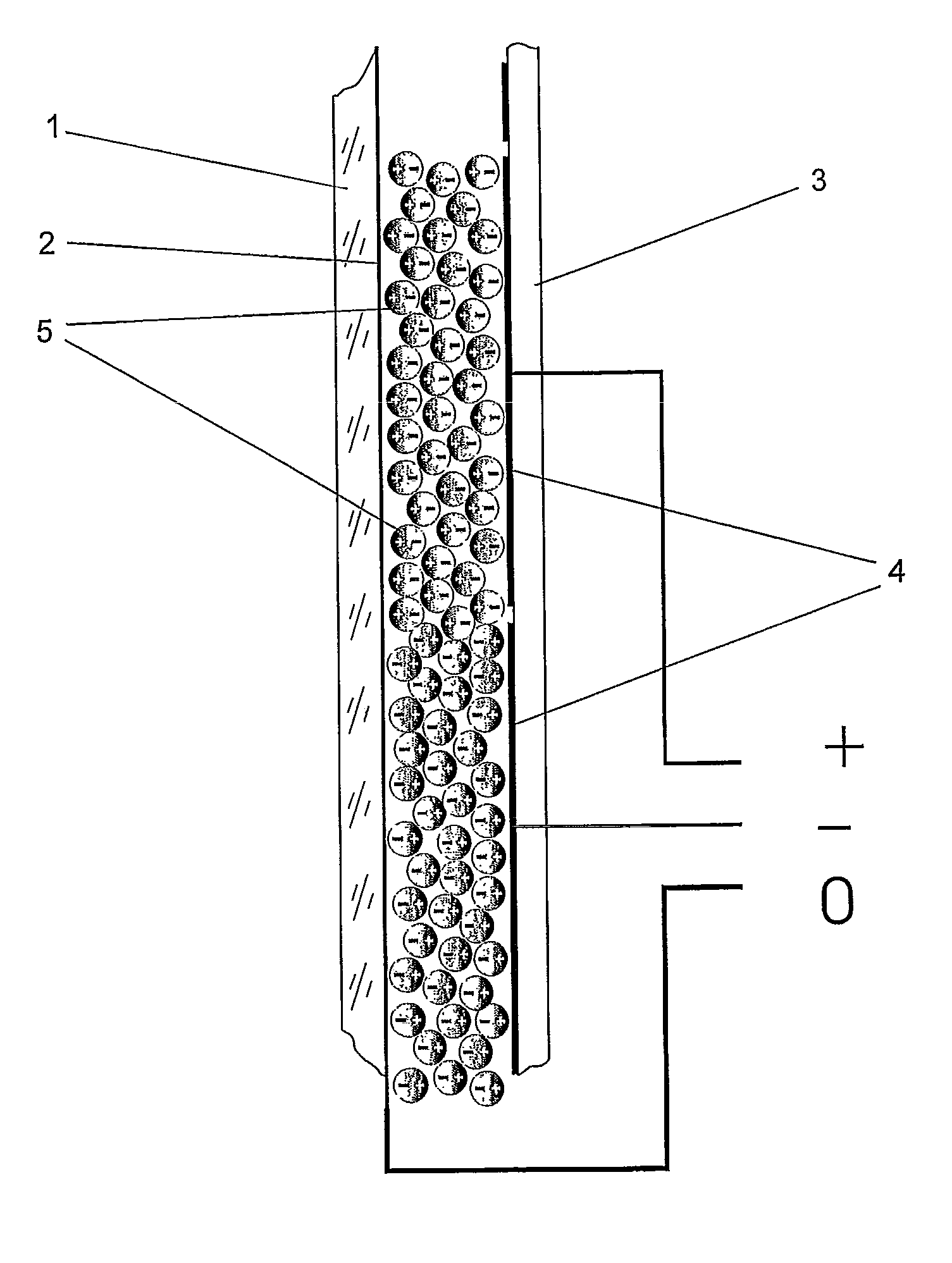

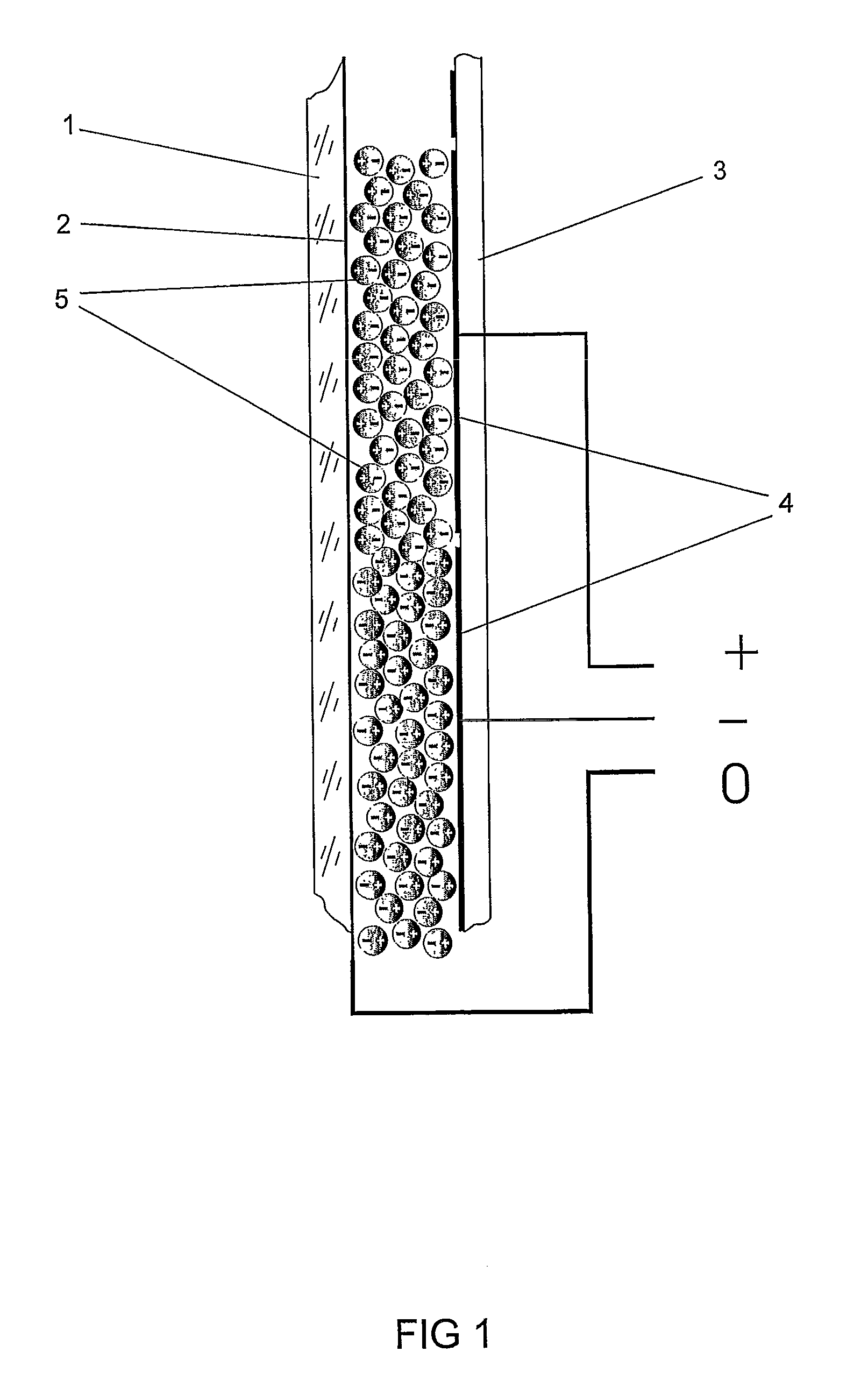

Active optical element, method of producing the same

InactiveUS8383010B2Increase contrastReduce energy consumptionOrganic dyesResistor housing/enclosing/embeddingWaxEmulsion

An active element that is based on an electret emulsion and that comprises particles of pre-polarized electret material as emulsion in neutral liquid and both poles of the particles are colored with different colors. For producing a neutral carrier liquid for the active element liquid fluorine carbon is used. For producing electret material for the active element solid polymerised fluorine carbon or electret wax is used. The active element is used for producing visual matrix displays, indicators, surfaces and surface coatings that change color by the application of a control voltage.

Owner:VISITRET DISPLAY OU

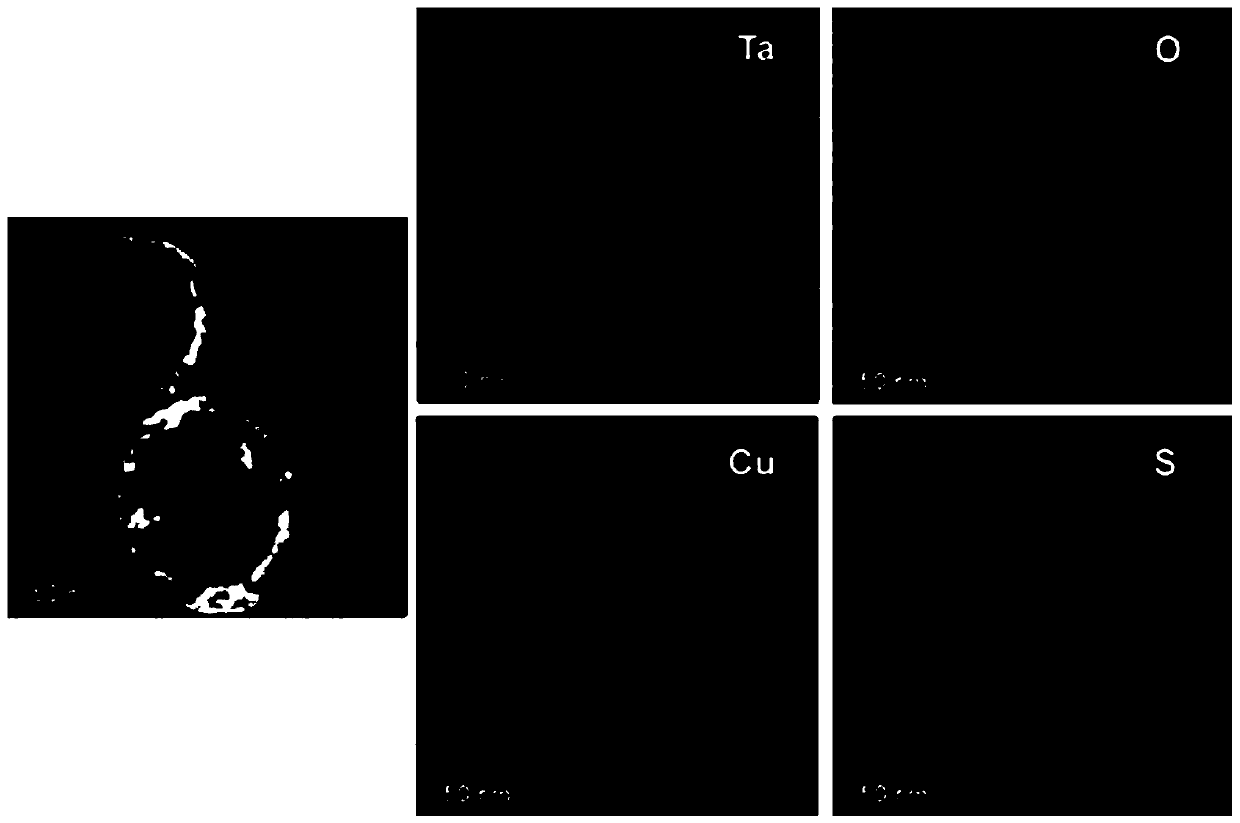

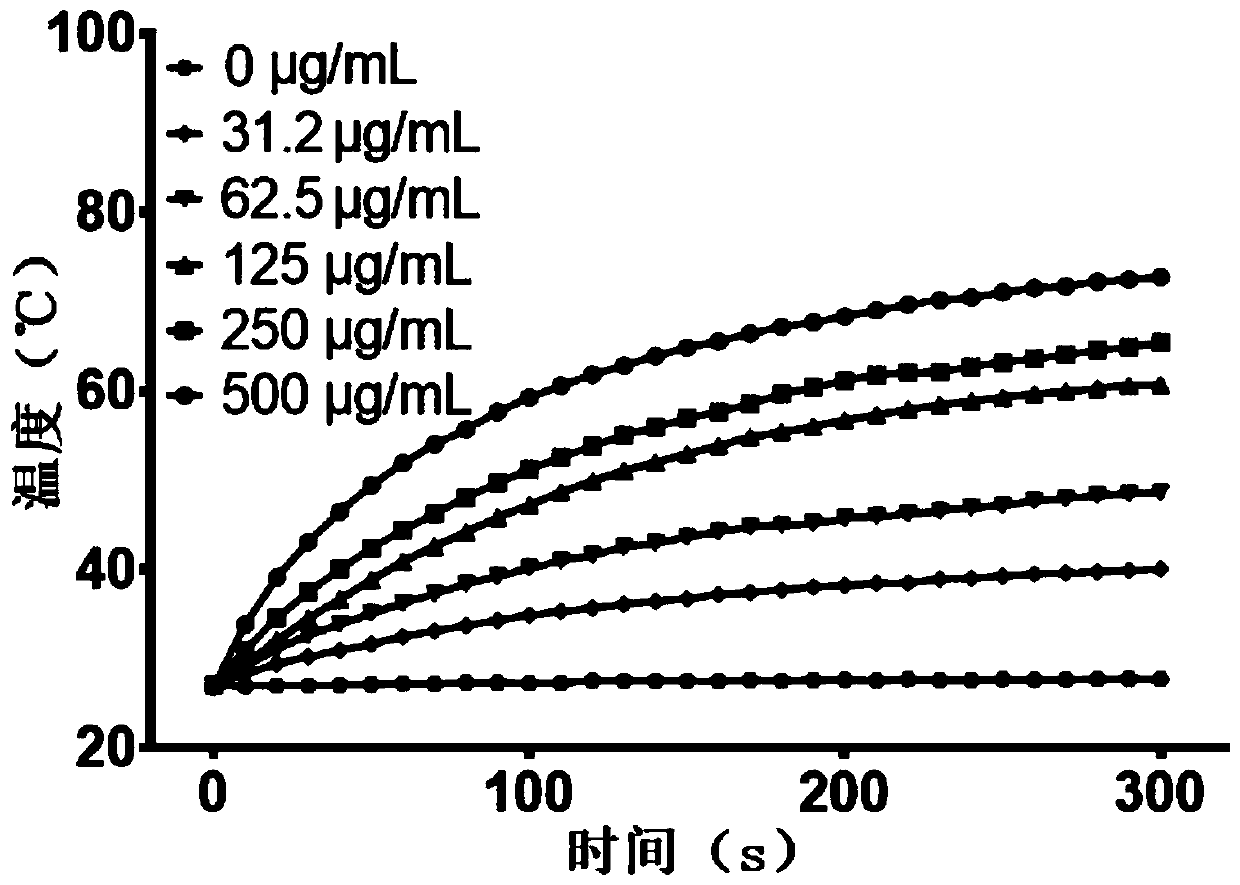

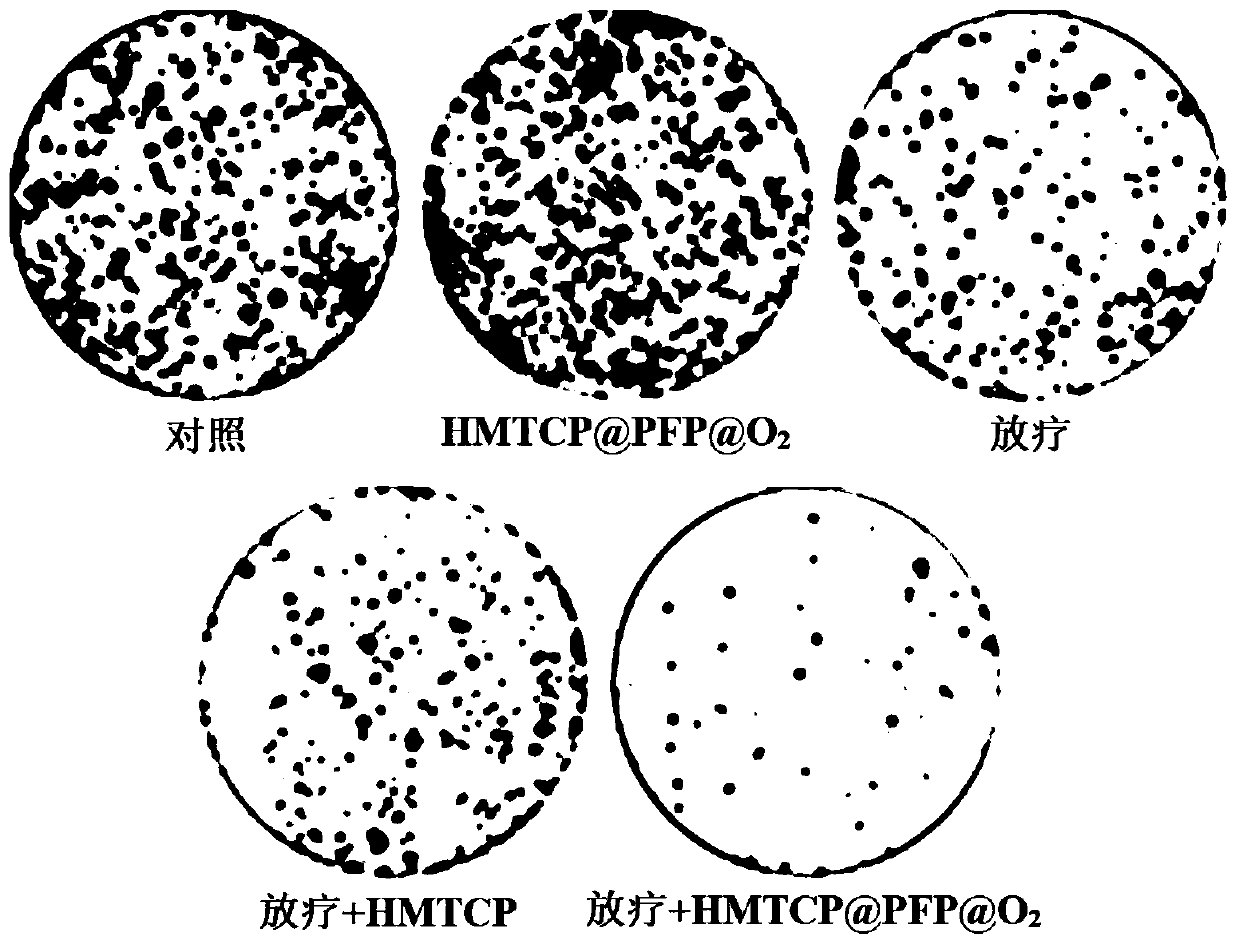

Composite nanoparticles as well as preparation method and application thereof

InactiveCN110859808AGood dispersionGood biocompatibilityPowder deliveryInorganic non-active ingredientsLiquid fluorinePolyethylene glycol

The invention discloses composite nanoparticles as well as a preparation method and an application thereof. The composite nanoparticles are composed of hollow mesoporous tantalum oxide nanoparticles,copper sulfide nanocrystals and oxygen-carrying liquid fluorocarbon, the copper sulfide nanocrystals grow on the surfaces of the hollow mesoporous tantalum oxide nanoparticles in situ, and cavities and pore channels of the hollow mesoporous tantalum oxide nanoparticles are filled with the oxygen-carrying liquid fluorocarbon. The preparation method of the composite nanoparticles comprises the following steps: 1) preparing hollow mesoporous tantalum oxide nanoparticles; 2) performing in-situ growth of copper sulfide; 3) performing silanization, 4) performing polyethylene glycol modification; and5) performing liquid fluorocarbon filling and oxygenation. The composite nanoparticles have the advantages of being good in dispersity and biocompatibility, good in tumor radiotherapy sensitization effect, high in photo-thermal conversion efficiency, stable in photo-thermal performance and the like, the synthesis is easy, and the price is low.

Owner:SOUTHERN MEDICAL UNIVERSITY

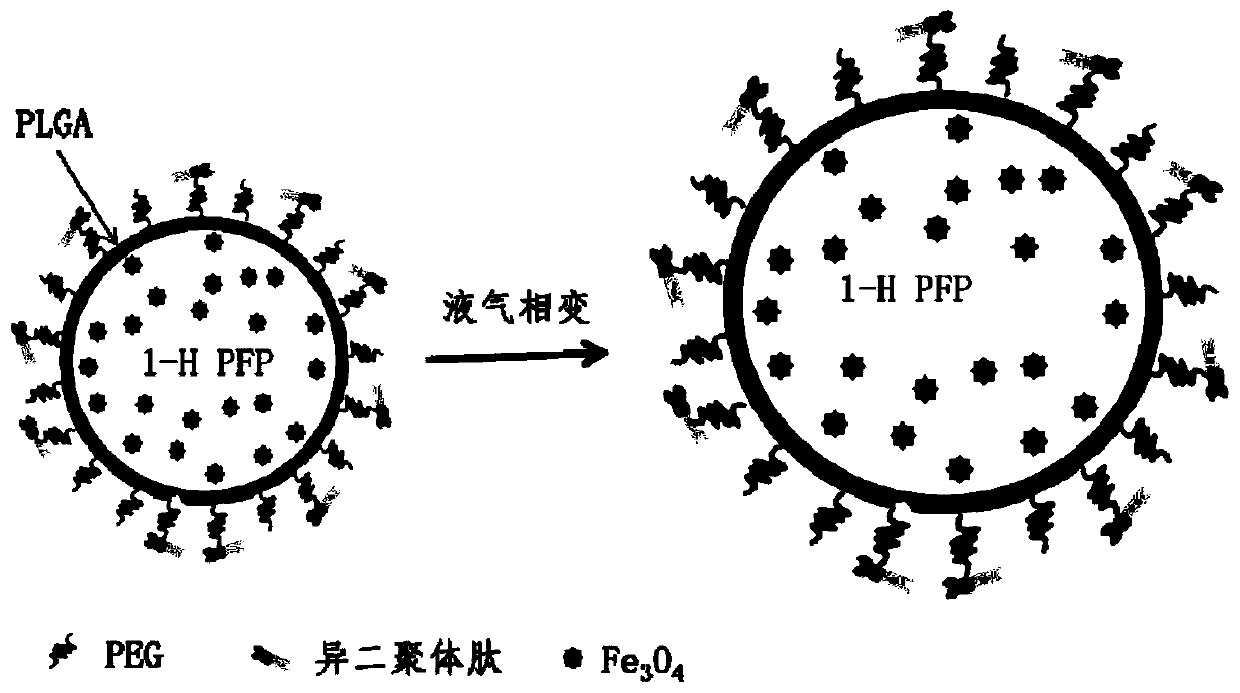

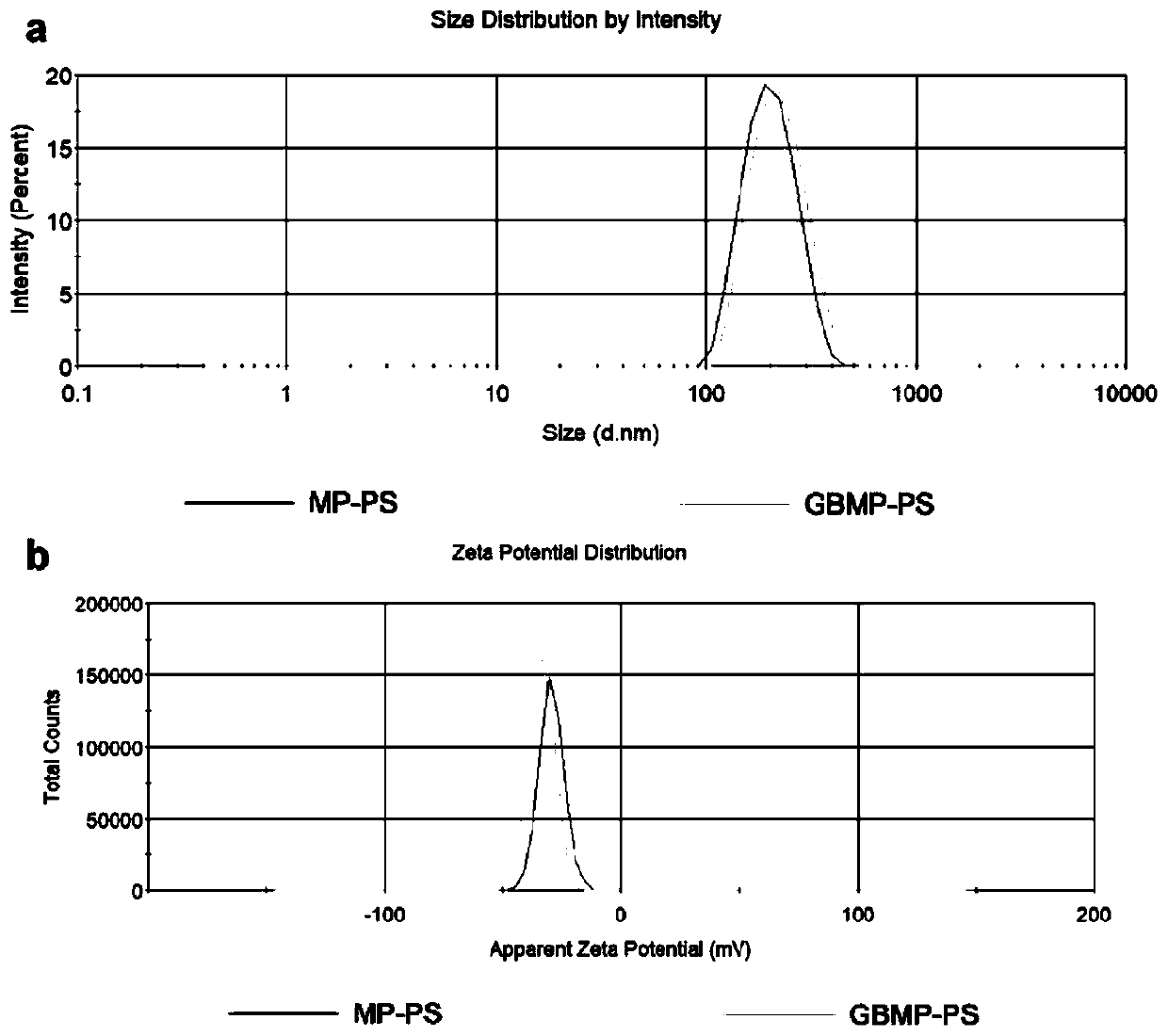

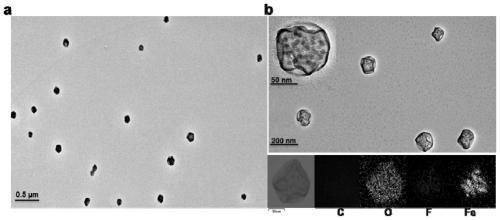

Bispecific PSMA/GRPr targeted bimodal imaging nano contrast agent as well as preparation method and application thereof

ActiveCN111558052AImprove hydrophilicityExtend systemic circulation timeGeneral/multifunctional contrast agentsEchographic/ultrasound-imaging preparationsDimerProstate cancer cell

The invention belongs to the field of contrast agents, and provides a bispecific PSMA / GRPr targeting bimodal imaging nano contrast agent, PLGA-PEG is used as a shell membrane, liquid fluorocarbon 1H-perfluoropentane and Fe3O4 nanoparticles are wrapped in the PLGA-PEG, and a heterodimer polypeptide is connected to the shell of the PLGA-PEG. The invention also provides an application of the contrastagent in preparing a medicine for diagnosing or treating prostatic cancer. The invention also provides a preparation method of the contrast agent. The average particle size of the prepared nano contrast agent is 213.7 + / -65.27 nm; Fe3O4 nanoparticles play a role in magnetic resonance imaging, 1H-perfluoropentane has the characteristics of liquid-gas phase change and has the advantages of stability and low energy required by phase change, the effects of ultrasonic and photoacoustic imaging, drug controlled release and the like are played, and the designed polypeptide can efficiently and specifically target prostate cancer cells. The nano contrast agent provided by the invention can simultaneously target two important target points PSMA and GRPr of prostate cancer.

Owner:RENJI HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

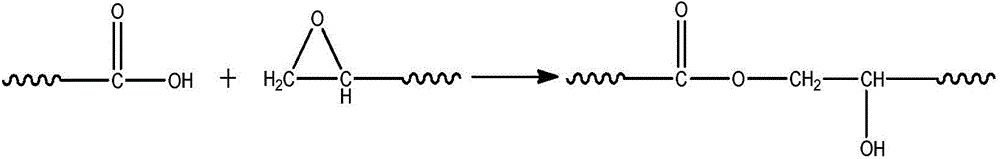

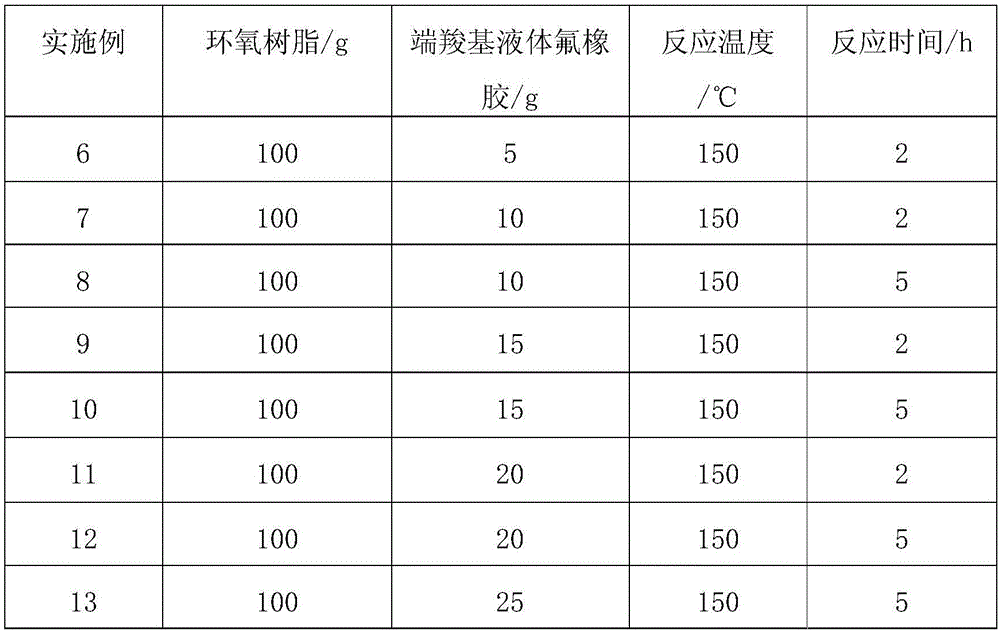

Preparing method for carboxyl-terminated liquid fluorine rubber toughening modified epoxy resin system

The invention discloses a preparing method for a carboxyl-terminated liquid fluorine rubber toughening modified epoxy resin system. The preparing method comprises the steps that carboxyl-terminated liquid fluorine rubber and epoxy resin serve as raw materials and are heated to 150 DEG C, a reaction is carried out for 2-5 h under the nitrogen protection, and a modified epoxy resin prepolymer is prepared with a one-step method. The synthesizing method is easy to implement, safe and high in yield. The invention further discloses a curing method for the carboxyl-terminated liquid fluorine rubber toughening modified epoxy resin prepolymer. According to the curing method, a proper curing agent such as hexahydrophthalic anhydride and polyether amine is selected, curing is carried out at 60-80 DEG C for 2 h, at 125 DEG C for 1.5 h and at 260 DEG C for 2 h, the toughness of a curing product is greatly improved, the maximum tensile strength reaches 31.6 MP, and the maximum elongation at break reaches 45.5%.

Owner:胡瑞忠

Active optical element, method of producing the same

An active element that is based on an electret emulsion and that comprises particles of pre-polarized electret material as emulsion in neutral liquid and both poles of the particles are coloured with different colours. For producing a neutral carrier liquid for the active element liquid fluorine carbon is used. For producing electret material for the active element solid polymerised fluorine carbon or electret wax is used. The active element is used for producing visual matrix displays, indicators, surfaces and surface coatings that change colour by the application of a control voltage.

Owner:VISITRET DISPLAY OU

High-corrosion-resistance aluminum alloy composite and preparation method thereof

InactiveCN109022955AImprove high temperature resistanceGood chemical stabilityPretreated surfacesCoatingsElastomerLiquid fluorine

The invention belongs to the technical field of aluminum alloy nanocomposites, and particularly relates to a high-corrosion-resistance aluminum alloy composite and a preparation method thereof. The high-corrosion-resistance aluminum alloy composite comprises an aluminum alloy composite body and a corrosion-resistant coating. The corrosion-resistant coating is a carborane-liquid fluorine polymer coating. The aluminum alloy composite body comprises matrix aluminum alloy and a reinforcement phase distributed in the matrix aluminum alloy. The reinforcement phase is graphene wrapped with SiO2. According to the high-corrosion-resistance aluminum alloy composite, the corrosion resistance of the aluminum alloy is enhanced through the carborane-liquid fluorine polymer coating, so that the chemicalcorrosion resistance of an obtained product is greatly improved. Liquid fluorine elastomers have excellent chemical resistance, carborane has excellent high-temperature resistance and chemical stability, and thus, the corrosion resistance of the aluminum alloy can be greatly improved by coating the surface of the aluminum alloy with a polymer of the liquid fluorine elastomers and the carborane.

Owner:SHANDONG INNOVATION METAL TECH

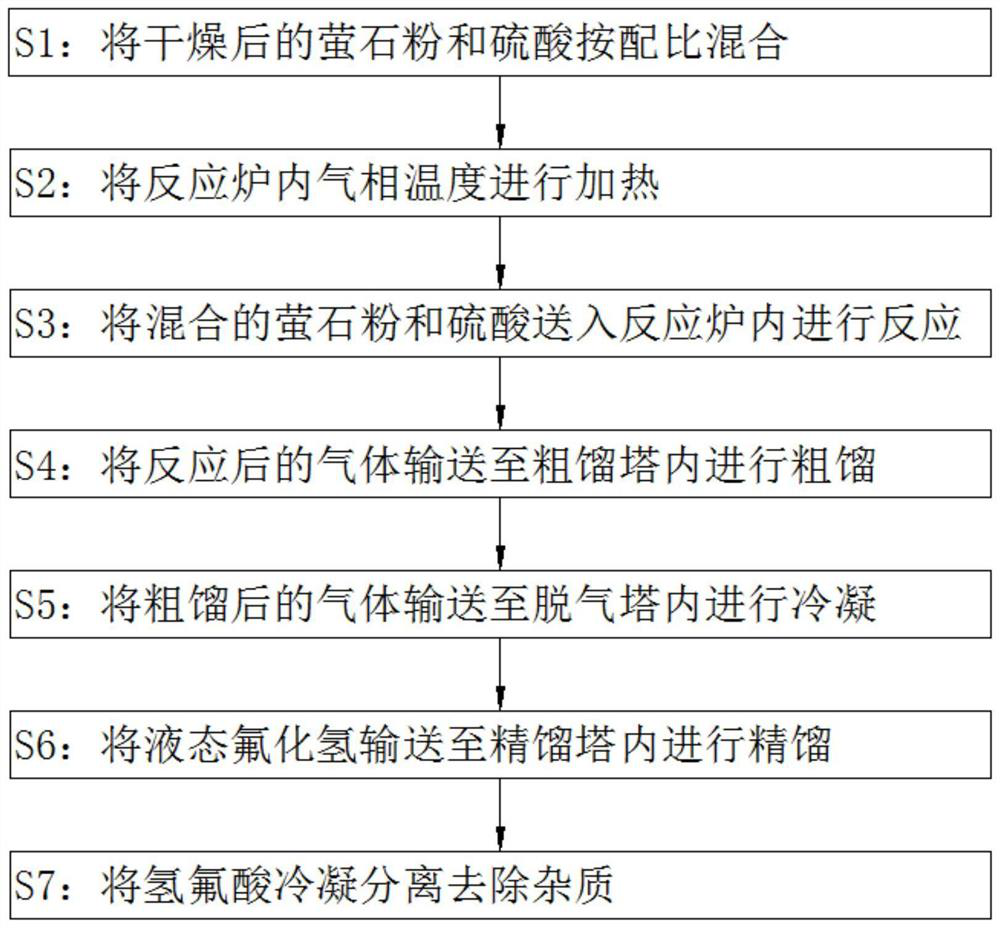

Preparation method of high-purity hydrofluoric acid

PendingCN113213427AAdequate responseImprove reaction efficiencyHydrogen fluorideHydrogen fluorideDistillation

The invention belongs to the field of preparation of hydrofluoric acid, particularly relates to a preparation method of high-purity hydrofluoric acid, and provides the following scheme aiming at the problem that the purity of the prepared hydrofluoric acid solution is reduced due to the fact that a liquid hydrogen fluoride solution is inconvenient to fully and quickly remove impurities in the existing hydrofluoric acid preparation process. The method comprises the following steps that S1, mixing dried fluorite powder and sulfuric acid in proportion; s2, heating a reaction furnace; s3, feeding the mixed fluorite powder and sulfuric acid into the reaction furnace for reaction; s4, conveying reacted gas into a crude distillation tower for crude distillation; s5, conveying the gas subjected to crude distillation into a degassing tower for condensation; s6, conveying the liquid hydrogen fluoride into a rectifying tower to be rectified; s7, subjecting hydrofluoric acid to condensation separation to remove impurities. According to the invention, the liquid hydrogen fluoride solution can be subjected to sufficient and rapid impurity removal conveniently, and therefore the purity of the prepared hydrofluoric acid solution can be improved.

Owner:SINOPHARM CHEM REAGENT

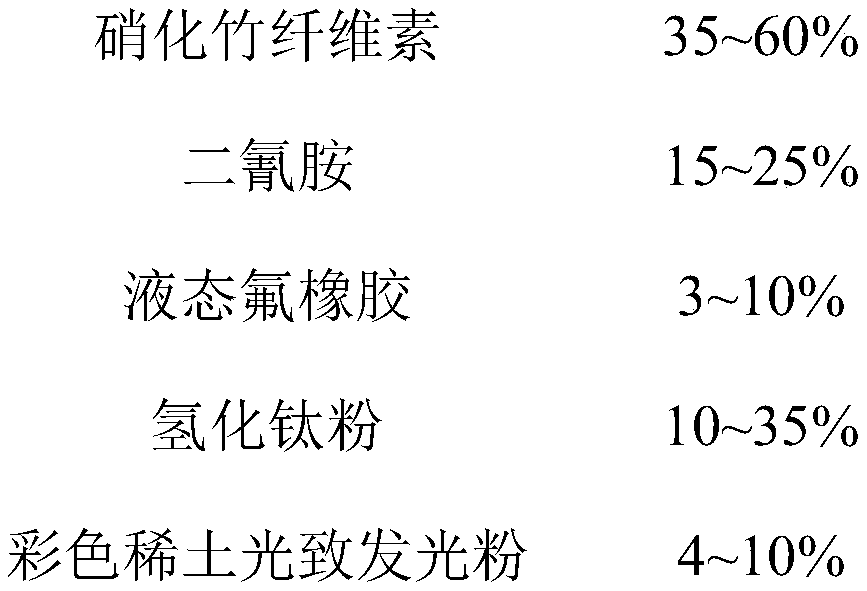

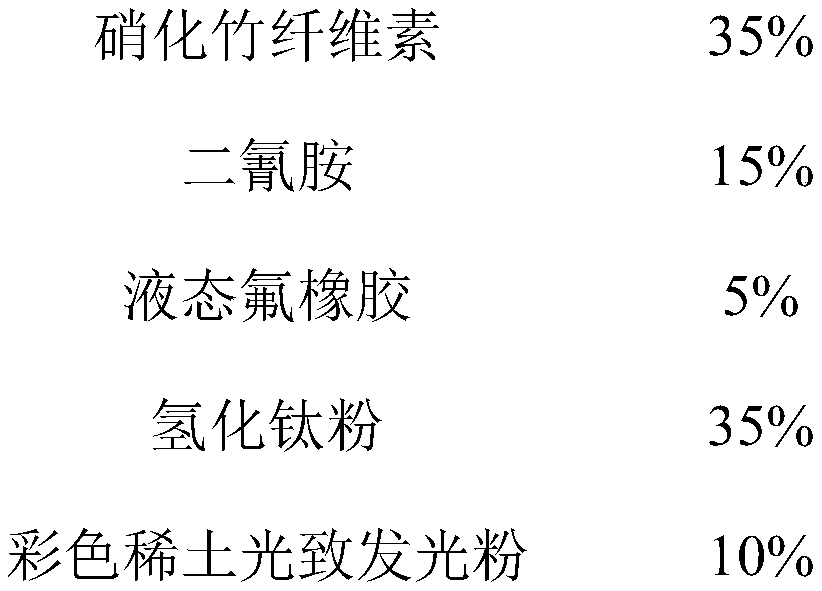

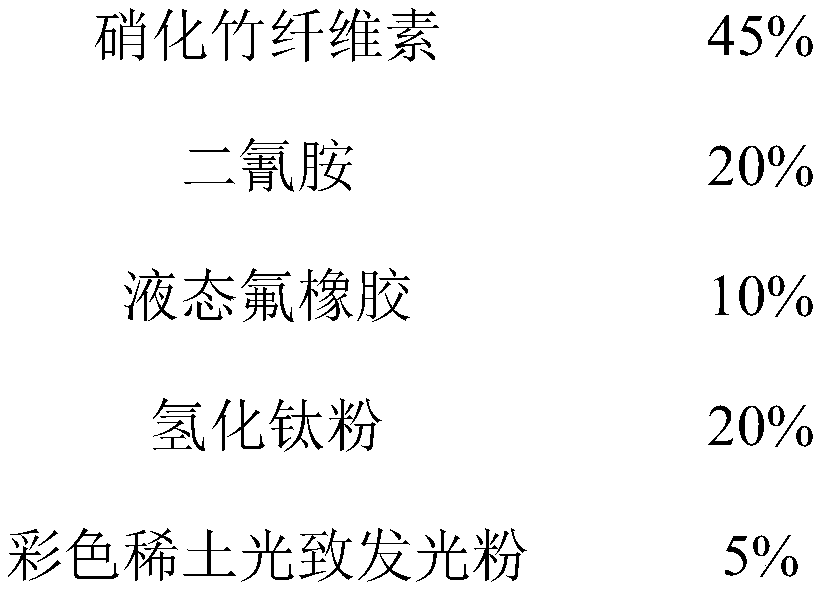

Colored light cold firework powder and preparation method thereof

PendingCN111039731ALow costMeet viewing needsNon-explosive/non-thermic compositionsNitrocellulosePhotoluminescence

The invention relates to a colored light cold firework powder and a preparation method thereof, and belongs to the technical field of civil entertainment fireworks. The preparation method comprises the following steps: weighing nitrocellulose, dicyandiamide, liquid fluororubber, titanium hydride powder and colored rare earth photoluminescence powder; dividing the liquid fluororubber into two parts, wherein the first part is 0.1-0.5% of the total mass of the titanium hydride powder and the colored rare earth photoluminescence powder, and the rest is the second part; mixing the weighed titaniumhydride powder and colored rare earth photoluminescence powder, dropwise adding the first part of liquid fluororubber, kneading, sieving and drying to obtain luminescent granulated powder; and mixingthe nitrocellulose, dicyandiamide and the luminescent granulated powder, dropwise adding the second part of liquid fluororubber, granulating, and drying to obtain the colored light cold firework powder. The colored light cold firework powder provided by the invention is low in cost of raw materials required for preparation, rich in color during setting off, and green and environment-friendly in setting off process.

Owner:江西吉润花炮新材料科技有限公司

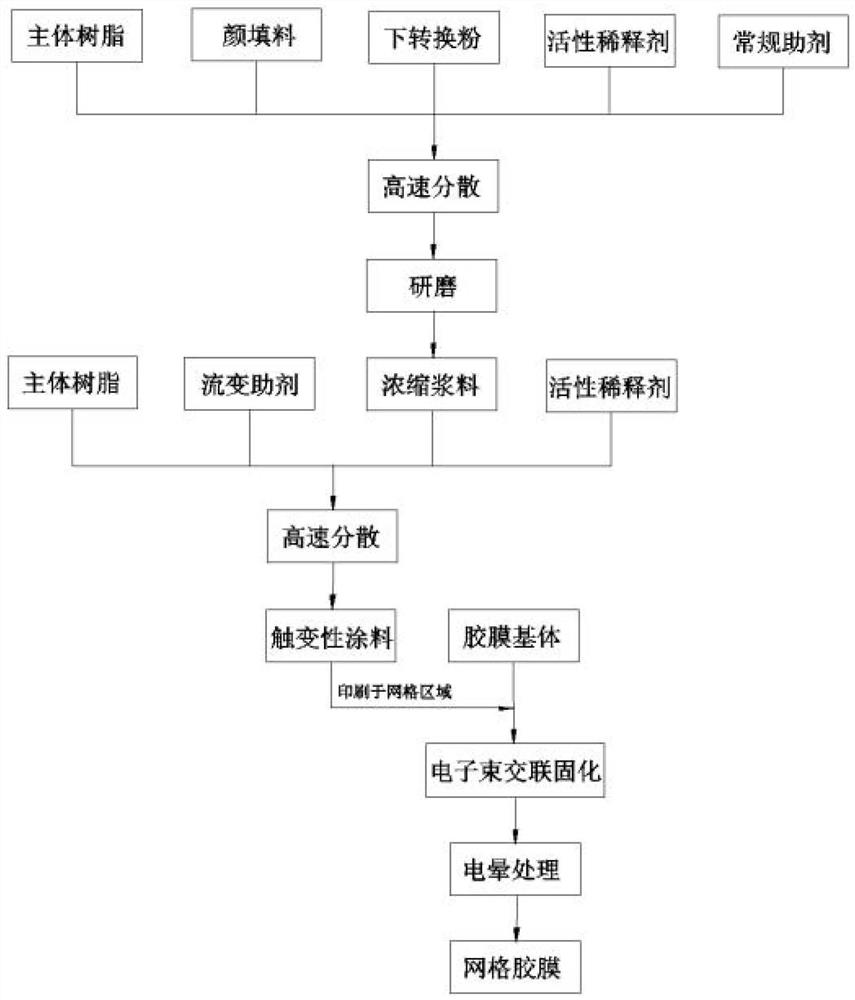

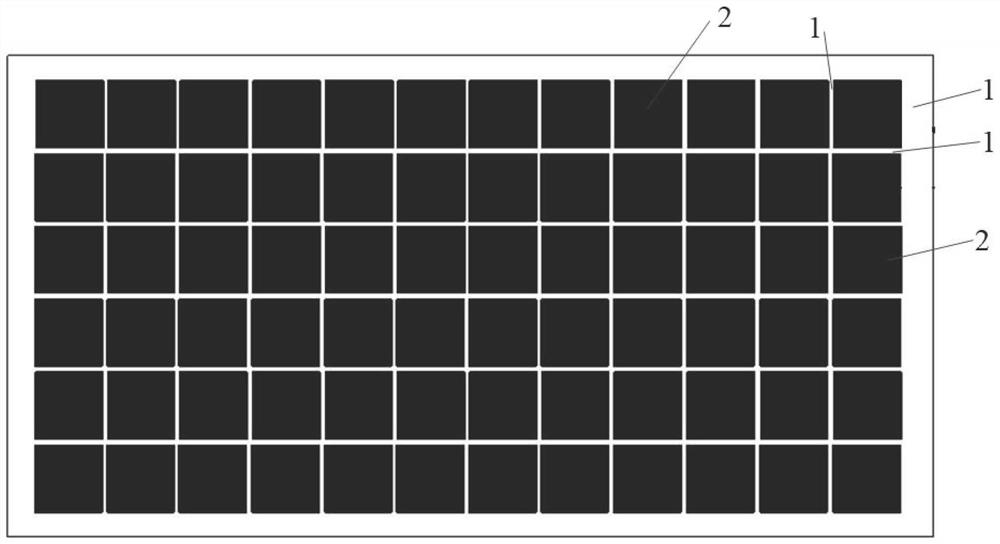

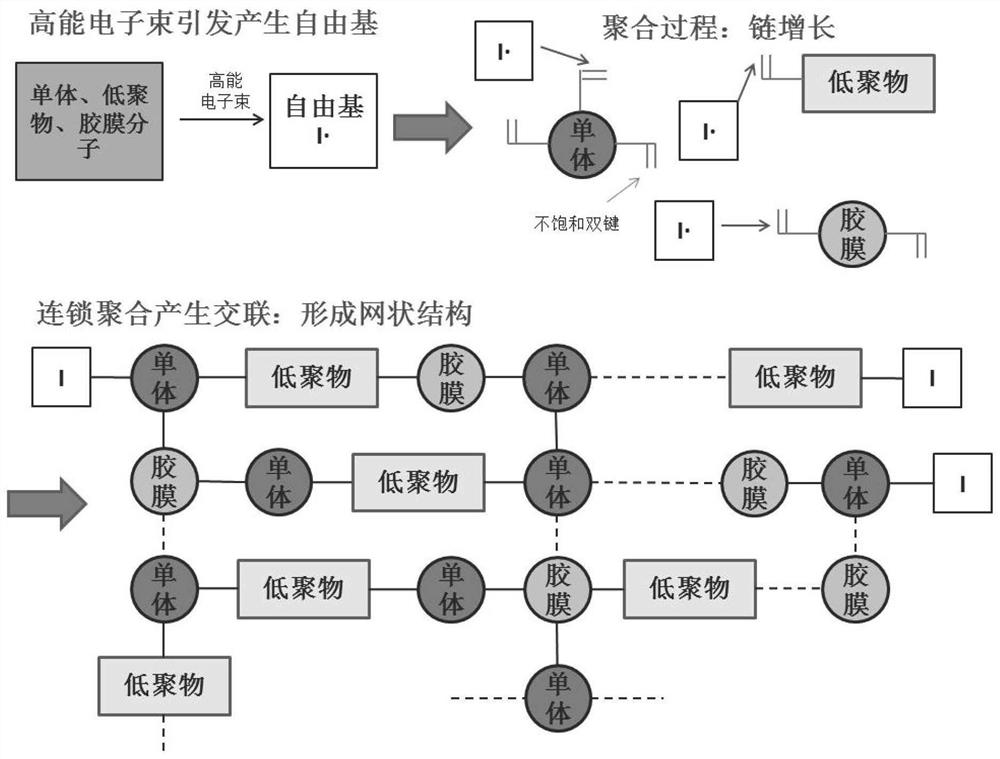

Weather-resistant fluorine coating, weather-resistant fluorine coat, photovoltaic adhesive film and preparation method thereof

InactiveCN112552813AImproved rheological propertiesUniform thicknessPolyurea/polyurethane coatingsPhotovoltaic energy generationLiquid fluorinePolymer chemistry

The invention belongs to the technical field of liquid fluorine coatings for photovoltaic packaging adhesive films, and particularly relates to an electron beam cured weather-resistant fluorine coating, a weather-resistant fluorine coat, a photovoltaic packaging adhesive film and a preparation method thereof. The weather-resistant fluorine coating comprises the following raw materials in parts byweight: 40 to 65 parts of matrix resin, 20 to 50 parts of a pigment filler, 10 to 20 parts of an active diluent, 2 to 6 parts of a conventional auxiliary agent, 1 to 4 parts of a rheological additive,and 0.5 to 3 parts of down-conversion nano powder. Fluororesin and an ultraviolet conversion material are used, so that the weather fastness and durability of the coating can be effectively guaranteed; and meanwhile, by improving the rheological property and the crosslinking property of the weather-resistant coating, the coating is fully infiltrated on the surface of the adhesive film and forms effective chemical bond bonding through curtain-shaped electron beam radiation, and the weather-resistant coating is suitable for being used for printing in a grid region of the photovoltaic packagingadhesive film. According to the weather-resistant fluorine coat formed after electron beam cross-linking curing and corona treatment, the coat and an adhesive film matrix are not prone to layering, and the weather-resistant fluorine coat has the advantages of being uniform in thickness, good in adhesive force, excellent in aging performance and the like.

Owner:常州威斯敦粘合材料有限责任公司

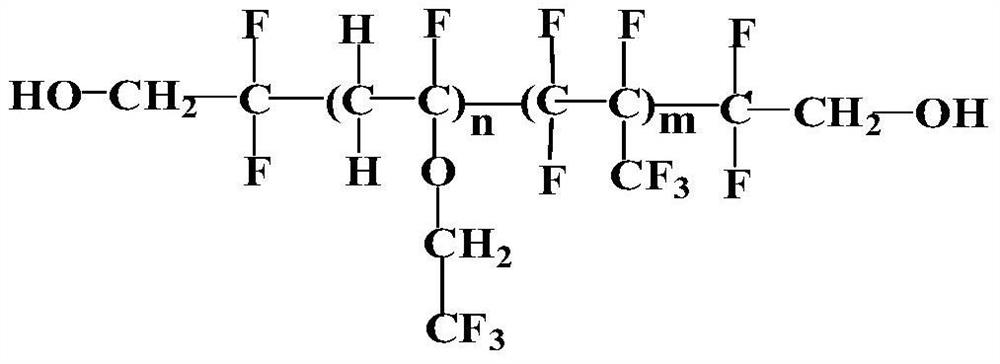

High-strength high-toughness fluorine-containing polyurethane and preparation method thereof

The invention discloses high-strength high-toughness fluorine-containing polyurethane and a preparation method thereof. The preparation method comprises the following steps: step 1, adding hydroxyl-terminated liquid fluorine rubber and low-molecular dihydric alcohol into a reaction container, vacuumizing and removing water; step 2, adding dropwise a mixture of isocyanate, dibutyltin dilaurate, ethyl acetate and dimethyl sulfoxide into the product obtained in the step 1 for a reaction to obtain a fluorine-containing polyurethane prepolymer, with the mass ratio of the product obtained in the step 1 to isocyanate to dibutyltin dilaurate to ethyl acetate to dimethyl sulfoxide being 50: (5-8): 0.1: 20: 10; step 3, dissolving a fluorine-containing micromolecule chain extender in trifluorotoluene, and adding the mixture into the product in the step 2 for reaction, with the mass ratio of the product obtained in the step 2 to the fluorine-containing chain extender to the benzotrifluoride being (85-88): (1-5): (0.5-2.5); and 4, dissolving the product in the step 3 in acetone, and reacting to obtain a pure product. According to the fluorine-containing polyurethane obtained by the invention, the tensile strength and the elongation at break are improved, and the hardness is reduced.

Owner:无锡氟越邦维新材料有限公司

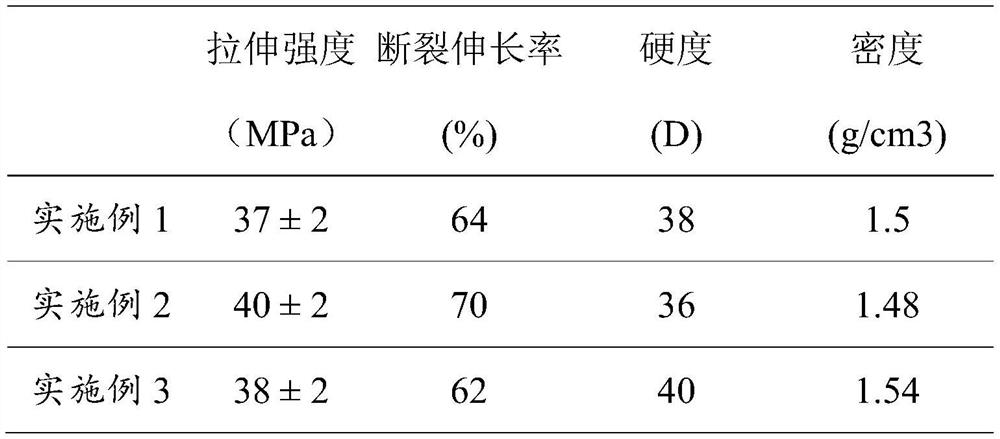

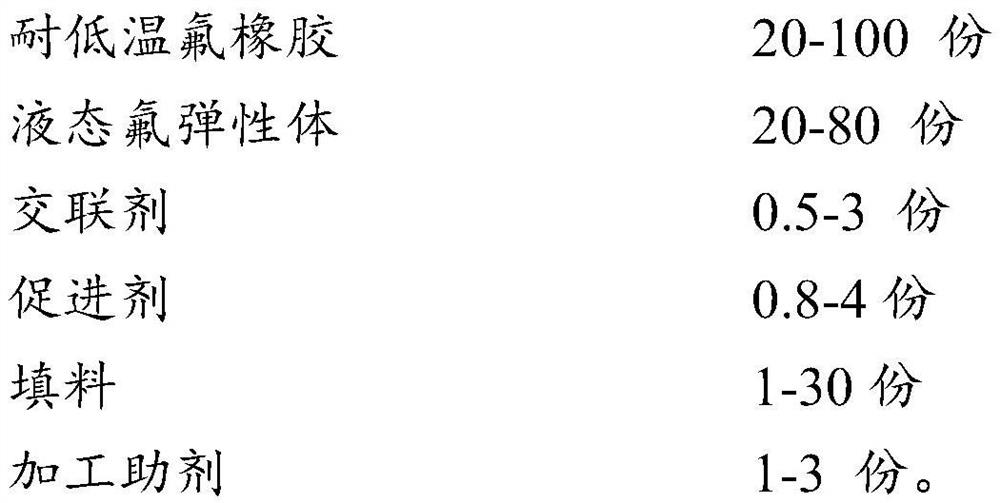

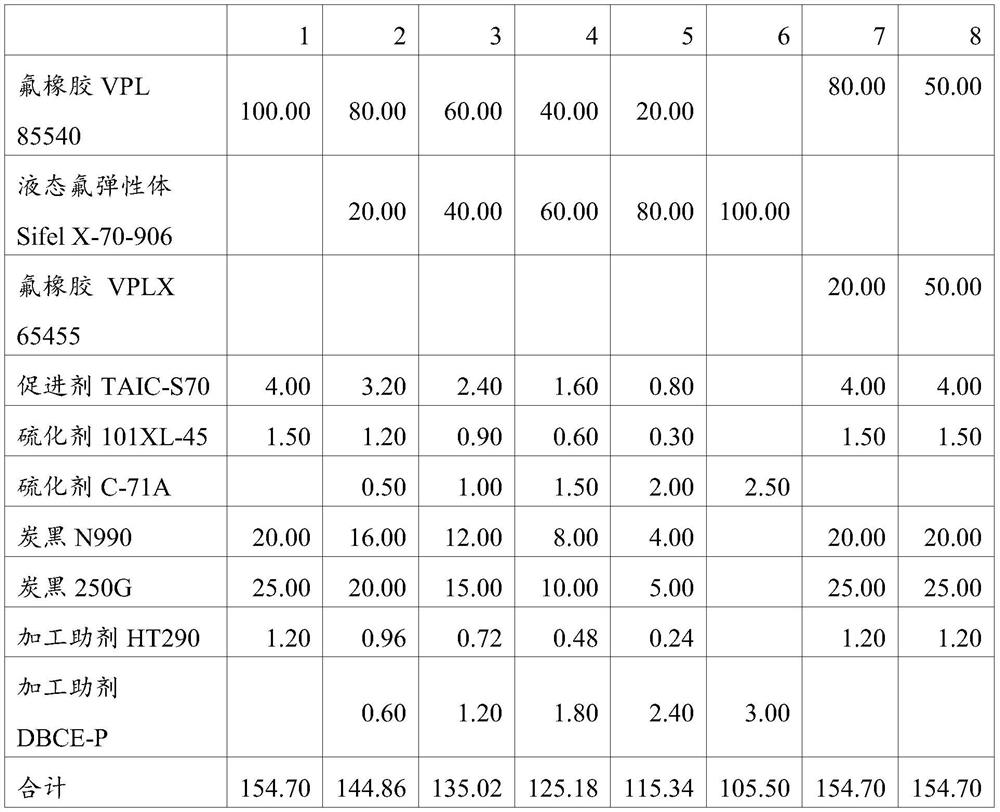

Low-temperature-resistant fluororubber composition and application thereof

ActiveCN112592548AImprove low temperature resistanceGood chemical resistanceRubber materialPolymer science

The invention belongs to the technical field of polymer rubber materials, and discloses a low-temperature-resistant fluororubber composition as well as a preparation method and application thereof. The fluororubber composition is prepared from the following raw materials in parts by weight: 20-100 parts of fluororubber, 20-80 parts of a liquid fluoroelastomer, 0.5-3 part of a cross-linking agent,0-4 parts of an accelerant, 1-30 parts of a filler and 1-3 parts of a processing aid. The composition is heated, pressurized and vulcanized to prepare the rubber composition. The rubber composition isexcellent in low-temperature resistance and chemical medium resistance, and can be widely applied to low-temperature corrosion-resistant environment working conditions in the petrochemical industry.

Owner:SHANGHAI REAL SEALING TECH CO LTD

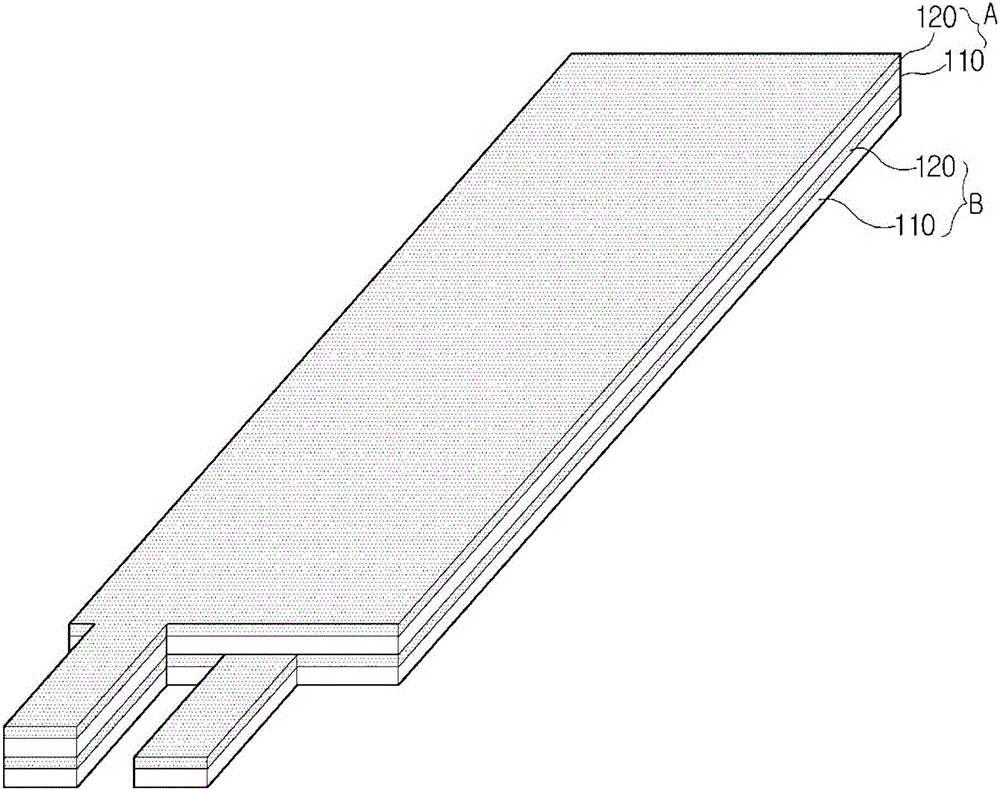

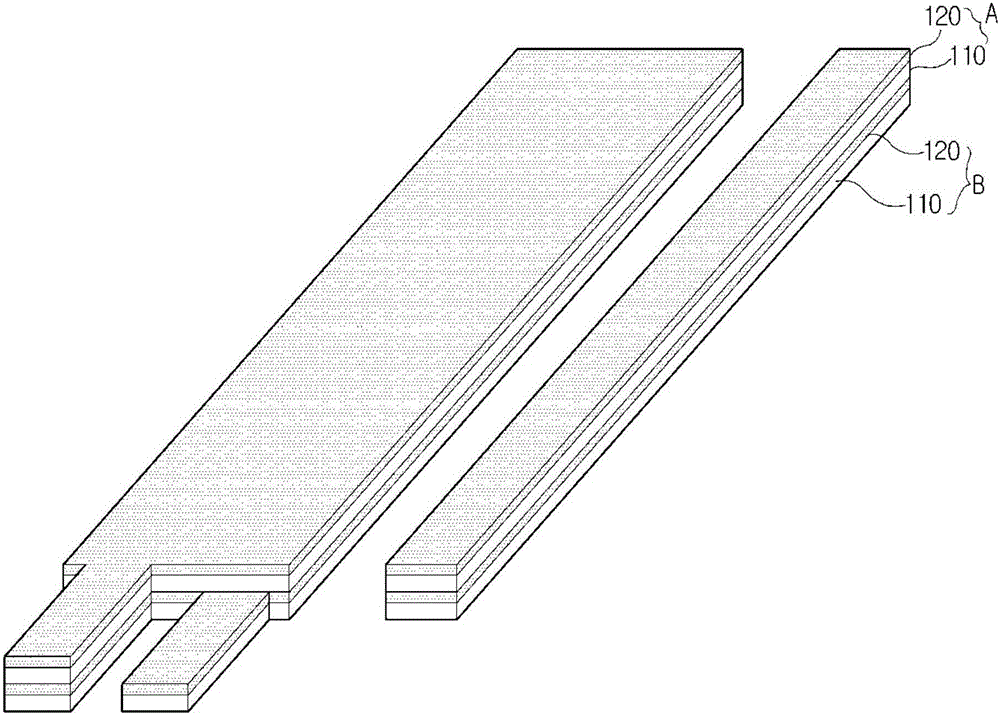

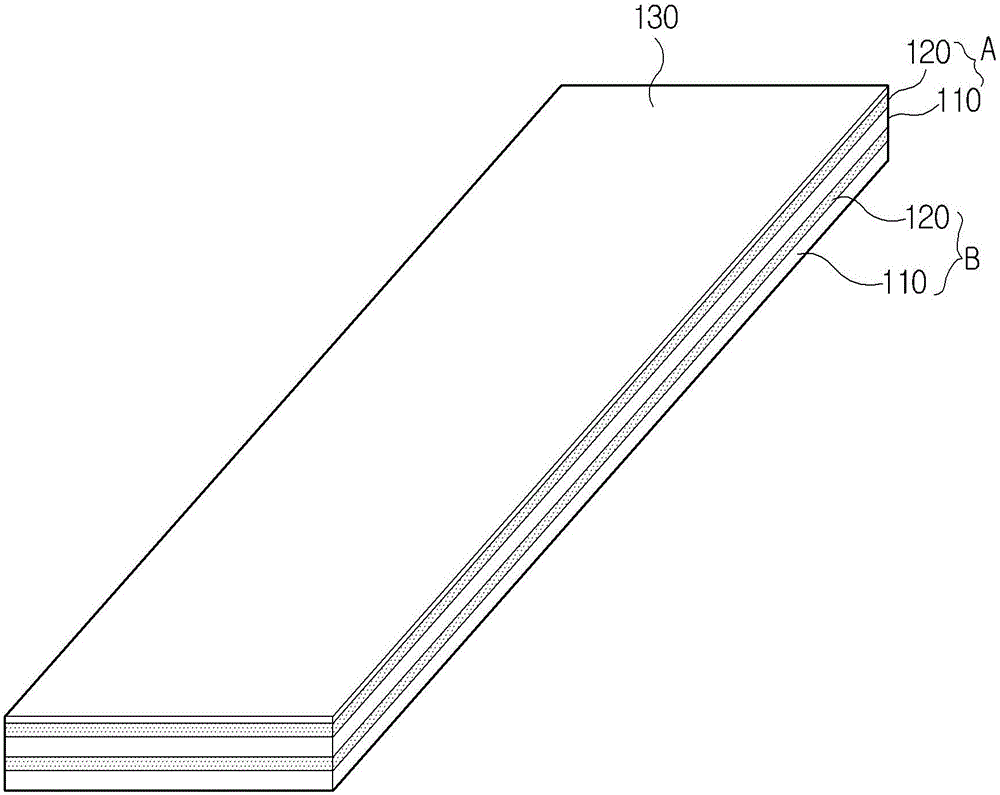

Leak sensor for side detection

A leak sensor includes a base layer which is formed by soaking a plate-shaped structure into a resin solution, particularly a fluorine-based resin solution, or formed of a plate-shaped structure of a resin, particularly a fluorine-based resin; and a sensor layer in which a leak detection part having a predetermined area is formed by coating or printing a mixture of a liquid resin or a liquid fluorine-based resin and a conductive material on the base layer in a predetermined pattern, wherein the leak detection part of the sensor layer is formed on a side surface of the sensor layer to be exposed to the outside. Therefore, even though the sensor is not located just under the leaked fluid, the sensor becomes in contact with the fluid, and thus can detect the fluid leakage.

Owner:FLOWNIX

A novel liquid defluoridation agent and its preparation method and application

ActiveCN111302465BGood defluoridation effectPlay the role of adsorption and flocculationGeneral water supply conservationWater contaminantsAluminium chlorideAluminium chlorohydrate

The invention discloses a novel liquid defluoridation agent, its preparation method and application, and belongs to the technical field of fluorine-containing wastewater treatment. The liquid defluoridation agent of the present invention is composed of the following components by mass fraction: polyaluminum chloride 25%, polyaluminum ferric chloride 17%, magnesium sulfate 9%, N,O-carboxymethyl chitosan 6%, coagulation aid 3%, purified water 40%. When the fluorine-removing agent of the invention is used to treat low-concentration fluorine-containing wastewater, the fluoride ion concentration of the effluent can be less than or equal to 1.0 mg / L, and the fluoride-removing effect is good.

Owner:山东环瑞生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com