Preparing method for carboxyl-terminated liquid fluorine rubber toughening modified epoxy resin system

A technology of epoxy resin system and liquid fluororubber, which is applied in the field of preparation of carboxyl-terminated liquid fluororubber toughened and modified epoxy resin system, which can solve problems such as easy cracks, limited application, and brittle cured substances, and achieve conversion rate High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

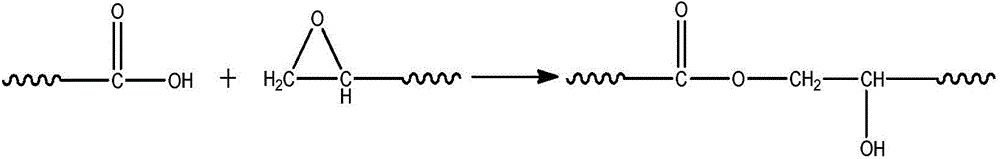

Method used

Image

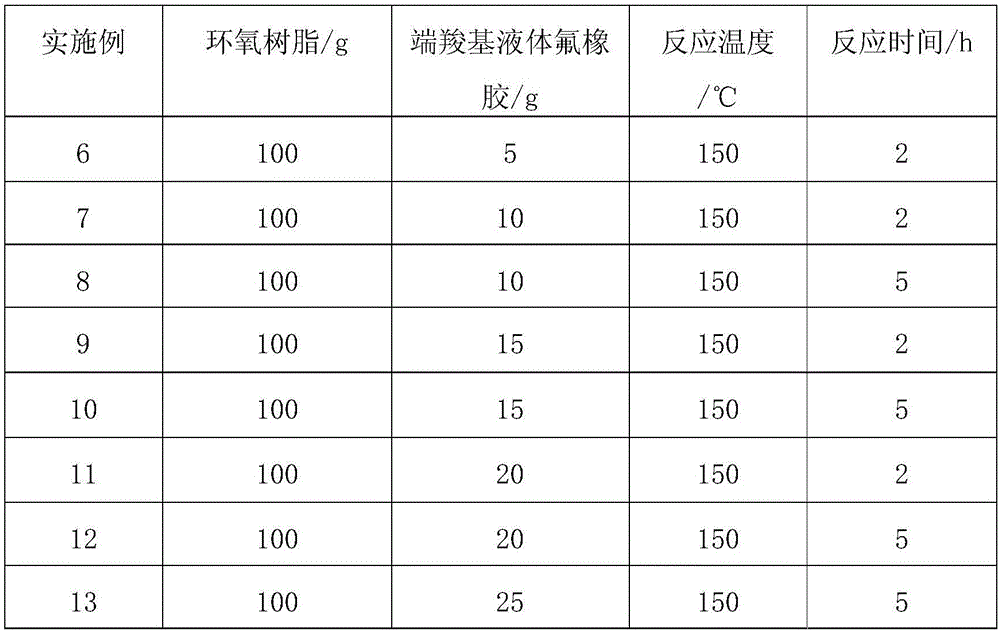

Examples

Embodiment 1

[0020] Add 100g of epoxy resin E51 and 5g of carboxyl-terminated liquid fluororubber (vinylidene fluoride-hexafluoropropylene copolymer) into a 500ml three-necked flask equipped with a thermometer, stirrer and nitrogen device, heat in an oil bath, and turn on the nitrogen Valve, heated to 150°C while stirring, reacted for 3h under nitrogen protection, and the product was determined by infrared analysis at 1763cm -1 The characteristic peak of the carboxyl group disappears, indicating that basically all the carboxyl groups participate in the reaction, and there is no other loss of the epoxy group, and finally a carboxyl-terminated liquid fluororubber modified epoxy resin prepolymer is obtained.

Embodiment 2

[0022] Add 100g of epoxy resin E51 and 15g of carboxyl-terminated liquid fluororubber (vinylidene fluoride-hexafluoropropylene copolymer) into a 500ml three-necked flask equipped with a thermometer, stirrer and nitrogen ventilation device, heat in an oil bath, and turn on the nitrogen gas Valve, heated to 150°C while stirring, reacted for 3h under nitrogen protection, and the product was determined by infrared analysis at 1763cm -1 The characteristic peak of the carboxyl group disappears, indicating that the carboxyl group has all participated in the reaction, and the epoxy group has no other loss, and finally a carboxyl-terminated liquid fluororubber modified epoxy resin prepolymer is obtained.

Embodiment 3

[0024] Add 100g of epoxy resin E51 and 20g of carboxyl-terminated liquid fluororubber (vinylidene fluoride-hexafluoropropylene copolymer) into a 500ml three-necked flask equipped with a thermometer, stirrer and nitrogen device, heat in an oil bath, and stir While raising the temperature to 150°C, react in a nitrogen atmosphere for 3 hours, and the others are the same as in Example 1 to obtain an epoxy resin prepolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com