Direct separation method of silicon tetrafluoride and anhydrous hydrogen fluoride mixed gas

A technology of silicon tetrafluoride and mixed gas, applied in the direction of fluorine/hydrogen fluoride, silicon halide compound, hydrogen fluoride, etc., can solve the problem of difficult separation of silicon tetrafluoride and hydrogen fluoride gas, no replacement of silicon tetrafluoride, no description of the product Purity and other issues, to achieve the effect of convenient equipment selection, reduce heat load, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

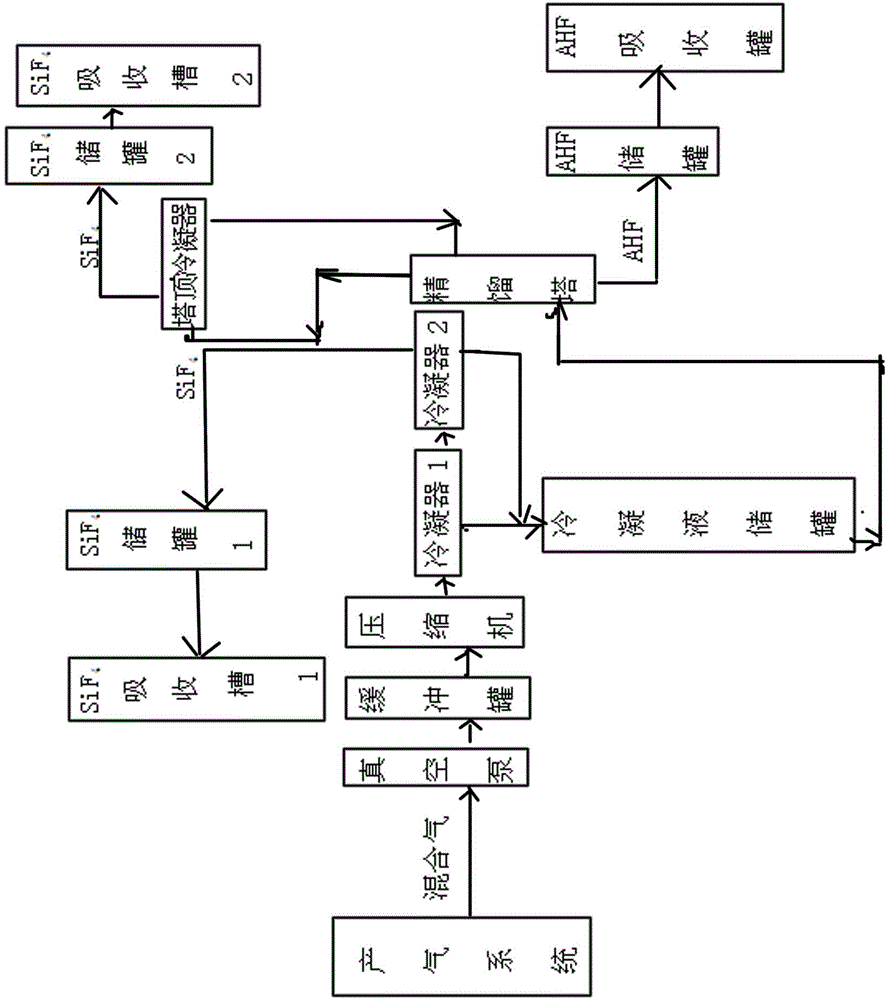

Image

Examples

Embodiment 1

[0036] Follow the steps below to separate silicon tetrafluoride and anhydrous hydrogen fluoride mixed gas:

[0037] a. Control the vacuum degree of hydrogen fluoride and silicon tetrafluoride output system by vacuum pump to -0.02MPa, adjust the outlet exhaust pressure of vacuum pump to 0.13MPa, and pump the mixed gas of hydrogen fluoride and silicon tetrafluoride to a buffer tank of 0.5 cubic meters for collection . The gas is compressed to 0.5Mpa by the compressor. After compression, the gas temperature is about 90°C and enters the condenser 1. After cooling to 40~45°C, most of the hydrogen fluoride gas is liquefied, and the silicon tetrafluoride remains in the gas phase.

[0038]b. The liquid phase in step a enters the condensate storage tank, the gas phase enters the condenser 2 and continues cooling to -25°C with ethylene glycol-water solution, the residual hydrogen fluoride gas is condensed again, and enters the condensate storage tank, and the gas phase obtains a purity ...

Embodiment 2

[0041] a. Control the vacuum degree of hydrogen fluoride and silicon tetrafluoride output system by vacuum pump to -0.02MPa, adjust the outlet exhaust pressure of vacuum pump to 0.13MPa, and pump the mixed gas of hydrogen fluoride and silicon tetrafluoride to a buffer tank of 0.5 cubic meters for collection . Then the gas is compressed to 0.6MPa by the compressor and enters the condenser 1. After compression, the gas temperature is about 90°C. After cooling to 40-45°C, most of the hydrogen fluoride gas is liquefied, and the silicon tetrafluoride remains in the gas phase.

[0042] b. The liquid phase in step a enters the condensate storage tank, the gas phase enters the condenser 2 and continues cooling to -25°C with ethylene glycol-water solution, the residual hydrogen fluoride gas is condensed again, and enters the condensate storage tank, and the gas phase obtains a purity ≥ 99.0wt% silicon tetrafluoride gas product is sent to silicon tetrafluoride storage tank 1 for storage...

Embodiment 3

[0045] a. Control the vacuum degree of hydrogen fluoride and silicon tetrafluoride output system by vacuum pump to -0.02MPa, adjust the outlet exhaust pressure of vacuum pump to 0.13MPa, and pump the mixed gas of hydrogen fluoride and silicon tetrafluoride to a buffer tank of 0.5 cubic meters for collection . Then the gas is compressed to 0.7MPa by the compressor. After compression, the gas temperature is about 90°C and enters the condenser 1. After cooling to 40~45°C, most of the hydrogen fluoride gas is liquefied, and the silicon tetrafluoride remains in the gas phase.

[0046] b. The liquid phase in step a enters the condensate storage tank, and the gas phase enters the condenser 2 and continues cooling to -20°C with ethylene glycol-water solution to condense the residual hydrogen fluoride gas again, and enters the condensate storage tank, and the gas phase obtains purity ≥99.0wt% silicon tetrafluoride gas product, and sent to silicon tetrafluoride storage tank 1 for storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com