Patents

Literature

40results about How to "Reduce the number of plates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

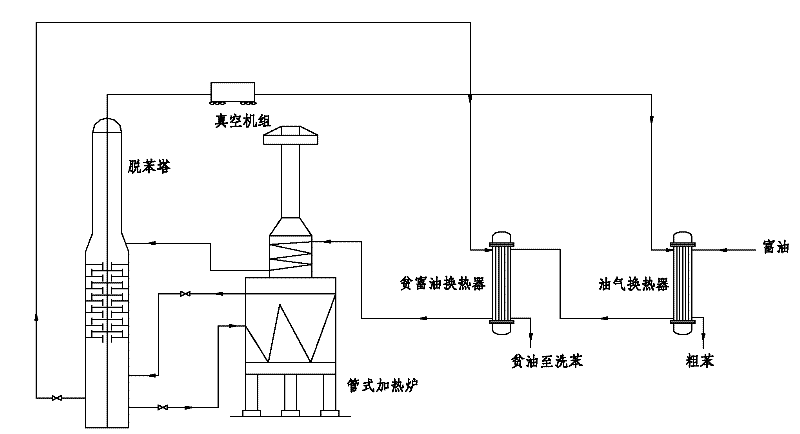

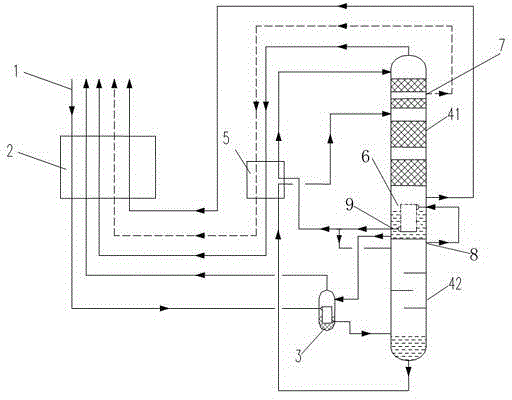

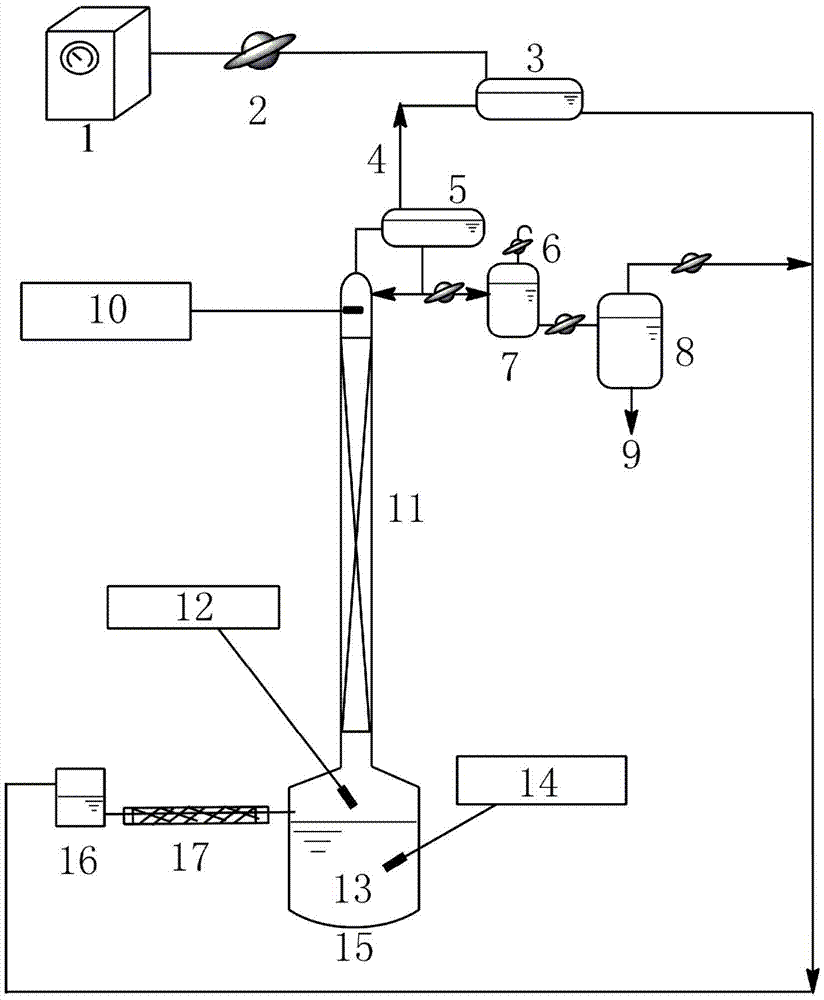

Tubular furnace method pressure-reduced debenzolization and distillation process

InactiveCN102199070AReduce the temperatureGood for volatilizationDistillation purification/separationCombustible gas purificationBenzeneProcess engineering

The invention discloses a tubular furnace method pressure-reduced debenzolization and distillation process. The process comprises the following steps of: carrying out heat exchange on rich oil from a benzene washing section by using an oil-gas heat exchanger and a lean oil-rich oil heat exchanger, entering the convection section of a tubular heating furnace for heating to 175-185 DEG C, then entering a debenzolization tower for debenzolization and distillation, collecting a crude benzene product from the tower top and returning lean oil at the tower bottom to a benzene washing tower, wherein the tower top pressure of the debenzolization tower is 13.3-70 kPa and the tower bottom pressure is 23.3-80 kPa; and the tower top temperature is 40-80 DEG C and the tower bottom temperature is 195-270 DEG C. Compared with traditional debenzolization processes, the pressure-reduced debenzolization and distillation process mainly has the advantages that: 1. the operation can be carried out under a negative pressure, and steam stripping can be omitted; 2. the yield of crude benzene is improved by 0.05-0.35%; 3. steam is not used; 4. since a regenerator is not used, the process structure is more compact and the occupation area is smaller; and 5. One oil-water separator is omitted, the regenerator is not used and a novel debenzolization tower is designed, thus effectively saving equipment investment cost.

Owner:上海同特化工科技有限公司

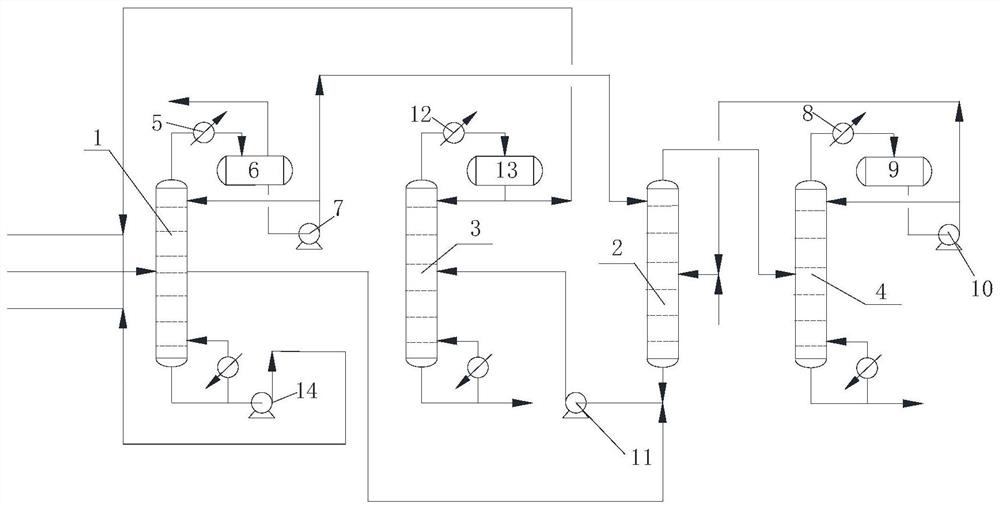

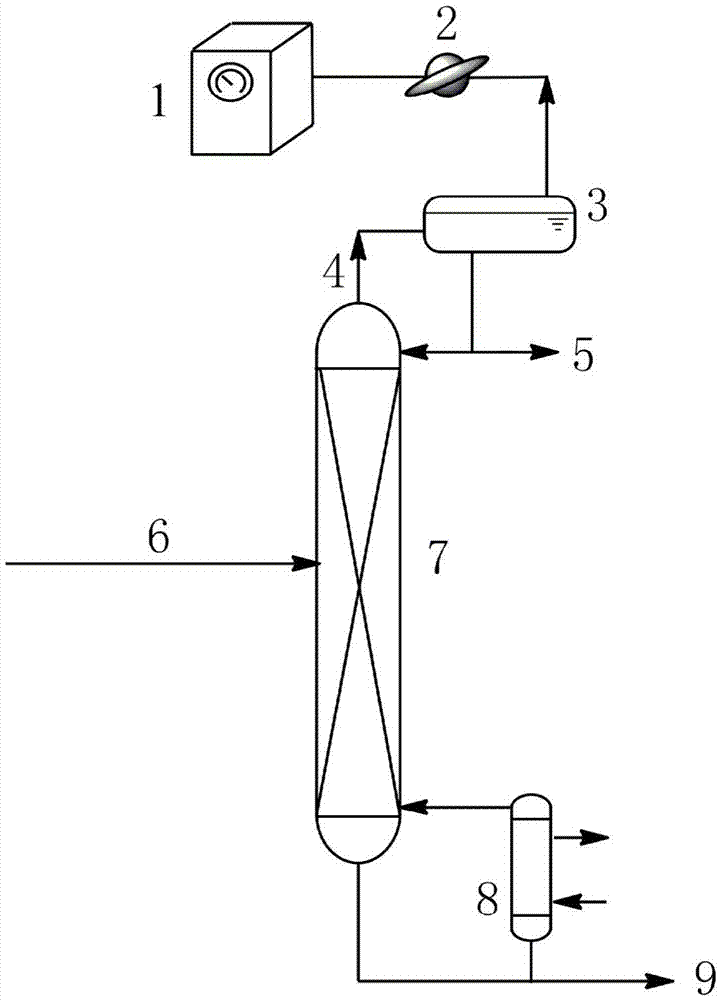

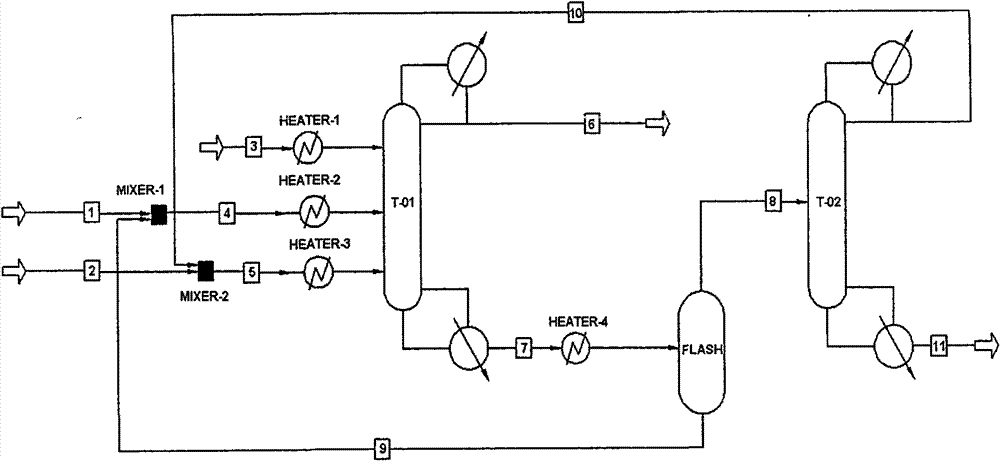

Method for separating cyclohexane and cyclohexene by extraction and rectification

InactiveCN102134177AReduce the number of platesLess investmentDistillation purification/separationSulfolaneCyclohexene

The invention discloses a method for separating cyclohexane and cyclohexene by extraction and rectification, which comprises the following steps of: a) performing extraction and rectification on the mixed solution of the cyclohexane and the cyclohexene in an extraction and rectification tower, wherein the extraction agent is sulfolane, the cyclohexane is obtained at the top of the tower, and rich solvent solution of the cyclohexene and the sulfolane extraction agent is obtained at the bottom of the tower; and b) delivering the rich solvent solution obtained at the bottom of the extraction and rectification tower to a solvent recovery tower, wherein the cyclohexene is obtained at the top of the solvent recovery tower, and the reclaimed sulfolane extraction agent obtained at the bottom of the tower is returned to the step a) to recycle. By the separation method, high-purity cyclohexane and cyclohexene products can be obtained, the extraction agent can be recycled by reclaiming, the separation efficiency can be improved, and equipment investment and process energy consumption are remarkably reduced.

Owner:HEBEI MINHAI CHEM +1

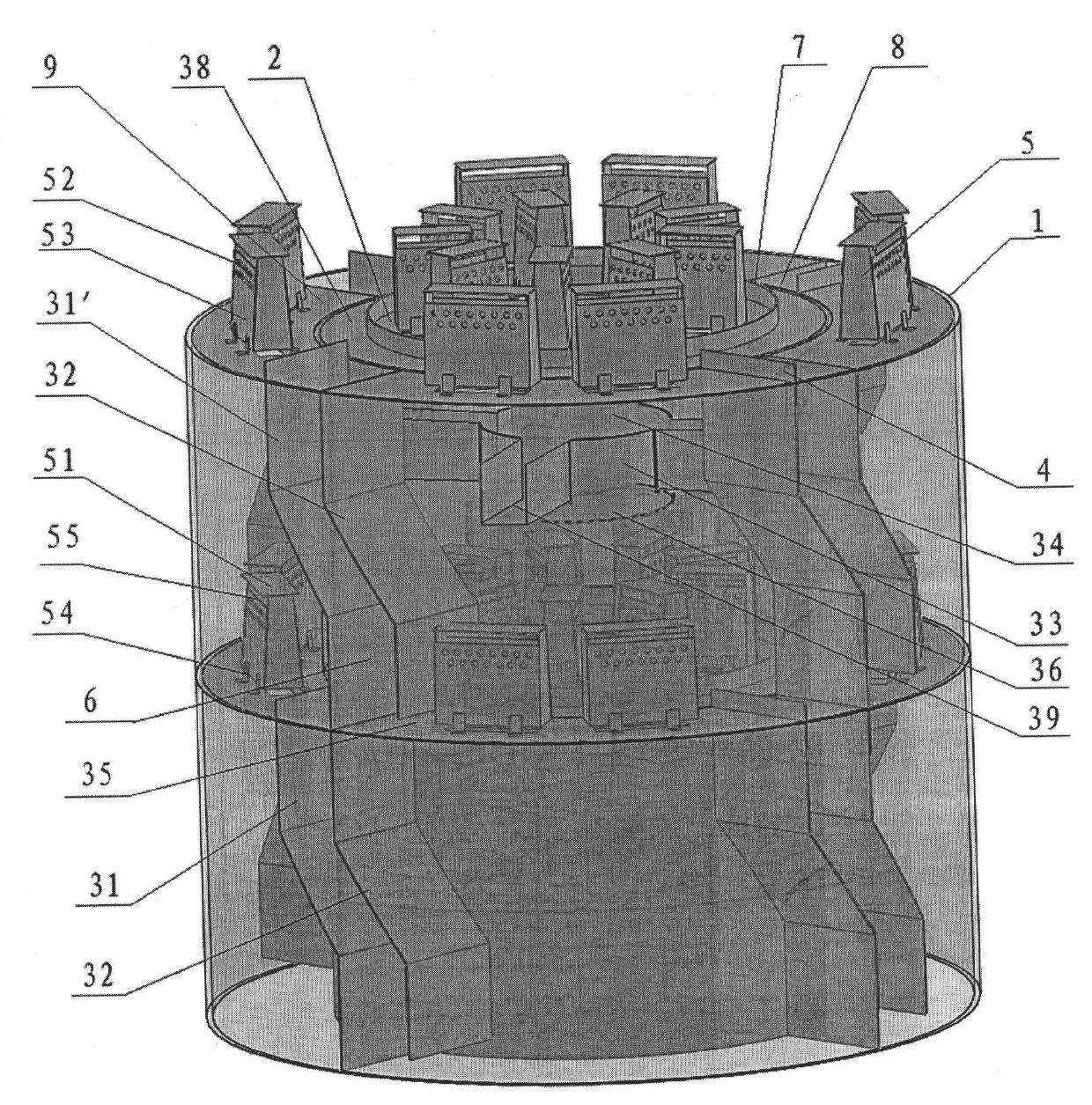

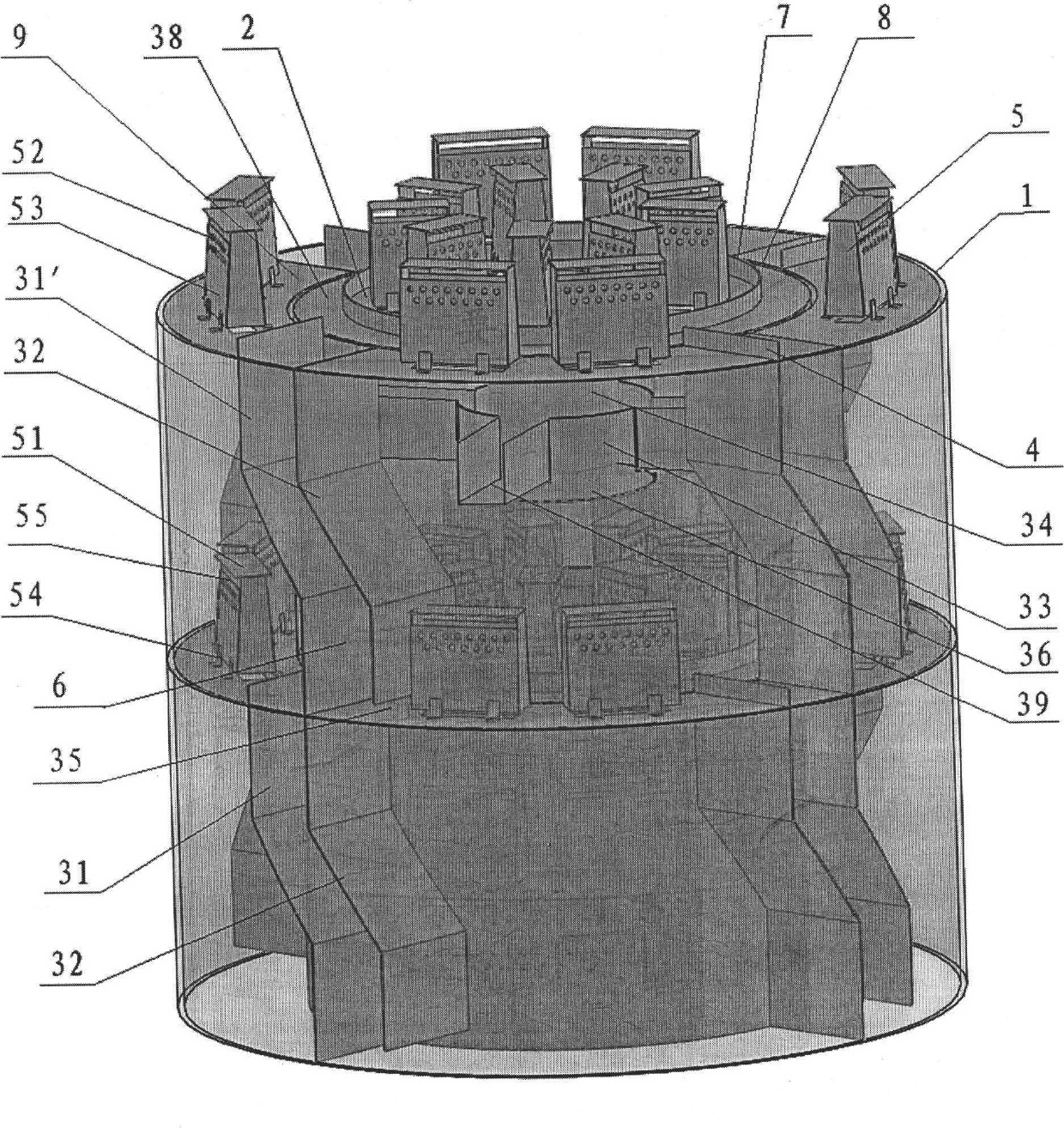

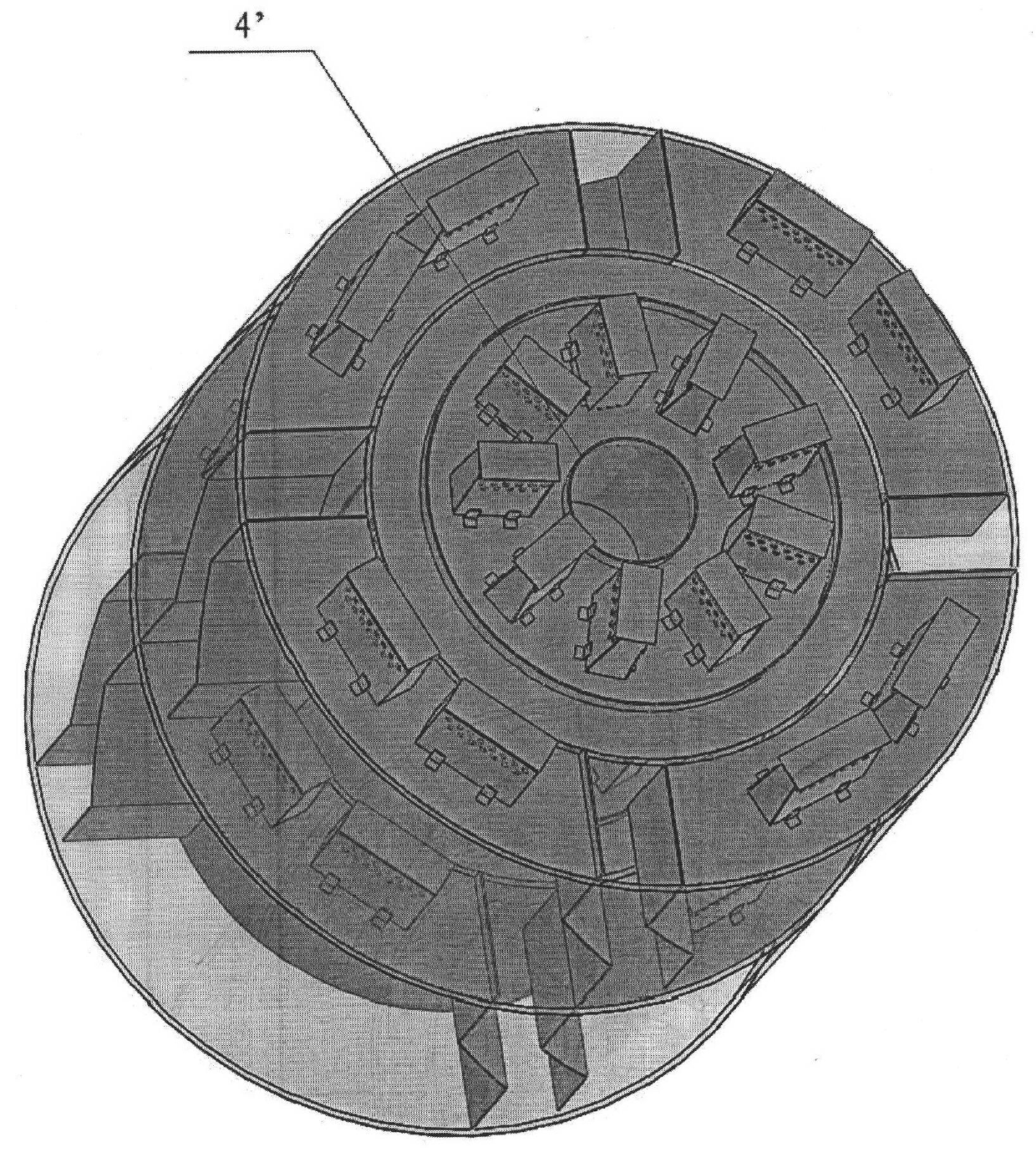

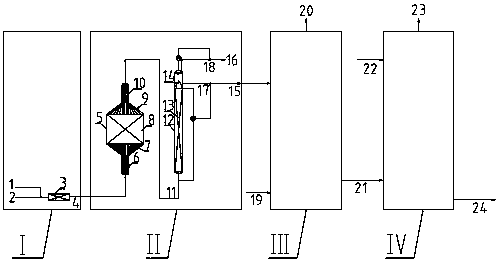

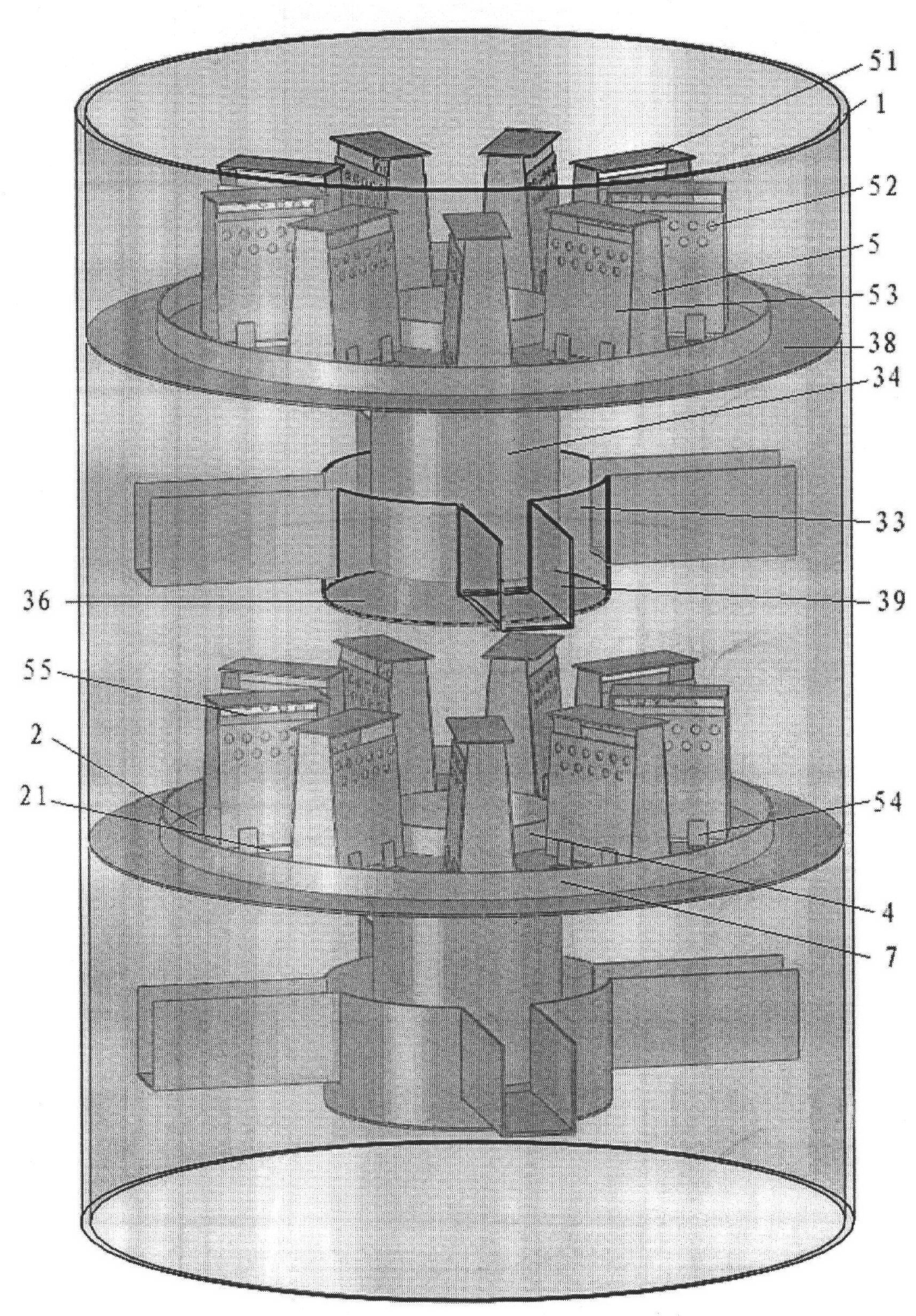

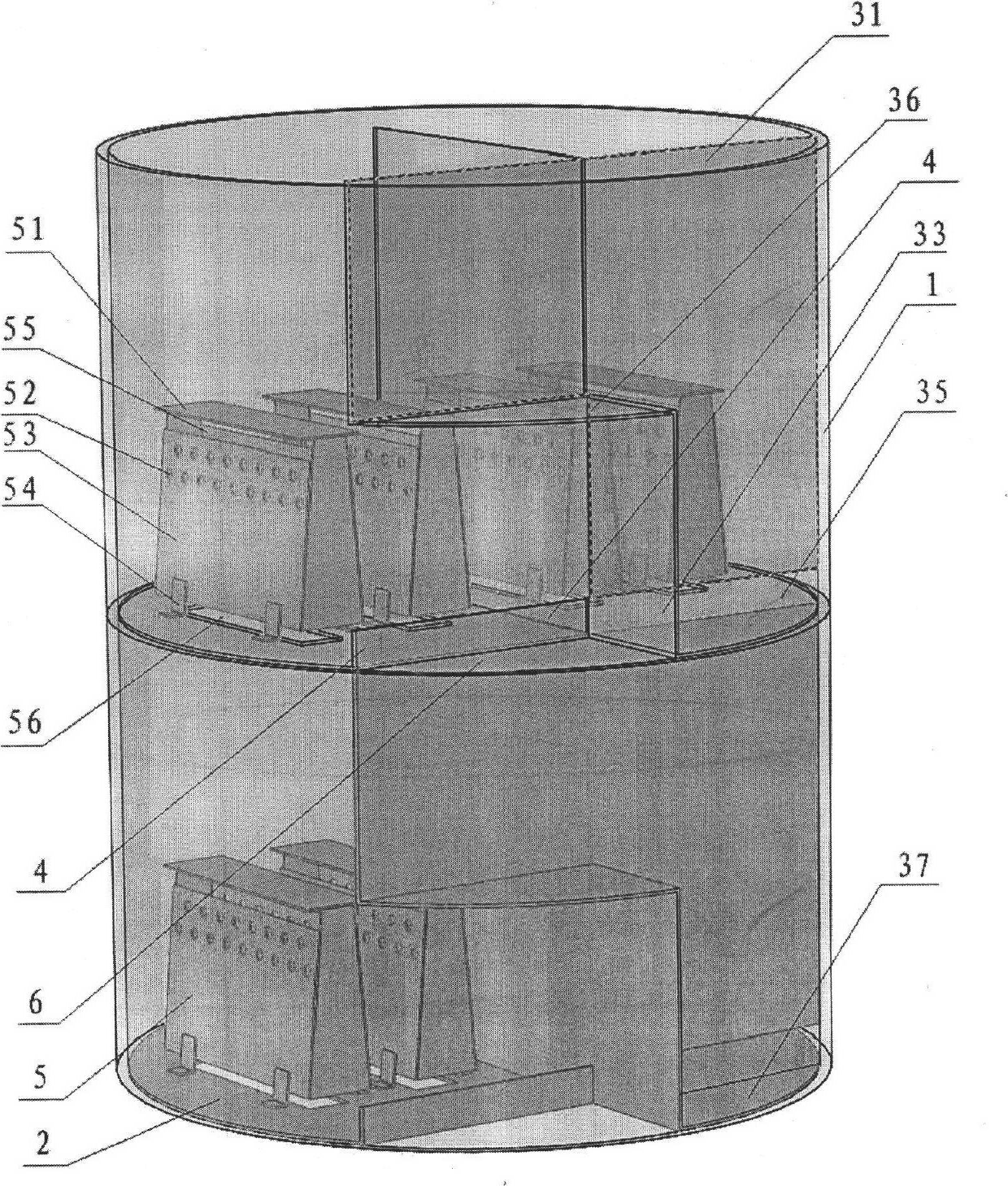

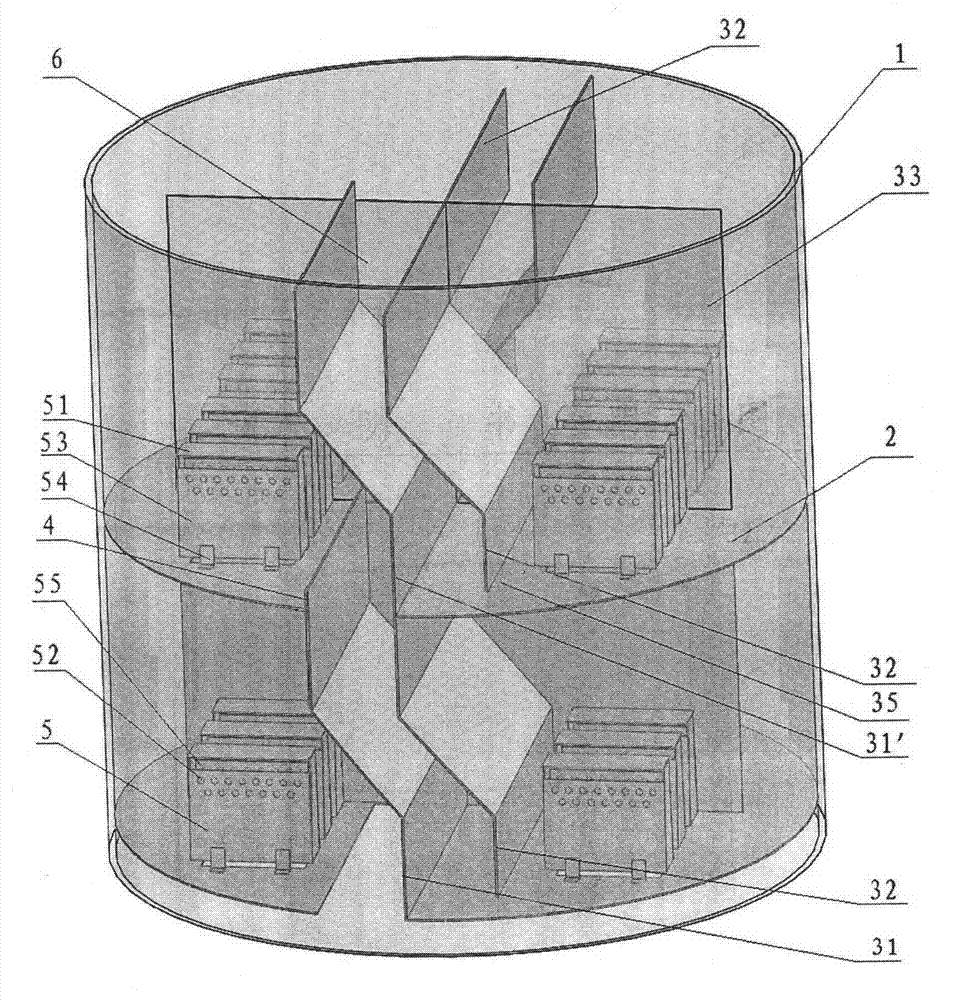

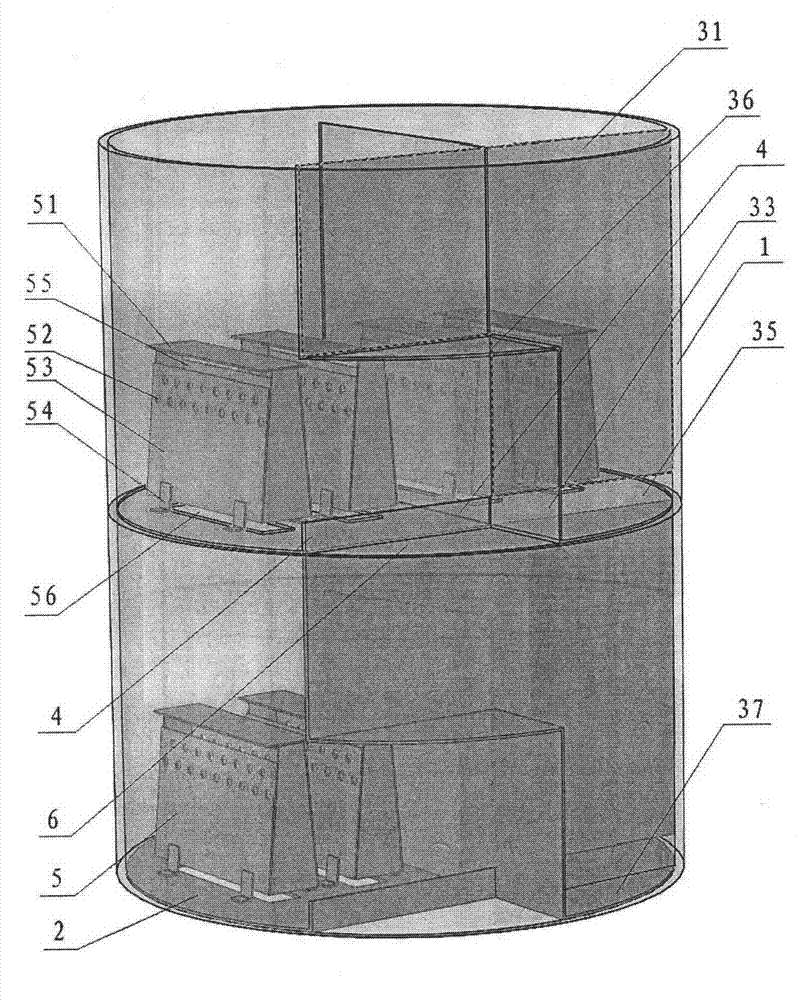

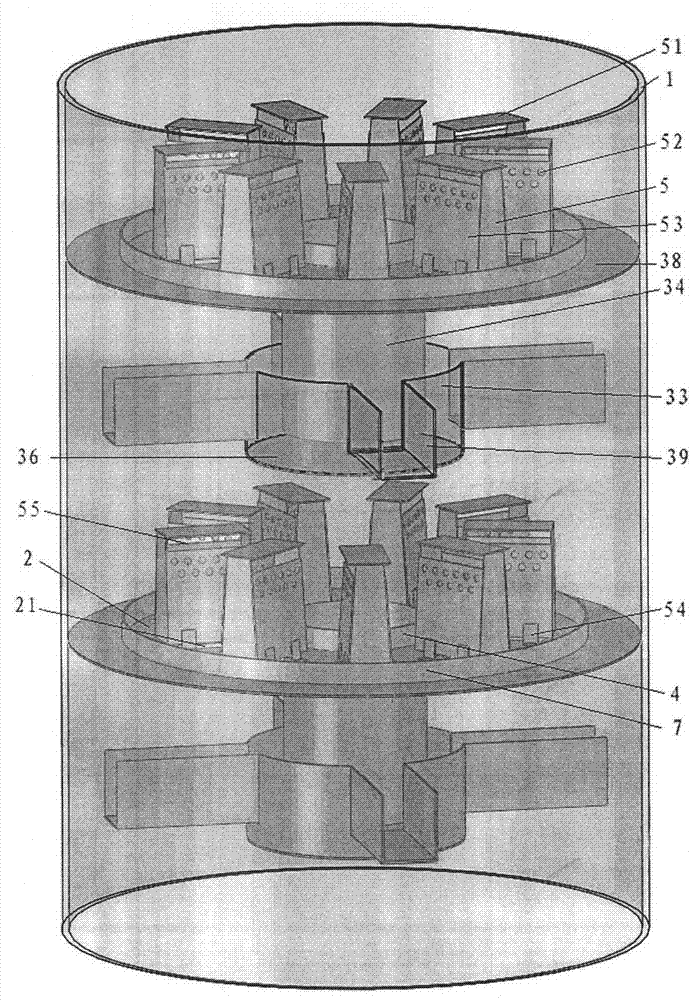

Liquid parallel flow composite tower

ActiveCN101905089AImprove mass transfer efficiencySmall diameterOrganic compound preparationDispersed particle separationChemical industryEngineering

The invention relates to a liquid parallel flow composite tower which is gas-liquid contact equipment used in a mass transfer process, a heat transfer process and the like in fields such as chemical industry, oil refining, petrochemical industry, pharmacy, environmental protection and the like. The composite tower comprises a tower body, wherein the tower body consists of an inner tower and an outer tower; the inner tower is sleeved in the outer tower; tower plates corresponding to cross sections of the tower body are arranged in the inner tower and the outer tower respectively; and each tower plate is provided with a down-flow system which can allow liquid on each layer of tower plates to flow in the same direction. The composite tower has the advantages of realizing large-flux mass transfer of liquid, preventing a stagnation zone from being formed on the tower plate, increasing an effective mass transfer area, enhancing treating capability, enhancing gas-liquid mass transfer average driving force on the tower plate and further improving the mass transfer efficiency of the tower plate.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

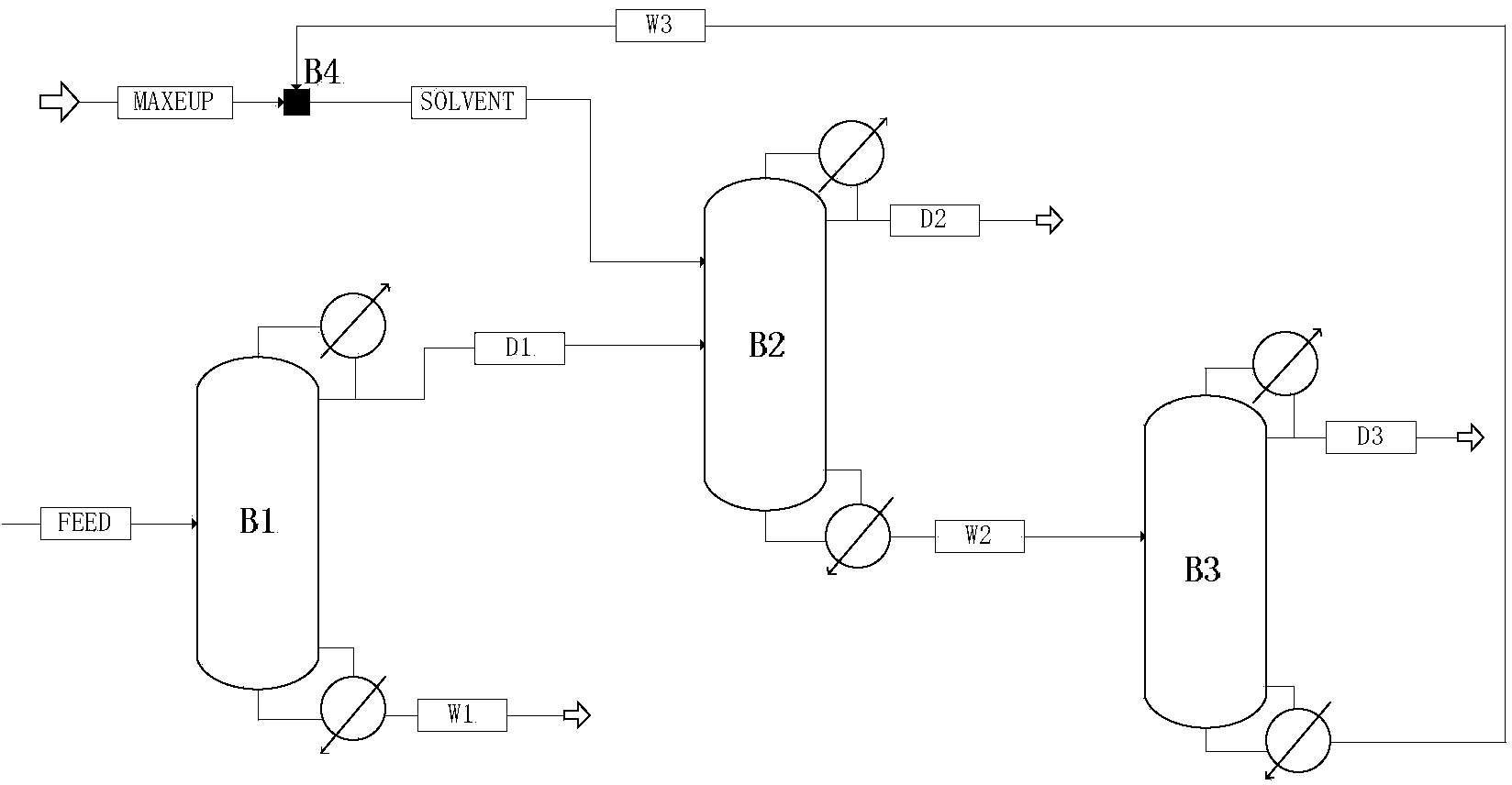

Air separation fractionating tower system and technology utilizing air separation fractioning tower system to prepare low-purity oxygen

InactiveCN104677052AReduce exhaust pressureReduce overall energy consumptionSolidificationLiquefactionLiquid oxygenAir separation

The invention discloses an air separation fractionating tower system and a technology utilizing the air separation fractionating tower system to prepare low-purity oxygen. The pressure air is subject to heat exchange by a main heat exchanger and a liquid oxygen evaporator and is converted into partially liquefied air, then the air is separated into oxygen-rich liquid air and nitrogen in a lower tower of the fractionating tower, and the oxygen-rich liquid air enters an upper tower of the fractionating tower; the nitrogen is cooled into liquid nitrogen in the condensing evaporator, and is sent into the upper tower of the fractionating tower through an overcooler; each material in the upper tower of the fractionating tower is separated into low-purity liquid oxygen and nitrogen, and the low-purity liquid oxygen is subject to heat exchange and gasifying with the nitrogen at the lower part of the lower tower of the fractionating tower in the condensing evaporator, is subject to heat exchange by the condensing evaporator and the main heat exchanger, and is sent out as a product; the low-purity liquid oxygen is also subject to heat exchange by the liquid oxygen evaporator and the main heat exchanger, and is sent out as the product. The air separation fractionating tower system has the advantages that the low-purity oxygen and high-purity oxygen with different purities and pressures can be simultaneously produced, the operation pressure is low, the extraction rate is high, the energy consumption is little, the equipment investment is low, the requirements of low-purity oxygen and high-purity oxygen in multiple industries can be well met, and the air separation fractionating tower system is suitable for industrial production.

Owner:开封东京空分集团有限公司

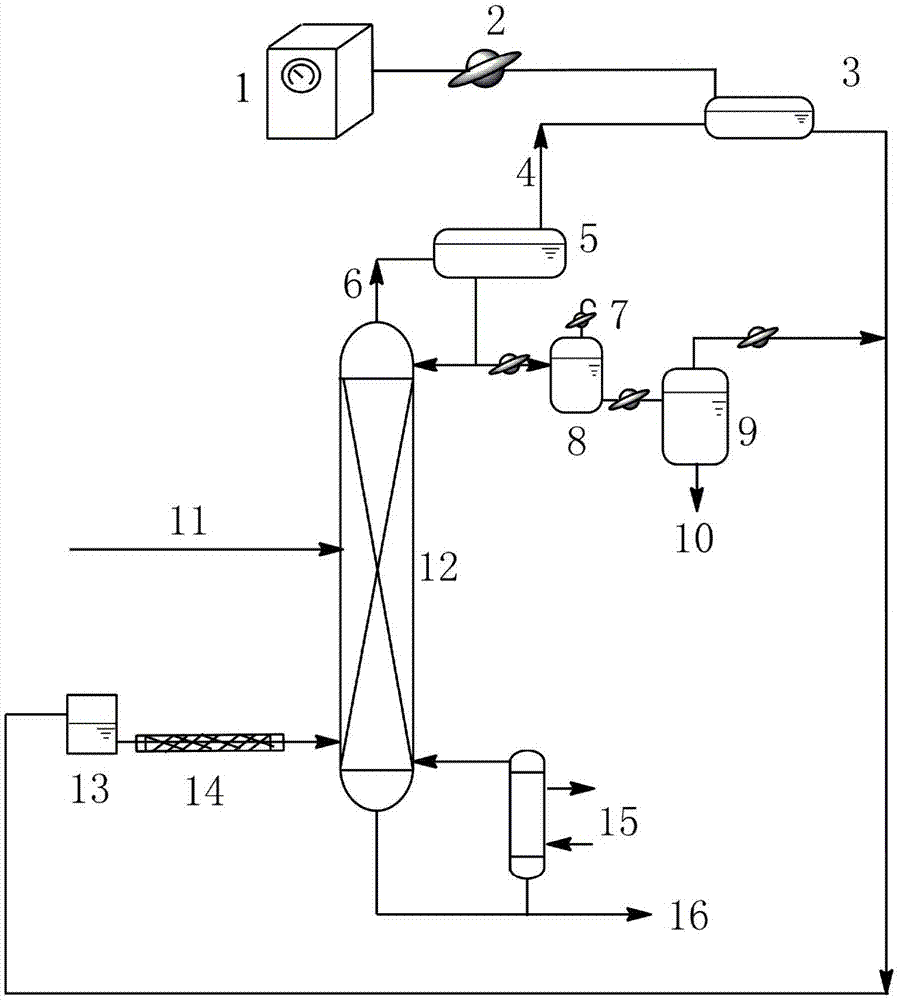

High-efficiency extraction process in hydrogen peroxide production process

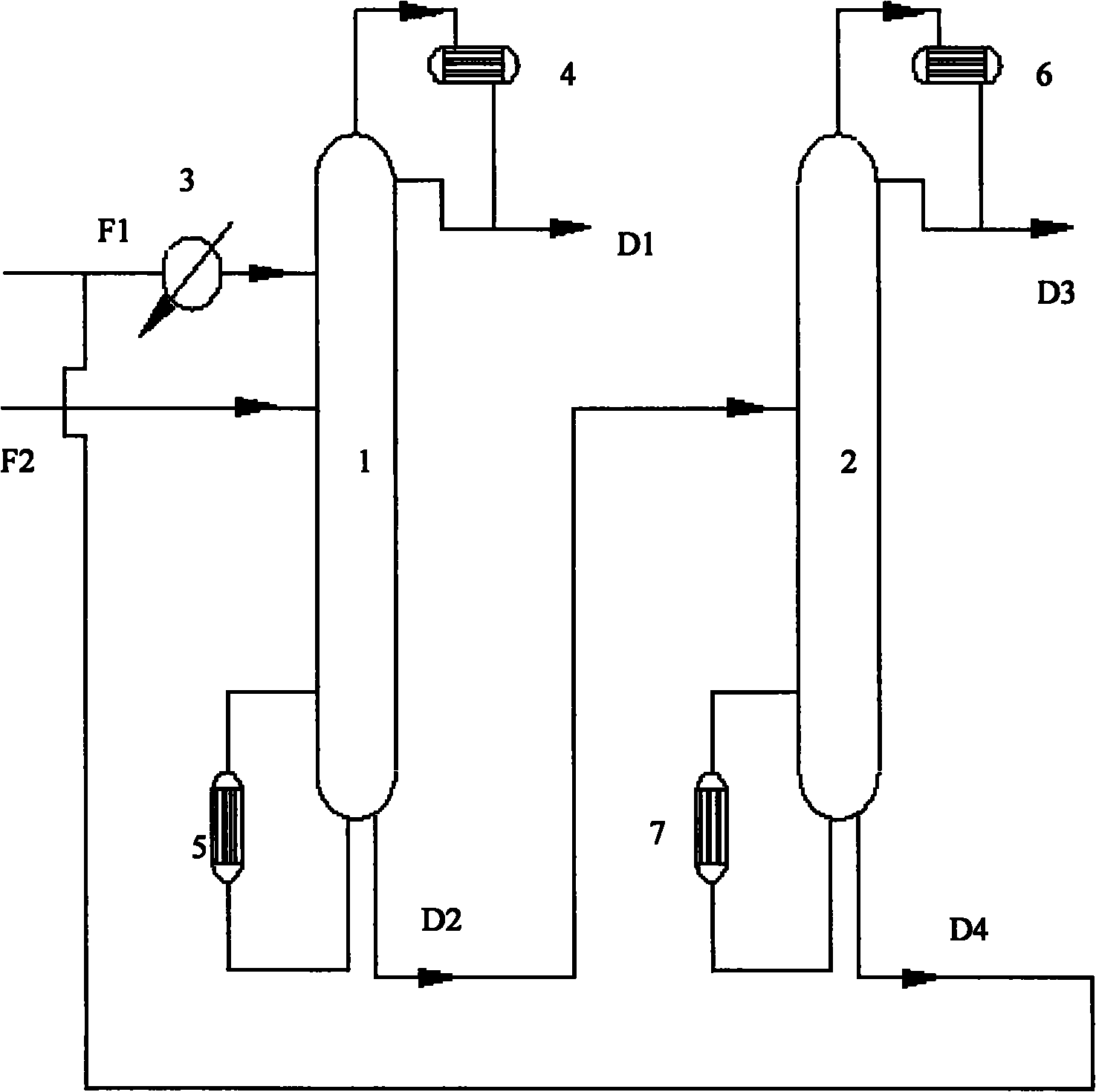

ActiveCN105621364AImprove extraction efficiencyReduce the number of platesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationTower

The invention discloses a high-efficiency extraction process in a hydrogen peroxide production process. According to the invention, in an extraction process of an anthraquinone method for producing hydrogen peroxide; an extraction tower I and an extraction tower II are arranged; an oxidation liquid is divided into two parts which are an oxidation liquid I and an oxidation liquid II; pure water is introduced from the top of the extraction tower I, and the oxidation liquid I is introduced from the bottom of the extraction tower I; the two phases are subjected to countercurrent extraction in the extraction tower I; raffinate is discharged from the top of the extraction tower I, and is subjected to separation in a liquid / liquid separator, such that a heavy phase and a light phase are obtained; the heavy phase is mixed with extract liquid from the bottom of the extraction tower I, and the mixture of the heavy phase and the extract liquid from the bottom of the extraction tower I is introduced from the top of the extraction tower II; the light phase is mixed with the oxidation liquid II, and the mixture of the light phase and the oxidation liquid II is introduced from the bottom of the extraction tower II; the two phases are subjected to countercurrent extraction in the extraction tower II; a tower top raffinate phase is introduced into a post-treatment process; and the tower bottom extraction liquid is the high-concentration hydrogen peroxide product. The high-efficiency extraction process provided by the invention is provided aiming at the defects of prior arts. The process has the advantages of high mass transfer rate, high Murphree efficiency, high product concentration, low raffinate content, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

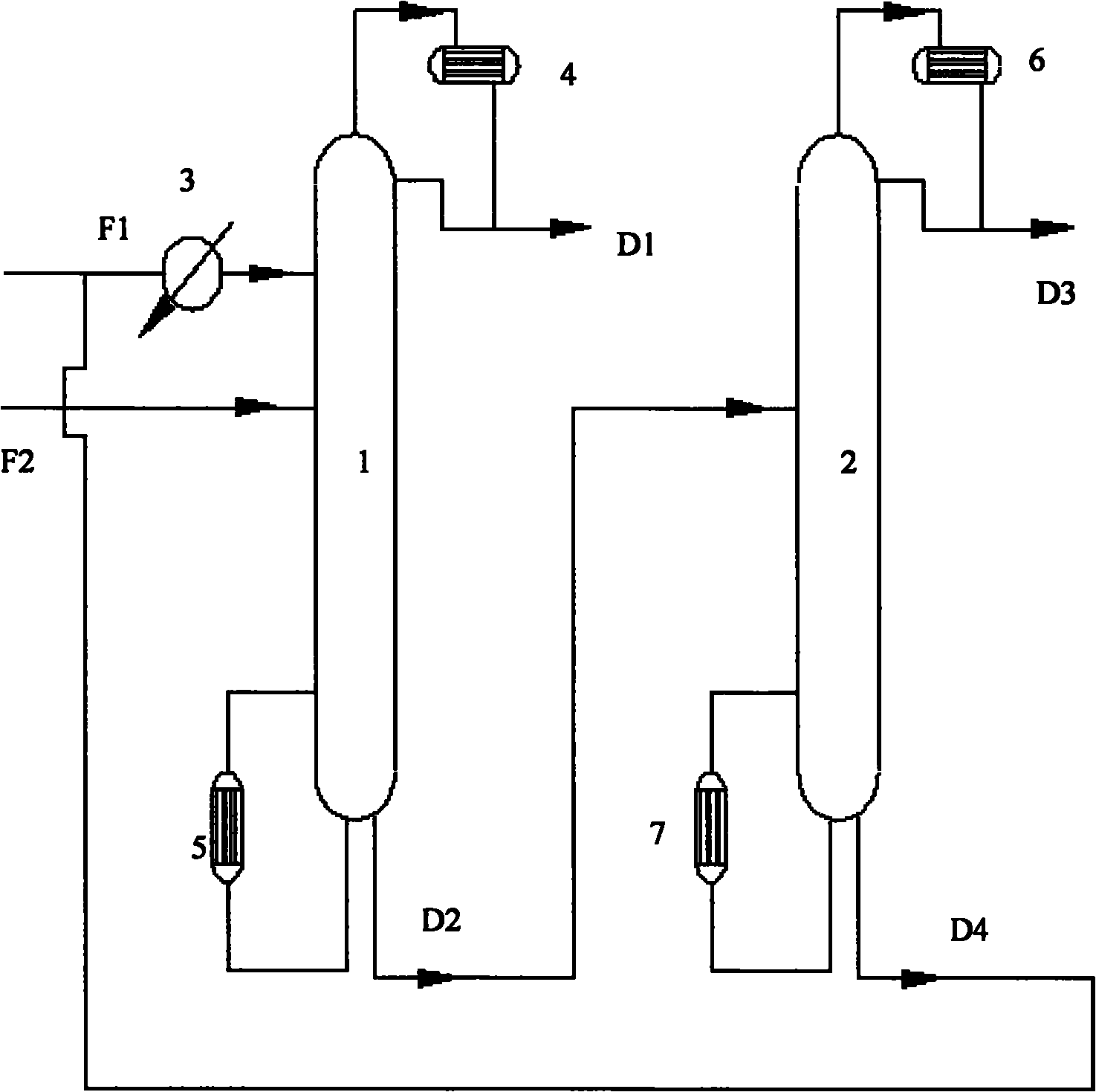

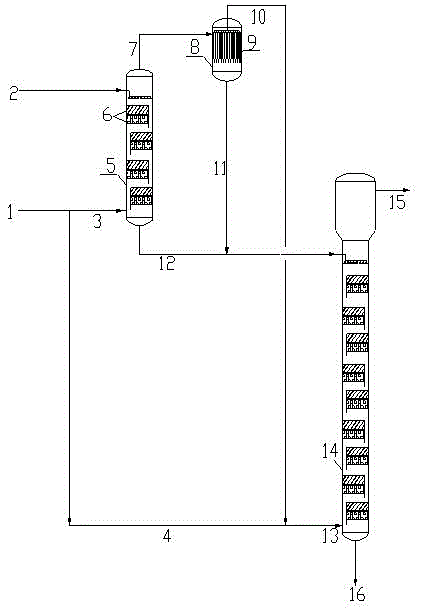

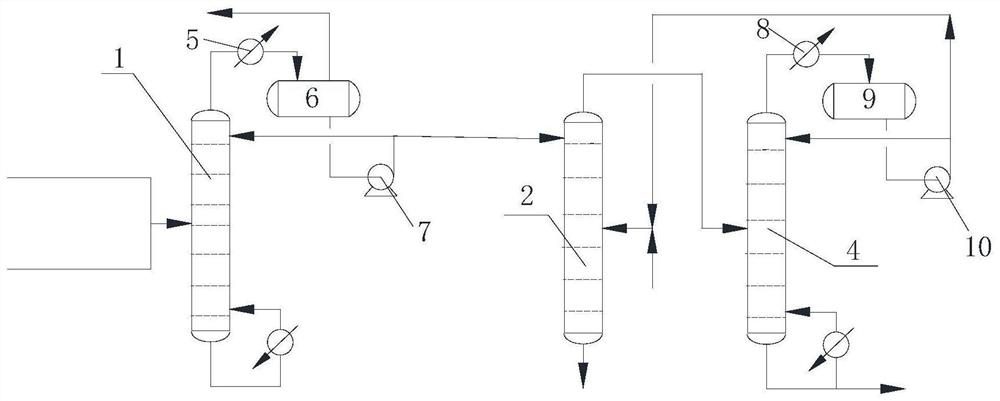

Process for separating ethylbenzene from C8 arene

InactiveCN104387224AReduce the number of platesReduce energy consumptionDistillation purification/separationO-XyleneTower

The invention discloses a process for separating ethylbenzene from C8 arene. The process comprises the following steps: separating a C8 arene mixture by virtue of a rectifying tower (B1) to obtain an o-xylene from the bottom of the tower, and separating a tower top distillate in an extraction rectifying tower (B2) to obtain ethylbenzene flowing out of the top of the extraction rectifying tower (B2); separating a tower bottom distillate in an extracting agent recovery tower (B3) to obtain a mixture of p-xylene and m-xylene from the top of the tower; and recycling an extracting agent from the bottom of the tower in the extraction rectifying tower (B2). Compared with a precise rectifying method, the process disclosed by the invention has the advantages that the number of tower plates is obviously reduced, the energy consumption is reduced, the separation effect is significant, the purity of ethylbenzene can reach more than 99%, and the extracting agent is easy to recover and can be recycled.

Owner:NANJING UNIV OF TECH

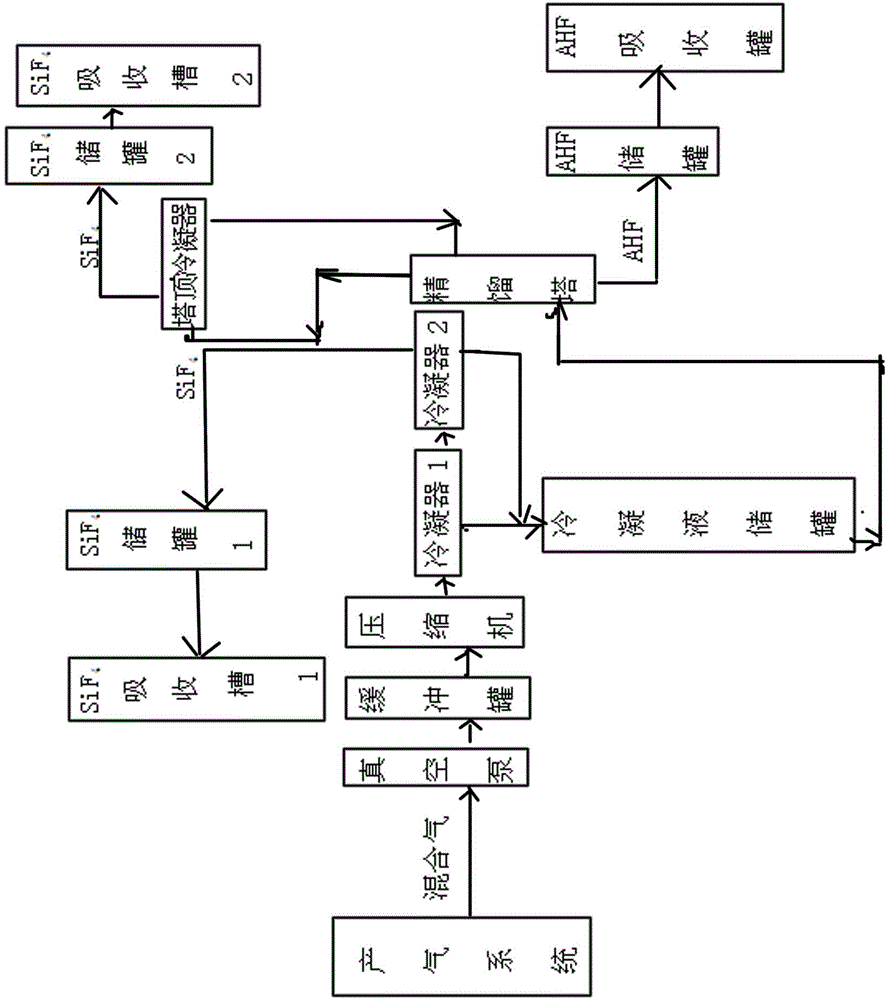

Direct separation method of silicon tetrafluoride and anhydrous hydrogen fluoride mixed gas

ActiveCN104671210AEasy to separateImprove controllabilityHydrogen fluorideHalogenated silanesChemical industryLiquid fluorine

The invention relates to the technical field of fluorine chemical industry, and in particular relates to a direct separation method of a silicon tetrafluoride and anhydrous hydrogen fluoride mixed gas. The method comprises the following process steps: a, collecting a silicon tetrafluoride and hydrogen fluoride mixed gas, which is obtained by pyrolysis of fluosilicic acid, compressing through a compressor, entering a condenser 1, cooling, and entering obtained liquefied hydrogen fluoride to a condensate storage tank; b, feeding the cooled silicon tetrafluoride gas to a condenser 2, further cooling with an ethylene glycol-water solution, removing residual hydrogen fluoride to obtain a silicon tetrafluoride gas and entering a silicon tetrafluoride storage tank 1 to store; and c, carrying out rectification and purification on liquid phases in the step a and the step b, and controlling the operation pressure and the overhead condensation temperature of a rectifying tower to obtain the refined liquid hydrogen fluoride product. The method has the advantages of being feasible to operate, low in investment, low in energy consumption, and free of difficult-to-treat waste, and is an economical, efficient and environment-friendly separation method; and equipment is not corroded.

Owner:YUNNAN TIANAN CHEM CO LTD +1

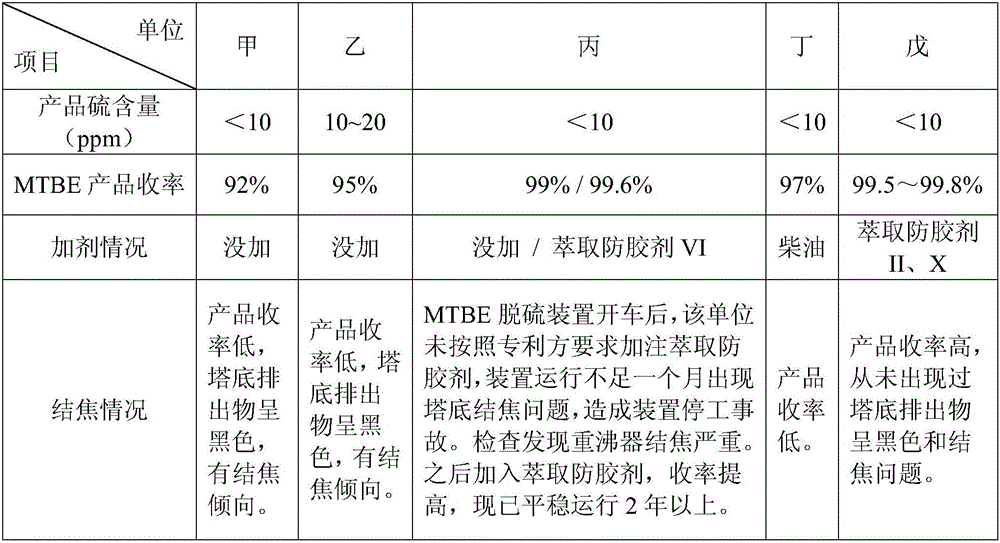

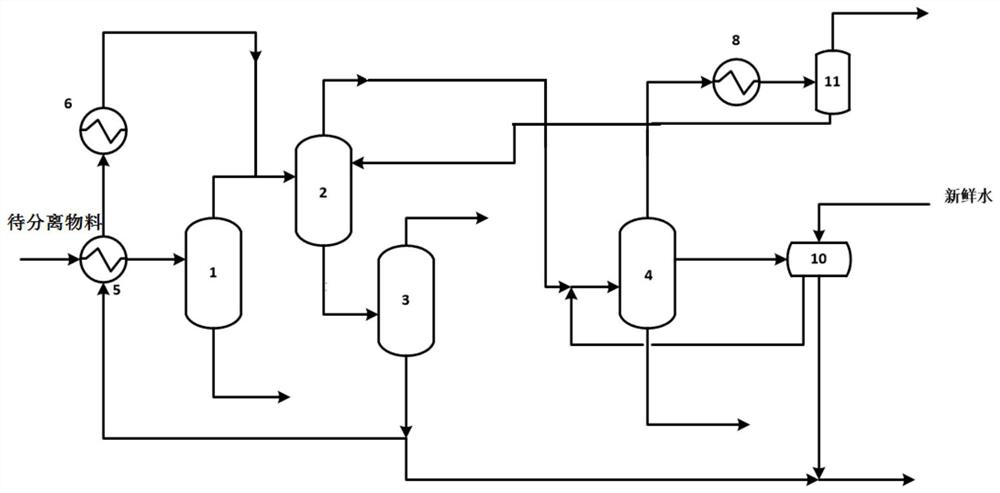

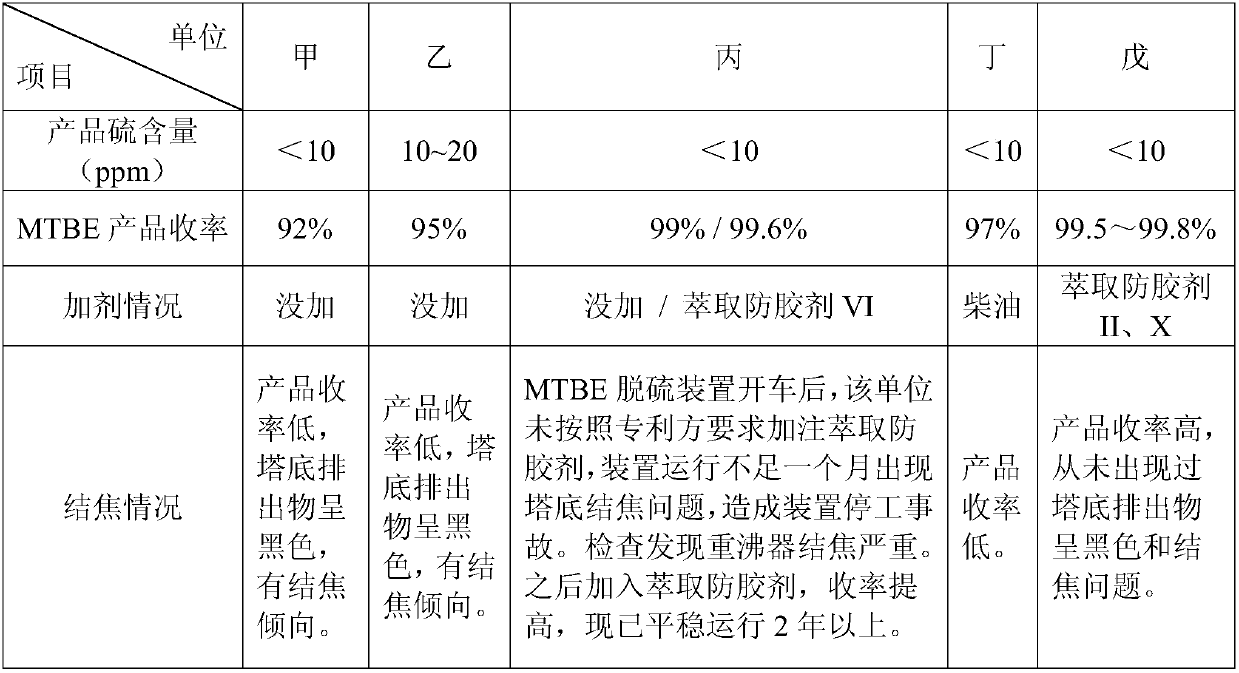

Extraction anti-gum agent for MTBE desulfurization

ActiveCN105777500ANo three wastes producedSufficient vaporization rateEther separation/purificationExtractive distillationRefluxExtractive distillation

The invention relates to an extraction anti-gum agent for MTBE desulfurization.The extraction anti-gum agent at least contains a solvent with the boiling point ranging from 80 DEG C to 150 DEG C, and the solvent at least contains one or a mixture of two or more of C7 (and above) aromatic hydrocarbons with the boiling point ranging from 110 DEG C to 150 DEG C.The extraction anti-gum agent can efficiently remove sulfide in MTBE and also can effectively prevent coking at the bottom of an extractive distillation tower; on the premise of guaranteeing a high vaporization rate of the distillation tower, vaporization of sulfide can be effectively reduced, the distribution gradient of sulfide in the tower can be effectively reduced, and the number of tower plates needed for distillation or the reflux ratio can be effectively decreased, so that investment or operation cost is significantly lowered; the extraction anti-gum agent has a strong extraction effect on low-boiling-point sulfide; recovery or additional treatment is not needed, and no waste is generated.

Owner:HEBEI REFINING TECH CO LTD

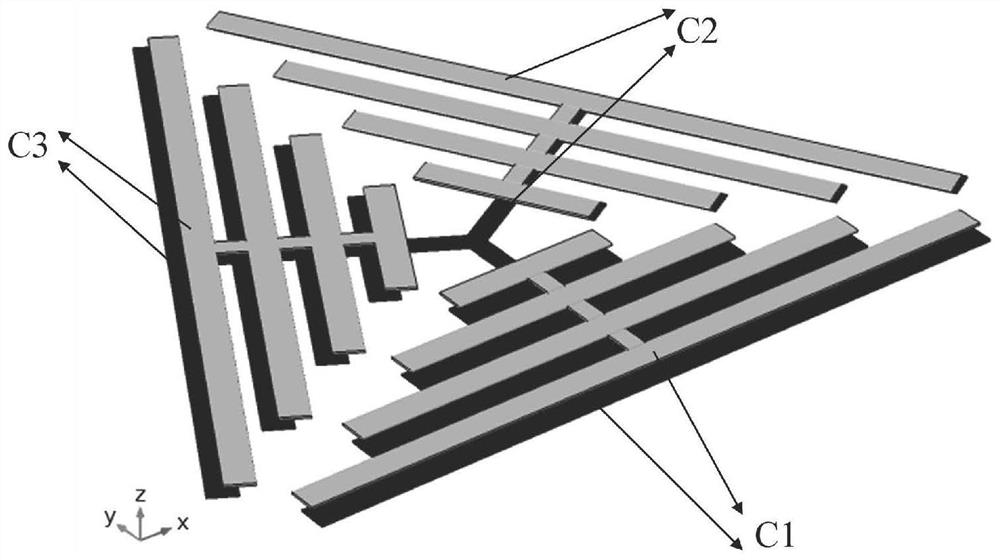

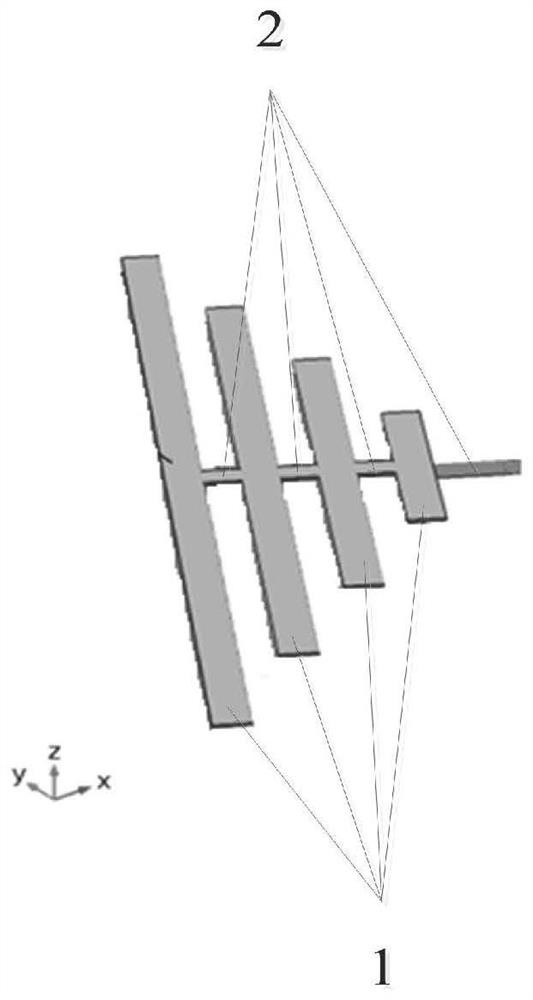

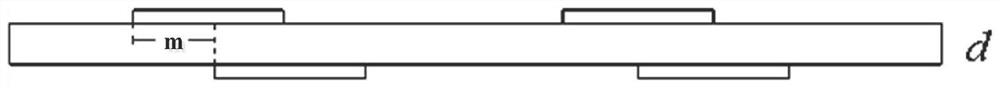

Capacitive touch sensor

ActiveCN111766010AReduce the number of platesReduce the number of capacitorsForce measurementApparatus for force/torque/work measurementTactile sensorCapacitance

The invention provides a capacitive touch sensor. A single sensing unit structure of the capacitive touch sensor is triangular, and is composed of an upper polar plate, a lower polar plate and a dielectric layer. The upper polar plate and the lower polar plate are correspondingly arranged; the upper polar plate comprises three first polar plates, the lower polar plate comprises three second polarplates, the first polar plates and the second polar plates are isosceles triangles with vertex angles of 120 degrees, the vertex angles of the three first polar plates are oppositely arranged, top ends of the three second polar plates are connected with one another, and the three first polar plates and the three second polar plates jointly form three independent capacitors; and through a structural arrangement, the number of polar plates and the number of capacitors are reduced, and a measurement circuit is greatly simplified so that accurate measurement and decoupling of a three-dimensional force are realized.

Owner:BEIHANG UNIV +1

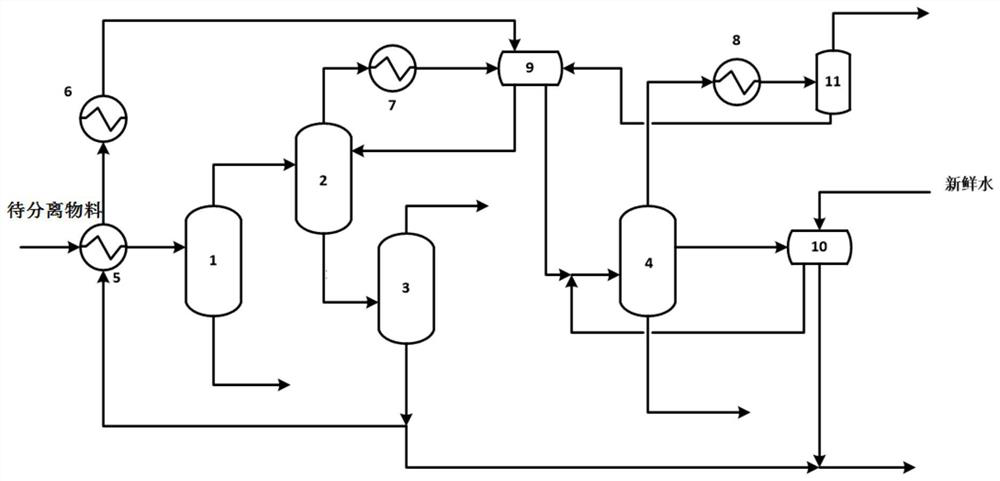

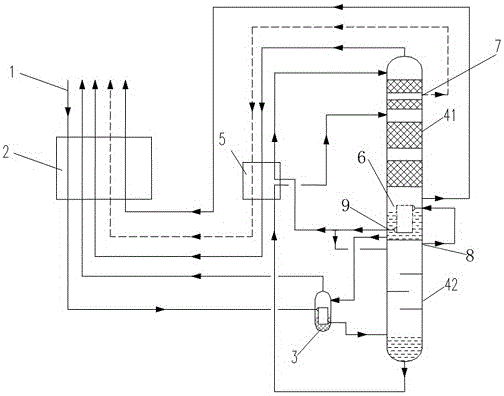

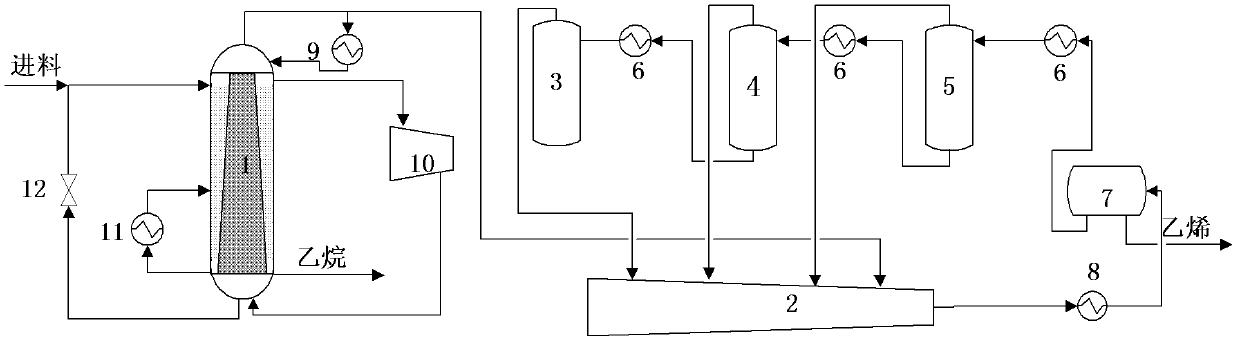

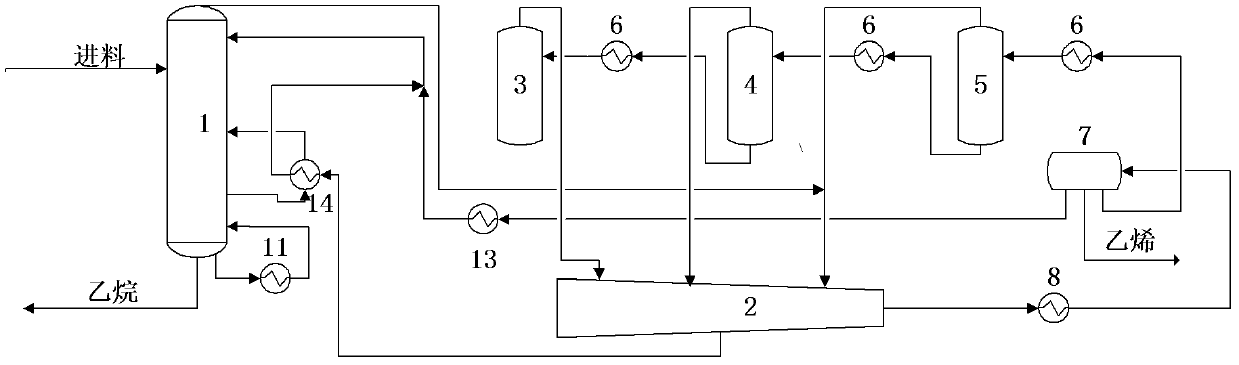

System and method for producing hydrogen peroxide through anthraquinone method

ActiveCN109678119AUniform responseQuality improvementPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationFixed bed

The invention discloses a system and method for producing hydrogen peroxide through an anthraquinone method. The system comprises the four unit processes of hydrogen dissolving, hydrogenation, oxidation and extraction, wherein a hydrogenation unit comprises a series fixed bed and upflow-type tubular reactors, and working liquid and hydrogen are subjected to a hydrogenation reaction in the hydrogenation unit to obtain hydrogenation liquid; an oxidation unit comprises an oxidation tower, the hydrogenation liquid and oxygen-containing gas are subjected to an automatic oxidation reaction to obtainoxidation liquid; and an extraction unit comprises an extraction tower, hydrogen peroxide in the oxidation liquid is extracted by the water, and thus a high-concentration hydrogen peroxide product isobtained. According to the system and method, the anthraquinone hydrogenation reaction rate can be significantly improved, the anthraquinone hydrogenation reaction efficiency can be significantly improved, the uniformity of the reaction process is maintained, side reactions are less, the obtained hydrogenation liquid is good in quality, small in by-product number and low in viscosity, the gas-liquid mass transfer rate in the oxidation process is increased, the extraction efficiency in the extraction process is improved, the oxidation time is significantly shortened, and the number of actual tower plates of the extraction tower is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

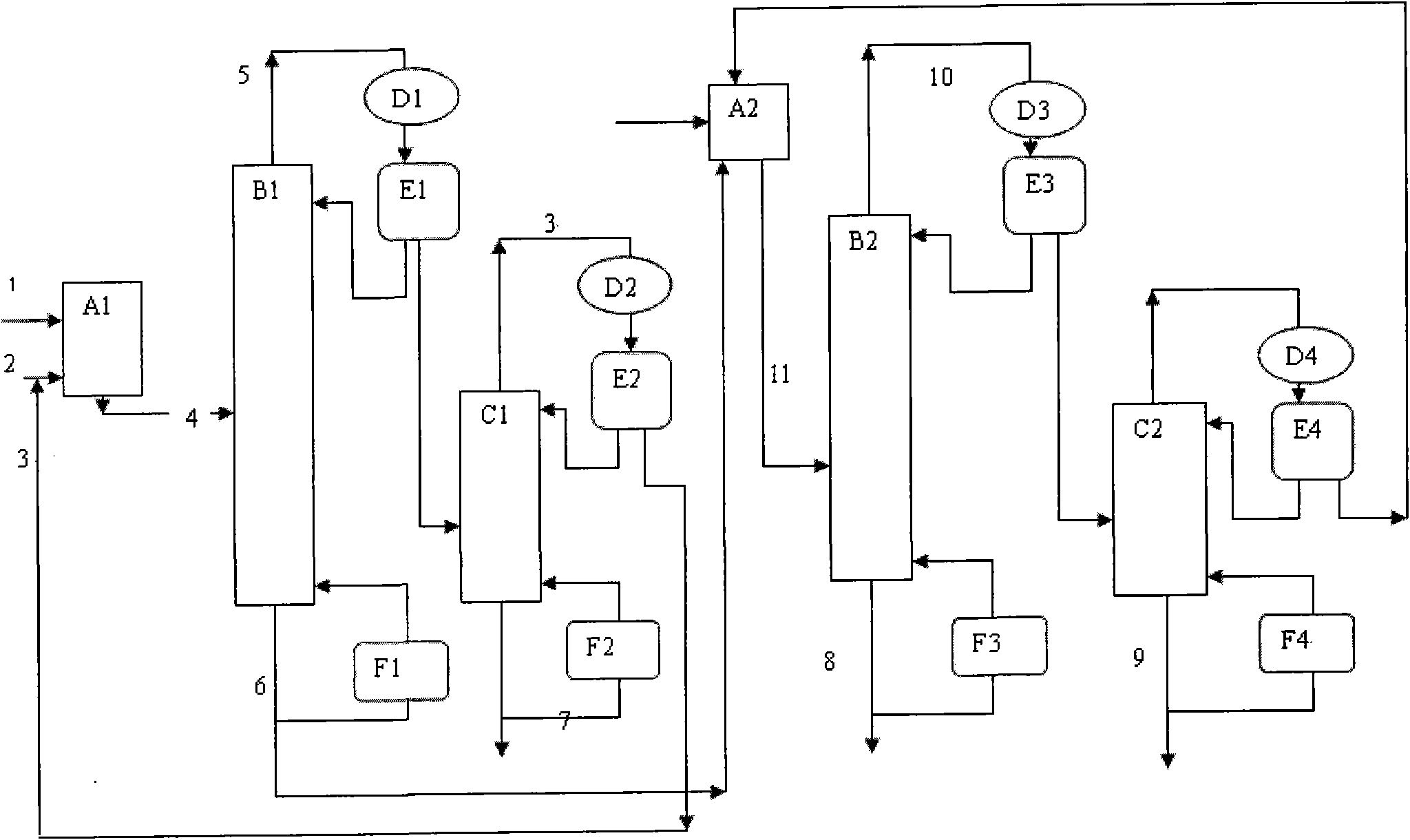

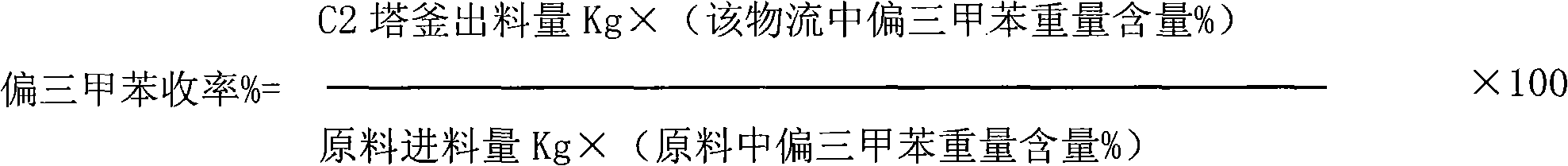

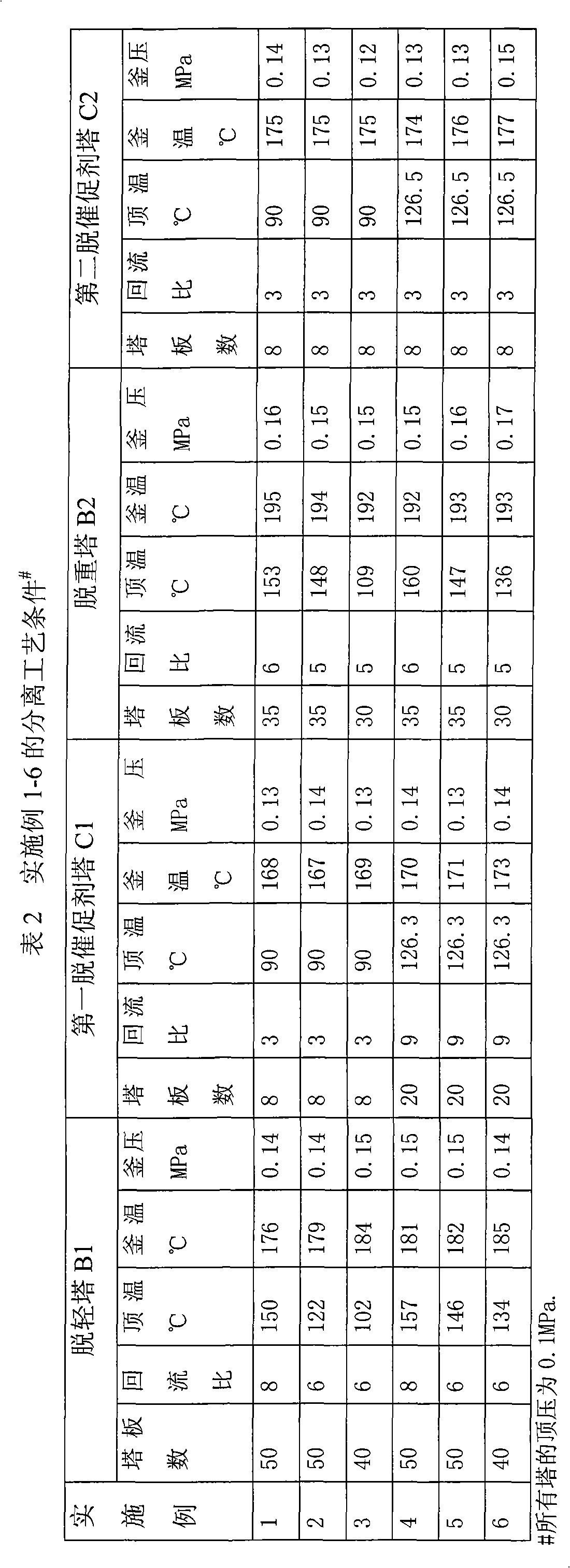

Method for separating pseudocumene from C9 aromatic hydrocarbon

ActiveCN102464556AReduce the number of platesLess investmentDistillation purification/separationTowerToluene

The invention discloses a method for separating pseudocumene from C9 aromatic hydrocarbon, which is characterized in that an accelerator is added during the rectification process, the accelerator is one of dimethyl carbonate or diethyl carbonate. The method comprises the following steps: 1) a C9 aromatic hydrocarbon mixture and the accelerator are mixed and introduced in a lightness-removing tower, a light component is elicited by the lightness-removing tower, a heavy component is elicited by a tower kettle; 2) the light component in the step 1) is introduced in a first accelerator removal tower, the accelerator is elicited from the top of the tower, the light component material flow is elicited by the tower kettle; 3) the heavy component and the accelerator in the step 1) are mixed and then introduced in a weight-removing tower, the material flow is respectively elicited from the tower top and the tower kettle; 4) the material flow elicited from the weight-removing tower in the step 3) is introduced in a second accelerator removal tower, the accelerator is elicited from the top of the tower, the pseudocumene product can be elicited from the tower kettle. The obtained pseudocumene has the advantages of high productivity and high yield, the production apparatus requires less plate number.

Owner:CHINA PETROLEUM & CHEM CORP +1

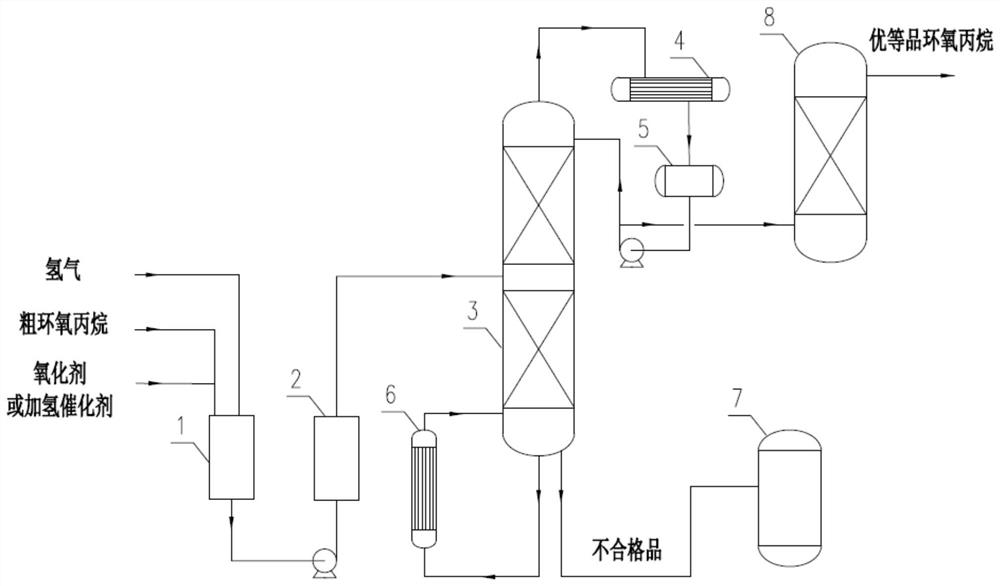

Method and system for dealdehyding and upgrading epoxypropane

PendingCN113072523AReduce the reflux ratioReduce energy consumptionOrganic chemistryPtru catalystProcess engineering

The invention discloses a method for dealdehyding and upgrading epoxypropane, which comprises the following steps of: (1) under the action of an oxidizing agent, carrying out oxidation reaction on an aldehyde compound of an epoxypropane crude product; or under the action of a hydrogenation catalyst, carrying out hydrogenation reduction reaction on the aldehyde compound of the epoxypropane crude product and hydrogen; and (2) feeding the material obtained by the reaction in the step (1) to a rectification tower for rectification treatment to obtain a low-aldehyde-value epoxypropane product. The method also comprises the following step of: feeding a material obtained by reaction in the step (1) into a membrane separator for membrane separation, and feeding a product on the permeation side of the membrane separator into a rectification tower for rectification treatment. The aldehyde in the epoxypropane crude product is subjected to oxidation or reduction reaction, the boiling point of the impurity obtained by the reaction is greatly different from that of epoxypropane, and a superior product can be obtained through rectification. Compared with direct rectification, the method has the advantages that the reflux ratio is reduced, and the number of tower plates is reduced.

Owner:南京佳华科技股份有限公司

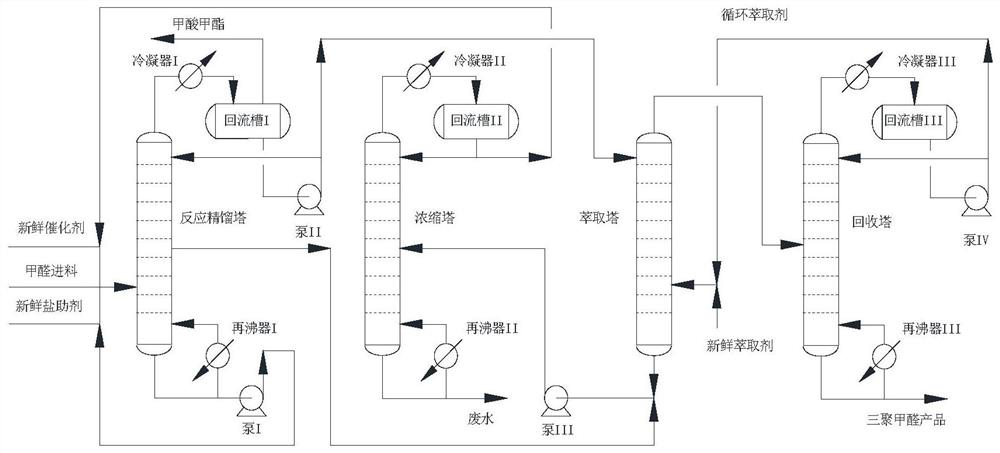

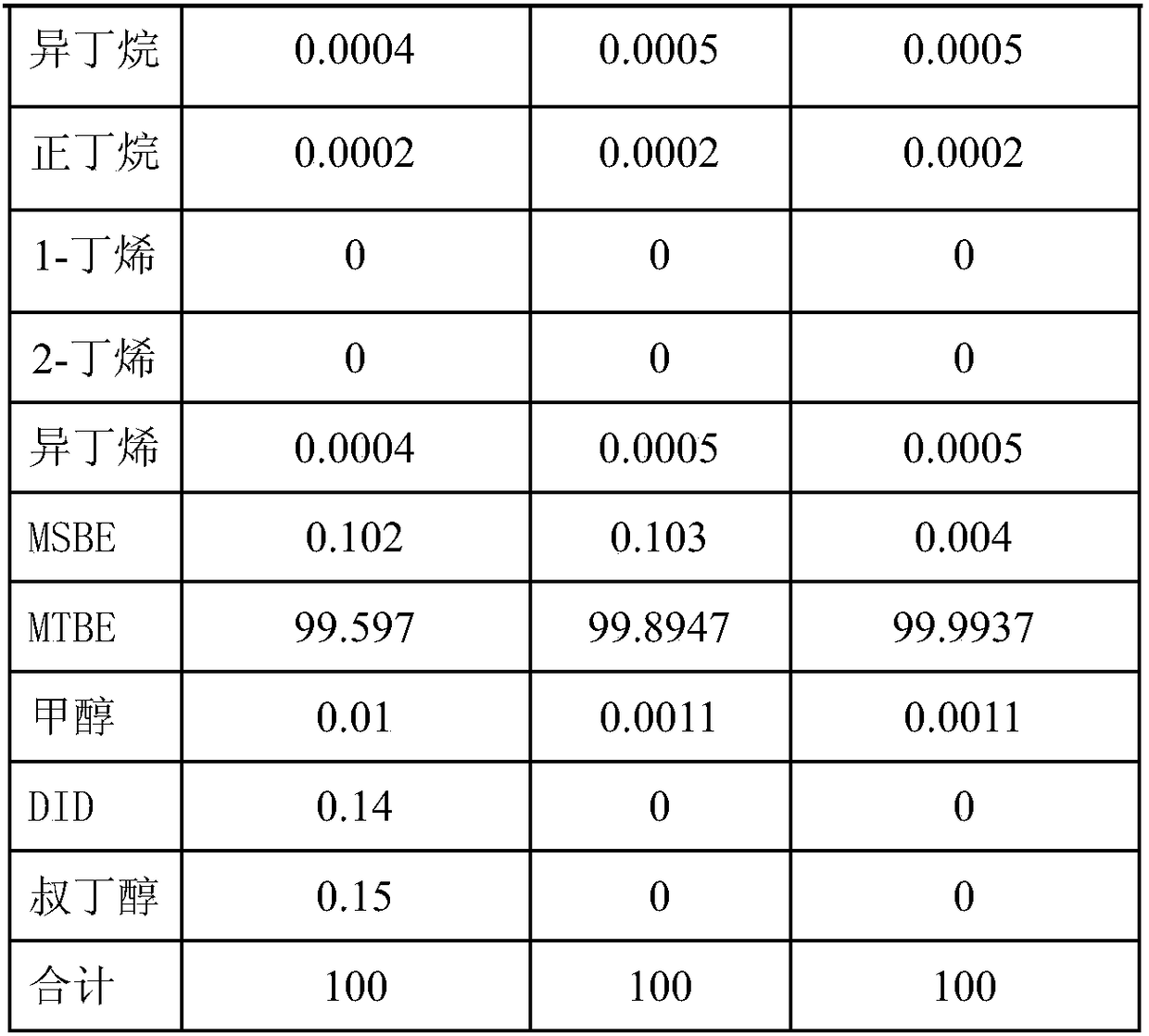

Device and method for synthesizing trioxymethylene by salt effect reactive rectification

PendingCN112237749AEfficient separationImprove product qualityOrganic chemistryChemical industryPolyoxymethylenePhysical chemistry

The invention discloses a device and a method for synthesizing trioxymethylene by salt effect reactive rectification. The device comprises a reactive rectification tower, an extraction tower, a concentration tower, a recovery tower and the like; the method comprises the following steps: (1) reacting and rectifying to generate a trioxymethylene synthetic liquid; (2) extracting the trioxymethylene synthetic liquid to obtain an extract phase rich in trioxymethylene and a raffinate phase rich in water and formaldehyde; (3) concentrating the raffinate phase to recover the formaldehyde solution; and(4) separating and recovering the extraction agent from the extraction phase to obtain a trioxymethylene product. The device and the method for synthesizing trioxymethylene by salt effect reactive rectification are high in formaldehyde conversion rate, high in production efficiency, high in trioxymethylene product purity, short in process and low in energy consumption, and have popularization andapplication performance.

Owner:鄂尔多斯应用技术学院

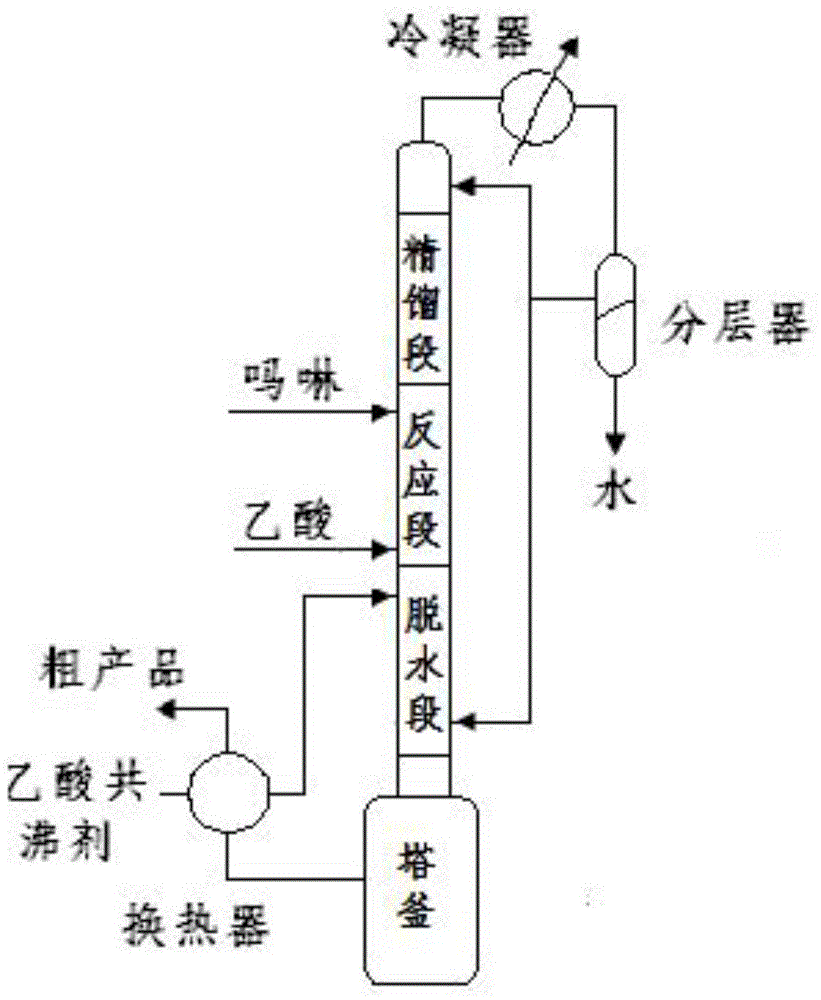

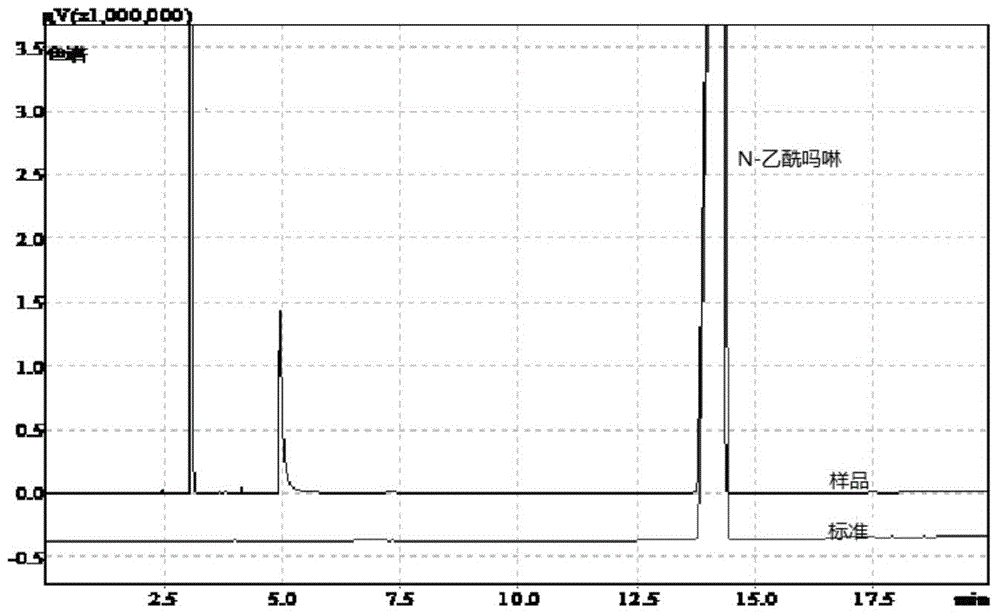

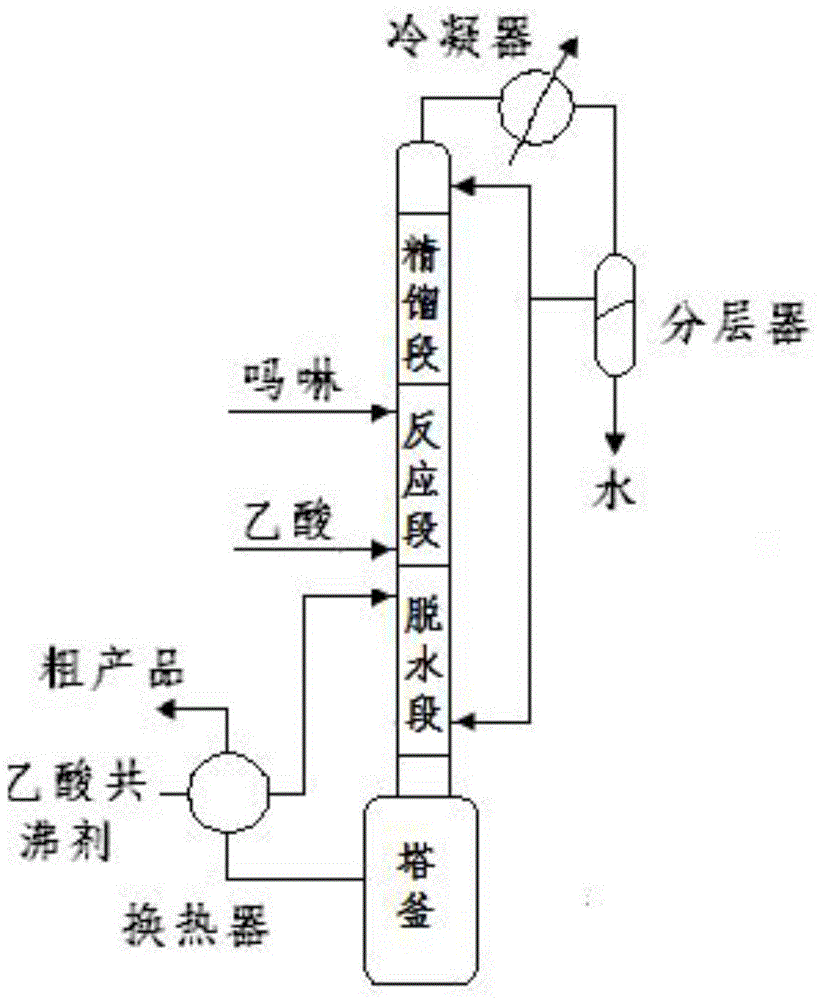

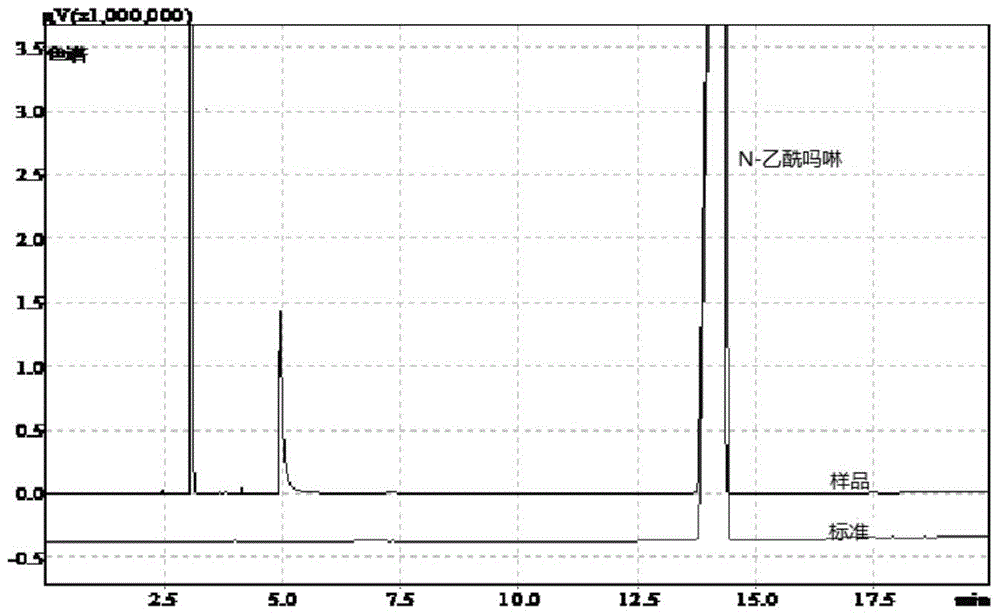

Method for synthesizing N-acetylmorpholine

The invention relates to a method for synthesizing N-acetylmorpholine. The method comprises the following steps of adding N-acetylmorpholine, an acetic acid entrainer, a dehydrating agent and water into a tower bottom, heating until a residue is boiled, raising vapor, condensing, layering condensate into an oil phase and an aqueous phase, accumulating the aqueous phase in a layering device, refluxing the oil phase from an upper material inlet of a rectifying section, when the tower top temperature reaches 84.6 DEG C, adding morpholine from the upper material inlet of a reaction section, adding acetic acid from the lower material inlet of the reaction section, adding the acetic acid entrainer from the upper material inlet of a dehydrating section, reacting morpholine and acetic acid to produce morpholine salt, dehydrating morpholine salt to produce N-acetyl morpholine and water, azeotroping water and the dehydrating agent, passing through the dehydration section, the reaction section and rectifying section to enter the condenser for condensing, layering the condensate into the oil phase and an aqueous phase, extracting the aqueous phase, refluxing the oil phase and extracting N-acetylmorpholine from the tower bottom. The method for synthesizing N-acetylmorpholine is high in production efficiency, low in energy consumption, small in device investment, short in process and free of pollution and the large-scale continuous production can be achieved.

Owner:YANTAI UNIV

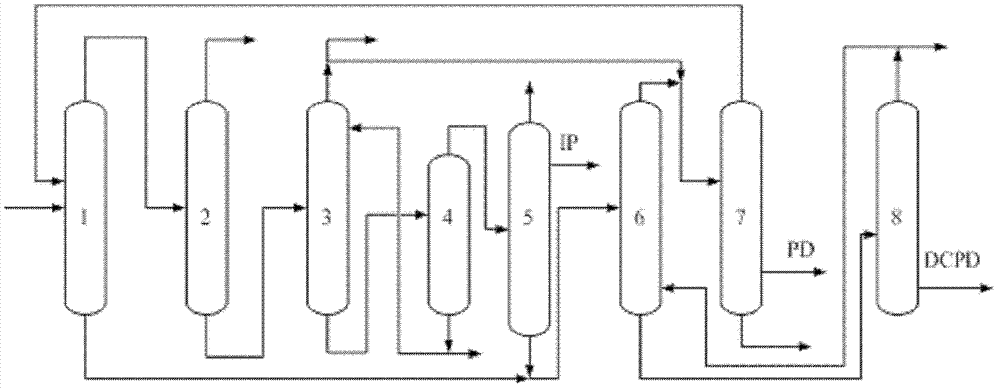

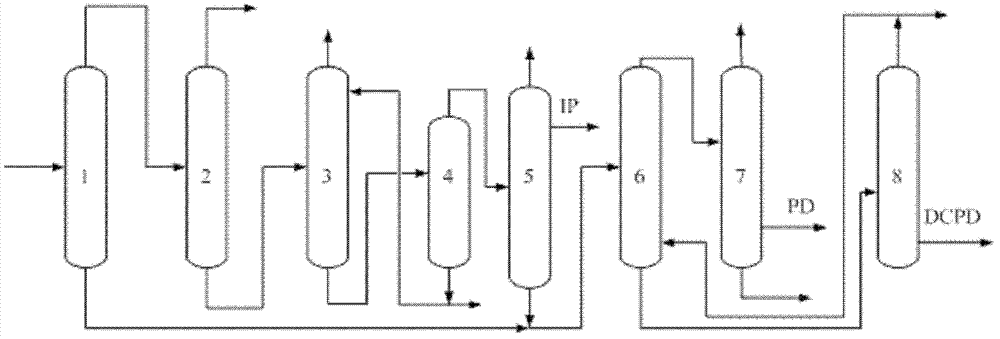

Method for separating C5 fraction

ActiveCN103086833AReduce in quantityLess investmentDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionExtractive distillationPiperylene

The invention discloses a method for separating C5 fraction. The method comprises the steps of pretreatment, extractive distillation, isoprene refining, piperylene refining, and dicyclopentadiene refining. During the isoprene refining process, isoprene is separated through azeotropic rectification, and azeotropic material flow is a product from an extractive distillation tower top. The flow rate ratio of the azeotropic material flow to the C5 removing tower top recovered material is 0.01-1. The two are mixed and are delivered into an isoprene tower. A plate number of the isoprene tower is 70-90. A reflux ratio is 15-25. With the method provided by the invention, isoprene product yield and purity can be improved, isoprene tower plate number and reflux ratio can be reduced, and equipment investment and operation cost can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

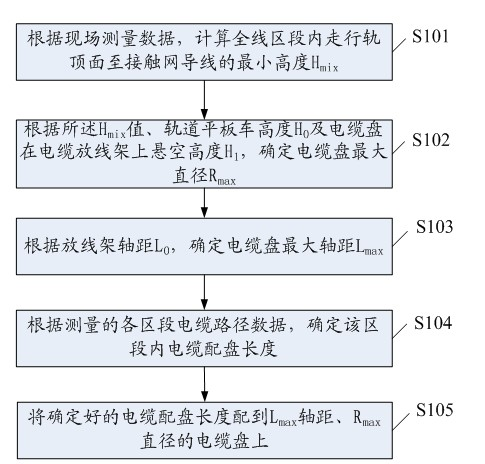

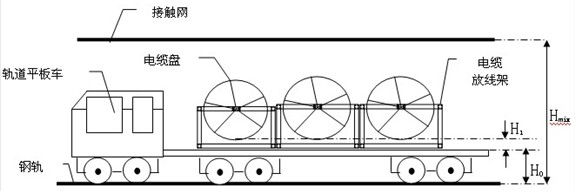

Ring network cable reel distribution process

ActiveCN102582469AReduce the number of platesReduce shipping costsTrolley linesRing networkEngineering

The invention discloses a ring network cable reel distribution process. The ring network cable reel distribution process includes steps of calculating the minimum height Hmix from the top of a traveling track to a lead of a contact net in a whole wire region according to field measured data; determining the largest diameter Rmax of cable reels according to the Hmix value, the height H0 of a track flat car and the suspension height H1 of the cable reels on a cable paying-off rack; determining the largest axle distance Lmax of the cable reels according to the axle distance L0 of the paying-off rack; determining cable reel distribution length in the region according to measured cable path data in various regions; and distributing the determined cable reel distribution length to the cable reels with the axle distance of Lmax and the diameter of Rmax, and increasing cable distribution quantity of each cable reel to the greatest extent. The quantity of the cable reels and utilization quantity of intermediate heads of cables can be reduced. As the utilization quantity of the intermediate heads of the cables is reduced, fault points of the cables after live operation are reduced, and safety of the ring network cables after live operation is improved.

Owner:ELECTRICITY AFFAIR ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP

An anthraquinone method for producing hydrogen peroxide system and anthraquinone method for producing hydrogen peroxide

ActiveCN109678119BShorten the flow pathReduced Diffusion EscapePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesReaction rateFixed bed

The invention discloses a system and method for producing hydrogen peroxide through an anthraquinone method. The system comprises the four unit processes of hydrogen dissolving, hydrogenation, oxidation and extraction, wherein a hydrogenation unit comprises a series fixed bed and upflow-type tubular reactors, and working liquid and hydrogen are subjected to a hydrogenation reaction in the hydrogenation unit to obtain hydrogenation liquid; an oxidation unit comprises an oxidation tower, the hydrogenation liquid and oxygen-containing gas are subjected to an automatic oxidation reaction to obtainoxidation liquid; and an extraction unit comprises an extraction tower, hydrogen peroxide in the oxidation liquid is extracted by the water, and thus a high-concentration hydrogen peroxide product isobtained. According to the system and method, the anthraquinone hydrogenation reaction rate can be significantly improved, the anthraquinone hydrogenation reaction efficiency can be significantly improved, the uniformity of the reaction process is maintained, side reactions are less, the obtained hydrogenation liquid is good in quality, small in by-product number and low in viscosity, the gas-liquid mass transfer rate in the oxidation process is increased, the extraction efficiency in the extraction process is improved, the oxidation time is significantly shortened, and the number of actual tower plates of the extraction tower is decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

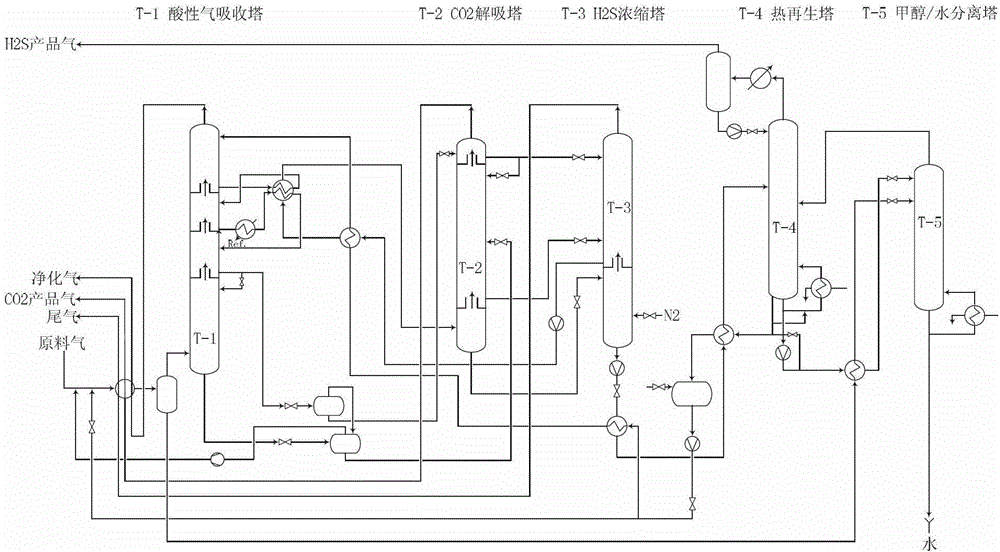

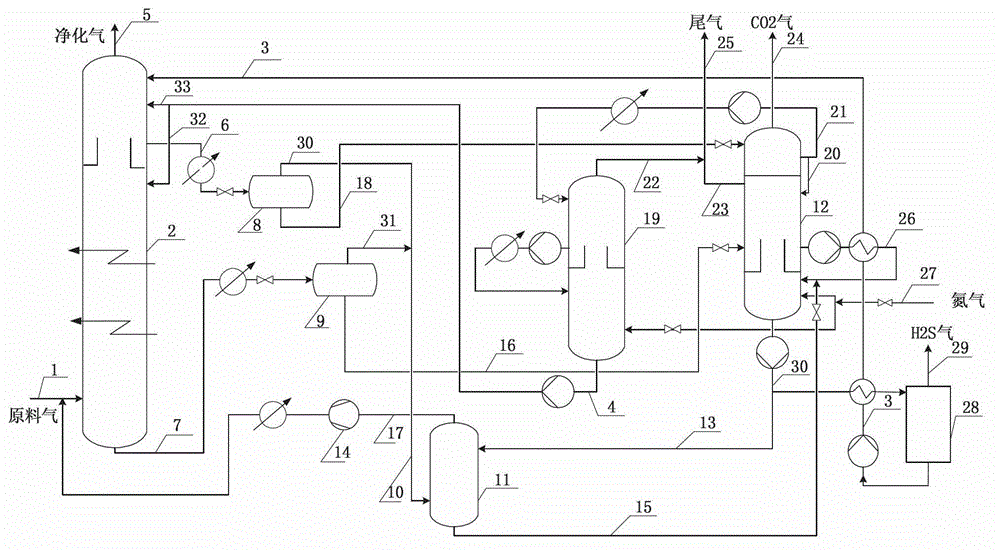

Energy-saving one-step rectisol method

ActiveCN102806000BReduce loadEfficient use ofDispersed particle separationAir quality improvementProduct gasSulfide

An energy-saving one-step rectisol method belongs to the technical field of gas purification. The method is characterized in that two or three desulfuration segments of an absorption tower employ a sulfur-free semi-lean solution for absorption; intersegment coolers are adopted; the desulfuration segments can remove sulfide and approximately 50-60% of CO2 from virgin gas simultaneously; only one decarbonization segment of the absorption tower is adopted; a lean solution is used at the top of the tower, and the sulfur-free semi-lean solution is added; flash steam is absorbed by a sulfur-containing semi-lean solution in the medium-pressure flash evaporation process; after most of CO2 in the flash steam is absorbed, the solution is delivered to a lower tower of an H2S concentrating tower for gas stripping; a sulfur-free methanol solution gas stripping tower is additionally adopted and divided into one or two segments; solutions at the segments are heated appropriately before entering the tower; and the sulfur-free semi-lean solution is delivered to the absorption tower after the gas stripping. The energy-saving one-step rectisol method has the effects and benefits that the number of plates of the absorption tower is reduced by about 20%, the tower diameter is shortened, the circulation volume of a methanol lean solution is reduced, the regeneration load of a rich solution is also reduced, the energy consumption of a device is saved by about 30%, and the device investment is saved.

Owner:DALIAN JIACHUN GAS PURIFICATION TECH DEV

Separation method of polyol mixture

ActiveCN106866369AReduce the number of platesReduce energy consumptionOrganic compound preparationHydroxy compound preparationPolyolAlcohol

The invention discloses a separation method of a mixture of polyols with similar boiling points. Glycol containing dihydric fusels (1,2-butylene glycol and 1,2-butylene glycol) is adopted as the feedstock of a reduced pressure rectifying tower, and a weakly polar gaseous extraction agent is introduced to the bottom of the tower, so relative volatility between the 1,2-butylene glycol and 1,2-butylene glycol which have the same weak polarity and the glycol with strong polarity is improved, and the separation efficiency of rectification is improved. The invention provides a novel rectification method of the dihydric fusels from the glycol. The boiling point of the gaseous extraction agent is far lower than that of the dihydric alcohols, and the gaseous extraction agent is easy to separate and can be recycled, so the material consumption and the energy consumption in the separation process are reduced. The method allows the 1,2-butylene glycol and 1,2-butylene glycol to be separated from the glycol, and allows highly pure glycol and concentrated 1,2-butylene glycol and 1,2-butylene glycol byproducts to be obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of separation method and device of ethanol and ethyl acetate

ActiveCN110878006BMeet product quality requirementsHigh purityOrganic compound preparationCarboxylic acid esters preparationAlcohol ethylDistillation

The invention relates to the field of separation of ethanol and ethyl acetate, and discloses a method and device for separating ethanol and ethyl acetate, the method comprising: 1) separating materials containing ethanol and ethyl acetate in an ethanol separation tower Distillation and separation, the top of the tower obtains a second distillate, and the bottom of the tower obtains a second residue mainly containing ethanol and water; the second residue is rectified in an ethanol rectification tower, and ethanol is obtained at the top of the tower; 2) The second distillate and water are mixed and contacted in the overhead separator of the ethanol separation tower for extraction and separation to obtain a water phase and an oil phase; 3) the oil phase is rectified in an ethyl acetate rectification tower , the fourth distillate was obtained at the top of the column, and ethyl acetate was obtained at the bottom of the column. The ethanol and ethyl acetate separation method and device provided by the invention can simultaneously obtain high-purity ethanol and ethyl acetate products, meeting the product quality requirements of industrial alcohol and industrial ethyl acetate.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

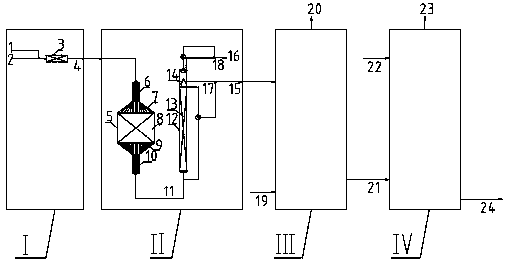

Stereo mass transfer liquid co-flow tower

ActiveCN101905088AEliminates liquid stagnation zonesIncrease the effective mass transfer areaOrganic compound preparationDispersed particle separationMass transferEngineering

The invention relates to a stereo mass transfer liquid co-flow tower, which is a gas-liquid contact device used in processes of mass transfer, heat transfer and the like in the fields of chemical engineering, oil refining, petrifaction, pharmacy, environmental protection and the like. The tower comprises a tower body and multilayer continuous mass transfer tower plates; each layer of continuous mass transfer tower plate comprises a tower plate, a stereo mass transfer element and a down-flow system; and the down-flow system of the continuous mass transfer tower plate enables liquid on each layer of tower plate in the tower to flow in the same direction so that a retention area is not left on the tower plate, an effective mass transfer area is enlarged, the treatment capability is increased, the average push force of gas-liquid transfer on the tower plates is improved and the mass transfer efficiency of the tower plates is further improved.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

A kind of extraction anti-gel agent for mtbe desulfurization

ActiveCN105777500BNo three wastes producedSufficient vaporization rateEther separation/purificationExtractive distillationRefluxExtractive distillation

The invention relates to an extraction anti-gum agent for MTBE desulfurization.The extraction anti-gum agent at least contains a solvent with the boiling point ranging from 80 DEG C to 150 DEG C, and the solvent at least contains one or a mixture of two or more of C7 (and above) aromatic hydrocarbons with the boiling point ranging from 110 DEG C to 150 DEG C.The extraction anti-gum agent can efficiently remove sulfide in MTBE and also can effectively prevent coking at the bottom of an extractive distillation tower; on the premise of guaranteeing a high vaporization rate of the distillation tower, vaporization of sulfide can be effectively reduced, the distribution gradient of sulfide in the tower can be effectively reduced, and the number of tower plates needed for distillation or the reflux ratio can be effectively decreased, so that investment or operation cost is significantly lowered; the extraction anti-gum agent has a strong extraction effect on low-boiling-point sulfide; recovery or additional treatment is not needed, and no waste is generated.

Owner:HEBEI REFINING TECH CO LTD

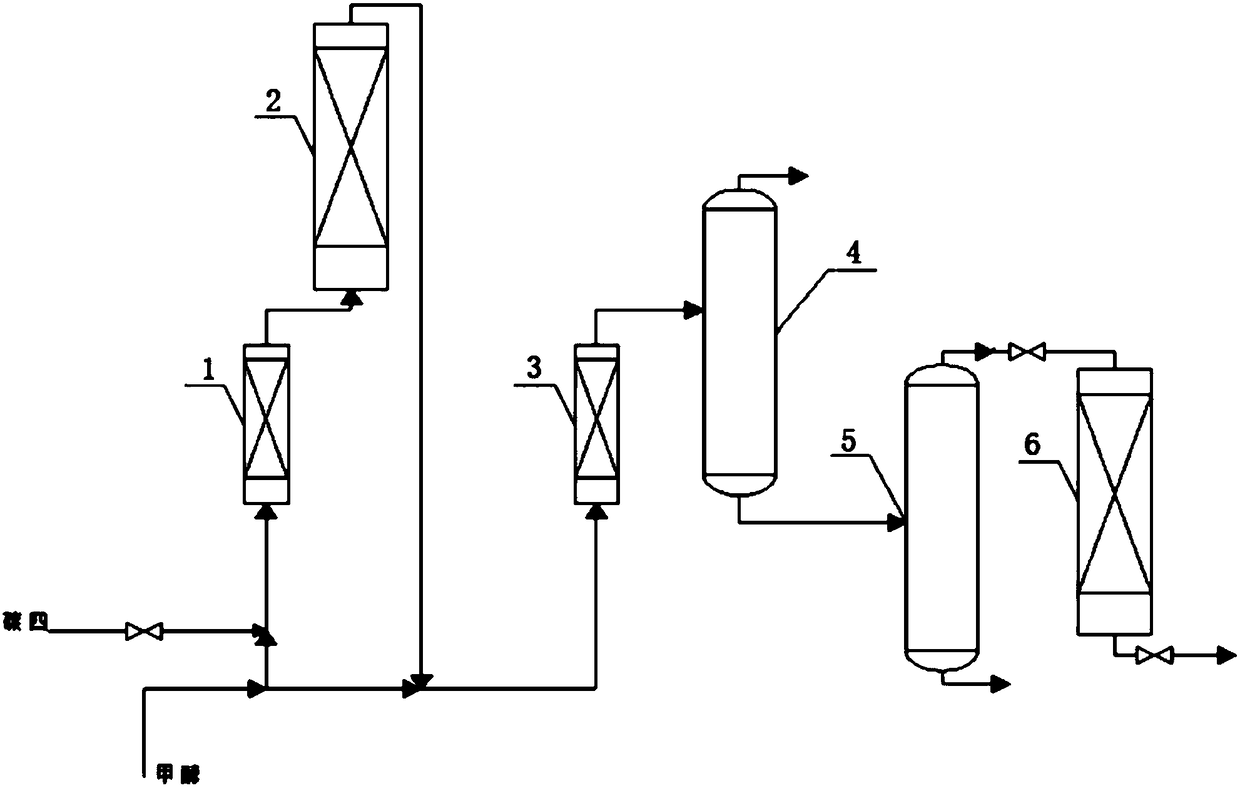

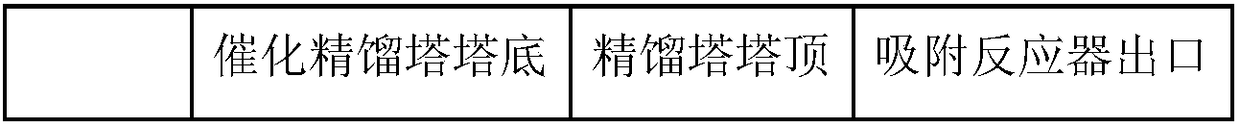

High-purity MTBE production process

ActiveCN109384653AReduce the number of platesReduce energy consumptionEther separation/purificationChemical industryStatic mixerTower

The invention relates to a high-purity MTBE production process, which comprises: a, completely mixing C4 and partial methanol to form a homogeneous phase; b, carrying out an etherification reaction onthe obtained mixture; c, feeding the mixture after the reaction and the remaining methanol into a second static mixer; d, feeding the mixture from the second static mixer into a catalytic rectification tower, continuously carrying out a catalytic rectification reaction on the isobutene and the methanol in the mixture under the action of a catalyst to generate MTBE, and separating C4, methanol andMTBE through rectification; e, feeding the crude product obtained from the bottom of the catalytic rectification tower, and further purifying the MTBE product through rectification; and carrying outadsorbing refining on the product from the top of the rectification tower, such that it is ensured that the product can meet the quality requirement. According to the present invention, with the high-purity MTBE production process, the production of the high-purity MTBE is ensured, and the production process is simplified; and by using the adsorbing refining process, the number of the trays of therectification tower is reduced so as to reduce the energy consumption of the separation device.

Owner:CHINA PETROLEUM & CHEM CORP

A high-efficiency extraction process in the production process of hydrogen peroxide

ActiveCN105621364BIncrease mass transfer driving forceReduce total mass transfer/separation unit countPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationMixed oxide

The invention discloses a high-efficiency extraction process in the production process of hydrogen peroxide, including the following content: in the extraction process of producing hydrogen peroxide by anthraquinone method, an extraction tower I and an extraction tower II are arranged, and the oxidation liquid is divided into two parts: the oxidation liquid I and the oxidation liquid Liquid II, pure water is introduced from the top of extraction tower I, oxidized liquid I is introduced from the bottom of extraction tower I, and the two phases are extracted countercurrently in extraction tower I; after the raffinate is discharged from the top of extraction tower I, the After separation by the separator, the heavy phase and the light phase are obtained; the heavy phase is mixed with the extraction liquid at the bottom of the extraction tower I, and introduced from the top of the extraction tower II together, and the light phase is mixed with the oxidation liquid II, and together are introduced from the bottom Introduction, the two phases are extracted countercurrently in the extraction tower II, the liquid phase of the raffinate at the top of the tower is introduced into the post-treatment process, and the extract at the bottom of the tower is the high-concentration hydrogen peroxide product. Aiming at the deficiencies of the prior art, the high-efficiency extraction process of the present invention has the advantages of fast mass transfer rate, high veneer efficiency, high product concentration and low raffinate.

Owner:CHINA PETROLEUM & CHEM CORP +1

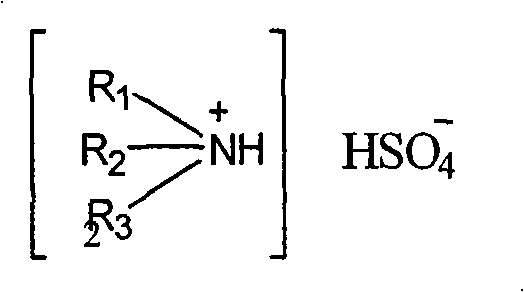

Process for continuously generating methyl acetate by reactive distillation taking ionic liquid as catalyst

ActiveCN101560151BGuaranteed purityReduce loadOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsGas phaseIonic liquid

A process for continuously generating methyl acetate by reactive distillation taking ionic liquid as a catalyst is as follows: raw materials are preheated, acetic acid is input from the upper segment of a reactive distillation tower, ionic liquid is input from the central segment of the tower and methanol is input from the lower segment of the tower simultaneously, the central segment of the reactive distillation tower is a reaction zone, the product of methyl acetate is extracted from the top of the tower, the catalyst of ionic liquid is extracted from the bottom of the tower and enters a flash drum for flash evaporation, the liquid extracted from the bottom of the flash drum is the catalyst of ionic liquid which returns to the reactive distillation tower, gas phase evaporated from the flash drum is mixed vapour of water and methanol, which is input to a methanol recovery tower, raw material of methanol is extracted from the top of the methanol recovery tower after being separated, and returns to the reactive distillation tower to be raw material, water is extracted from the bottom of the methanol recovery tower and is discharged. The process of the invention discharges no waste acid water, the material of devices of the required towers is only 316L stainless steel and can reduce the corrosion for the devices and one-time investment remarkably, energy consumption decreases bymore than 15% simultaneously, therefore the production cost of final product reduces by more than 30%.

Owner:NANJING UNIV

Stereo mass transfer liquid co-flow tower

ActiveCN101905088BImprove mass transfer efficiencySmall diameterOrganic compound preparationDispersed particle separationEngineeringTower

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

An air separation fractionation tower system and a process for preparing low-purity oxygen using the system

InactiveCN104677052BReduce the temperatureRelieve pressureSolidificationLiquefactionFractionationEngineering

The invention discloses an air separation fractionating tower system and a technology utilizing the air separation fractionating tower system to prepare low-purity oxygen. The pressure air is subject to heat exchange by a main heat exchanger and a liquid oxygen evaporator and is converted into partially liquefied air, then the air is separated into oxygen-rich liquid air and nitrogen in a lower tower of the fractionating tower, and the oxygen-rich liquid air enters an upper tower of the fractionating tower; the nitrogen is cooled into liquid nitrogen in the condensing evaporator, and is sent into the upper tower of the fractionating tower through an overcooler; each material in the upper tower of the fractionating tower is separated into low-purity liquid oxygen and nitrogen, and the low-purity liquid oxygen is subject to heat exchange and gasifying with the nitrogen at the lower part of the lower tower of the fractionating tower in the condensing evaporator, is subject to heat exchange by the condensing evaporator and the main heat exchanger, and is sent out as a product; the low-purity liquid oxygen is also subject to heat exchange by the liquid oxygen evaporator and the main heat exchanger, and is sent out as the product. The air separation fractionating tower system has the advantages that the low-purity oxygen and high-purity oxygen with different purities and pressures can be simultaneously produced, the operation pressure is low, the extraction rate is high, the energy consumption is little, the equipment investment is low, the requirements of low-purity oxygen and high-purity oxygen in multiple industries can be well met, and the air separation fractionating tower system is suitable for industrial production.

Owner:开封东京空分集团有限公司

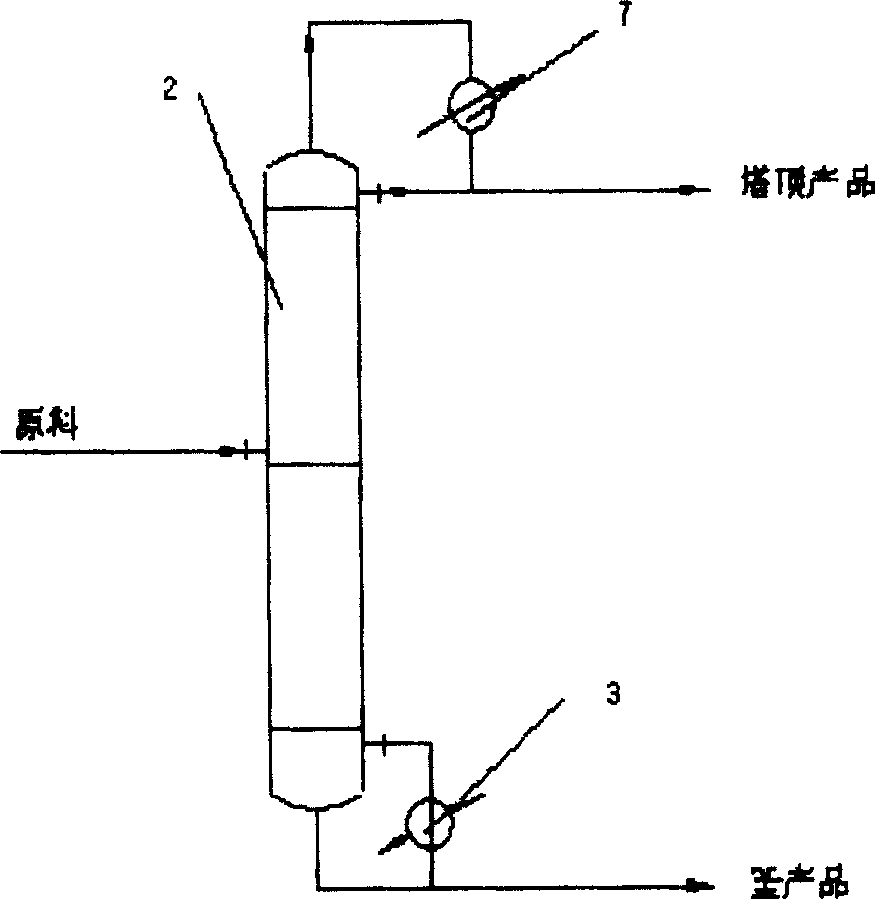

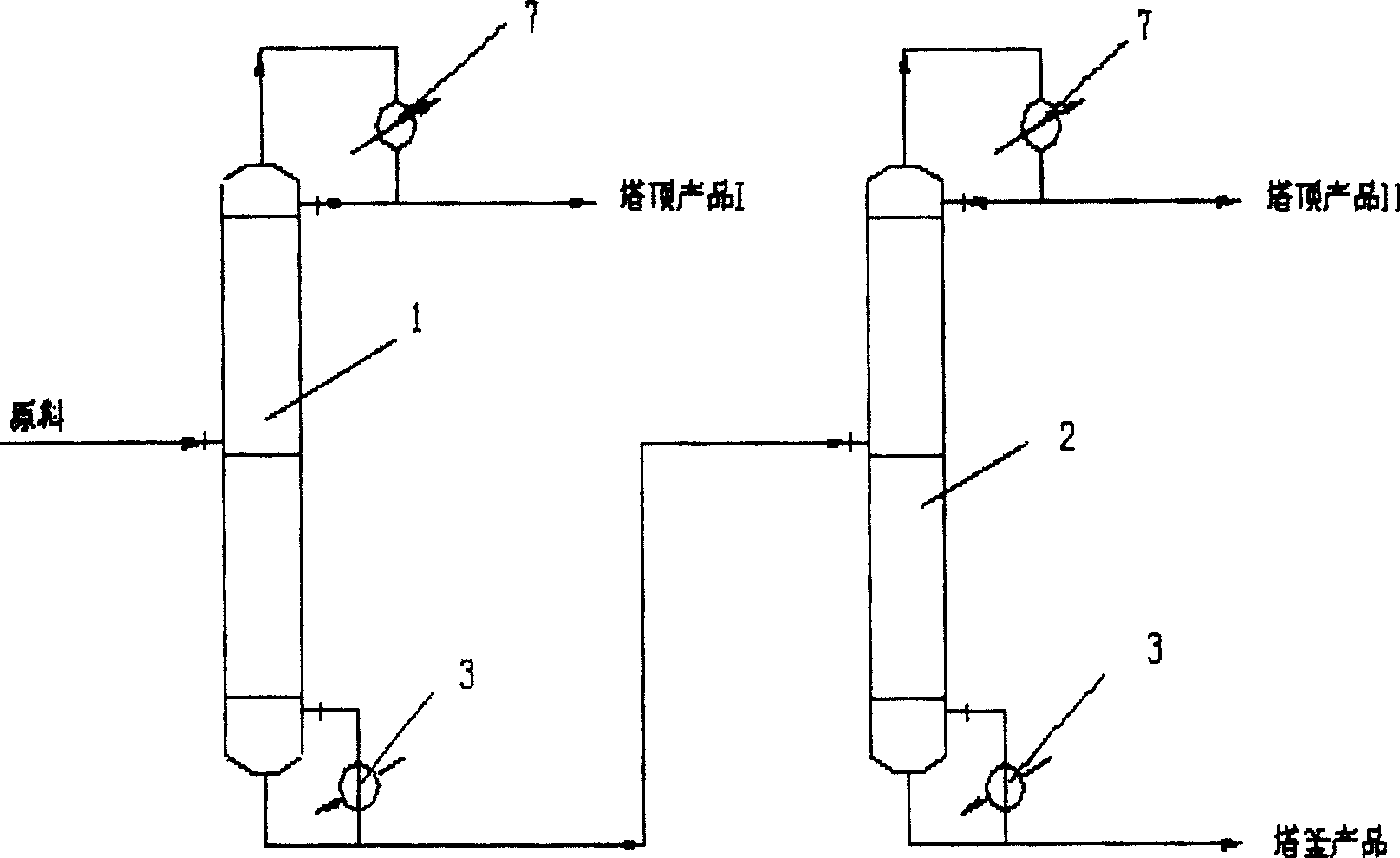

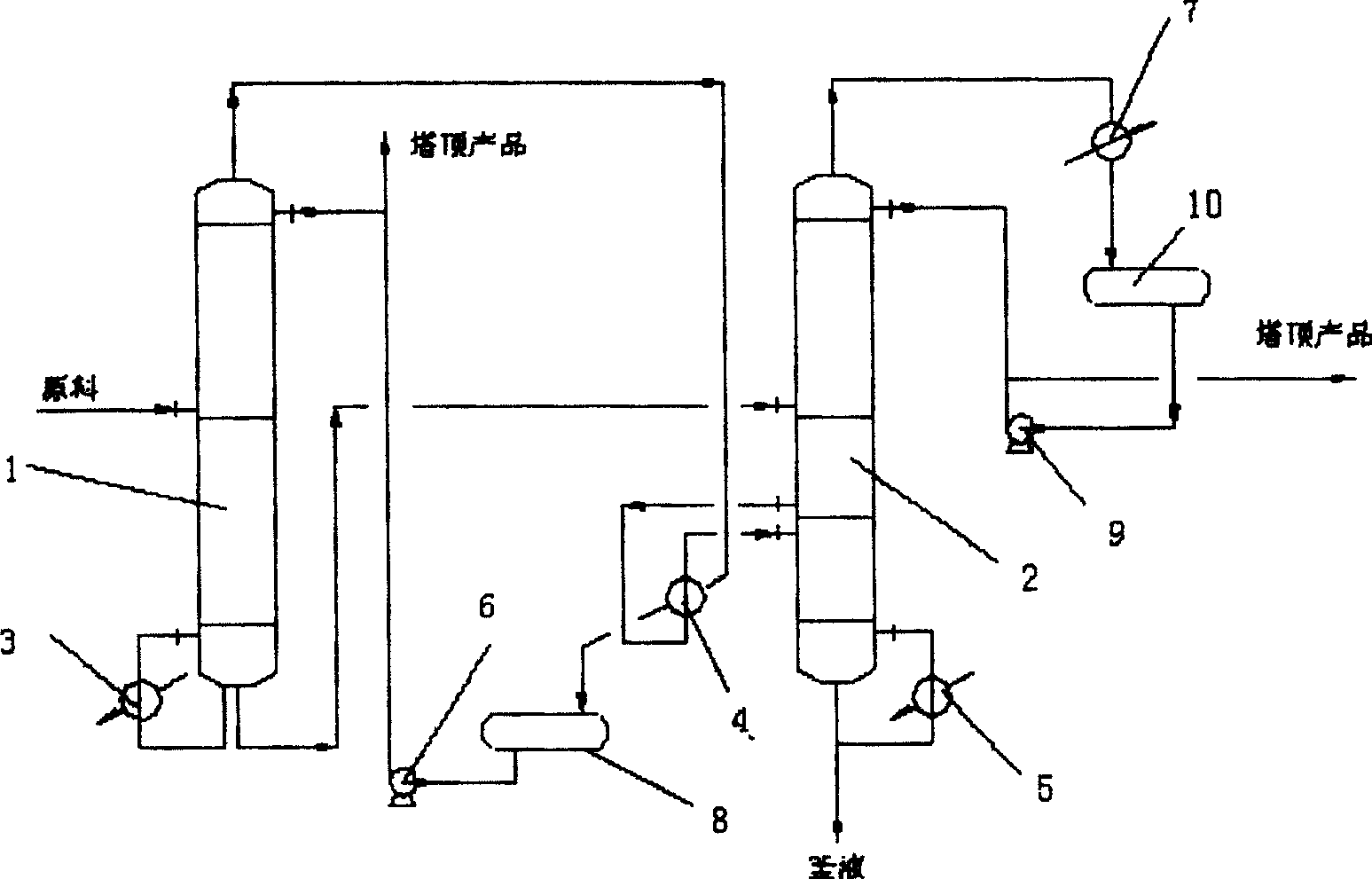

Energy saving method and equipment for rectification separation

ActiveCN100486662CMeet separation requirementsTo achieve the purpose of thermal couplingFractional distillationRefluxReboiler

The invention relates to an equipment and method for saving energy conservation in selective evaporation. The equipment involves A and B rectification tower in series. The bottom of Tower A connects the reboiler. The export of Tower A connects the import of Tower B. The export of Tower A on the top connects middle reboiler, reflux accumulator, reflux pump. The bottom of Tower B connects middle reboiler. The top of Tower B connects condenser, reflux accumulator, reflux pump. The heat of condensation of Tower A is as the load of middle reboiler when connected Tower B. Part of the heat of condensation reflows to the tower and other is as the product. In Tower B, the light product boils over from the top. Some reflows to tower and other is as the product. The heat is from condenser and middle reboiler and attaches the light-load adjustment reboiler to achieve connecting in series, the mightiness coupling between condenser and middle reboiler. The design is reasonable; the effect on saving energy is obvious.

Owner:PETROCHINA CO LTD

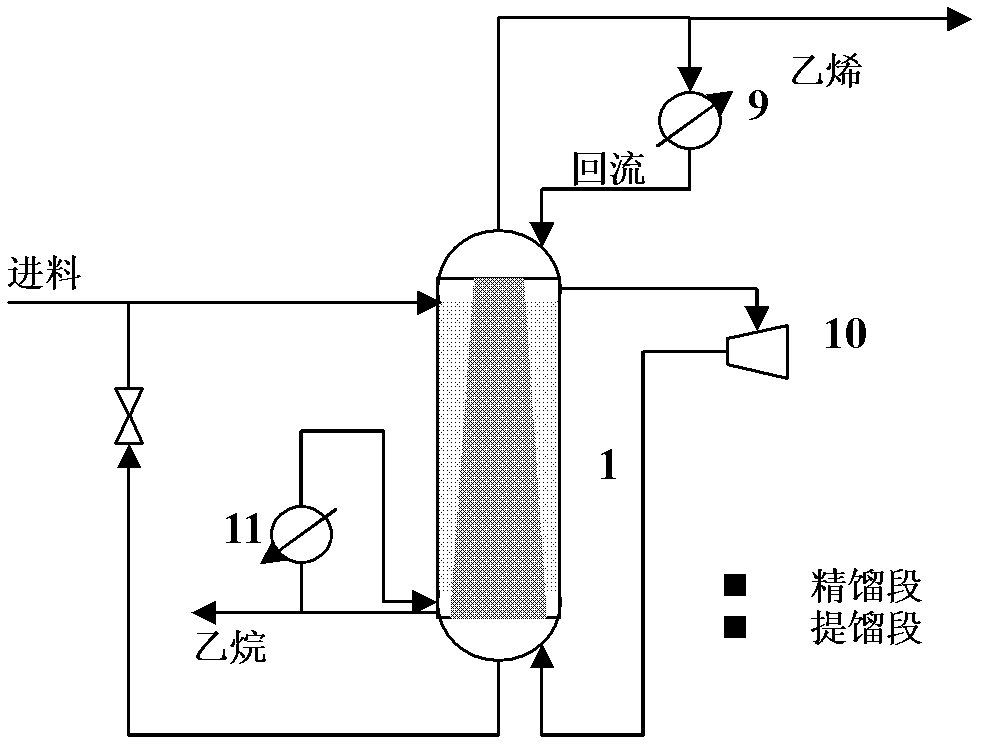

Internal energy integration non-compression reflux device for ethylene separation and process flow thereof

InactiveCN102500119BReduce the number of platesReduce energy consumptionDistillation purification/separationEthylene productionRefrigeration compressorPolymer science

The invention relates to an internal energy integration non-compression reflux device for ethylene separation. The reflux device comprises an ethylene tower, an ethylene refrigeration compressor, an ethylene refrigeration compressor suction tank, an ethylene refrigerant user, an ethylene refrigerant buffer tank, an ethylene refrigerant condensation cooler, an ethylene overhead condenser, an ethylene tower compressor, an ethylene bottom reboiler and a reducing valve. A specific process flow comprises the following steps: feeding a material from a previous process into the ethylene tower; passing a produced liquid from the tower top of a rectifying section through the ethylene refrigeration compressor and the ethylene refrigerant condensation cooler and then entering into the ethylene refrigerant buffer tank; returning back the produced liquid phase from the tower bottom of the rectifying section to the top of a stripping section through the reducing valve; passing a produced gas phase from the top of the stripping section through the ethylene tower compressor and then entering into the bottom of the rectifying section, and recovering circular ethane from the bottom of the stripping section; successively feeding refrigerants into the ethylene refrigeration compressor suction tank from the buffer tank and providing cold energy for a refrigerant user; and returning back a gas-phase material flows from the tops of various suction tanks for refrigeration and compression. By using the device, the power consumption of the refrigeration compressor can be reduced so as to reduce the total energy consumption of an ethylene device.

Owner:TIANJIN UNIV

A kind of method for synthesizing n-acetylmorpholine

The invention relates to a method for synthesizing N-acetylmorpholine. The method comprises the following steps of adding N-acetylmorpholine, an acetic acid entrainer, a dehydrating agent and water into a tower bottom, heating until a residue is boiled, raising vapor, condensing, layering condensate into an oil phase and an aqueous phase, accumulating the aqueous phase in a layering device, refluxing the oil phase from an upper material inlet of a rectifying section, when the tower top temperature reaches 84.6 DEG C, adding morpholine from the upper material inlet of a reaction section, adding acetic acid from the lower material inlet of the reaction section, adding the acetic acid entrainer from the upper material inlet of a dehydrating section, reacting morpholine and acetic acid to produce morpholine salt, dehydrating morpholine salt to produce N-acetyl morpholine and water, azeotroping water and the dehydrating agent, passing through the dehydration section, the reaction section and rectifying section to enter the condenser for condensing, layering the condensate into the oil phase and an aqueous phase, extracting the aqueous phase, refluxing the oil phase and extracting N-acetylmorpholine from the tower bottom. The method for synthesizing N-acetylmorpholine is high in production efficiency, low in energy consumption, small in device investment, short in process and free of pollution and the large-scale continuous production can be achieved.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com