Stereo mass transfer liquid co-flow tower

A technology of three-dimensional mass transfer and mass transfer tower, which is applied in the field of gas-liquid contact equipment, can solve the problems of equipment and technical economy, unseen problems, reduction of reflux ratio of separation efficiency of co-current trays, etc., so as to increase the effective mass transfer area , Low liquid level gradient, the effect of reducing the diameter of the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

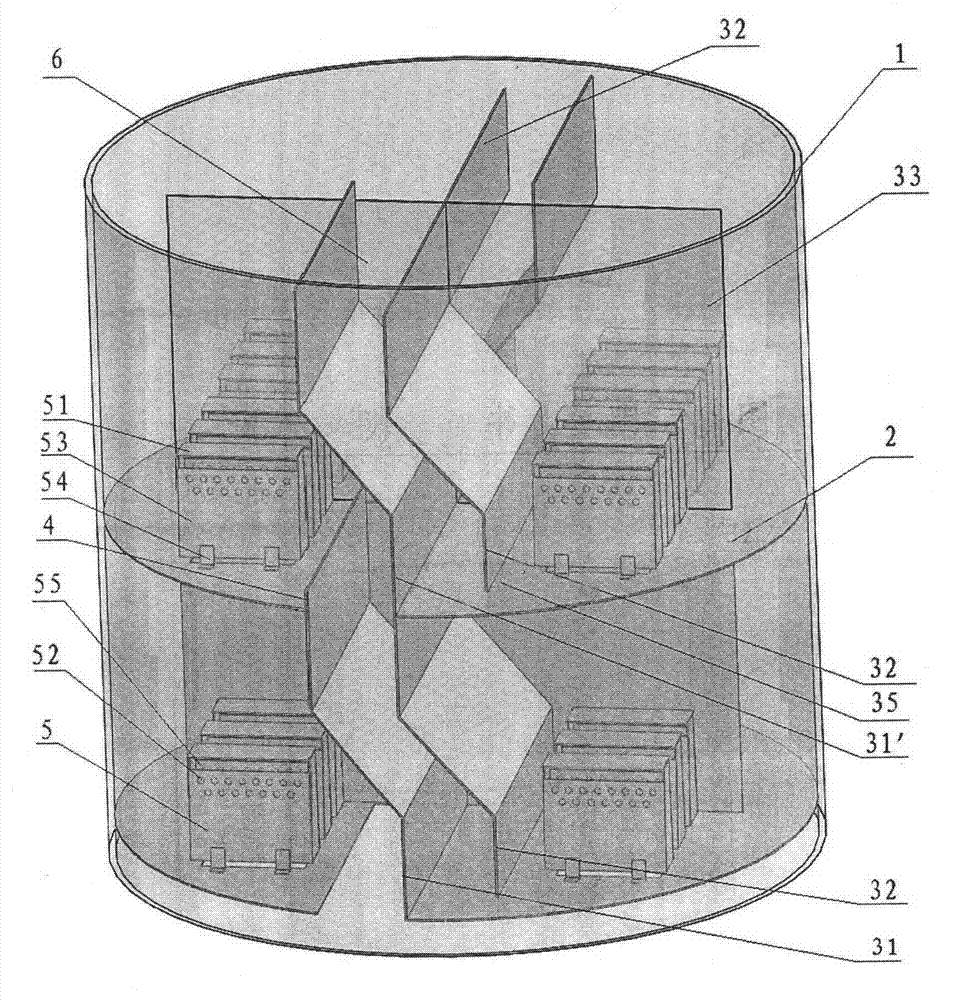

[0026] This example figure 1 Shown is a double helix liquid co-current column used for the purification of alcohol. It includes a tower body 1 and a multi-layer continuous mass transfer tray arranged in the tower body 1. Each layer of continuous mass transfer tray includes a tray 2 provided with a riser hole 21, a cap 5 above the riser hole and a downcomer. system.

[0027] Each continuous mass transfer tray is divided into two independent parts, and each independent tray 2 is provided with a set of downcomer system. The downcomer system is a splint-type downcomer, and two sets of downcomers are arranged in the same direction in the same direction as the diameter of the tower body 1 . Each set of downcomers includes baffled downcomer I 31, downcomer II 32, downcomer baffle 33 and overflow weir 4, and the downcomer channel between the downcomer I and downcomer II arranged in parallel 6. The top of the downcomer channel is provided with an overflow weir 4 perpendicular to the...

Embodiment 2

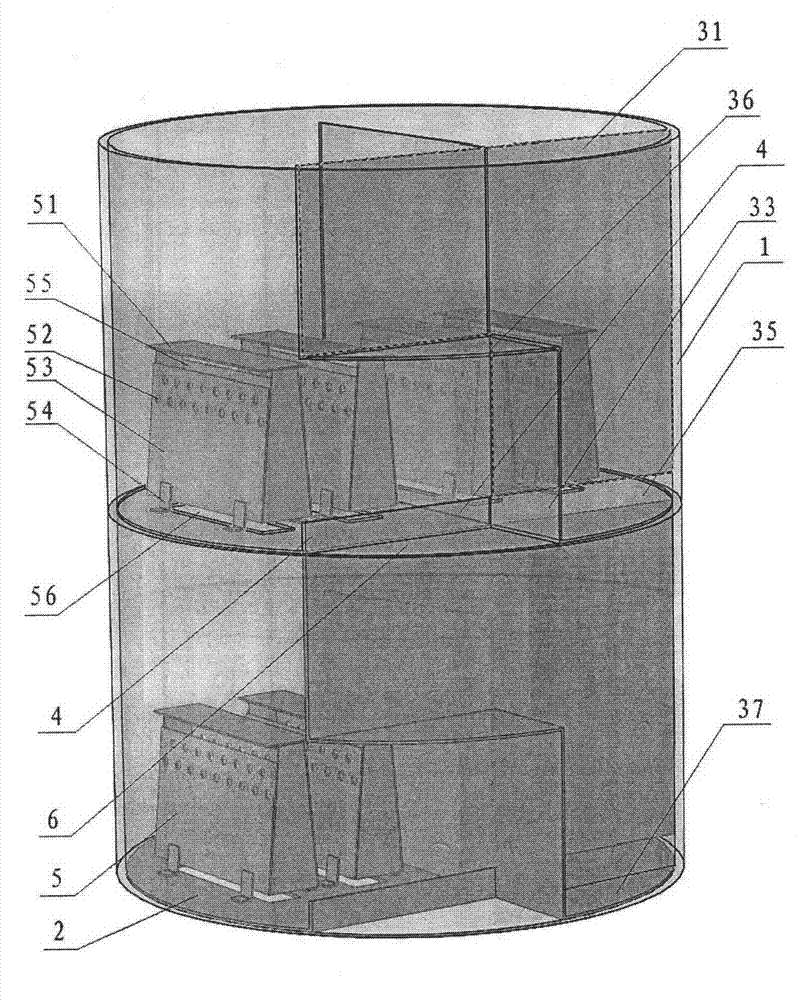

[0032] This example figure 2 Shown is a three-dimensional mass transfer liquid parallel flow tower, the difference from Example 1 is that each layer has only one continuous mass transfer tray, and the downcomer system of the continuous mass transfer tray is arranged on the same side of the tower body, It includes the downcomer plate I 31, the middle liquid receiving plate 36, the main liquid receiving plate 37 and the downcomer baffle 33; the downcomer baffle 33 is located on the longitudinal center line of the downcomer plate I and is vertically arranged with the downcomer plate I, The downcomer baffle is arranged vertically with the main liquid receiving plate, the top of the downcomer baffle 33 is connected to one end of the middle liquid receiving plate 36, and the lower end is connected to the main liquid receiving plate 37; the middle liquid receiving plate is located at the transverse center of the downcomer plate I The line is perpendicular to the downcomer plate I, t...

Embodiment 3

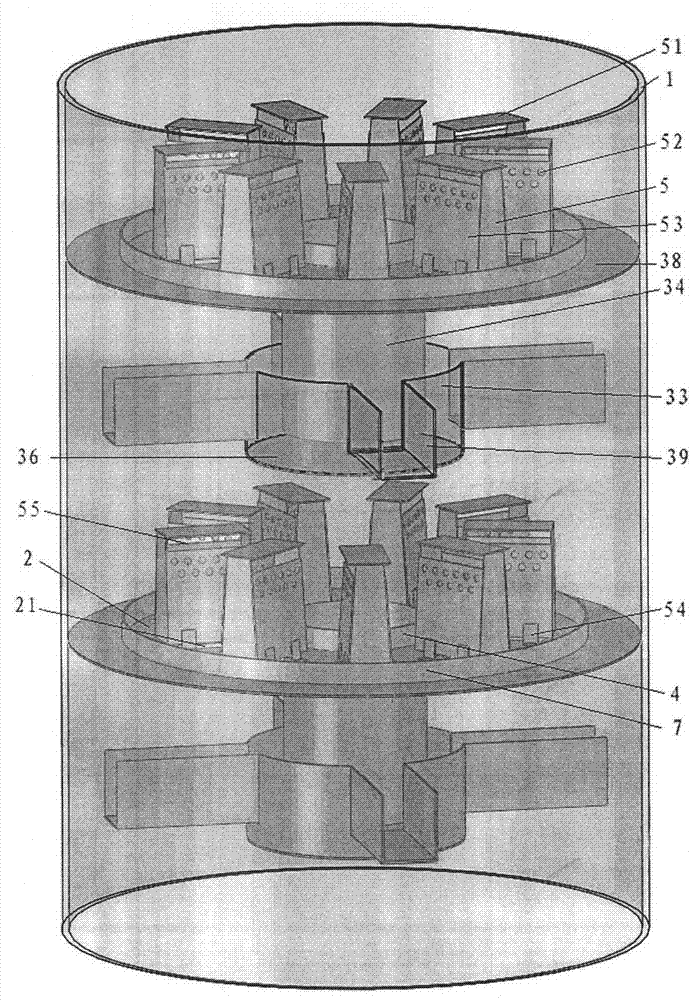

[0035] This example image 3 Shown is a kind of three-dimensional mass transfer liquid cocurrent flow tower, and embodiment The difference is that the downcomer system includes a central downcomer 34, a middle liquid receiving plate 36, a downcomer baffle 33, a guide tube 39 and an annular liquid receiving plate 38; the middle liquid receiving plate and the central downcomer are arranged in a circle An overflow weir 4 is provided on the tray corresponding to the inlet of the central downcomer; the central downcomer passes through the center of the tray and is located above the middle liquid receiving pan, and the diameter of the central downcomer is smaller than the diameter of the middle liquid receiving pan ; The peripheral interval of the liquid receiving plate in the middle is vertically provided with a guide tube 39, and a downcomer baffle 33 is arranged between each guide tube, and the guide tube is an upper opening channel steel, and the bottom height of the guide tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com