Three dimension electrode reaction unit

A reaction device, three-dimensional electrode technology, applied in water/sludge/sewage treatment, water/sewage treatment, dispersed particle separation, etc., can solve the problem that three-dimensional electrodes are difficult to overcome short-circuit current, etc., to achieve improved treatment effect, high electrolytic cell Face-to-body ratio, to achieve the effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

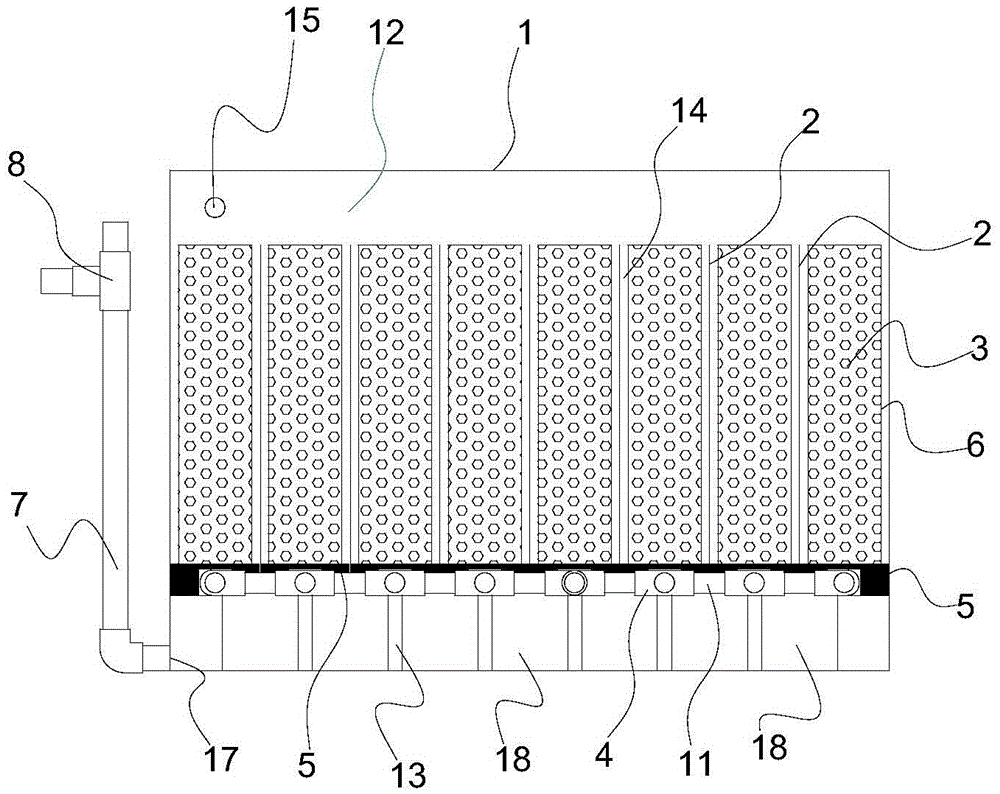

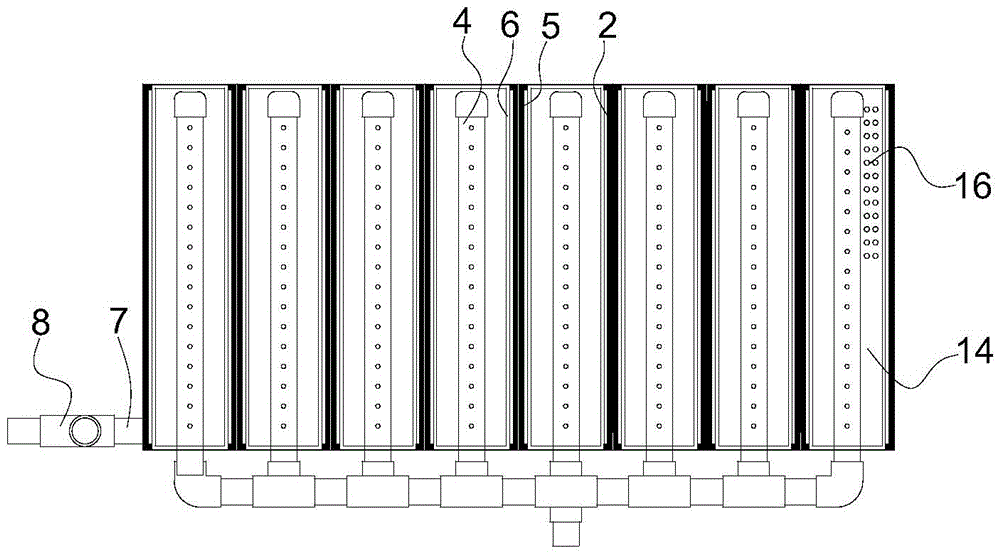

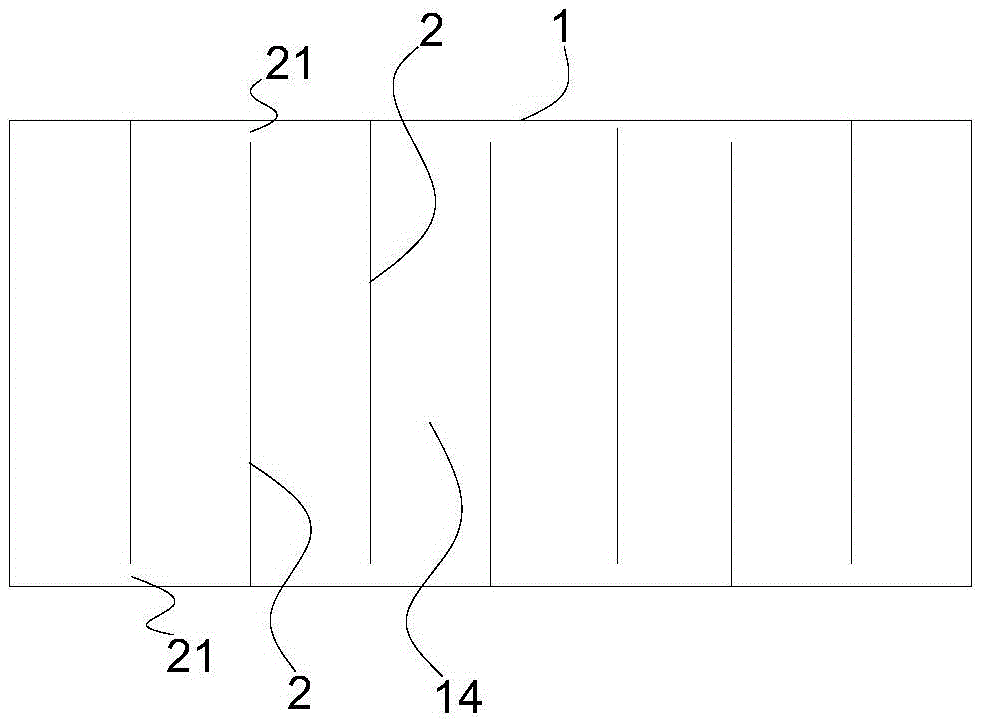

[0031] Such as figure 1 shown, combined with figure 2 , the present invention provides a three-dimensional electrode reaction device, which includes a casing 1, a plurality of plate-type main electrodes 2, a plurality of particle electrodes 3, and a plurality of aeration tubes 4.

[0032] A partition plate 11 is arranged in the middle of the housing 1 and is divided into an upper reaction zone 12 and a lower water outlet chamber 13 by the partition plate 11. The housing 1 of the reaction zone 12 is provided with a water inlet 15 for sewage to flow in. Reaction zone 12. The water outlet chamber 13 is provided with a water outlet 17, and the treated purified water flows into the water outlet chamber 13 and is discharged through the outlet. Specifically, the water inlet 15 is connected to the external water inlet pipe 9, and the lower part of the water inlet pipe 9 is provided with evenly spaced small holes to ensure uniform water inlet. The water outlet 17 is externally conn...

Embodiment 2

[0041] The three-dimensional electrode reaction device of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 4 As shown, the three-dimensional electrode reaction device is provided with two, respectively corresponding to a primary reactor a and a secondary reactor b, the water inlet pipe 9 of the primary reactor a communicates with the water outlet pipe 7 of the secondary reactor b, A cushion layer 19 is provided at the bottom of the secondary reactor b.

[0042] In the three-dimensional electrode reaction device of the present invention, the sewage flows along the pole plates in each compartment 14, avoiding short flow of sewage, making the sewage mix more uniform and shortening the residence time. The bottom of each compartment 14 is equipped with an aeration device 4, and the upper part is covered with an insulating frame 5 whose surface is a fine wire mesh. The insulating basket 5 protects the aeration tube from being pressed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com