Inorganic coating anti-bacterial fiber and preparation thereof

An antibacterial fiber and inorganic coating technology, which is applied in the field of inorganic antibacterial agents and their preparation, can solve the problems of low utilization rate of sunlight, affect the appearance of white or light-colored products, and have no antibacterial performance, and achieve high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

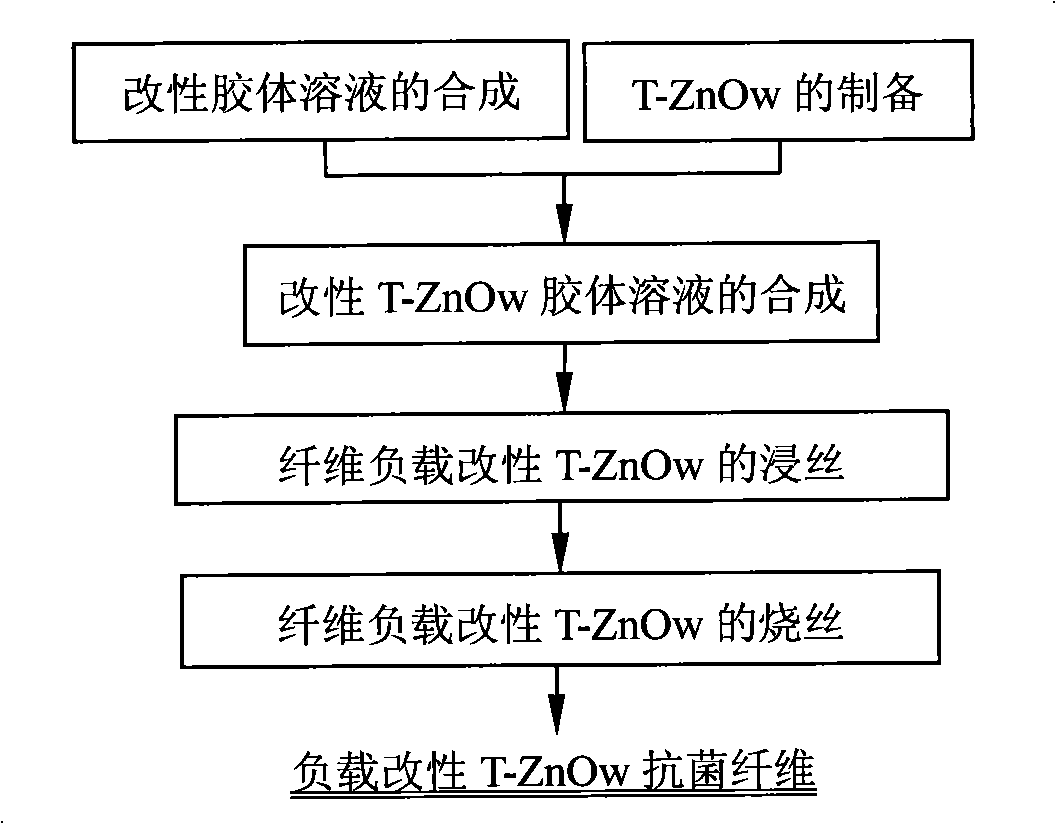

Method used

Image

Examples

Embodiment 1

[0028] Example 1: AgNO 3 , polyvinylpyrrolidone and ammonia water are all analytical reagents

[0029] Preparation of silver modified T-ZnOw colloidal solution: 80g AgNO 3Dissolve in 1L of deionized water to obtain a silver nitrate solution with a silver concentration of 50g / L, add 10ml of a 0.0025mol / L polyvinylpyrrolidone solution under stirring, and then add ammonia water dropwise until the pH value is 8 to obtain silver-containing ions colloidal solution. Take 1 L of the colloidal solution containing silver ions above, and add 100 g of T-ZnOw to the colloidal solution under ultrasonic conditions, so that T-ZnOw is uniformly dispersed in the sol system.

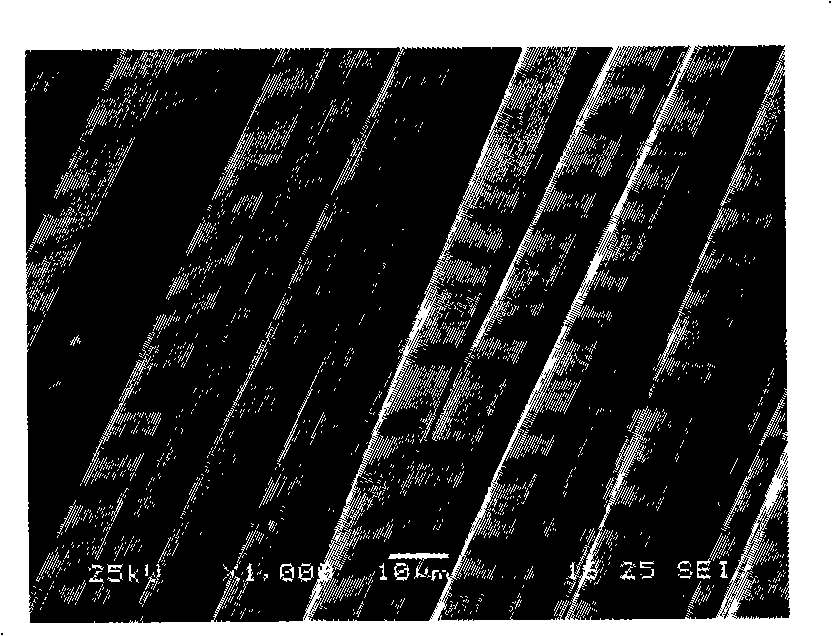

[0030] Fiber-loaded modified T-ZnOw: Activated carbon fibers were degummed by sintering at 800°C for 10 minutes under the protection of nitrogen, then soaked in an aqueous solution system under ultrasonic conditions, and then dried at 120°C, and the obtained clean activated carbon fibers were placed in an ultrasonic stat...

Embodiment 2

[0031] Embodiment 2: Titanium sulfate, sodium dodecylbenzenesulfonate, sodium carbonate are all analytical reagents

[0032] Preparation of titanium dioxide modified T-ZnOw colloidal solution: Dissolve 200g of titanium sulfate in 1L of deionized water to obtain a titanium sulfate solution with a titanium concentration of 40g / L, add 0.0025mol / L dodecylbenzenesulfonate under stirring Sodium carbonate solution 5ml, then dropwise add 0.1mol / L sodium carbonate solution until the pH value is 2 to obtain a titanium-containing colloidal solution. Take 1L of the above titanium-containing colloidal solution, and add 80 g of T-ZnOw to the colloidal solution under ultrasonic conditions, so that T-ZnOw is uniformly dispersed in the sol system.

[0033] Carbon fiber loaded modified T-ZnOw: The carbon fiber is degummed by sintering at 750°C for 10min under the protection of nitrogen, and then soaked in an aqueous solution system under ultrasonic conditions, and then dried at 120°C. The modi...

Embodiment 3

[0034] Example 3: Fe(NO 3 ) 3 9H 2 O, polyethylene glycol and ammonia water are all analytical reagents

[0035] α-Fe 2 o 3 The preparation of modified T-ZnOw colloidal solution: 150gFe(NO 3 ) 3 9H 2 O is dissolved in 1L deionized water to obtain iron concentration and is the ferric nitrate solution of 60g / L, adds 0.0025mol / L polyethylene glycol solution 8ml under the condition of stirring, then drips ammoniacal liquor to pH value is 7, obtains containing Colloidal solution of iron. Take 1 L of the above iron-containing colloidal solution, and add 120 g of T-ZnOw to the colloidal solution under ultrasonic conditions, so that T-ZnOw is uniformly dispersed in the sol system.

[0036] Aramid fibers loaded with modified T-ZnOw: Aramid fibers are soaked in an aqueous solution system under ultrasonic conditions, and then dried at 120°C, and the resulting clean aramid fibers are put into Soak the silk in the solution for 3 minutes, load the modified T-ZnOw on the aramid fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com