Extraction anti-gum agent for MTBE desulfurization

An extraction and anti-glue technology, applied in extractive distillation, ether separation/purification, ether preparation, etc., can solve the problems of large vapor-phase reflux, coking at the bottom of desulfurization tower, etc., and achieve the effect of promoting complexation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

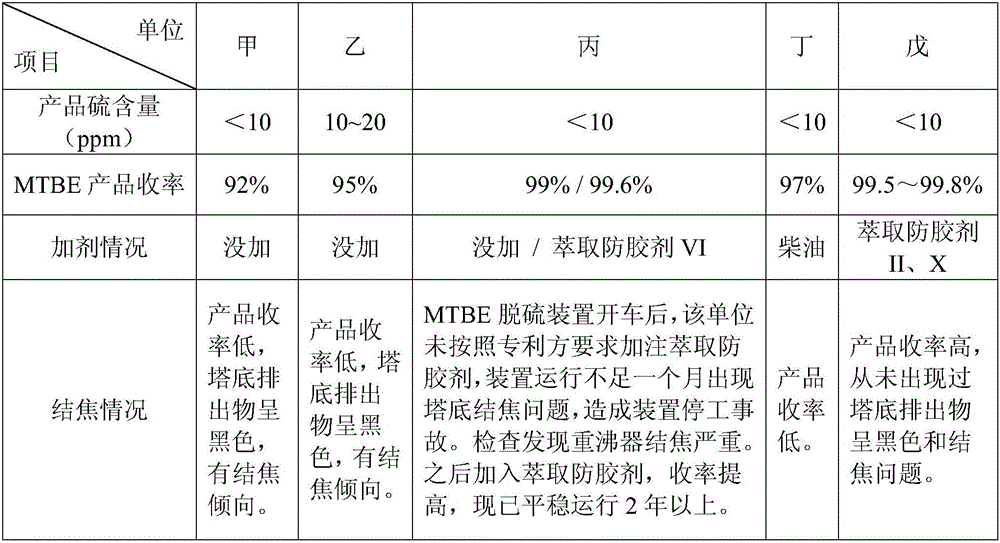

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An extraction anti-adhesive agent for MTBE desulfurization, in parts by weight, it consists of the following components:

[0035] 100 parts of toluene

[0036] 1 part of 2,6-di-tert-butyl-p-cresol

[0037] The above-mentioned components are conventionally mixed according to the stated ratio to obtain the extraction anti-adhesive agent I of the present invention.

[0038]In the extraction anti-adhesive agent I, the boiling point of toluene is 110°C, which is similar to that of dimethyl disulfide, and has strong solubility for sulfides. As a sulfur storage agent at the bottom of the tower, it can dilute the concentration of sulfides at the bottom of the tower; 2 , 6-di-tert-butyl-p-cresol effectively reduces the occurrence of free radical chain reaction as a free radical blocker, so that the extraction anti-adhesive agent I of the present embodiment can effectively remove MTBE by extraction in actual production The sulfur compounds in the extractive distillation column ...

Embodiment 2

[0040] An extraction anti-adhesive agent for MTBE desulfurization, in parts by weight, it consists of the following components:

[0041] 50 parts of toluene

[0042] 50 parts of tert-butanol

[0043] 5 parts of 2,6-di-tert-butyl-p-cresol

[0044] The above-mentioned components are conventionally mixed according to the stated ratio to obtain the extraction anti-adhesive agent II of the present invention.

[0045] In the extraction anti-adhesive agent II, the boiling point of toluene is 110°C, which is similar to that of dimethyl disulfide, and it has strong solubility for sulfide. It is used as a sulfur storage agent at the bottom of the tower to dilute the concentration of sulfide at the bottom of the tower; tert-butyl Alcohol has a boiling point of 80°C. As the main component of the vaporized phase at the bottom of the tower, it can be well enriched in the middle and lower parts of the tower, and the minimum amount of addition can meet the production needs of a large amount...

Embodiment 3

[0047] An extraction anti-adhesive agent for MTBE desulfurization, in parts by weight, it consists of the following components:

[0048] 80 parts of toluene

[0049] 20 parts of isopropanol

[0050] 2 parts of 2-methyl-4-mercapto-6-tert-butylphenol

[0051] The above-mentioned components are conventionally mixed according to the stated ratio to obtain the extraction anti-adhesive agent III of the present invention.

[0052] In the extraction anti-adhesive agent III, the boiling point of toluene is 110°C, which is similar to that of dimethyl disulfide, and it has a strong solubility for sulfides. It is used as a sulfur storage agent at the bottom of the tower to dilute the concentration of sulfides at the bottom of the tower; Alcohol has a boiling point of 82°C, and is composed of toluene and isopropanol with a boiling point of 80-110°C as the main vaporized solvent at the bottom of the tower. Since the boiling point of the solvent is between the boiling point of MTBE and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com