Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

A technology of lithium iron phosphate and precursors, which is applied in the field of sintering preparation methods and sintering equipment for new energy battery materials, and can solve problems such as inability to realize large-scale production, inability to step by step continuous microwave sintering, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

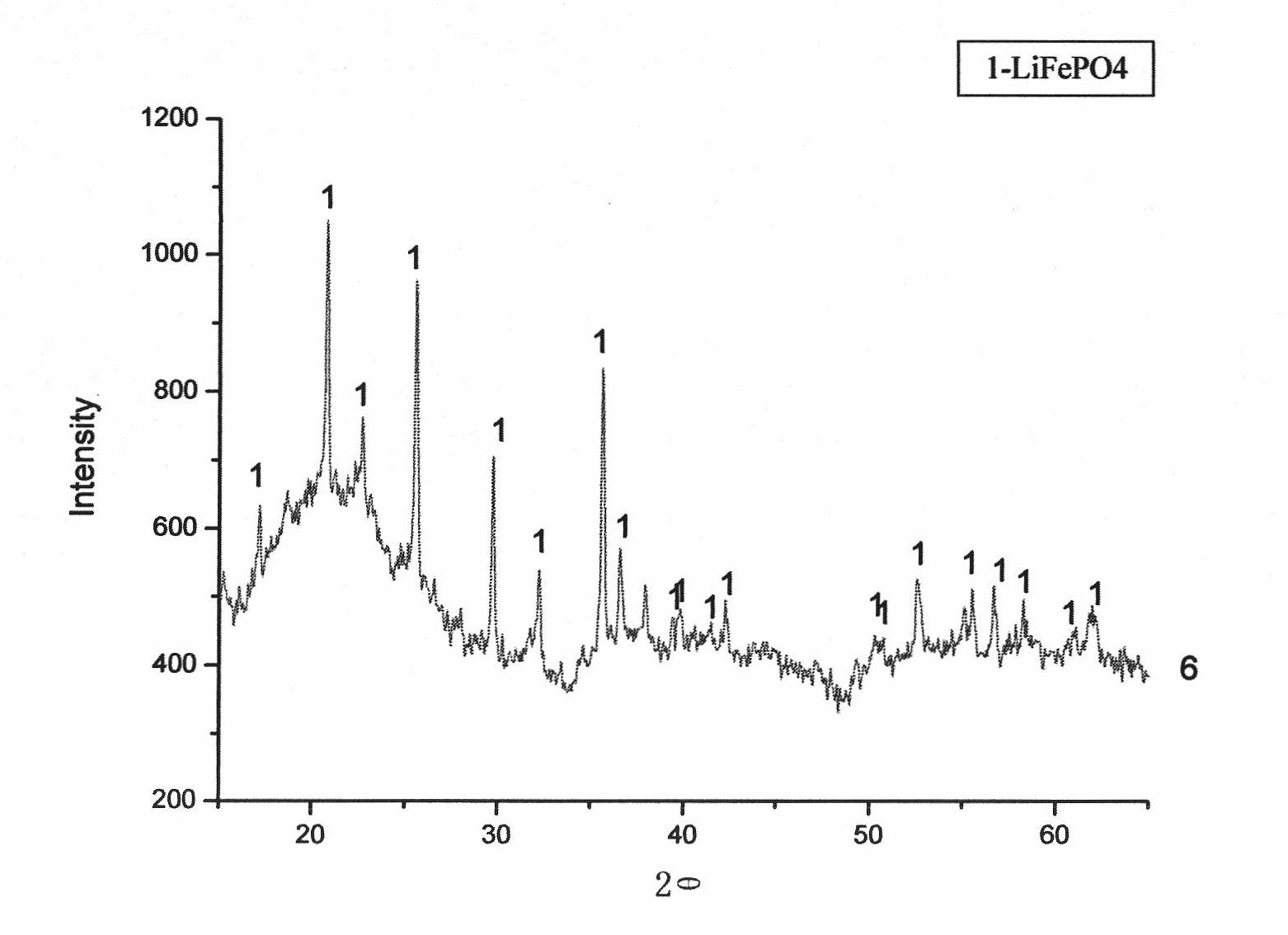

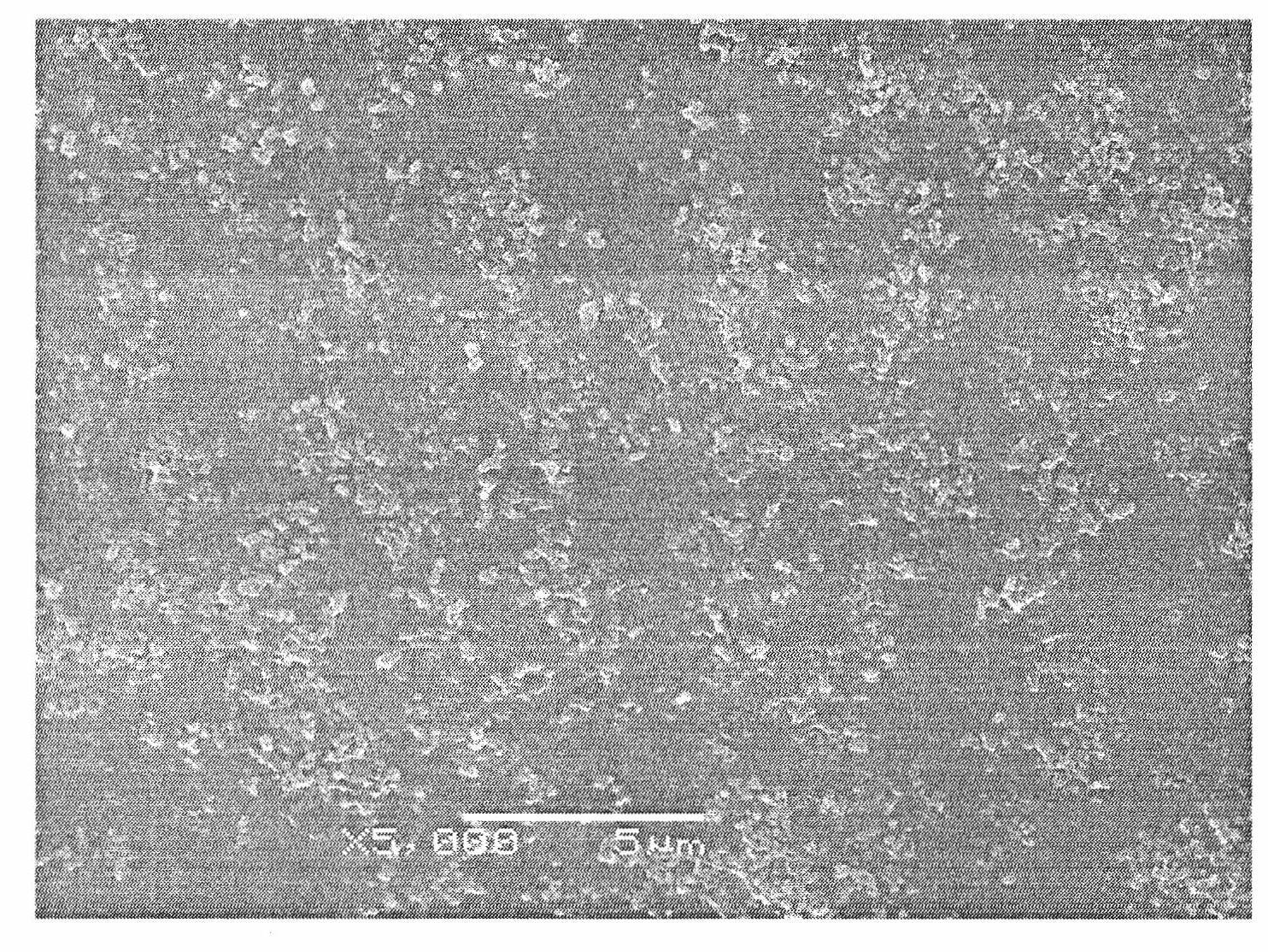

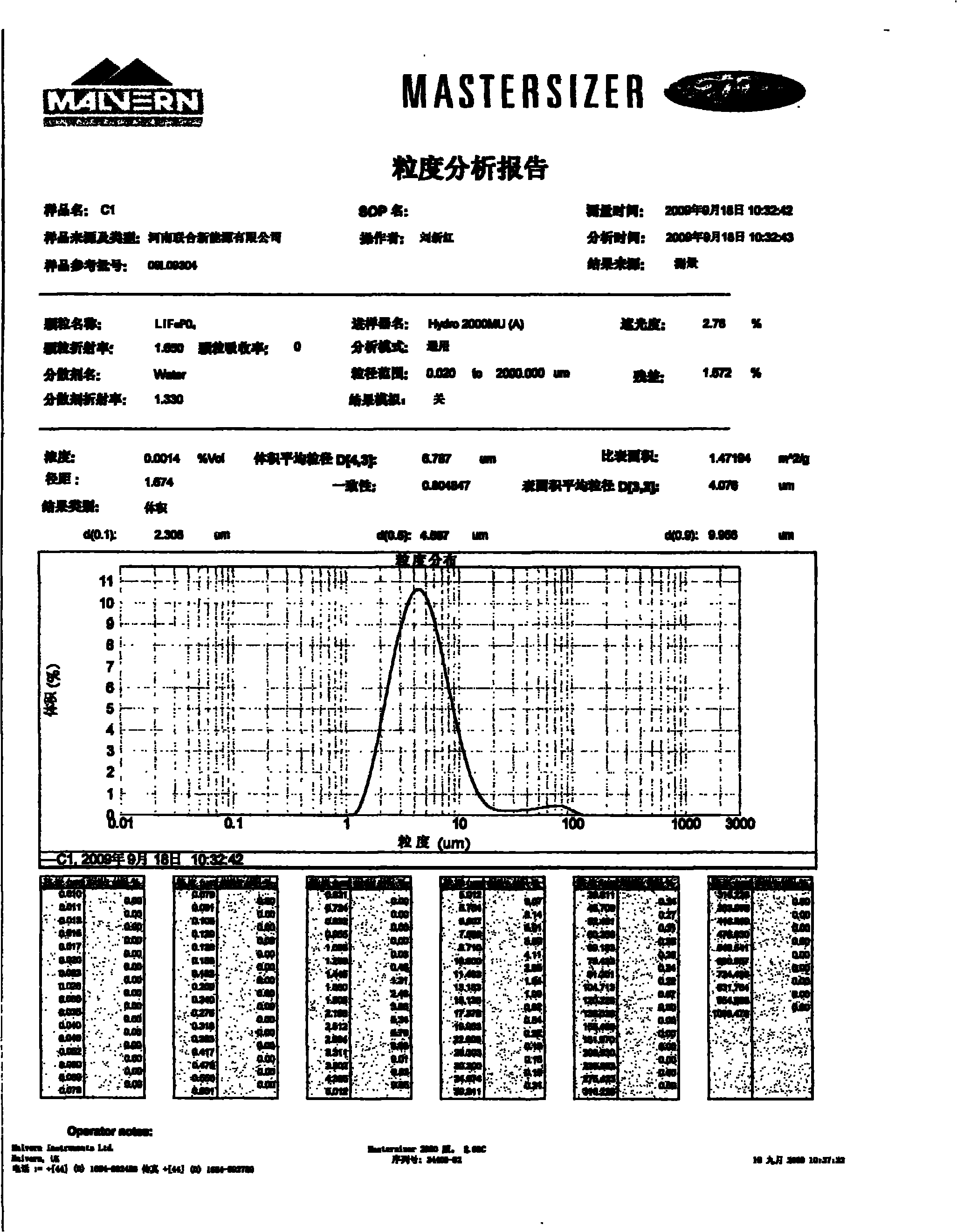

[0102] Example 1: First, according to the inventor's patent application No. 200810237321.8, "Precursor of Lithium Iron Phosphate and Preparation Method of Rechargeable Battery Electrode", the precursor of lithium iron phosphate was prepared, and then iron phosphate was prepared by microwave sintering as follows lithium:

[0103] (1) Pretreatment of the lithium iron phosphate precursor material: feed it into the feeder at a rate of 50 kg per hour. The lithium iron phosphate precursor material is distributed in the pretreatment furnace section 3 of the sintering furnace through an auger conveyor. After vacuuming, nitrogen gas is input. In a nitrogen-protected non-oxidizing atmosphere, microwave heaters are used for heating. The total heating power is 12kw. Control the temperature at 90°C and heat for 30 minutes;

[0104] (2) Pre-sintering of lithium iron phosphate precursor material: in a non-oxidizing atmosphere under the protection of nitrogen, the pre-treated lithium iron ph...

Embodiment 2

[0107] Example 2: First, according to the inventor's patent application No. 200810237321.8, "Precursor of Lithium Iron Phosphate and Preparation Method of Rechargeable Battery Electrode", the precursor of Lithium Iron Phosphate was prepared, and then Lithium Iron Phosphate was prepared by sintering as follows :

[0108] (1) Pretreatment of the lithium iron phosphate precursor material: feed it into the feeder at a rate of 60 kg per hour. Distribute 15 kilograms of lithium iron phosphate precursor materials in the pretreatment furnace section 3 of the sintering furnace through an auger conveyor, vacuumize to a vacuum degree of 9 Pa, and use a microwave heater to heat in a non-oxidizing atmosphere. With a power of 15kw, heat for 15 minutes at 120°C;

[0109] (2) Pre-sintering of lithium iron phosphate precursor material: in a non-oxidizing atmosphere with a vacuum degree of less than 10 Pa, distribute the pre-treated lithium iron phosphate precursor material through the auger c...

Embodiment 3

[0111] Example 3: First, according to the inventor's patent application No. 200810237321.8, "Precursor of Lithium Iron Phosphate and Preparation Method of Rechargeable Battery Electrode", the precursor of lithium iron phosphate was prepared, and then sintered to prepare lithium iron phosphate by the following steps :

[0112] (1) Pretreatment of lithium iron phosphate precursor material: feed it into the feeder at a rate of 90 kg per hour. Distribute 15Kg of lithium iron phosphate precursor material in the pretreatment furnace section 3 of the sintering furnace through the auger conveyor, input argon gas after vacuuming, and use a microwave heater to heat under the protection of argon gas, with a total heating power of 15kw. Heat at 90°C for 10 minutes;

[0113] (2) Pre-sintering of lithium iron phosphate precursor material: in a non-oxidizing atmosphere protected by argon, the pre-treated lithium iron phosphate precursor material is distributed in the pre-sintering furnace s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com