Patents

Literature

92results about How to "Reduce vaporization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

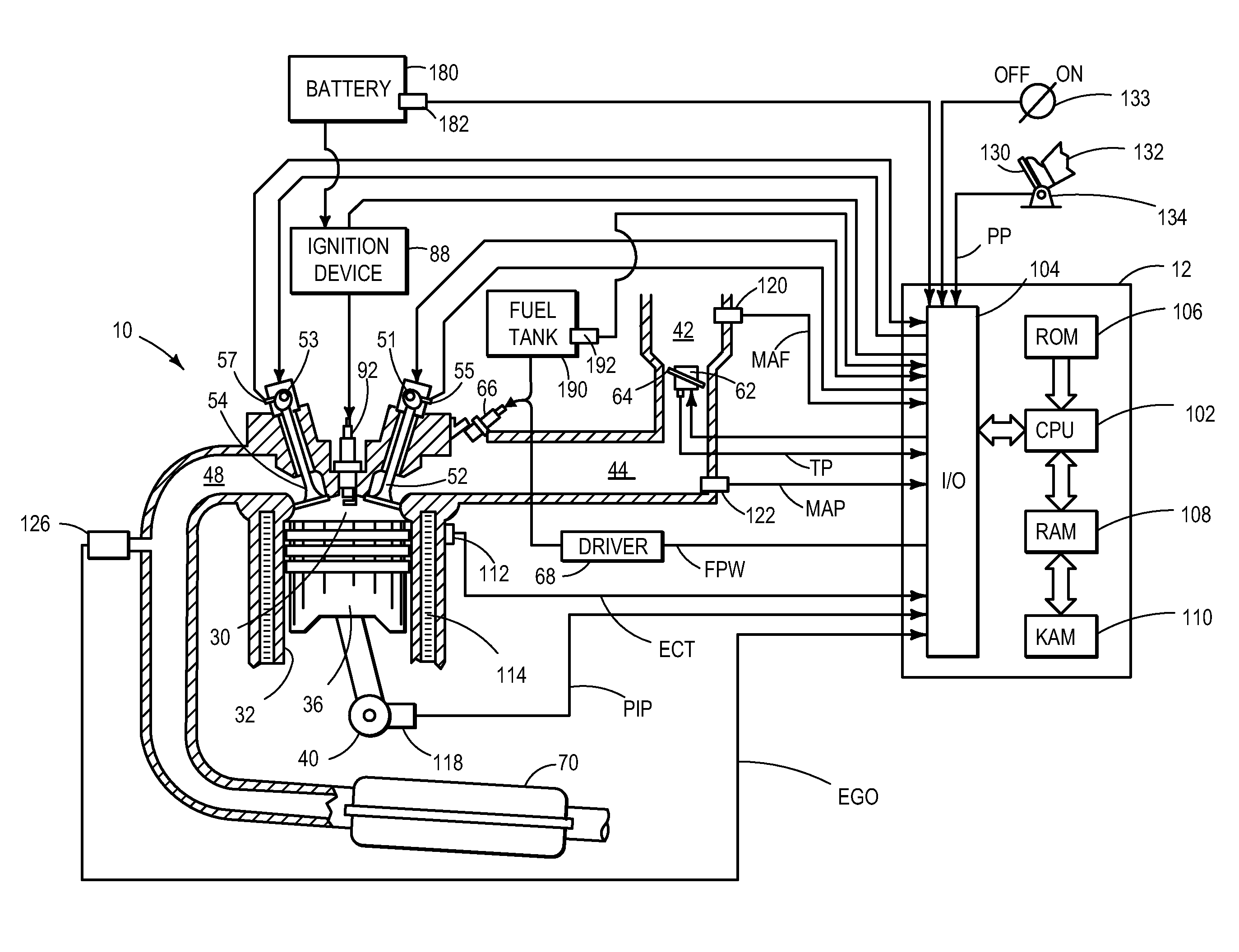

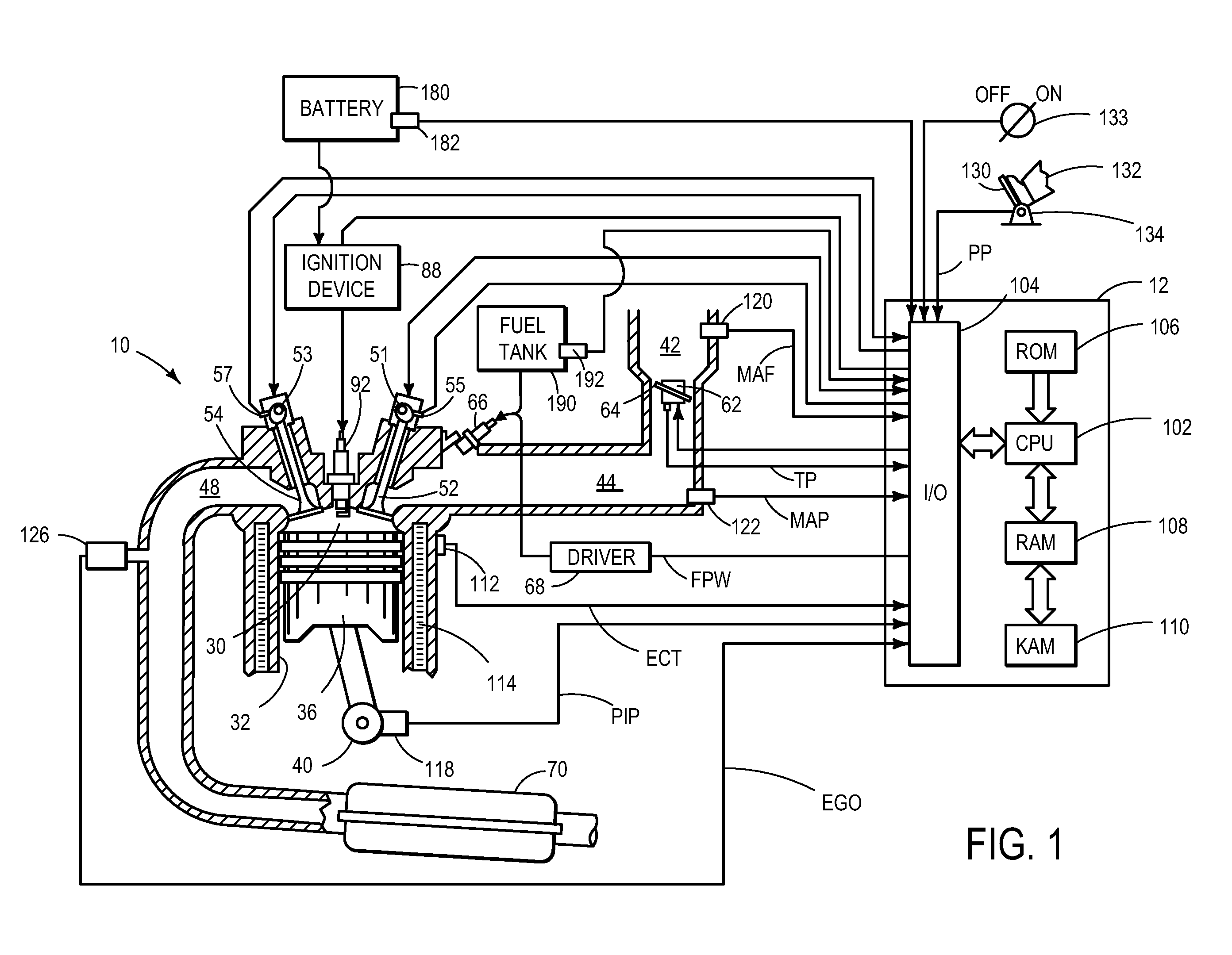

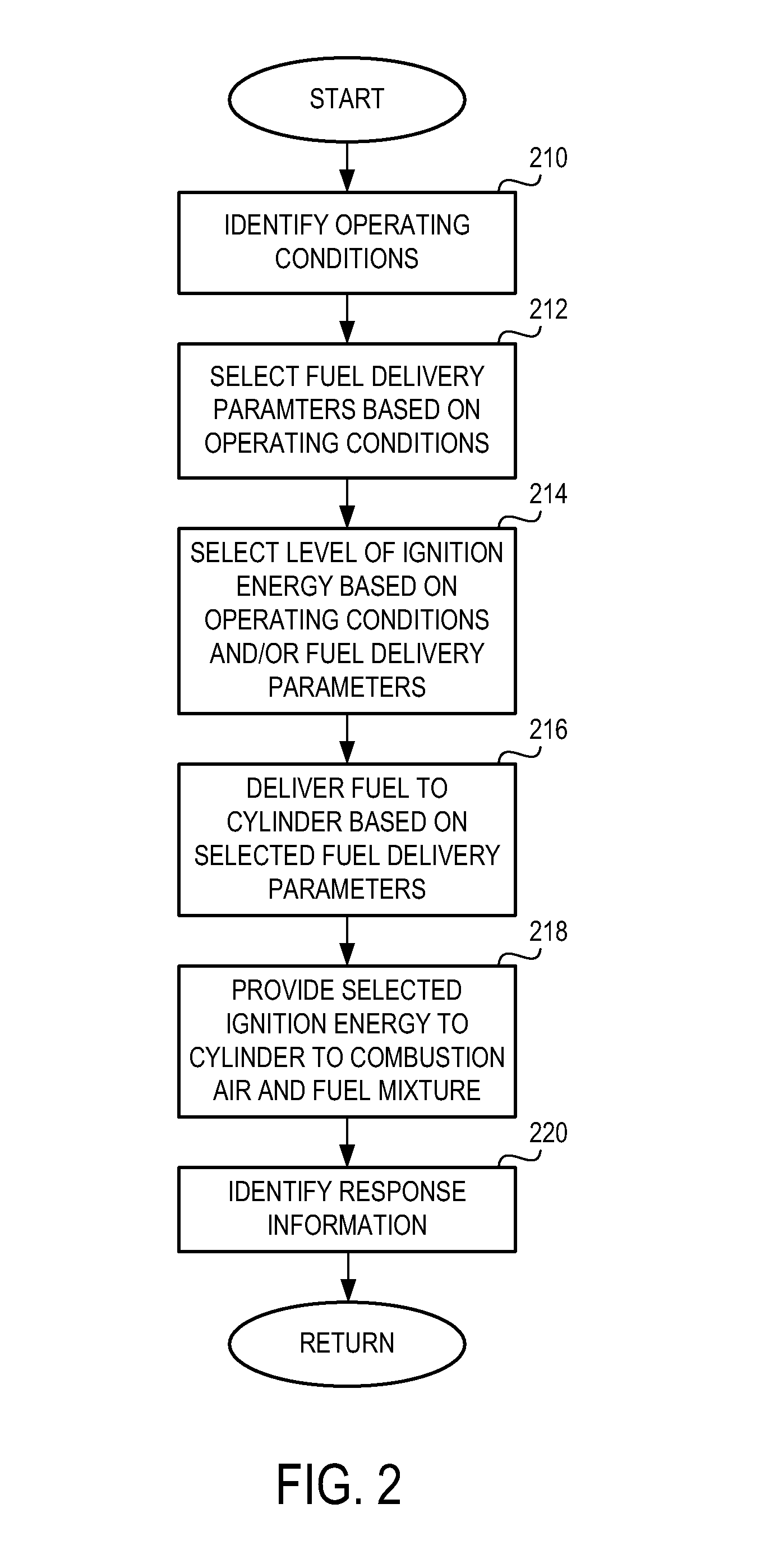

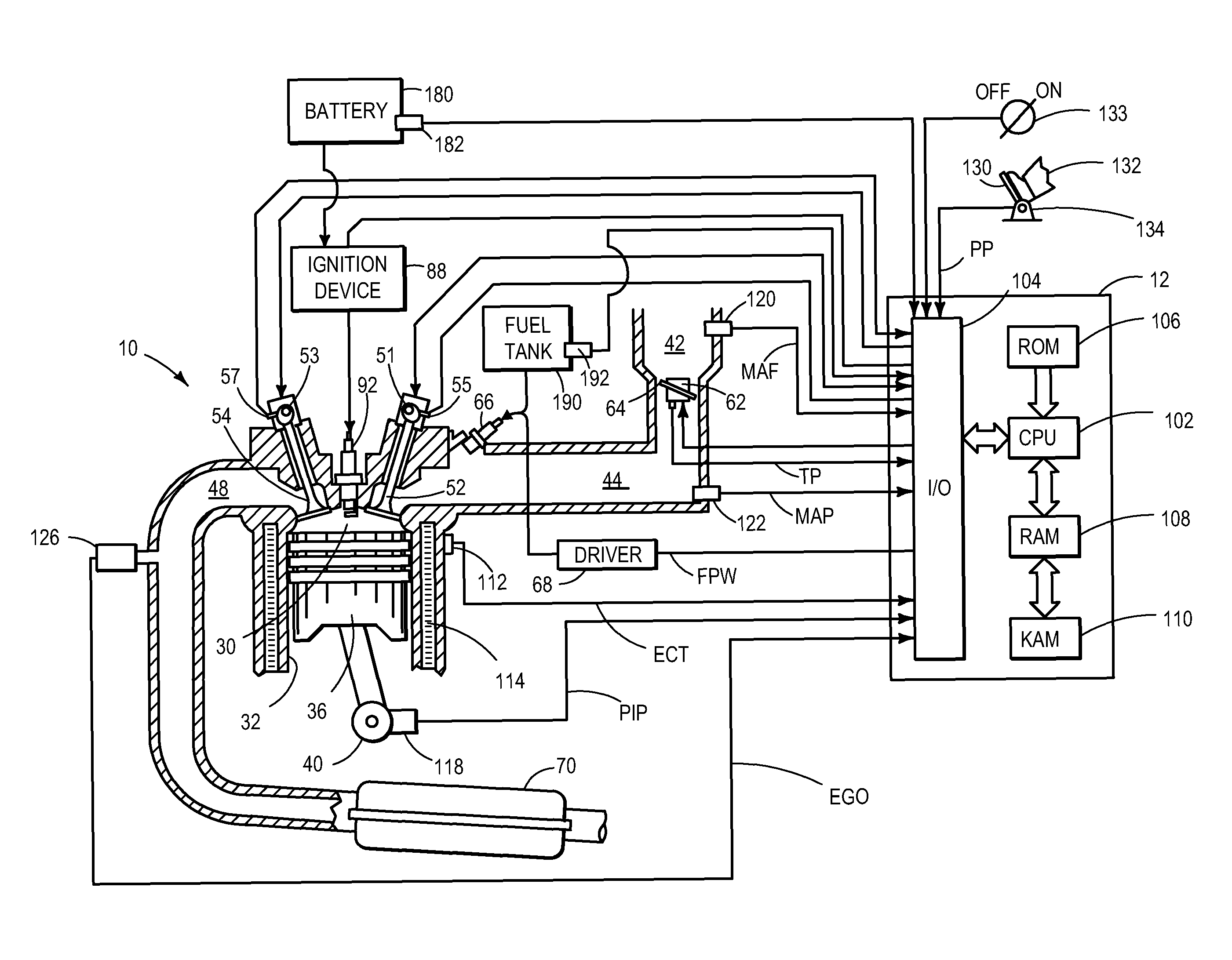

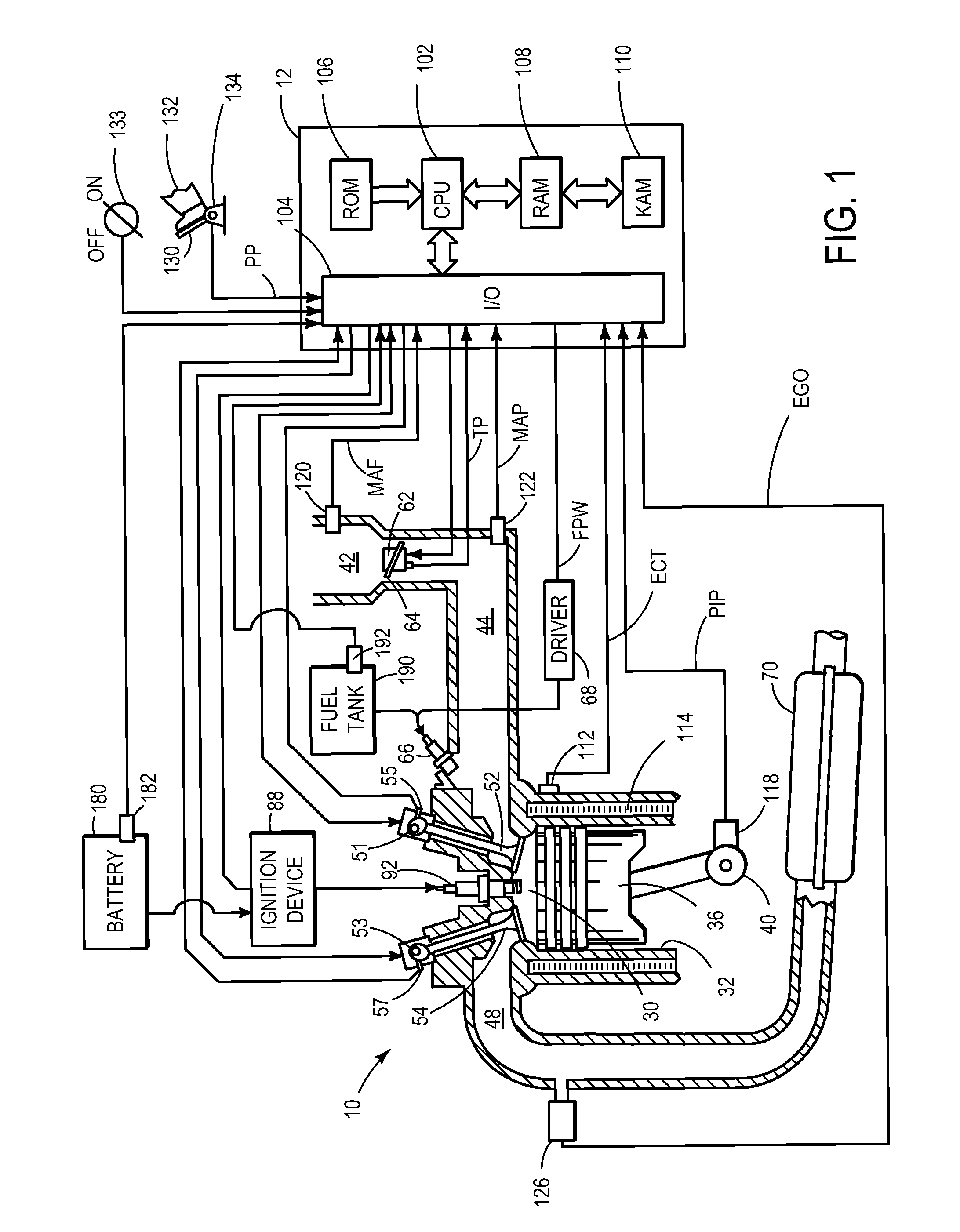

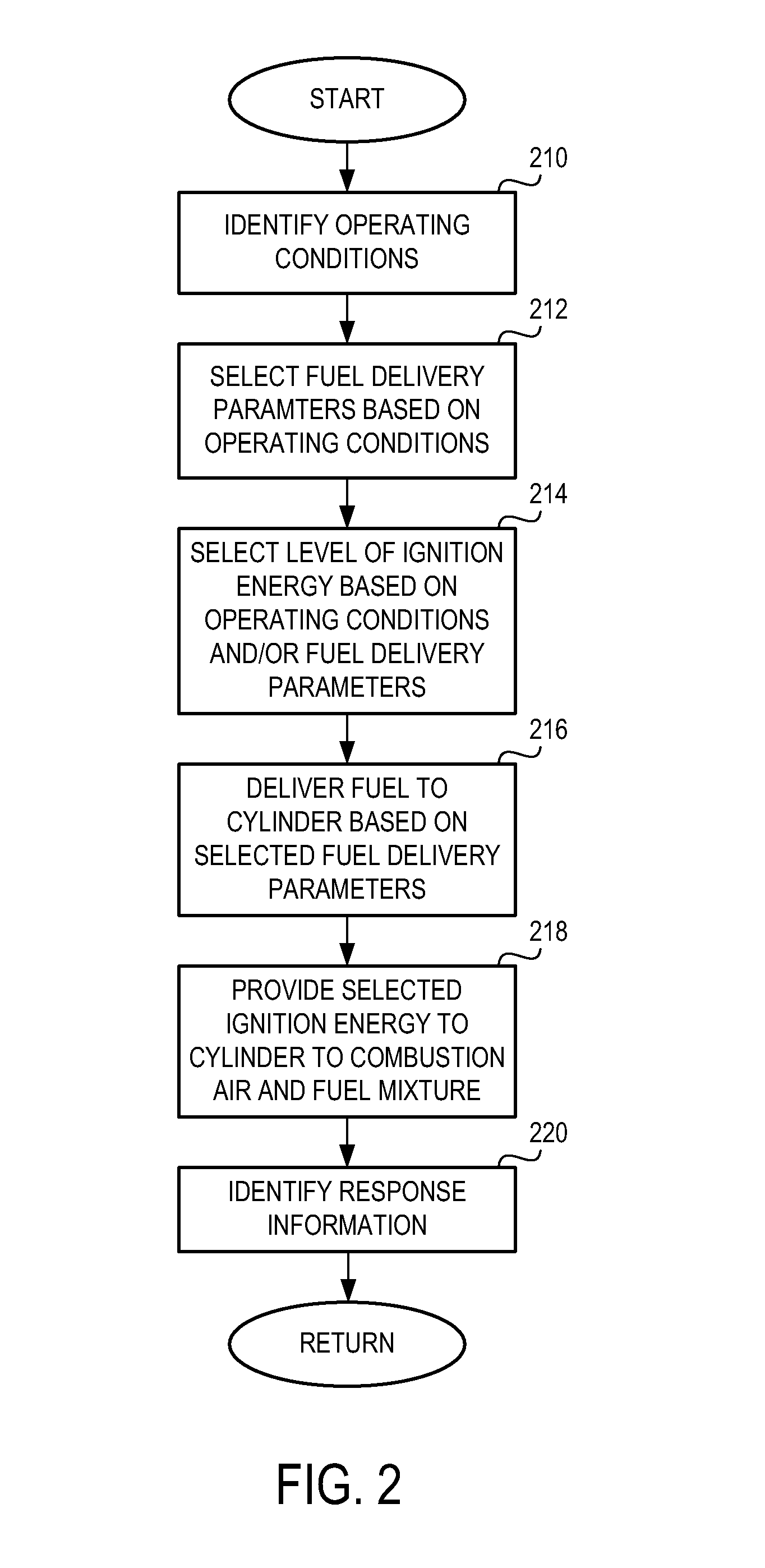

Ignition Energy Control for Mixed Fuel Engine

InactiveUS20090114188A1Improve combustion qualityImprove the level ofElectrical controlOther installationsEnergy controlControl system

As one example, an engine system for a vehicle is provided, including an internal combustion engine having at least one cylinder; a fuel system configured to provide a fuel to the cylinder; an ignition system including at least a spark plug; a control system configured to vary a level of ignition energy provided to the cylinder via the spark plug in response to a composition of the fuel provided to the cylinder by the fuel system. A method of operating the engine system by varying a level of ignition energy provided to the engine after a start-up is also provided.

Owner:FORD GLOBAL TECH LLC

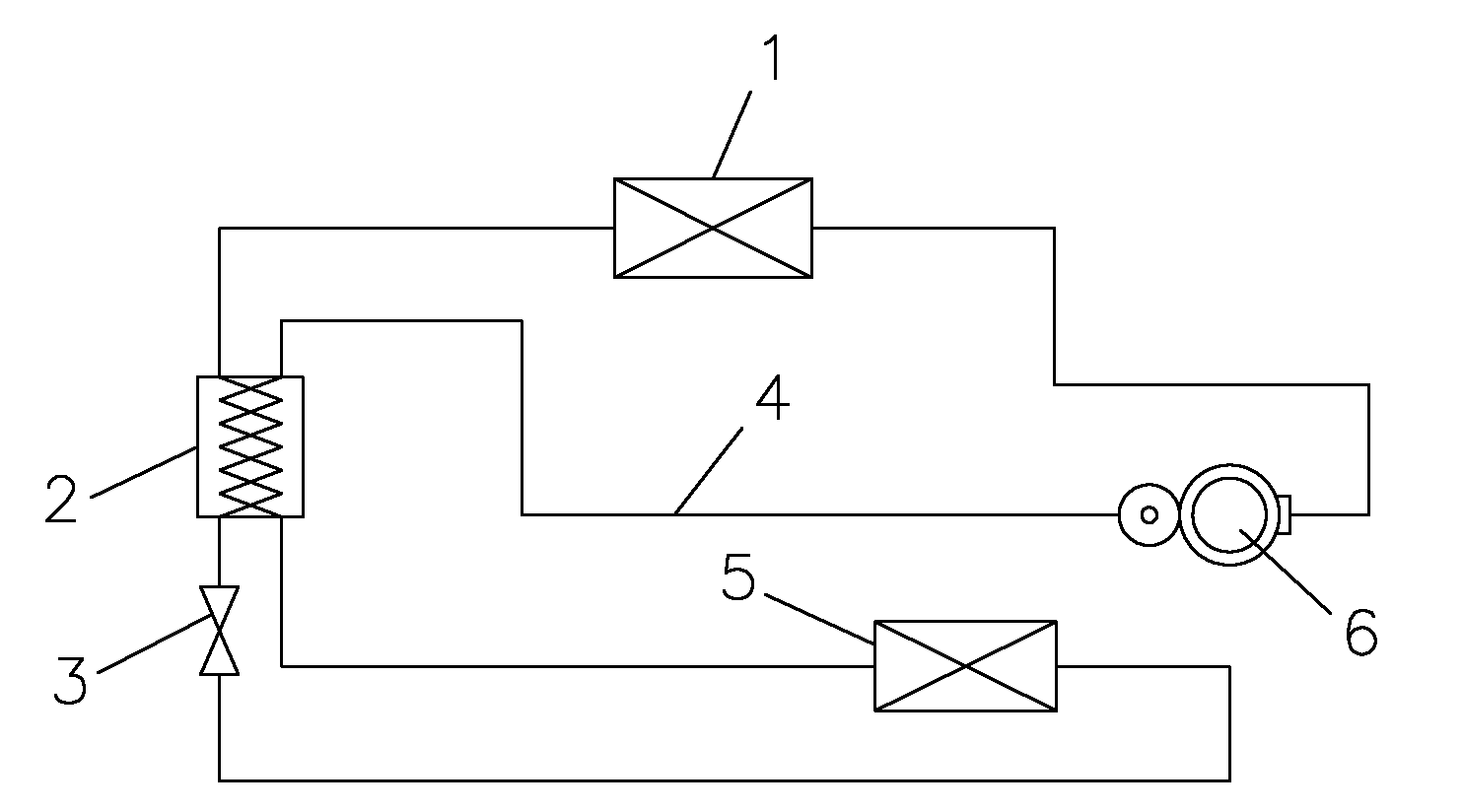

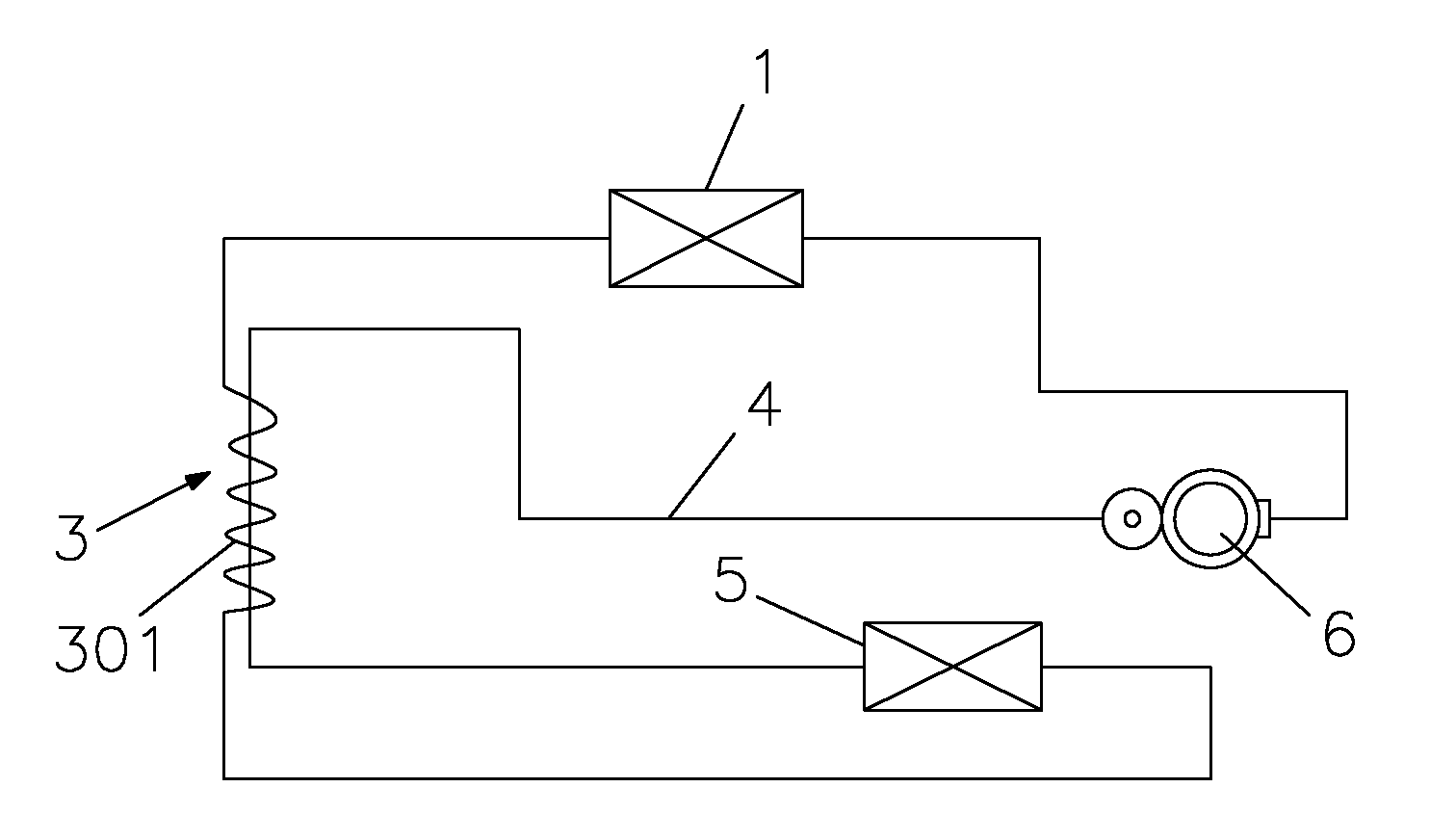

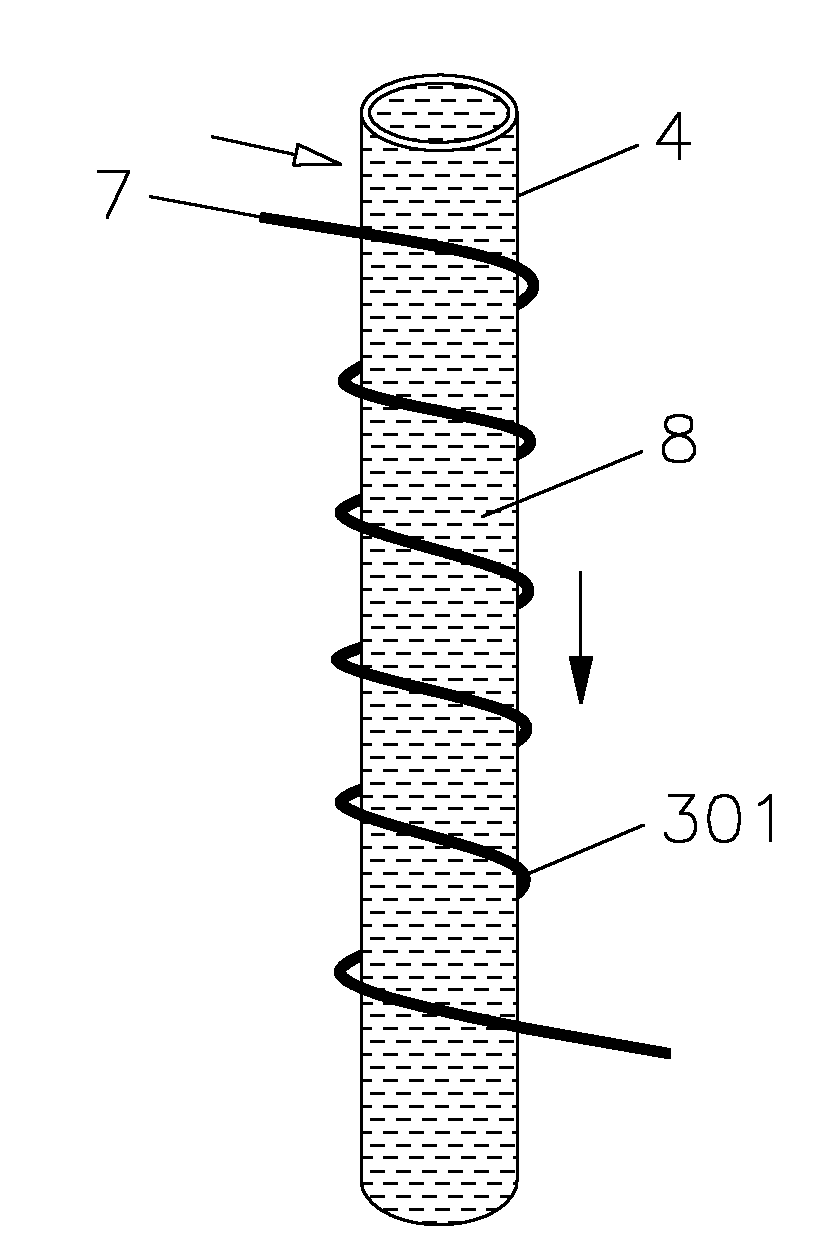

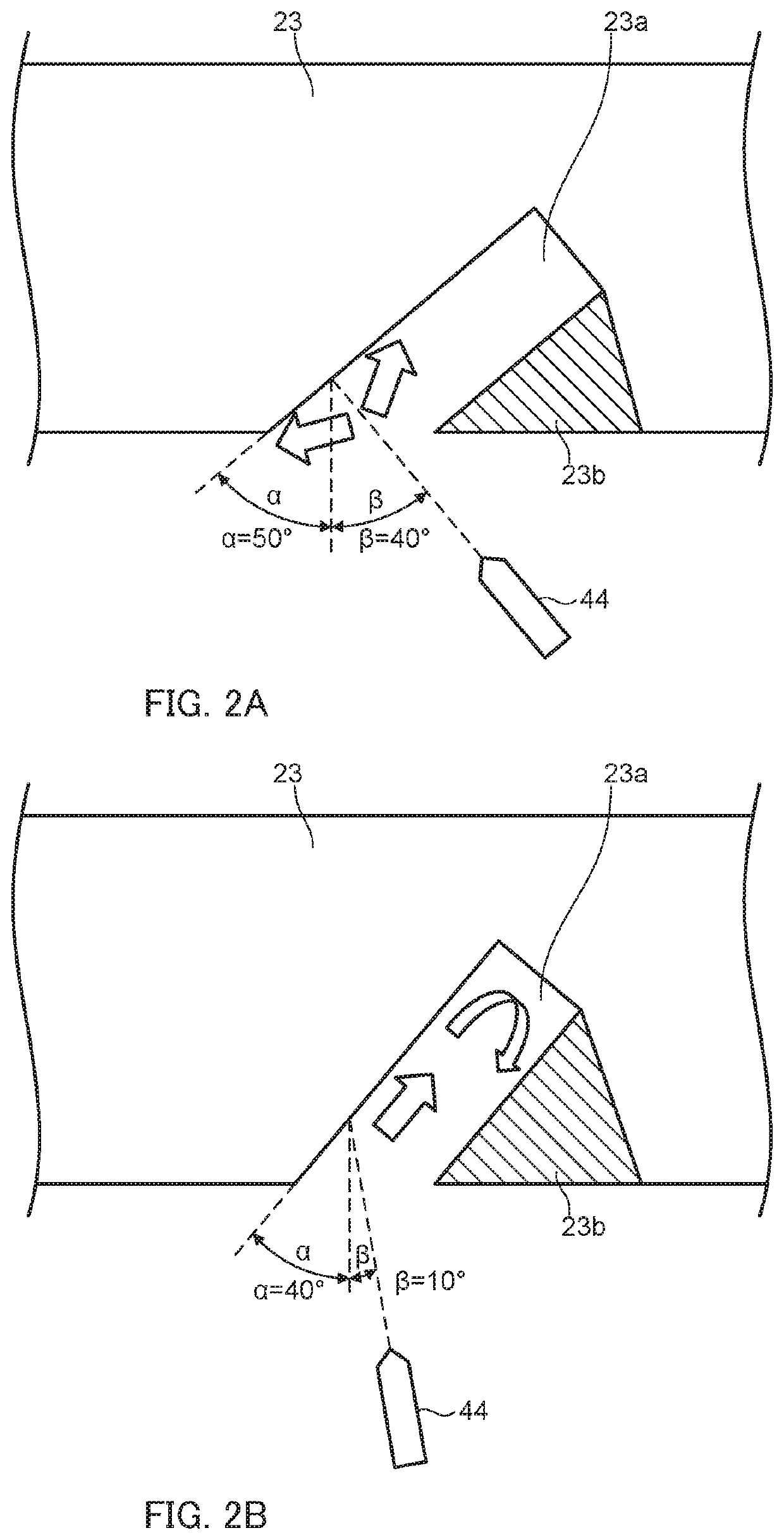

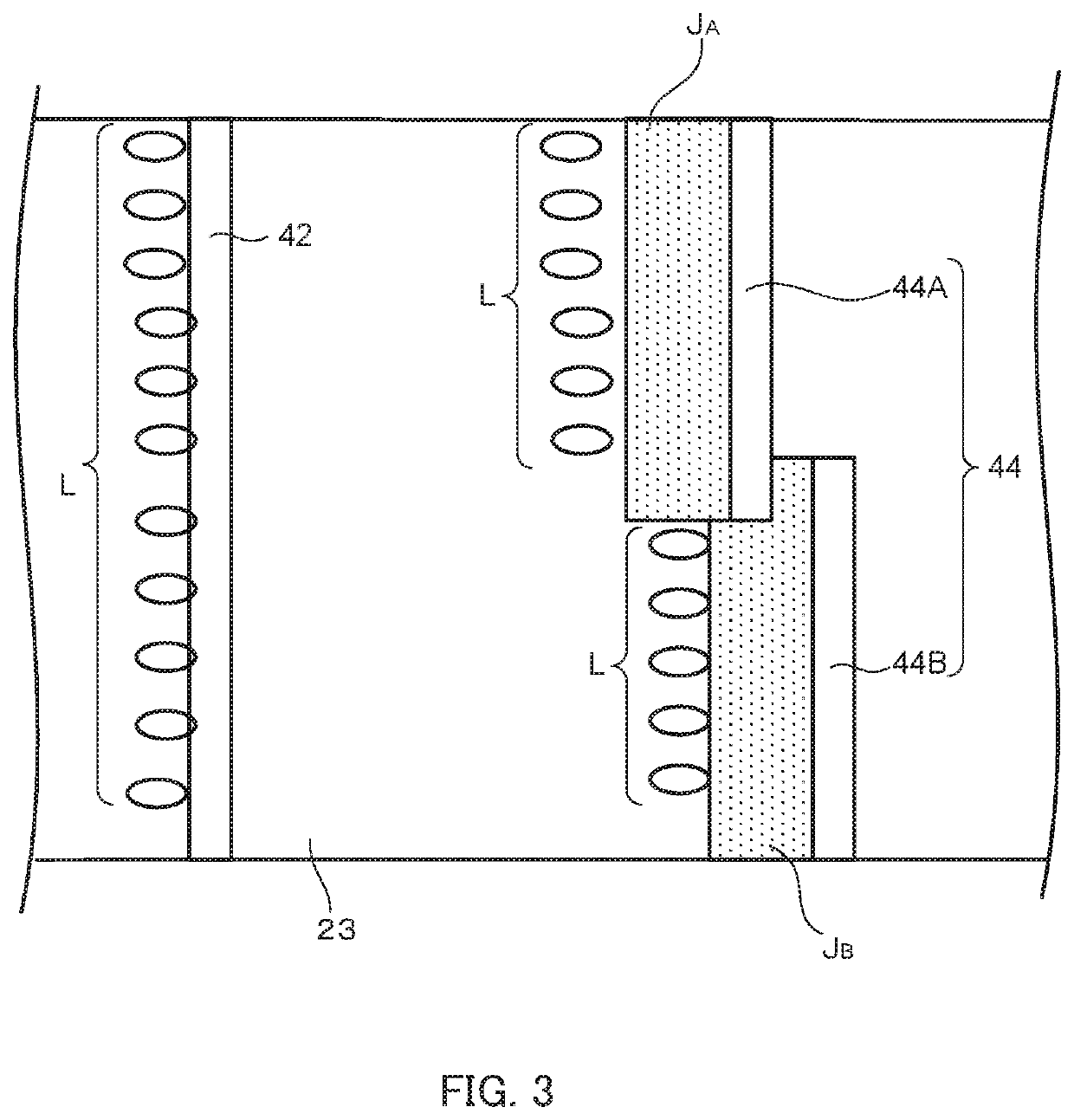

Backheating method and backheating structure for heat pump air conditioner

InactiveCN101979938AReduce the temperatureReduce vaporizationHeat recovery systemsFluid circulation arrangementEvaporationEngineering

The invention discloses a backheating method and a backheating structure for a heat pump air conditioner, which can improve the performance of the air conditioner. The backheating structure comprises heat exchangers A and B, a compressor, and a throttling element connected between the heat exchangers A and B, wherein the heat exchanger B is connected with the compressor by an air suction pipe of the compressor; and a higher-temperature coolant in the throttling element performs heat exchange with a lower-temperature coolant in the air suction pipe of the compressor. In the backheating method and the backheating structure, the temperature of the coolant in the throttling element can be reduced by performing backheating in a throttling process, thereby retarding the evaporation of the coolant and the change of the dryness of the coolant, making more stable the flow regime of the coolant and reducing inevitable loss; and the dryness of the coolant at an outlet of the throttling element is reduced, namely, the degree of subcooling of the air conditioner is increased, so the cooling capacity of the air conditioner can be improved. The backheating method and the backheating structure for the heat pump air conditioner can improve the cooling or heating performance of the heat pump air conditioner; and the backheating structure is simplified to a certain extent so as to be convenient to manufacture and save the cost.

Owner:四川长虹空调有限公司

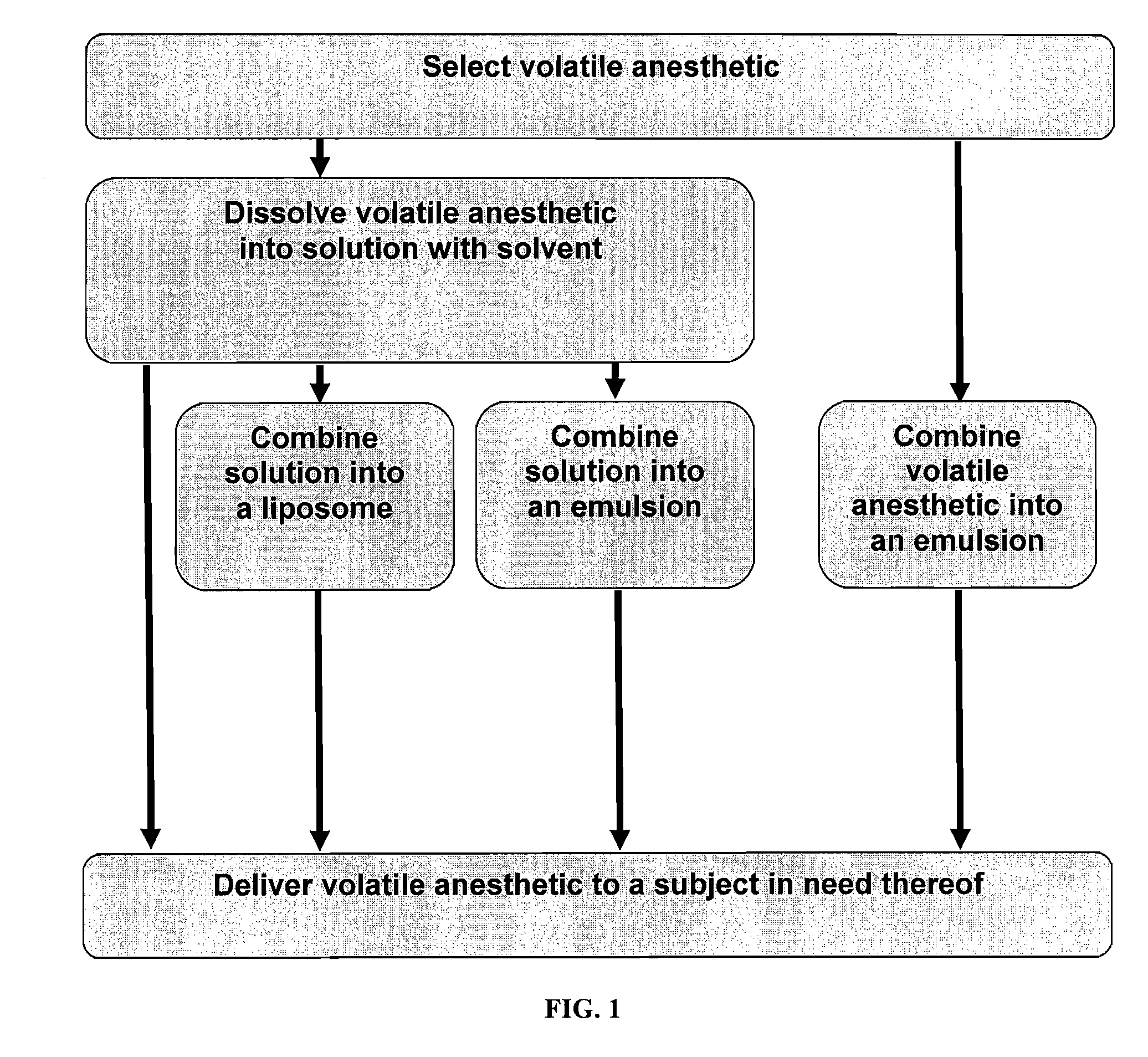

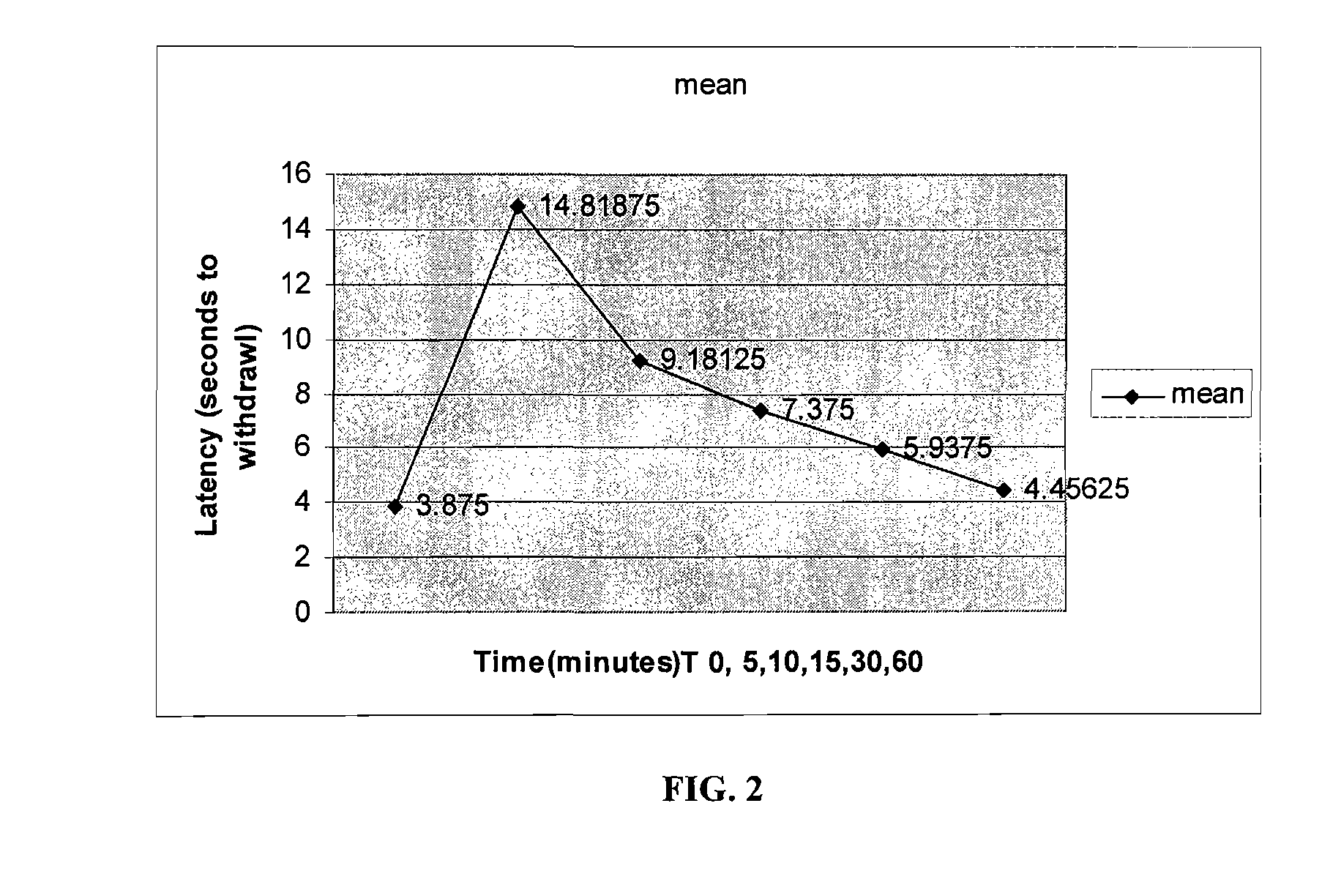

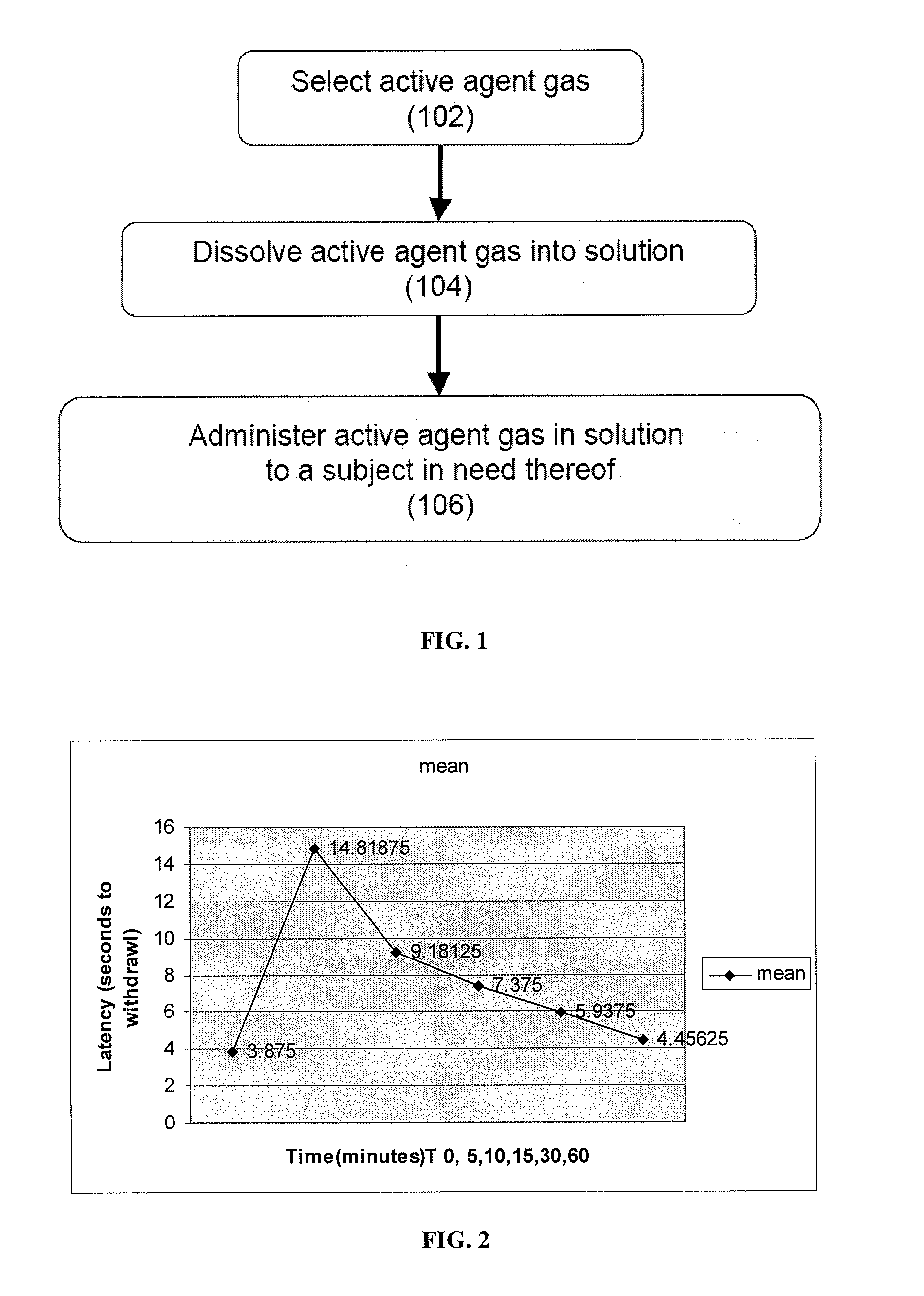

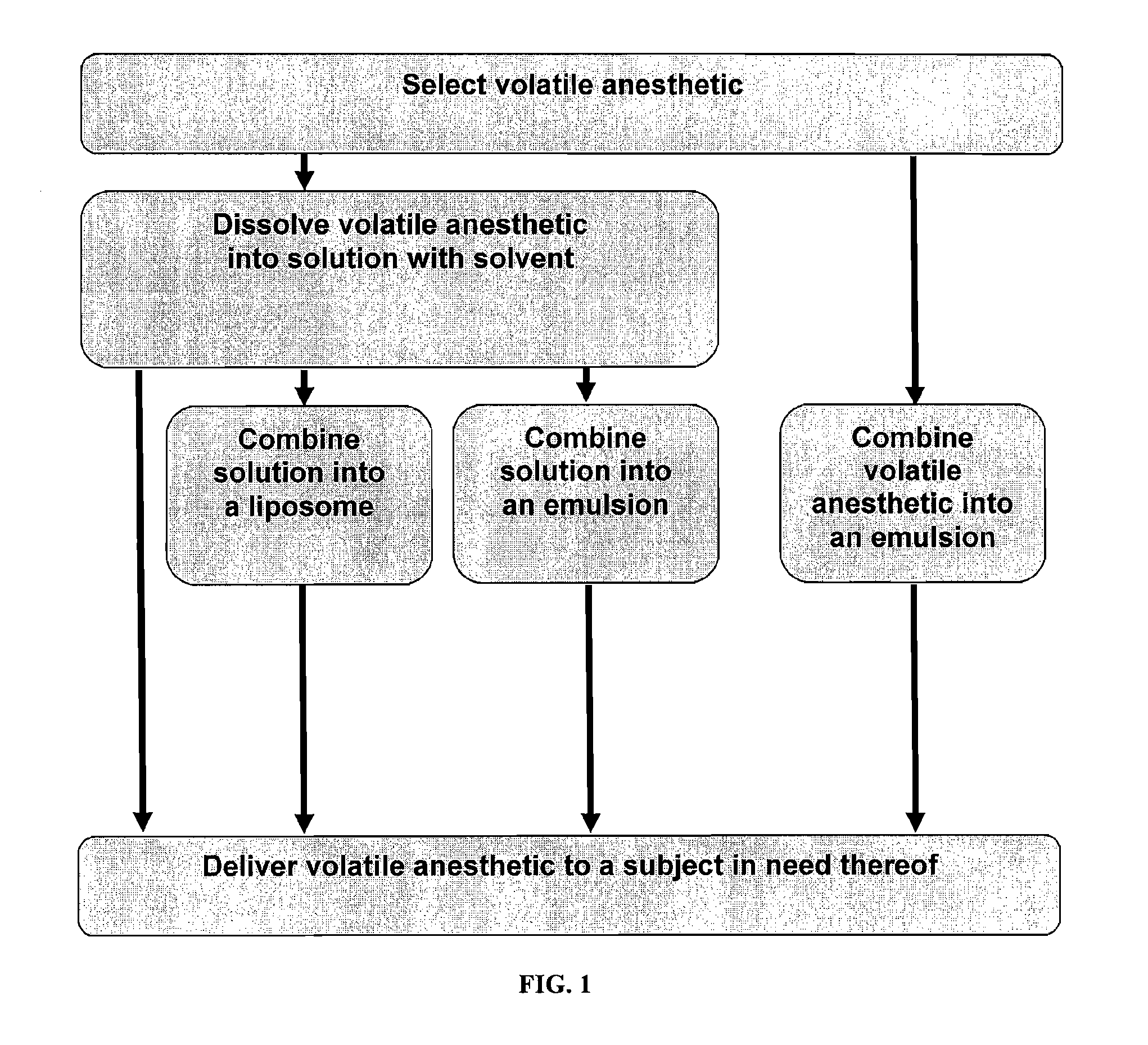

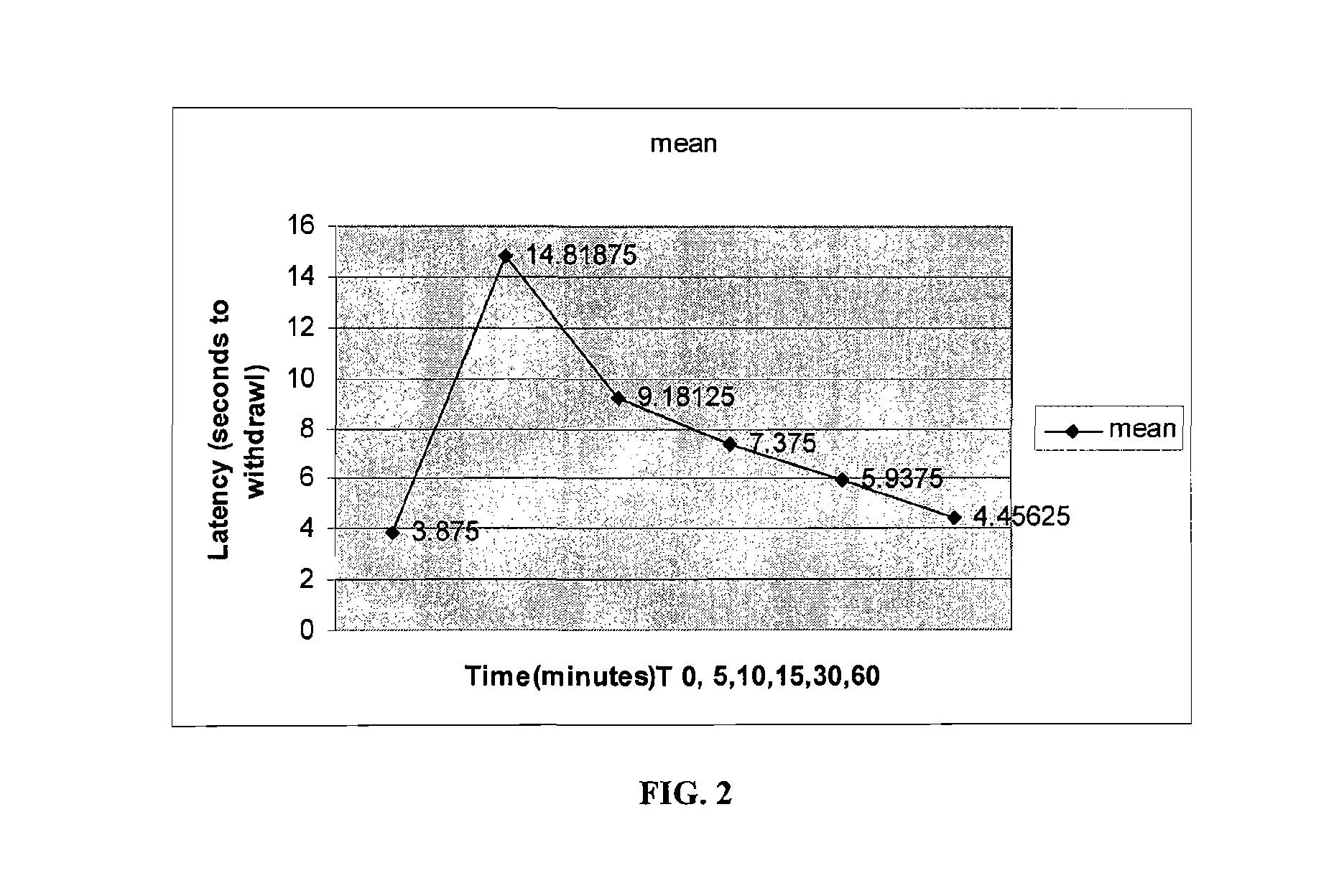

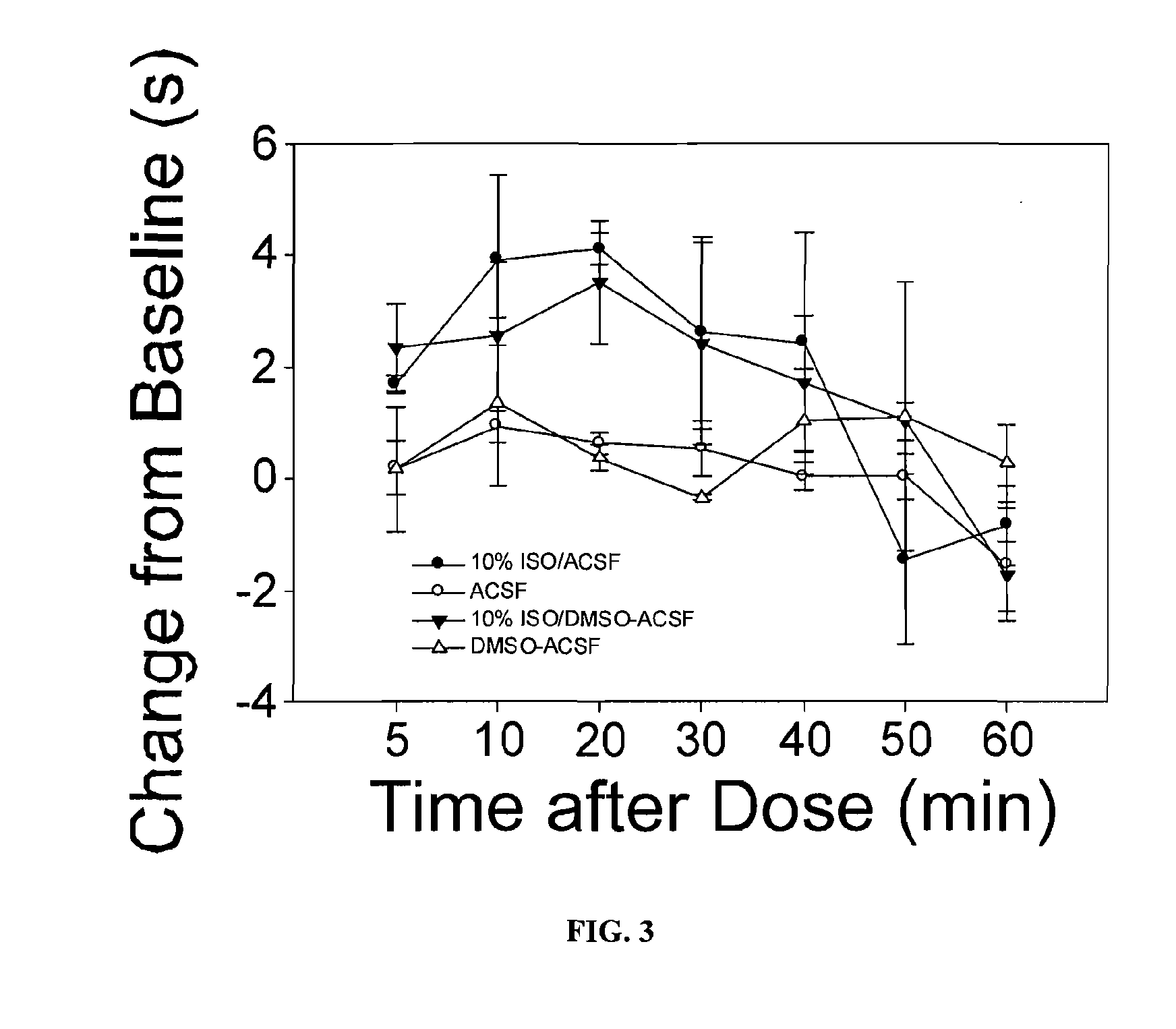

Volatile Anesthetic Compositions and Methods of Use

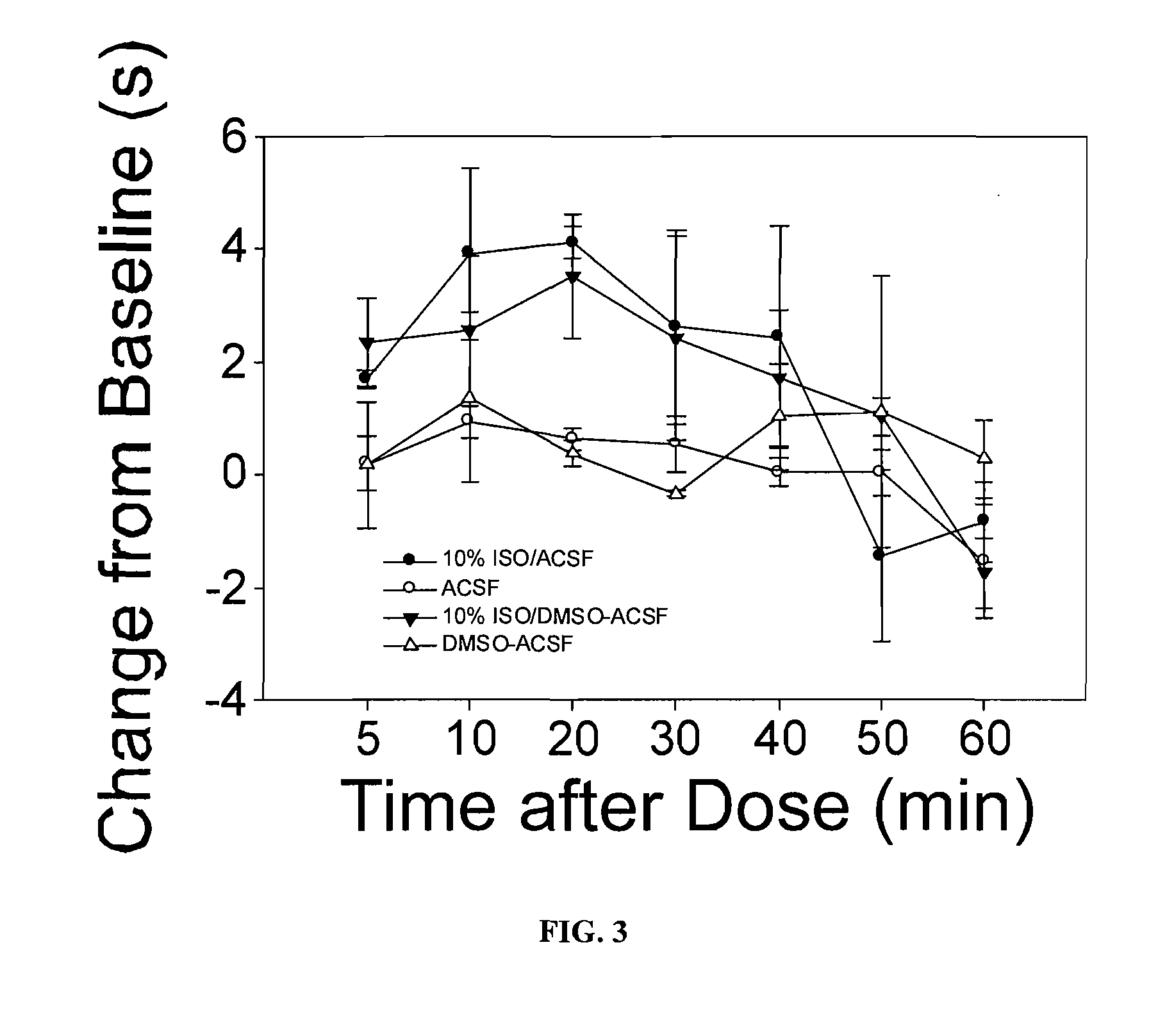

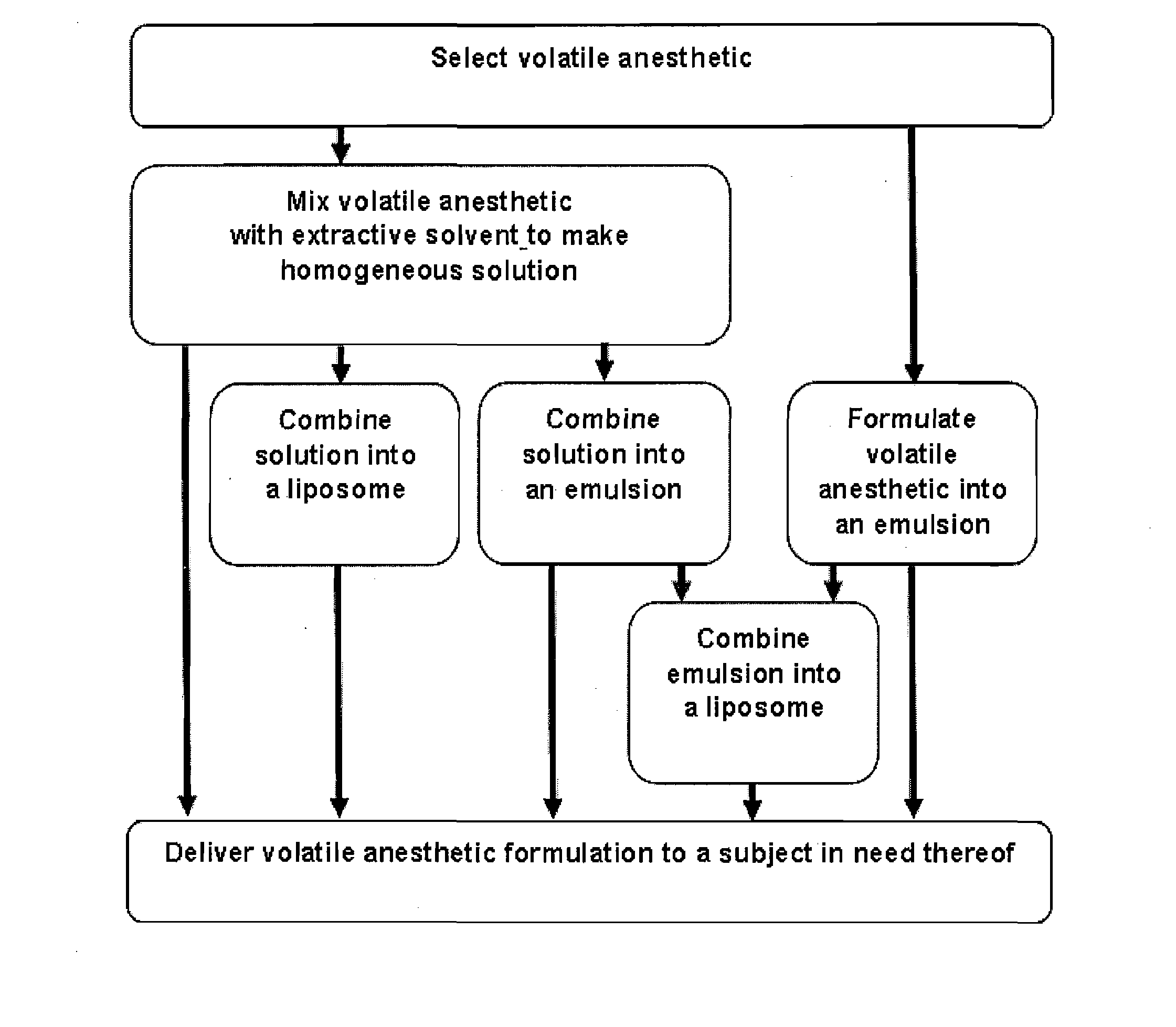

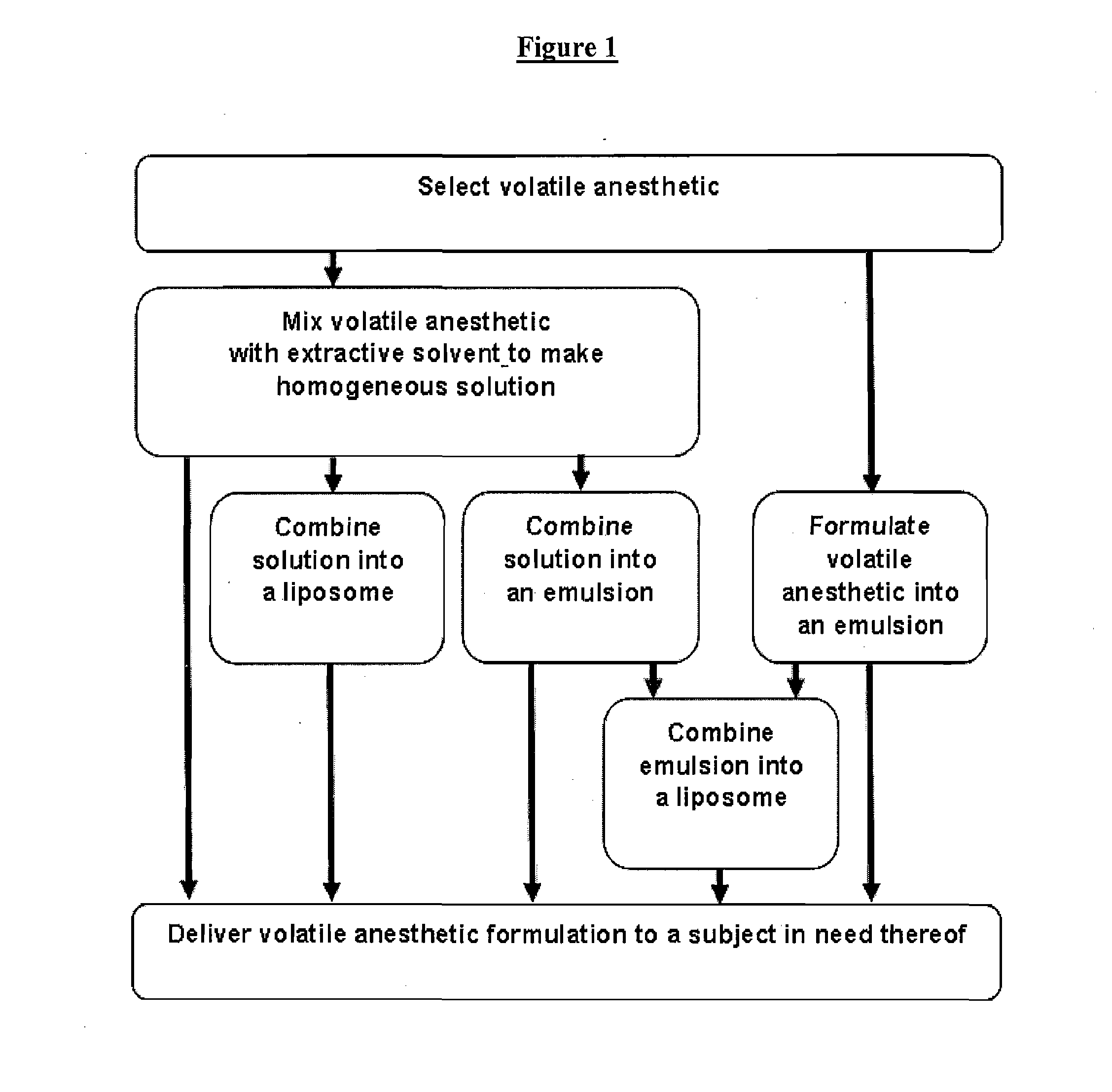

InactiveUS20110159078A1Excellent characteristicsImprove propertiesBiocideNervous disorderEmulsionMotor function

The present invention provides methods for reducing pain in a subject in need thereof by delivering a volatile anesthetic in a solution or an emulsion that can additionally include an extractive solvent in an amount effective to reduce pain without substantially interfering with motor function. Chronic or acute pain may be treated, or the volatile anesthetic may be delivered as a regional anesthetic to a subject to anesthetize a portion of the subject prior to surgery. Dosing regimes including a one-time administration, continuous and / or periodic administration are contemplated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Novel Formulations of Volatile Anesthetics and Methods of Use for Reducing Inflammation

ActiveUS20120171281A1Reduce vaporizationReduce evaporationBiocideHalogenated hydrocarbon active ingredientsAnesthesiaInflammation

The present invention provides methods for treating inflammation or a wound in a subject in need of such wound treatment or inflammation treatment by delivering a volatile anesthetic to the wound or the inflammation site.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

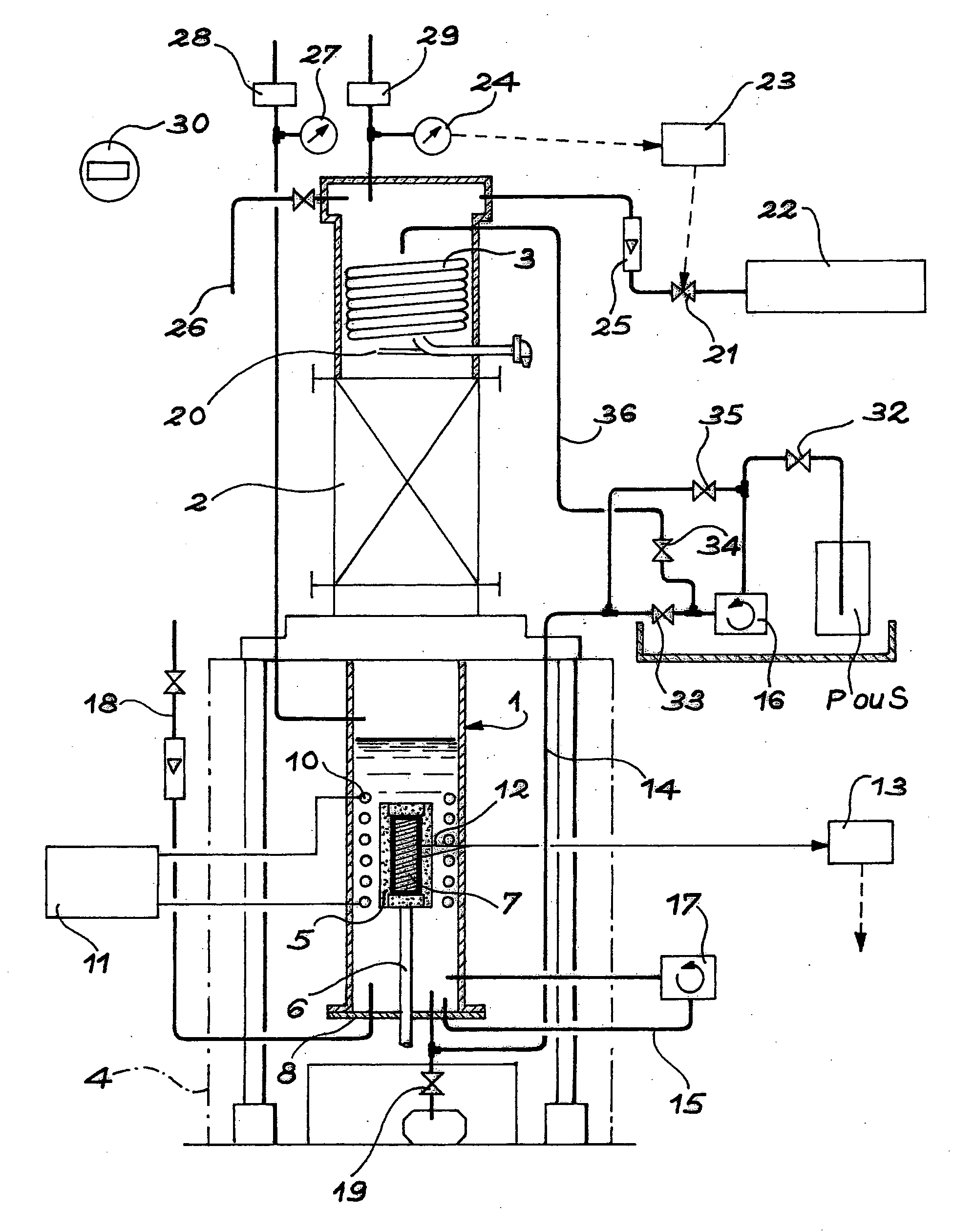

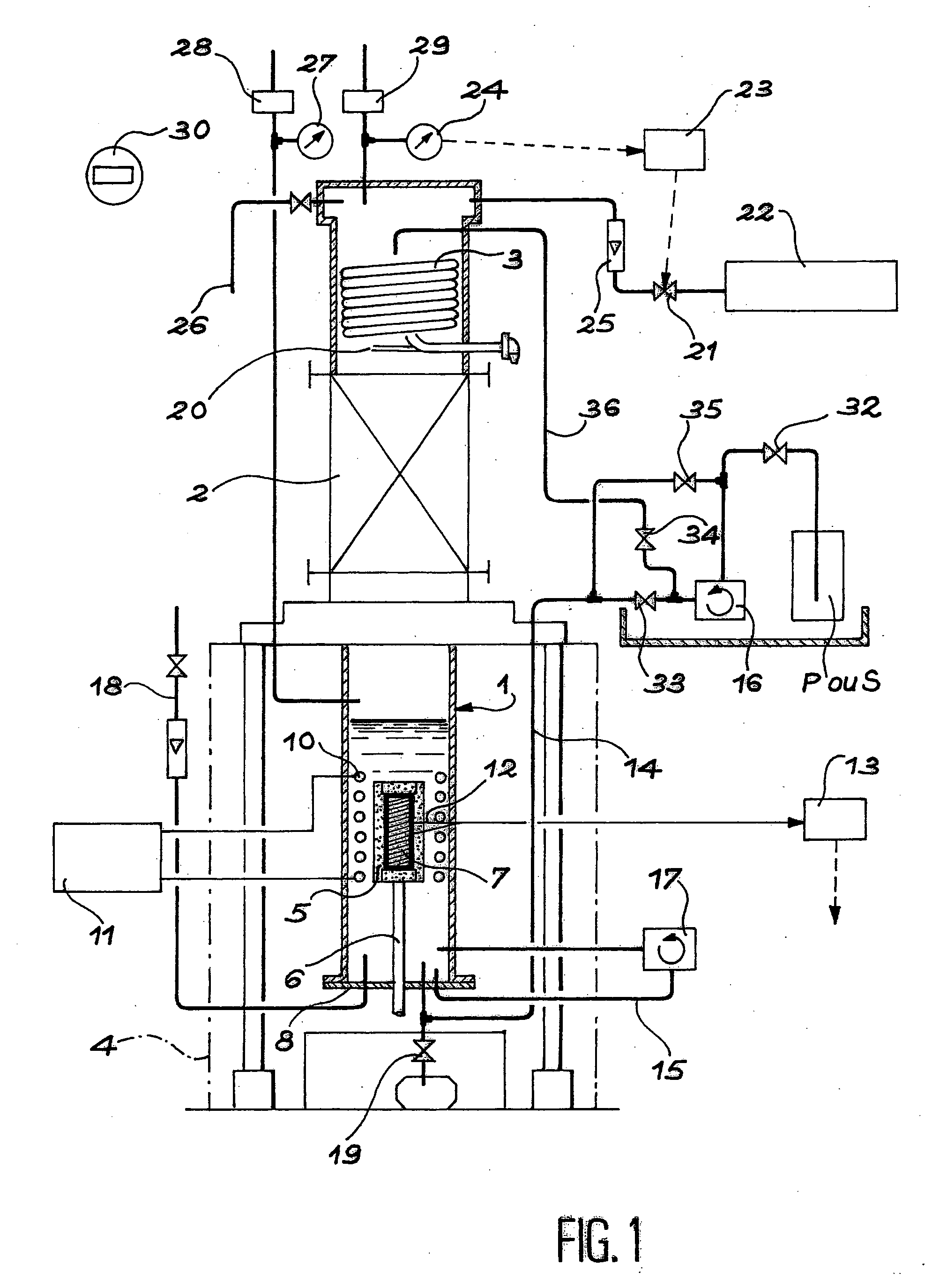

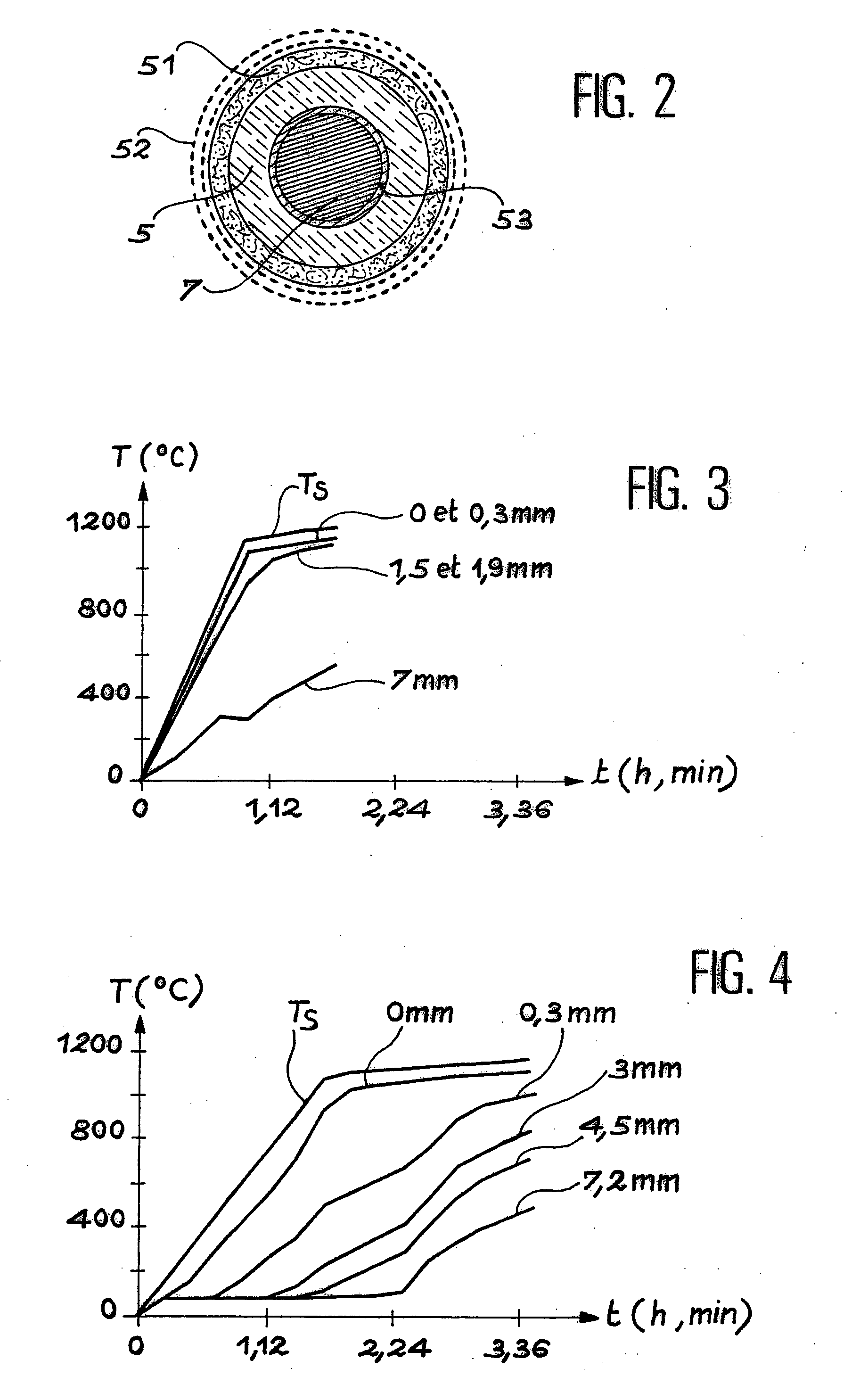

Methods for calefaction densifaction of a porous structure

InactiveUS20040022956A1Increase porosityReduce flow effectPretreated surfacesCoatingsChemistryDecomposition

The invention relates to a film-boiling densification method for a porous structure (mixed gas-liquid method) (5) consisting in immersing of the porous structure into a liquid precursor, a hydrocarbon, for example, and heating the system in order to deposit the decomposition product of said liquid precursor, for example carbon, into the pores of the porous structure, characterized in that the flow of the liquid precursor entering the porous structure is reduced, for example by means of a filter (52) made of polytetrafluorethylene surrounding the structure so as to reduce the vaporization phenomenon of the liquid precursor around the porous structure to be densified.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

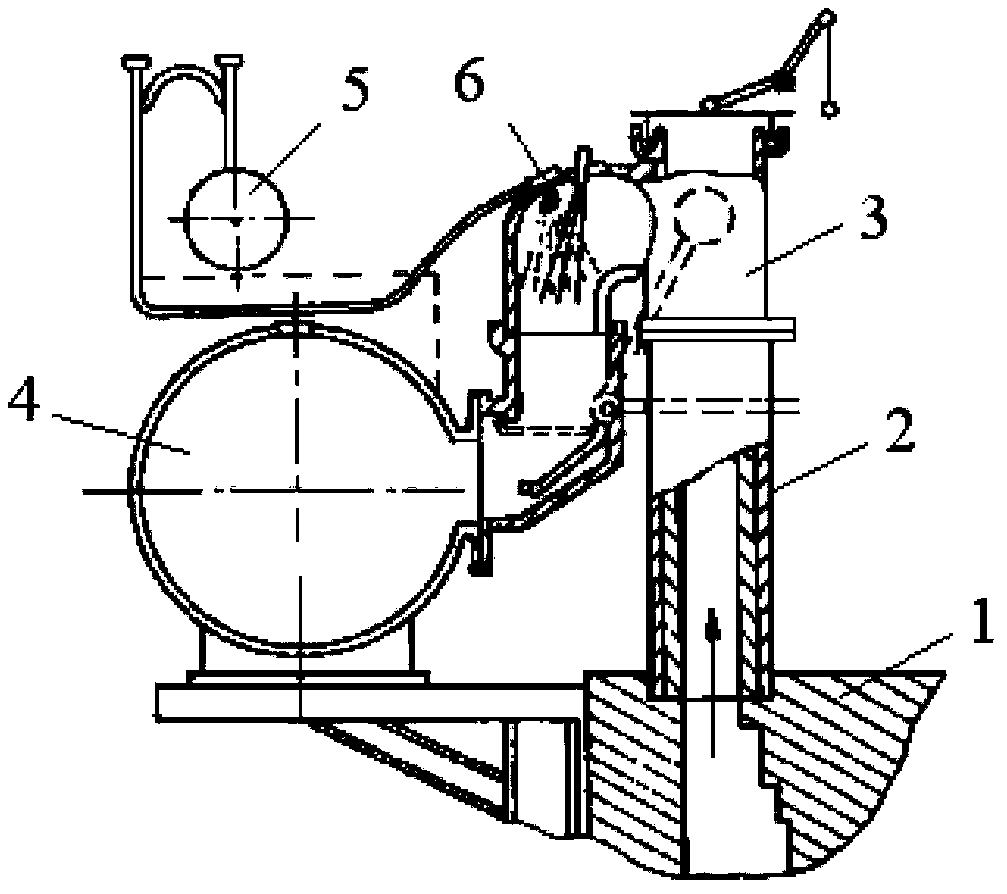

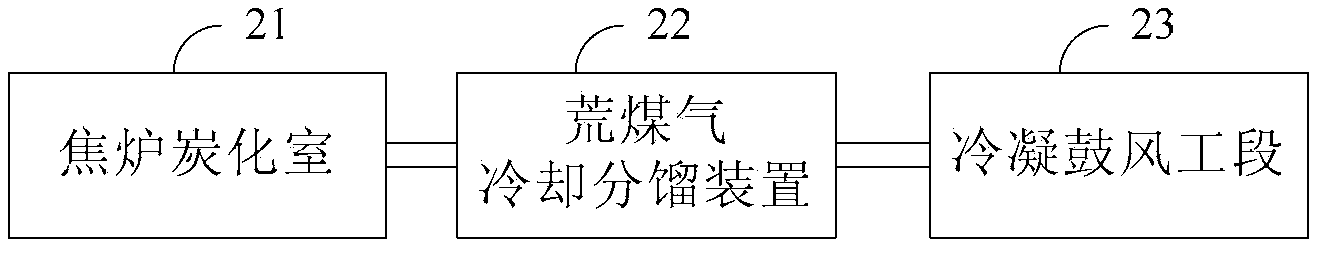

Raw gas cooling and fractionation method and coking apparatus

ActiveCN103509608AImprove recycling efficiencyReduce energy consumptionGas purification by non-gaseous materials condensationDistillation gas withdrawalBoiling pointFractionation

The invention provides a raw gas cooling and fractionation method and a coking apparatus. The raw gas cooling and fractionation method is used for recycling raw gas discharged from a coking chamber of a coke oven; according to the method, the raw gas discharged from the coking chamber of the coke oven is cooled step by step, and different fractions in the raw gas are extracted step by step according to the boiling points of the fractions in the sequence from high boiling point to low boiling point. With the raw gas cooling and fractionation method, energy consumption and pollution are reduced, production cost is lowered down, and recovery efficiency of the raw gas is improved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

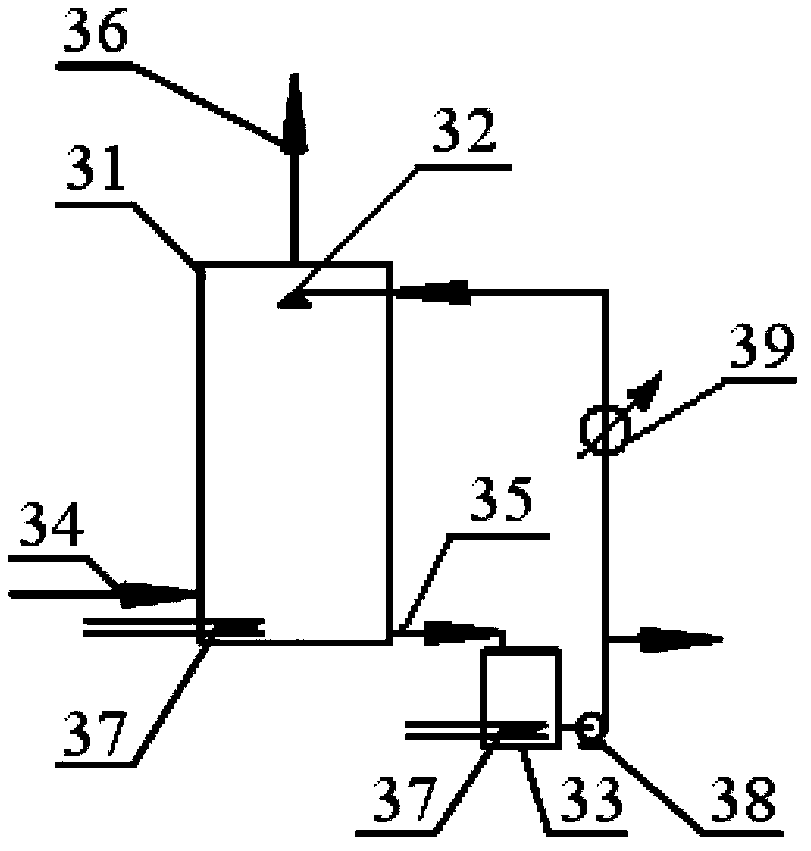

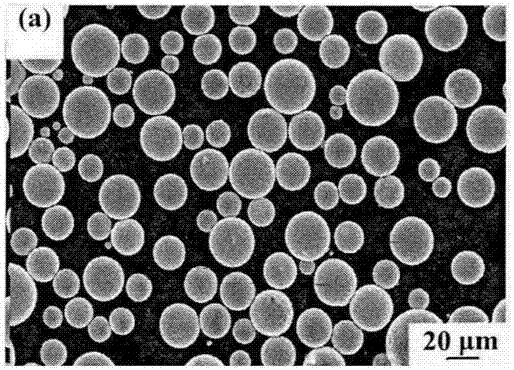

Preparation method and application of high-purity dense spherical molybdenum powder

ActiveCN107309434AHigh purityLow costAdditive manufacturing apparatusMolten spray coatingImpurityParticle-size distribution

The invention provides a preparation method and application of high-purity dense spherical molybdenum powder and belongs to the technical field of spherical metal powder material preparation. Conventional reduction molybdenum powder serves as the raw material, the particle size range of the granulated molybdenum powder is controlled actively by adjusting the granulation process, the molybdenum powder subjected to degumming, impurity removal and sintering is further screened, the particle size of the granulated molybdenum powder before plasma spheroidizing is effectively controlled, and it is beneficial to granularity control over the final granulated molybdenum powder. The particle size distribution of the molybdenum powder subjected to granulation and screening processing is narrow, vaporization and the burning loss of the molybdenum powder in the plasma spheroidizing process can be effectively lowered in cooperation with spherification process parameters, such as the input power, the powder feeding rate and the gas flow, it is beneficial to stability of the production process, and production efficiency and product quality are greatly improved; through introduction of hydrogen gas into the degumming, impurity removal and sintering processes of the molybdenum powder, the impurity content of the molybdenum powder before spherification is effectively lowered; and meanwhile, screening, spherification, cooling and collection of the molybdenum powder are all operated under the protection atmosphere of argon gas, and the oxygen content of a product is effectively lowered.

Owner:云航时代(重庆)科技有限公司

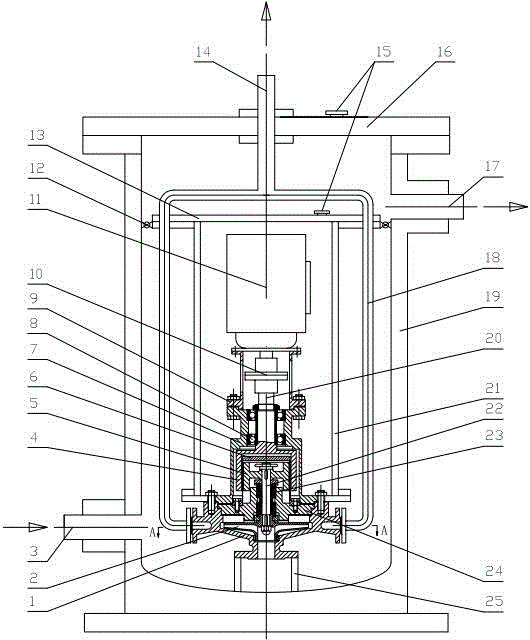

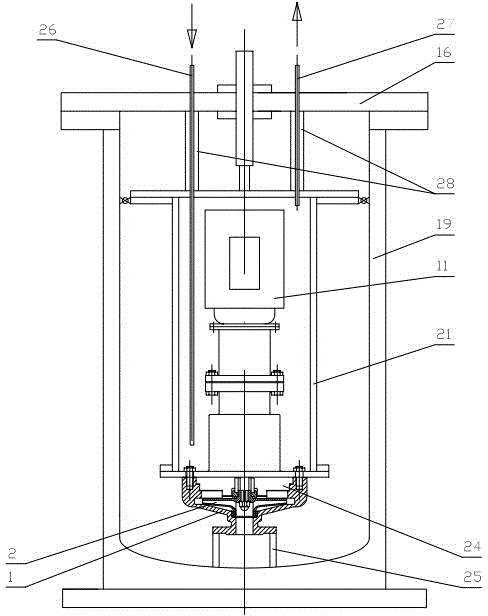

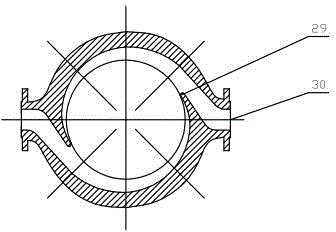

Submerged double-discharging magnetic driving pump for conveying liquefied natural gas

ActiveCN104564711ACompact structureReasonable structurePump componentsPump installationsImpellerEngineering

The invention provides a submerged double-discharging magnetic driving pump for conveying liquefied natural gas. The submerged double-discharging magnetic driving pump for conveying the liquefied natural gas comprises an external high vacuum heat insulation container which is that an evaporated gas outlet is formed in the upper part of one sidewall and while a liquefied natural gas inlet is formed in the lower part of the other sidewall, and an outer sealing cover is mounted on the top part through a flange; an internal high vacuum heat insulation container is mounted inside, and an inner sealing cover is mounted on the top part of the internal high vacuum heat insulation container through the flange; a liquefied natural gas outlet is formed in the center of the inner sealing cover; an impeller housing is fixed to the inner wall of the bottom part of the external high vacuum heat insulation container by axial supporting, and an impeller is mounted to the impeller housing through a central shaft; the upper part of the impeller housing is fastened to the bottom part of the internal high vacuum heat insulation container through a fastening part; a connecting seat is mounted in the impeller housing; a central shaft is mounted in the middle part of the connecting seat through a sliding bearing and extends into the internal high vacuum heat insulation container; a submerged double-discharging magnetic part is mounted at the central shaft. The submerged double-discharging magnetic driving pump is compact and reasonable in structure, convenient to operate, high in sealing performance, safe and reliable to use, and low in vibration noise.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

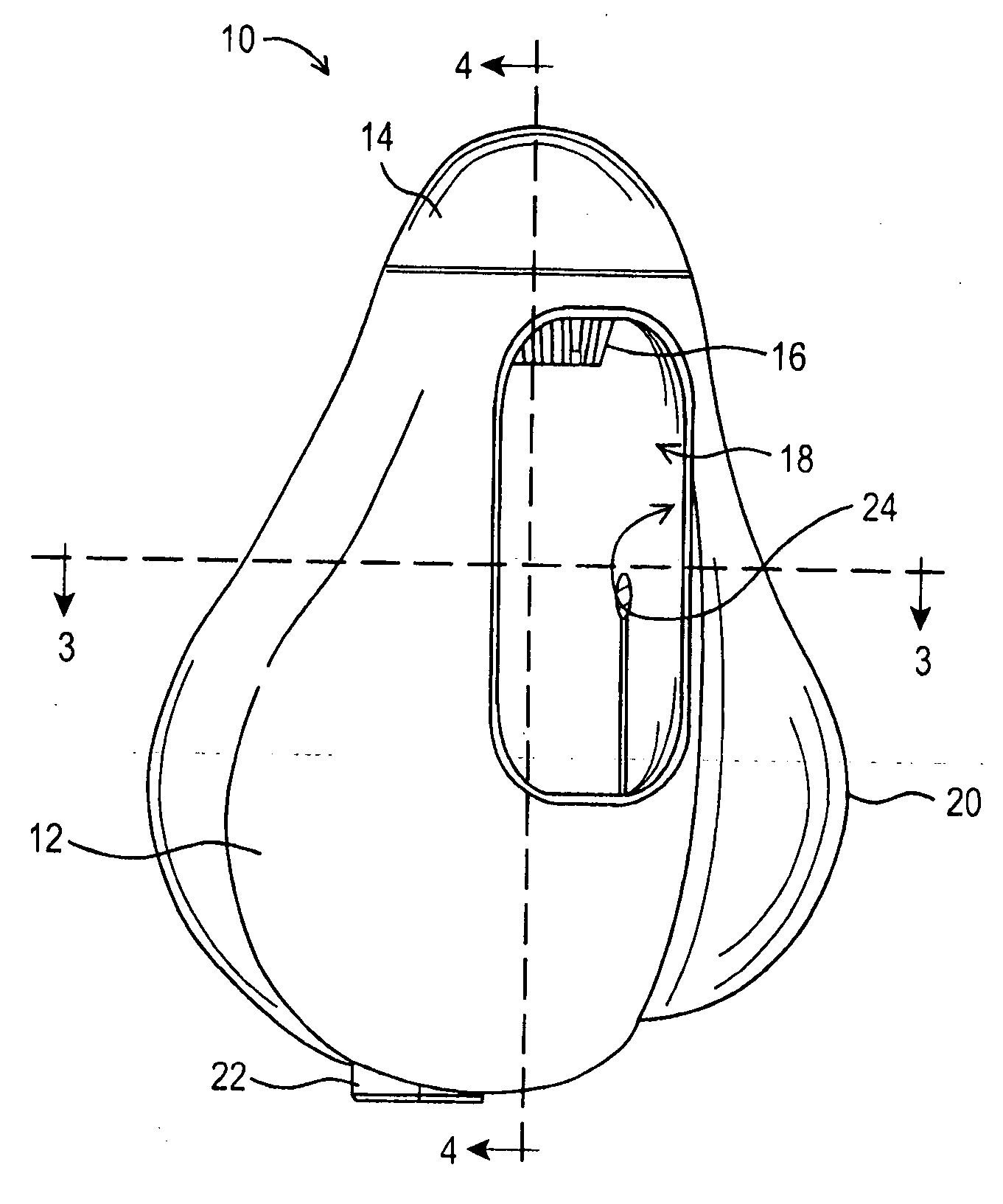

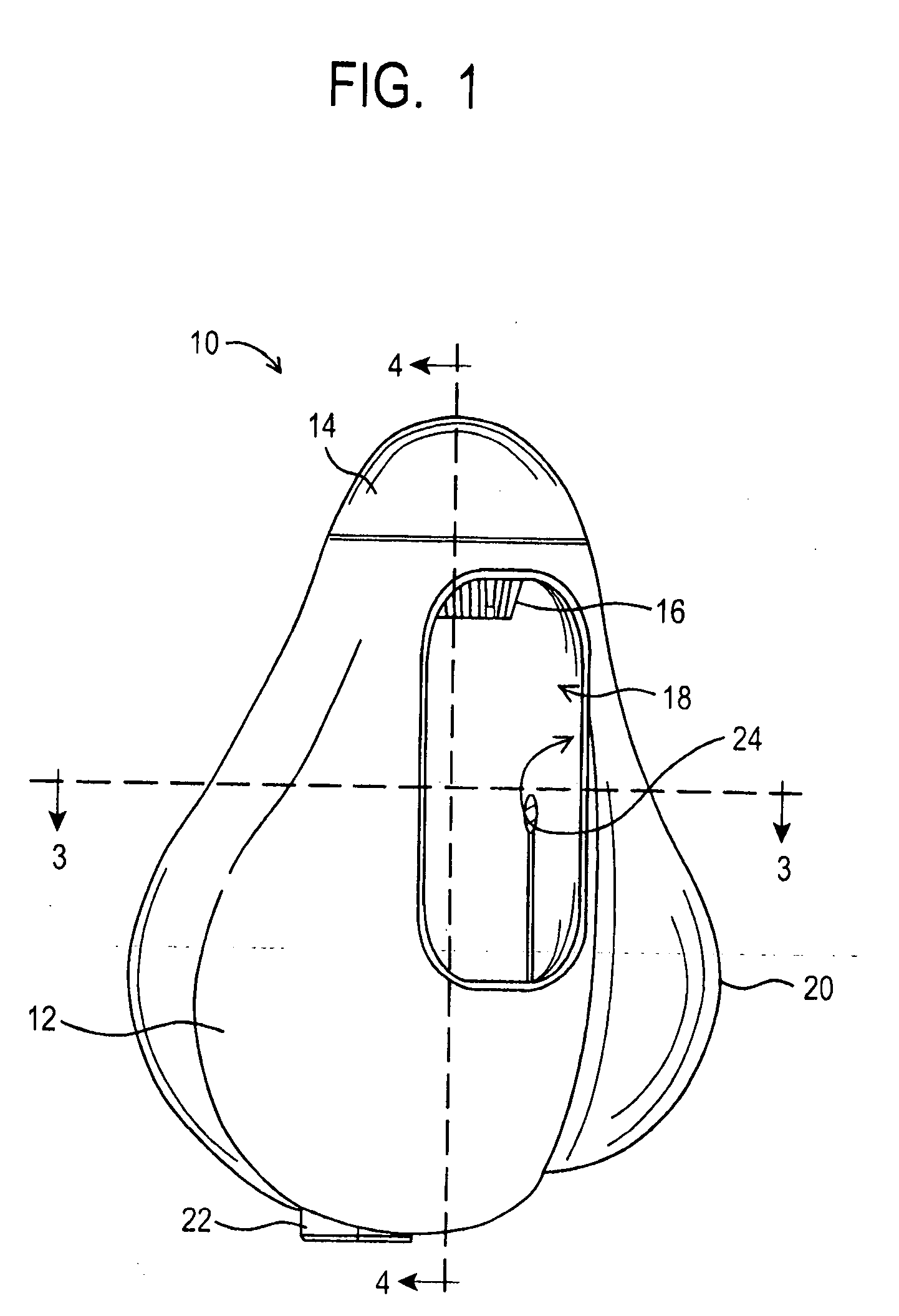

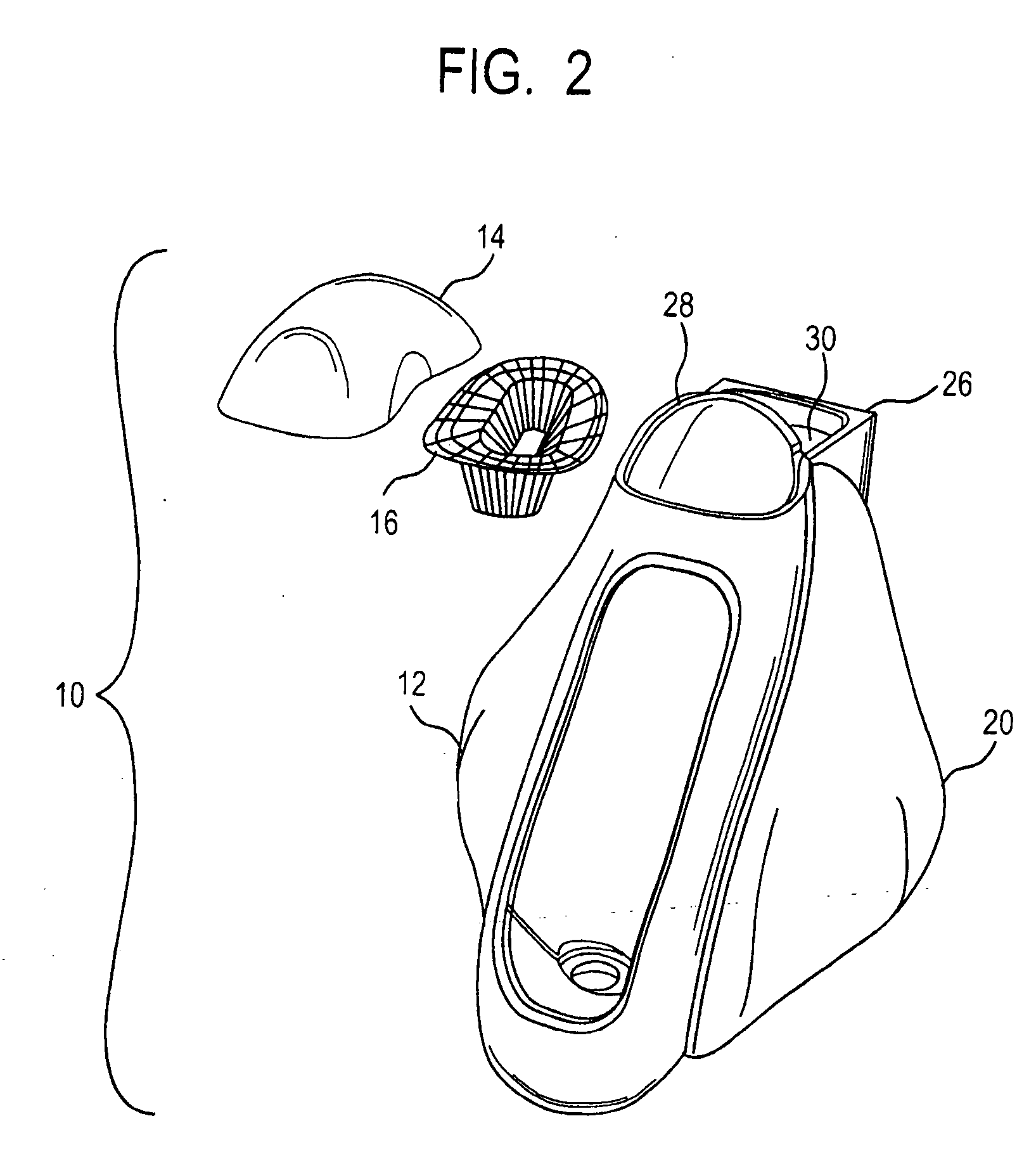

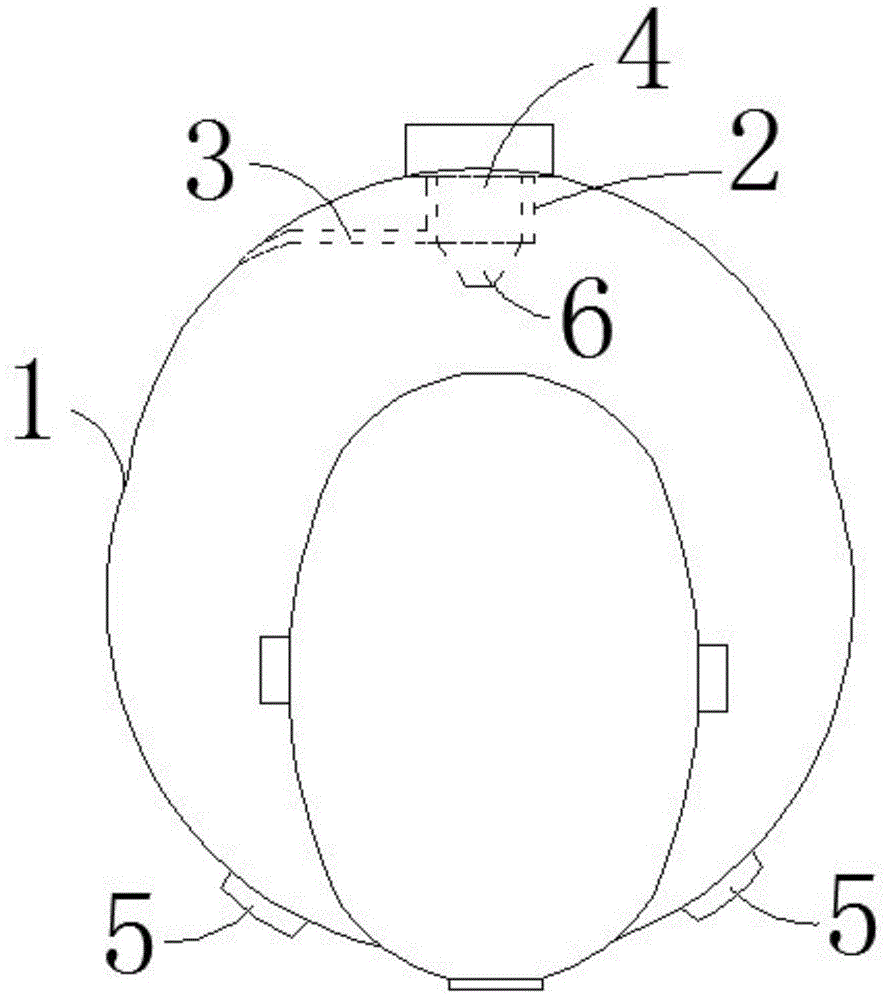

Anti-splashback urinal

ActiveUS20070151011A1Reduce splashbackReduce vaporizationUrinalsFlushing devicesDraining tubeAir filter

An anti-splashback urinal, comprising a bowl for receiving a user's urine, the bowl having a surface with a curvilinear shape designed to reduce the angle of impact between the urine and the surface and to carry the urine down and away from a user; an aperture, through which the user deposits the urine into the bowl, the aperture being off-center with respect to the bowl; and a drain that is offset aligned from the aperture. The urinal may also include a custom outer cover having a shape and color / pattern to complement the room. In a preferred embodiment of the invention, the urinal is equipped with a low flow flush system having an armature that dispenses water at a low flow rate. The armature preferably comprises a plumbing tubing bent into a shape complementary to said urinal, and equipped with misting nozzles. In a particular embodiment, the urinal further comprises an air filter, which optionally may be a water stripper, connected to an air exhaust system, wherein air from the urinal enters the air exhaust system through the air filter, and wherein the air exhaust system is connected to a fan.

Owner:BROWN CHAD

Method for planting polygonatum cyrtonema

InactiveCN105594426AGrowth inhibitionReduce entryCultivating equipmentsPlant cultivationIsolation effectPesticide residue

The invention discloses a method for planting polygonatum cyrtonema. The method comprises the steps of site selection, land preparation, seed selection and planting, weeding, topdressing, timely irrigation and drainage, bud removal, disease and pest control and harvesting. According to the method, rice husk is adopted for coverage to preserve heat and moisture, the conditions of soil watering hardening are effectively avoided, the good breathability of soil is maintained, and the respiration effect of plant rhizomes is promoted. Due to the isolation effect of the rice husk, worm eggs and grass seeds can be effectively prevented from entering soil of the earth's surface, the investment on pest and disease control and intertillage weeding is reduced, pesticide residue is avoided, the green and pollution-free production is achieved, and the quality of polygonatum cyrtonema is guaranteed. According to the method, after the harvesting of polygonatum, the rice husk can be subject to steam sterilization and then be subject to waterlogged compost to serve as base fertilizer, not only can further improve soil structure, but also can reduce invested cost.

Owner:ANHUI SUNRICH AGRI COMPREHENSIVE DEV CO LTD

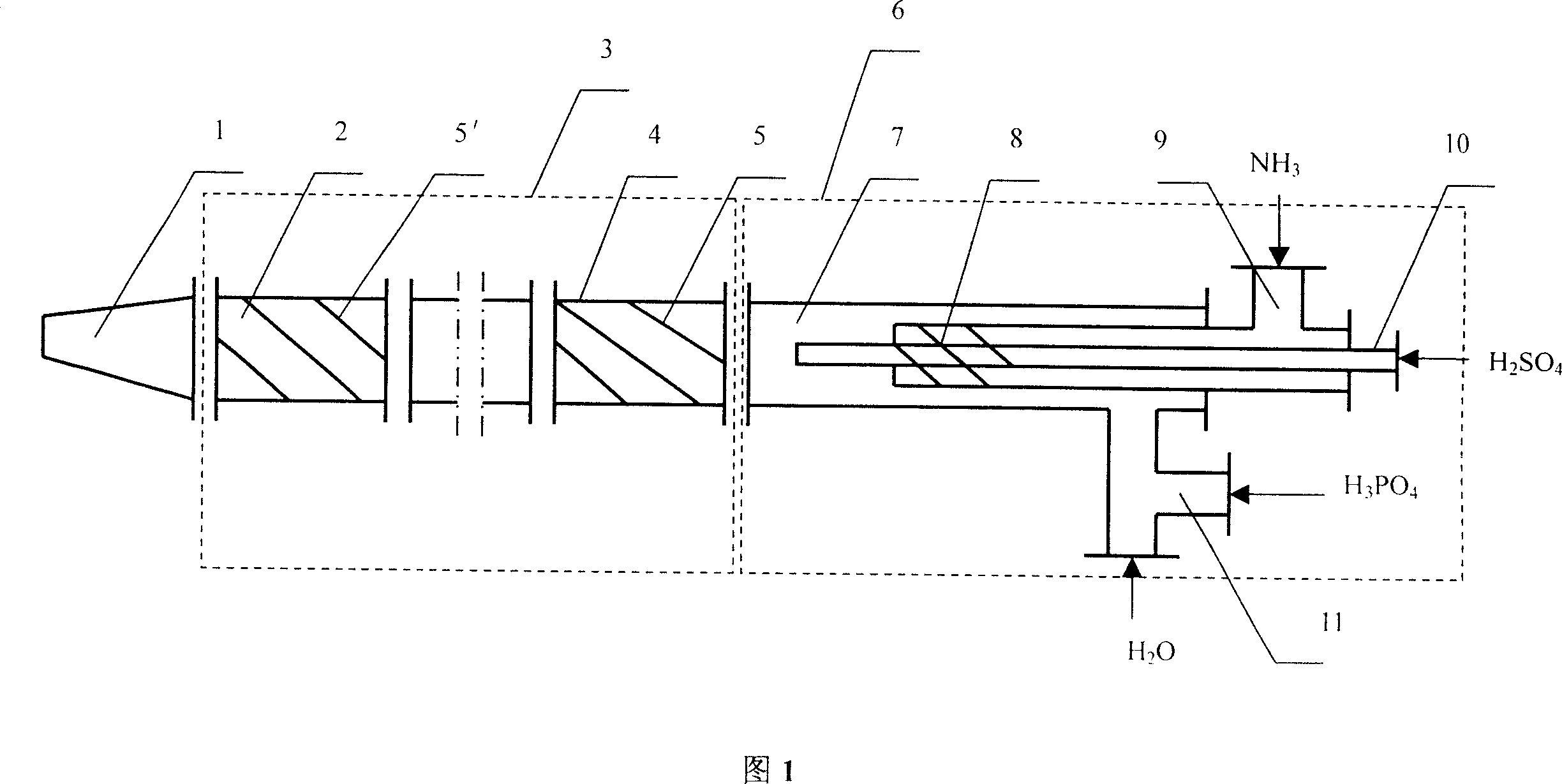

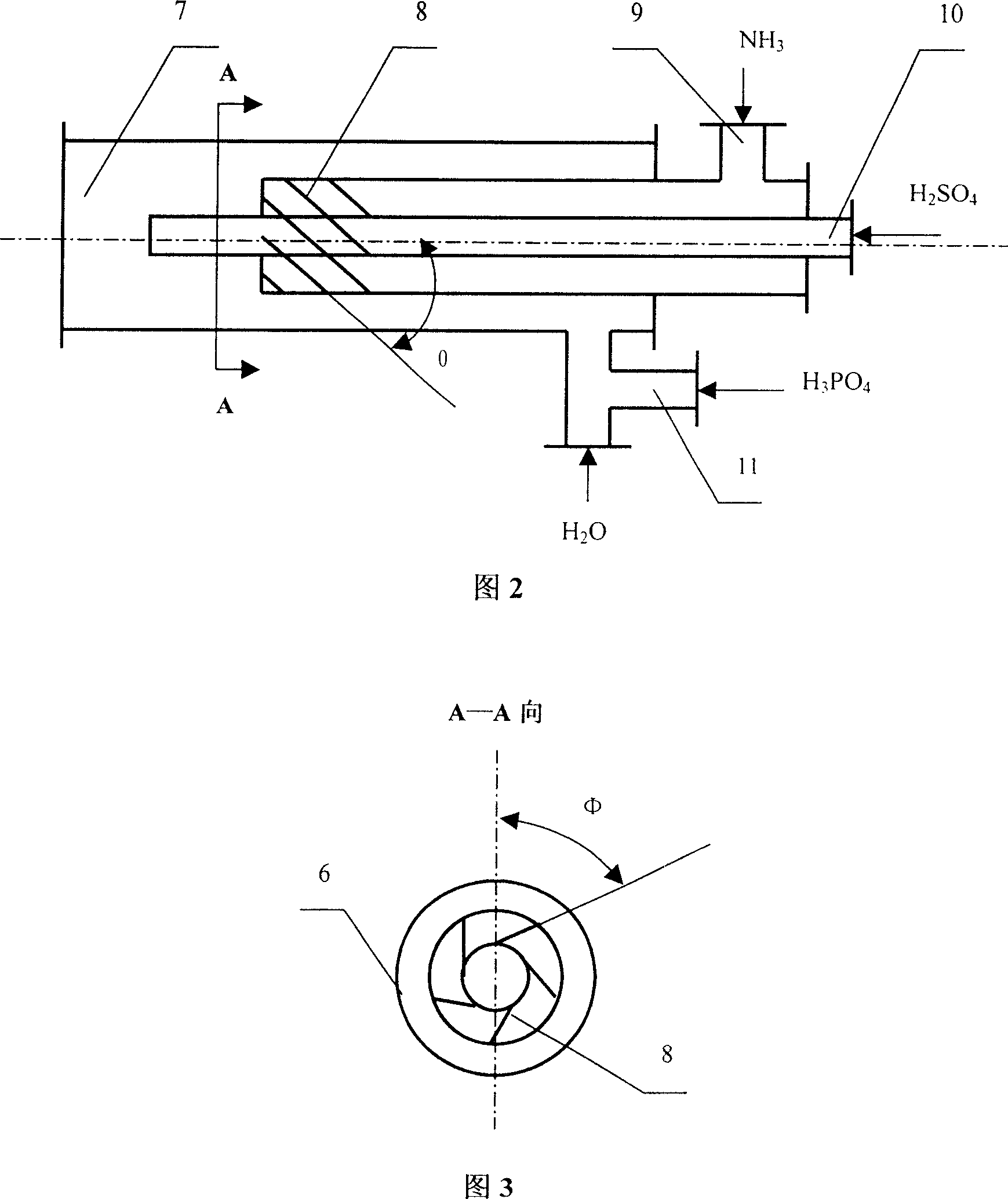

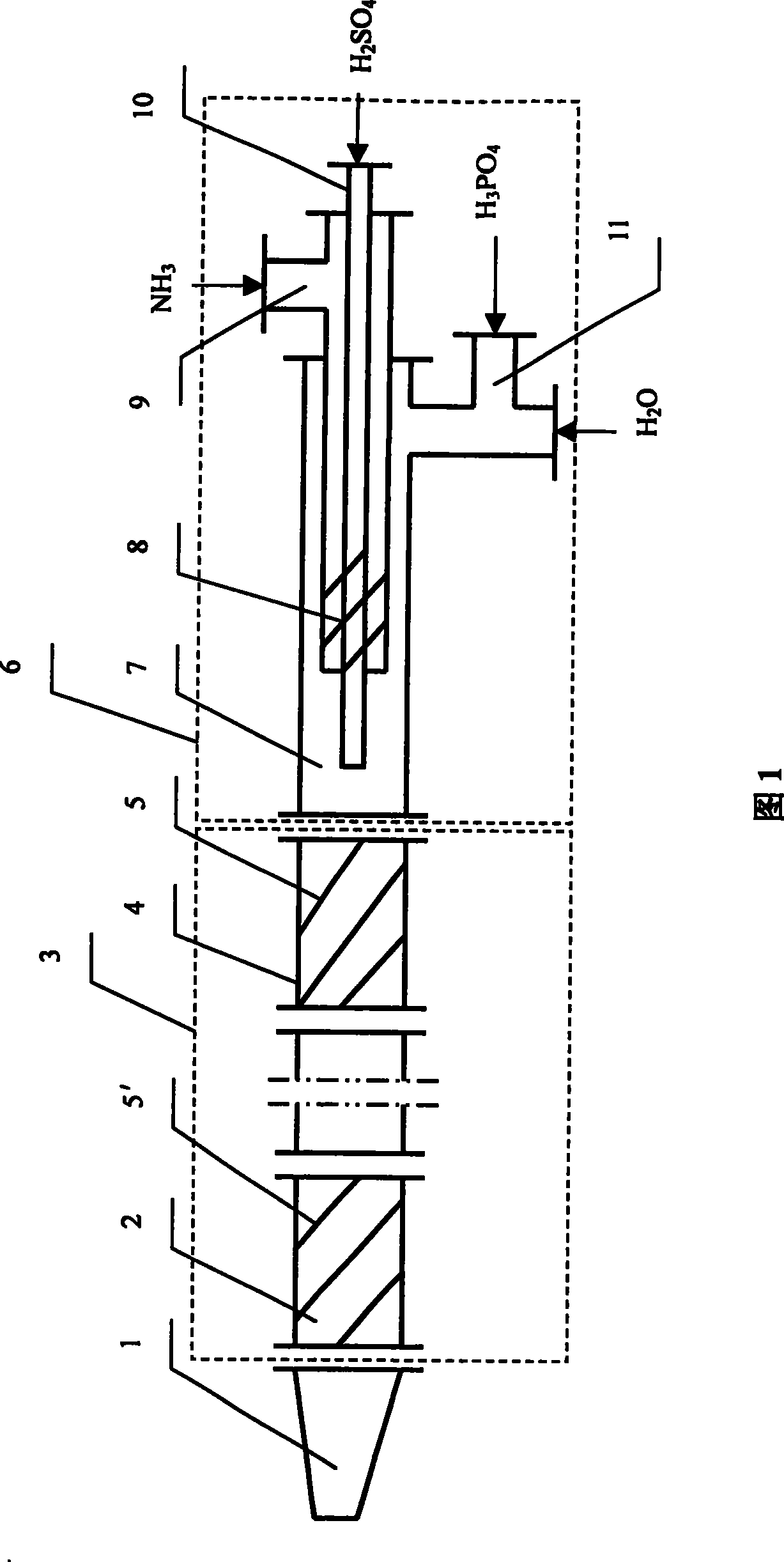

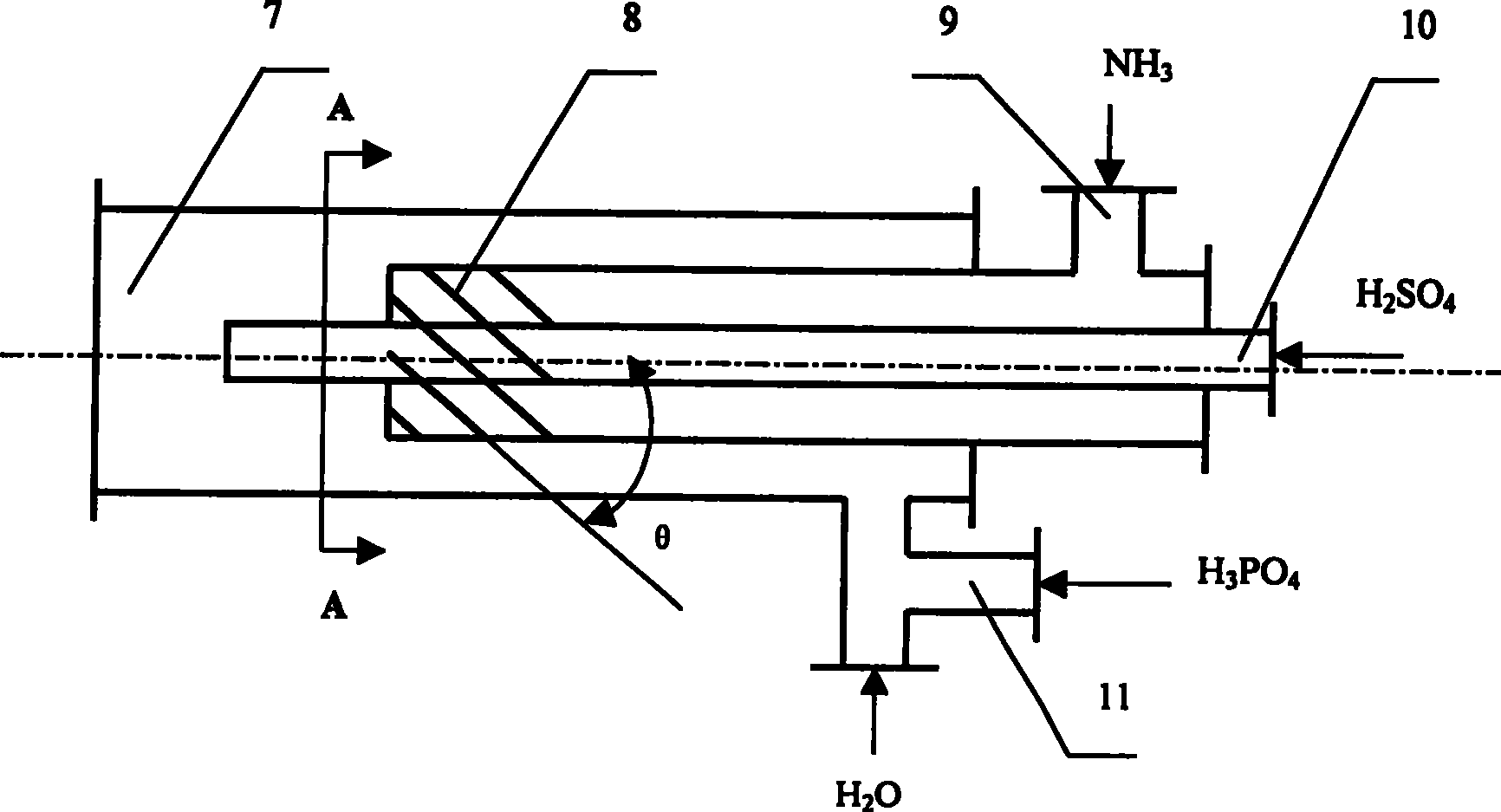

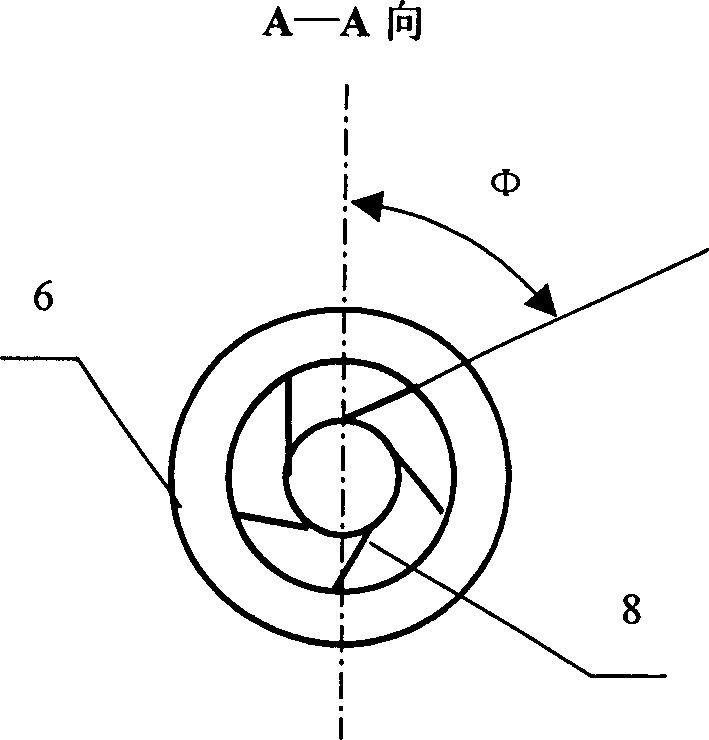

Improved tubular reactor

InactiveCN1986042ADissolve fastLess corrosiveAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersGas phaseSlurry

The improved tubular reactor includes one reactant mixing section, one reactant reacting section and one reaction product outputting nozzle. It features the reactant mixing section with one spiral jetting mixer and the reactant reacting section with one spiral mixer. The material contact order and the spiral jetting mixer in the reactant mixing section are regulated properly to control the mixing degree, contact area and reaction speed to ensure homogeneous mixing of the materials and moderate reaction speed. The spiral mixer in the reactant reacting section mix the gas phase, the liquid phase and the solid phase gradually for homogeneous, smooth, mild and full reaction to form high quality well atomized slurry.

Owner:中国-阿拉伯化肥有限公司

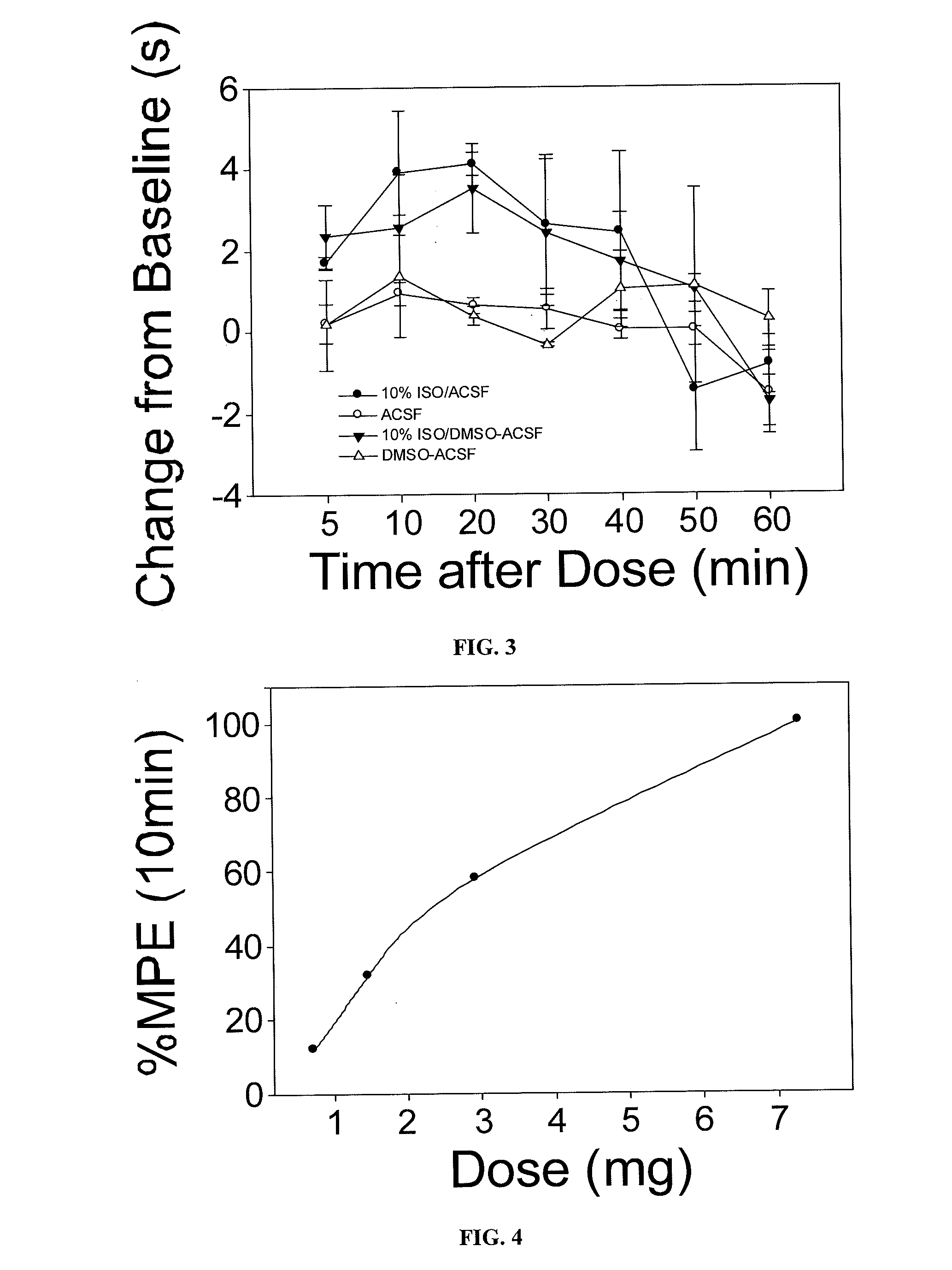

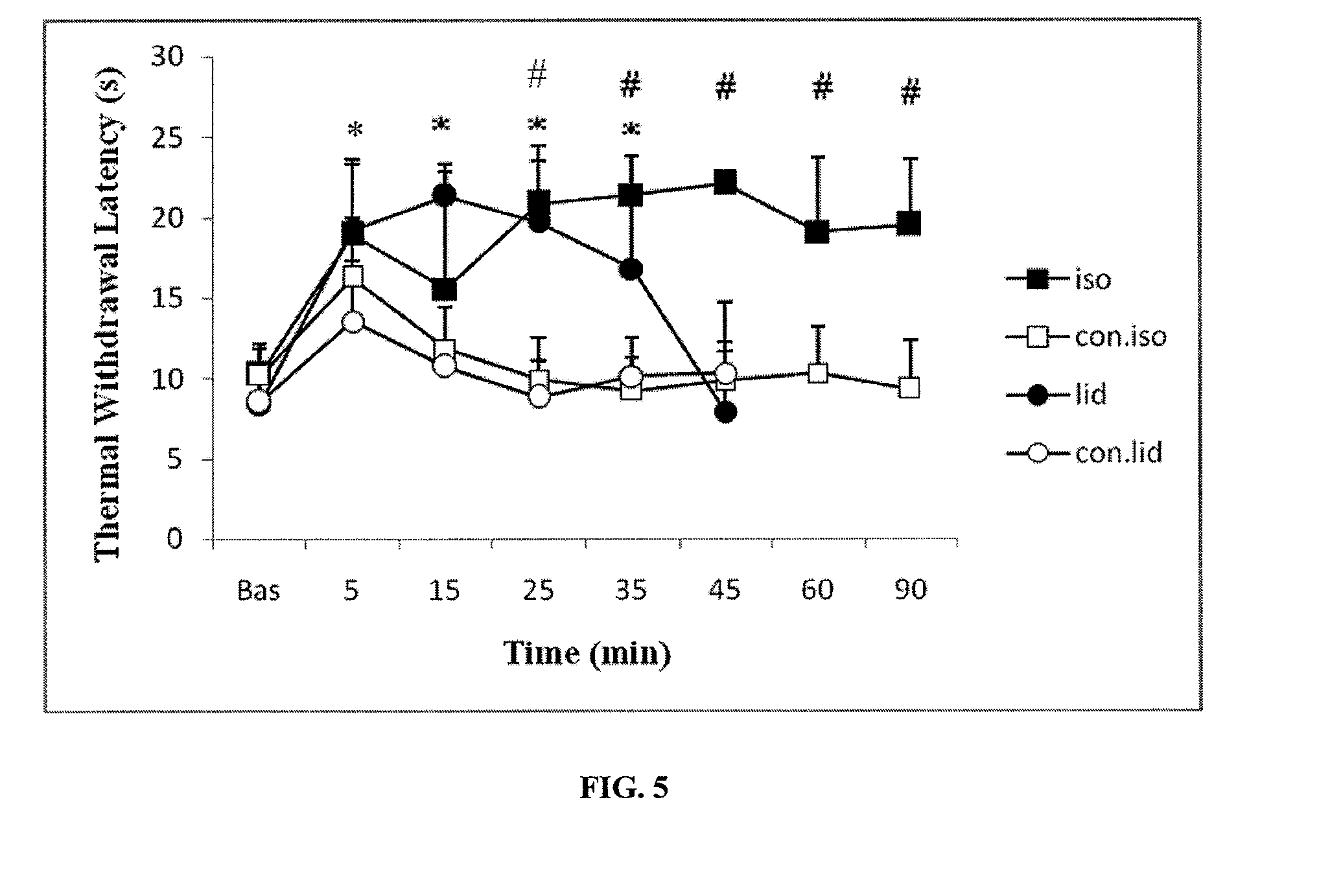

Volatile anesthetic compositions comprising extractive solvents for regional anesthesia and/or pain relief

ActiveUS20110039944A1Rapidly titratableRapid onsetHalogenated hydrocarbon active ingredientsBiocideRegimenSolvent

The present invention provides methods for reducing pain in a subject in need of such pain reduction by delivering, e.g., intrathecally or epidurally, a volatile anesthetic dissolved in a solution comprising an extractive solvent, e.g., DMSO or NMP, in an amount effective to reduce pain. Chronic or acute pain may be treated, or the anesthetic may be delivered as a regional anesthesia to a subject to anesthetize a portion the subject prior to a surgery, hi certain embodiments, isoflurane, halothane, enflurane, sevoflurane, desflurane, methoxyflurane, or mixtures thereof may be used. Dosing regimens including a one-time administration, continuous and / or periodic administration are contemplated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Preparation method for hexamethylene diisocyanate biruet

ActiveCN102702476AHigh yieldReaction is easy to controlUrea derivatives preparationOrganic compound preparationDiluentSolvent

The invention discloses a preparation method for hexamethylene diisocyanate biruet, according to the method, azeotrope formed by a mixture of deionized water and a polar aprotic solvent is heated into a temperature of 30-100 DEG C; hexamethylene diisocyanate monomer is put into a reactor, and the temperature is maintained at 90-140 DEG C; the azeotrope is dropped into the reactor at a dropping speed of 0.05-0.20g / min; the temperature is increased into 110-150 DEG C in a mixing state, and the azeotrope is reacted for 1-4h; the temperature is reduced below 40 DEG C for cooling and discharging; and the discharging material enters into a separation device for separating a solvent and hexamethylene diisocyanate biruet ingredient, and a solid content of hexamethylene diisocyanate biruet ingredient is adjusted between 50 percent and 90 percent by a diluent. According to the preparation method, new solvent is not needed for addition, production formula and operation process are not required to be changed, only the monomer of isocyanate and water are added to realize continuous production, and the real clean production is realized via zero-release.

Owner:SOUTH CHINA UNIV OF TECH +1

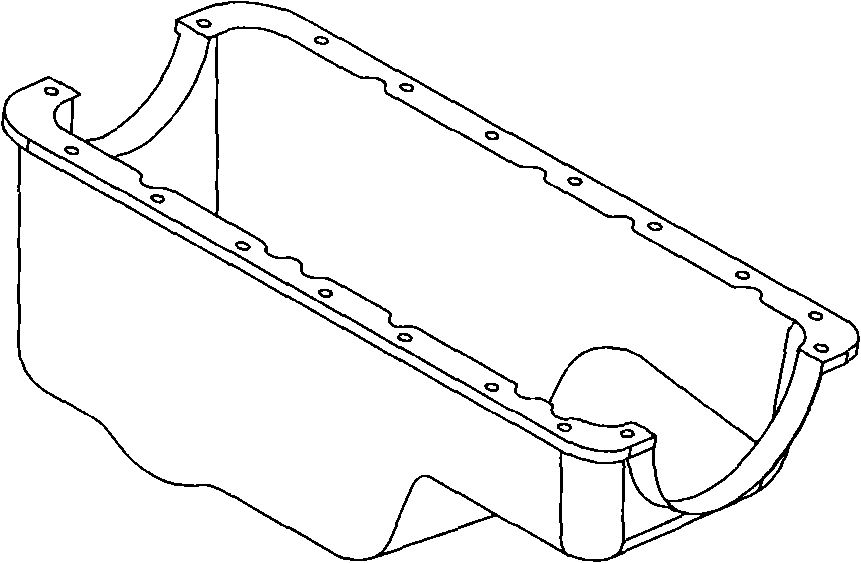

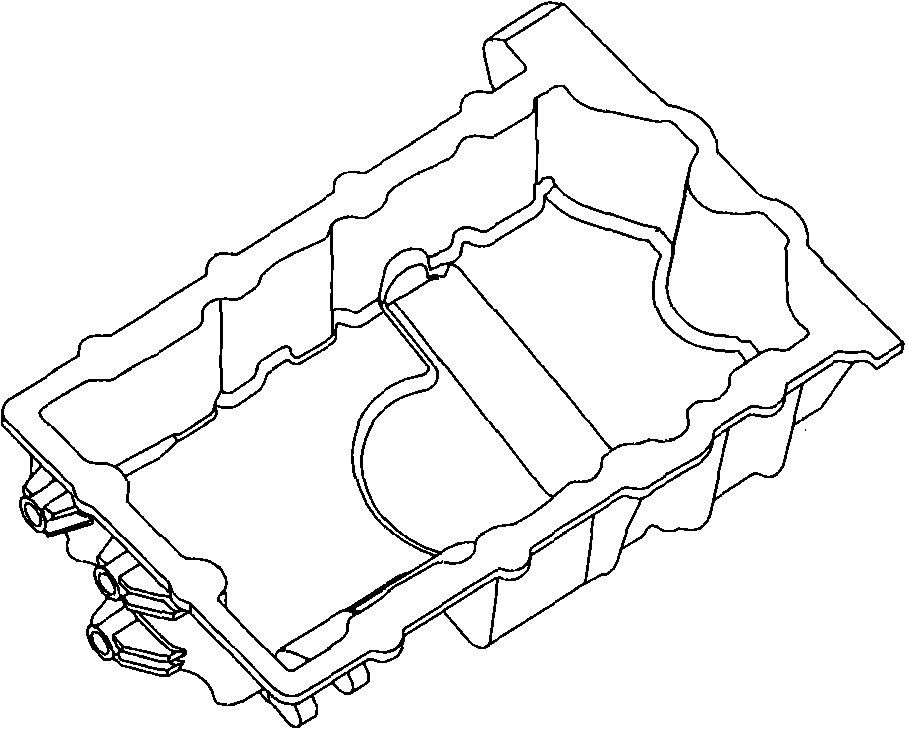

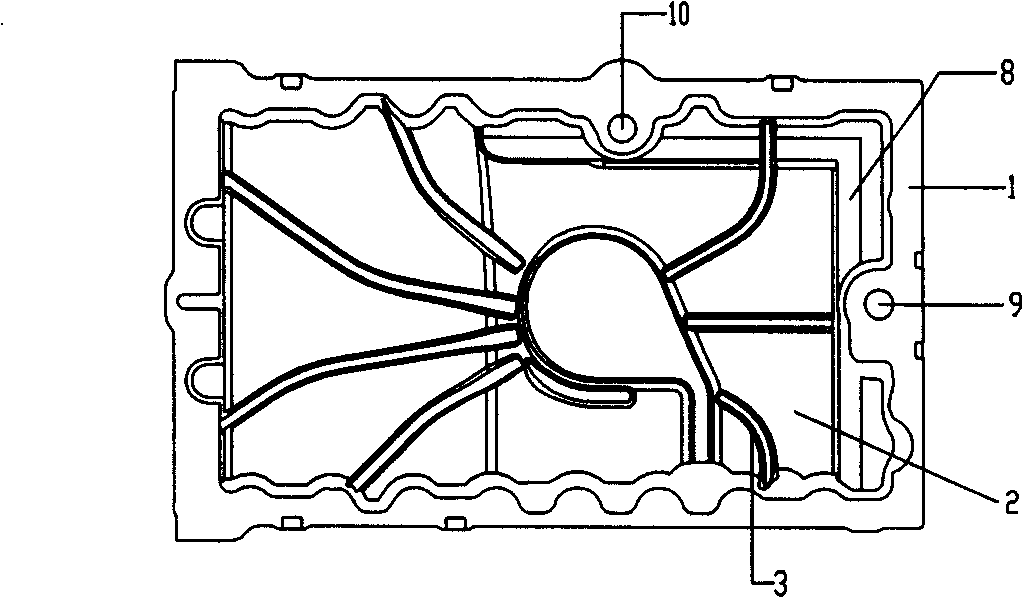

Engine oil bottom shell

InactiveCN101265821ANot easy to leakReduce noiseMachines/enginesEngine lubricationSEMI-CIRCLEHigh pressure

The invention provides an oil pan for motors, which comprises a large end face of the oil pan, an internal cavity of the oil pan, a back end face and a bottom of the oil pan, and is characterized in that the internal cavity of the oil pan is provided with internal cavity reinforcement that can reinforce and reduce noises; the bottom of the oil pan is provided with bottom reinforcement; the back end face of the oil pan is provided with back end reinforcement; the back end face of the oil pan is designed into a semi-circle shape, which is similar to the end face shape of the gear-box, and two bolt holes that connect the oil pan and the gear-box are added on the back end face of the oil pan, so the oil pan can be connected with the gear-box directly. The oil pan is set higher than the high-pressure oil channel to favor the arrangement of the whole machine. As the twisted reinforcement that can reinforce and reduce noises are arranged in the internal cavity and the bottom of the oil pan, the noise of oil pan is reduced. As two bolt holes that connect the oil pan and the gear-box are added on the back end face of the oil pan, the oil pan can be connected with the gear-box directly, thereby reducing the guard plates for the motor and the gear-box, reducing the procedure for assembly and reducing the cost. As the high-pressure oil channel is arranged in the internal cavity of the oil pan, the oil channel can convey the high-pressure oil from the oil pump to the motor frame, which is favorable to the arrangement of the whole machine.

Owner:CHERY AUTOMOBILE CO LTD

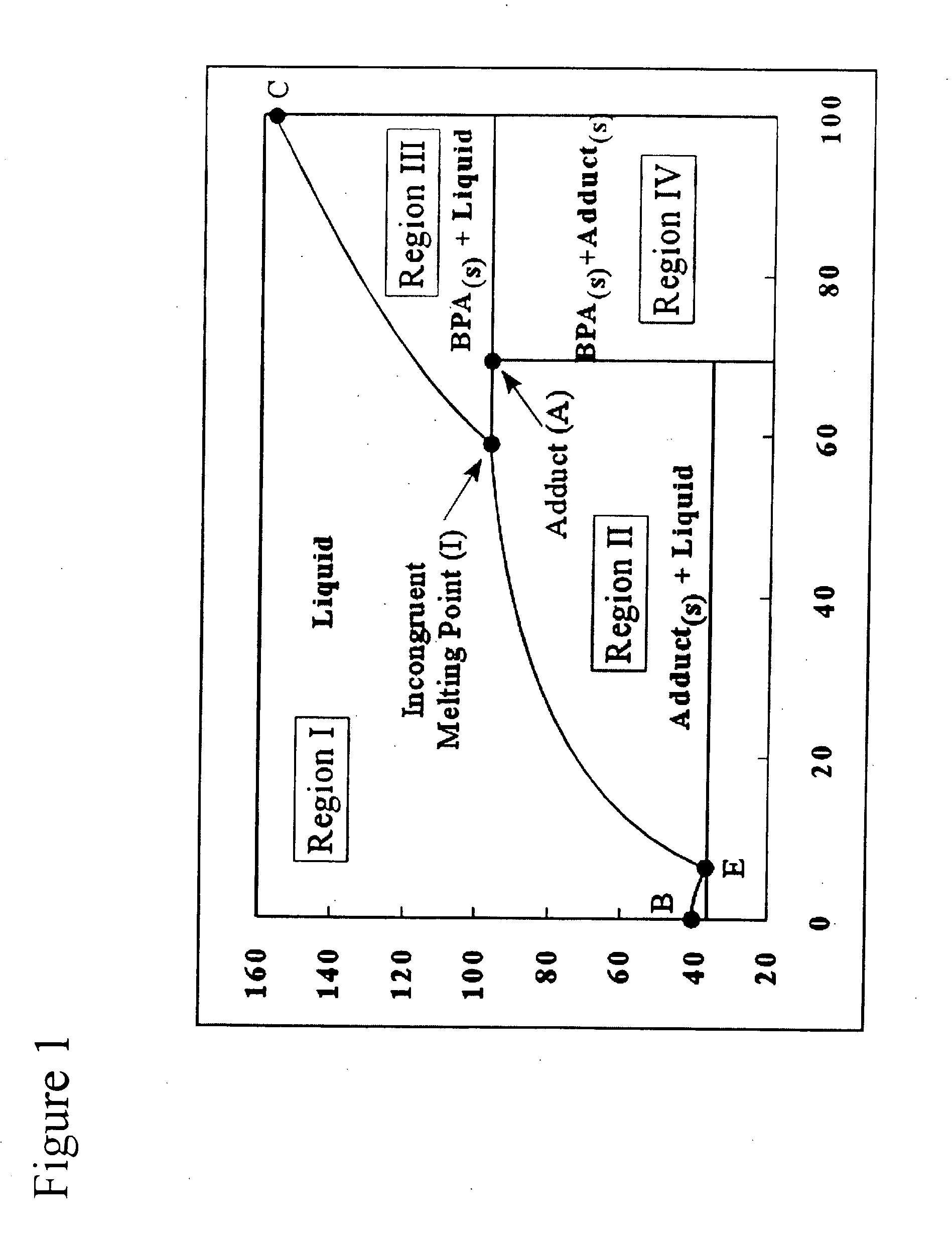

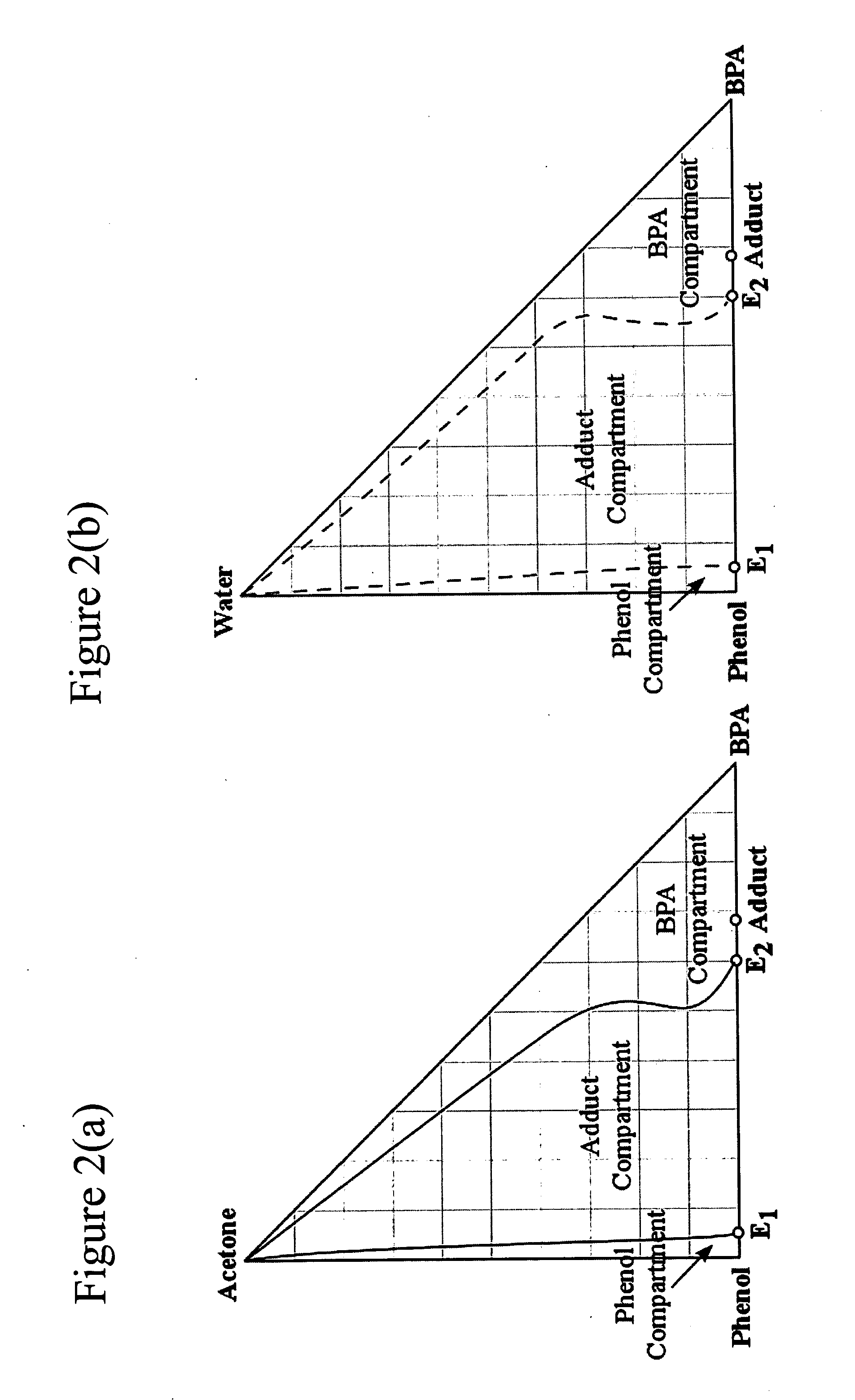

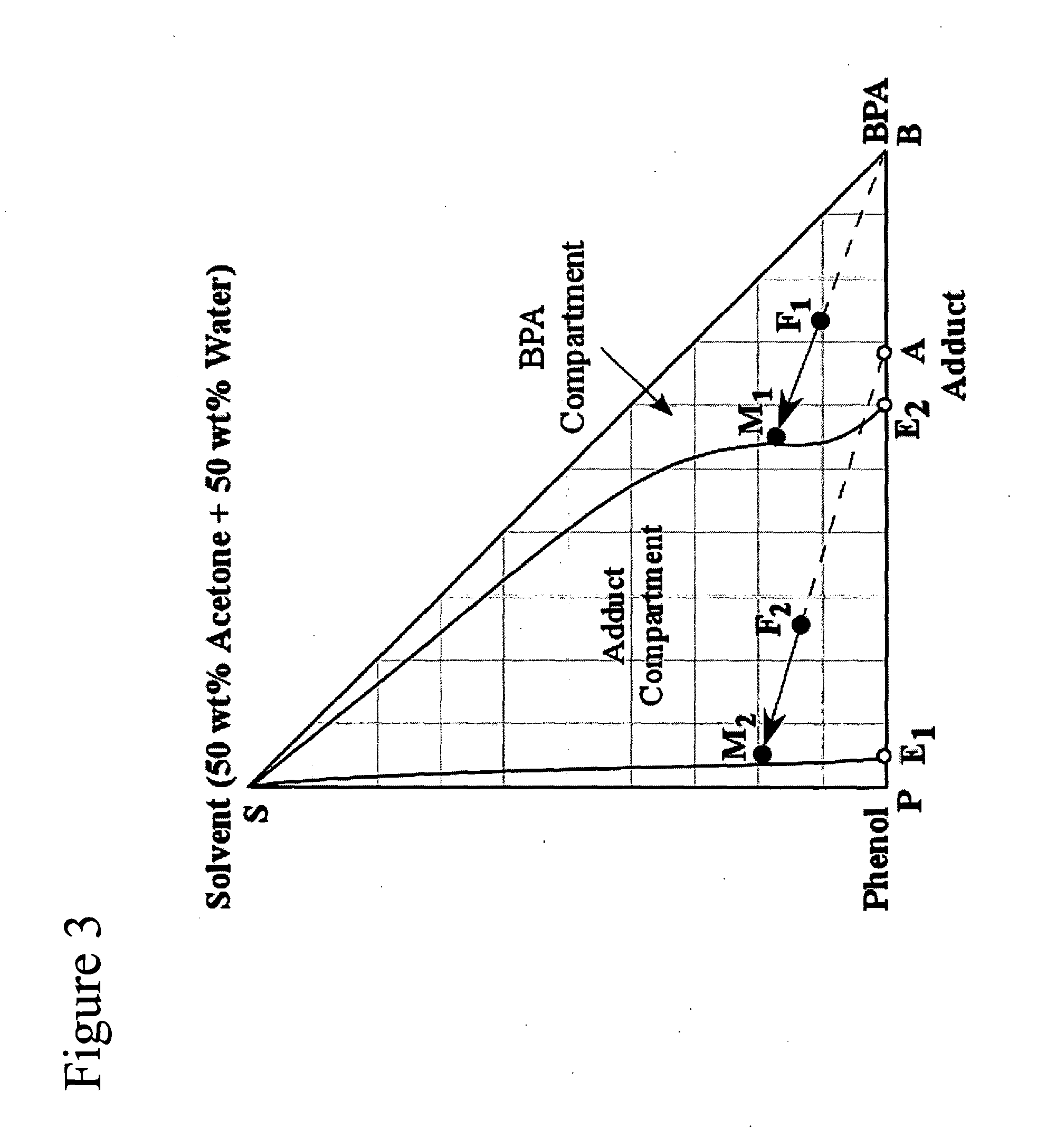

System and method of producing bisphenol-A (BPA) using two stage crystallization

InactiveUS20050075520A1Eliminate needInexpensive systemOrganic chemistryOrganic compound preparationSolventPhenol

A system and method are provided wherein the phase equilibrium of a system comprised of Phenol, Bisphenol-A and a solvent mixture comprising Acetone and Water is selectively controlled such that either crystalline Bisphenol-A, or an adduct of Bisphenol-A and Phenol is crystallized from the product solution. The present invention provides for the recovery of pure Bisphenol-A (BPA) by direct crystallization from solution.

Owner:MITSUBISHI CHEM CORP

Volatile anesthetic compositions and methods of use

ActiveUS20130273141A1Excellent characteristicsImprove propertiesBiocideNervous disorderEmulsionSolvent

The present invention provides methods for reducing pain in a subject in need thereof by delivering a volatile anesthetic in a solution or an emulsion that can additionally include an extractive solvent in an amount effective to reduce pain without substantially interfering with motor function. Chronic or acute pain may be treated, or the volatile anesthetic may be delivered as a regional anesthetic to a subject to anesthetize a portion of the subject prior to surgery. Dosing regimes including a one-time administration, continuous and / or periodic administration are contemplated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

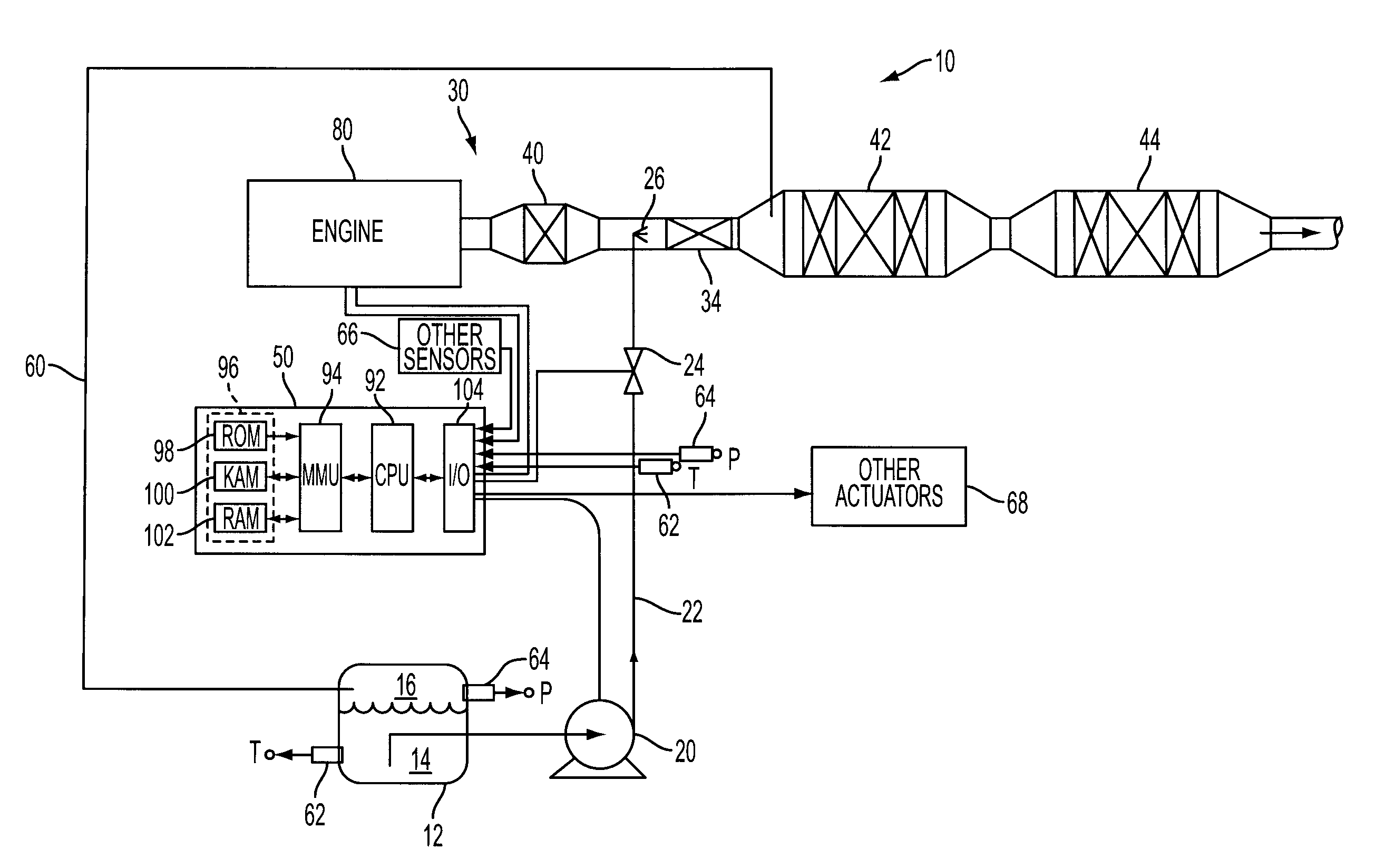

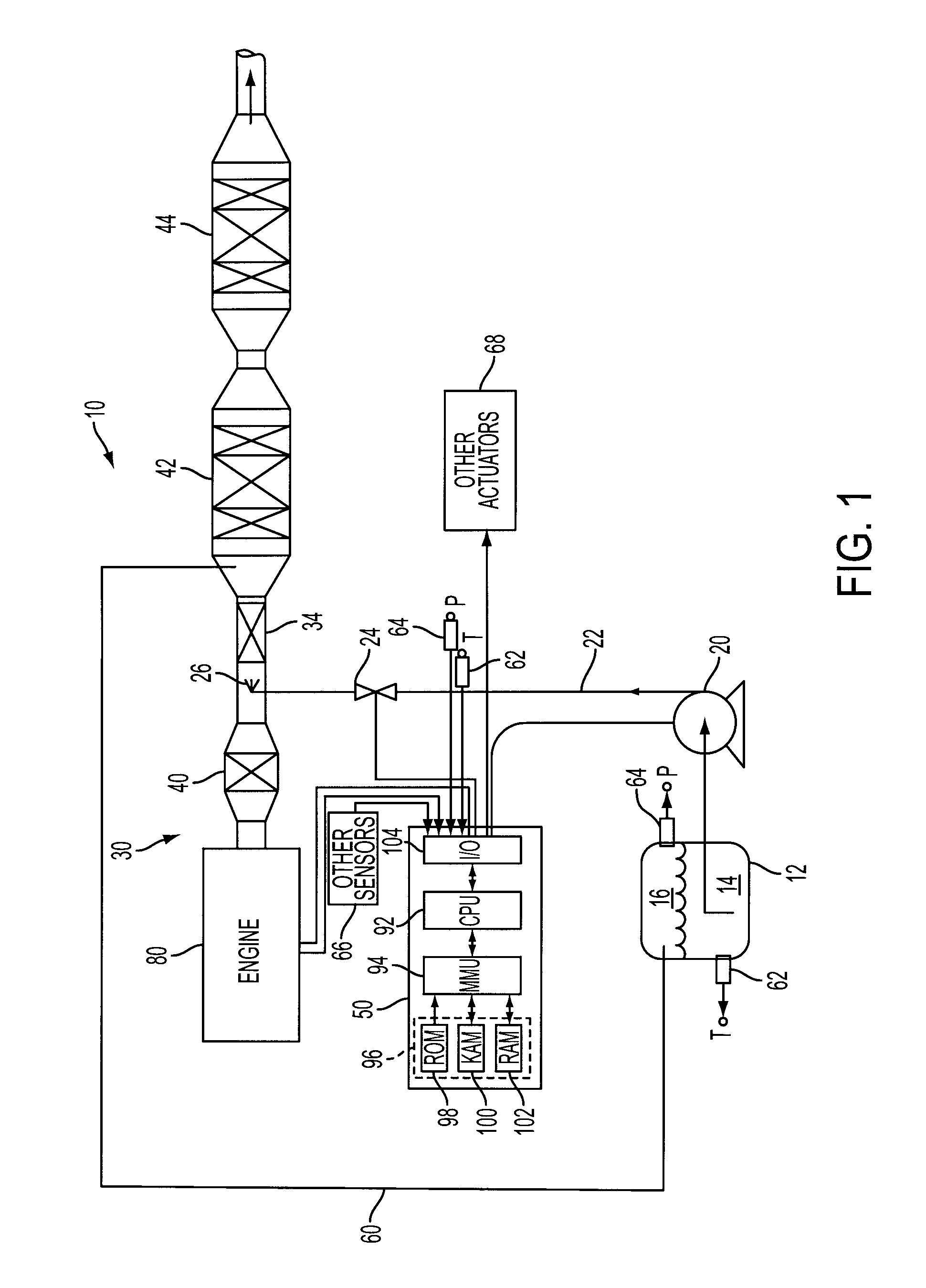

Venting of on-board vehicle emissions treatment system with pressure assist

InactiveUS20070289288A1Reduce vaporizationIncrease couplingInternal combustion piston enginesNon-fuel substance addition to fuelDistribution systemAutomotive engineering

A system and method for venting an on-board vehicle emissions treatment substance storage and distribution system that selectively dispenses an emissions treatment substance from a storage tank on the vehicle to an exhaust system of the vehicle include pressurizing the storage tank during engine operation and coupling the storage tank to the exhaust system upstream of an ammonia storage element to reduce and direct any escaping ammonia toward the rear of the vehicle away from a refueling location.

Owner:FORD GLOBAL TECH LLC

Method for combining coal tar fractional distillation and hydro-conversion

InactiveCN101629105AReduce total usageGood choiceTreatment with hydrotreatment processesCombined methodFractional distillation

The invention relates to a method for combining coal tar fractional distillation and hydro-conversion. Initial coal tar extracts a first fraction and a second fraction which have different boiling ranges in coal tar extraction parts; and the first fraction enters a first hydro-conversion part and the second fraction enters a second hydro-conversion part. By selecting each suitable hydro-conversion operation condition on fractions with different boiling ranges, the method has the advantages of optimized operation condition, stable operation, catalyst usage reduction, and operation period extension, and is particularly suitable for the large-scale hydro-conversion of full fraction coal tar.

Owner:何巨堂

Ignition energy control for mixed fuel engine

InactiveUS8584650B2Increase temperatureReduce vaporizationElectrical controlOther installationsEnergy controlEngineering

A method of operating an engine including varying a level of ignition energy provided to the engine during an engine start is provided. For example, the ignition energy level may be varied responsive to the amount of alcohol in fuel delivered to the engine in order to improve cold engine starting with higher alcohol fuels.

Owner:FORD GLOBAL TECH LLC

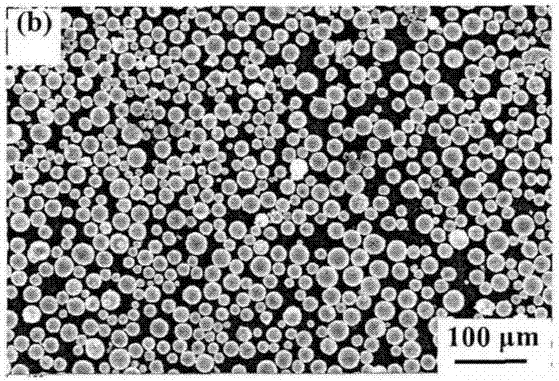

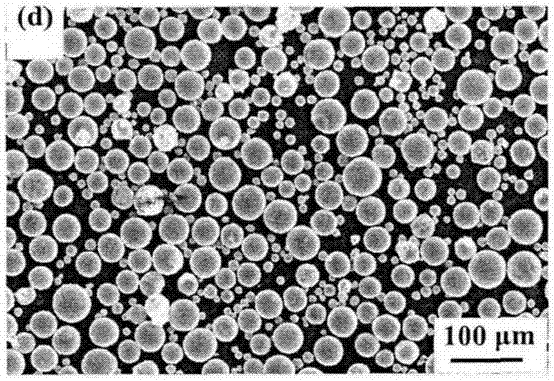

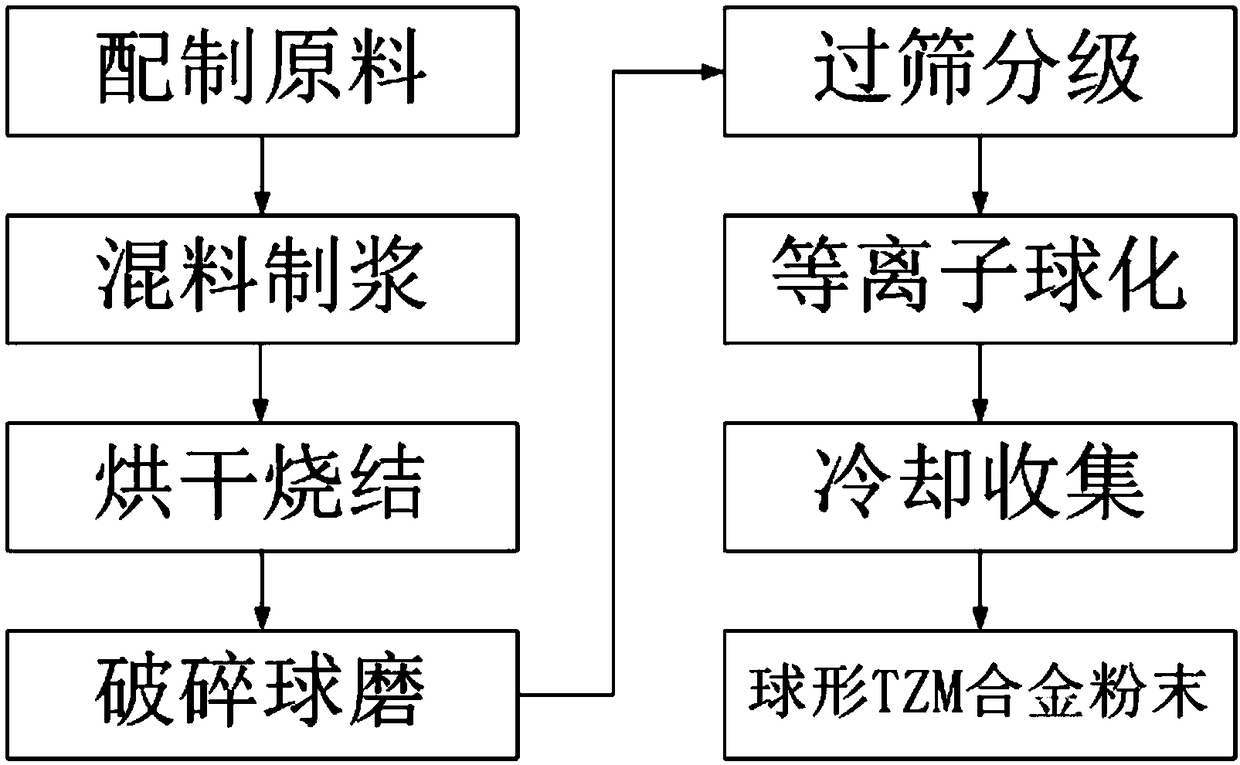

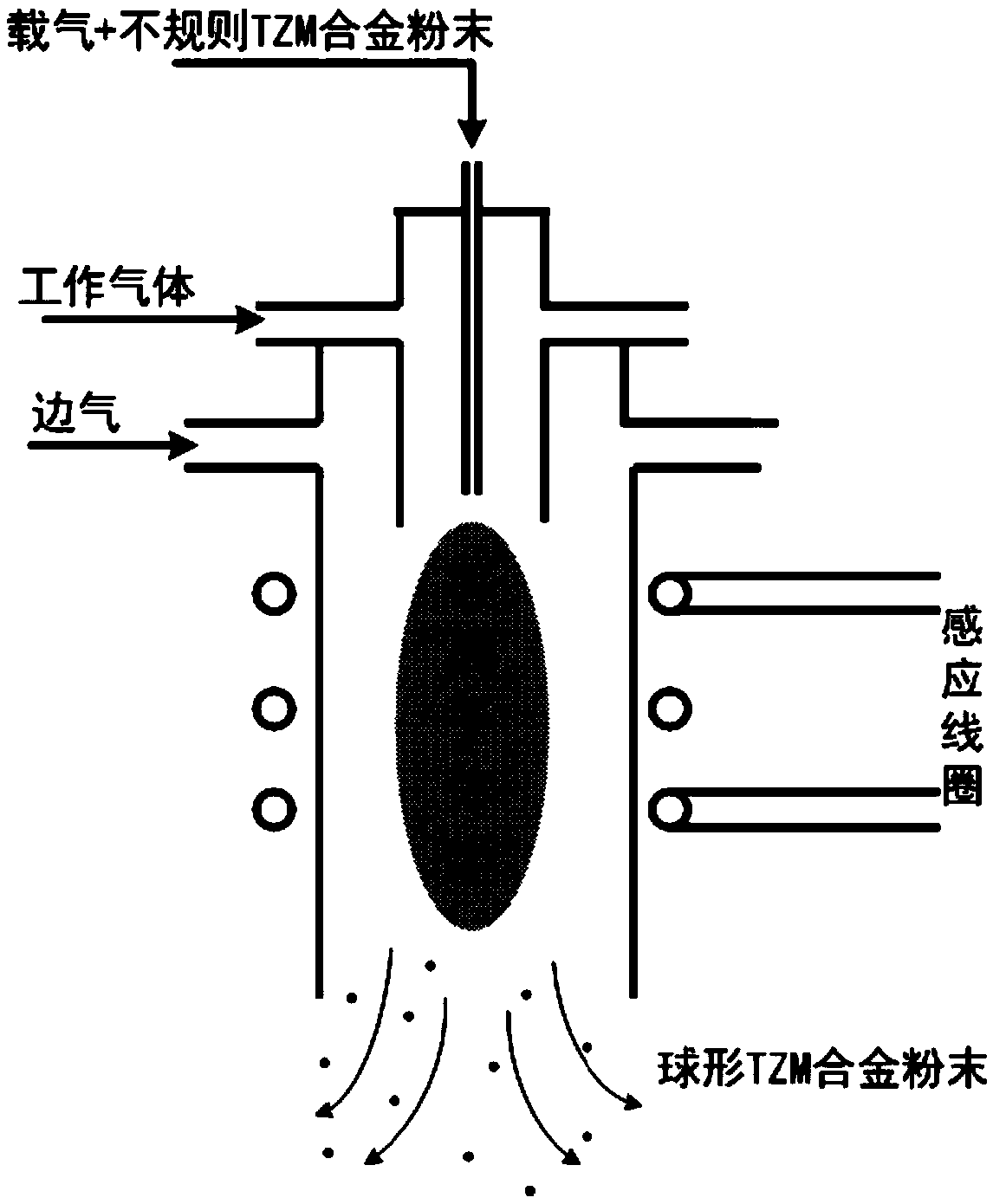

Method for preparing spherical Titanium-Zirconium-Molybdenum alloy powder

ActiveCN109332717ASpeed up meltingPowder state optimizationTransportation and packagingMetal-working apparatusZirconium hydrideTitanium zirconium

The invention provides a method for preparing spherical Titanium-Zirconium-Molybdenum (TZM) alloy powder, and belongs to the technical field of metal powder material preparation. The method for preparing the spherical Titanium-Zirconium-Molybdenum (TZM) alloy powder comprises the steps that reduced molybdenum (Mo) powder, titanium hydride (TiH2) powder, zirconium hydride (ZrH2) powder and graphitepowder are adopted as basic raw materials to prepare raw powder which conforms to the alloy stoichiometry; absolute ethyl alcohol is added into the raw powder to prepare slurry, and thorough stirringis carried out for uniform mixing; the slurry is subjected to vacuum drying, and powder is sintered under a reducing atmosphere; the alloy powder sintered blank is subjected to ball-milling to be sufficiently broken; the ball-milled alloy powder is sieved and irregular TZM alloy powder within a certain particle size range is selected out; the irregular TZM alloy powder is fed into an inductivelycoupled plasma torch, the TZM alloy powder is rapidly melted under a high temperature, and molten alloy droplets form a spherical shape under the action of surface tension; and the molten spherical TZM alloy droplets are separated from a high temperature region of plasma and rapidly cooled under the protection of inert gas to form the spherical TZM alloy powder.

Owner:云航时代(重庆)科技有限公司

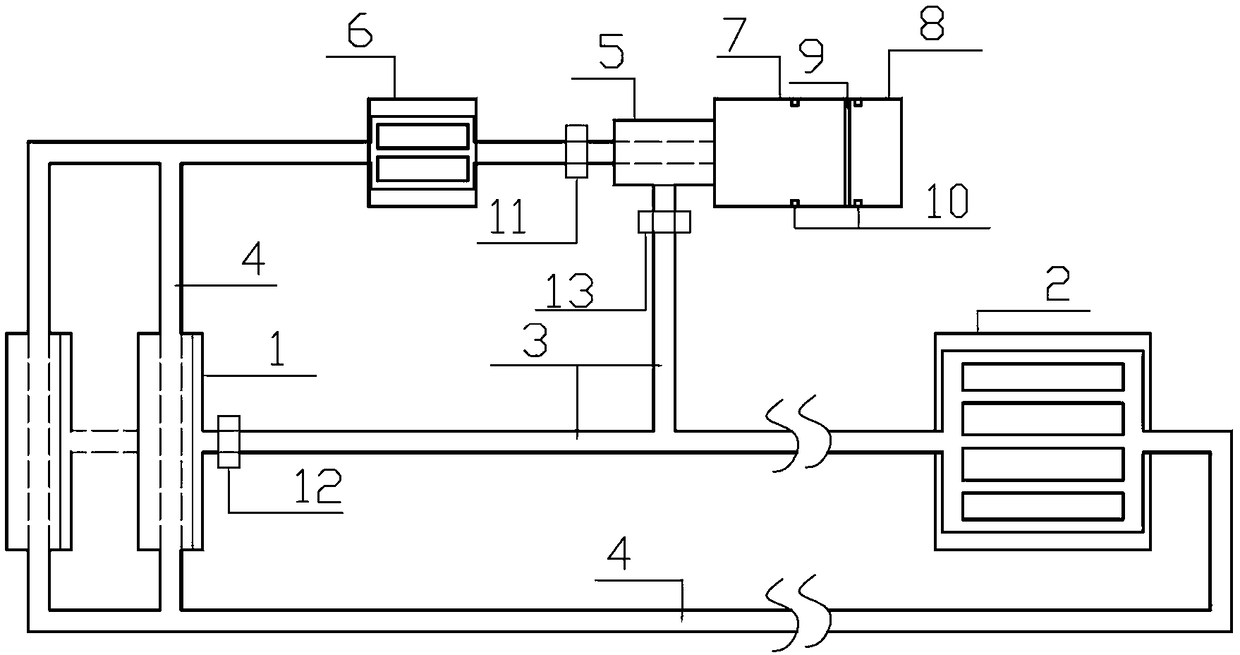

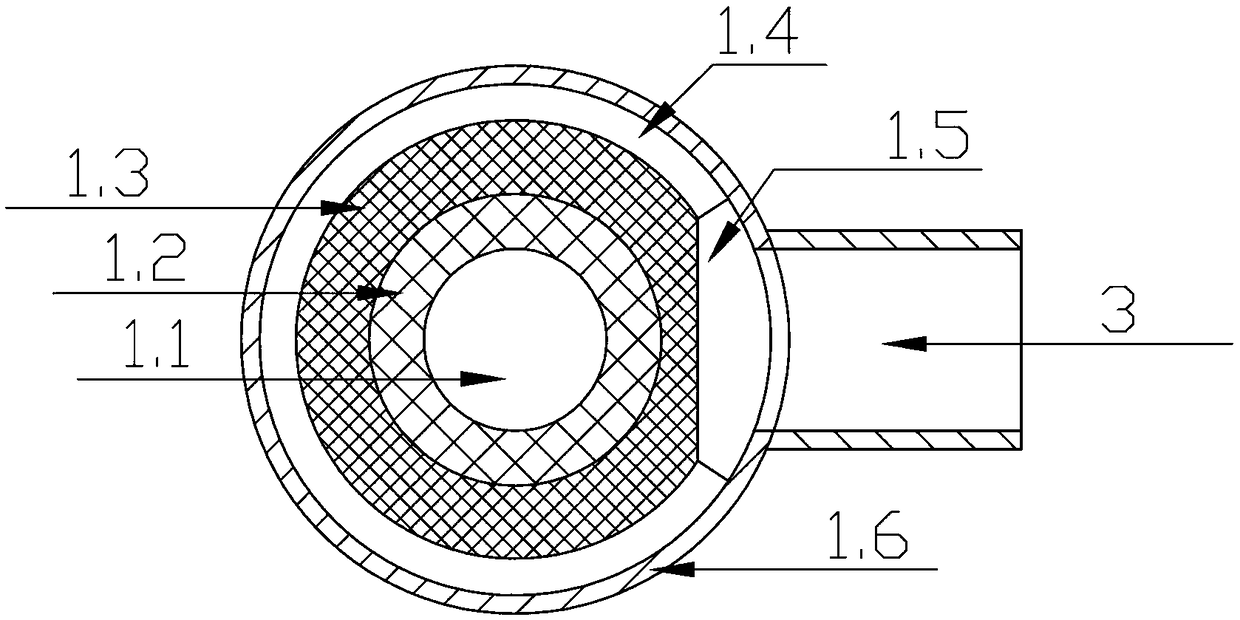

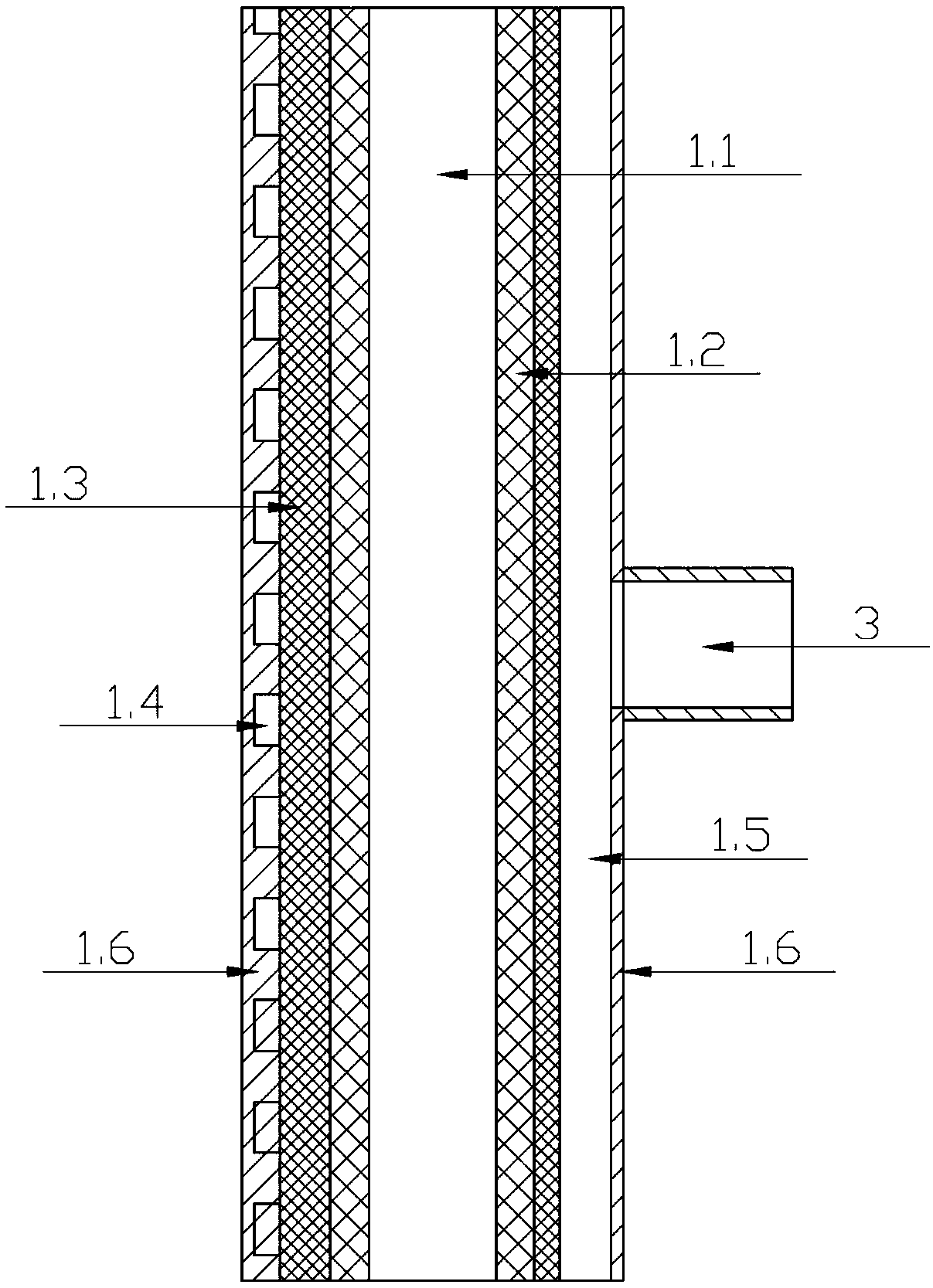

Capillary pump loop heat pipe with outer space working capacity and working method

ActiveCN109458864AAbility to workCapable of working in outer spaceIndirect heat exchangersEvaporationEngineering

The invention discloses a capillary pump loop heat pipe with an outer space working capability and a working method. The heat pipe comprises a main evaporator, a main radiation heat dissipation plate,a steam pipeline, a liquid phase pipeline, a liquid storage chamber, an adjusting chamber, an auxiliary evaporator, an auxiliary radiation heat dissipation plate, a main liquid phase pipeline valve,a main steam valve and an auxiliary steam valve; the main evaporator comprises a liquid phase channel area, a liquid absorption core area, a steam channel area an outer pipe wall and the like; the liquid absorption core comprises an evaporation liquid absorption core and a heat insulation liquid absorption core, wherein the evaporation liquid absorption core and the heat insulation liquid absorption core are provided with different materials and equivalent pore diameters; the starting of the auxiliary evaporator is optimized through the squeezing effect of the steam before starting, the auxiliary radiation heat dissipation plate and the auxiliary evaporator are used for leading out liquid-phase working medium with bubbles in the main evaporator and eliminating the bubbles, the problem of heat leakage in the stable operation stage is solved, so that the operation stability of the heat pipe is improved; the liquid storage chamber is used for separating the liquid storage area and the adjusting area, so that the adjusting sensitivity is improved, and the energy consumption is reduced; and the heat pipe structure has a wide practical prospect in the field of external space heat dissipation.

Owner:XI AN JIAOTONG UNIV

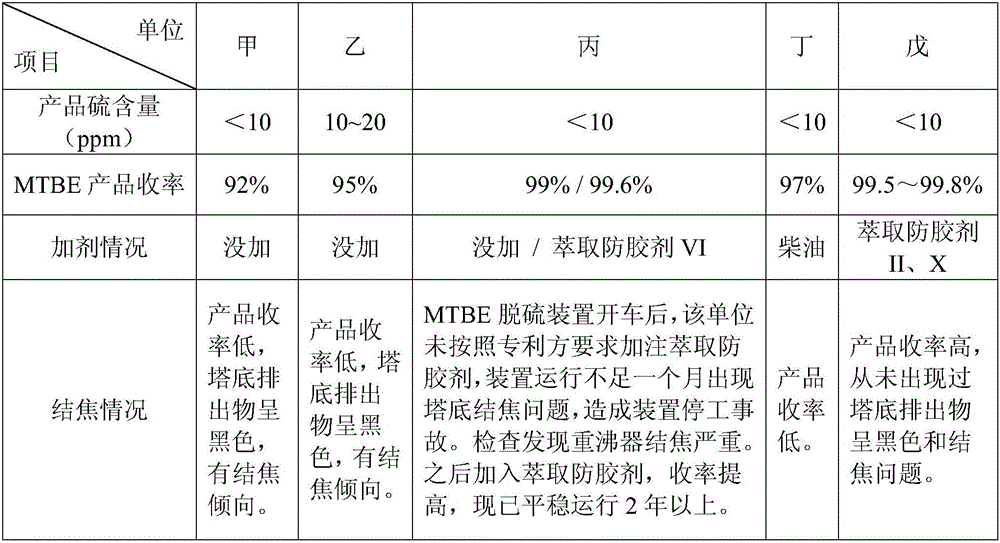

Extraction anti-gum agent for MTBE desulfurization

ActiveCN105777500ANo three wastes producedSufficient vaporization rateEther separation/purificationExtractive distillationRefluxExtractive distillation

The invention relates to an extraction anti-gum agent for MTBE desulfurization.The extraction anti-gum agent at least contains a solvent with the boiling point ranging from 80 DEG C to 150 DEG C, and the solvent at least contains one or a mixture of two or more of C7 (and above) aromatic hydrocarbons with the boiling point ranging from 110 DEG C to 150 DEG C.The extraction anti-gum agent can efficiently remove sulfide in MTBE and also can effectively prevent coking at the bottom of an extractive distillation tower; on the premise of guaranteeing a high vaporization rate of the distillation tower, vaporization of sulfide can be effectively reduced, the distribution gradient of sulfide in the tower can be effectively reduced, and the number of tower plates needed for distillation or the reflux ratio can be effectively decreased, so that investment or operation cost is significantly lowered; the extraction anti-gum agent has a strong extraction effect on low-boiling-point sulfide; recovery or additional treatment is not needed, and no waste is generated.

Owner:HEBEI REFINING TECH CO LTD

Method of recycling butanol through tetracycline hydrochloride crystallization mother liquor

ActiveCN103242137AEliminate static layering operationsEliminate pollutionHydroxy compound separation/purificationZeotropic mixtureTetracycline Hydrochloride

The invention relates to a method of recycling butanol through tetracycline hydrochloride crystallization mother liquor, and belongs to the technical field of pharmacy. The method comprises the following steps of: adding sulfuric acid in the tetracycline hydrochloride crystallization mother liquor at room temperature, and then, distilling the mother liquor to obtain a mixture of butanol and water, dewatering the mixture through an organic pervaporation membrane device or inorganic pervaporation membrane device to respectively obtain butanol and dialysate, utilizing the obtained butanol in the extraction process of tetracycline hydrochloride, mixing the obtained dialysate with the residual distillate of the distilling process, distilling to obtain an azeotropic mixture of butanol and water, mixing the obtained zeotropic mixture of butanol and water with the next batch of tetracycline hydrochloride crystallization mother liquor with sulfuric acid, continuing the treatment process, and treating the obtained secondary residual distillate in an environmental protection device. The method provided by the invention has the advantages of simple technique, convenience for operation, energy conservation, emission reduction, high yield and low cost.

Owner:JIANGSU SAIDELI PHARMA MACHINE

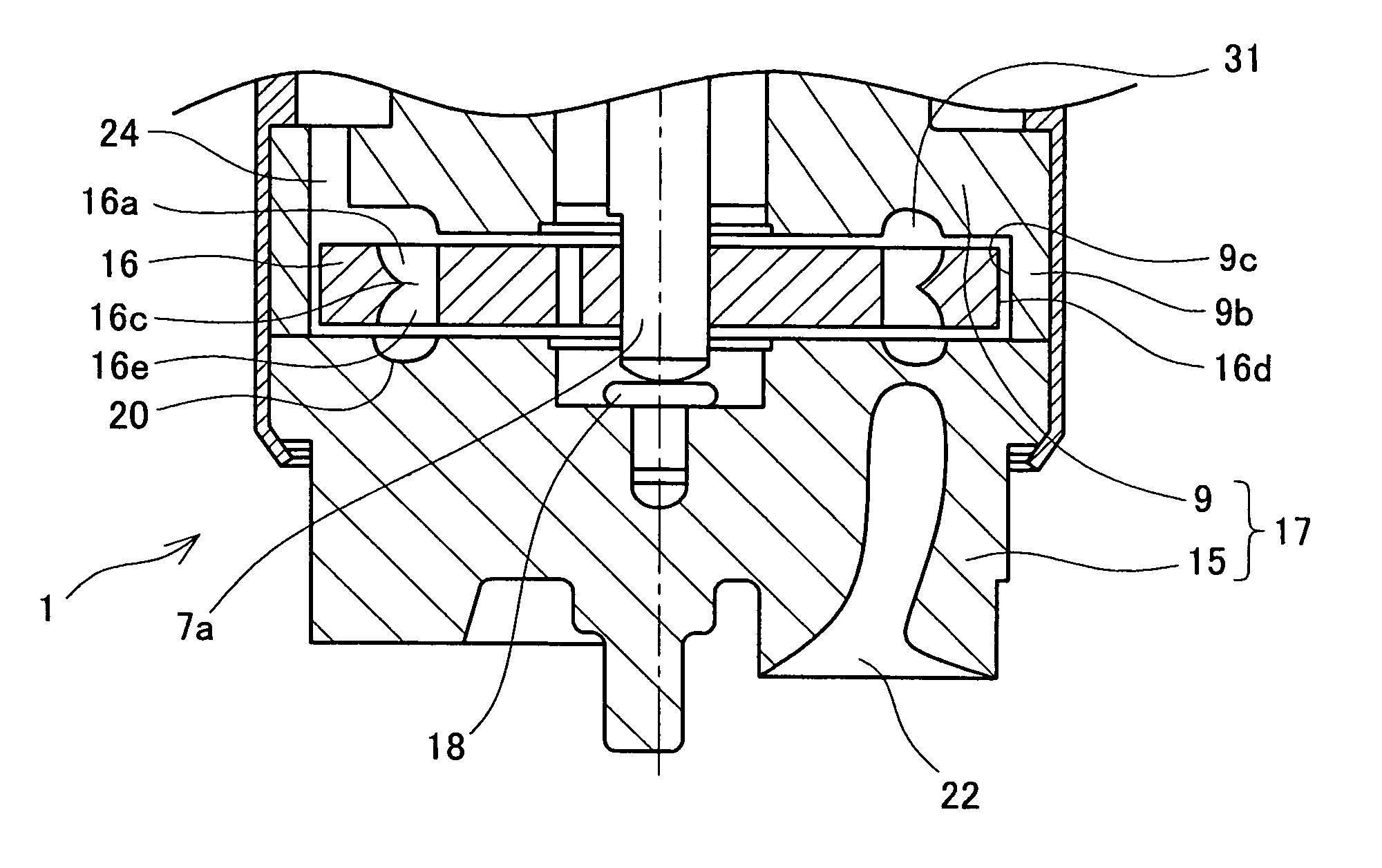

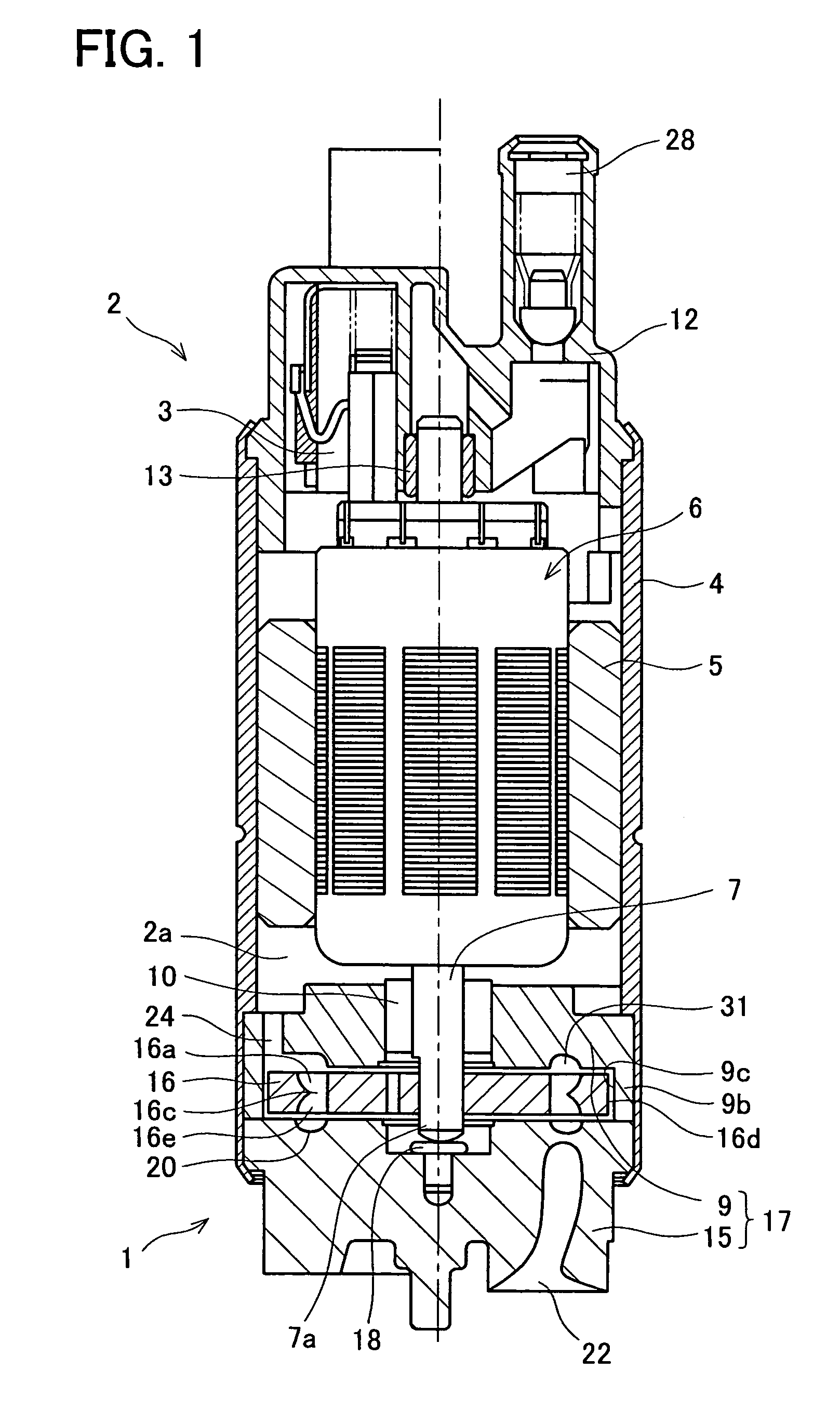

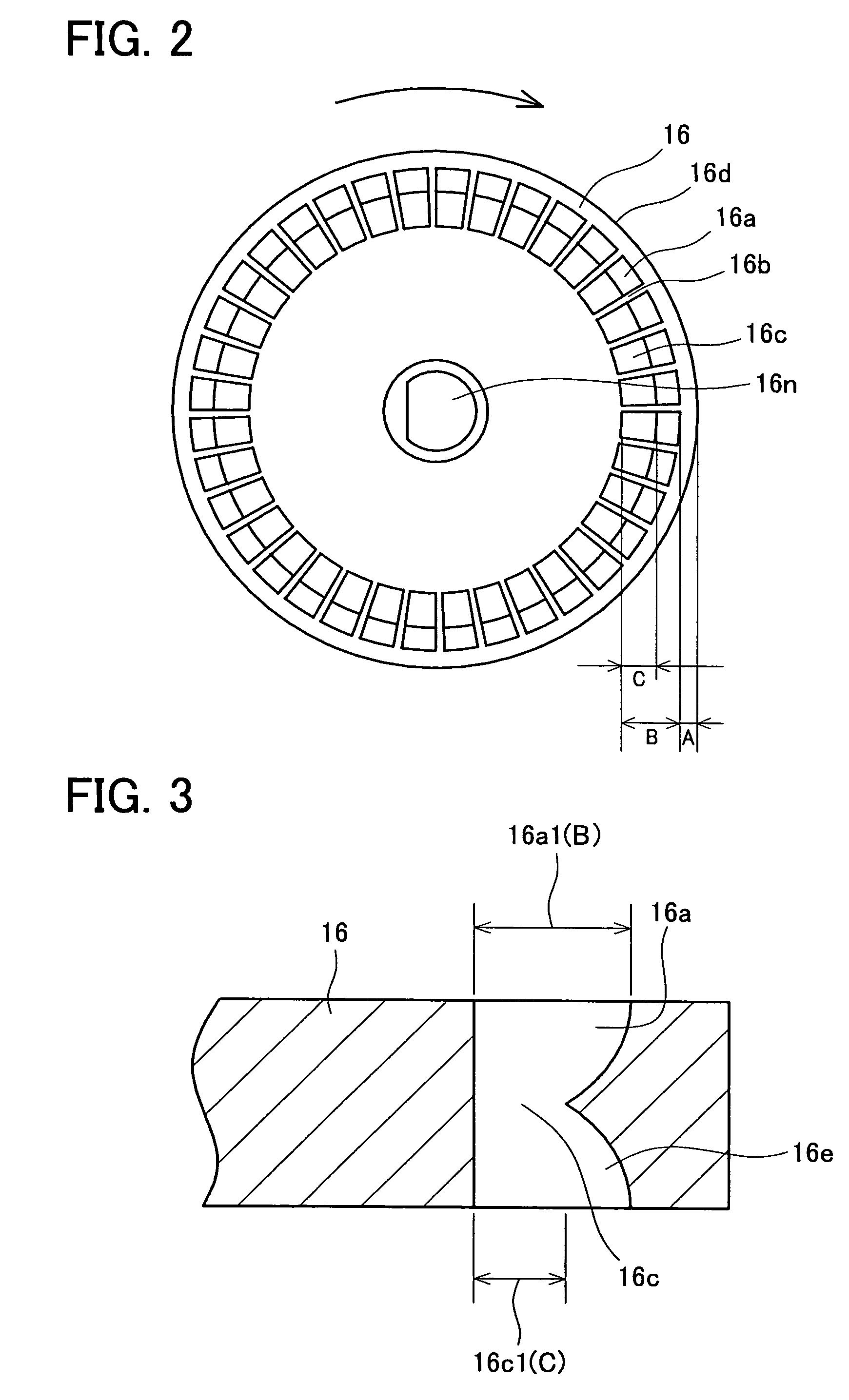

Fuel pump

InactiveUS7264440B2Speed up the flowInsufficient quantitySpecific fluid pumpsCircumferential flow pumpsImpellerEngineering

A fuel pump in which fuel can pass smoothly through through-holes of an impeller is taught. Through-holes communicate concavities formed in upper and lower faces of the impeller. These through-holes are formed at an inner side region within the concavities. When the impeller rotates, the rotational speed of the portion provided with the through-holes is slower than in the case where these through-holes are formed at the outer side region within the concavities. As a result, the fuel in the vicinity of the through-holes within the concavity has a slower rotational speed, and consequently the fuel passes easily through the through-holes.

Owner:AISAN IND CO LTD

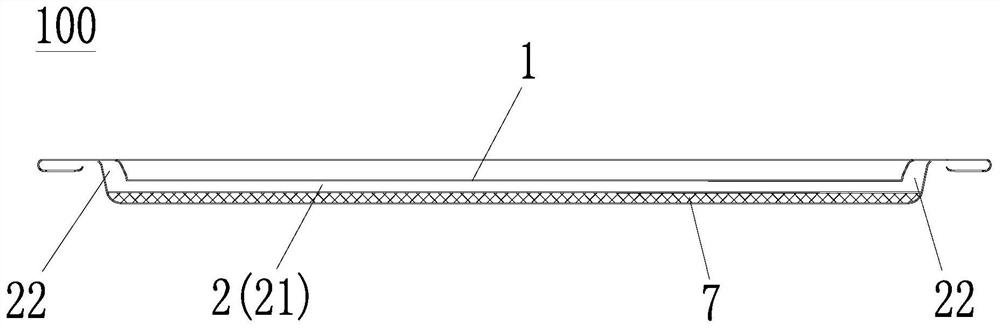

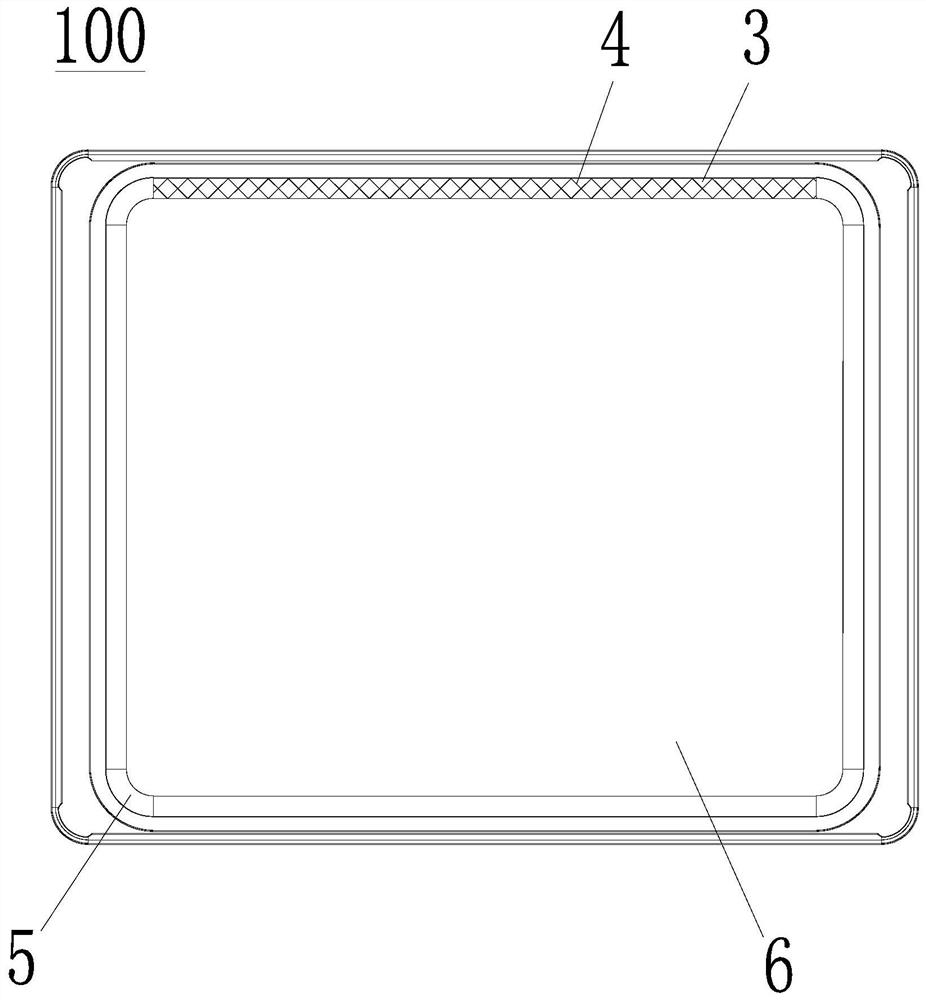

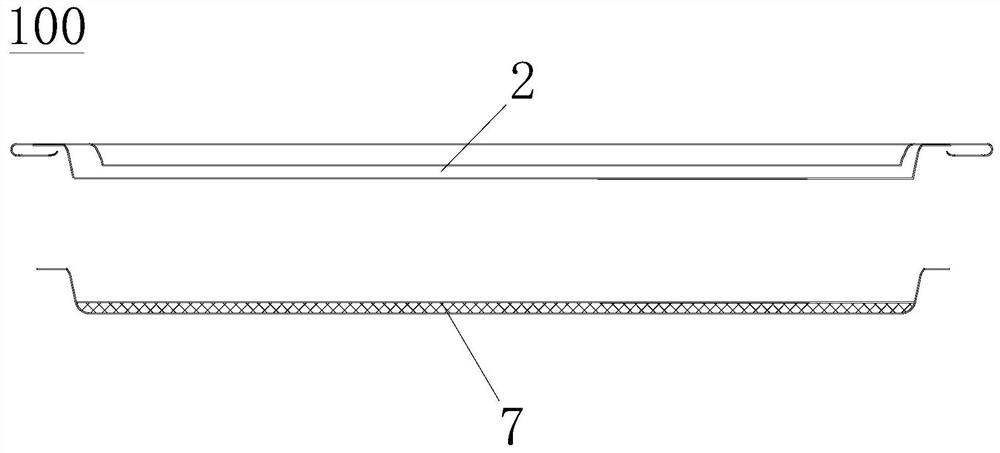

Baking tray and oven

PendingCN111700514AReduce the temperatureReduce vaporizationBaking vesselsRoasters/grillsLiquid stateHome appliance

The invention belongs to the field of household appliances, and discloses a baking tray and an oven, and the baking tray comprises: a hollow interlayer wall which is at least formed at the bottom of the baking tray and is internally provided with a hollow interlayer cavity; a liquid-gas phase change working medium which is positioned in the hollow interlayer cavity and can be converted into a gasstate from a liquid state when being heated to a phase change temperature; and an exhaust port which communicates with the hollow interlayer cavity so that the gaseous liquid-gas phase change workingmedium can be exhausted outwards. The baking tray disclosed by the invention can continuously transfer heat to the liquid-gas phase change working medium when the temperature rises so as to realize self-cooling; particularly, when the liquid-gas phase change working medium is heated to the phase change temperature and is changed from the liquid state to the gas state, mass heat is absorbed, the working medium temperature is maintained at a phase change temperature point; meanwhile, the surface temperature of the baking tray is maintained to be close to the phase change temperature, oil liquidon the baking tray can be effectively prevented from being vaporized into lampblack, the user experience is improved, the pressure in the hollow interlayer cavity can be kept stable by arranging the exhaust port, and when the liquid-gas phase change working medium is water, the water vapor can also achieve the humidifying and tender baking effects.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

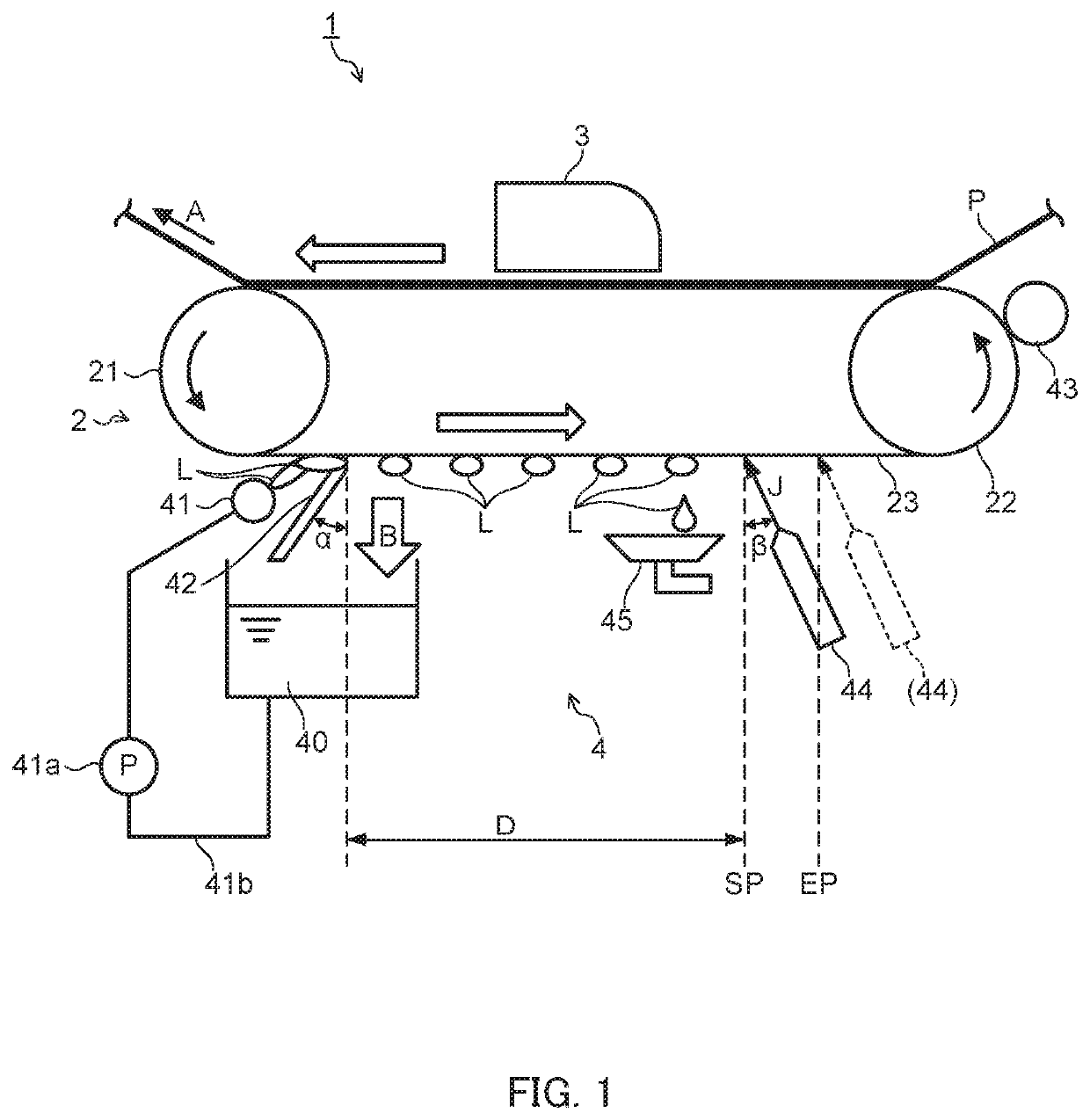

Belt cleaning device and ink-jet image forming apparatus

InactiveUS20200039261A1Reduce vaporizationOther printing apparatusProcess engineeringImaging equipment

Owner:KONICA MINOLTA INC

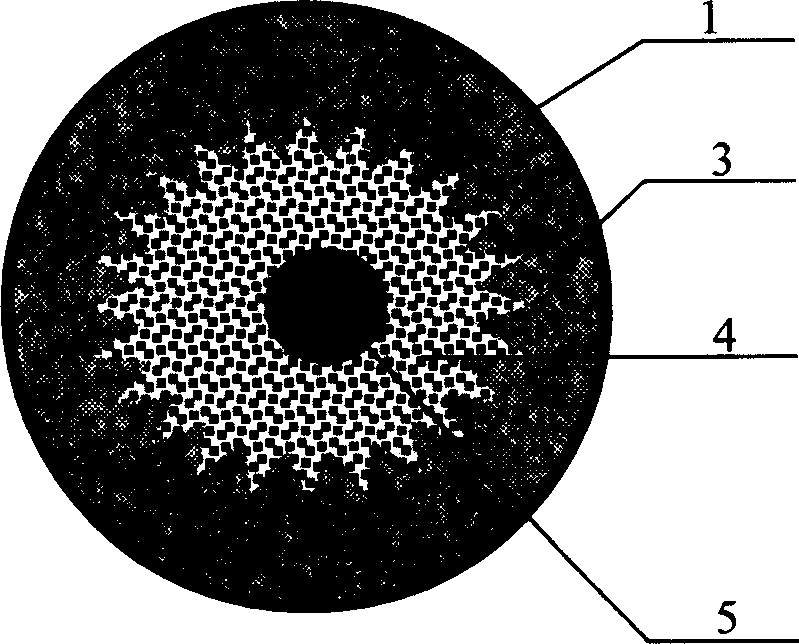

Compound coate with with powder core and its making process

The present invention is compound coated wire with powder core for treating molten iron or steel and its making process. The compound coated wire consists of steel belt coating and coated powder material, and features that the coated powder material includes inner powder containing metal element with boiling temperature lower than that of the metal liquid to be treated and an outer powder layer containing functional elements with boiling temperature higher than that of the metal liquid to be treated. The making process is one three-step material distribution process completed in a coated wire machine. The present invention has the advantages of lowered evaporation amount and utilization rate of the inner powder.

Owner:包头文鑫实业有限公司

Improved tubular reactor

InactiveCN1986042BDissolve fastLess corrosiveAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersGas phaseSlurry

The improved tubular reactor includes one reactant mixing section, one reactant reacting section and one reaction product outputting nozzle. It features the reactant mixing section with one spiral jetting mixer and the reactant reacting section with one spiral mixer. The material contact order and the spiral jetting mixer in the reactant mixing section are regulated properly to control the mixingdegree, contact area and reaction speed to ensure homogeneous mixing of the materials and moderate reaction speed. The spiral mixer in the reactant reacting section mix the gas phase, the liquid phase and the solid phase gradually for homogeneous, smooth, mild and full reaction to form high quality well atomized slurry.

Owner:中国-阿拉伯化肥有限公司

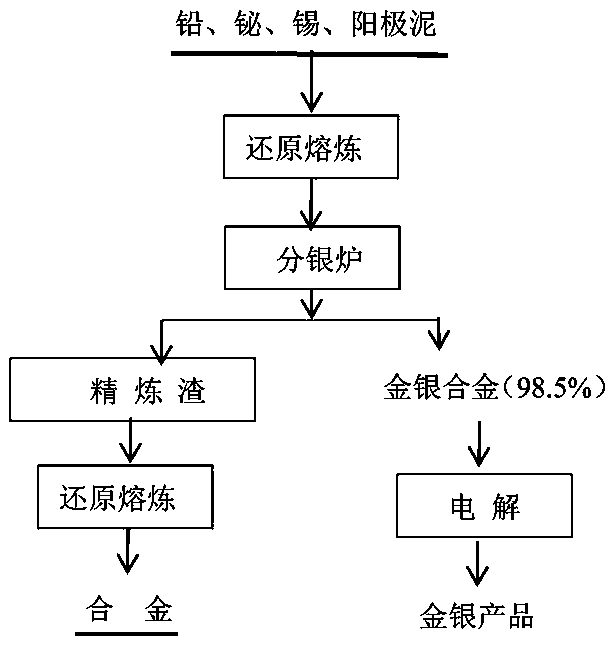

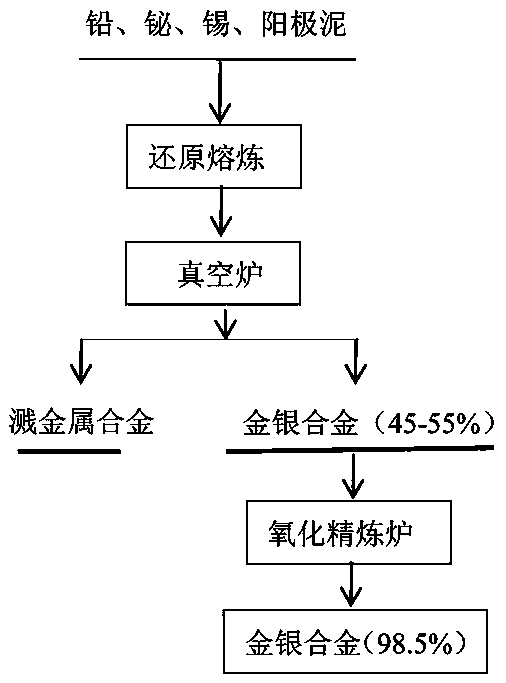

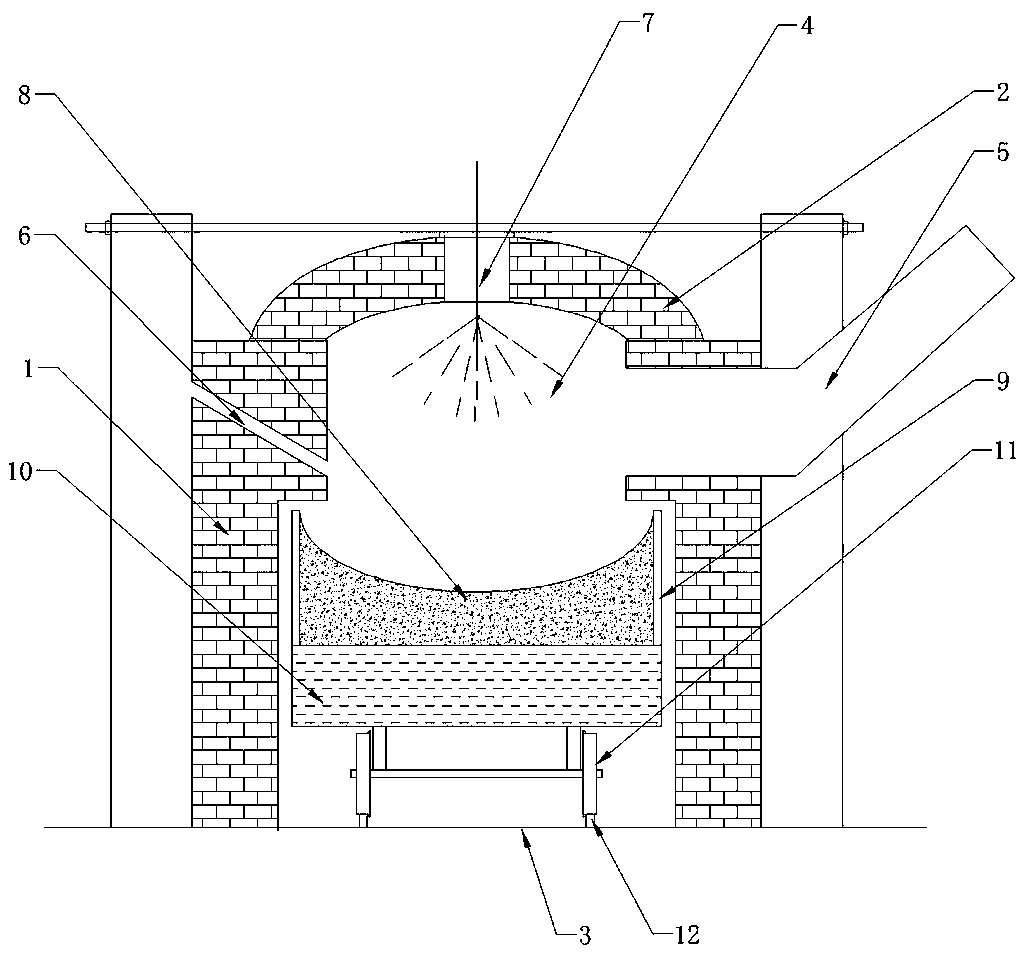

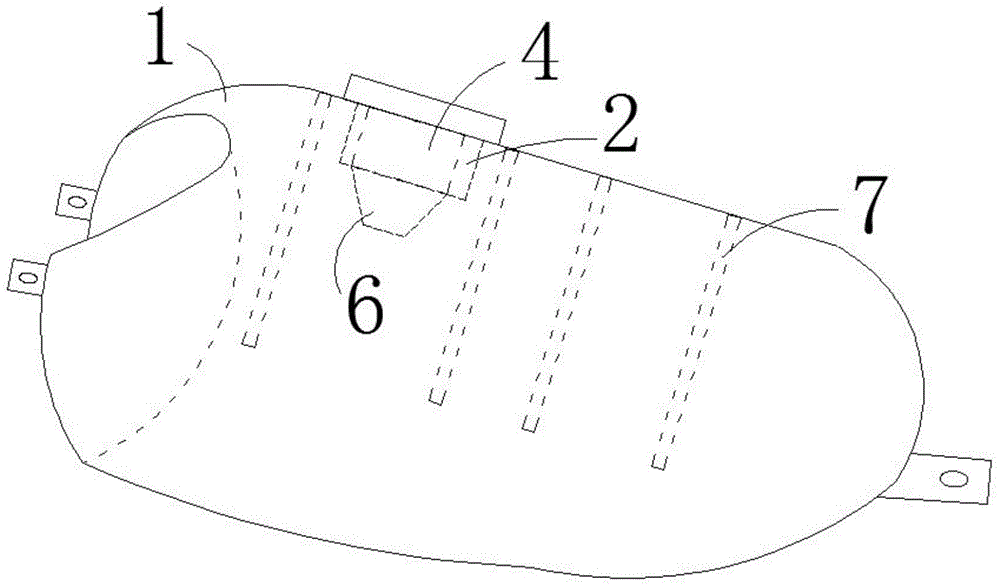

Precious metal alloy purification and enrichment technology and oxidizing refining furnace

The invention relates to a precious metal alloy purification and enrichment technology and an oxidizing refining furnace. The technology comprises the following steps of: carrying out reduction smelting on anode mud containing lead, bismuth and tin, separating a gold-silver alloy by using a vacuum furnace, and removing impurities by using the oxidizing refining furnace. The oxidizing refining furnace for the purification and enrichment of the precious metal alloy comprises a tunnel furnace body constructed by a furnace wall (1), a furnace roof (2) and a furnace bottom (3); and a hearth (8), ahearth base (9) and a moving furnace bed (10) are arranged below a furnace chamber space (4). The technology is simple and convenient, can reduce the production cost, increases the direct yield of gold and silver to 97.5 to 99%, and is environmentally-friendly and safe. The oxidizing refining furnace has the characteristics of large processing capacity, low energy consumption and high automation level.

Owner:郴州雄风环保科技有限公司

Motorcycle fuel tank

The invention relates to a motorcycle fuel tank which comprises a fuel tank body, wherein the fuel tank body is fixedly installed on a motorcycle frame, and an air hole is formed in the bottom of the front end of the fuel tank body; a fuel outlet nozzle is arranged at the bottom of the tail end of the fuel tank body; a fuel drainage groove is formed in the upper part of the fuel tank body, a through tube is arranged at one side of the fuel drainage groove, the through tube is communicated to the outer side of one side face of the fuel tank body, and a fuel filling port is formed in the fuel drainage groove; a clamping plate capable of being clamped on the motorcycle frame is fixedly arranged at the bottom of the fuel tank body; and a thermal insulating layer is arranged outside the fuel tank and is made of a PC resistant board. Compared with the prior art, the motorcycle fuel tank provided by the invention has the advantages that the fuel tank can be subjected to thermal insulation, the discharge of fuel or accumulated water at the fuel filling port can be accelerated, and the shaking of fuel in the fuel tank along with a motorcycle body is inhibited.

Owner:CHONGQING CITY DAZU DISTRICT LIBANG MACHINE PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com