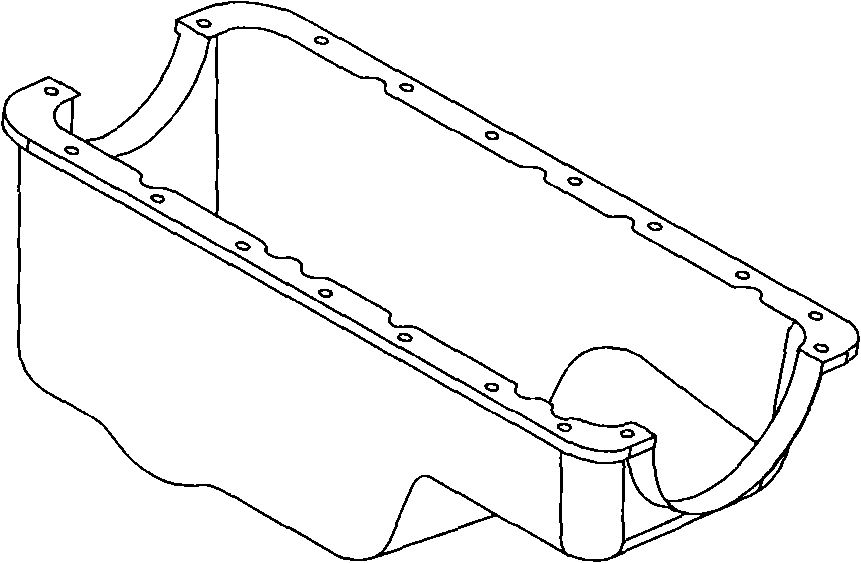

Engine oil bottom shell

A technology of engine oil and oil pan, which is applied in the direction of engine components, machine/engine, engine lubrication, etc., to achieve the effect of reducing assembly processes, increasing costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

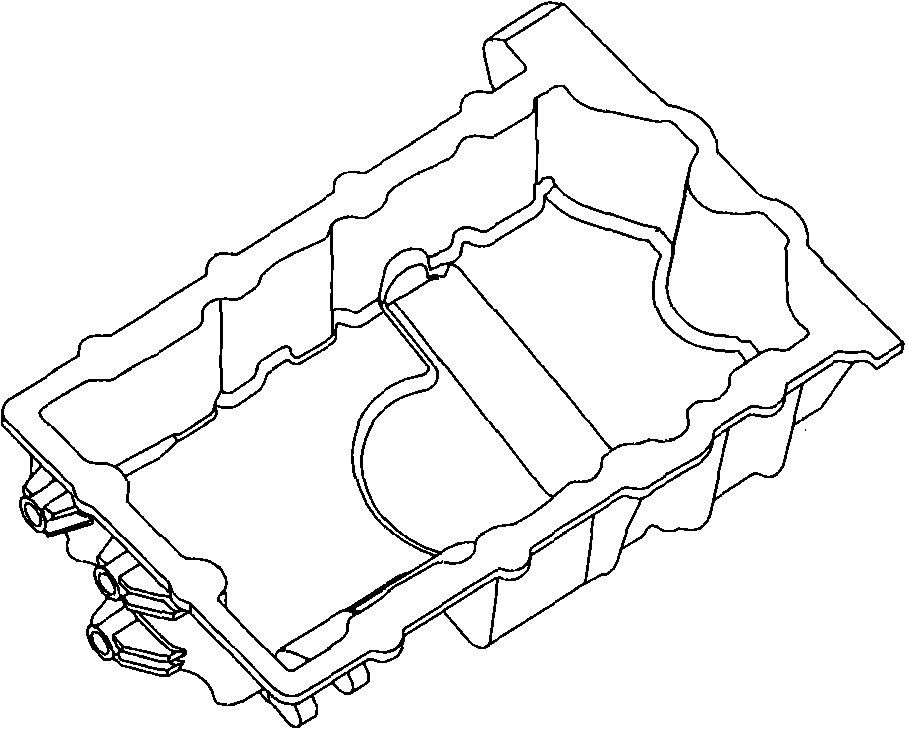

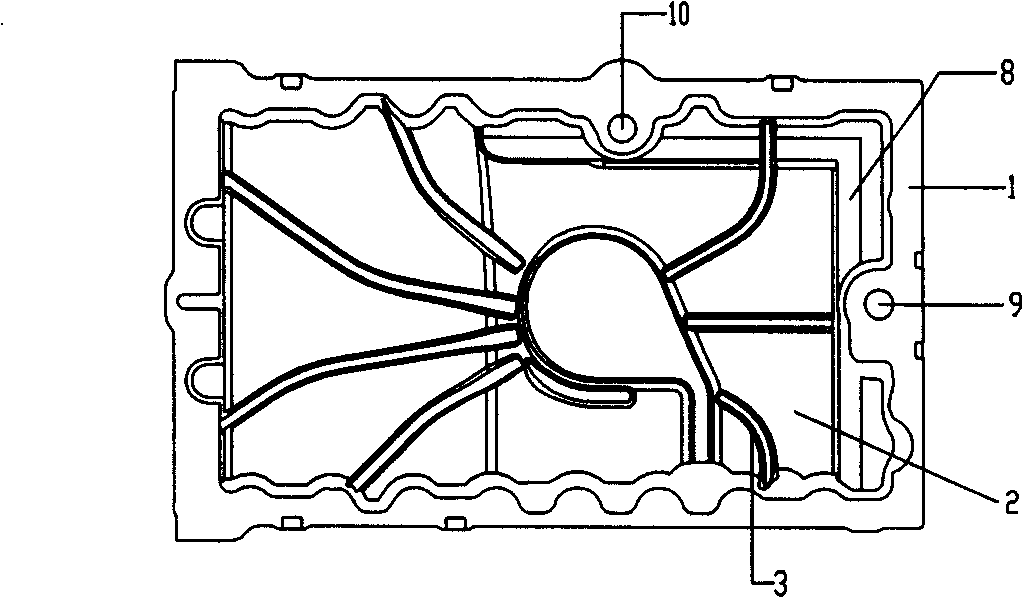

[0019] Example 1, in image 3 , 4 Among them, an engine oil pan, including a large end surface 1 of the oil pan is a horizontal plane, which is directly assembled with the cylinder body by liquid sealant. The sealing effect is good, and the oil is not easy to seep out. Ribs 3 in the inner cavity of the oil pan are arranged in a zigzag direction in the inner cavity 2 of the oil pan, and these ribs form radiation lines, so that sound waves overlap each other and are attenuated. The noise of the volume chamber in vibration is minimized. Bottom ribs 4 staggered horizontally and vertically are arranged at the bottom of the oil pan, which can strengthen the strength of the oil pan and reduce noise. The rear end surface 5 of the oil pan is designed to be a semicircle similar to the profile of the front end surface of the transmission case. Bolt holes 7 for the bolts connected to the transmission are arranged on the oil sump rear face 5 . When this design is adopted, the oil pan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com