Disc type positioning spacer

A spacer and disk-shaped technology, which is applied in the field of disk-shaped positioning spacers, can solve problems such as low work efficiency, increased operation difficulty, and increased use cost, and achieves the effects of improving efficiency and safety, simple and convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

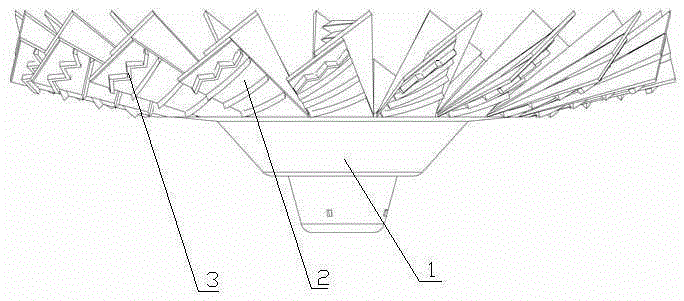

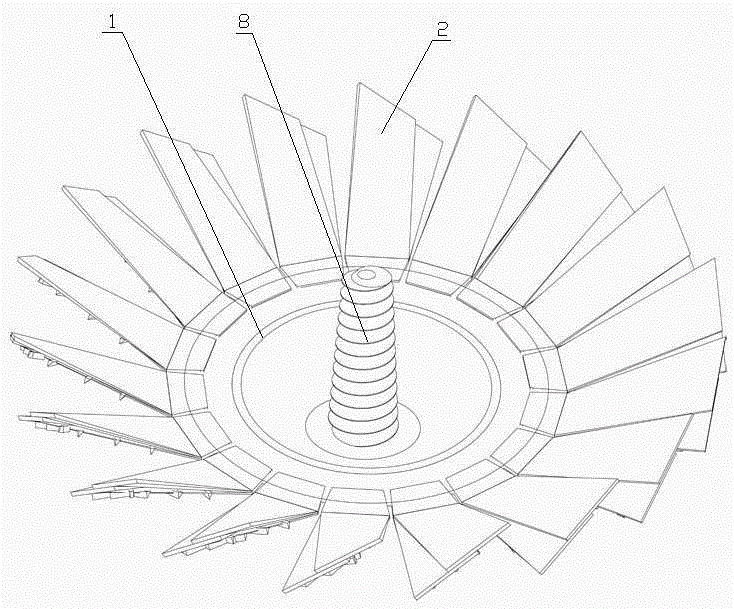

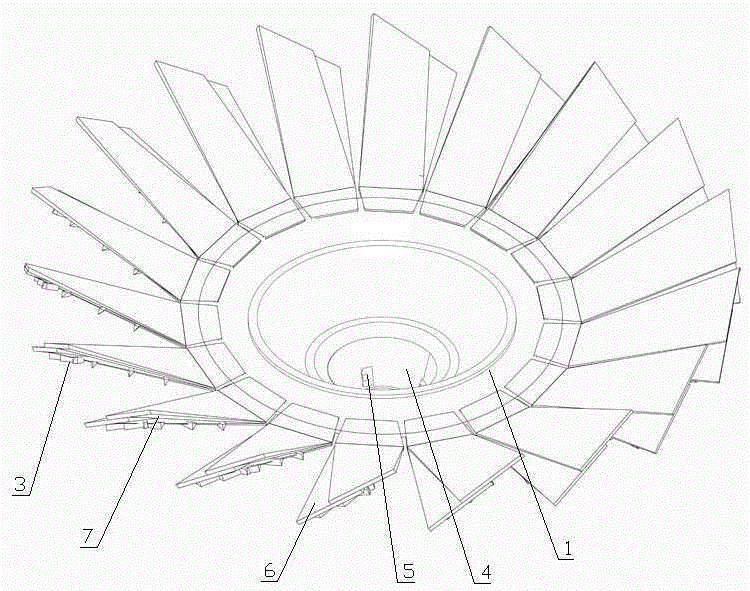

[0019] Such as Figure 1-4 The disc-shaped positioning spacer shown is provided with a baffle plate 1, and a connection hole 4 is provided on the upper side of the center of the baffle plate 1, and a fixed rod 8 perpendicular to the baffle plate is plugged into the connection hole 4, and the fixed rod 8 can move upwards and The connection holes 4 are separated, and elastic positioning flaps 2 are evenly distributed on the periphery of the retaining plate 1, the positioning flaps are fan-shaped or trapezoidal, and the lower side of the positioning flaps is provided with a sliding blocking strip 3. The inner end of the positioning wing 2 is fixedly connected to the baffle plate. The inner ends of the positioning wing are located on the same plane and connected in sequence. When the outer side of the positioning wing 2 is bent upward and the outer edge is at the same height, the two adjacent positioning wings Adjacent sides of the plates are abutted against or superimposed on eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com