Tension hinge structure of steamer overhead door

A technology of tensioning mechanism and flipping door, applied in door/window fittings, building structure, steam cooking utensils, etc. The effect of closing, reducing the tension of the compression spring and increasing the pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

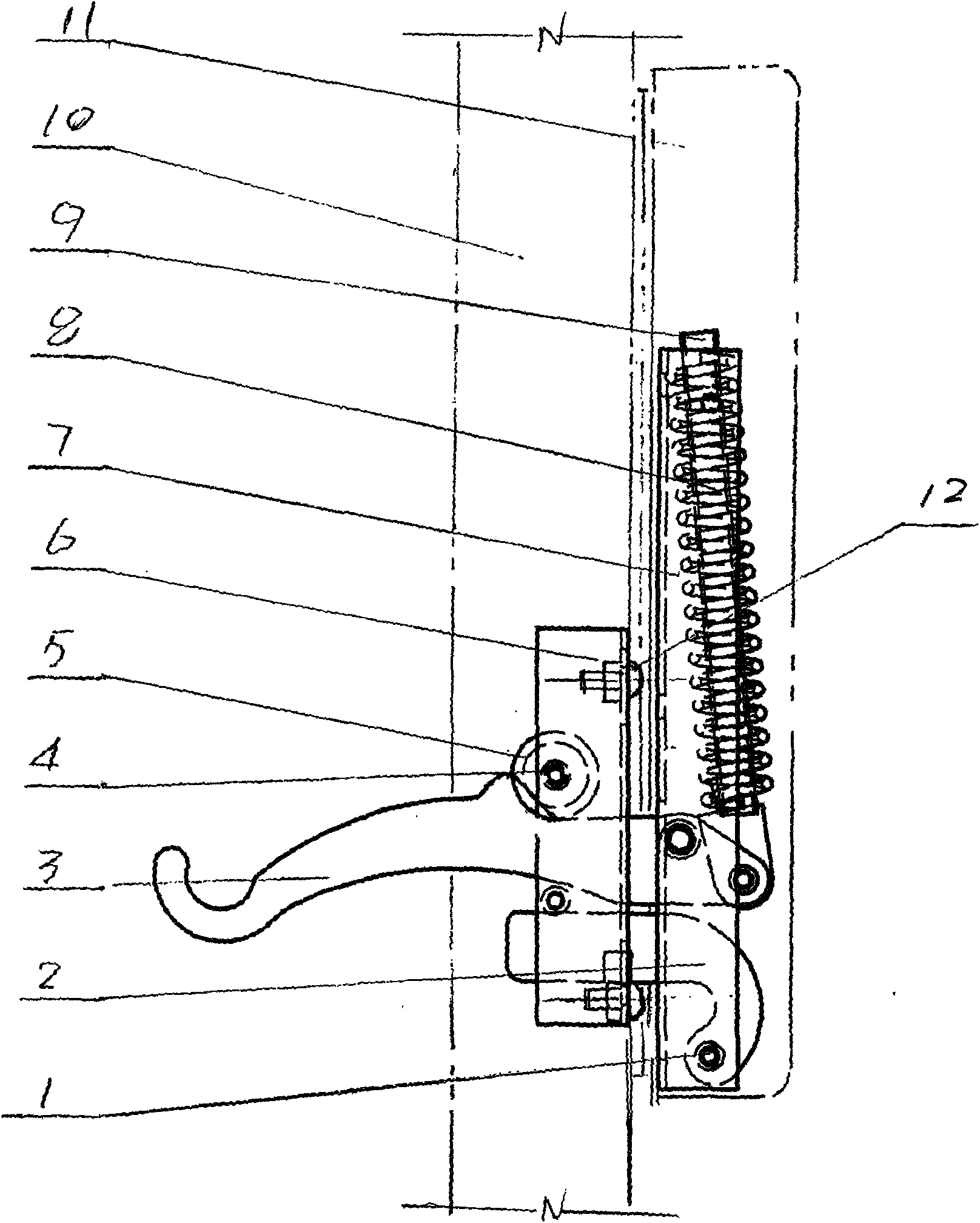

[0008] See attached picture,

[0009] Pulley fixed plate 6 adopts screw, nut 12 to be fastened on cabinet door post 10 installation hole positions. 9 is the compression spring fixing frame, the compression spring 8 is sleeved on the shaft of the fixing frame, and then inserted into the limit hole of the door leaf fixing plate 7, and the hinge 2 is connected to the hinge hole position of the door leaf fixing plate by using the hinge screw 1 according to the required position. Finally, the installed door leaf fixing plate 7 is placed in the fixed positions on both sides of the flap and is fastened with the flap by screws. The connecting rod locking piece 3 is placed in the door flap chute and connected with the compression spring fixing frame 9 through screws, and then the compression spring is pre-pressed to the installation position with a special clamp, and then the connecting rod locking piece 3 is connected to the door leaf fixing plate with screws. 7 positioning connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com