Press mounting fixture

A technology of fixtures and compression devices, which is applied in the field of press-fitting fixtures, can solve problems such as the lack of compression of the pressure plate, excessive clamping of the vise, and force deformation on the side of the workpiece, so as to achieve a stable arc structure, good compression effect, The effect of increasing the compression force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

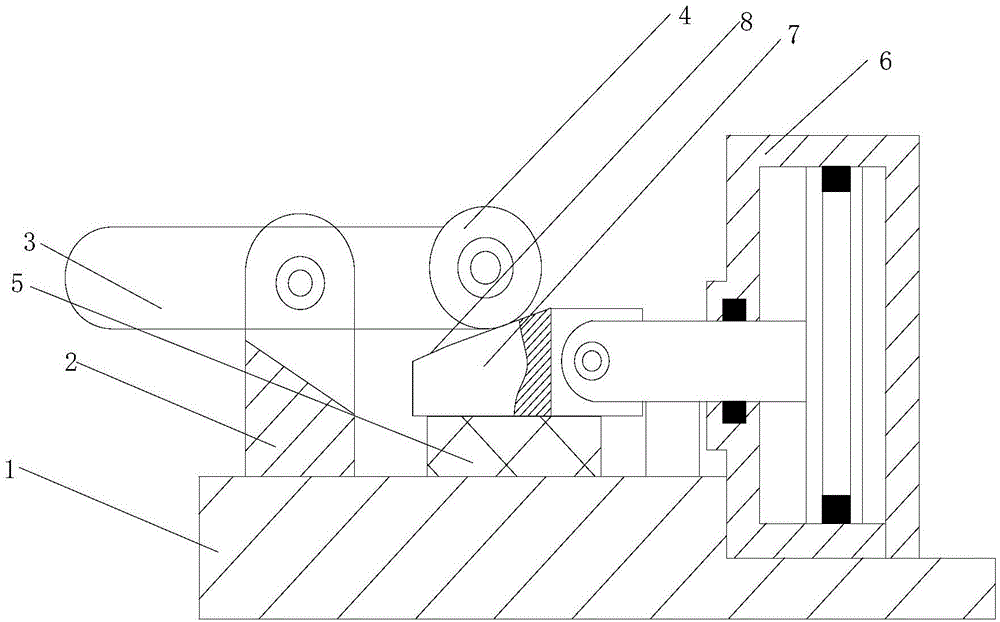

[0015] The pushing device includes an oil cylinder arranged on the base, and a trapezoidal pushing block connected to the telescoping end of the oil cylinder; the slope of the trapezoidal pushing block is in contact with the roller. Replacing the cylinder with an oil cylinder can effectively reduce the occupied space.

Embodiment 3

[0017] A guide block is provided between the base and the trapezoidal push block. Since the trapezoidal pushing block will move forward for a certain distance, in order to avoid the problem that the trapezoidal pushing block slides due to insufficient supporting force, the guide block is set to provide an upward supporting force for the trapezoidal pushing block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com