Patents

Literature

470results about How to "Good compression effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

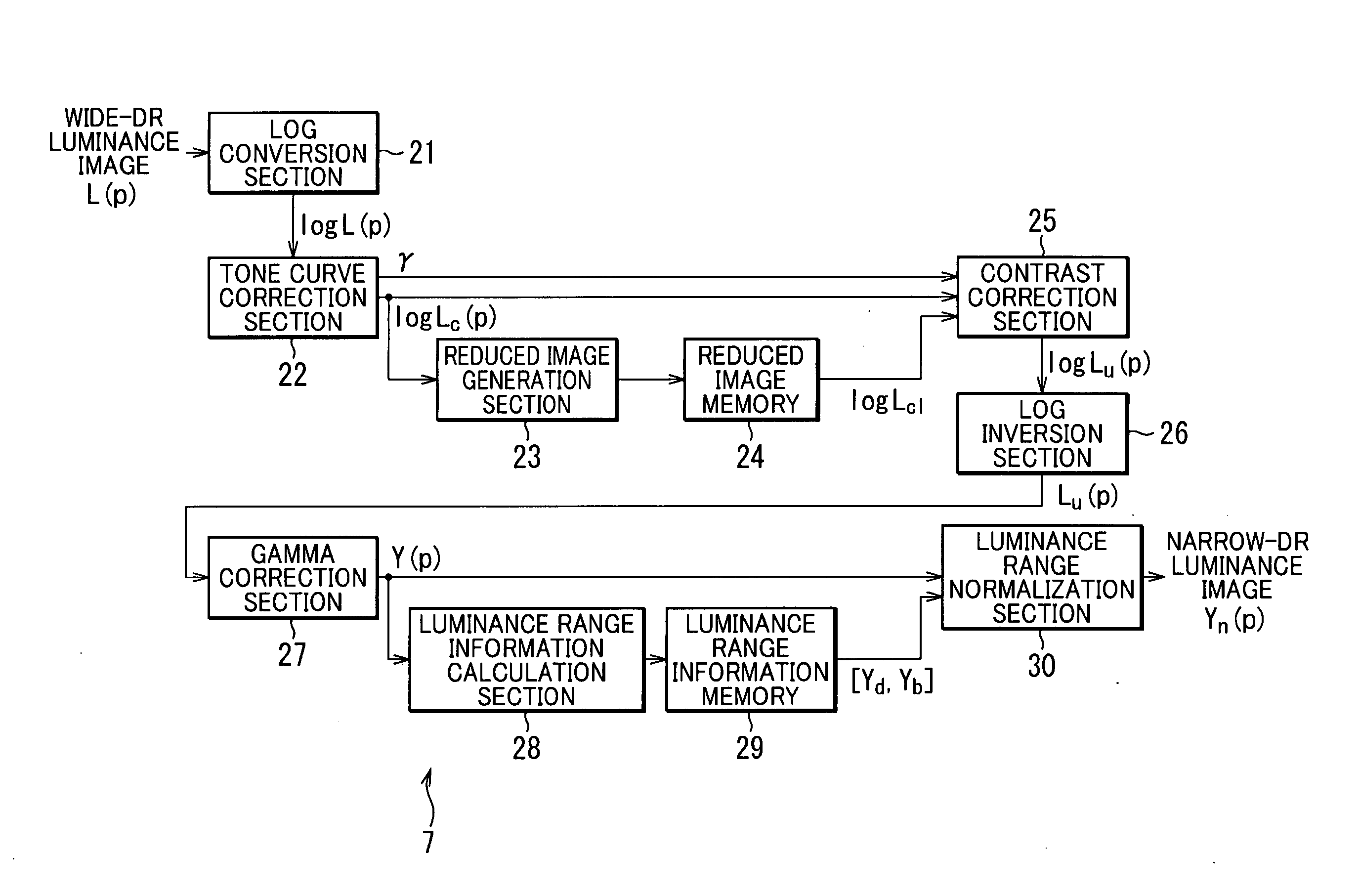

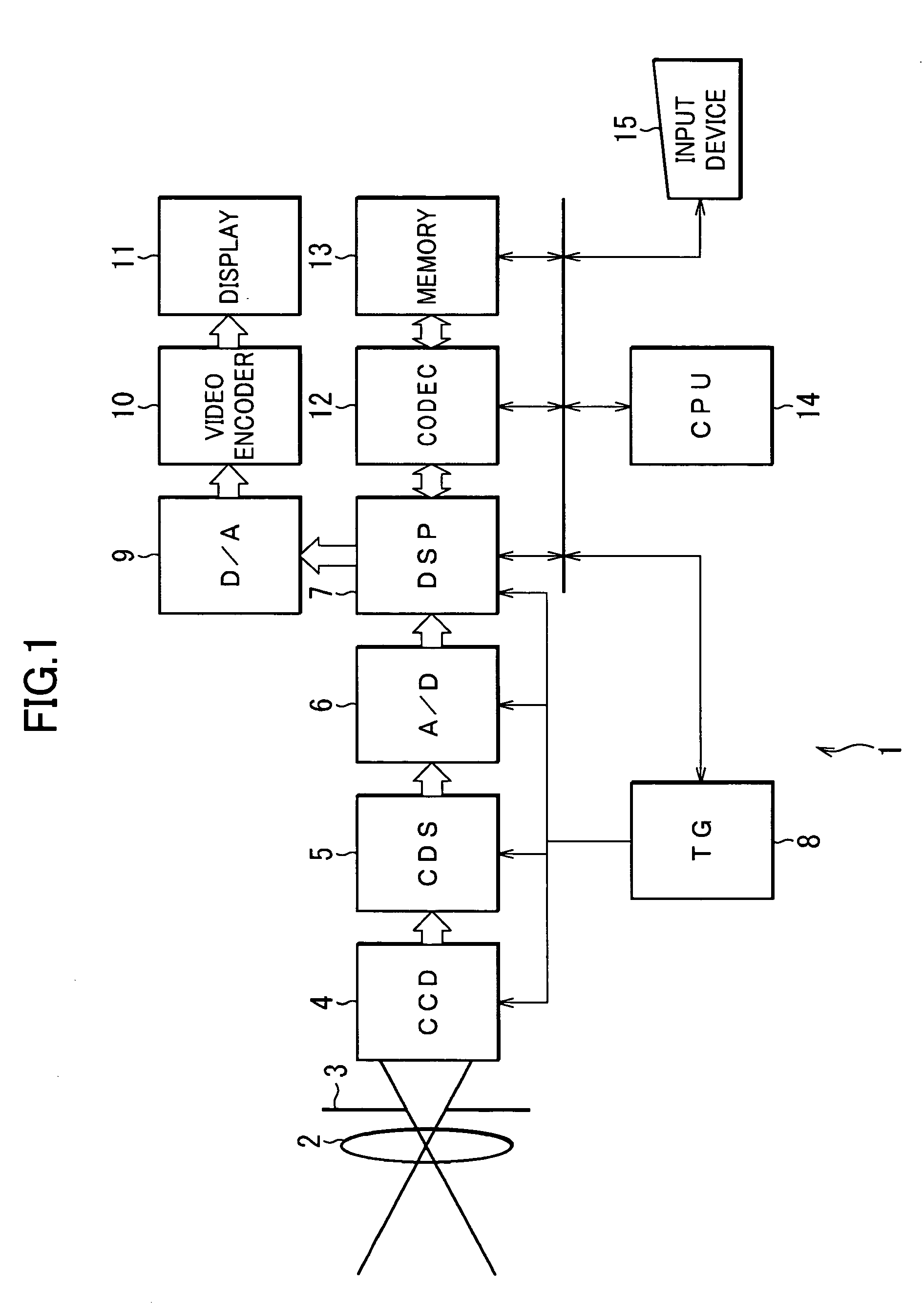

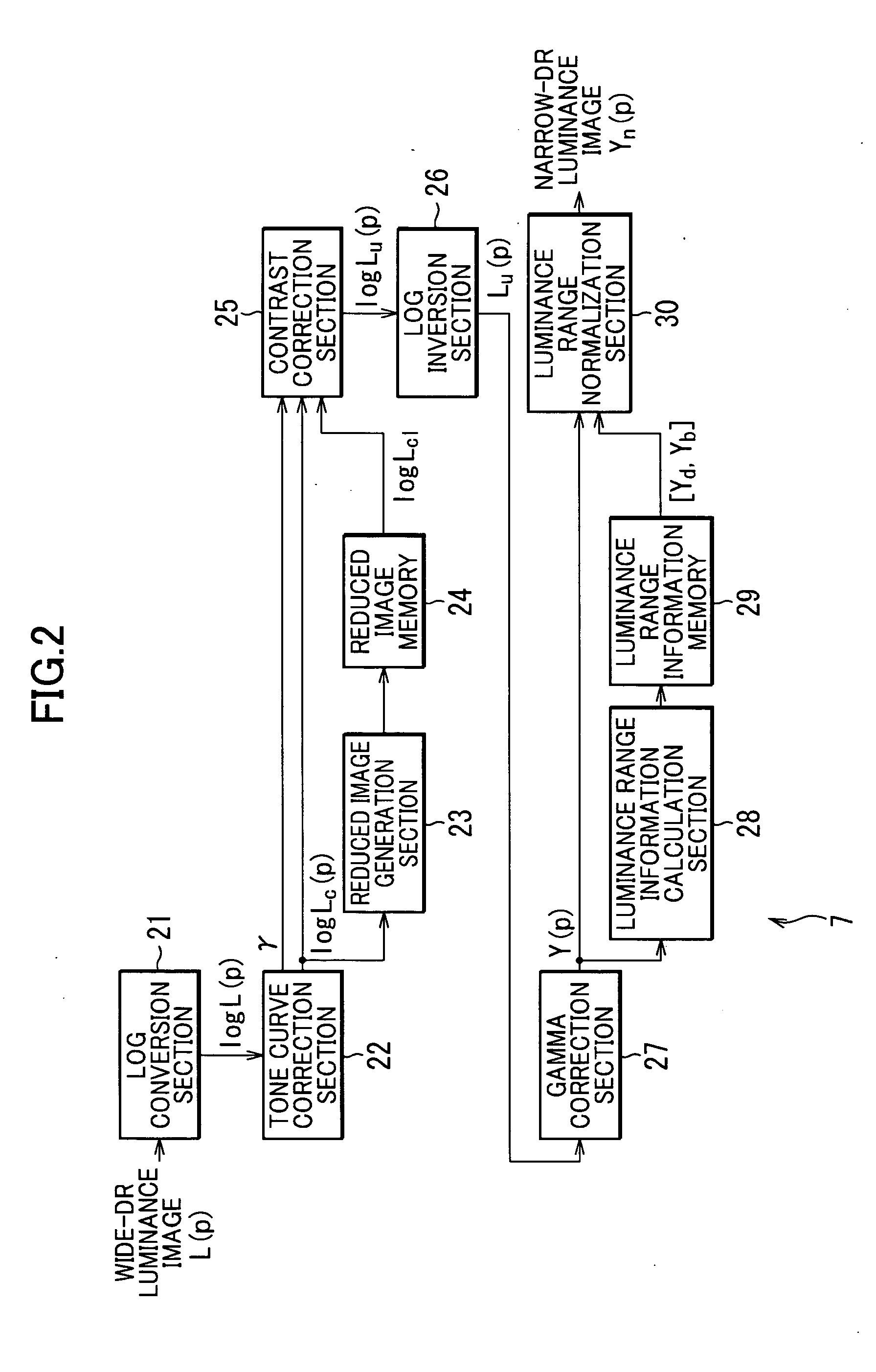

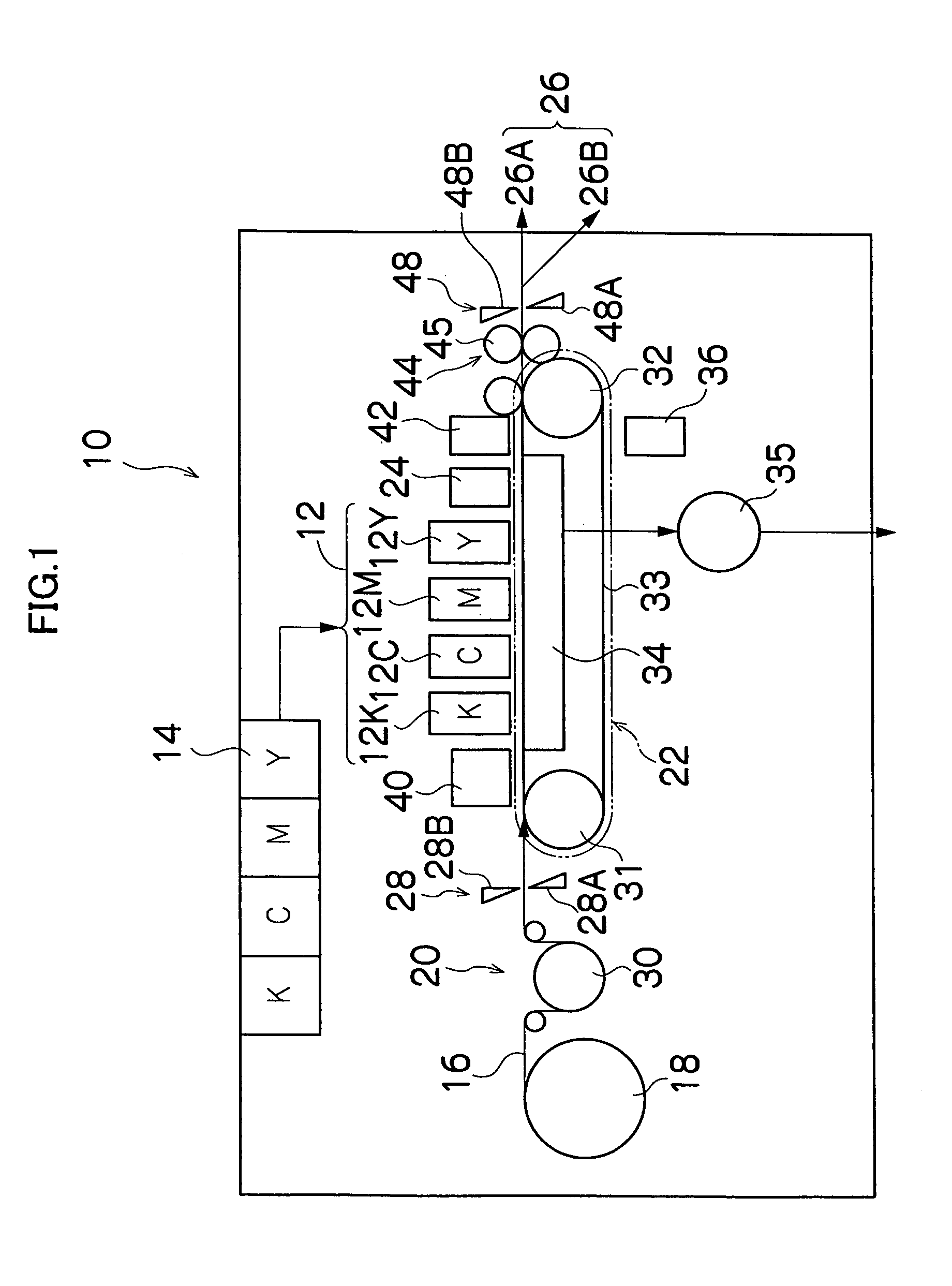

Image processing device and method

InactiveUS20050226526A1Less loadEasy hardware constructionImage enhancementTelevision system detailsDigital videoImaging processing

The present invention relates to an image processing apparatus and a method, and in particular to an image processing apparatus and a method preferably applicable to conversion of a wide dynamic-range image having a dynamic range of pixel values wider than the normal one to a narrow dynamic-range image having a narrower dynamic range of pixel values, and to enhancement of contrast. In step S1, an input wide-DR luminance image of the current frame is converted into a narrow-DR luminance image based on the intermediate information calculated for the previous frame's wide-DR luminance image. In step S2, the stored intermediate information of the previous frame is updated using the calculated intermediate information. In step S3, it is determined if there is any succeeding frame. If there is the succeeding frame, the process returns to step S1 and processes thereafter are repeated. The present invention is applicable to a digital video camera and the like.

Owner:SONY CORP

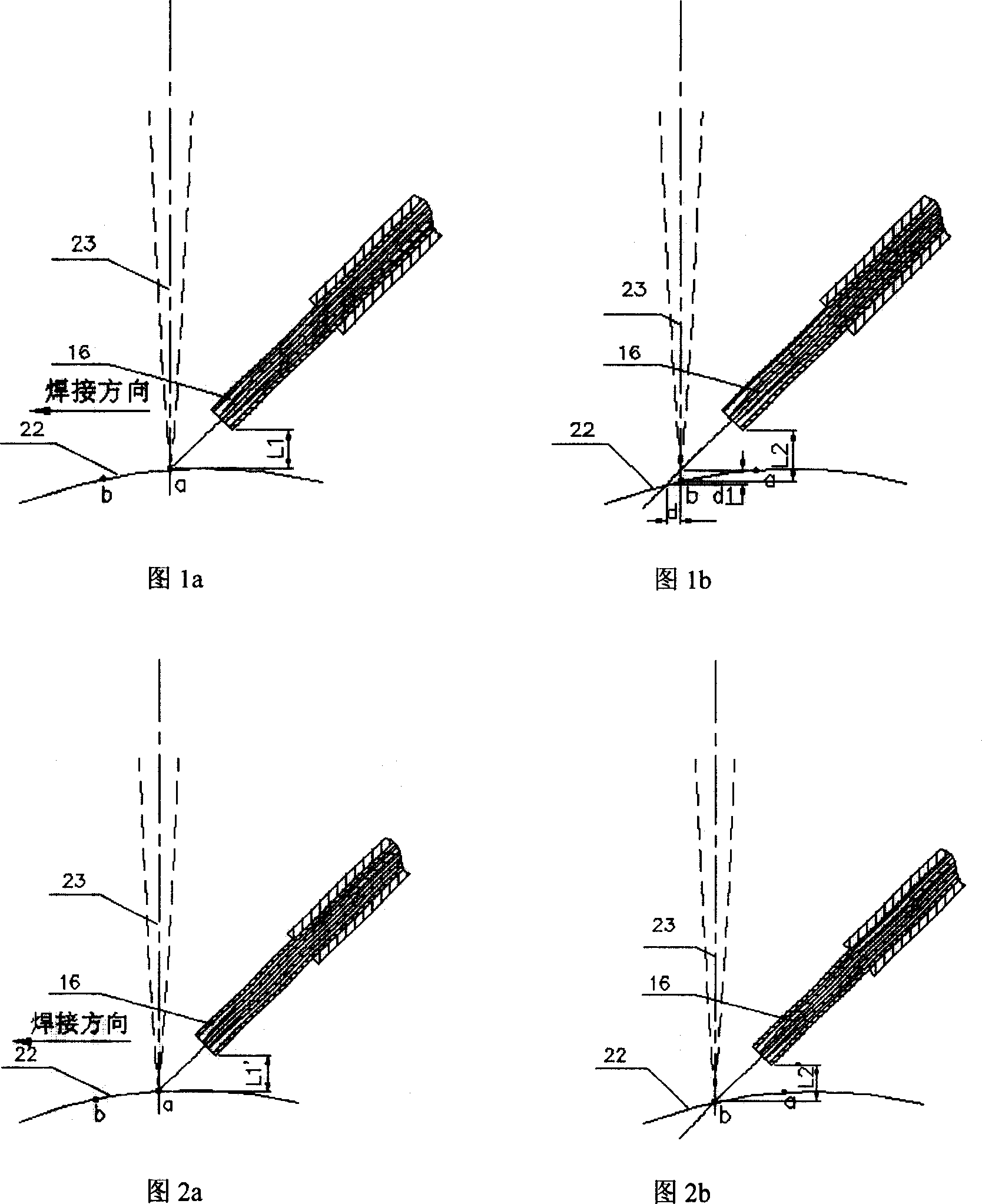

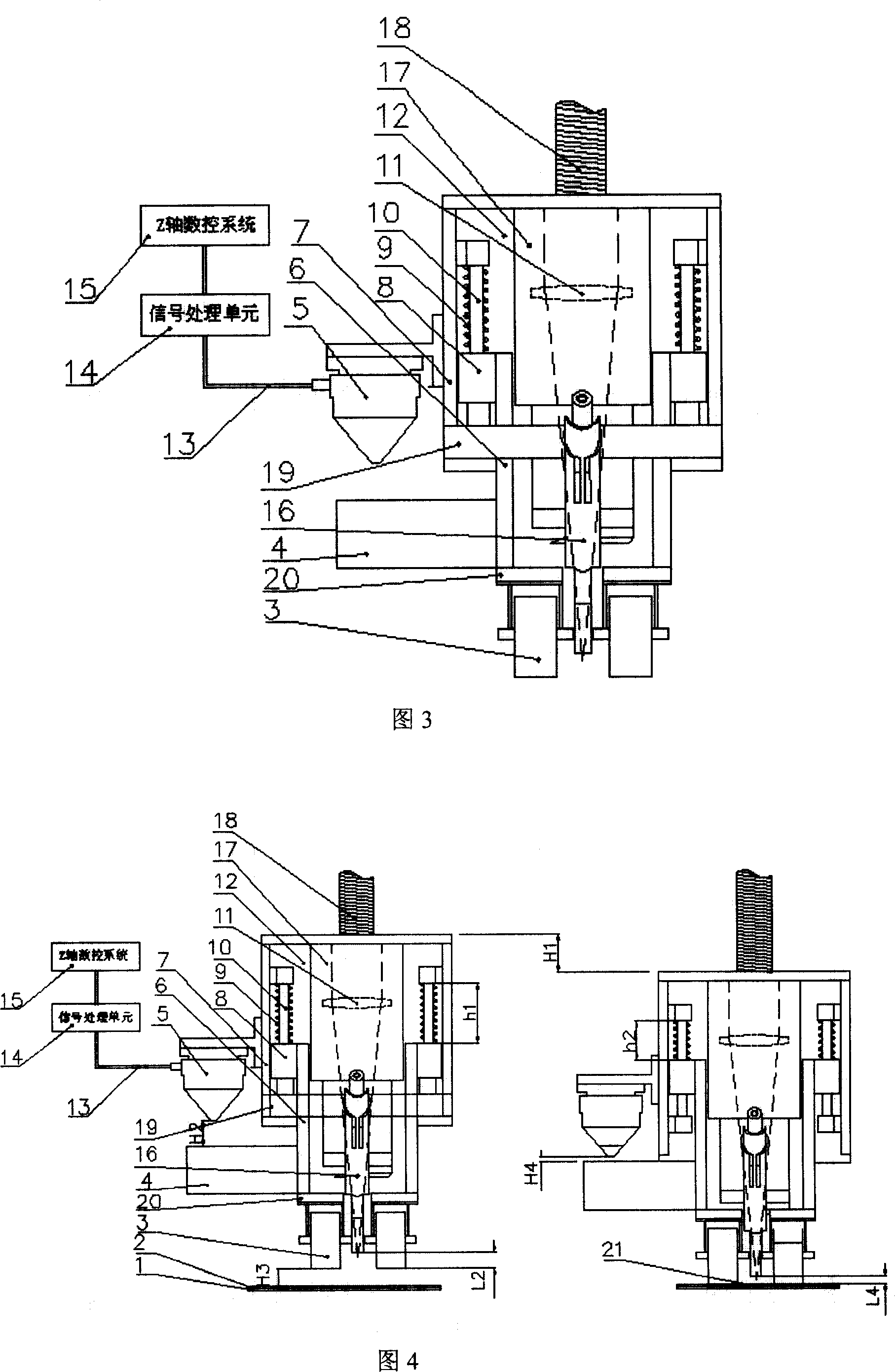

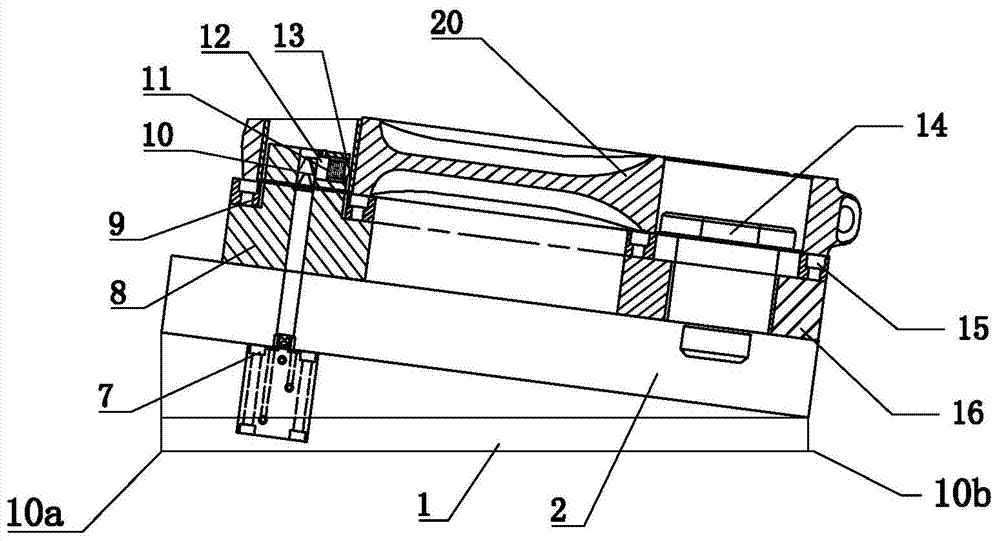

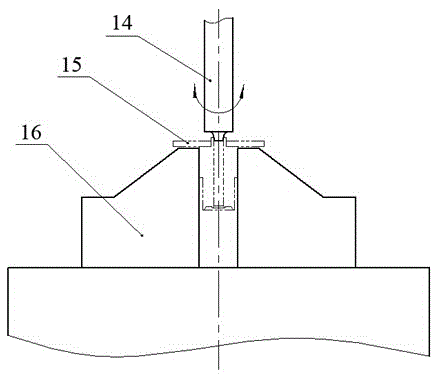

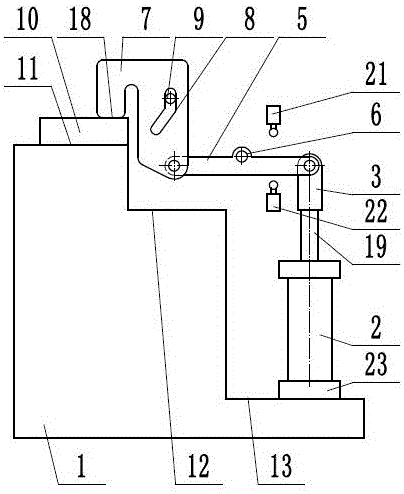

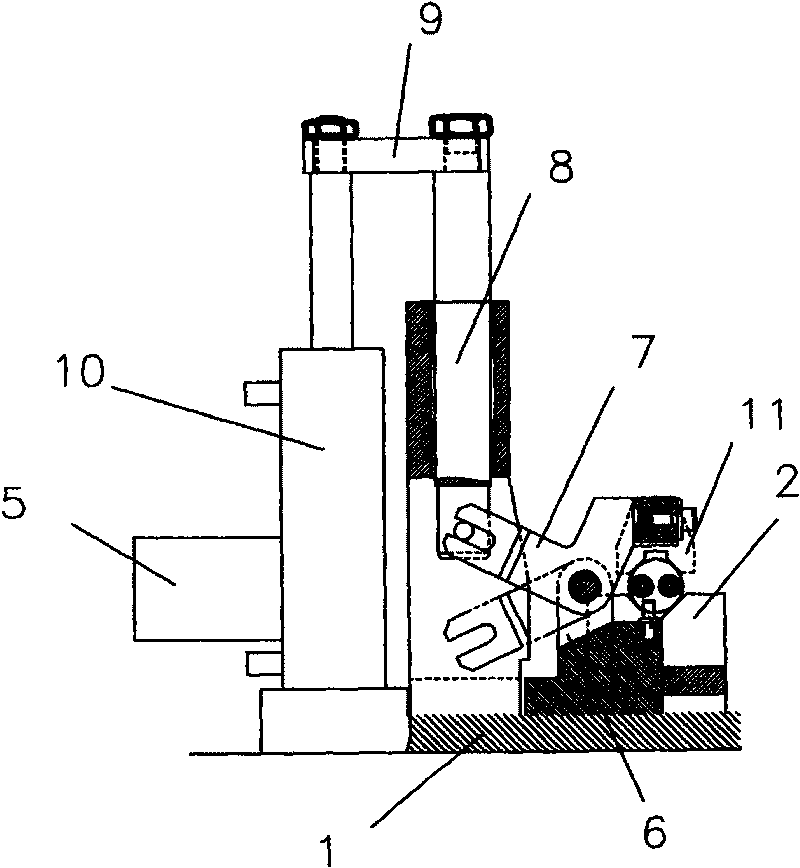

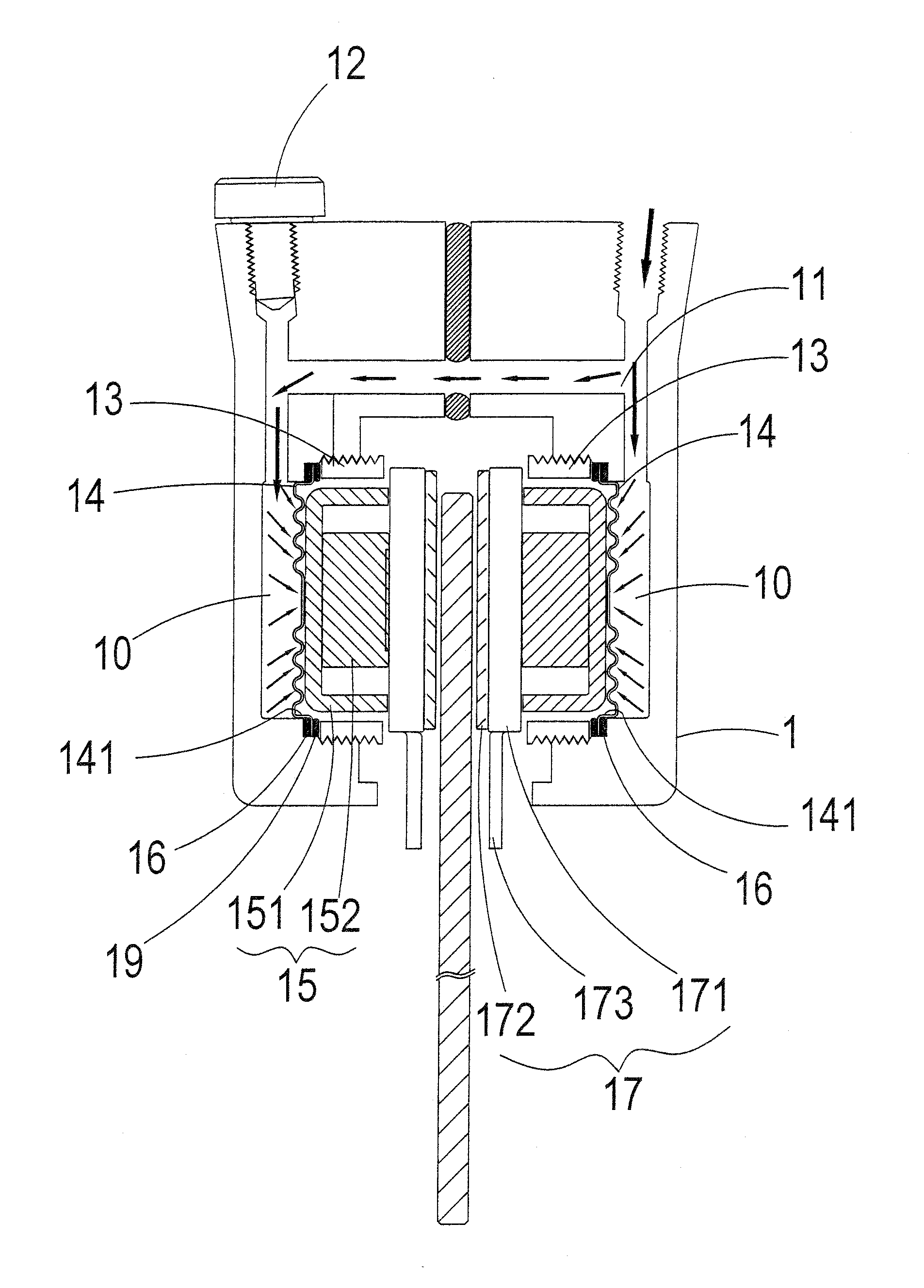

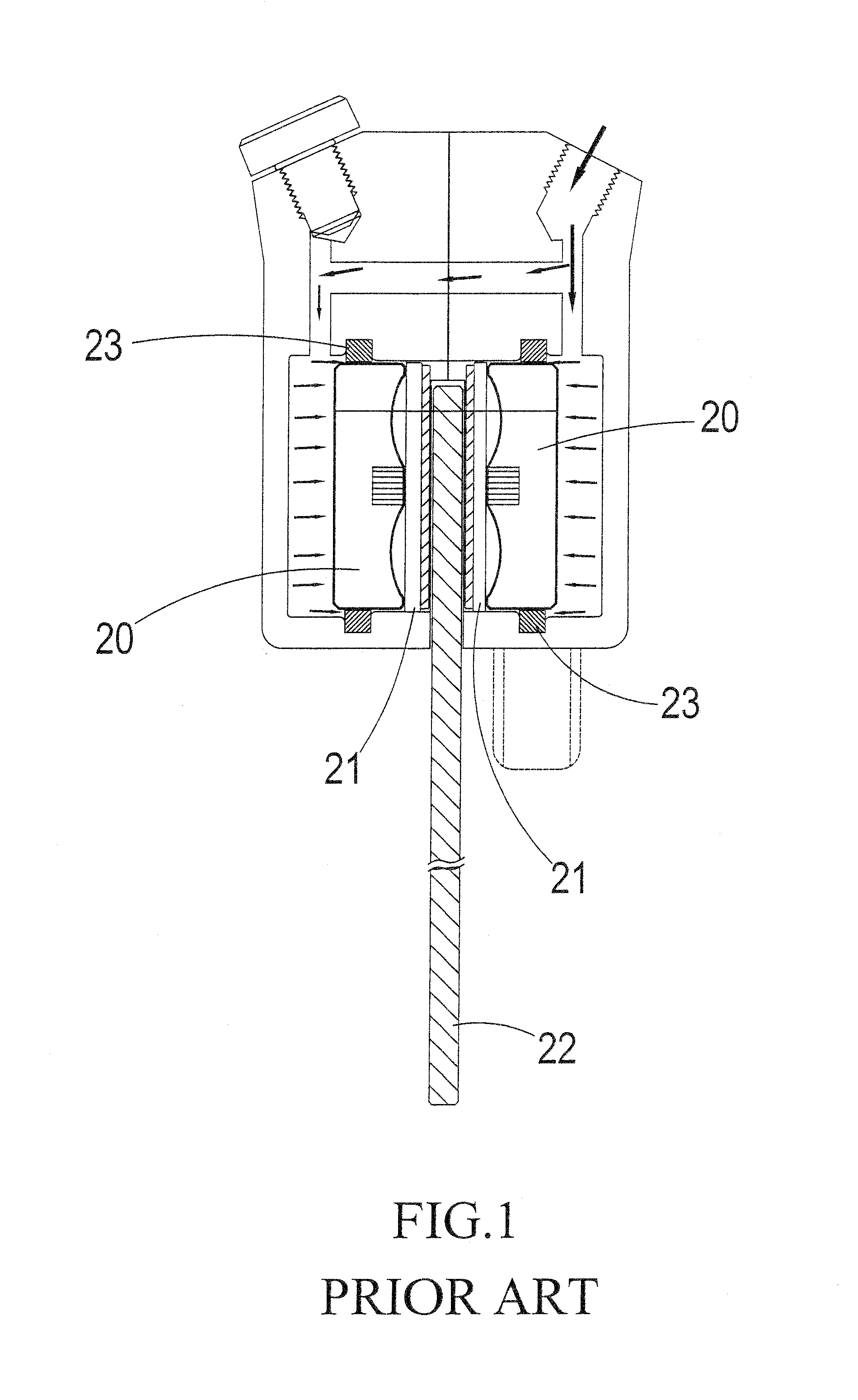

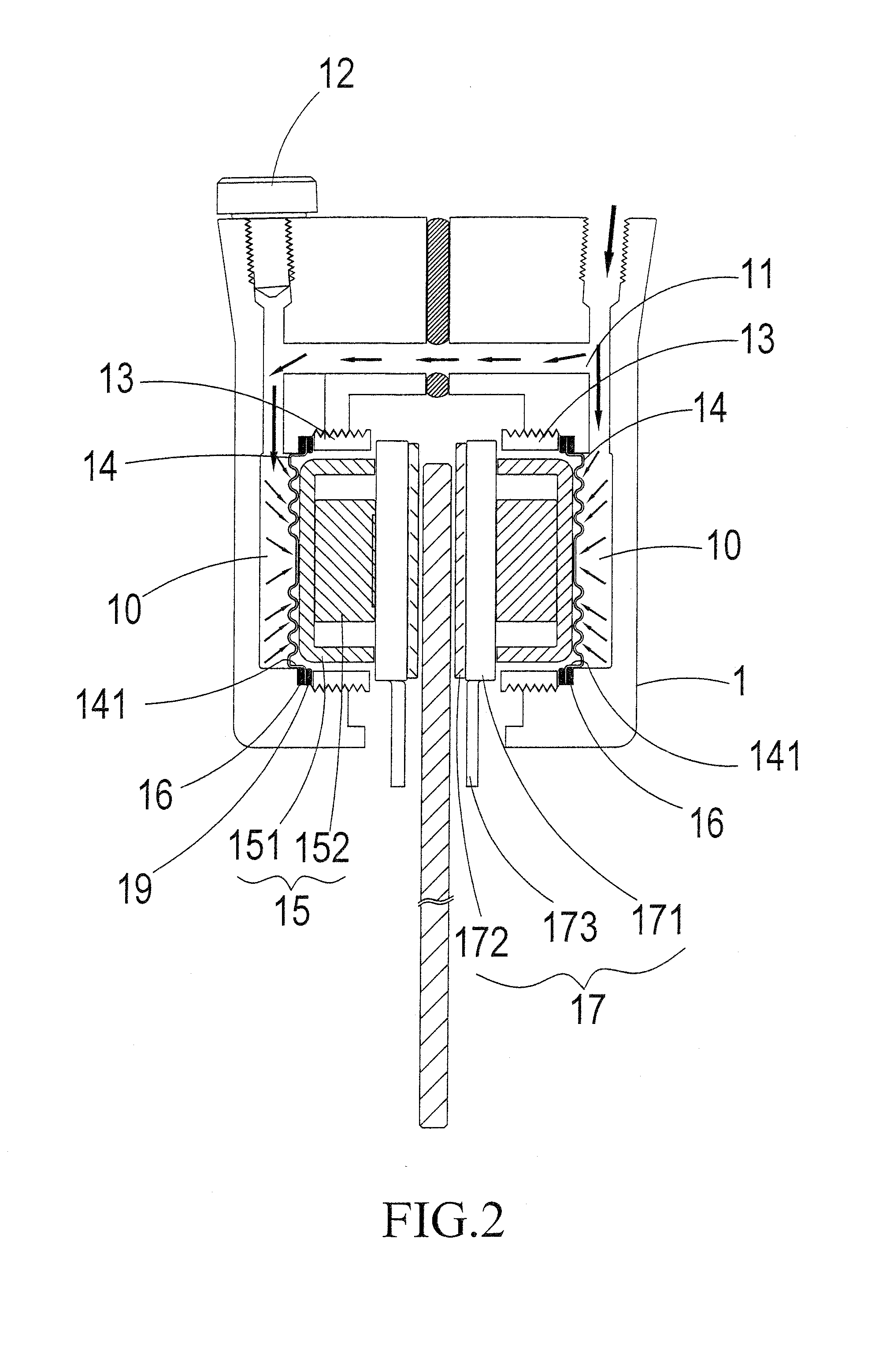

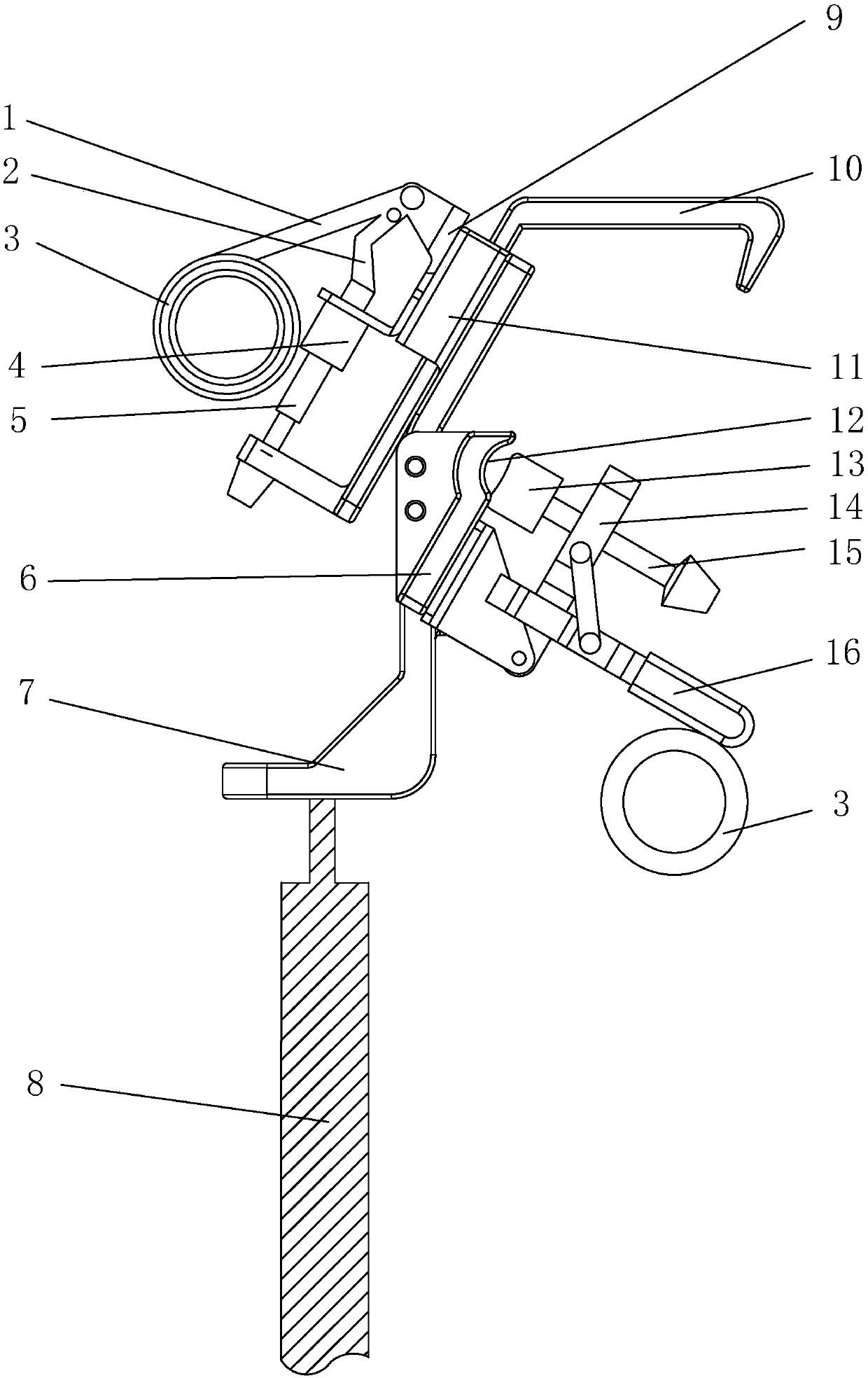

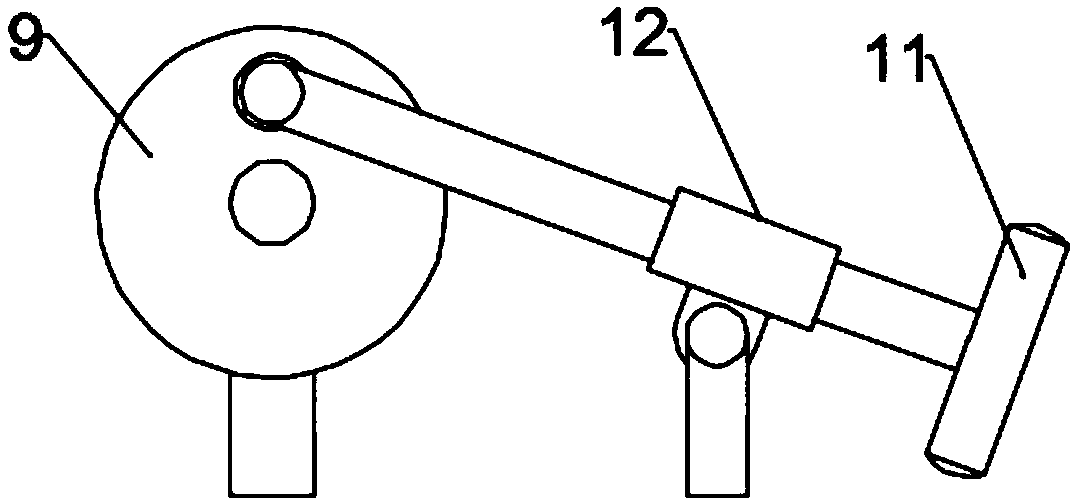

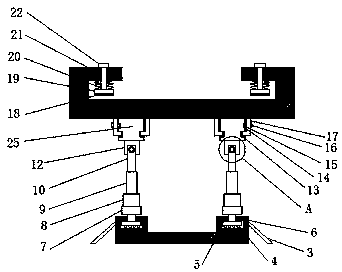

Laser welding head

InactiveCN101007369AGood compression effectReliable and stable laser welding qualityWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

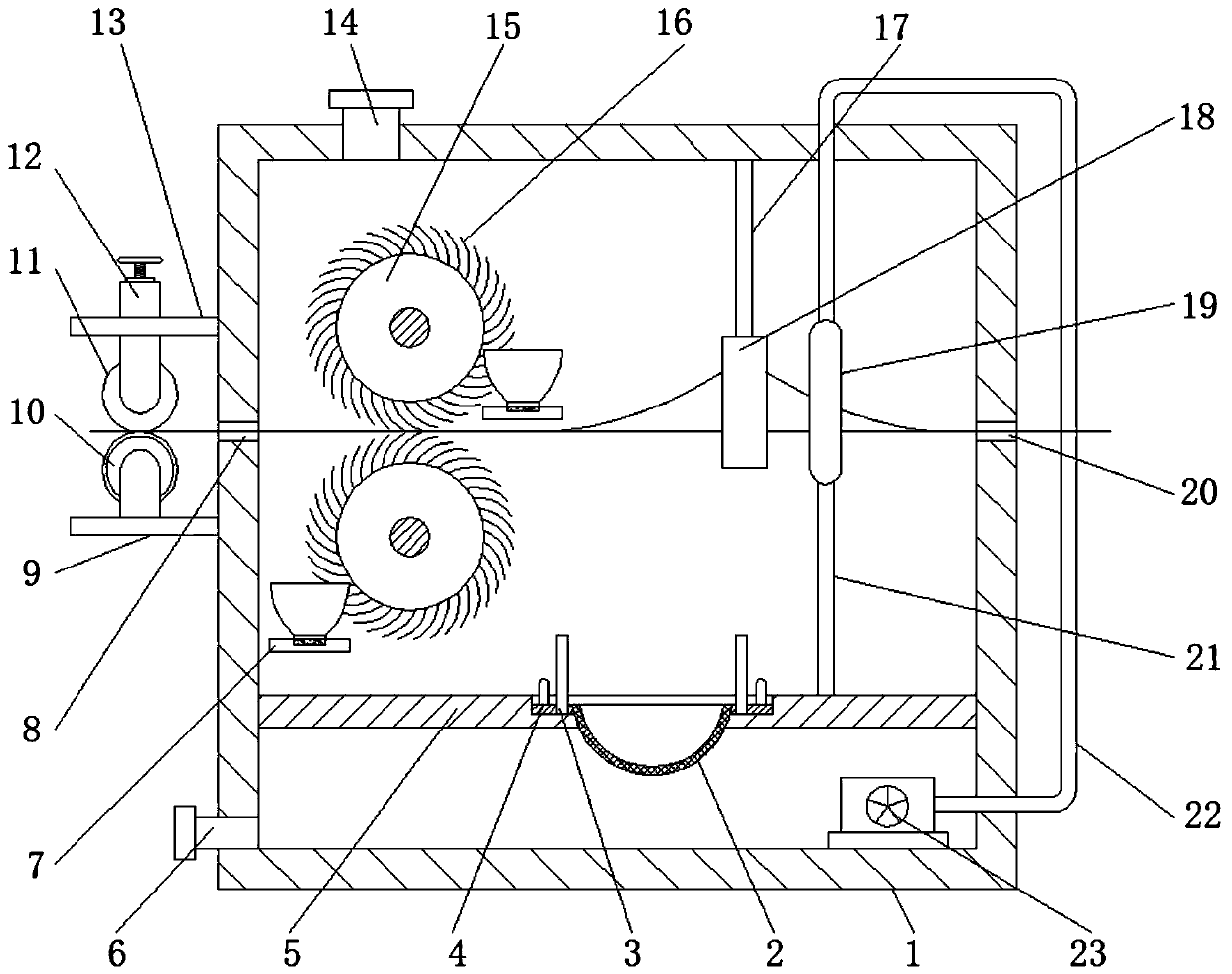

The invention involves a laser welding work head which belongs to laser materials welding technology field. It includes welding nozzle (16) and welding joints (17), it is characterized by: it also includes rack plate (12), static support plate (7), dynamic support plate (6), guide rail (10), spring (9), sliding block(8) and clamping components (3), height tracking sensor (5), high tracking reference plane (4), signal processing unit (14), Z-axle control system; Among them, the high tracking sensor (5) is installed on the outboard of static support plate (7) and under the high tracking reference plane which out the dynamic support plate (6).The beneficial effect of the invention is: in laser welding process, it ensures the clamping components (3) presses the workpiece tightly in constant pressure, ensures the relative position of laser welding nozzle to workpiece surface is constant and ensures the reliability and stability of laser welding quality.

Owner:BEIJING UNIV OF TECH

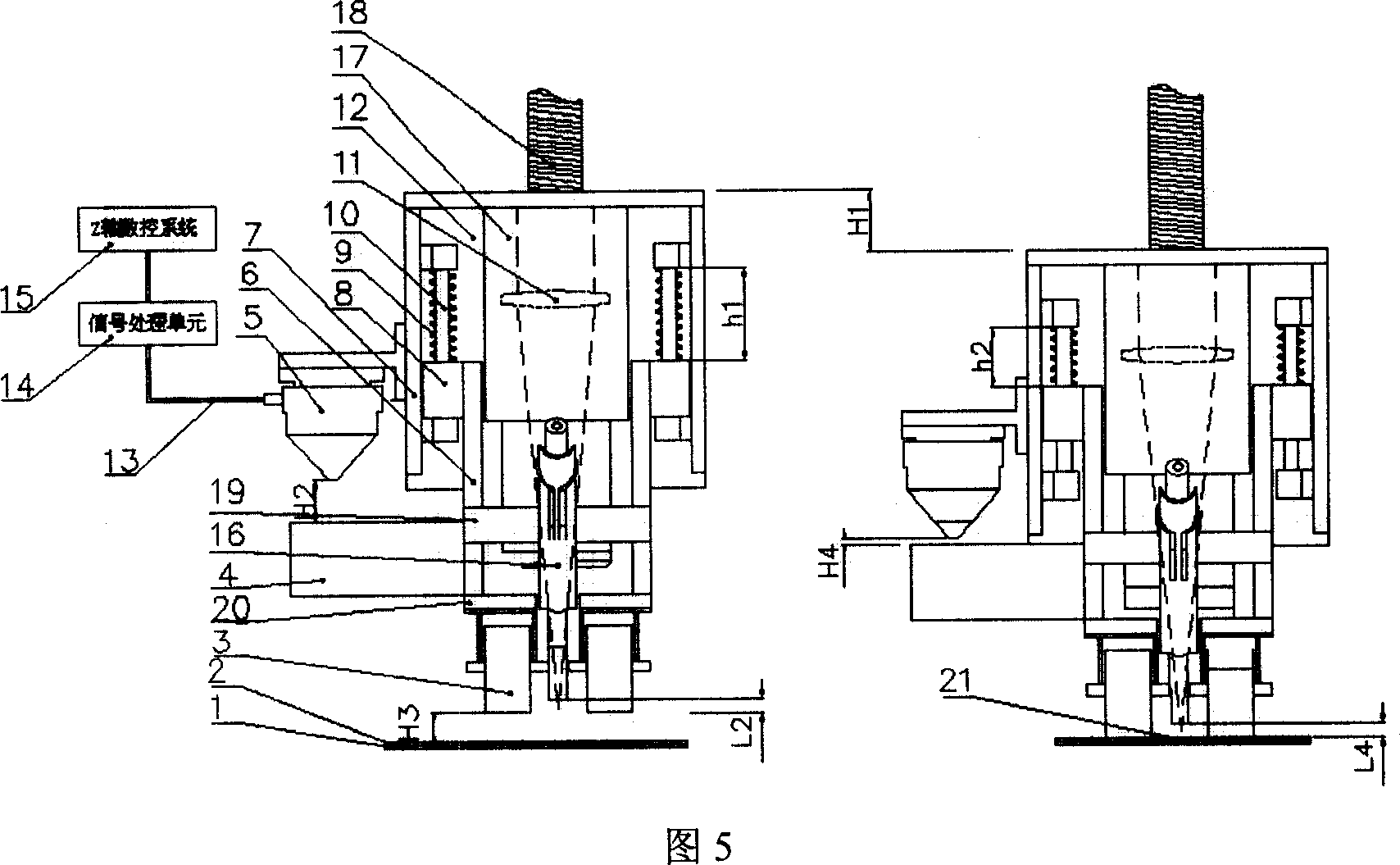

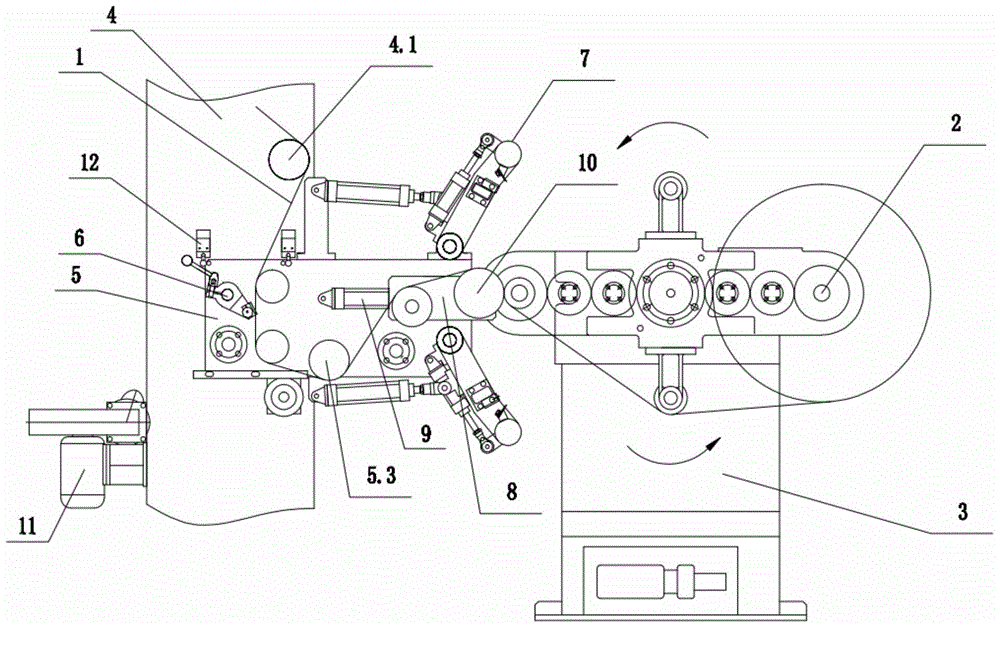

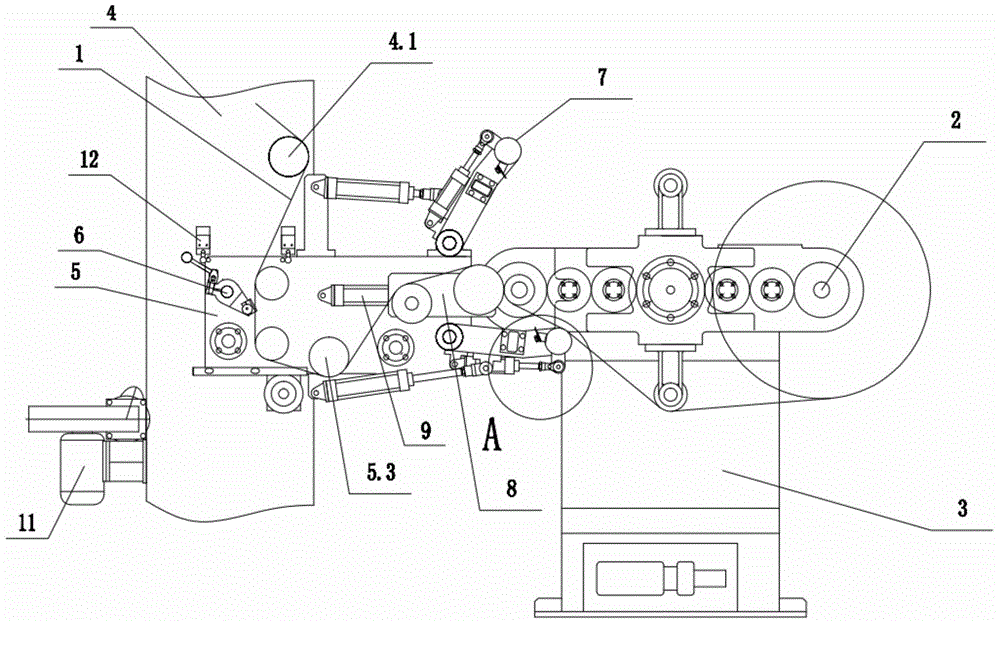

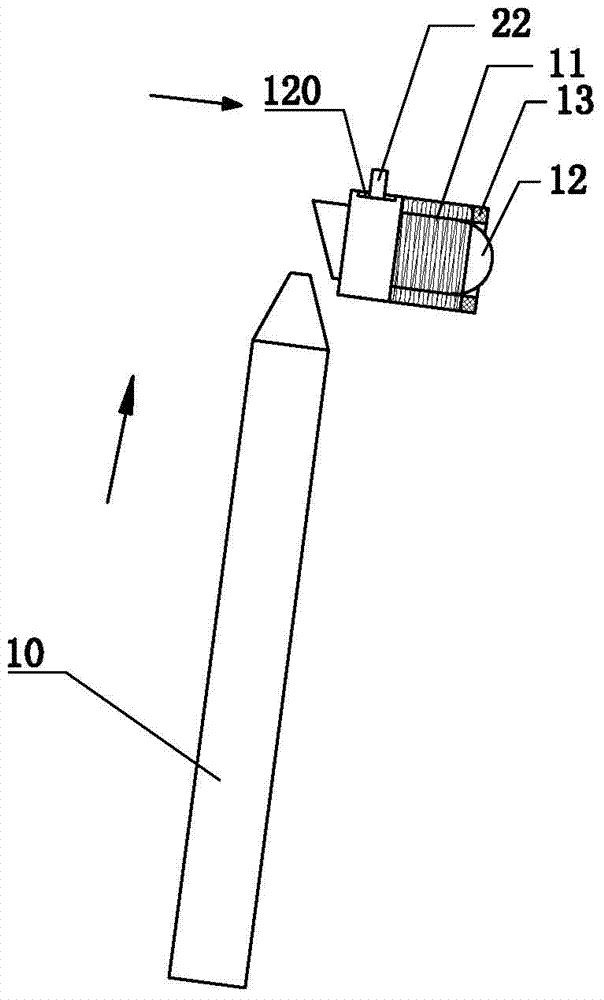

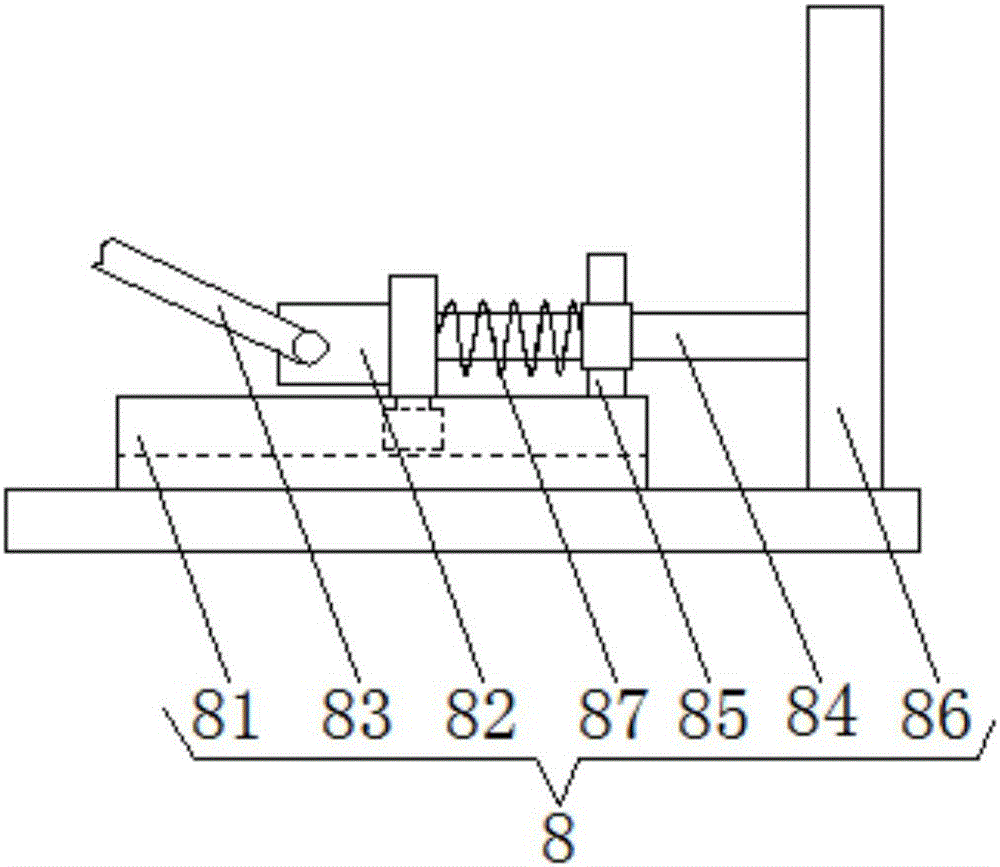

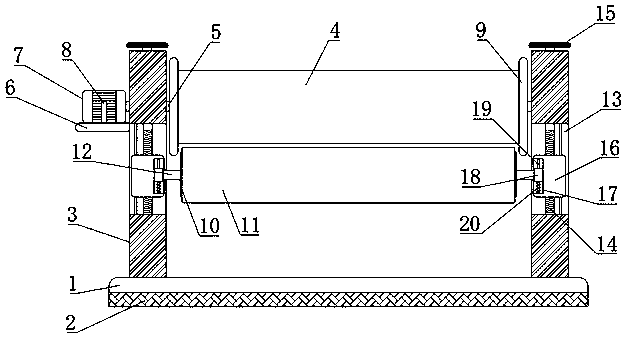

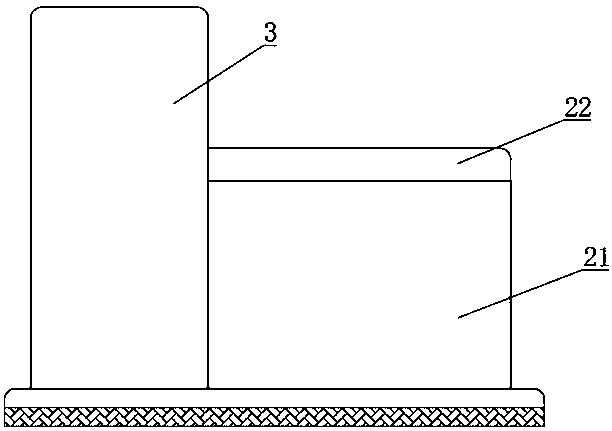

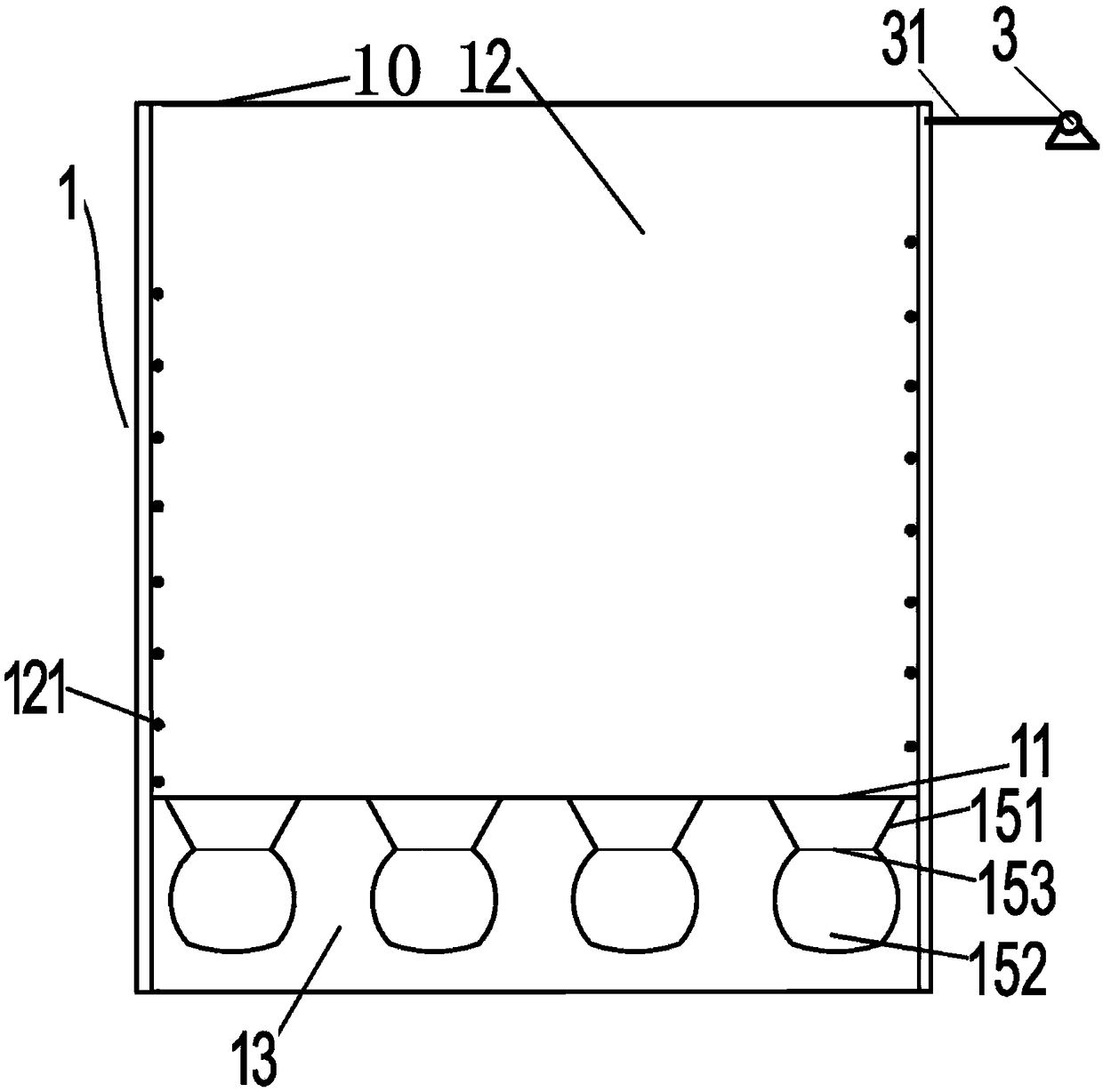

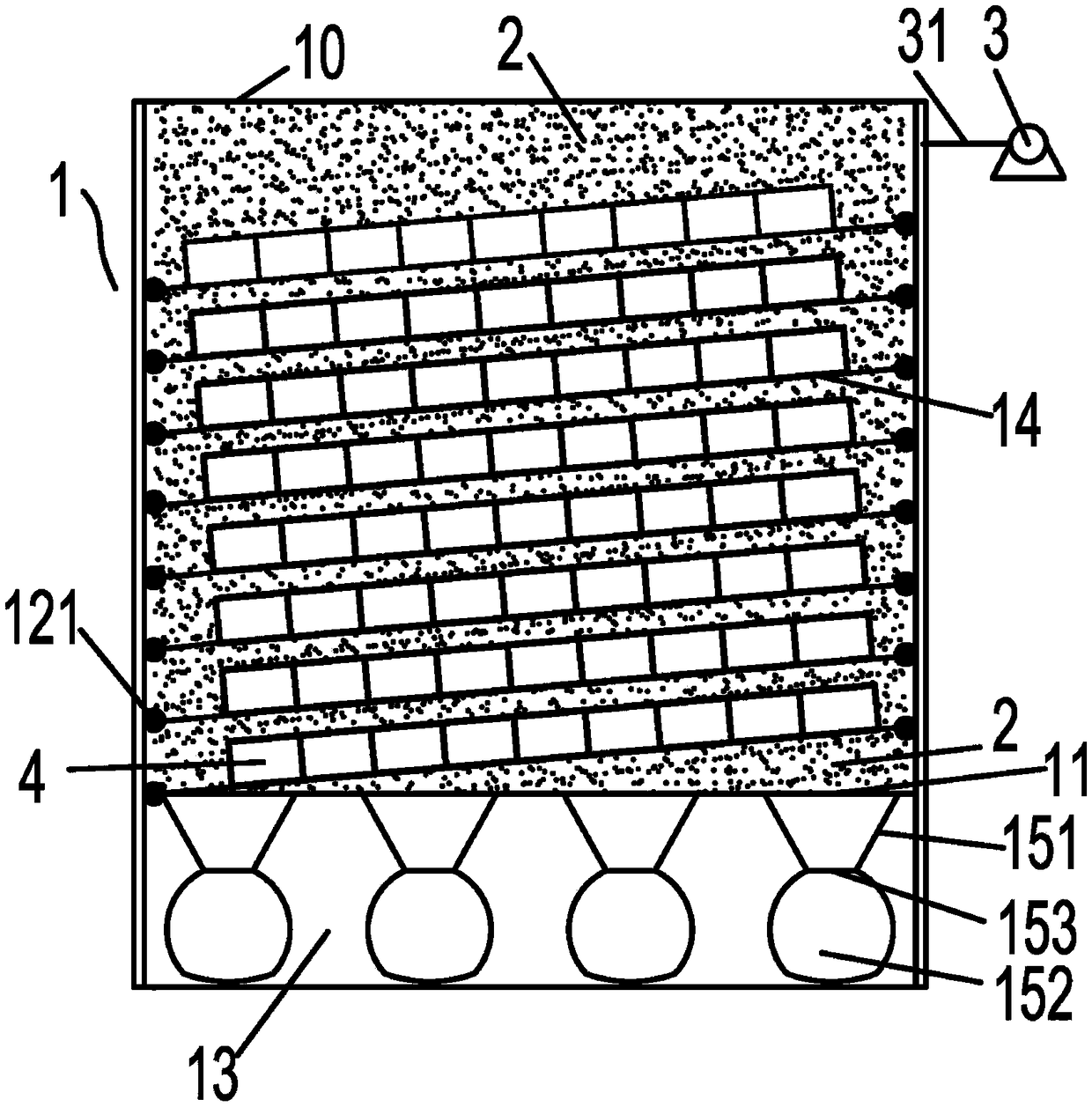

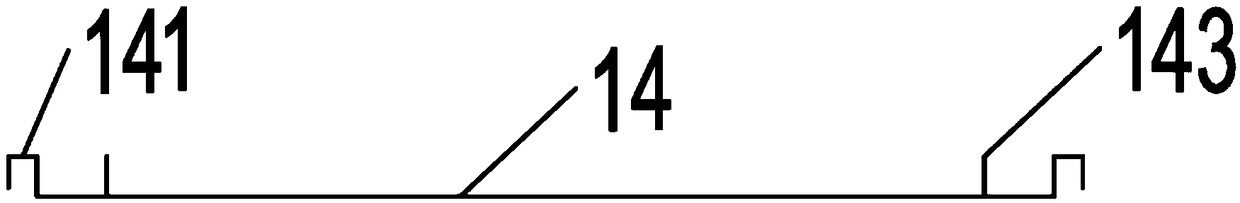

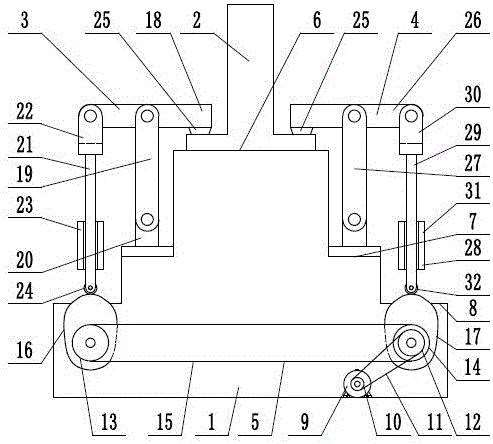

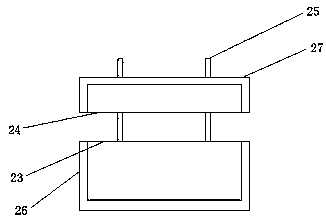

Automatic paper paving machine

ActiveCN103387071AGood compression effectLess prone to deflectionPackagingArticle deliveryPulp and paper industryPaper sheet

The invention relates to an automatic paper paving machine, comprising an unreeling mechanism and a paper conveying mechanism, wherein the output end of the unreeling mechanism is connected with the paper conveying mechanism; the output end of the paper conveying mechanism is connected with a lifting platform; a blowing mechanism is arranged at the output end of the paper conveying mechanism; a paper cutting mechanism is arranged above the blowing mechanism; the paper conveying mechanism comprises a paper sheet thickness adjusting device. According to the automatic paper paving machine with the structure, a drive roller and a driven roller in the paper conveying mechanism are good in a pressing effect, paper sheets conveyed are flat and do not easily deflect, the paper paving precision is high, the driven roller and the drive roller can automatically adapt to the paper sheets with different thickness through a spring, and the universality is strong; the lifting platform is integrated with the paper conveying mechanism, the space is greatly saved, the blowing mechanism is used for assisting in conveying the paper sheets and preventing the paper sheets from flying up or stopping; a paper knife in the paper cutting mechanism is circular, the cutting is very rapid, and the cutting edge of the paper knife is lower than the surfaces of the paper sheets, so that two edges of the paper sheets can be completely cut off.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

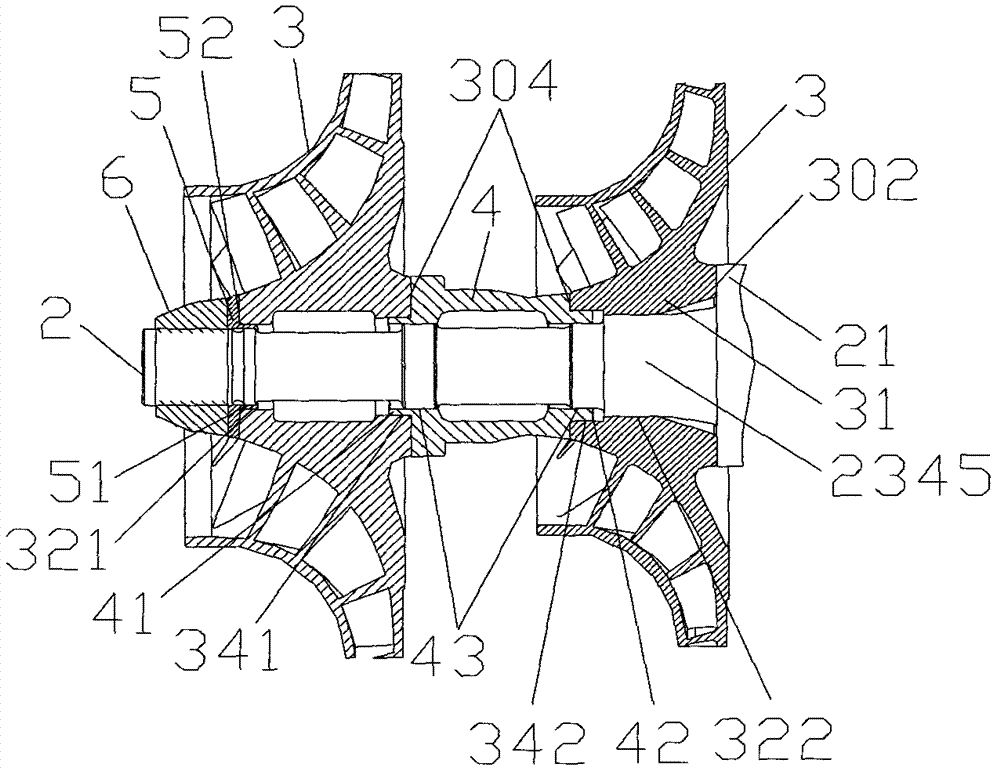

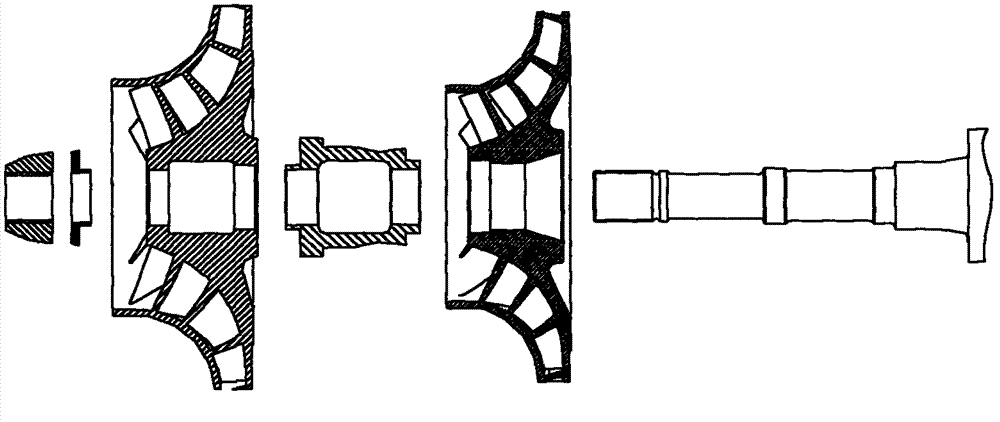

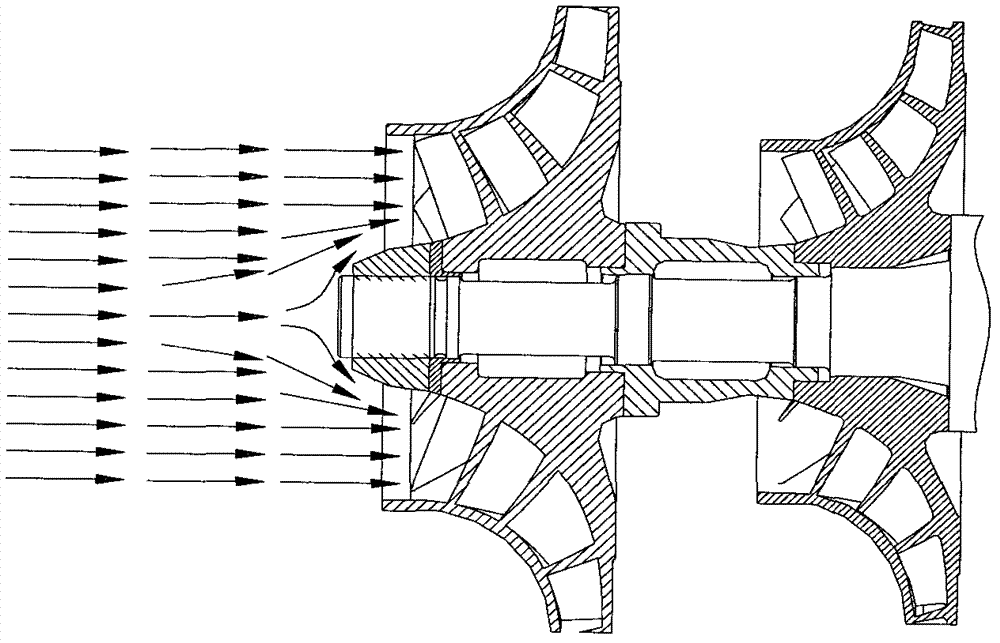

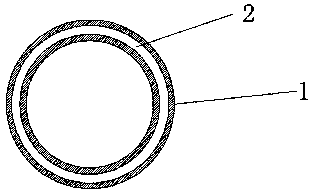

High-speed hydrodynamic machine and composition method and assembly method of rotor of high-speed hydrodynamic machine

InactiveCN103362860AReduced carrying capacityEasy to disassemblePump componentsPumpsImpellerDrive motor

The invention relates to a high-speed hydrodynamic machine of which the rotating speed is above 6000rpm, particularly between 7000rpm and 20000rpm. The high-speed hydrodynamic machine comprises a driving motor and a rotor, wherein the rotor comprises a driving motor rotating shaft and rotating impellers acting on fluid; and the rotating impeller are directly mounted on the driving motor rotating shaft, connected in a keyless manner, positioned together with the driving motor rotating shaft in an interference manner through hot-pressing in a radial direction, and compressed and pushes against a radial flange of the rotating shaft by a locking structure in an axial direction. In addition, the invention further relates to a composition method and an assembly method of the rotor of the high-speed hydrodynamic machine with the rotating speed above 6000rpm. According to the machine, since the rotating impellers are directly mounted on the driving motor rotating shaft, the transmission efficiency is improved greatly, the rotor is simpler to dismount simultaneously, and the impellers and the rotating shaft are good in coaxiality and sealability, and low in vibration.

Owner:GREE ELECTRIC APPLIANCES INC

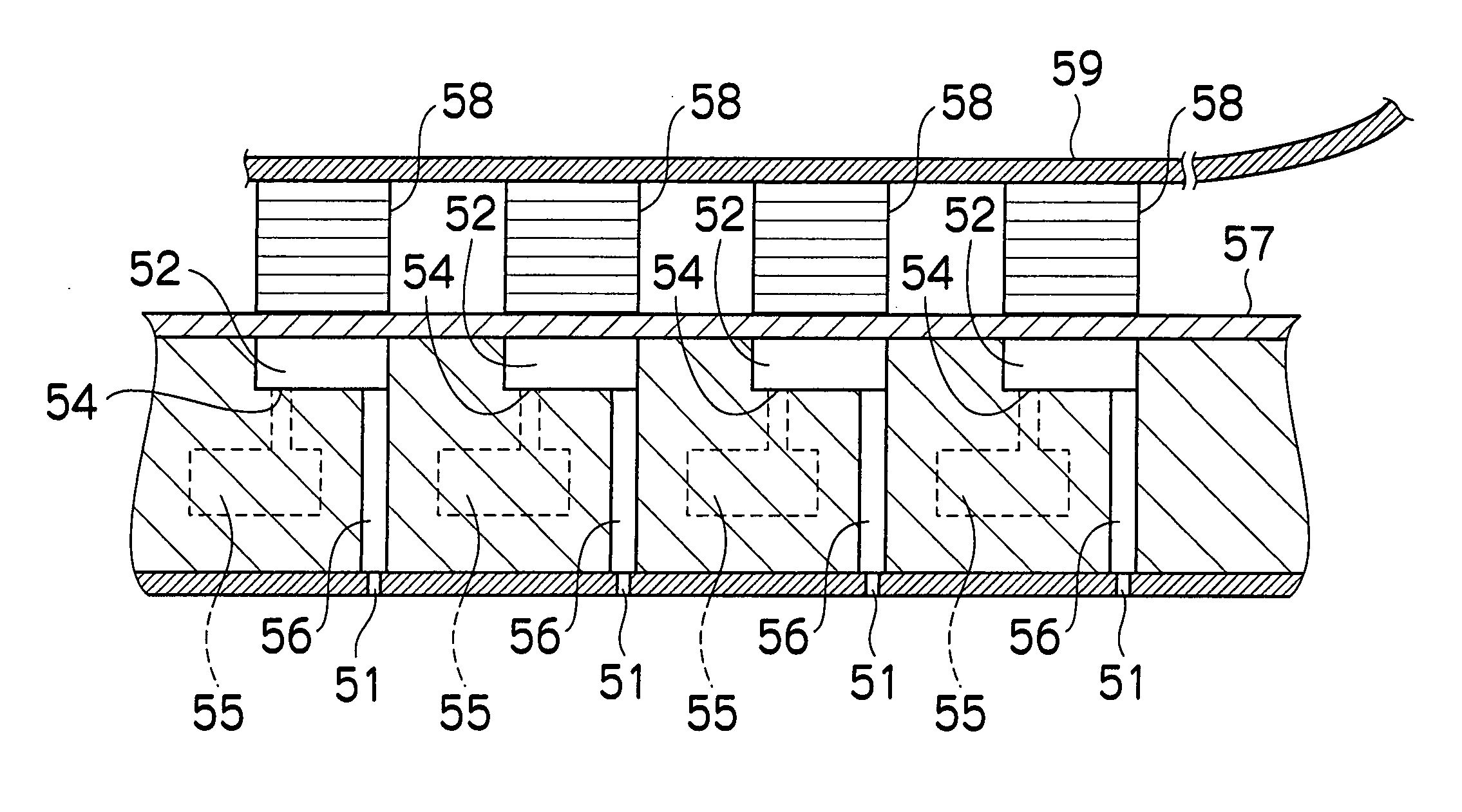

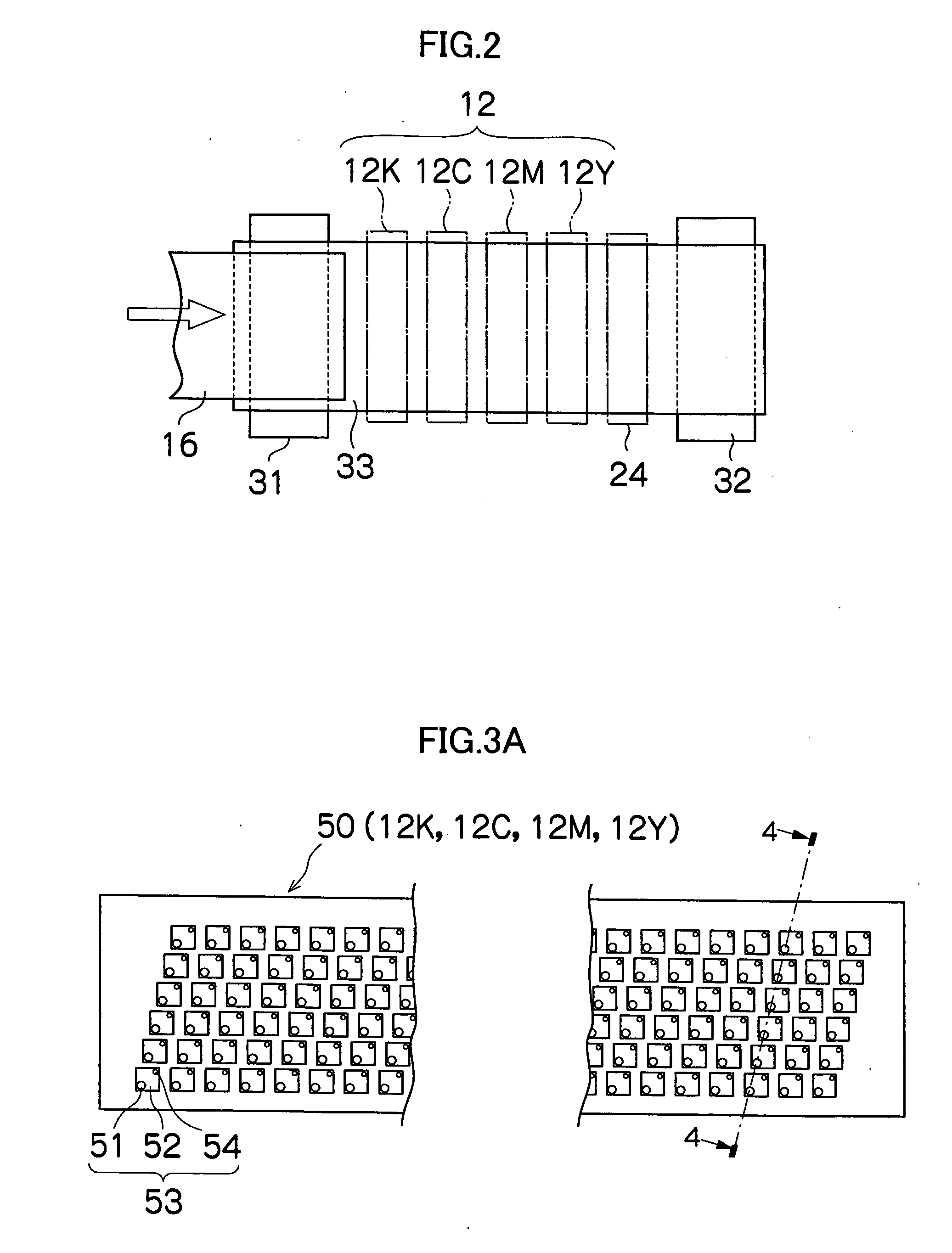

Droplet discharge head and inkjet recording apparatus

A droplet discharge head comprising: a plurality of nozzles for discharging droplets, a plurality of pressure chambers provided correspondingly to the plurality of nozzles and filled with liquid to be discharged from the nozzles, a vibration plate constituting one of the wall surfaces of the pressure chambers, and a plurality of laminated piezoelectric bodies fixedly joined at independent positions on the vibration plate that correspond to the plurality of pressure chambers; wherein the end portion of the laminated piezoelectric bodies on the side opposite from the joint surface with the vibration plate is formed into an unrestricted end that is displaceable in the direction of pressure applied to the vibration plate by the laminated piezoelectric bodies, and pressure is applied to the liquid inside the pressure chamber via the vibration plate by expansion and contraction displacement produced by the laminated piezoelectric bodies to discharge droplets from the nozzles.

Owner:FUJIFILM CORP

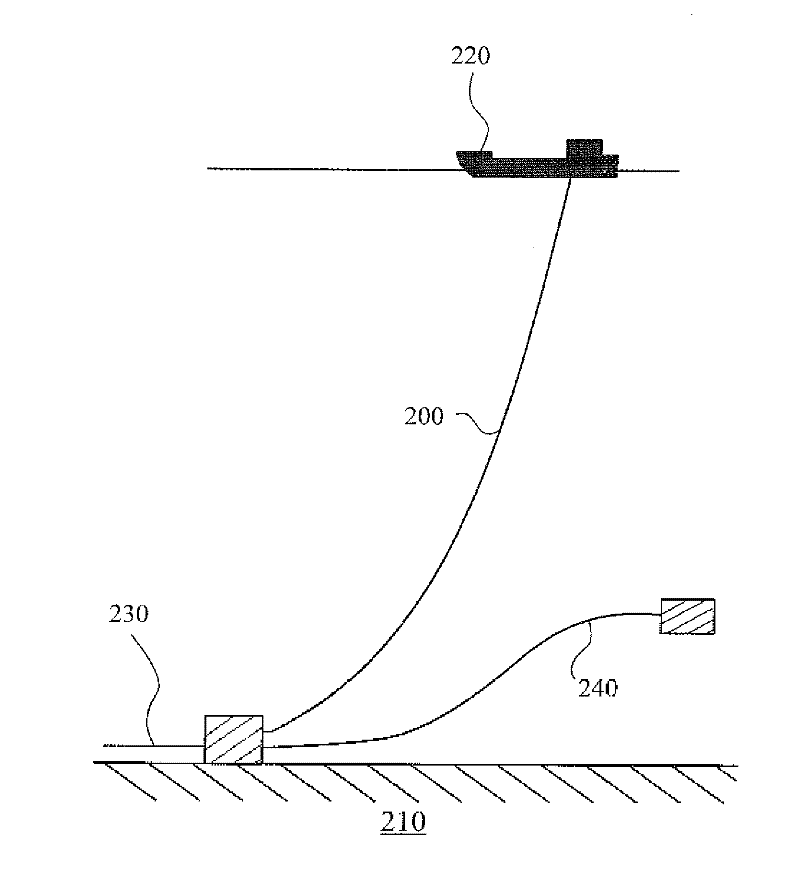

Enhanced protection

ActiveCN102272504APrevent movementGood compression effectDrilling rodsFlexible pipesEngineeringConductor Coil

A method for manufacturing flexible pipe body and flexible pipe body of a type suitable for transporting production fluids are disclosed. The flexible pipe body includes an armour layer comprising interlocked windings of armour tape comprising at least one armour locating element and a reinforcement layer comprising a layer of reinforcement tape comprising at least one reinforcement locating element over the armour layer. The armour locating element and reinforcement locating element locate windings of the reinforcement tape with respect to respective windings of the armour tape.

Owner:GE OIL & GAS UK LTD

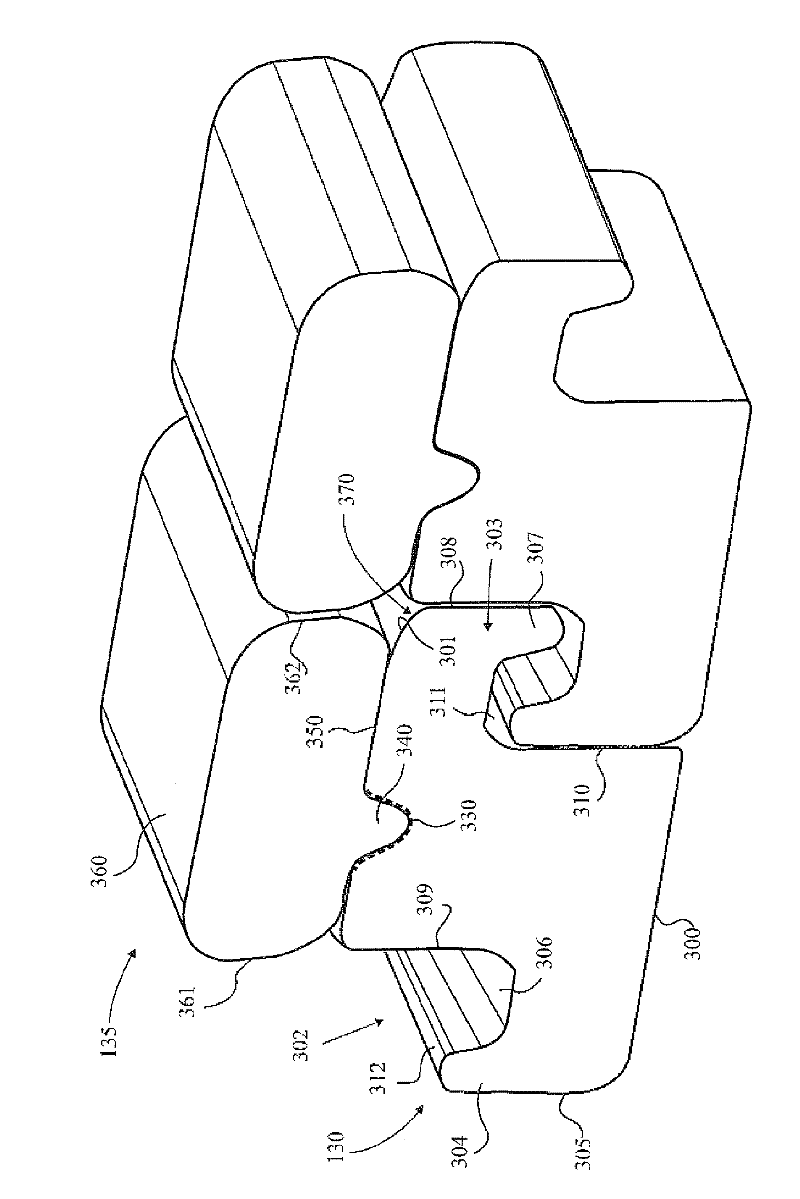

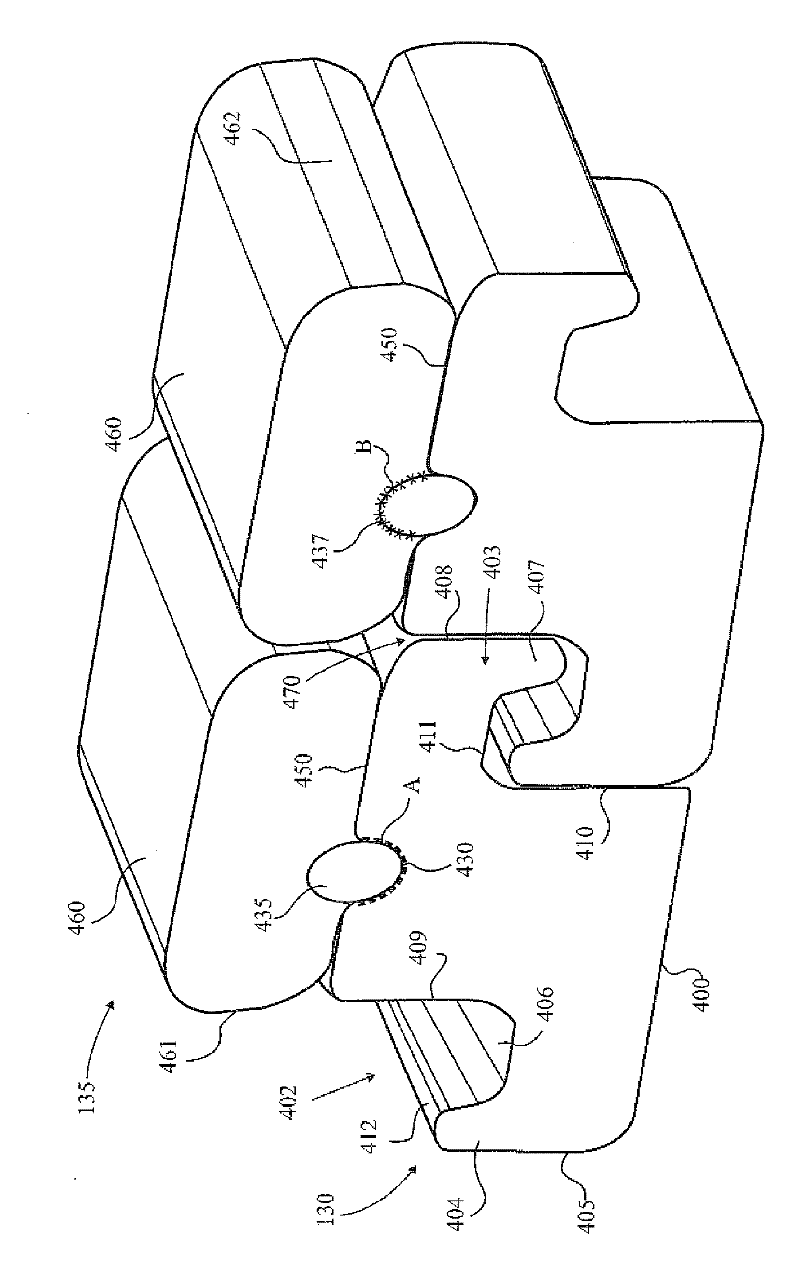

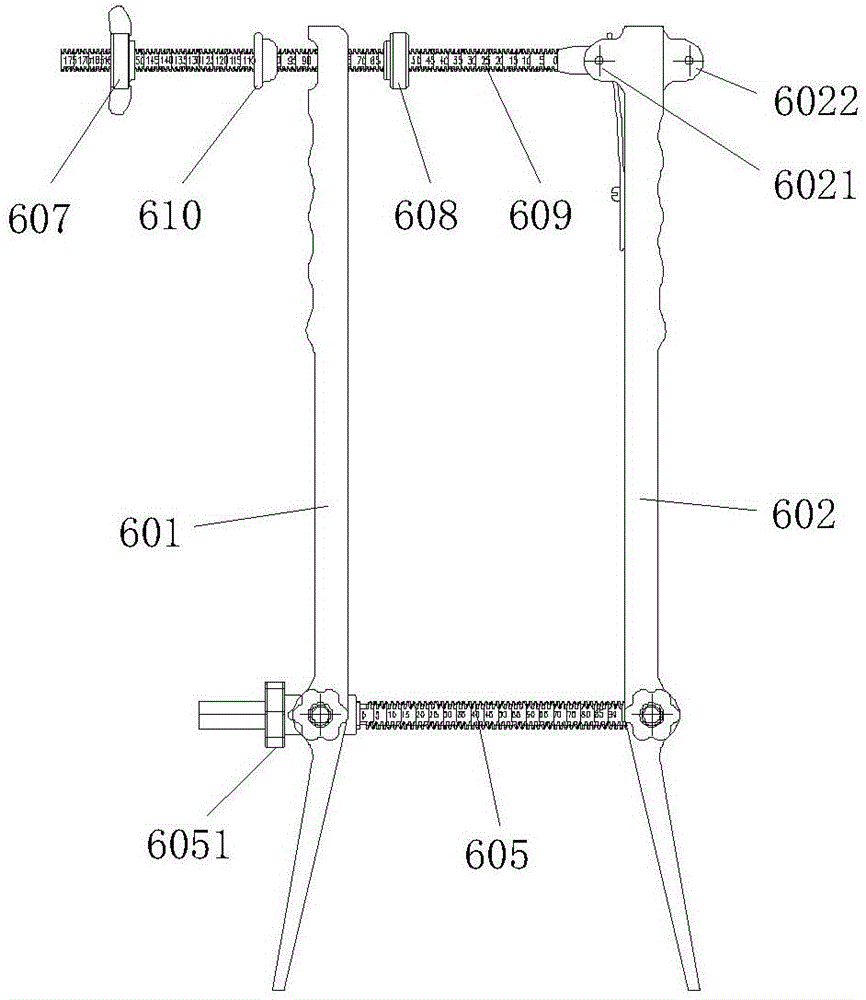

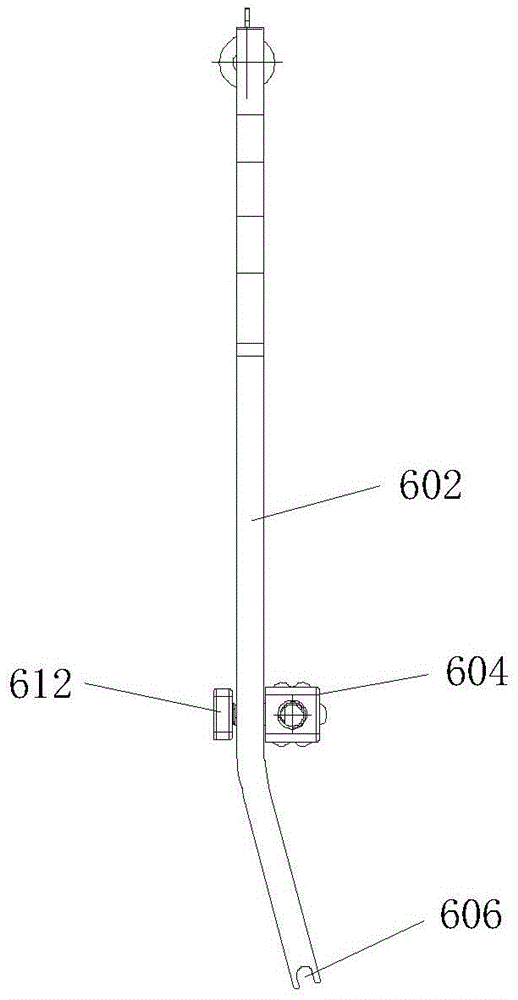

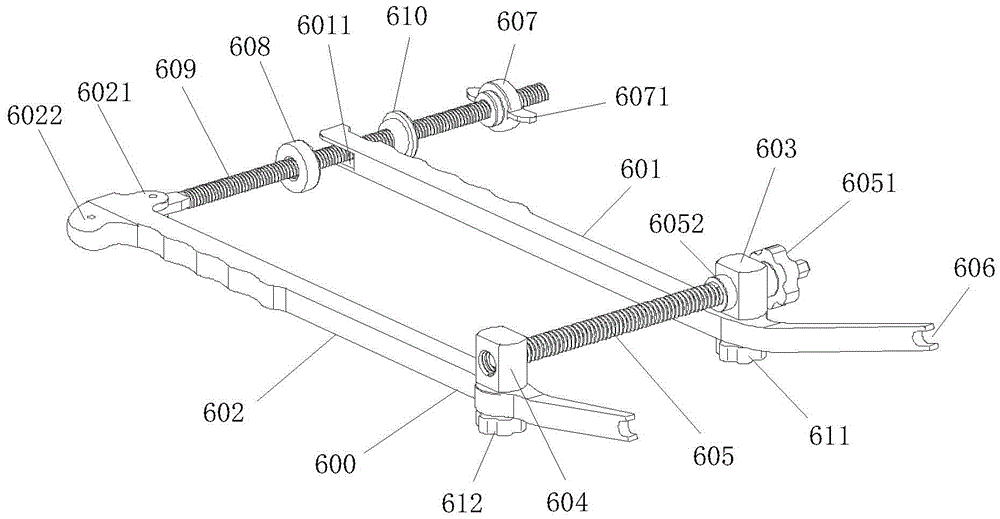

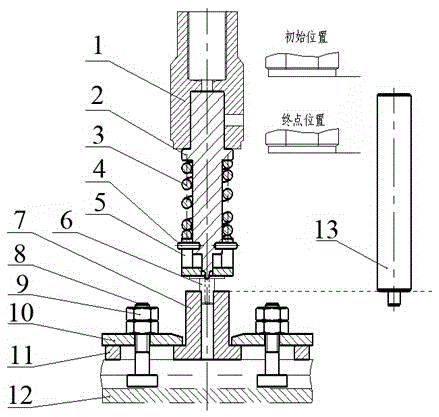

Commonly-used percutaneous pedicle screw stick internal fixing system

The invention discloses a commonly-used percutaneous pedicle screw stick internal fixing system which comprises a pedicle screw, a longitudinal connection stick, a puncture cone, a guide pin, an expansion core, a screw setting guide sleeve, a hollow flat file, a hollow screw tap, a screw feeder, a stick holder, a screw plug holder, a screwdriver, an opening pressurizer and a torsion resistance sleeve spanner. The opening pressurizer comprises a first opening pressurization arm, a second opening pressurization arm, a first connector, a second connector and a supporting stick. The first connector and the second connector with the adjustable distance are connected to the supporting stick. The first opening pressurization arm is detachably hinged to the first connector, and the second opening pressurization arm is detachably hinged to the second connector. One end of the first opening pressurization arm and one end of the second opening pressurization arm are each provided with a clamping groove. A progressive force application mechanism is connected between the other end of the first opening pressurization arm and the other end of the second opening pressurization arm. The system can be operated flexibly, easily, conveniently and rapidly in a labor-saving mode, can achieve gradual opening or pressurization at different times, and has the powerful and effective opening or pressurization effect.

Owner:贺新宁

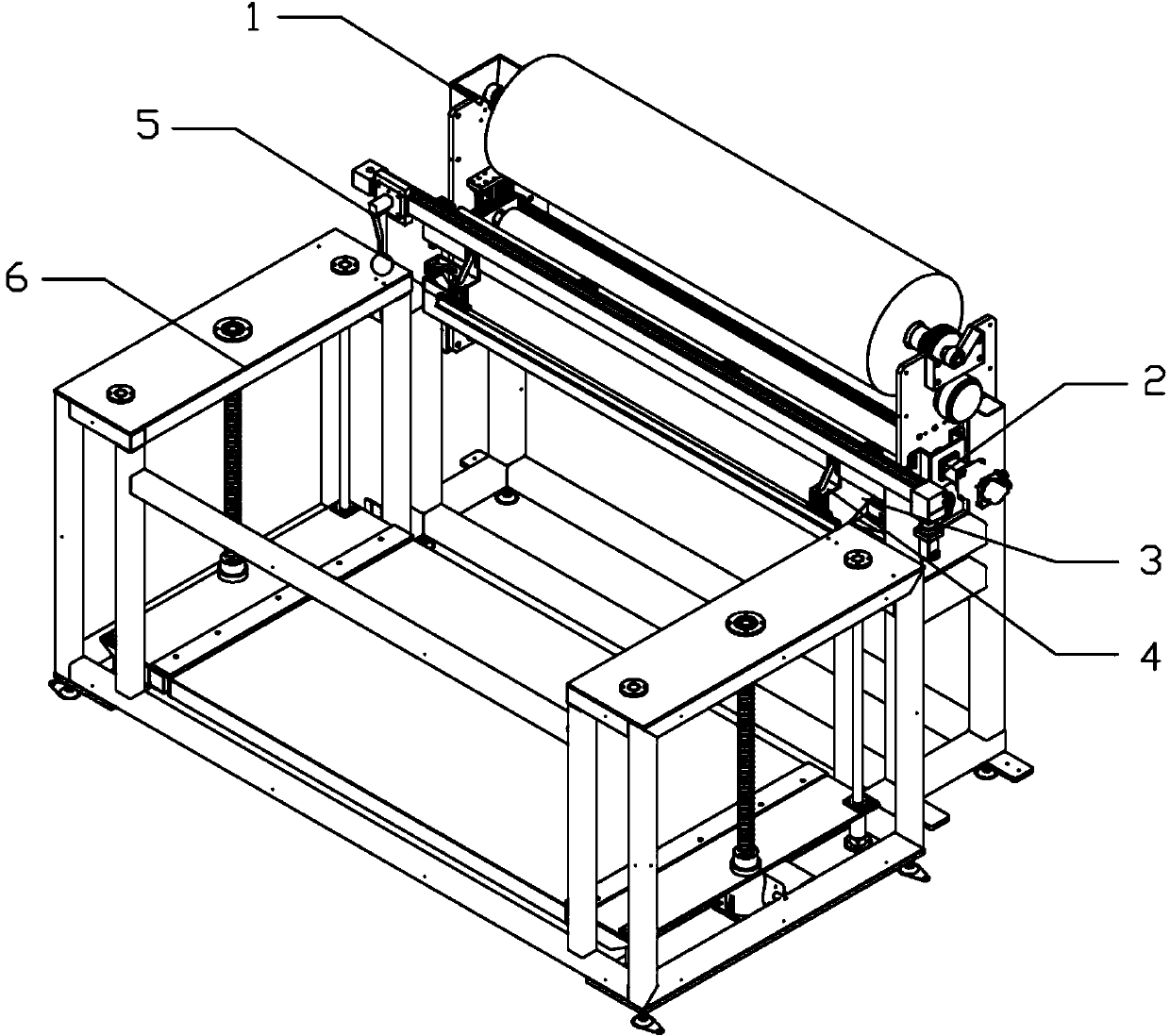

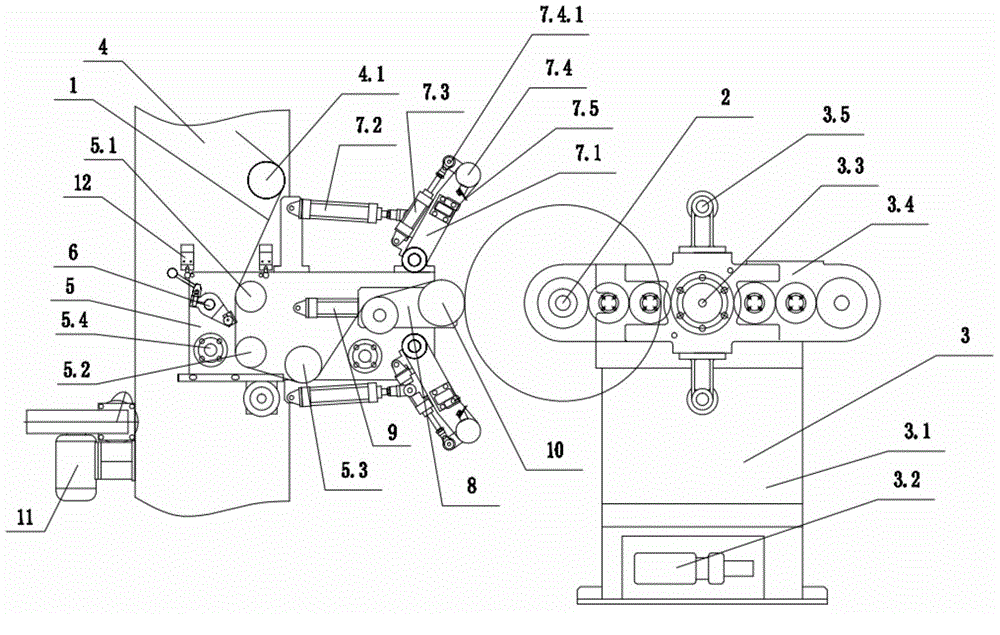

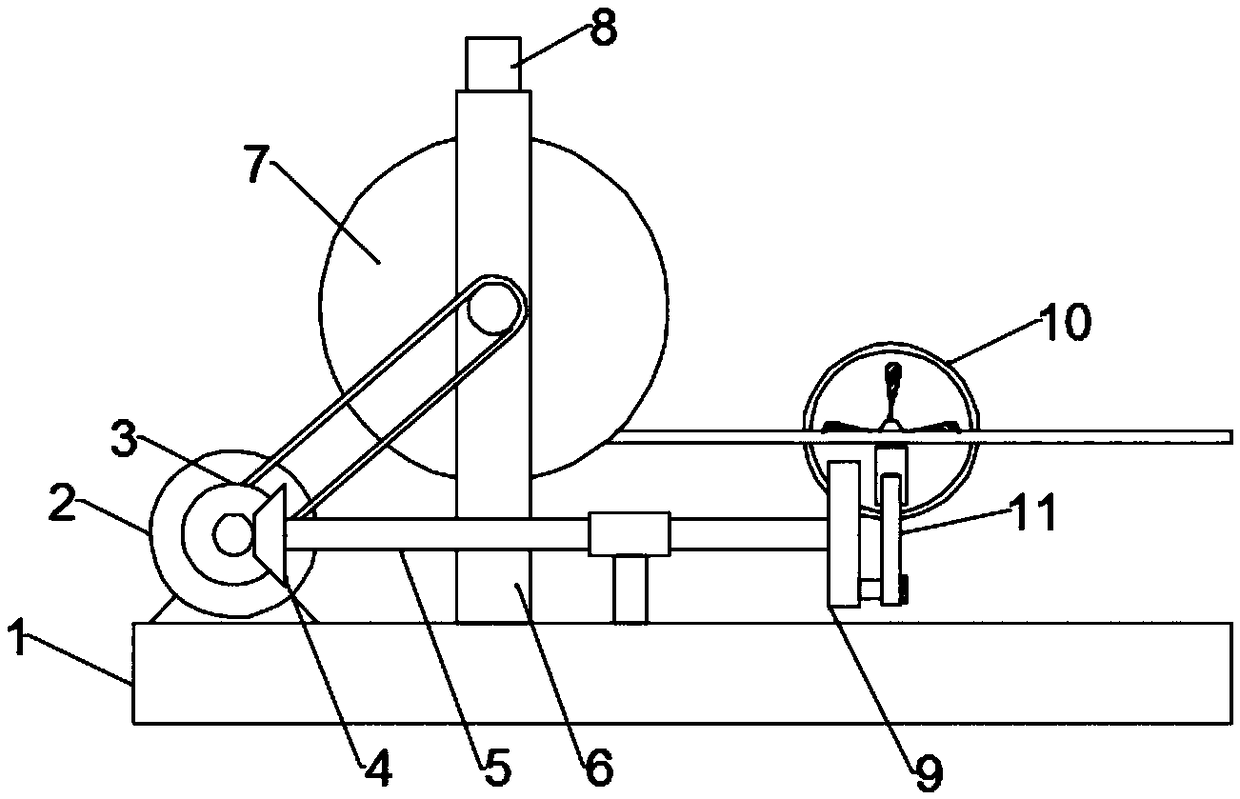

Multifunctional winding device used for machining winding drum material

ActiveCN104609230AImprove cut qualityImprove processing efficiencyArticle deliveryWebs handlingEngineeringConductor Coil

The invention discloses a multifunctional winding device used for machining winding drum material. The multifunctional winding device comprises a winding unit (3) which is used for winding the material film (1) around a material tube (2) and is capable of automatically replacing the material tube. The multifunctional winding device is characterized by further comprising an installing frame (4), a transverse movement plate (5), a splitting mechanism (6) and a cutting mechanism (7). The transverse movement plate (5) is arranged on the installing frame (4) in a sliding fit mode, the splitting mechanism (6) is arranged on the transverse movement plate (5) and used for splitting the material film (1), and the cutting mechanism (7) is used for cutting off the material film (1) wound around the material tube (5). The multifunctional winding device can automatically split, wind and cut the material film and is used for machining the winding drum material.

Owner:NINGBO XINDA PRINTING MACHINERY

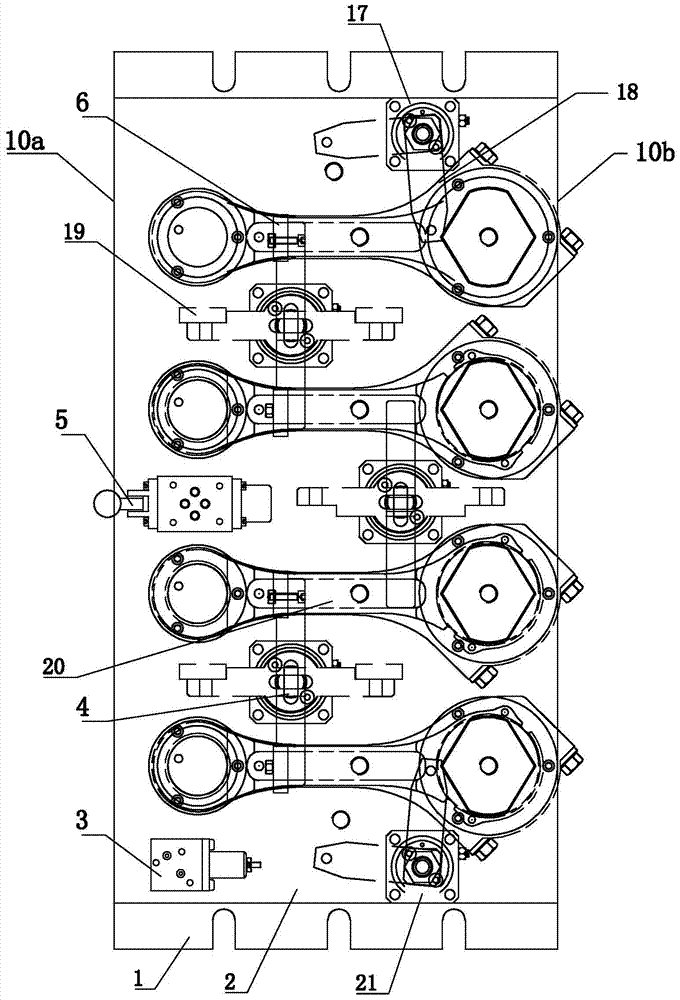

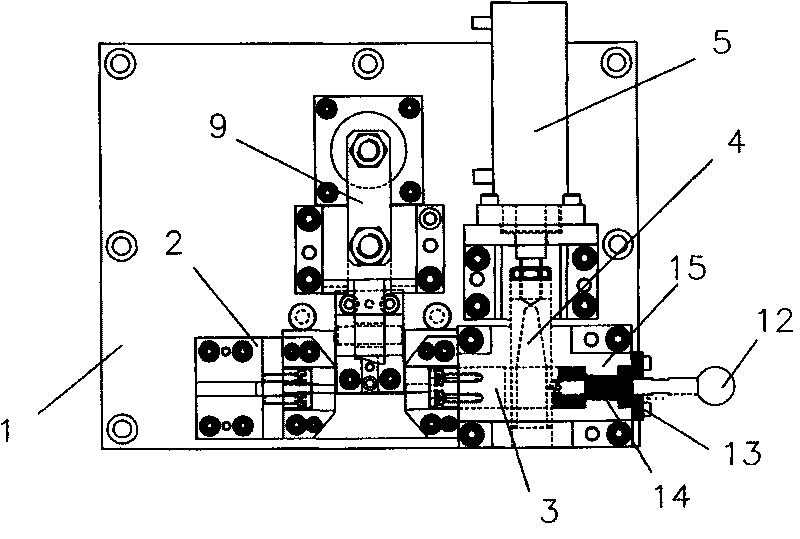

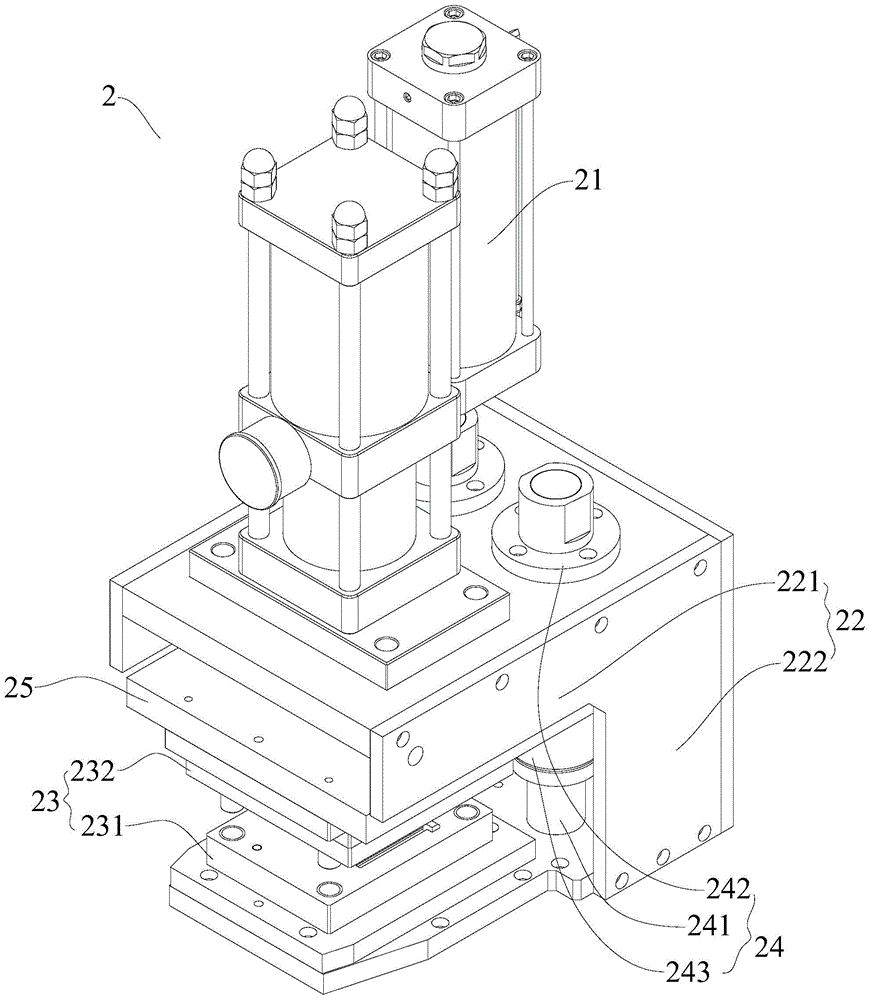

Hydraulic clamping and positioning device for slope processing of connecting rod

ActiveCN104325327AStable jobRapid positioningPositioning apparatusMetal-working holdersBaseboardEngineering

The invention discloses a hydraulic clamping and positioning device for slope processing of connecting rod. The hydraulic clamping and positioning device for slope processing of connecting rod comprises a baseboard provided with a clamp board, wherein a small end hole positioning device is arranged on the clamp board, the small end hole positioning device comprises a first cushion block provided with a first through hole, a horizontal through hole is formed in a boss of the first through hole, an ejecting column is arranged inside the horizontal through hole, a piston rod of a thin-wall oil cylinder extends from the first through hole and abuts against a cone head rod, the cone head slope of the cone head rod can push the slope of the ejecting column to position a small end hole, a large end hole positioning device comprises a second cushion block provided with a second through hole in the middle, a positioning pin of the second through hole positions a large end hole, and two single head pressing boards and a plurality of double head pressing boards are used for clamping a connecting rod. A hydraulic oil cylinder can fast position and clamp the small end hole, the large end hole is positioned by the positioning pin, the hydraulic oil cylinder also can fast control the pressing of the single head pressing boards and the double head pressing boards on the connecting rod of each working position, so that the connecting rod slope processing can be smoothly conducted, and the processing efficiency is improved.

Owner:山东盛祥智能制造有限公司

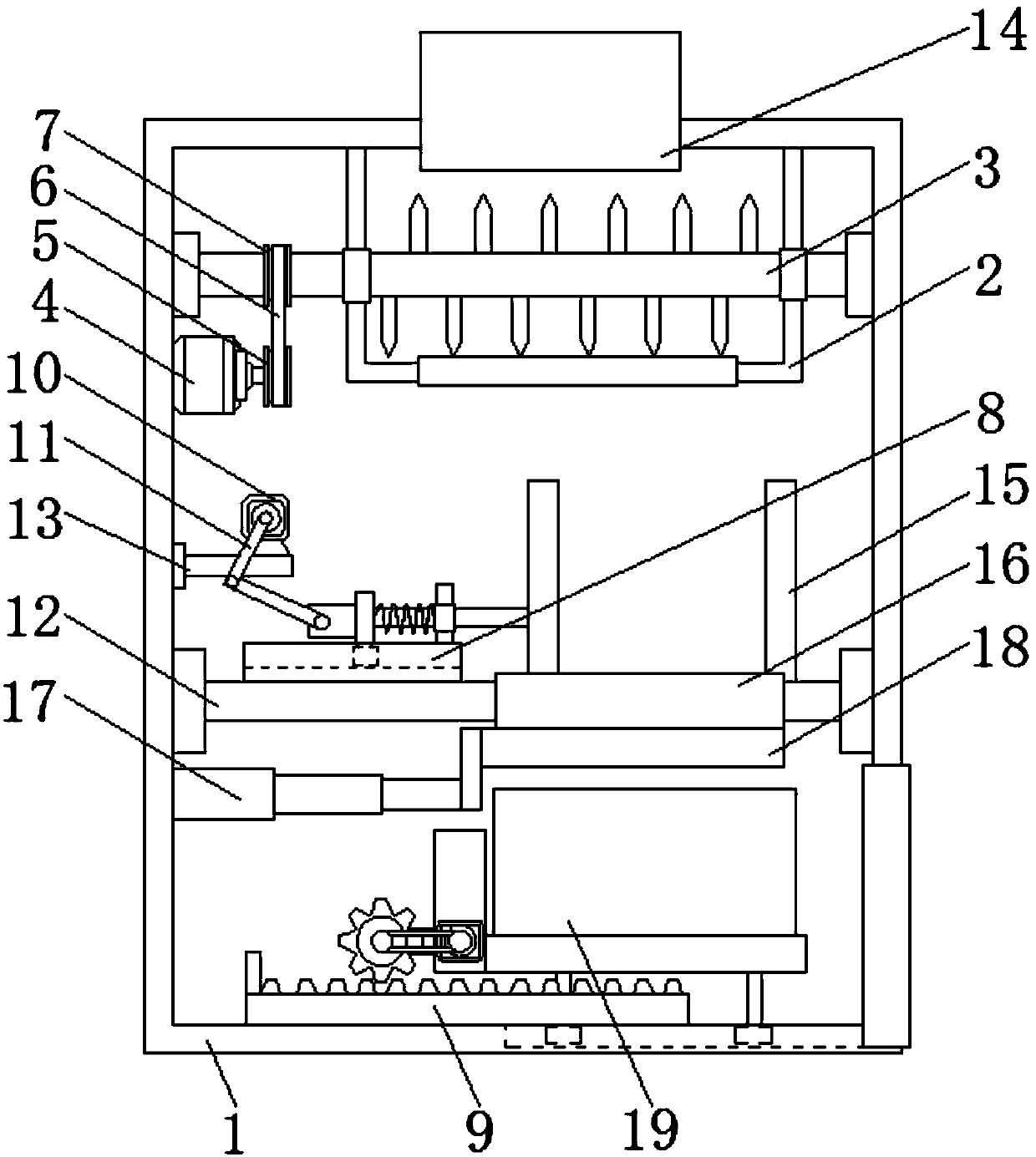

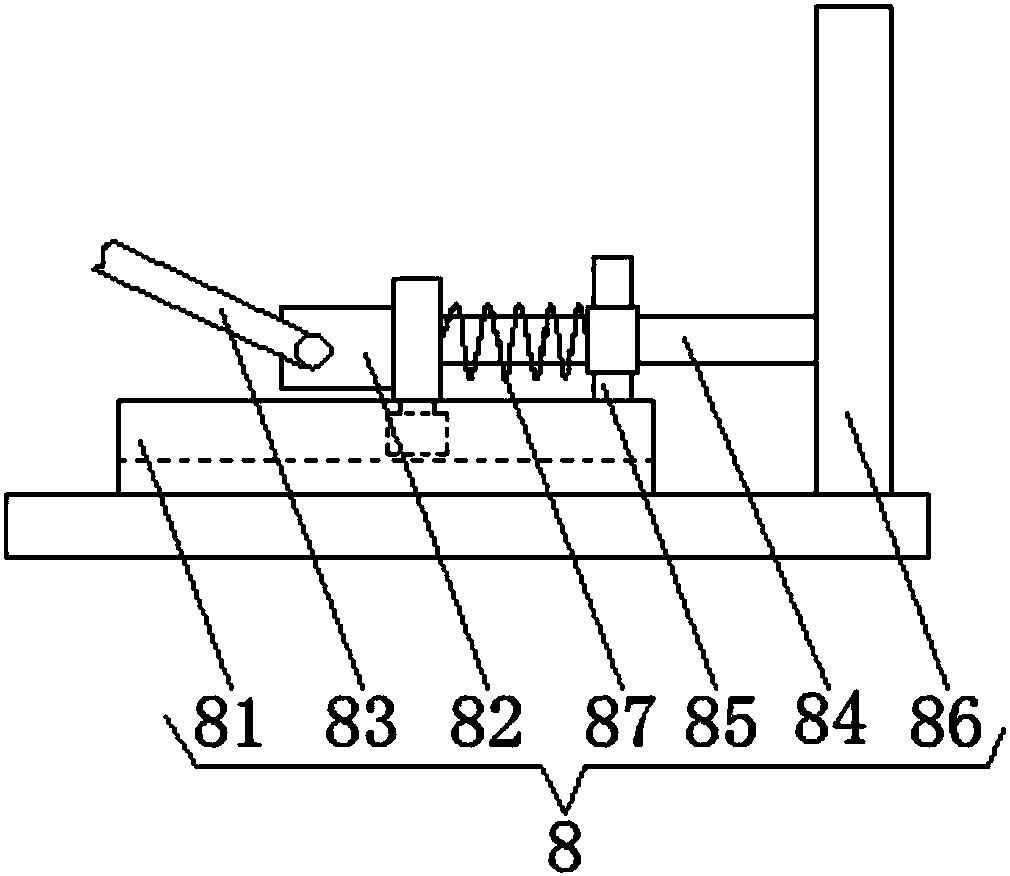

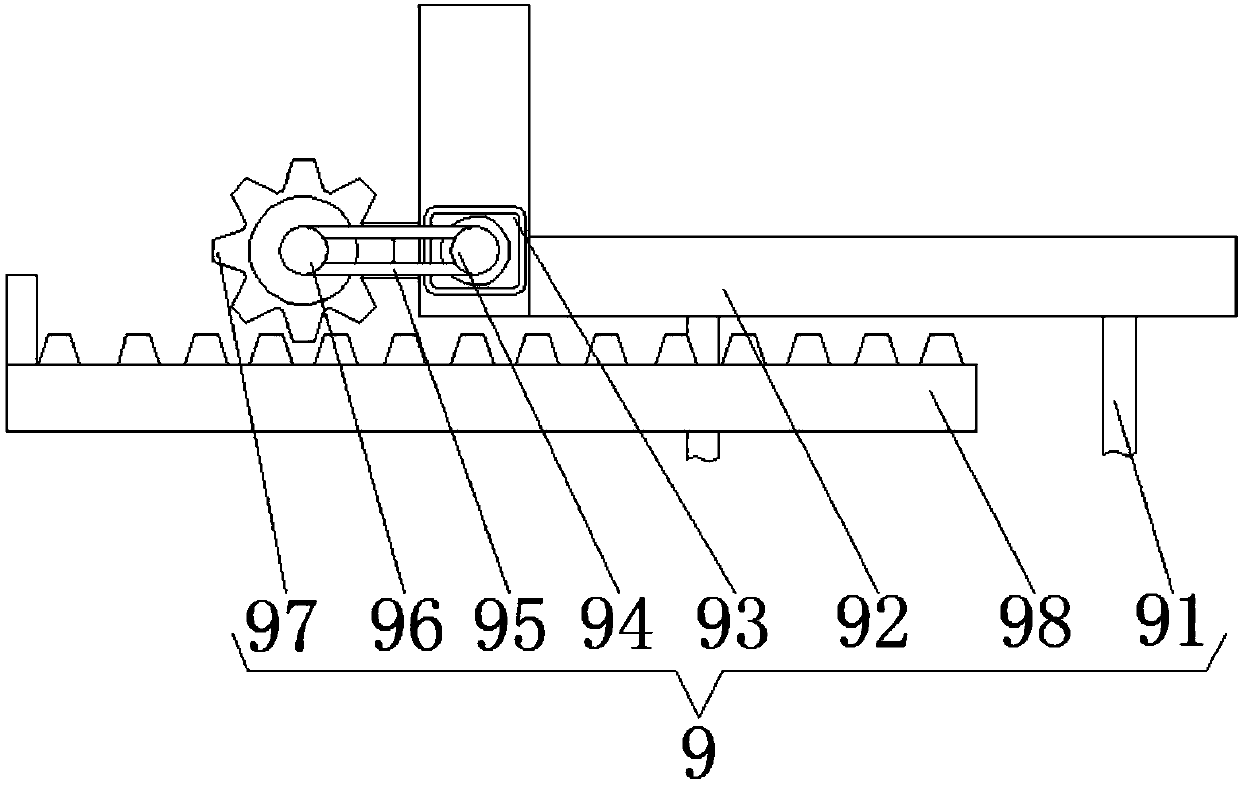

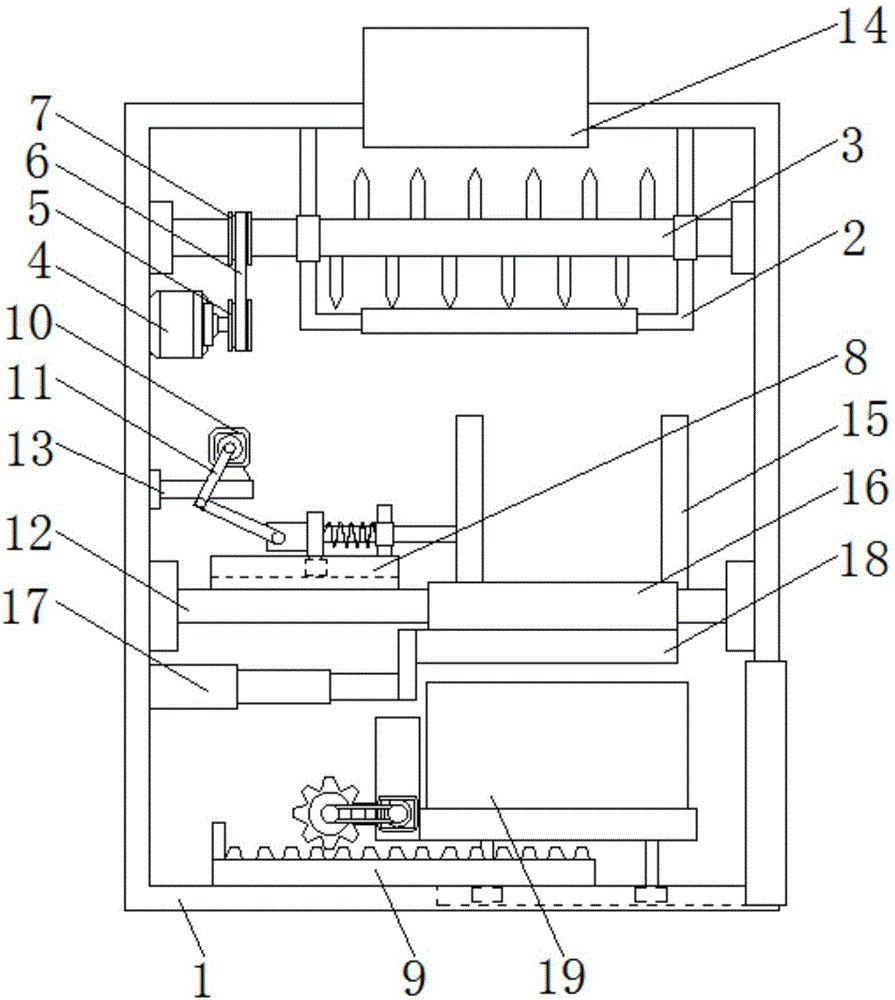

Office paper shredder facilitating cleaning of shredded paper

InactiveCN107716030AEasy to cleanCompletely destroyedGrain treatmentsPulp and paper industryPaper sheet

The invention discloses an office paper shredder facilitating cleaning of shredded paper. The office paper shredder comprises a shell, the top of the inner wall of the shell is fixedly connected witha crushing tank, a crushing shaft penetrates through the two sides of the crushing tank, and the top of the left side of the inner wall of the shell is fixedly connected with a crushing motor. An output shaft of the crushing motor is fixedly connected with a first belt wheel, the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt, and the axis ofthe second belt wheel is fixedly connected with the surface of the crushing shaft. The invention relates to the technical field of office equipment. According to the office paper shredder facilitatingcleaning of the shredded paper, paper is crushed in the crushing tank, the problem of document secret leakage caused by unthorough paper crushing is avoided, thorough destruction of secret documentsis guaranteed, the crushed waste paper is extruded to reduce the size of the waste paper, the situation that a discharge box is filled with the waste paper soon and normal use of the paper shredder isaffected is avoided, the cleaning frequency is reduced, and the use time after each cleaning is prolonged.

Owner:浙江两山信息科技有限公司

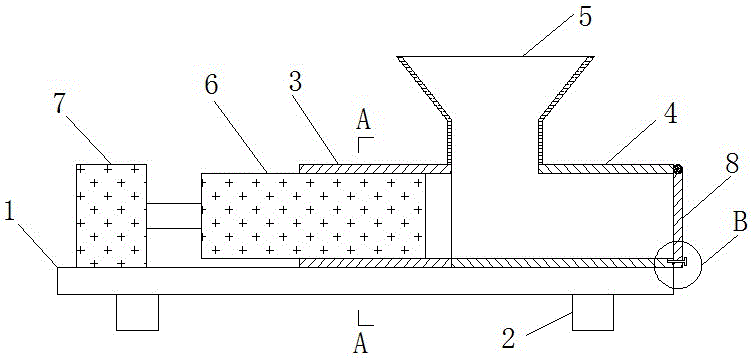

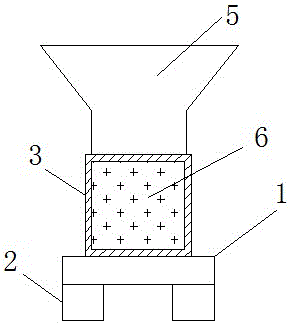

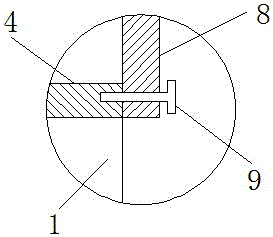

Ring-pull can compacting device for garbage recycling

The invention discloses a compacting device for pop cans used for garbage recycling, which comprises a workbench and supporting legs arranged at the bottom of the workbench. A guide sleeve and a compaction shell are arranged on the top of the workbench. The guide sleeve and the compaction shell A feed hopper is provided on the top of the body connection, the feed hopper is funnel-shaped, and the feed hopper is connected to the guide sleeve and the compaction shell, the guide sleeve is provided with a compaction column, and the working A hydraulic cylinder body is fixedly installed on the left side of the table top, and the output end of the hydraulic cylinder body is fixedly connected to the compaction column. The top of the right end of the compaction shell is hinged with an end cover, and the bottom of the end cover is connected by a screw. Attached to the compact housing. The present invention is a compacting device for pop cans used for garbage recycling, which has novel structure and convenient operation, adopts a small amount of multiple compaction method, has good compaction effect and high work efficiency, and mechanical operation replaces manual operation, which is convenient and fast, and has high practicality. sex.

Owner:长沙联博科技咨询有限公司

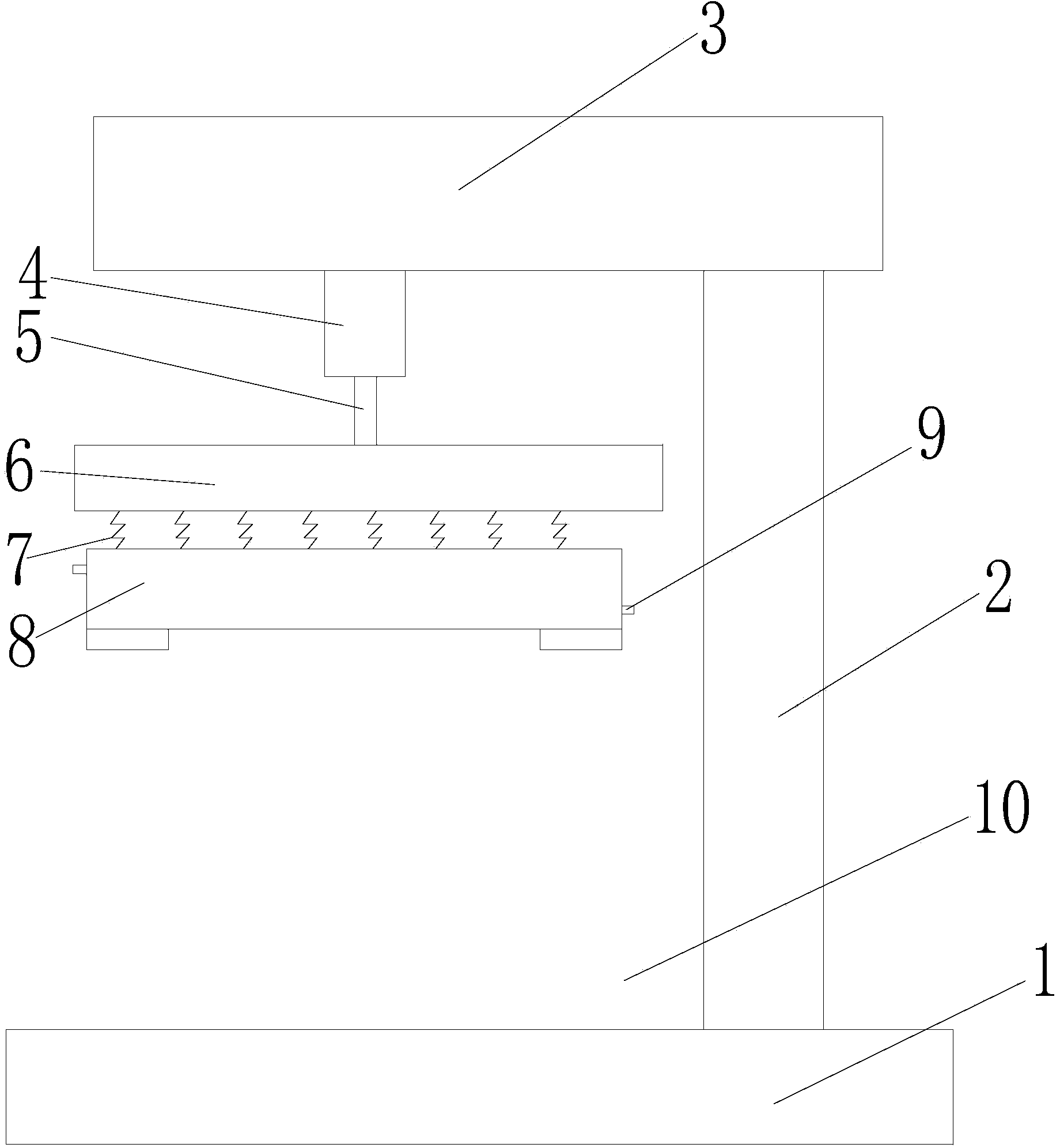

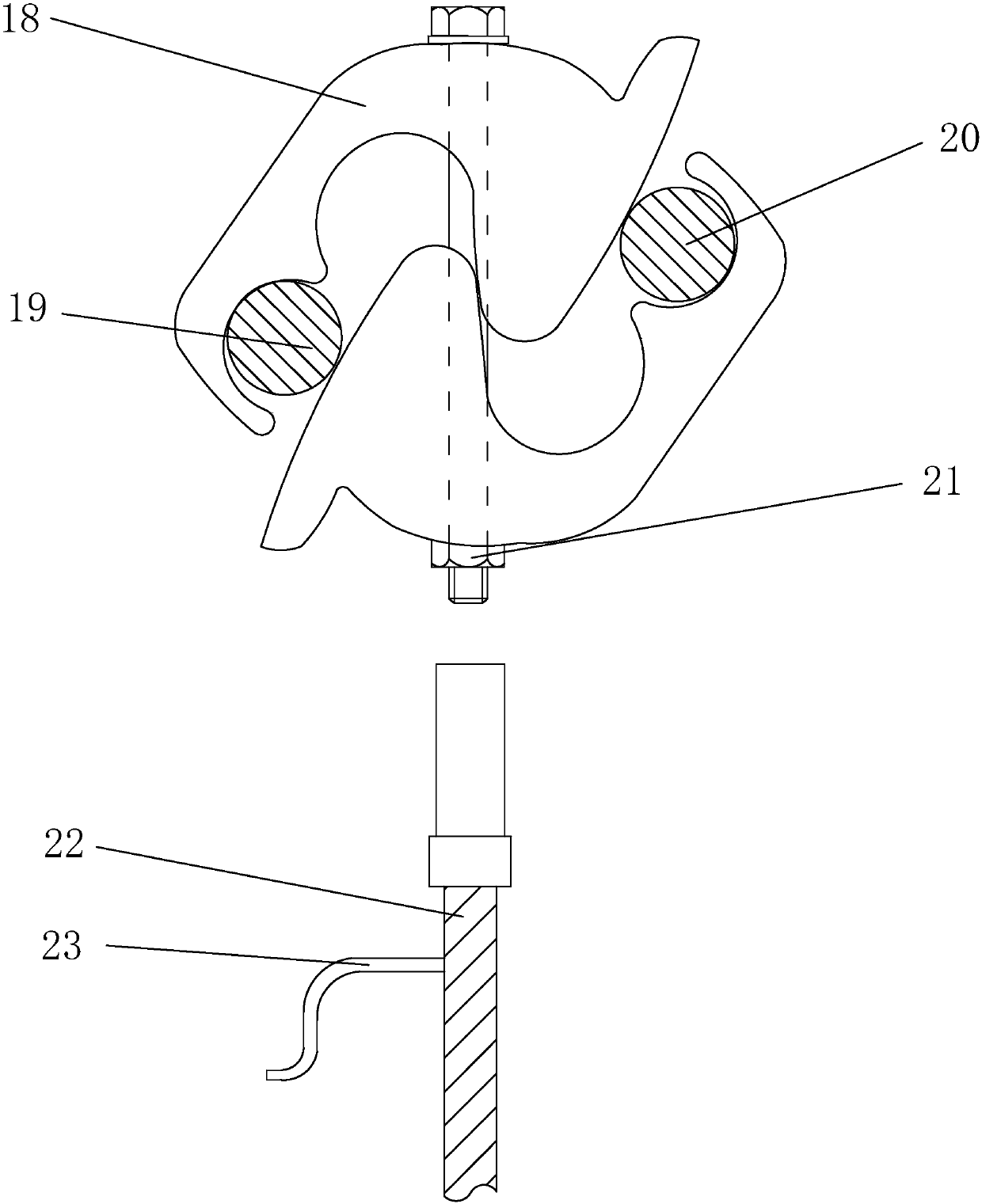

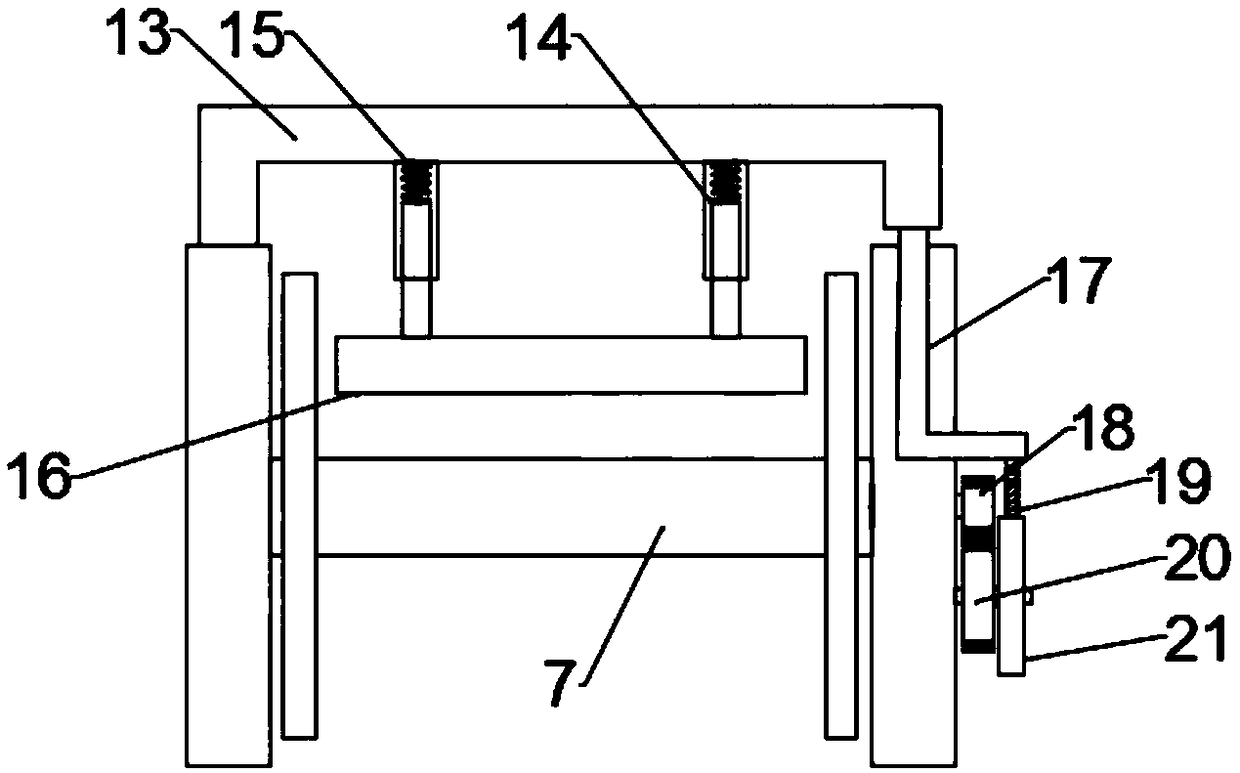

Method and device for combined stamping riveting

The invention discloses a method and device for combined stamping riveting. The method for combined stamping riveting comprises the steps that 1, a riveting puncher pin (2) assembly is driven by a press bar (1) of a press machine to be returned upwards to the highest point; 2, a supporting part and a sheet part of a workpiece (6) are installed in a positioning hole of a positioning base (7); 3, the press bar (1) of the press machine is re-started to be pressed downwards and moves to the position of an adjusted maximum stroke till a rivet of the workpiece (6) is turned over and deformed; and 4, the press bar (1) of the press machine is returned, the workpiece (6) is taken down, and riveting of the workpiece (6) is completed. According to the device for combined stamping riveting, a press machine is adopted to conduct riveting on the workpiece, riveting of the workpiece is uniform, stable and good in compression effect; in addition, by arranging the special structure, the coaxiality of the workpiece can also be ensured, and damage of the cylindrical surface of the workpiece is avoided. The device for combined stamping riveting is suitable for conducting riveting on the small-size sheet workpiece, and the effects that the riveted part is compact and reliable, the coaxiality dimensional precision is high, and end face attaching is good can be ensured.

Owner:GUIZHOU HONGLIN MACHINERY

Office paper shredding robot capable of cleaning shredded paper conveniently

PendingCN107520017AEasy to cleanCompletely destroyedGrain treatmentsPressesPulp and paper industryPaper sheet

The invention discloses an office paper shredding robot capable of cleaning shredded paper conveniently and relates to the technical field of office equipment. The office paper shredding robot comprises a shell. A shredding groove is fixedly connected to the top of the inner wall of the shell. A shredding shaft penetrates the two sides of the shredding groove. The top of the left side of the inner wall of the shell is fixedly connected with a shredding motor. An output shaft of the shredding motor is fixedly connected with a first belt wheel. The surface of the first belt wheel is connected with a second belt wheel through a belt in a transmission manner. The axis of the second belt wheel is fixedly connected with the surface of the shredding shaft. According to the office paper shredding robot capable of cleaning the shredded paper conveniently, the paper is shredded in the shredding groove, the problem that the paper is not shredded thoroughly and consequently confidential data of files are leaked is avoided, it is guaranteed that the confidential files are destroyed thoroughly, the shredded waste paper is extruded, the size of the waste paper is reduced, it is avoided that a discharging box is filled with waste paper soon and consequently the normal use of the paper shredding is influenced, the cleaning frequency is reduced, and the use time after cleaning each time is prolonged.

Owner:浙江两山信息科技有限公司

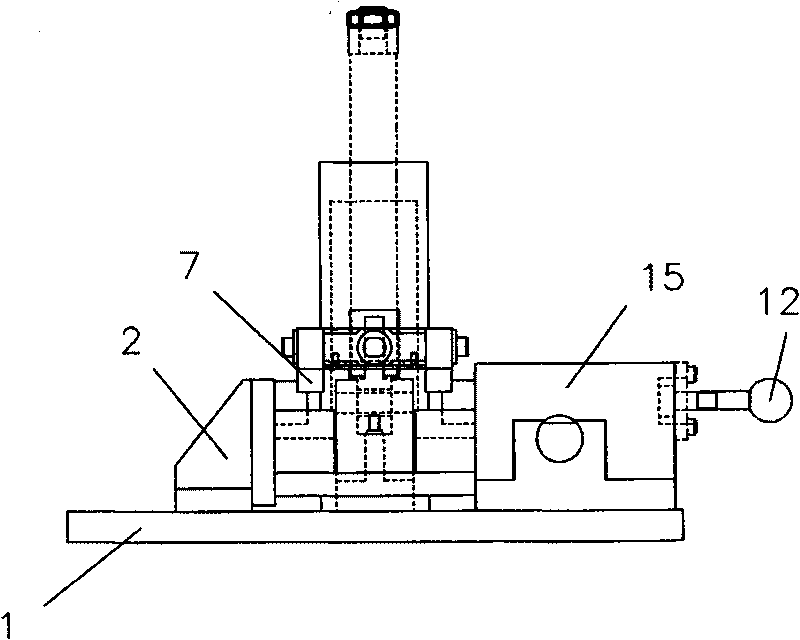

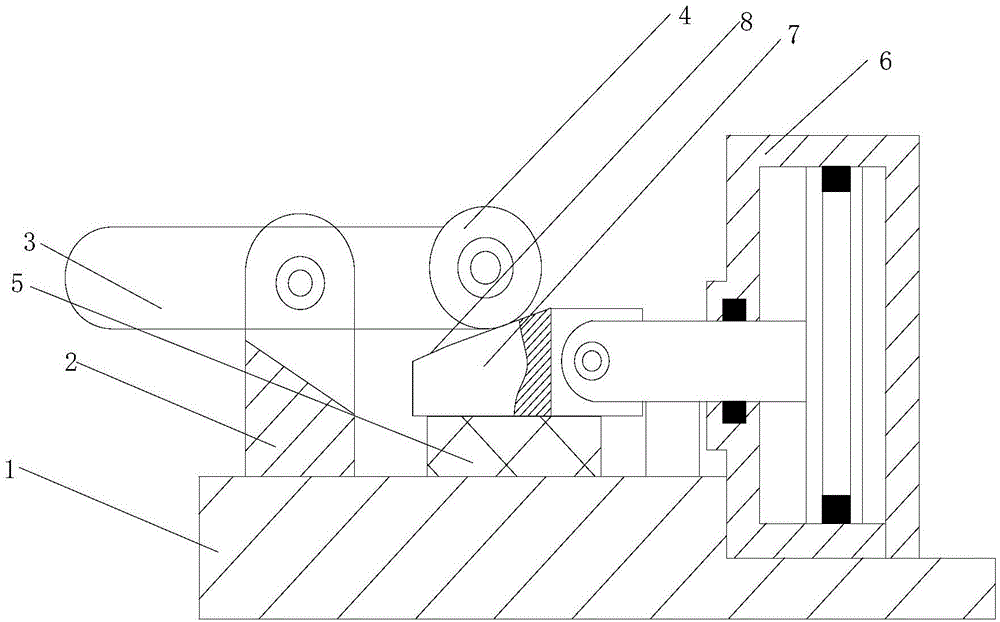

Clamping device for drilling tube parts

InactiveCN102744614APrecise positioningGood compression effectPositioning apparatusMetal-working holdersPistonEngineering

The invention discloses a clamping device for drilling tube parts. The clamping device for drilling tube parts comprises a base, and a positioning mechanism and a clamping mechanism arranged on the base. The positioning mechanism comprises a first bracket and a second bracket which are provided with circular grooves. The clamping mechanism is arranged between the first bracket and the second bracket and comprises a rotary clamping air cylinder, wherein a pressure arm is arranged at a piston end of the rotary clamping air cylinder. An arc-shaped groove is arranged on a working face of the pressure arm. According to the clamping device for drilling tube parts, tubes are manually placed in the circular grooves on the first and second brackets first, the circular grooves are in surface contact with the tubes, and then the pressure arm is driven by the rotary clamping air cylinder to rotate and ascend automatically to press the tubes, so that the tubes are positioned accurately, and pressed effectively, the processing efficiency is improved, and the potential safety hazard is eliminated.

Owner:SUZHOU KEBER PRECISION MACHINERY

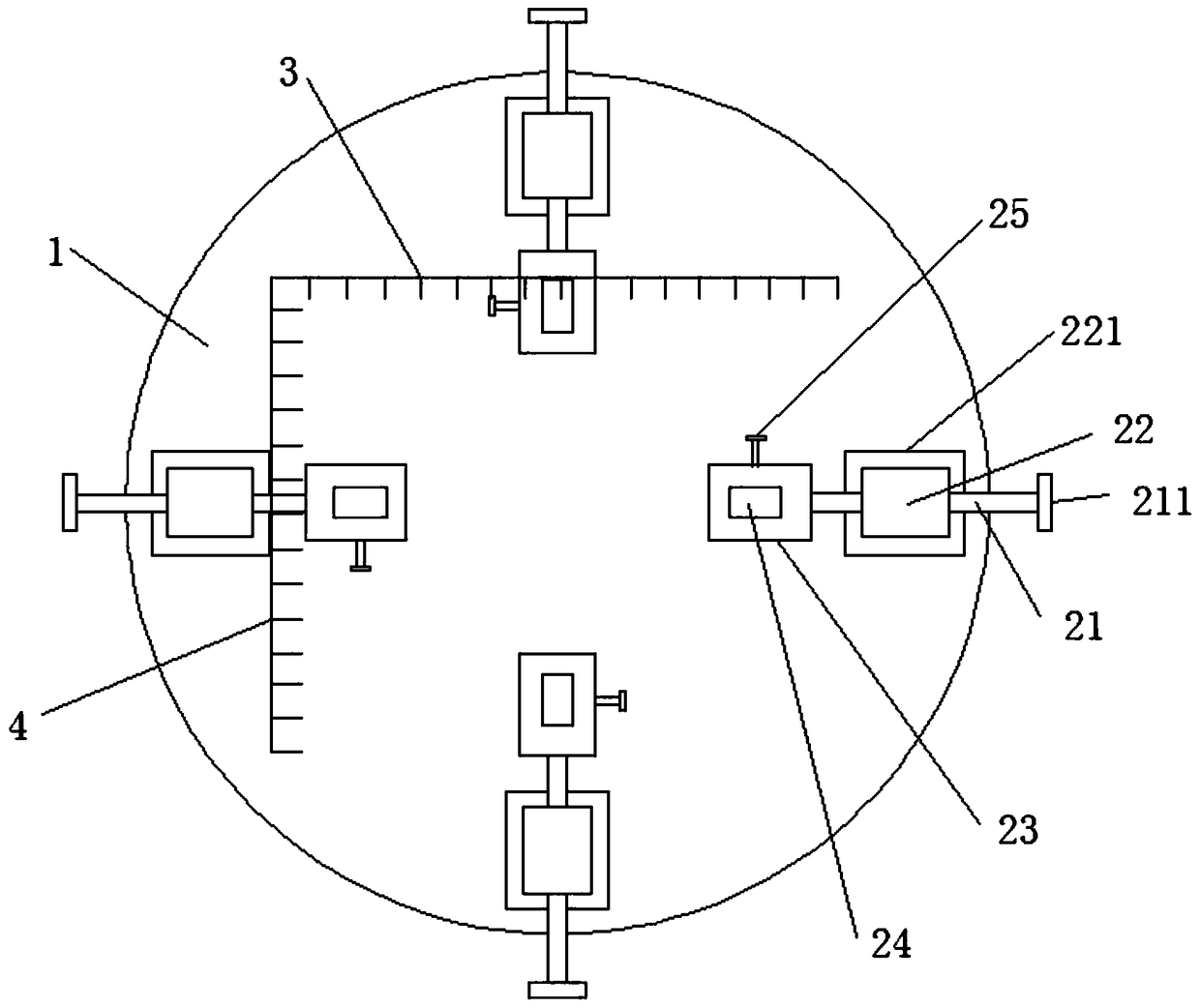

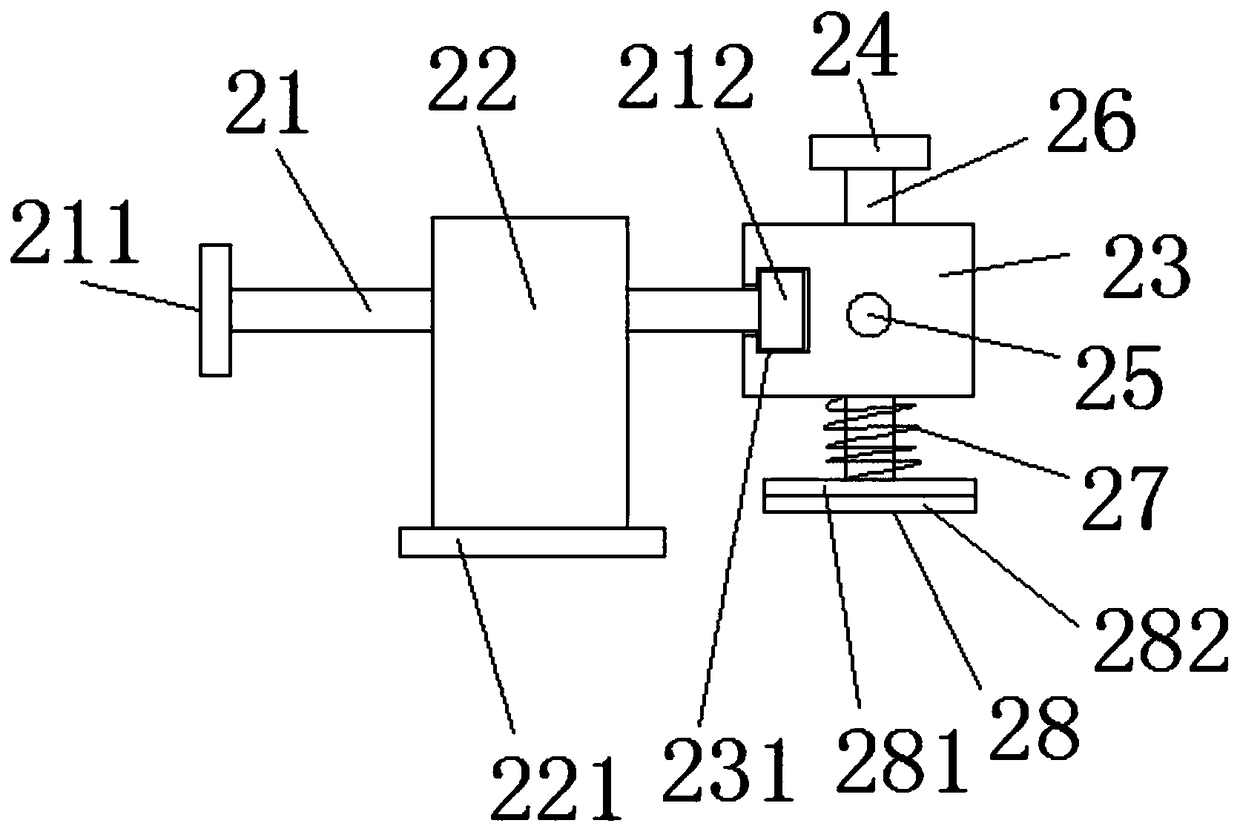

Plate fixing device

InactiveCN109500632ACompress fullyMove fullyPositioning apparatusGrinding work supportsEngineeringAnnular array

The invention relates to the technical field of furniture plate production, and discloses a plate fixing device comprising a worktable. The worktable is provided with a plurality of pressing mechanisms which are arranged in a ring array, and each pressing mechanism comprises a fixed seat, a screw rod, a pressing rod and a compression spring; the fixed seat is fixed to the worktable, and one end ofthe screw rod extends out of the fixed seat horizontally; the extension end of the screw rod is provided with a movable seat in a rotary clamping manner, and the other end of the screw rod is fixedlyprovided with a handle; the movable seat is internally provided with a vertical through hole, and one end of the pressing rod vertically extends out of the movable seat through the through hole downwards; the extension end of the pressing rod is fixedly provided with a pressing plate, and the part, between the pressing plate and the movable seat, of the pressing rod is provided with the compression spring in a sleeving manner; the other end of the pressing plate is provided with a baffle; the side face of the movable seat is provided with a puller bolt; and the pressing plate is of a double-layer composite structure comprising a pressing layer and an elastic layer. According to the plate fixing device, plates in various shapes and sizes can be pressed and fixed, and plates with uneven surfaces can be further pressed fully.

Owner:赣州市南康区万家源家具有限公司

Swinging type clamping device

InactiveCN106002410AGood compression effectGuaranteed up and down swing rangePositioning apparatusClampsDrive shaftEngineering

The invention provides a swinging type clamping device, and belongs to the technical field of machining. The swinging type clamping device comprises a supporting assembly, two or more levers and pressing plates, and a long strip-shaped workpiece is placed on a first step; a cylinder body of a driving cylinder is vertically mounted on a third step; the upper end of a piston rod is connected with the supporting assembly; a left supporting lug and a right supporting lug of the supporting assembly are symmetrically fixed on the left and right sides of a supporting plate; hinge holes are formed in the left supporting lug and the right supporting lug; a supporting shaft is fixed to a rack; the middle ends of the levers are hinged to the supporting shaft; a driving shaft is fixedly connected with one ends of the levers; the driving shaft penetrates through the hinge holes of the left supporting lug and the right supporting lug; the other ends of the levers are hinged to the lower ends of the pressing plates; pressing heads are arranged on the pressing plates; long holes are further formed in the pressing plates; and guide hinge pins are fixed to the rack, and penetrate through the long holes. According to the swinging type clamping device, the driving cylinder drives the plurality of pressing plates, the long strip-shaped workpiece is clamped, and the clamping effect is good.

Owner:桐乡守敬应用技术研究院有限公司

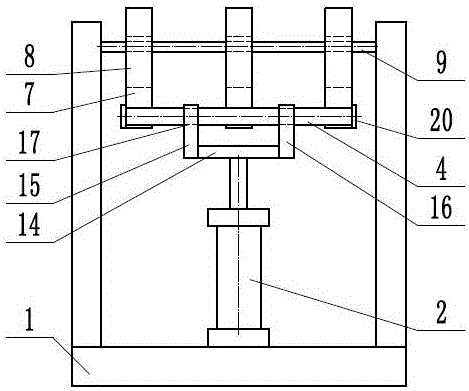

Elastic cooling and pressing fixture for PCB

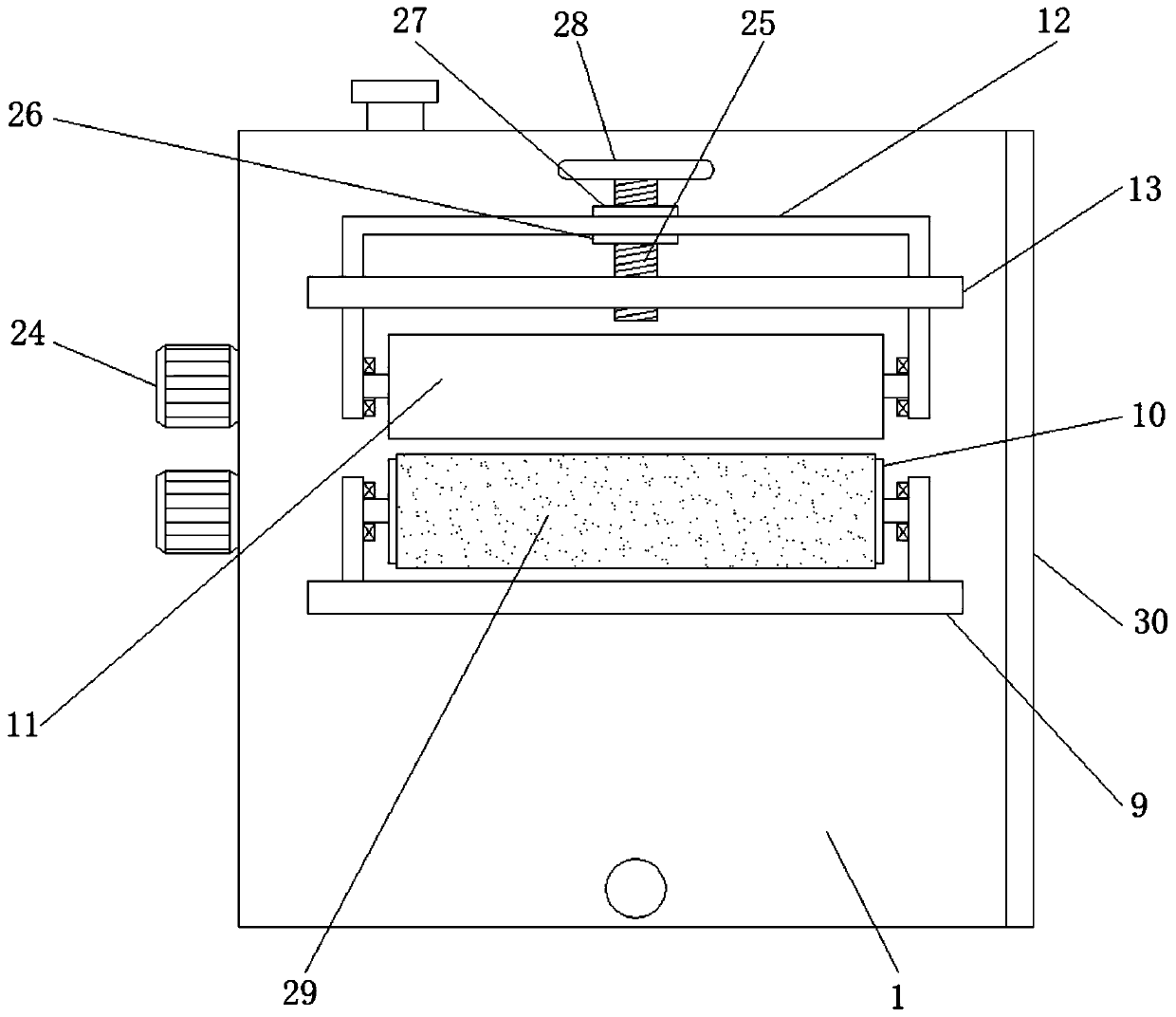

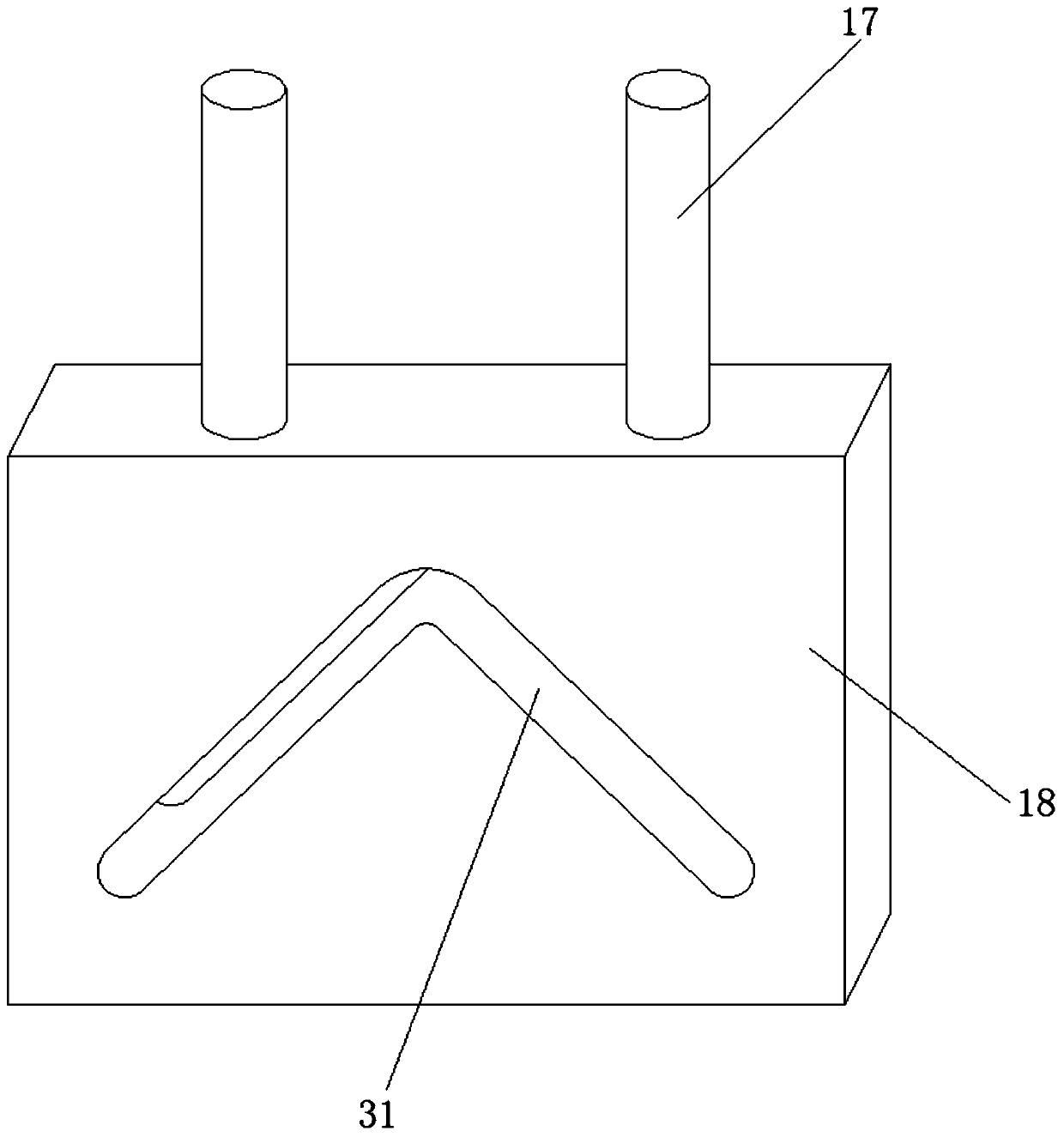

The invention discloses an elastic cooling and pressing fixture for a PCB. The elastic cooling and pressing fixture for the PCB comprises a support and is characterized by further comprising a cylinder, a movably plate, a plurality of springs, a pressing plate, a cooling pipe and a flexible pipe, wherein the support comprises a base, a supporting beam and a top plate, the supporting beam is arranged on the top of the base, the top plate is arranged on the top of the supporting beam, the cylinder is arranged on the bottom of the top plate, a cylinder rod of the cylinder is connected with the movably plate, the springs are arranged on the bottom of the movable plate, the pressing plate is arranged on the bottoms of the springs, the cooling pipe penetrates through the pressing plate, a water inlet and a water outlet of the cooling pipe are connected through the flexible pipe, the flexible pipe is cooled through a condenser, and an openable hole used for water injection is formed in the cooling pipe. The elastic cooling and pressing fixture for the PCB has the advantages that the structure is simple, the pre-pressing force is balanced, the pressing effect is good, the precision of pressing positions is high, the cooling speed is high, and the machining efficiency and the machining quality can be improved greatly.

Owner:SUZHOU KUEN ELECTRONICS TECH

Clamp for processing double-head piston ball pit

ActiveCN101704229APrevent rollbackPrevent looseningWork holdersHydraulic cylinderMechanical engineering

The invention discloses a clamp for processing a double-head piston ball pit, which mainly comprises a bottom plate. The bottom plate is provided with a positioning block and a puller rod seat, and the inside of the puller rod seat is provided with a puller rod which is positioned with the positioning block in a matching mode; the side of the puller rod is provided with a telescopic locking rod, and the locking rod is in transmission connection with a first hydraulic cylinder; the bottom plate is provided with a pressing arm seat, and the pressing arm seat is provided with a pressing arm; and the pressing arm is arranged on the pressing arm seat through a hinge structure, and one end of the pressing arm is positioned above the positioning block and clamped with the positioning block in the matching mode. The clamp can fix the puller rod through the locking rod and avoid the rollback phenomenon of the puller rod, so that work pieces are positioned more firmly in an axial direction; the pressing arm and the positioning block are matched, so the work pieces can be well pressed and fixed in a radial direction to prevent loosening, and the work pieces are positioned more firmly in the axial direction; the damage ratio of the work pieces is greatly reduced during the processing, and processing quality is also better.

Owner:ZHEJIANG YIFENG MACHINERY

High-precision textile equipment

ActiveCN108823946AStable outputAvoid wrinklesSevering textilesRotary pressesWrinkle skinMechanical engineering

The invention discloses high-precision textile equipment. The bottom end of a base is fixedly connected with a damping pad through bolts, anti-skid lines are arranged at the lower end of the damping pad, two supporting plates are symmetrically and fixedly connected to the upper end of the base, a rotating roller is arranged at the upper end between the two supporting plates, and rotating shafts are fixedly connected to the two ends of the rotating roller. The equipment has the advantages that cloth moving between a limiting roller and the rotating roller is tightly pressed through the limitingroller, so that output of the cloth on the rotating roller is stable, the problem that the cloth wrinkles when the cloth is not consistent after separating from the rotating roller is avoided, and therefore the cutting precision of the cloth on a workbench is improved. A rubber sleeve fixedly sleeving a pressing roller achieves an anti-skid function so that the cloth cannot deviate left and right, therefore the precision of the cloth on the workbench is improved, and the cutting precision is improved. By adjusting the distance between a pressing block and the cloth, the pressing effect of thepressing roller under the pressing block is optimal, and the cutting precision is improved.

Owner:嘉兴新国浩喷织股份有限公司

Hydraulic brake device

InactiveUS20130319801A1Relieve pressureIncreased fluid leakageFluid actuated brakesBrake actuating mechanismsEngineeringHydraulic fluid

A hydraulic brake device includes at least one caliper body that defines a pressure chamber, at least one elastic enclosure member that is arranged inside the caliper body to operate in combination with the pressure chamber and shows a corrugated configuration, and at least one brake pad mounting assembly, which is arranged on the elastic enclosure member at the side away from the pressure chamber. With fluid passages provided in communication with the pressure chamber, hydraulic fluid can be supplied to compress the elastic enclosure member for driving the brake pad mounting assembly and the brake lining assembly to effect braking. The corrugated configuration helps reducing deformational stress induced in the elastic enclosure member and also reducing operation resistance. A ventilation section is also provided on the caliper body to draw in fresh air for heat dissipating purposes.

Owner:FRILIGENTS

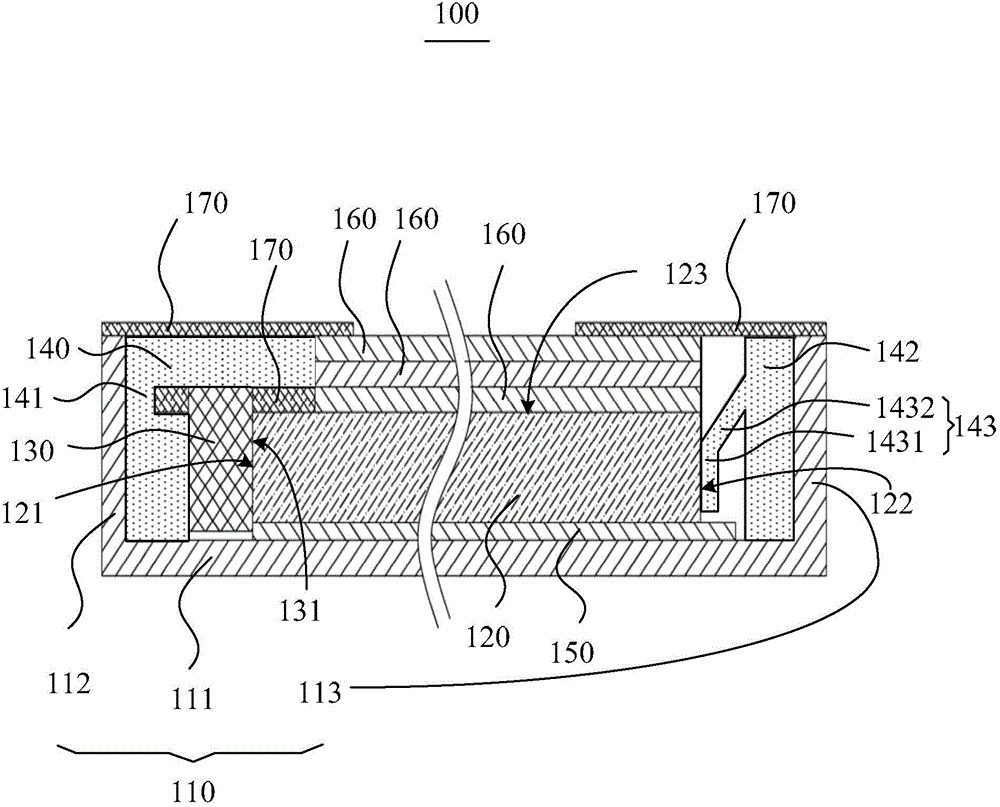

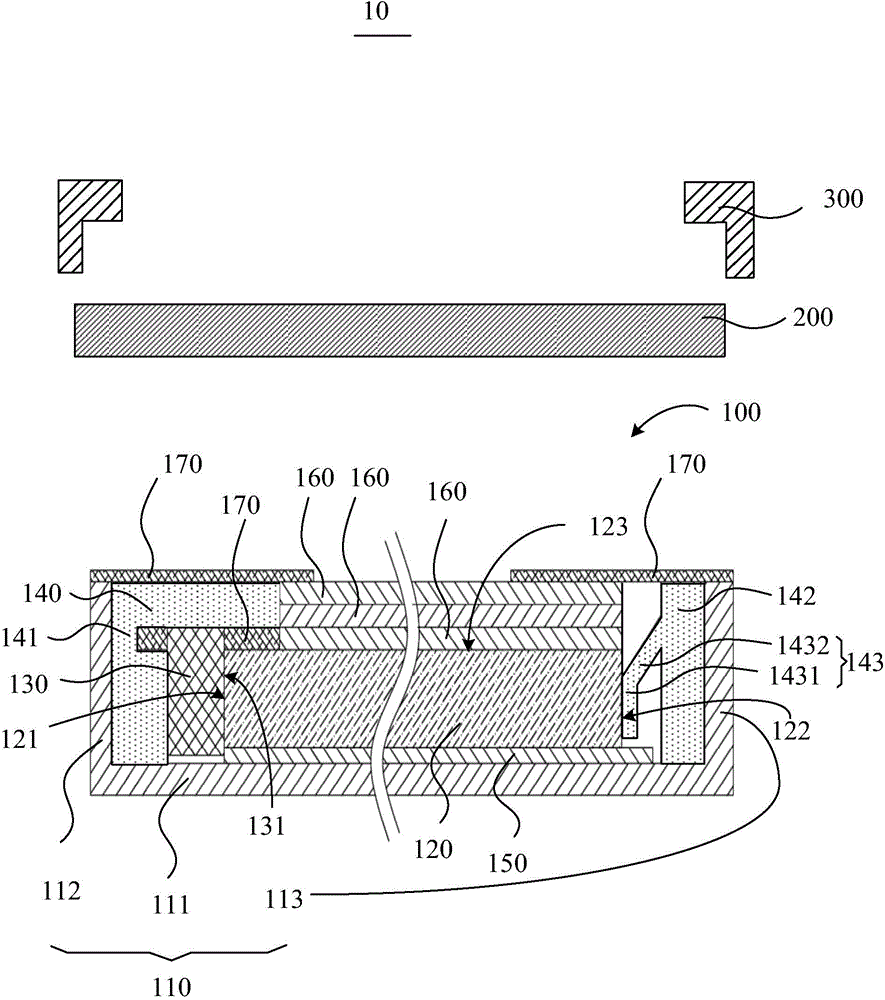

Backlight module and liquid crystal display device

InactiveCN104482423APrevent looseningIncrease light incidenceElectric lightingLight fasteningsLiquid-crystal displayLight guide

The invention discloses a backlight module and a liquid crystal display device. The backlight module comprises a backboard, a light guide plate, a light source and a rubber frame, wherein the backboard is used for accommodating the light guide plate, the light source and the rubber frame and comprises a base plate, a first sidewall and a second sidewall, wherein the first sidewall and the second sidewall extend towards the same direction along the two sides of the base plate; the light guide plate is arranged close to the base plate and comprises a first side surface and a second side surface which are arranged oppositely; the first side surface is arranged close to the light source and used as a light incident surface of the light guide plat; the rubber frame is arranged on the base plate and comprises a third sidewall and a fourth sidewall; the third sidewall is arranged between the first sidewall and the light source; the fourth sidewall is arranged between the second sidewall and the second side surface; the rubber frame also comprises at least one pressing mechanism; the pressing mechanism extends towards the second side surface of the light guide plate from the fourth sidewall and leans against the second side surface of the light guide plate so that the first side surface of the light guide plate is close to a light exit surface of the light source; the pressing mechanism and the rubber frame are integrally formed. The light guide plates of the backlight module and the liquid crystal display device are relatively high in light transmittance.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

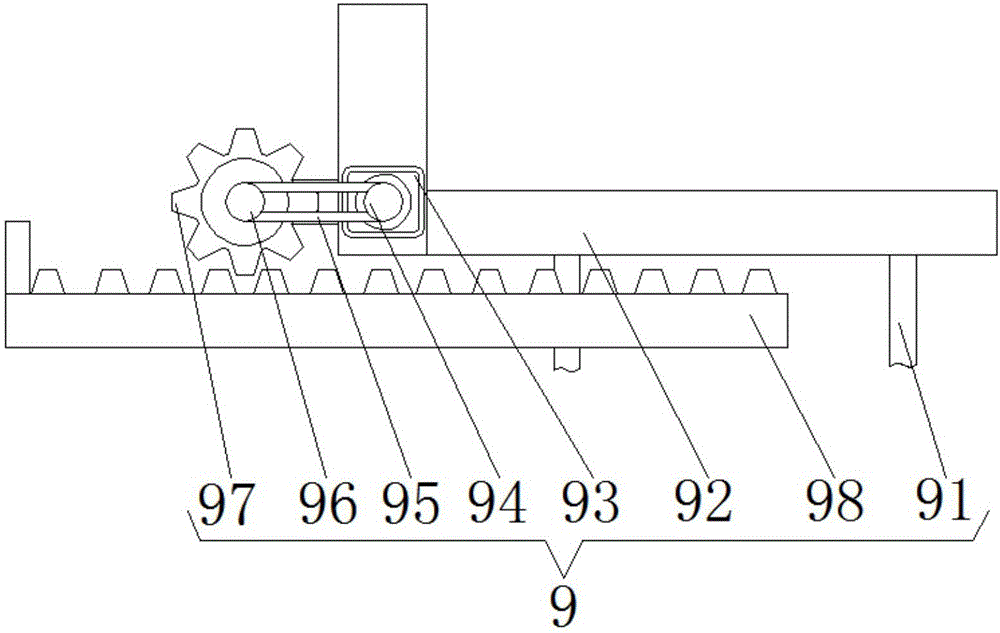

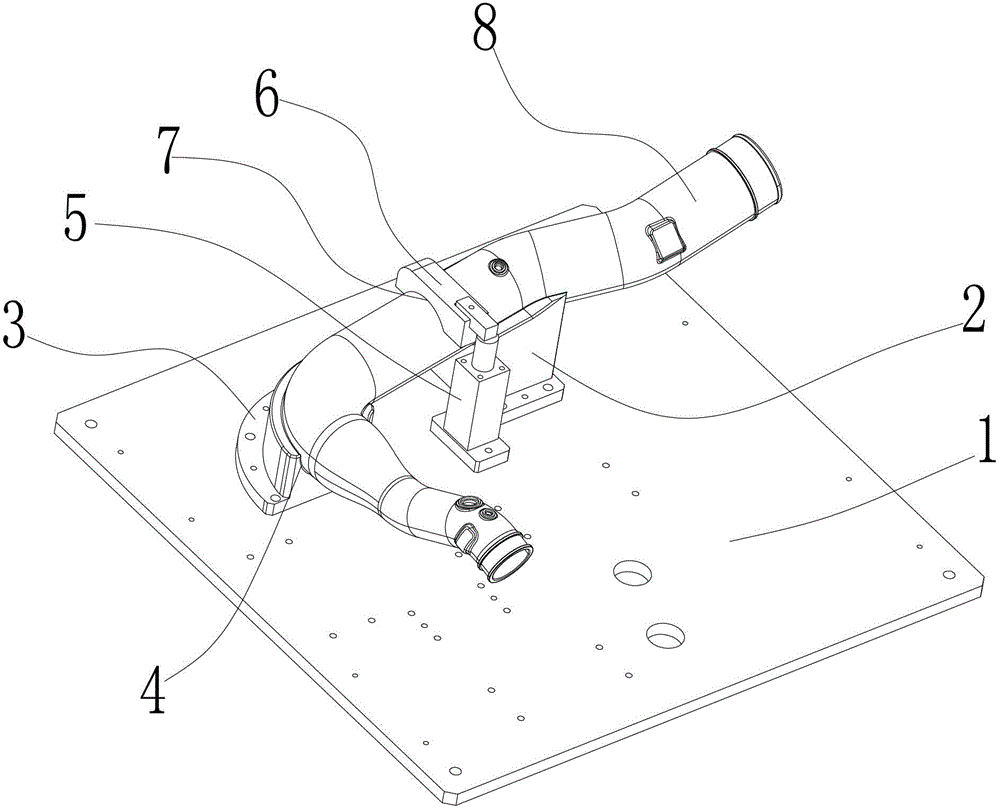

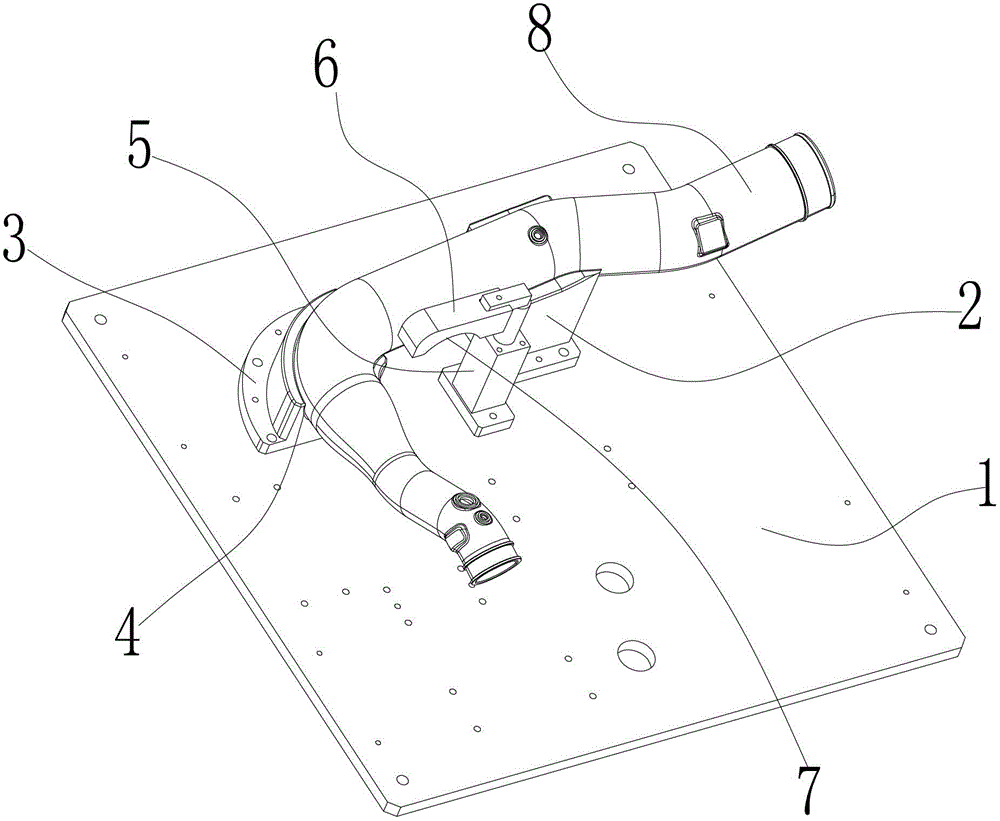

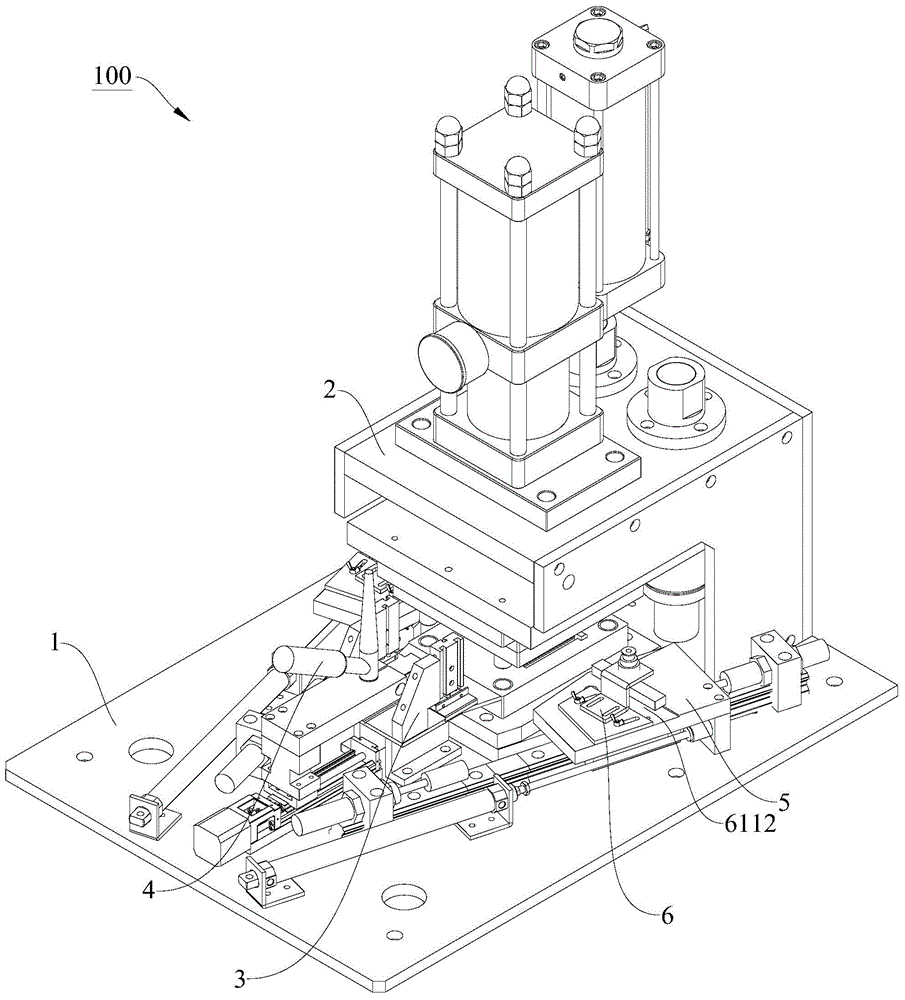

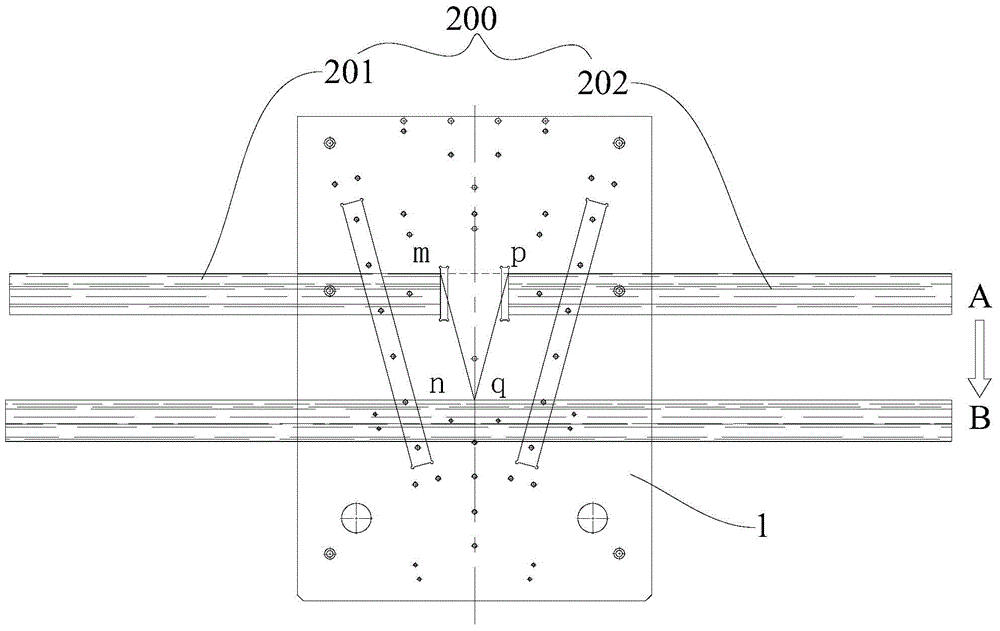

Automatic butt welding device

ActiveCN105729115AImprove connection efficiencyGood compression effectWelding/cutting auxillary devicesArc welding apparatusButt weldingButt joint

The invention discloses an automatic butt welding device. The automatic butt welding device comprises a main bearing plate, a stamping die set, a welding and clamping die set, a welding gun motion die set, two aligning and conveying die sets and two stamping and clamping die sets. The stamping die set is provided with a stamping die. The welding gun motion die set is provided with a welding gun. The welding and clamping die set is located between the welding gun motion die set and the stamping die set. The two aligning and conveying die sets are located on the two sides of the stamping die set and each comprise a leveling and abutting block, and the two leveling and abutting blocks can move towards each other in the direction from the stamping die set to the welding gun motion die set. The stamping and clamping die sets are used for pressing steel belts to be machined onto the leveling and abutting blocks. According to the automatic butt welding device, automatic blanking, automatic butt joint and automatic welding of the steel belts can be completed; the two steel belts are driven by the two aligning and conveying die sets to move along a triangular path; and it is ensured that the steel belts are high in aligning precision and small in clearance and are even in seamless butt joint, and the connecting efficiency and the welding quality of the steel belts are improved.

Owner:BYD CO LTD

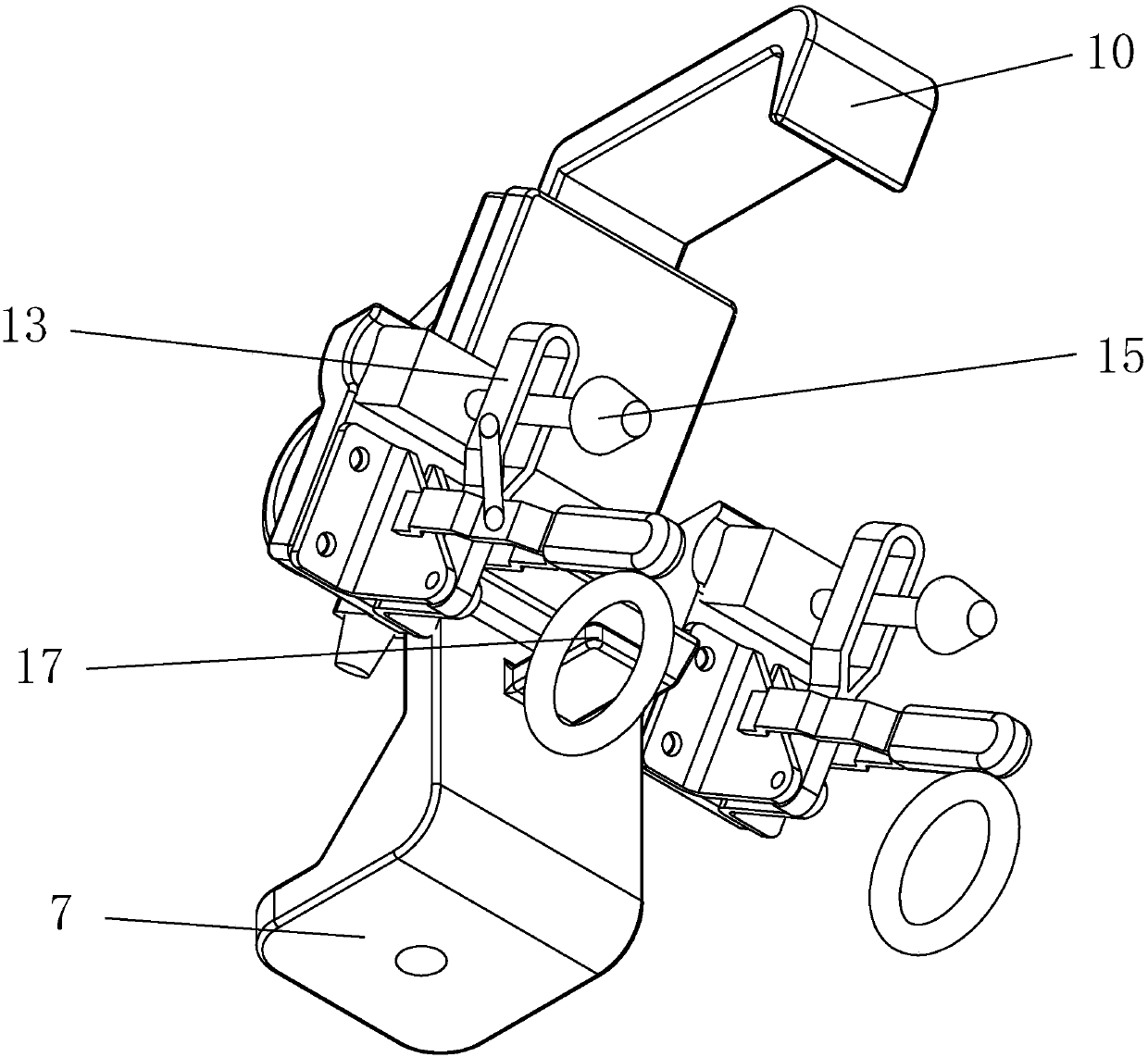

J-shaped wire clamp operating member

ActiveCN107681296AImprove fixation stabilityGood compression effectClamped/spring connectionsMulticonductor cable end piecesTransmission lineEngineering

The invention relates to the field of transmission line connection, and particularly relates to a J-shaped wire clamp operating member. The J-shaped wire clamp operating member comprises a main body,a sleeve operating rod and a supporting rod, and is characterized in that the main body is provided with a wire clamp clamping mechanism, the wire clamp clamping mechanism comprises a guide block fixed on the main body, a fixing base, a guide rod hinged with the fixing base, a connecting arm hinged with the guide rod, a guide column connected with the connecting arm, a clamping portion and a supporting portion, the clamping portion is attached to the wall of the main body and penetrates through a clearance of the guide block, the main body is provided with two lead pressing mechanisms, each lead pressing mechanism comprises a fixing bracket, a connecting rod hinged with the fixing bracket, an operating rod hinged with the fixing bracket and the connecting rod, a tightening bolt which is inthreaded connection with the connecting rod and a lead pressing block arranged on the tightening bolt. The J-shaped wire clamp operating member can operate under an electrified condition, is simple to operate, can be operated by a single person and is not restricted by the terrain. The J-shaped wire clamp operating member is wide in application range, improves the working efficiency and greatly improves the safety of workers.

Owner:STATE GRID ZHEJIANG TONGXIANG POWER SUPPLY +1

Wood and wood product drying method

ActiveCN109282577AEasy to controlReduce investmentDrying solid materials with heatHearth type furnacesHeat transfer efficiencyDrying time

The invention discloses a wood and wood product drying method. The wood and wood product drying method comprises the following steps that the wood or the wooden product is dried by taking the porous solid particles as a drying medium, and the temperature of the drying medium is kept to be 50-90 DEG C in the drying process. According to the wood and wood product drying method, the porous medium isused as a drying medium for wood and products of the wood, the heating is uniform, the heat transfer efficiency is high, the drying time is remarkably shortened, the drying quality is high, the dryingeffect is good, so that the drying defects such as warping during the drying process are avoided, the VOC in the drying process is prevented from being released into the air, is directly retained insand, and the environmental pollution is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

Cloth winding device with dedusting function

InactiveCN109019105AInnovative designGood compression effectWebs handlingEngineeringMechanical engineering

The invention discloses a cloth winding device with a dedusting function. The cloth winding device with the dedusting function comprises a workbench, a motor, a knocking mechanism, a winding roller and a pressing mechanism. Rotary shafts on the two sides of the winding roller are rotatably connected to the inner sides of fixing plates which are symmetrically arranged. The portions, in front of thewinding roller, of the rotary shafts penetrate through the fixing plates and are rotatably connected with an output shaft of the motor arranged on the workbench through belts. The pressing mechanismis arranged above the winding roller and comprises a movable rod, an abutting plate and an L-shaped rod, wherein the two ends of the movable rod are slidably connected into sliding grooves formed in the fixing plates, one end of the movable rod is fixedly connected with the L-shaped rod, the L-shaped rod is slidably connected into one sliding groove, and the lower end of the L-shaped rod is fixedly connected with a threaded rod. The cloth winding device is novel in design; when a rotary disc rotates, a hammer head of a knocking hammer is driven to swing back and forth upwards and downwards soas to hammer cloth in the winding process, and thus, dust on the cloth is stirred up and is then blown away through a fan.

Owner:宁波暄妍日化科技有限公司

Synchronous compressing device of inverted T-shaped workpiece

InactiveCN106695388AGood compression effectAvoid offsetPositioning apparatusMetal-working holdersInverted-T shapeEngineering

The invention provides a synchronous compressing device of an inverted T-shaped workpiece, and belongs to the technical field of clamp equipment. The synchronous compressing device comprises a left clamping assembly, a right clamping assembly and a synchronous driving assembly. A left driving cam and a right driving cam of the synchronous driving assembly are symmetrically and rotatably arranged on the two sides of a supporting base. A left chain wheel and a right chain wheel are connected through a chain. The left clamping assembly and the right clamping assembly are symmetrically arranged on the two sides of the supporting base. The middle end of a left pressing plate of the left clamping assembly is hinged to the upper end of a left rocking rod. A left pushing rod can be arranged on a left pushing rod support in a sliding upward and downward mode. A left pushing rod supporting lug is hinged to the left end of the left pressing plate. A left supporting rolling wheel is attached to the left driving cam. The middle end of a right pressing plate of the right clamping assembly is hinged to the upper end of a right rocking rod. A right pushing rod can be arranged on a right pushing rod support in a sliding upward and downward mode. A right supporting rolling wheel is attached to the right driving cam. According to the synchronous compressing device, the two sides of the lower end of the inverted T-shaped workpiece are synchronously clamped, deviation of the inverted T-shaped workpiece in the compressing process is effectively avoided, and the clamping stability is good.

Owner:魏俊杰

Charging pile

InactiveCN108656996ASolve the service lifeEasy to viewCharging stationsElectric vehicle charging technologyEnvironment effectEngineering

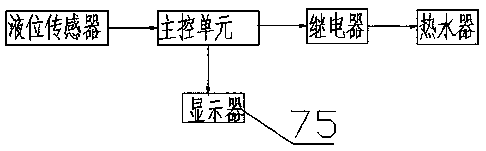

The invention discloses a charging pile. The charging pile comprises a charging pile body; a display control screen is arranged in the middle of the charging pile body, a main control unit is arrangedon the rear side of the display control screen, a wireless connection module is arranged on the right side of the main control unit, and a card swiping sensing area is arranged on the right side of the display control screen; the charging pile further comprises a shielding plate on the upper portion of the charging pile body, supporting rods used for supporting the shielding plate, and a chargingpile base at the bottom of the charging pile body; the bottoms of the supporting rods are connected with the charging pile base, and the tops of the supporting rods are connected with the shielding plate; a drinking water cabinet is arranged on the left side of the charging pile body and internally provided with a water heater and a water tank; and the drinking water cabinet is provided with a water injecting opening, a hot water outlet and a cold water outlet; a sealing cap is arranged on the water injecting opening, the water injecting opening communicates with a water inlet in the water tank through a water pipe, the drinking water cabinet is provided with an observation window, and the output end of the main control unit is connected with a relay used for controlling the water heaterto work. The charging pile is simple in structure and is not affected by rainwater and the severe environment, and the design of the drinking water cabinet is reasonable and humanized.

Owner:河南水天环境工程有限公司

Fabric cleaning device for mechanical processing of textiles

The invention discloses a fabric cleaning device for mechanical processing of textiles. The device comprises a cleaning box, wherein the inner wall of the cleaning box is provided with a clapboard, and the outer wall of the top of the clapboard is provided with a groove; the inner wall of the bottom of the groove is provided with a limiting rod, the outer wall of the limiting rod is connected witha filter plate slidably, handles are welded to the portions, close to the two sides, of the outer wall of the top of the filter plate respectively, and the outer wall of the bottom of the filter plate is provided with a fixing opening. According to the device, a fabric can be kept in a tight state in the conveying process, and correspondingly impurities can be more conveniently cleaned away through brushing; brushes on cleaning rollers can brush away the impurities on the fabric; when the brushes rotate to a brush groove in a slag collecting box, the brush groove can maintain the impurities such as piles adhered to the brushes in the slag collecting box, so that the brushes are automatically cleaned, the cleaning effect is better, the fabric can be bent at a certain angle from the middleposition, the impurities on the bent fabric can be more easily flushed away from the two sides, and the cleaning effect of the device is further improved.

Owner:程斌

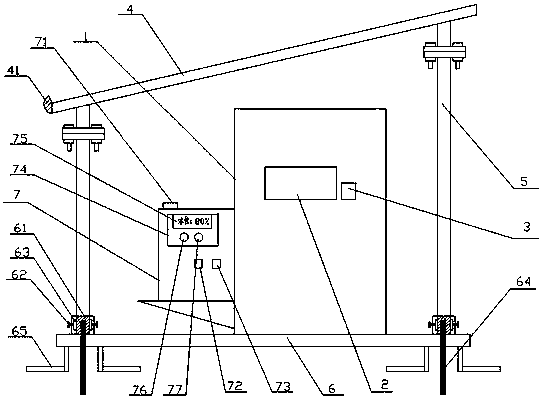

Support frame for solar cell panel

InactiveCN107809205AOptimize usage efficiencyImprove stabilityPhotovoltaic supportsSolar heating energyHydraulic cylinderEngineering

The invention discloses a support frame for a solar cell panel. The support frame comprises a circular base; a ring-shaped groove is formed in the upper end of the circular base; two sliding blocks are symmetrically arranged in the ring-shaped groove; the upper end of each sliding block is fixedly connected with a first connecting block; the ends, far away from the sliding blocks, of the first connecting blocks extend out of the ring-shaped groove and are respectively and fixedly connected with support blocks; the upper ends of the support blocks are respectively and fixedly connected with hydraulic cylinders; drive ends of the hydraulic cylinders are separately connected with a hydraulic rod; the upper end of each hydraulic rod is fixedly connected with a support plate; a U-shaped grooveis formed in the upper end of each support plate; a second connecting block is inserted into the U-shaped groove. The support frame is convenient in installation and disassembly of the solar cell panel, can adjust the angle and gradient of the solar cell panel, and fully increases the service efficiency of the solar cell panel.

Owner:余金铭

Press mounting fixture

InactiveCN104440305AFully automatedThe arc structure is stableWork clamping meansPositioning apparatusMechanical engineeringEngineering

Owner:常州依丝特纺织服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com