Multifunctional winding device used for machining winding drum material

A rewinding device and multi-functional technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of poor film flatness, and achieve low cost, good slitting quality and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

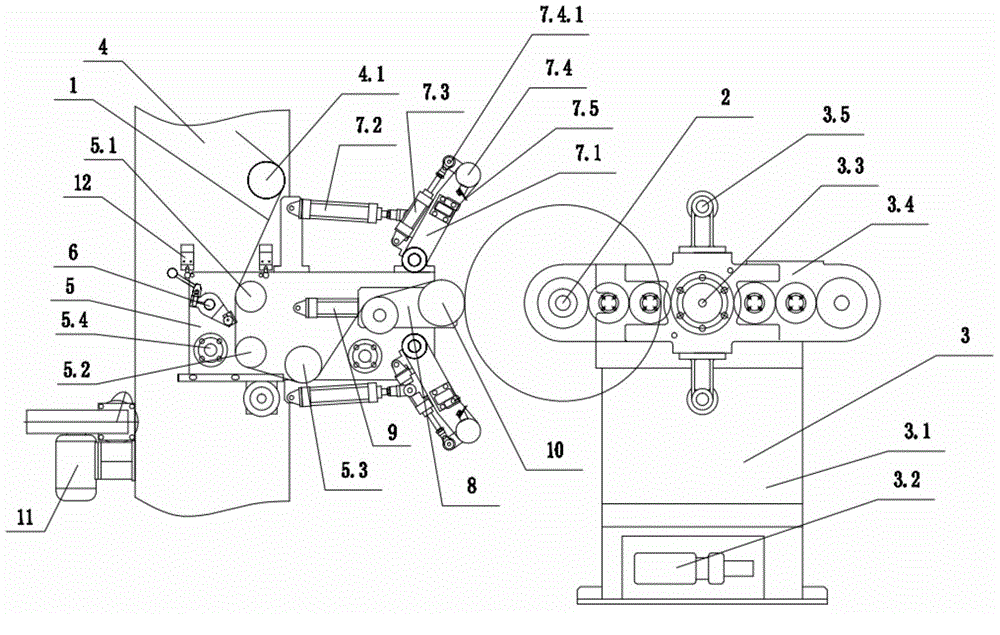

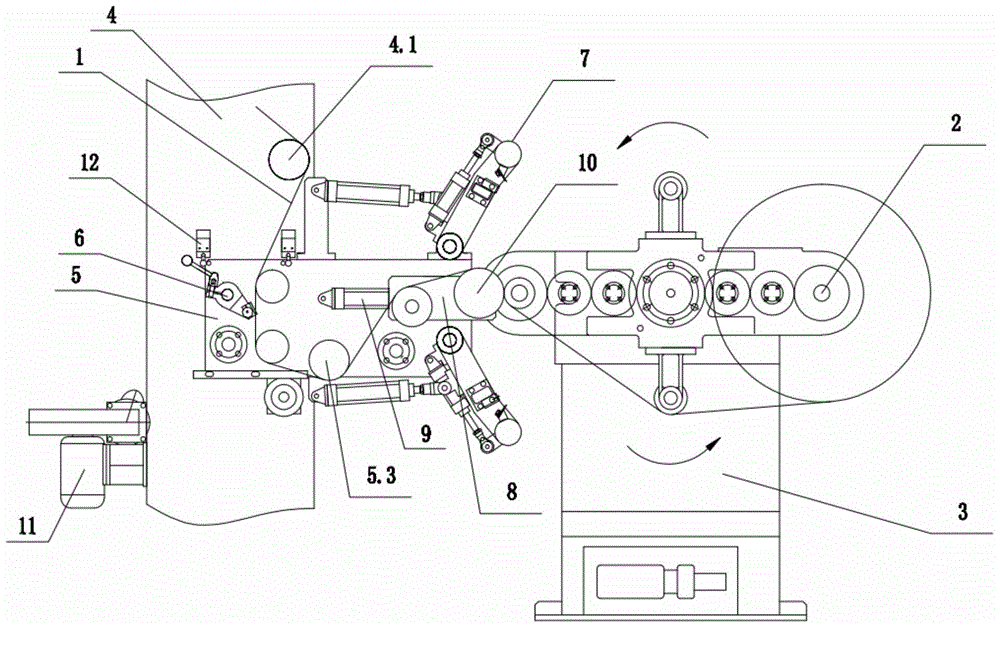

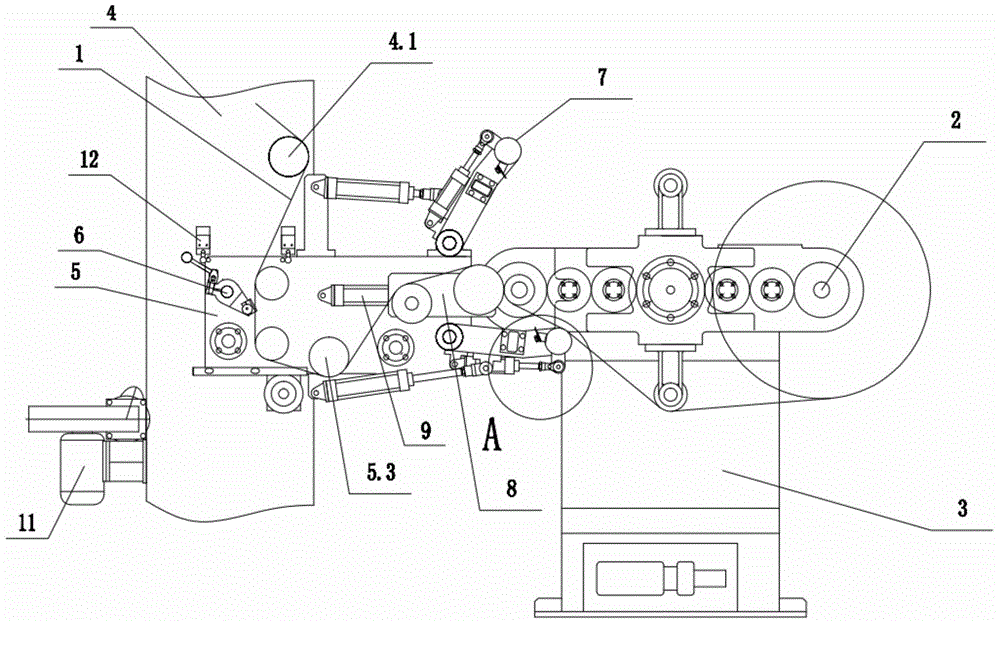

[0023] As shown in the figure, the present invention provides a multi-functional winding device for roll material processing, which includes a winding unit 3 for winding the material film 1 on the material cylinder 2 and realizing automatic replacement of the material cylinder , the described multi-functional winding device for roll material processing also includes a mounting frame 4, a traversing plate 5 slidingly fitted on the mounting frame 4, and a slitting plate on the traversing plate 5 A cutting mechanism 6 for the material film 1 and a cutting mechanism 7 for cutting the material film 1 on the barrel 5 after the winding is completed. The sliding fit between the above-mentioned traversing plate 5 and the mounting frame 4 means that the mounting frame 4 is provided with a guide rail, the traversing plate 5 is provided with a slide block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com