Method and device for combined stamping riveting

A punching riveting and riveting technology, applied in the field of metal processing, can solve the problems of the coaxiality of the parts that cannot be clamped, the surface needs to be smooth and the size of the workpiece is small, etc., and achieves good pressing effect, good end face fit, and coaxiality size high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

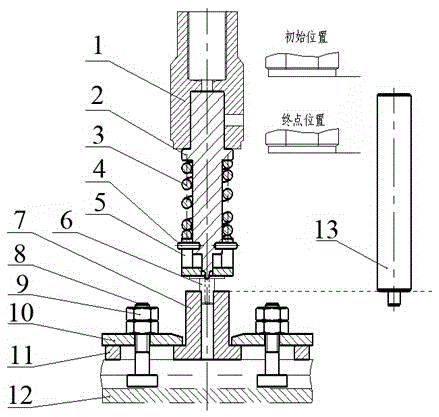

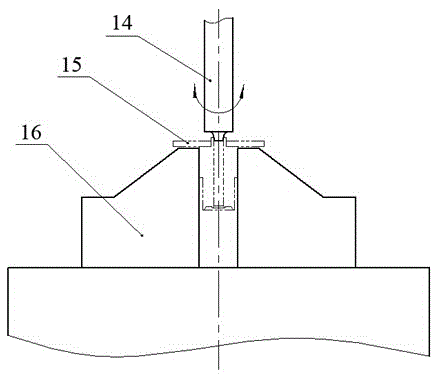

[0024] Such as figure 1 As shown, a certain type of product in production requires riveting thin plate parts with a thickness of 1.5mm to a cylindrical support to ensure that the riveting is firm and the coaxiality between parts is controlled within 0.04mm. The thickness of the thin plate part is 1.5mm, the diameter of the outer circle is 26mm, and the diameter of the middle hole is 4.3mm. The support is three-section cylindrical, with a through hole in the middle with a diameter of 2.8mm. The outer diameter of the first section of the cylinder at the upper end is 4.2mm and the length is 2.6mm. The outer diameter of the middle section of the cylinder is 11mm and the length is 8.8mm. The diameter of the third section of the cylinder is 9.1mm long 9.1mm. Among them, the first section is the rivet part, which is used for riveting the thin plate part to the part. Using the combined stamping riveting device of the present invention to rivet thin plate parts can ensure that the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com