Patents

Literature

111results about How to "Guaranteed compression effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

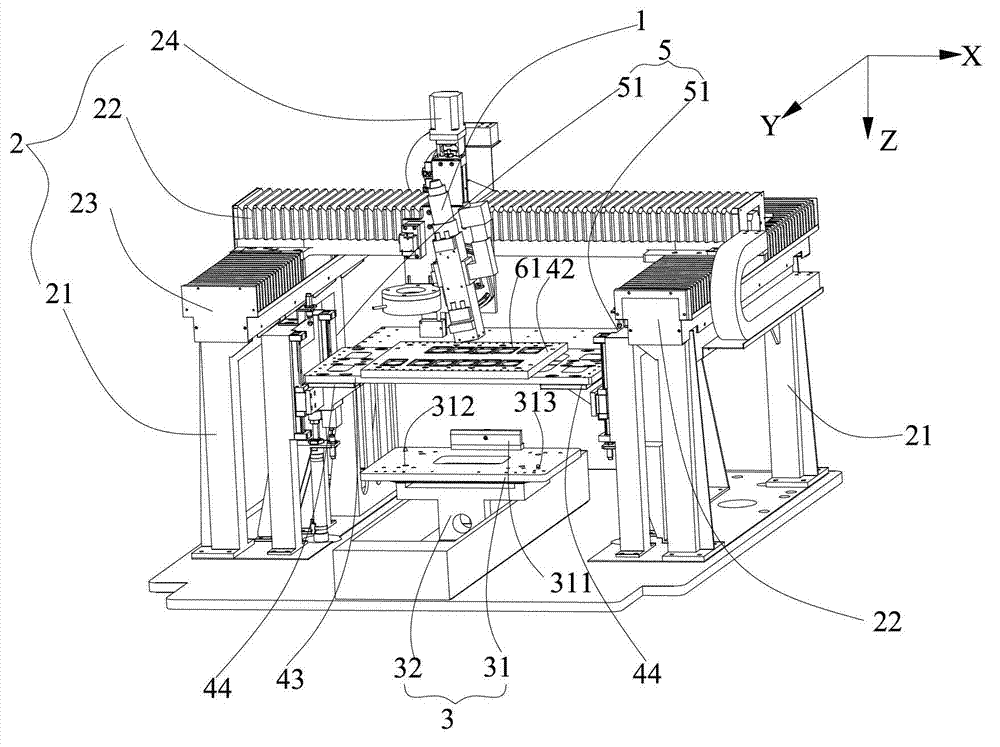

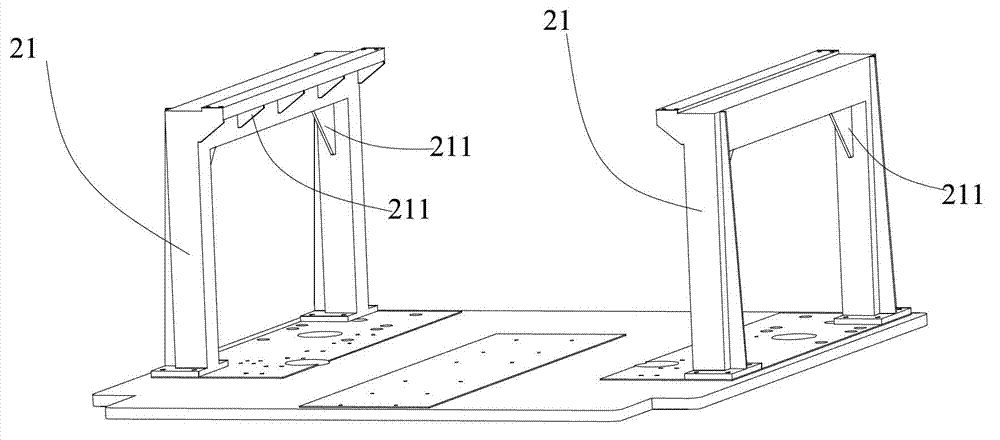

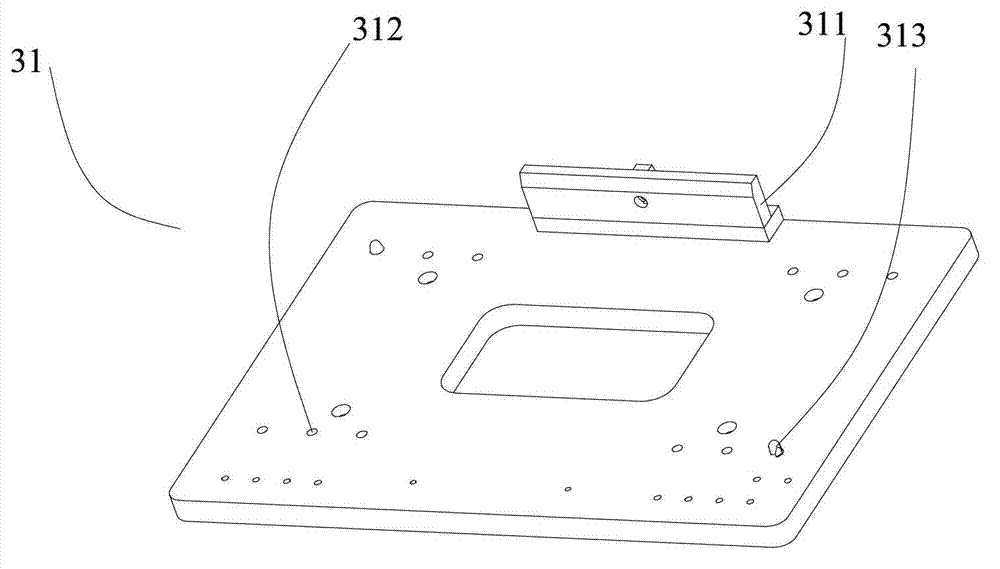

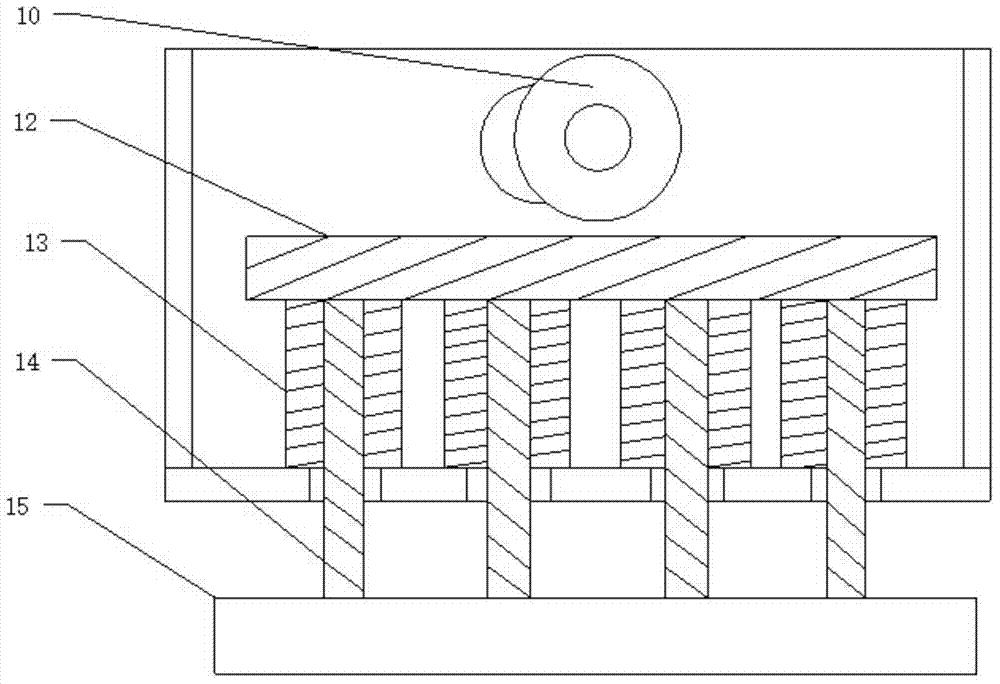

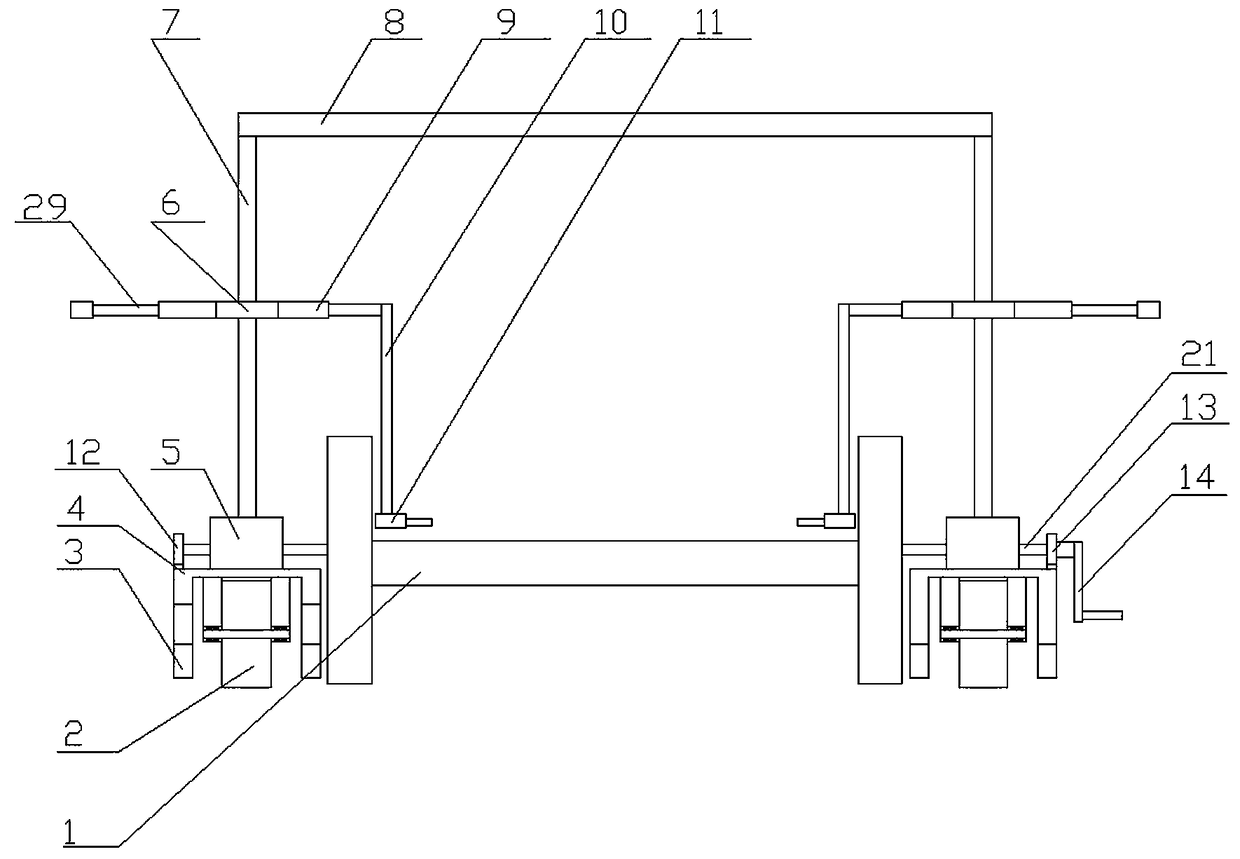

Full-automatic laser welder

ActiveCN103240527AGuaranteed compression effectSolving Automatic Laser Welding ProblemsLaser beam welding apparatusPortal frameLaser

The invention provides a full-automatic laser welder comprising a laser head, a laser head servo mechanism, a feeding and discharging device, a pressing mechanism and a transmission mechanism. The pressing mechanism comprises a plurality of pressing blocks and a pressing block support, wherein each pressing block is provided with a passage for laser emitted by the laser head to pass; and the pressing block support is elastically connected with each pressing block. The transmission mechanism is connected to the pressing block support to drive the pressing block support to move vertically so as to press or separate from corresponding connecting pieces. The laser head servo mechanism can further comprise two portal frames which are bilaterally and symmetrically arranged relative to the feeding and discharging mechanism along the X-direction, and each portable frame is provided with reinforcing ribs. The transmission mechanism can comprise a pair of transmission components which is bilaterally and symmetrically arranged relative to the feeding and discharging mechanism. The full-automatic laser welder can further comprise a gas cooling mechanism, a welding positioning unit and a controller. Therefore, pressing effects of welding spots of workpieces at different heights are guaranteed, welding temperature is lowered effectively, stability of a welding process is guaranteed, and welding optimal rate and efficiency are quite high.

Owner:CONTEMPORARY AMPEREX TECH CO

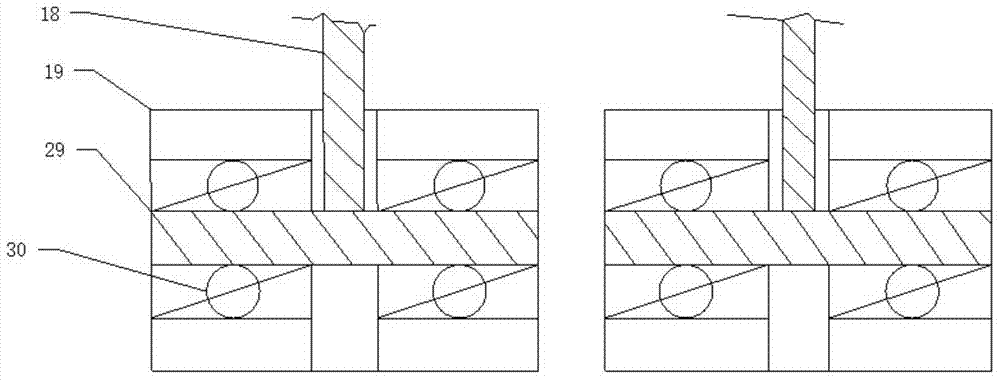

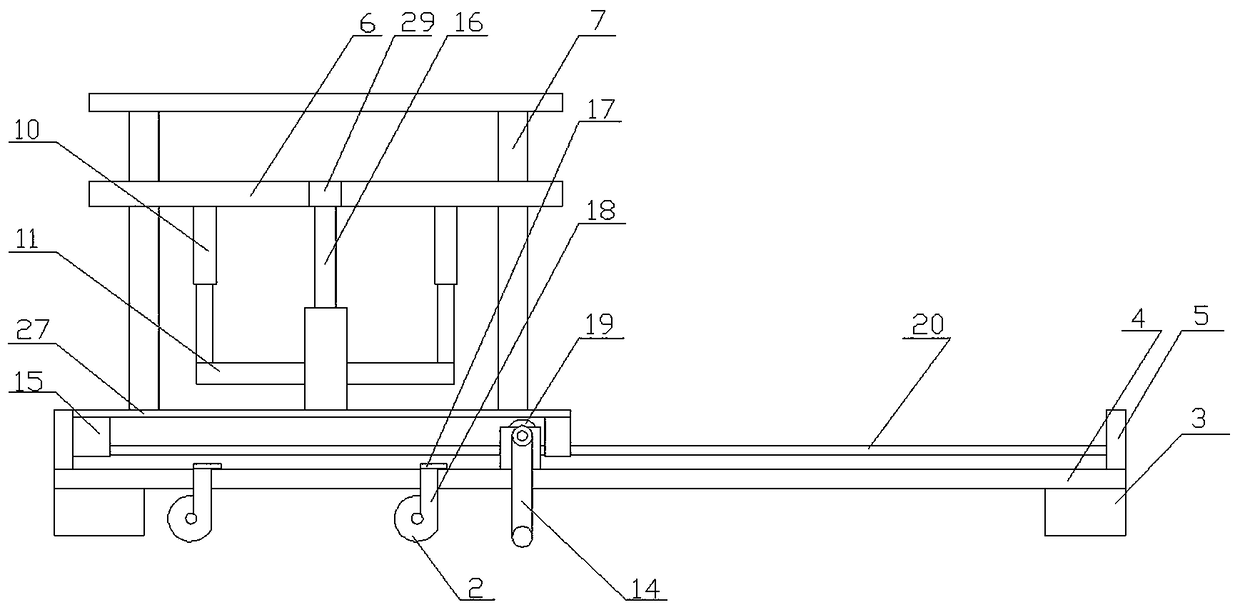

Waterproof and seepage-proofing coiled material paving equipment

ActiveCN104775571AGuaranteed laying effectGuaranteed compression effectRoof toolsRoads maintainenceEngineering

The invention discloses waterproof and seepage-proofing coiled material paving equipment, which comprises a machine body, an upper support frame and a lower support frame, wherein the upper support frame is arranged at two sides of the machine body, the lower support frame is arranged at two sides of the machine body and corresponds to the upper support frame, a coiled material rolling wheel is arranged on the upper support frame arranged at two sides, and a guide wheel is arranged on the lower support frame arranged at the two sides; a press wheel groove is also formed in the machine body, a second spring and a press wheel press plate elastically pressed by the second spring are respectively arranged in the press wheel groove, a propping rod passing through a through hole formed in the press wheel groove is formed in the press wheel press plate, the end part of the propping rod is connected with a press wheel, the press wheel corresponds to the guide wheel, and the waterproof and seepage-proofing coiled material paving equipment also comprises a main flame spray head and a preheating flame head corresponding to waterproof coiled materials. The waterproof and seepage-proofing coiled material paving equipment has the advantages that the structure is simple, the preheating flame head arranged on the machine body can be used for preheating the waterproof coiled materials, and the heating melting is enabled to be more sufficient in the heating melting process by using the main flame spraying head, the waterproof coiled material paving efficiency is high, in addition, the paving quality is good, and the waterproof effect is better.

Owner:河南景美环保工程有限公司

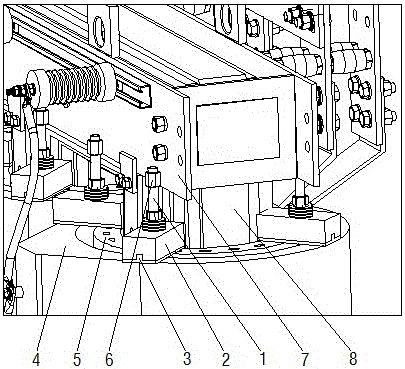

Automatic film covering equipment for plates

PendingCN108688290AAvoid damageQuality improvementLamination ancillary operationsLaminationCircular discEngineering

The invention relates to the technical field of film covering machines, in particular to automatic film covering equipment for plates. The automatic film covering equipment for the plates comprises arack, a conveying mechanism and a film covering mechanism, wherein the conveying mechanism conveys the plates on the rack and comprises a conveying belt and conveying rolls; the conveying belt is wound on the conveying rolls; a positioning baffle for positioning the front-back directions of the plates is arranged on the conveying belt; a guiding plate for limiting the left-right position of the plates is arranged on the rack; the film covering mechanism comprises a pressing and covering roll and a film supply assembly on the upper portion of the pressing and covering roll; the pressing and covering roll is movably connected with the rack; a pressure adjusting mechanism for adjusting downward pressure of the pressing and covering roll is arranged on the rack; a shaping roll is arranged on the rear side of the pressing and covering roll; disc hobs for cutting residual thin films are arranged on the shaping roll and correspond to the left sides and the right sides of the plates; side surface pressing rolls which press and cover the guiding plate are arranged at the position, which corresponds to the guiding plate, of the shaping roll; and a cutting assembly is arranged on the rear side of the shaping roll. Continuous film covering production of blocky plates is realized, after film covering, residual films are cut off and shaped immediately, the film covering quality is improved,and the production efficiency is high.

Owner:CHANGZHOU INST OF LIGHT IND TECH

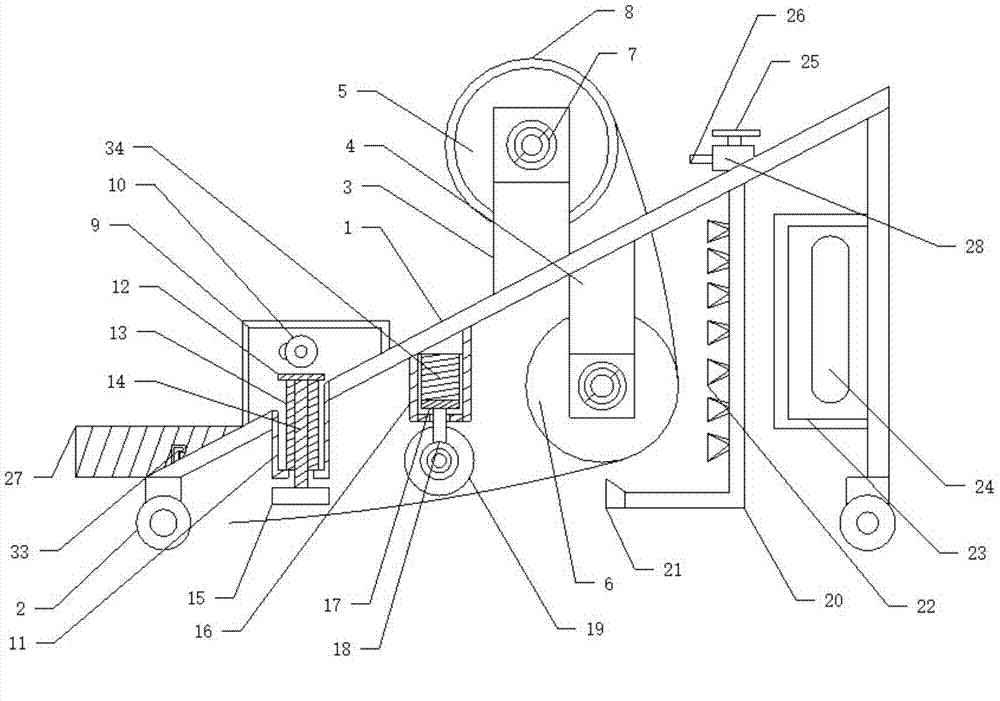

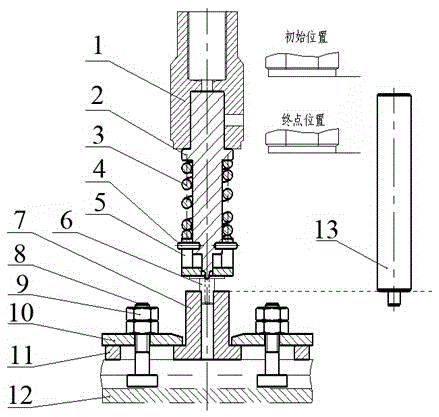

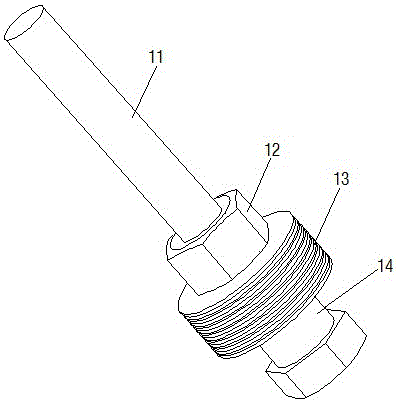

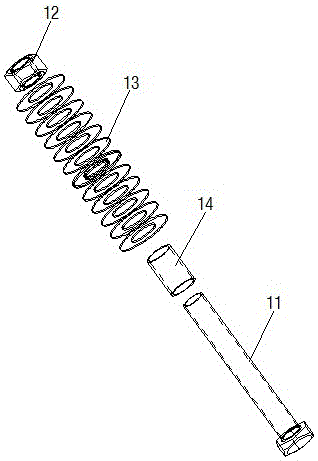

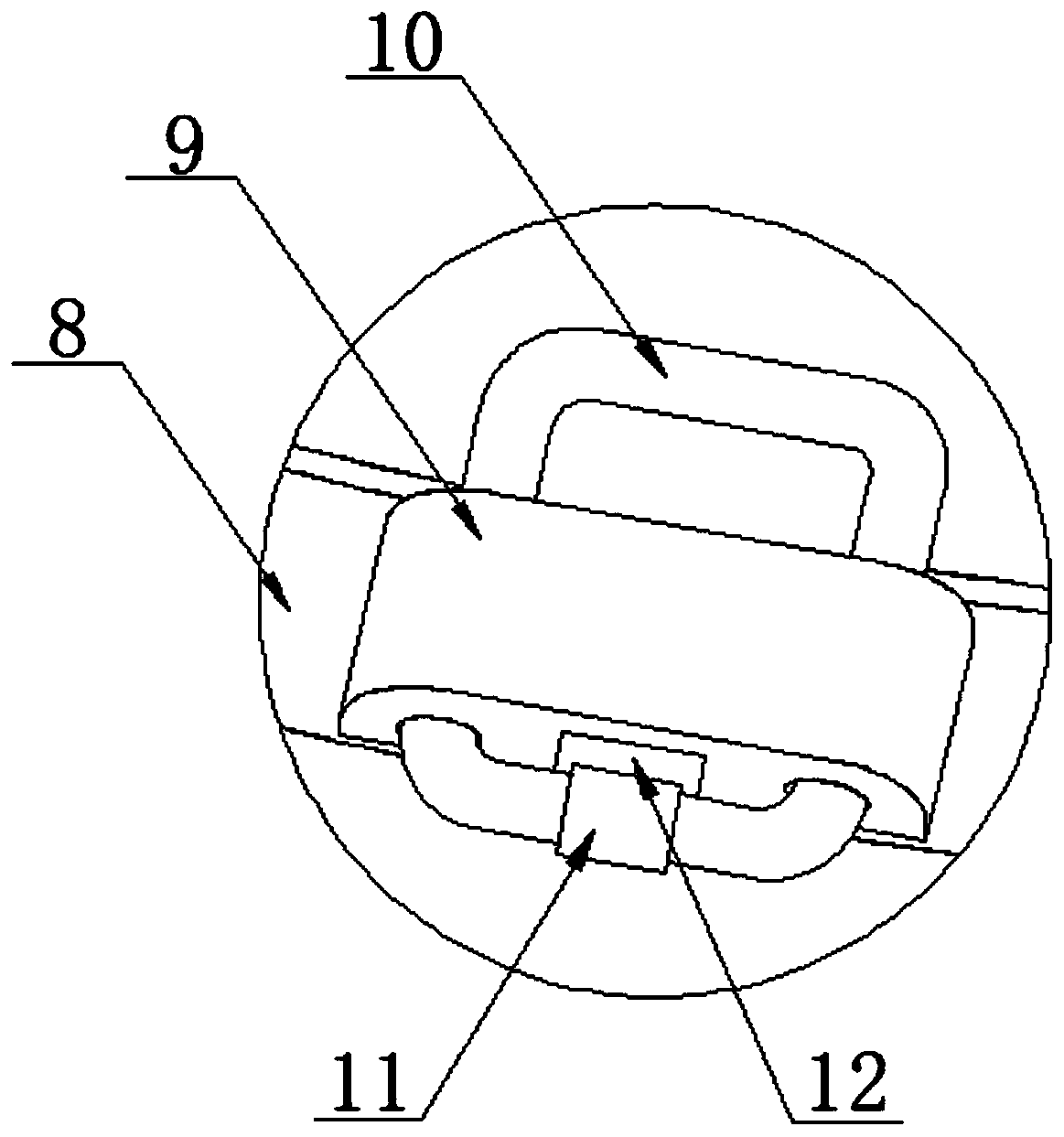

Method and device for combined stamping riveting

The invention discloses a method and device for combined stamping riveting. The method for combined stamping riveting comprises the steps that 1, a riveting puncher pin (2) assembly is driven by a press bar (1) of a press machine to be returned upwards to the highest point; 2, a supporting part and a sheet part of a workpiece (6) are installed in a positioning hole of a positioning base (7); 3, the press bar (1) of the press machine is re-started to be pressed downwards and moves to the position of an adjusted maximum stroke till a rivet of the workpiece (6) is turned over and deformed; and 4, the press bar (1) of the press machine is returned, the workpiece (6) is taken down, and riveting of the workpiece (6) is completed. According to the device for combined stamping riveting, a press machine is adopted to conduct riveting on the workpiece, riveting of the workpiece is uniform, stable and good in compression effect; in addition, by arranging the special structure, the coaxiality of the workpiece can also be ensured, and damage of the cylindrical surface of the workpiece is avoided. The device for combined stamping riveting is suitable for conducting riveting on the small-size sheet workpiece, and the effects that the riveted part is compact and reliable, the coaxiality dimensional precision is high, and end face attaching is good can be ensured.

Owner:GUIZHOU HONGLIN MACHINERY

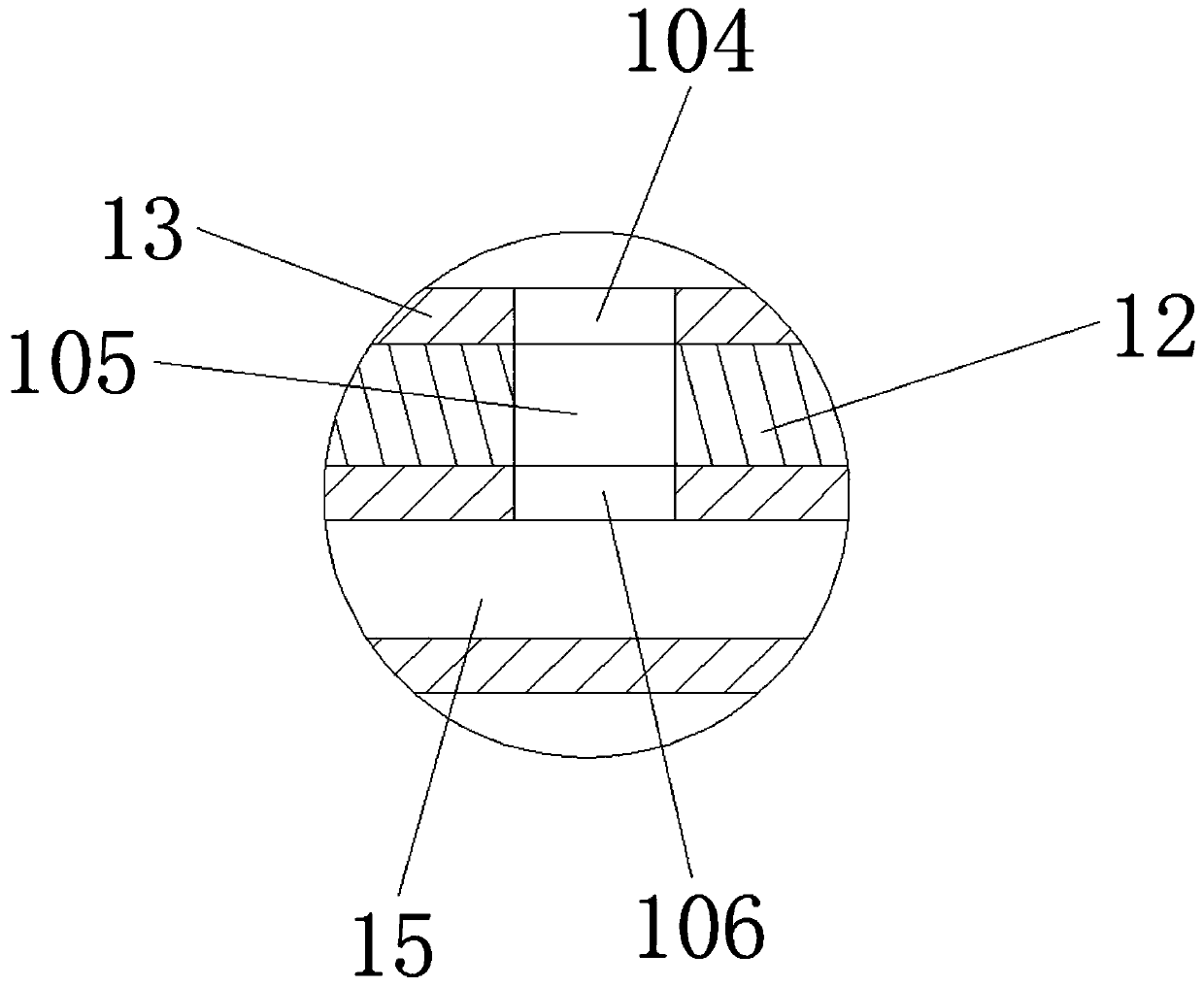

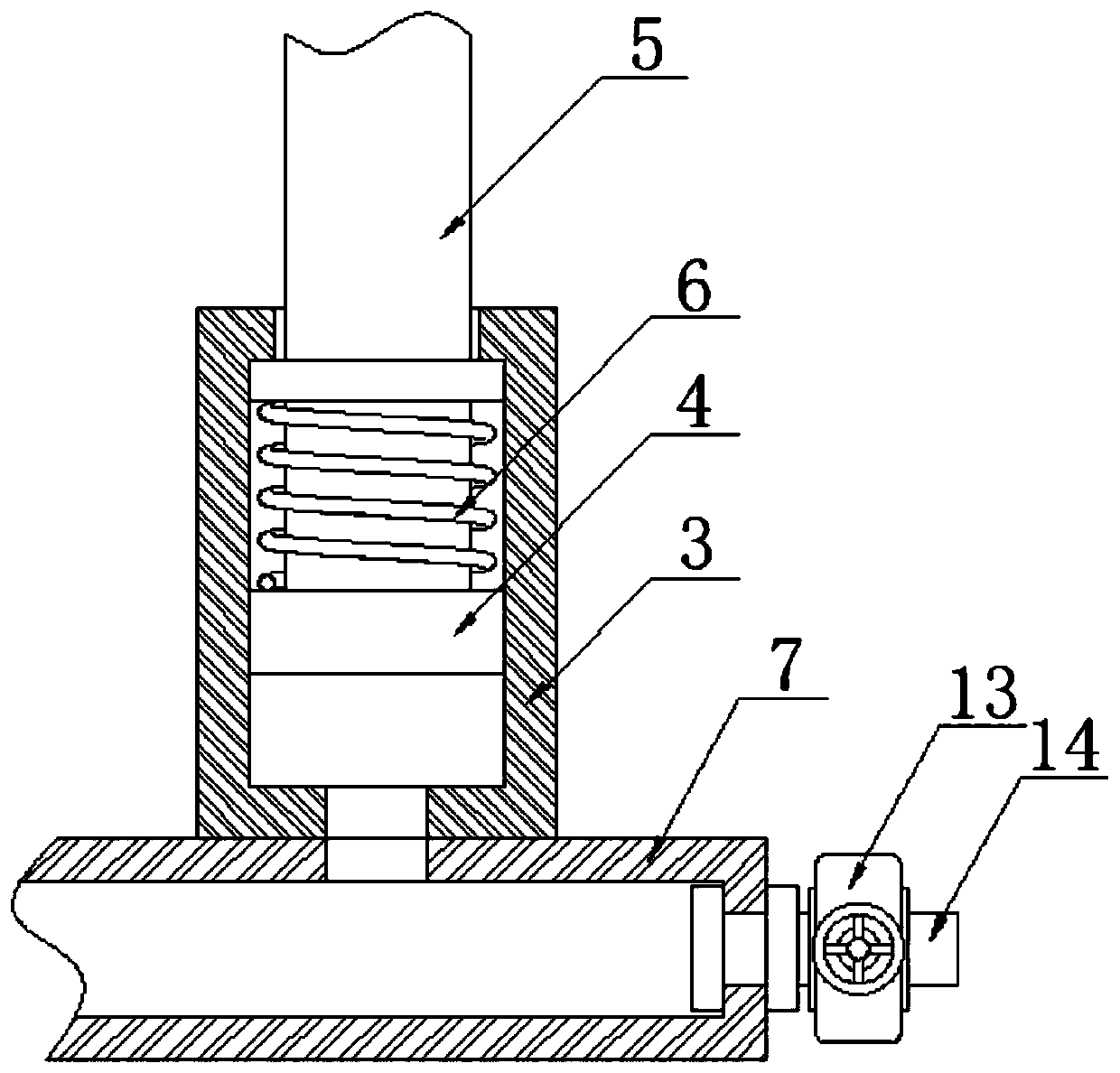

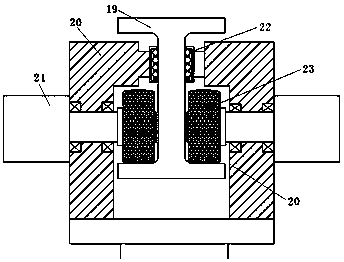

Dry type transformer and cushion block compressing structure thereof

ActiveCN106298198AEasy to useReduce gapTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention provides a dry type transformer and a cushion block compressing structure thereof. The cushion block compressing structure comprises a compressing bolt and a cushion block which are arranged along the up and down direction; a groove, into which a bolt head of the compressing bolt can be embedded, is arranged on the cushion block; a disc spring set sleeves the compressing bolt; the bottom disc spring in the disc spring set is in pressing fit with the cushion block; a compressing nut is screwed above the disc spring set on the compressing bolt; the top disc spring in the disc spring set is in pressing fit with the compressing nut; a guiding sleeve is sleeved in an inner hole of the disc spring set on the compressing bolt. The cushion block compressing structure has the beneficial effects that the existence of the guiding sleeve can reduce a clearance between the compressing bolt and the inner hole of the disc spring set; when the transformer is greatly vibrated in the transporting and running processes, the horizontal vibration of the disc springs in the disc spring set can be obviously reduced, so that the horizontal dislocation of the disc springs can be avoided; the use effect of the disc springs can be guaranteed; the compressing effect of the cushion block compressing structure and the normal safe use of the transformer can be lastly guaranteed.

Owner:STATE GRID CORP OF CHINA +4

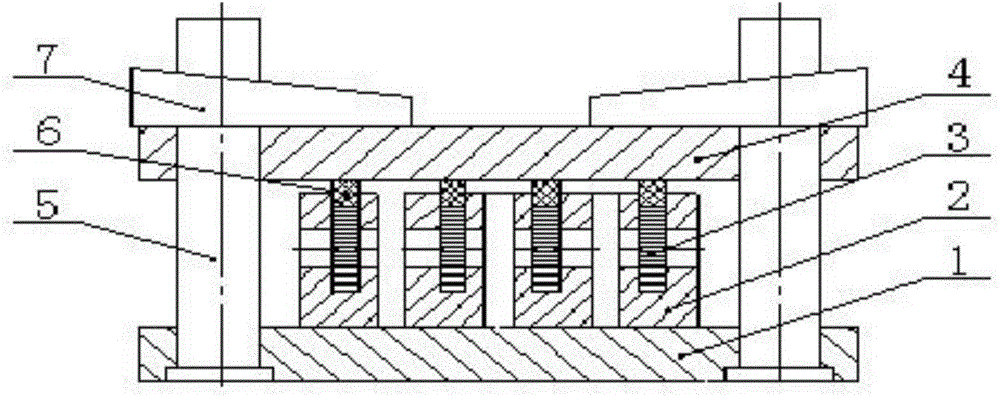

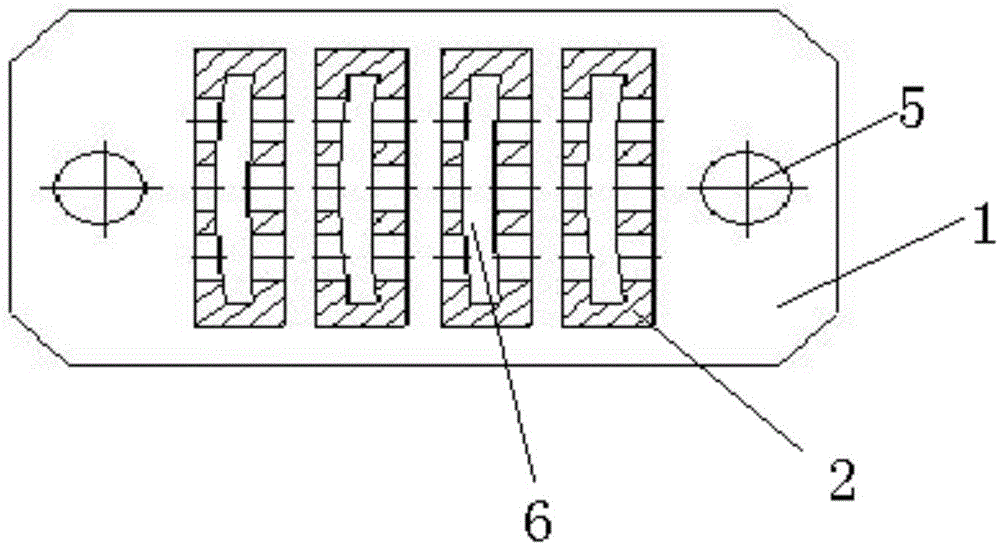

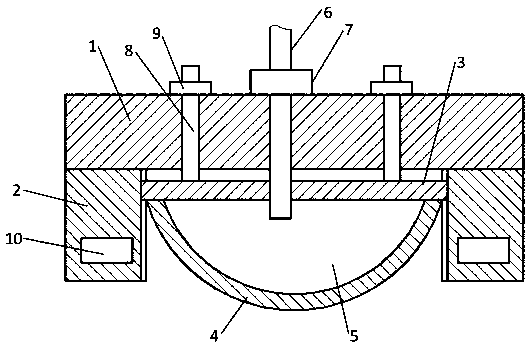

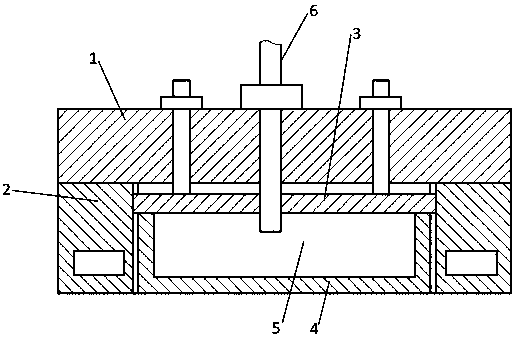

Hot sizing device and hot sizing method for thin-wall stamping part

ActiveCN104451047AAvoid misalignmentAvoid scrappingFurnace typesHeat treatment furnacesEngineeringMechanical engineering

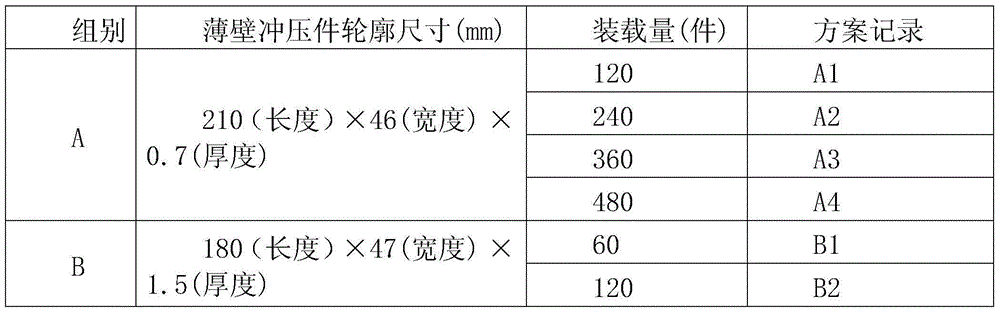

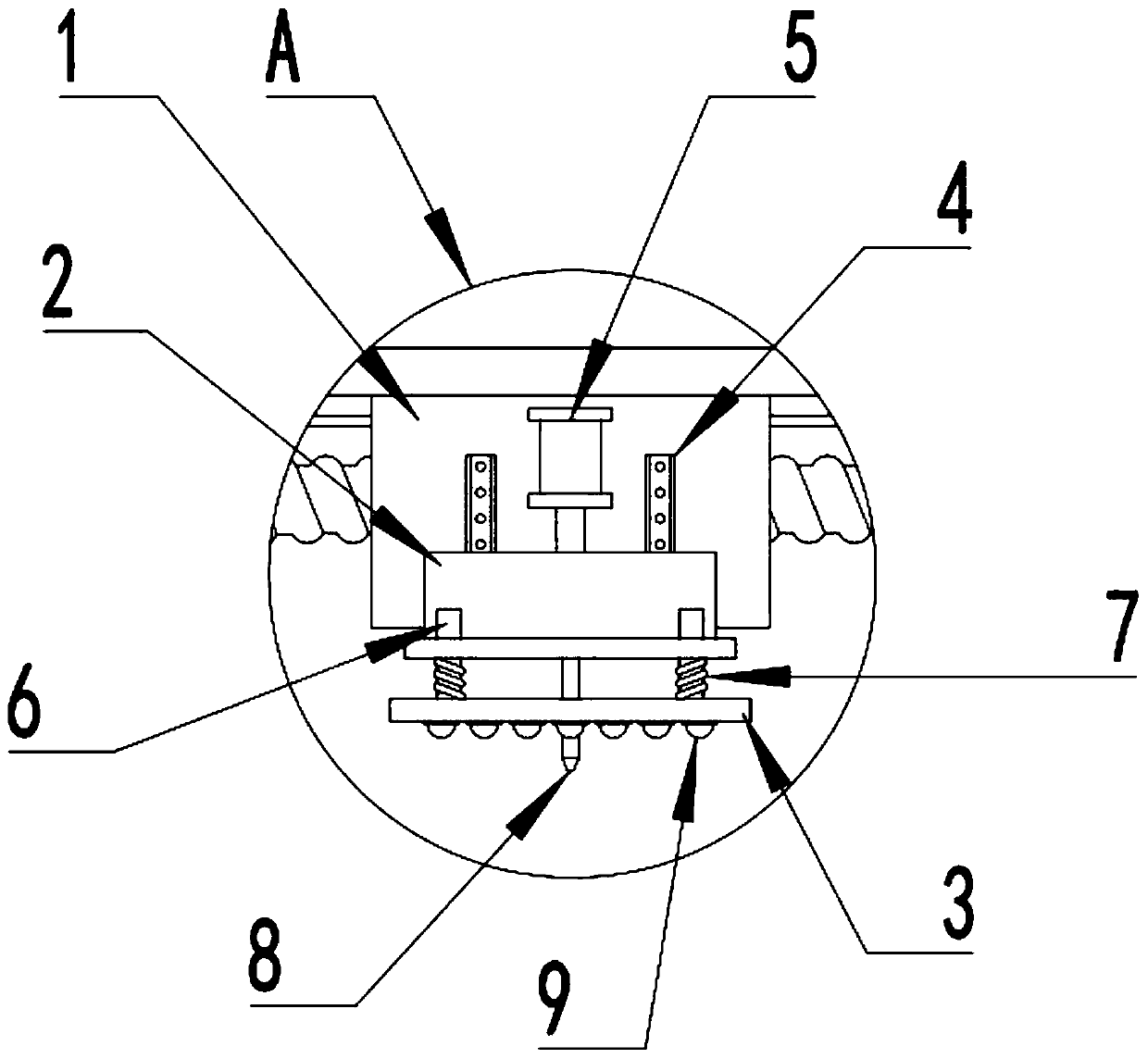

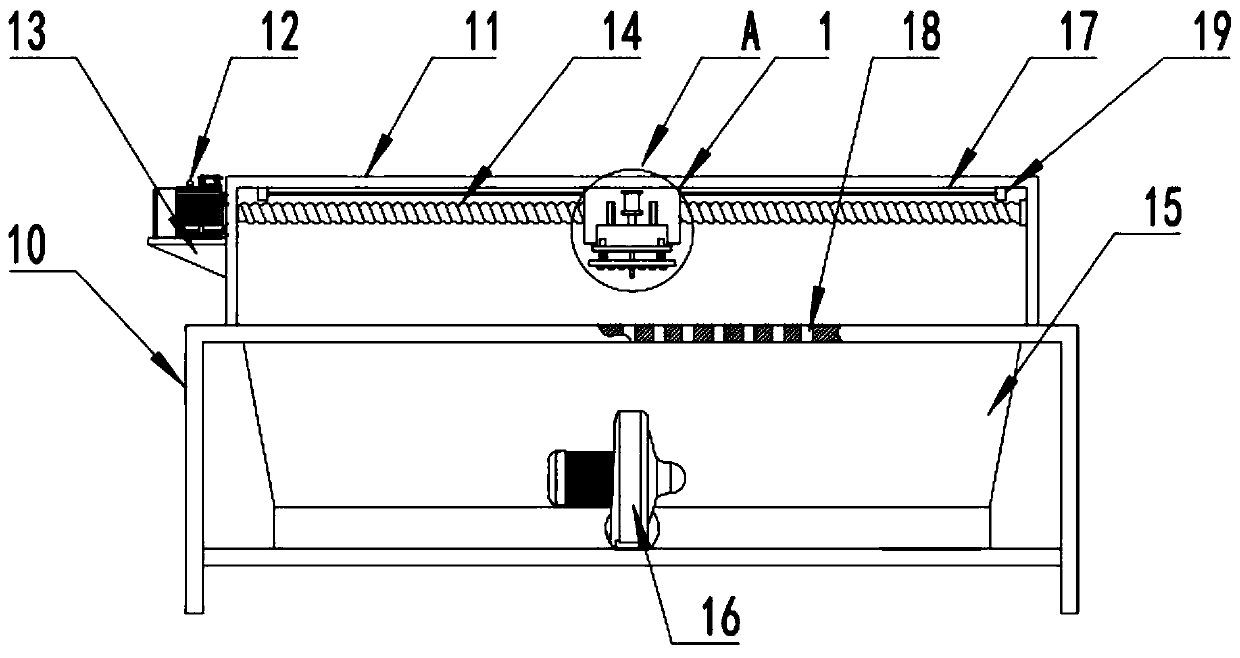

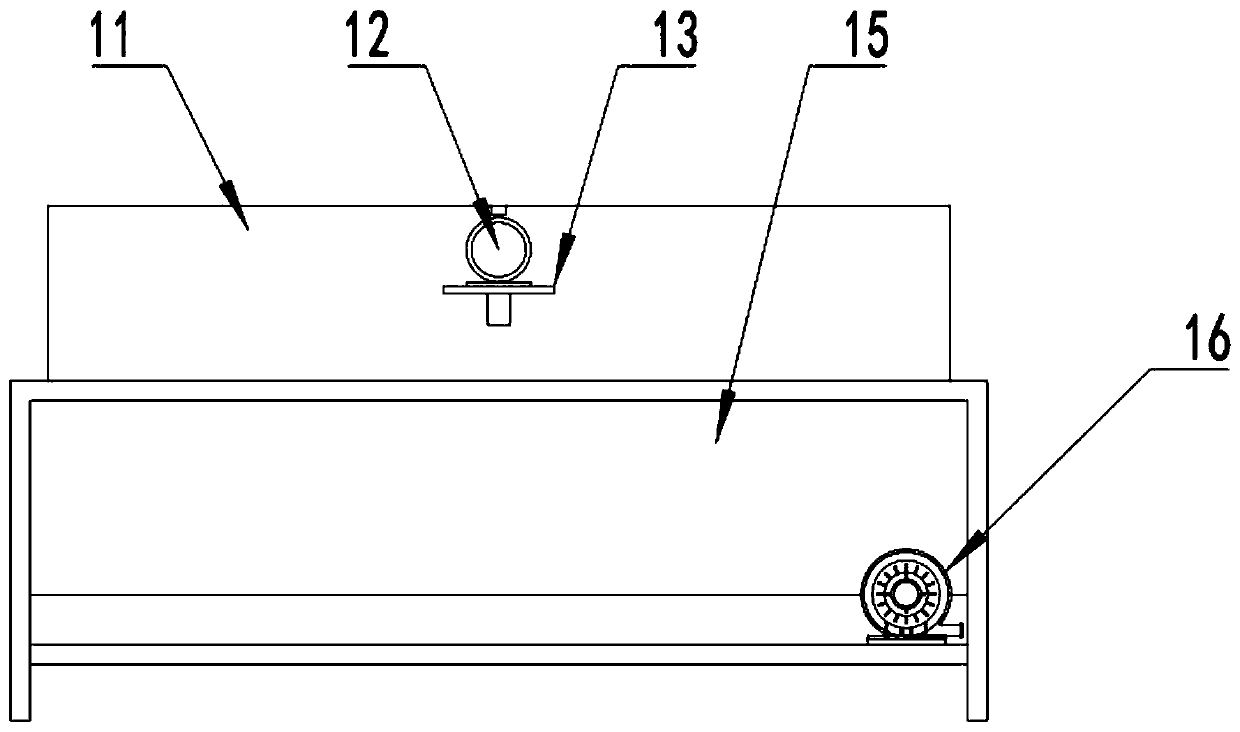

The invention discloses a hot sizing device and hot sizing method for a thin-wall stamping part, and aims at solving the problems of warping and deformation of the thin-wall stamping part which is subjected to hot sizing to improve the production efficiency and reduce the production cost. The adopted technical scheme is as follows: the hot sizing device comprises a bottom plate (1) and positioning pins (5), wherein the positioning pins (5) are fixedly arranged at two ends of the bottom plate (1); the bottom plate (1) is provided with a plurality of loading boxes (2), a plurality of thin-wall stamping parts (3) can be placed in the loading boxes (2) in a stacked way, cavities inside the loading boxes (2) are matched with the thin-wall stamping parts (3) in size structure, and the stacked height of the plurality of thin-wall stamping parts (3) is aligned to the upper planes of the loading boxes (2); and the upper ends of the loading boxes (2) are provided with press plates (4), and the press plates (4) are sleeved on the positioning pins (5) so as to press the thin-wall stamping parts (3) in holes of the loading boxes (2).

Owner:AECC AVIATION POWER CO LTD

Vibration tool cutting mechanism and cutting machine

InactiveCN110000842AAvoid creasesGuaranteed compression effectSevering textilesMetal working apparatusTool bitRelative motion

The invention discloses a vibration tool cutting mechanism. A moving base, a vibration tool base, an electric push rod and a vibration tool bit are included. The moving base is provided with the vibration tool base which is in sliding fit with the moving base. The vibration tool base is provided with the vibration tool bit. The moving base is further provided with the electric push rod for drivingthe vibration tool base to move. The bottom of the vibration tool base is elastically connected with a pressing plate. The pressing plate is located under the vibration tool base. The vibration toolcutting mechanism has the beneficial effects that when the vibration tool bit descends, the pressing plate can make contact with a to-be-cut workpiece firstly, the workpiece is pressed, and accordingly the situation of workpiece wrinkling during cutting is prevented; during cutting, the vibration tool bit and the to-be-cut workpiece need to relatively move, in the process, due to arranged balls, the phenomenon of workpiece wrinkling due to moving is avoided, the workpiece pressing effect can be guaranteed during moving, and the motion direction of the vibration tool base is not limited by theball design.

Owner:TIANJIN HONGGUANG WEIYE LASER TECH CO LTD

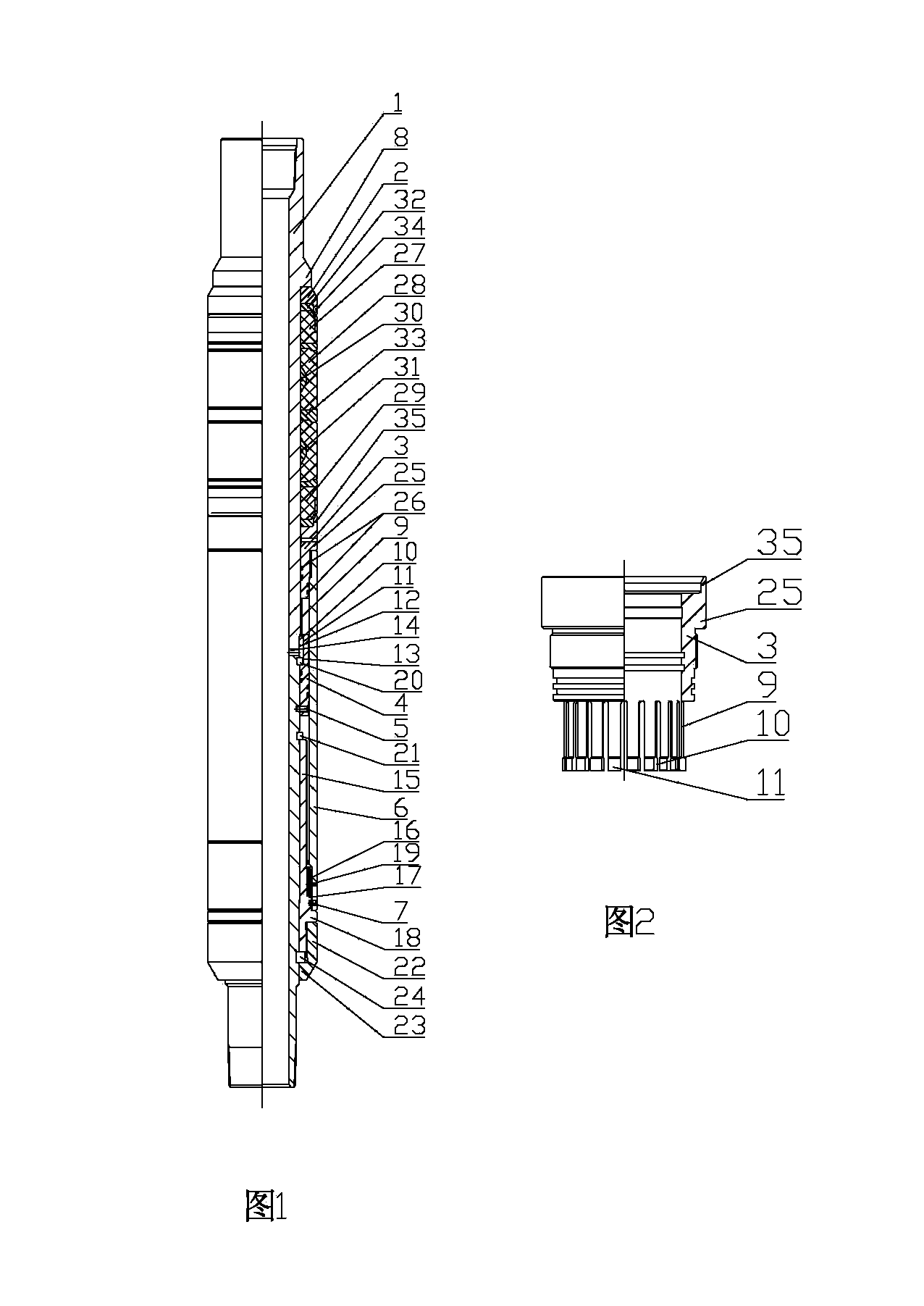

Reliable packer

The invention relates to the technical field of packers used in oil and gas field well cementing and completion operation, in particular to a reliable packer. The reliable packer comprises a shaft barrel body, a retaining sleeve, a rubber barrel packing device, a sealing collet, a plunger barrel, a plunger shear pin, a sealing barrel, a rubber barrel shear pin and an anti-unblock device, wherein a barrel outer boss is arranged on the outer side of the upper part of the shaft barrel body; the retaining sleeve, the rubber barrel packing device and the sealing collet are sleeved outside the shaft barrel body below the barrel outer boss from top to bottom in sequence; not less than two sealing claw sheets are distributed on the circumference of the lower part of the sealing collet at an interval; an inner claw block and an outer claw block are fixedly arranged on the inner side and the outer side of the lower part of each sealing claw sheet respectively. The reliable packer has a rational and compact structure, the interference acting force of the exterior to the plunger barrel during descending to a predetermined position can be effectively avoided, and a pressing effect of the packer on the outer claw blocks is guaranteed, so that the ascending of the sealing collet and mistaken setting caused thereby are effectively prevented, and the packer has good reliability to avoid the adverse effect on the subsequent construction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

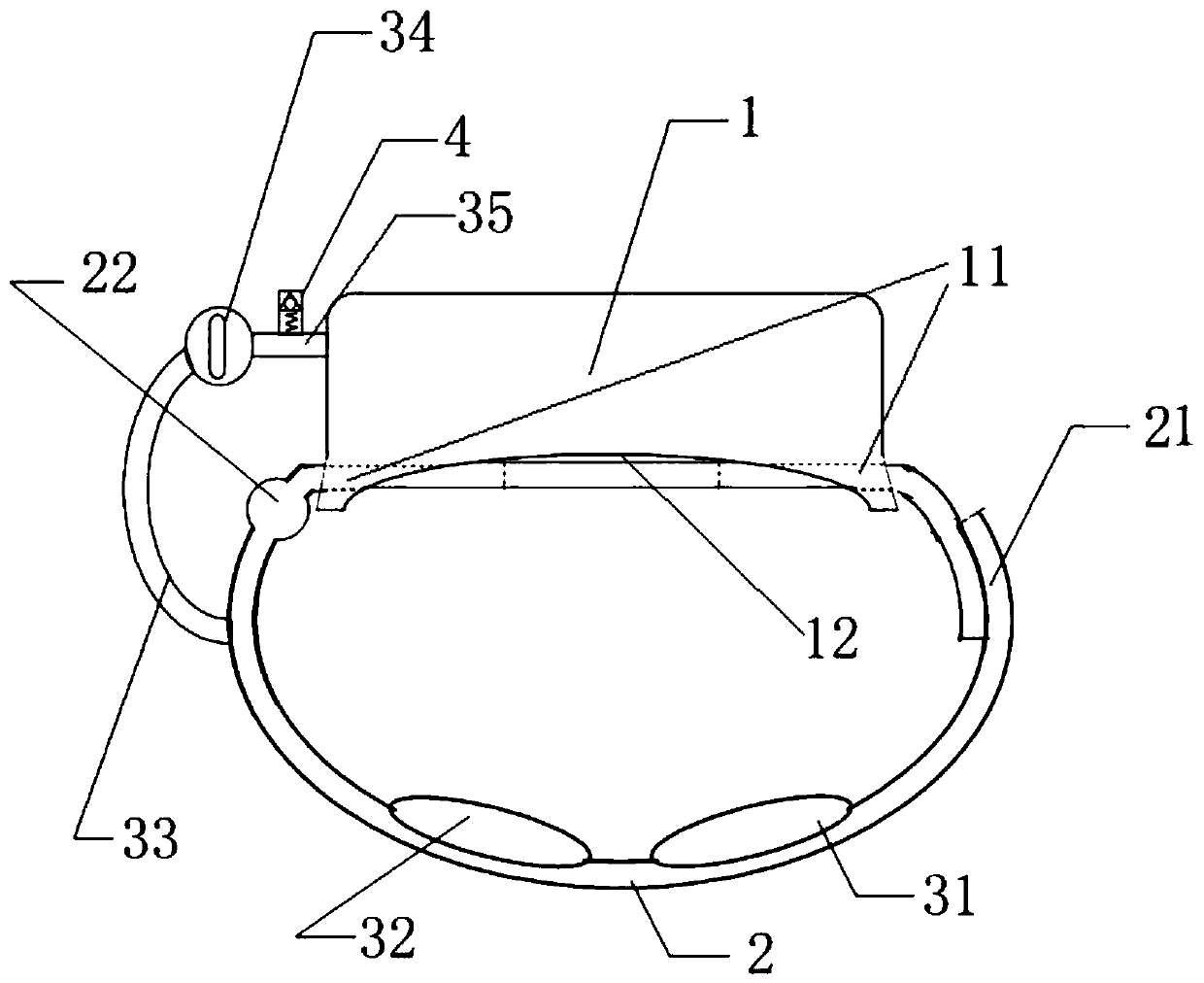

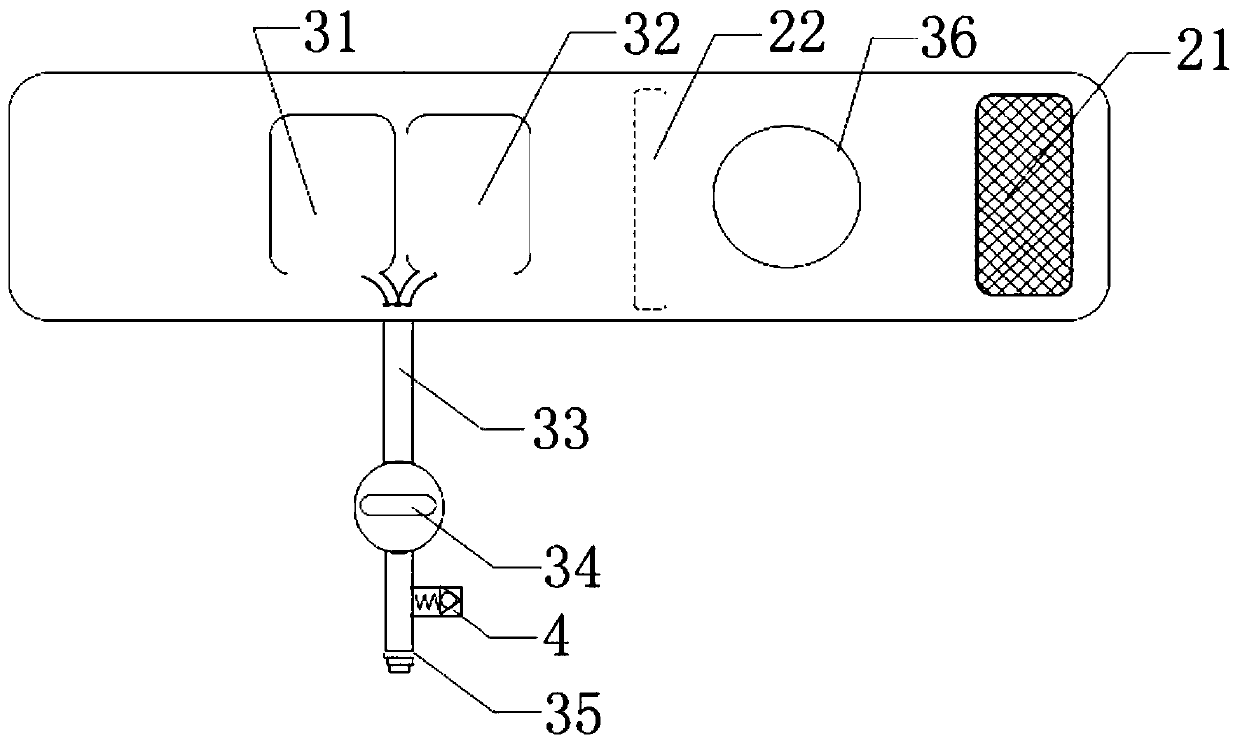

Air bag type artery compression hemostasis control system and corollary equipment thereof

ActiveCN111481253AEasy to calculateImprove comfortPump testingSurgerySaturation oxygenPostoperative hypotension

The invention relates to an air bag type artery compression hemostasis control system and corollary equipment thereof. The air bag type artery compression hemostasis control system comprises a controlmodule, and the control module is connected with a sensor, a display interaction panel and an air pump used for inflating and deflating a compression hemostasis air bag; the sensor monitors the bloodpressure and oxygen saturation of a human body in real time and also monitors the pressure of an output pipeline of the air pump; and the display interaction panel comprises a display screen and keys. The system has the beneficial effects that radial and ulnar artery compression hemostasis and vital sign monitoring are integrated; the changes of blood pressure, oxyhemoglobin saturation and heartrate of a patient are monitored in real time, the compression strength of the compressor is dynamically adjusted according to the blood pressure, accurate and intelligent compression hemostasis is achieved, adverse events such as postoperative hypotension, maloperation reflex and syncope can be monitored, and various postoperative complications are effectively reduced.

Owner:刘夙璇 +1

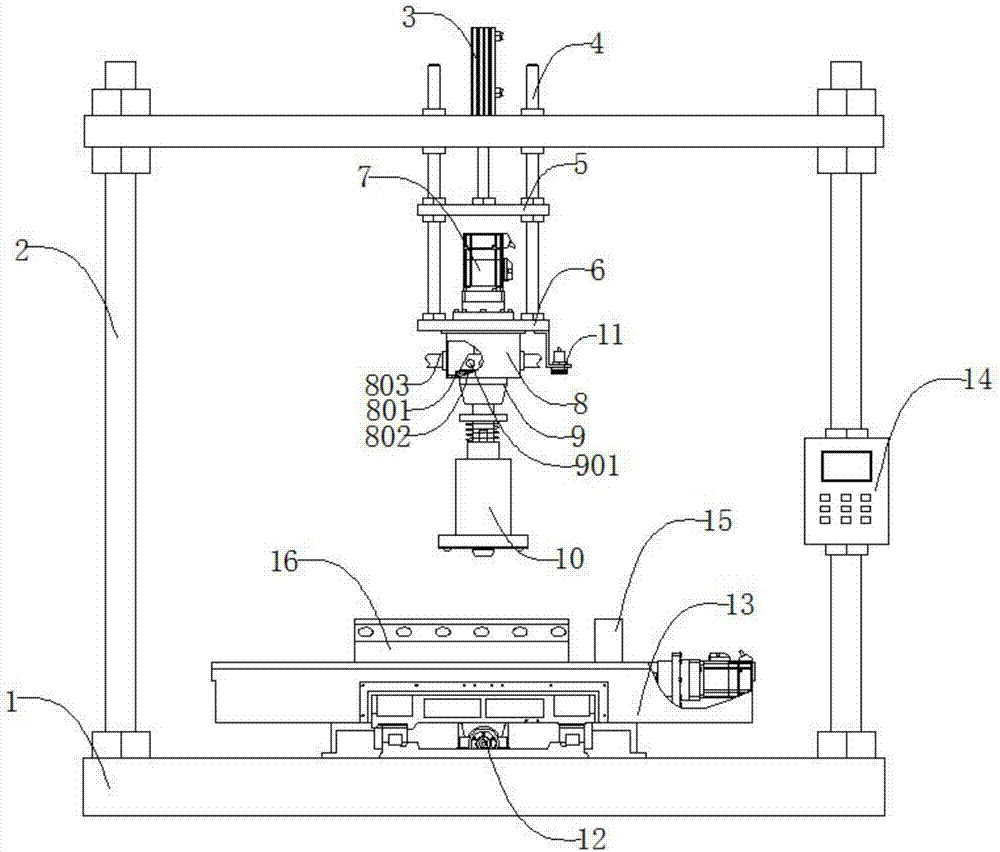

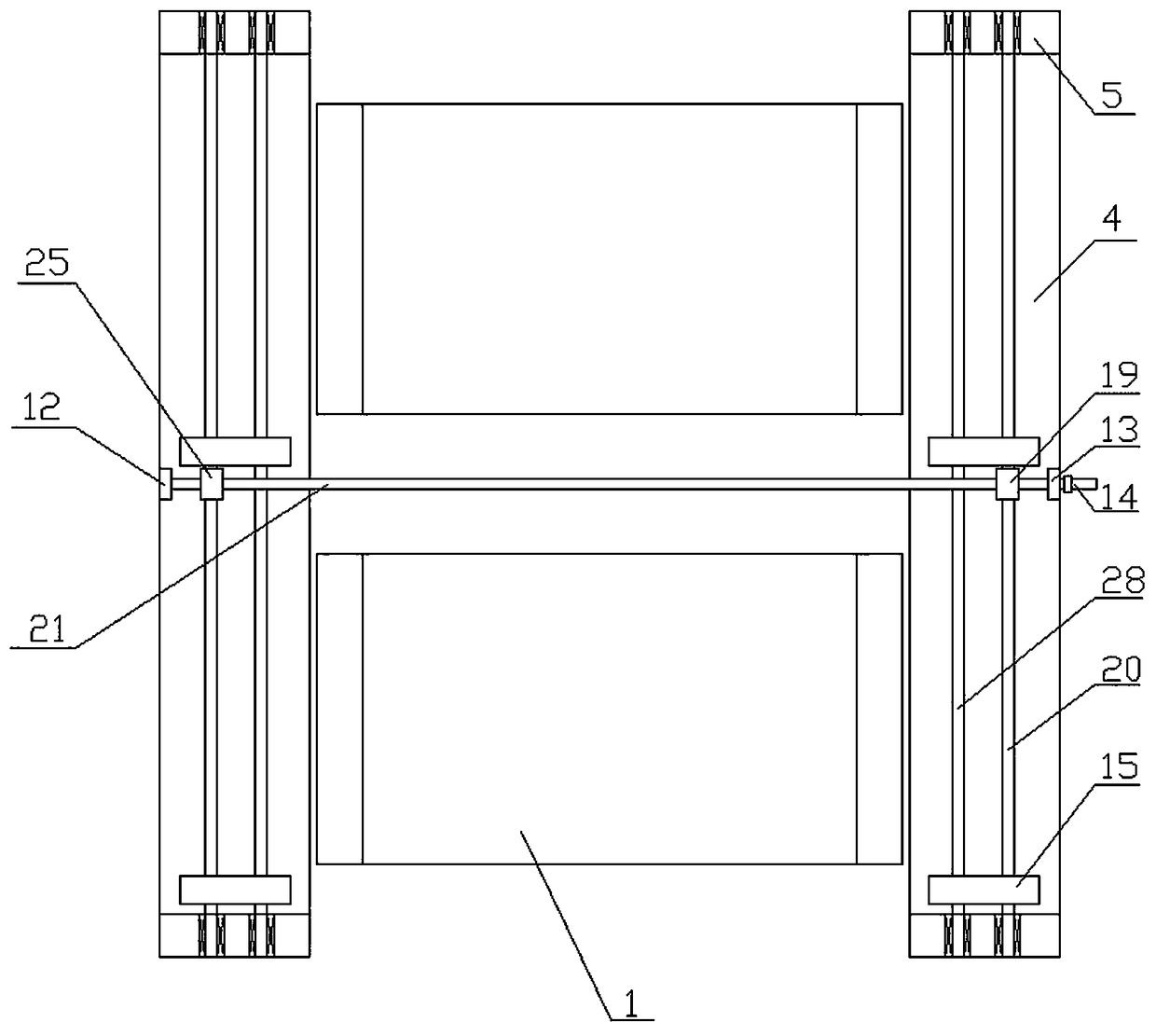

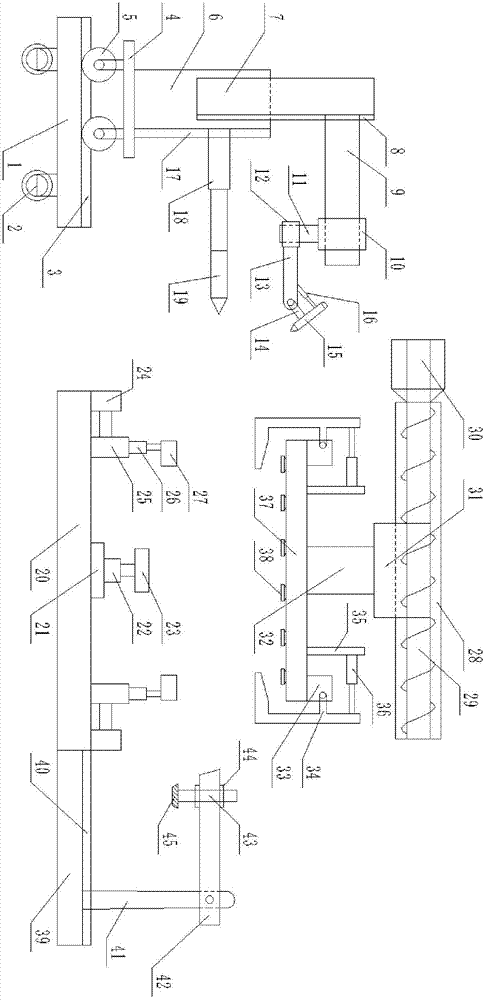

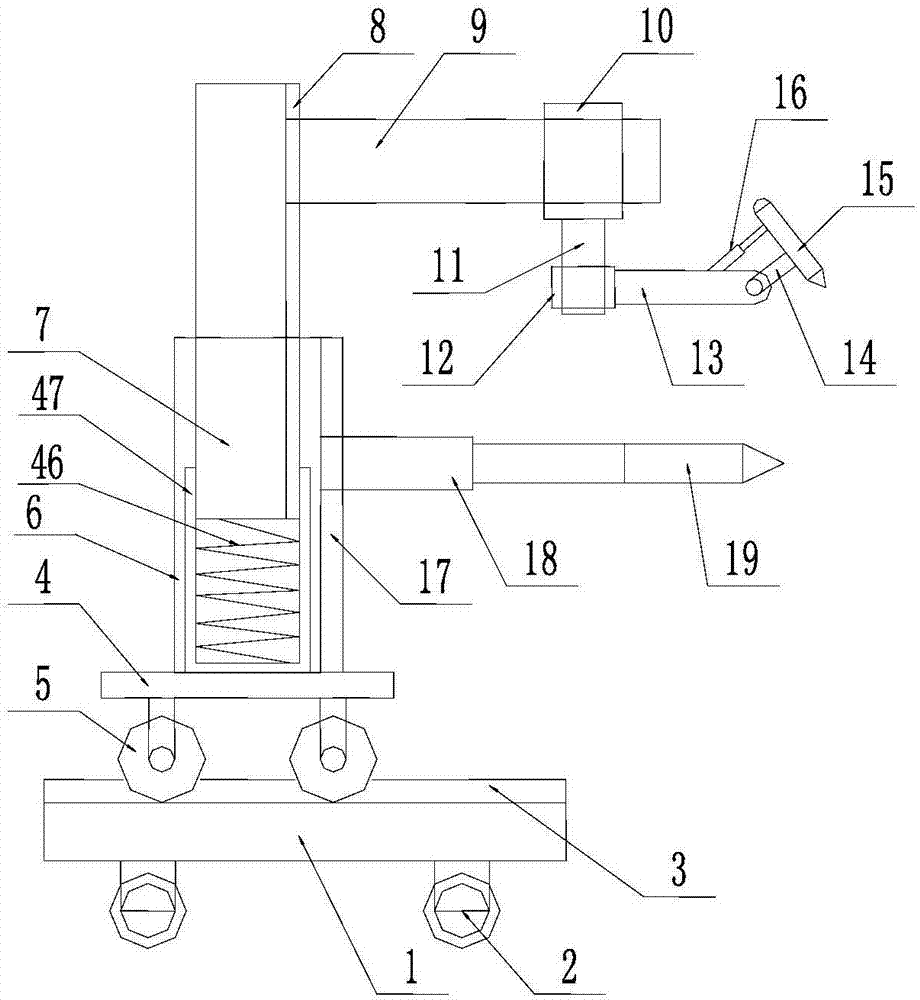

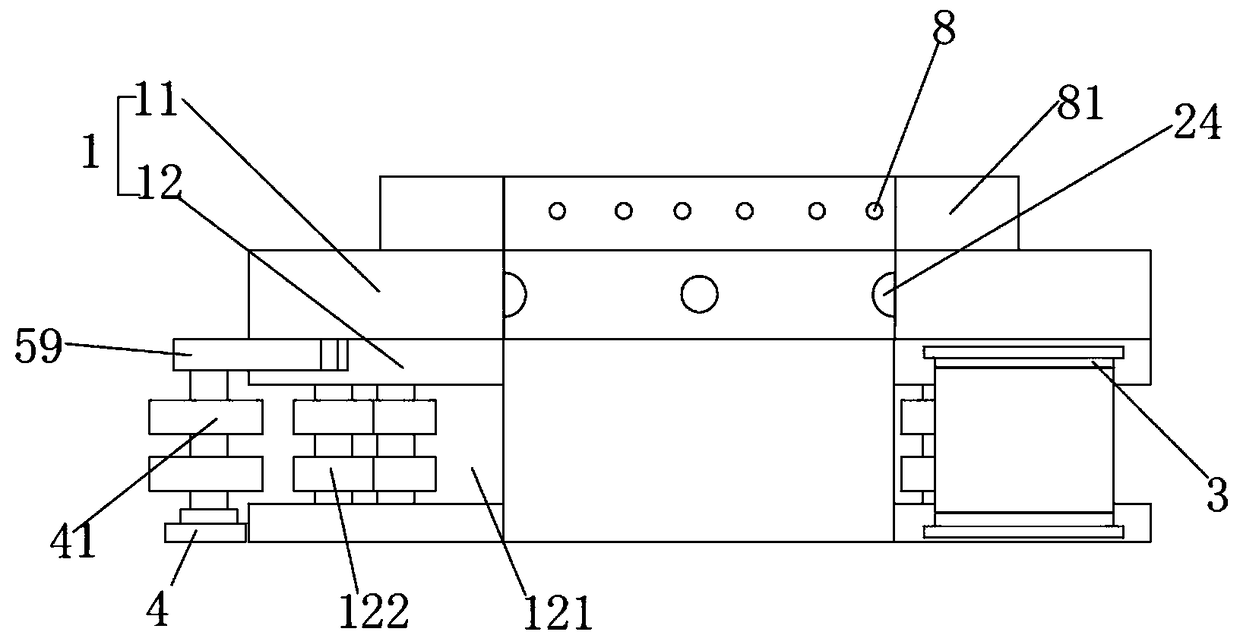

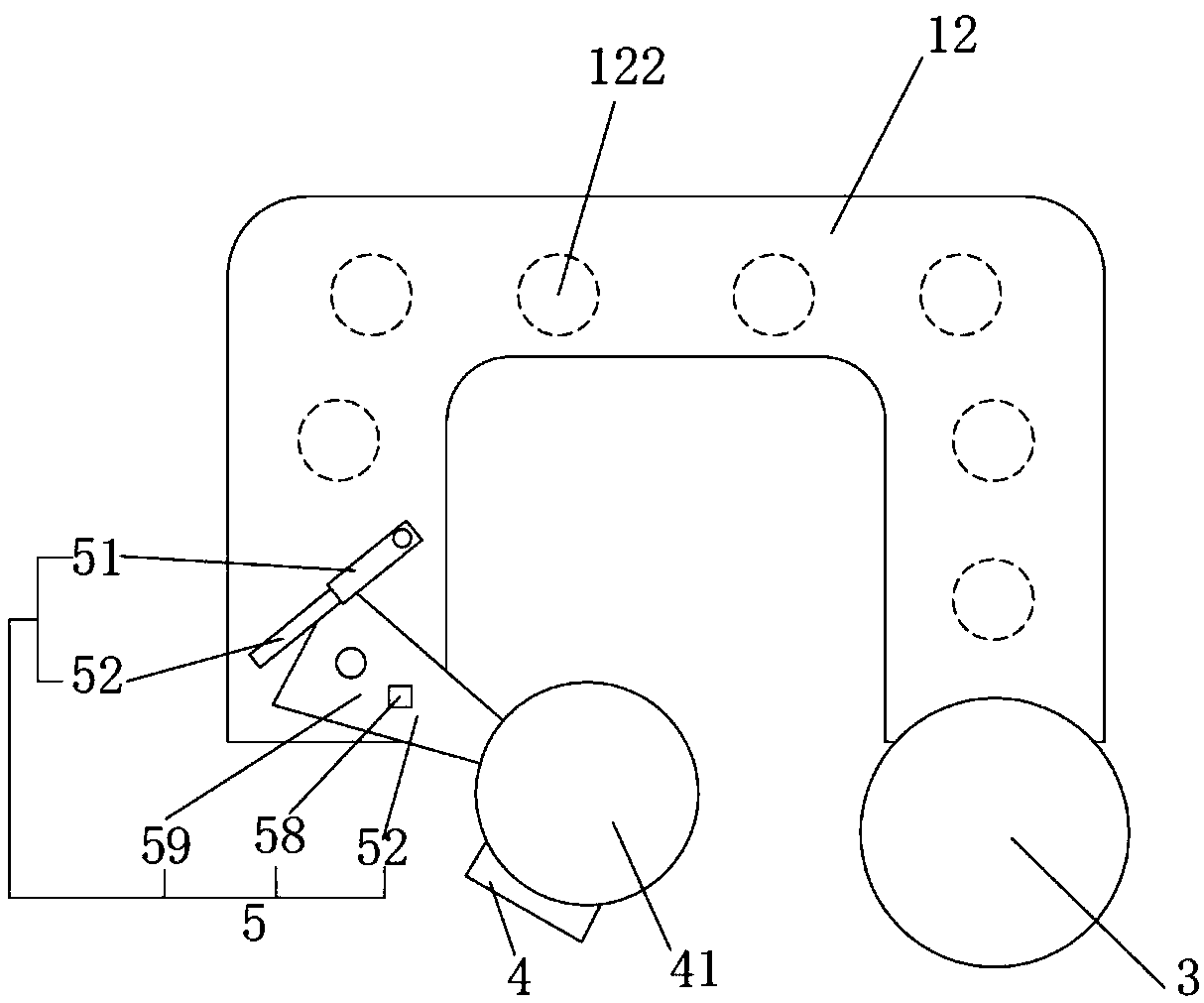

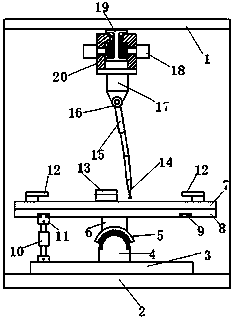

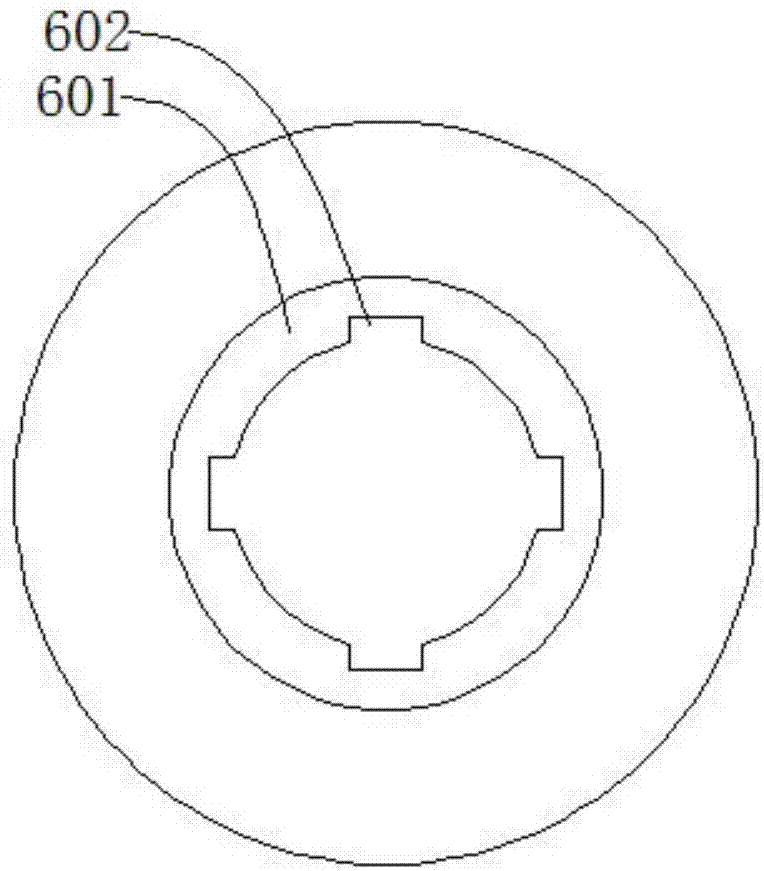

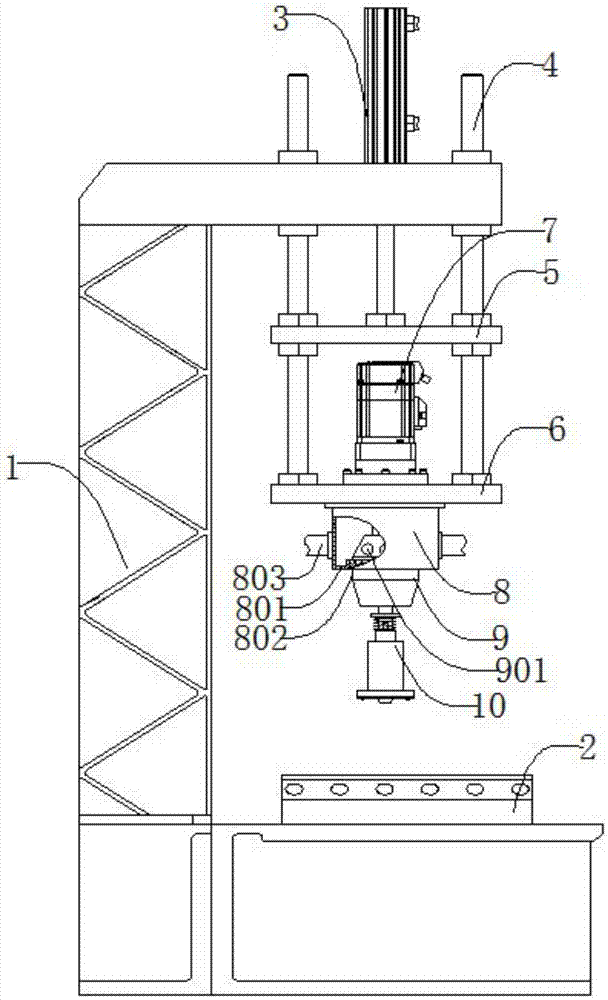

Slag removing machine for PCBhole

ActiveCN107457824ASimple device structureAvoid secondary attachmentMetal working apparatusElectronic waste recyclingElectric machinerySlag

The invention discloses a slag removing machine for a PCB hole. The slag removing machine for the PCB hole comprises a base, a door frame, an air cylinder, guide rods, an upper bearing plate, a lower bearing plate, a speed regulating motor, an air box, a clamping head, a pre-pressing drilling tool mechanism, a cross laser, a Y axis feeding mechanism, an X axis feeding mechanism, a controller, a marking block with a cross-shaped marking groove and a placing mold, wherein the guide rods are symmetrically arranged along the air cylinder; a PCB needing to be subjected to slag removing is placed in the placing mold, the controller controls the air cylinder to push the upper bearing plate to move down, thereby pushing the pre-pressing drilling tool mechanism to move down to compress the PCB tightly, the speed adjusting motor works to drive the drilling tool mechanism to extend out slowly, and a tool bit arranged on the drilling tool mechanism smashes and removes the slag adhered to the interior of the hole. The slag removing machine is simple in structure, and can effectively remove the slag and dust adhered to the inner wall of the PCB hole, environmental protection is achieved, the dissociative waste slag can be collected to prevent secondary adhesion of the waste slag, and simultaneously pre-pressing can automatically carried out, so that the hole wall is prevented from being damaged due to deformation of the PCB, and the yield of the PCB is improved.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

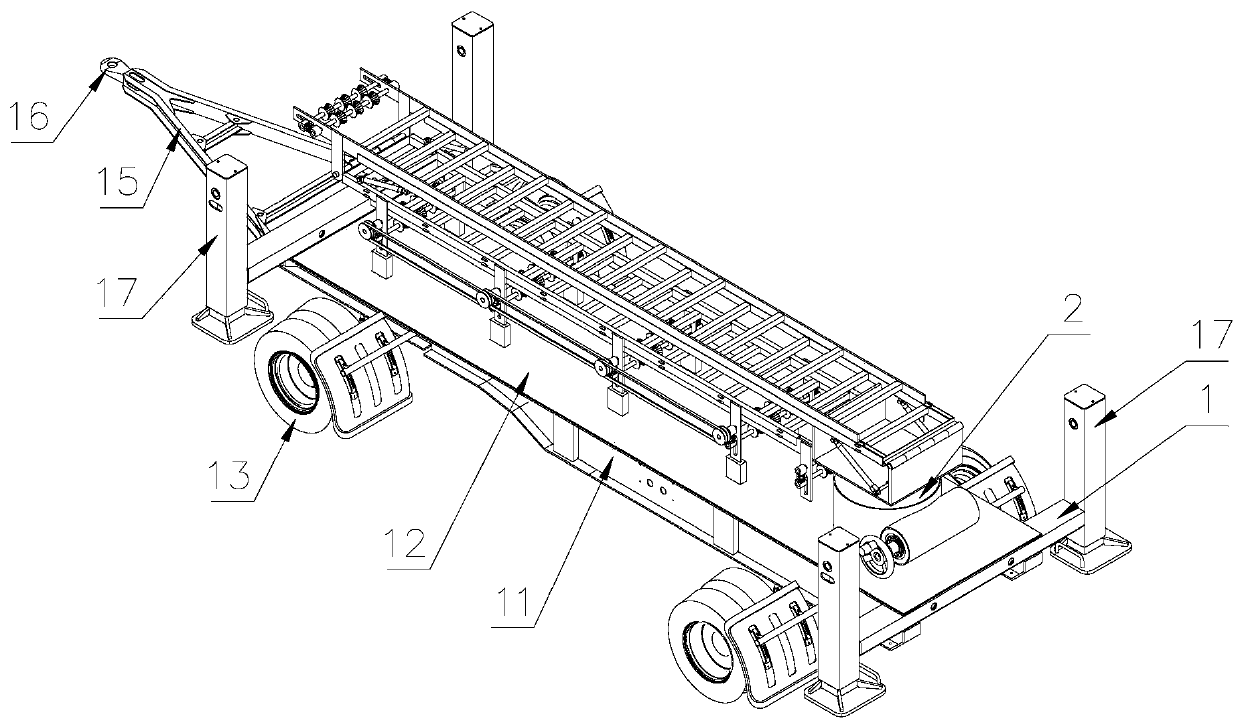

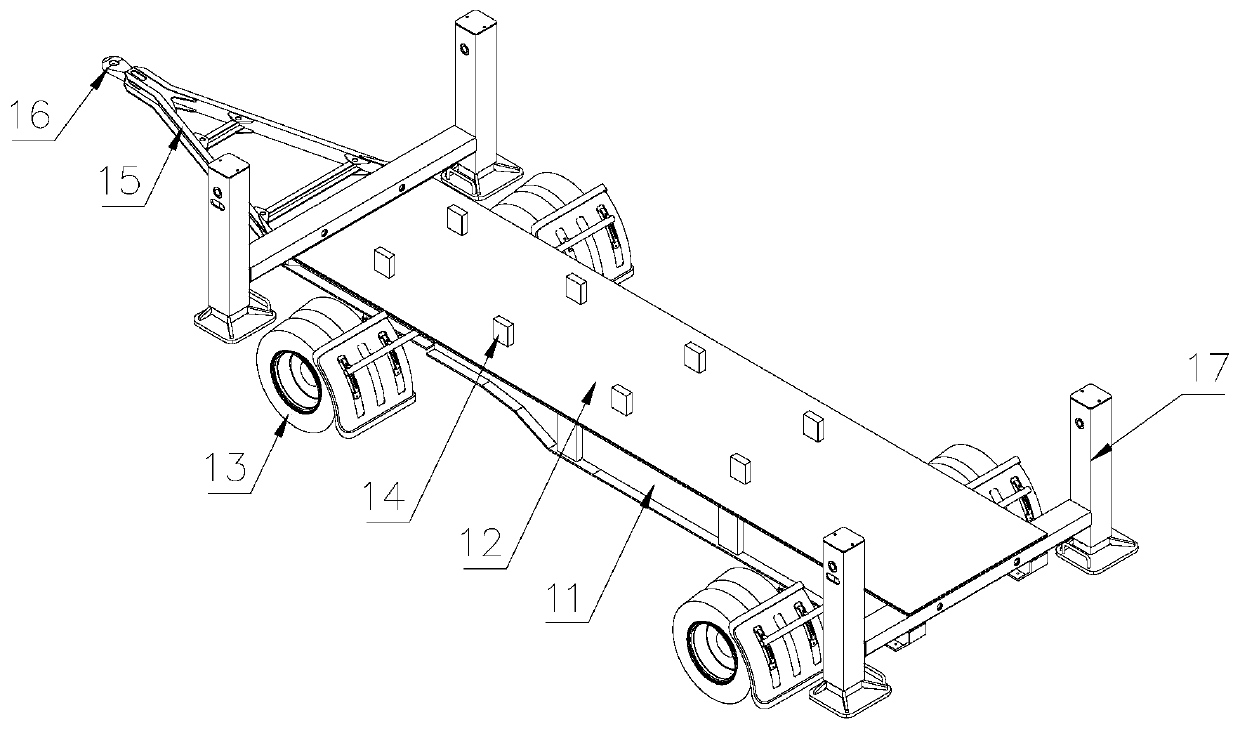

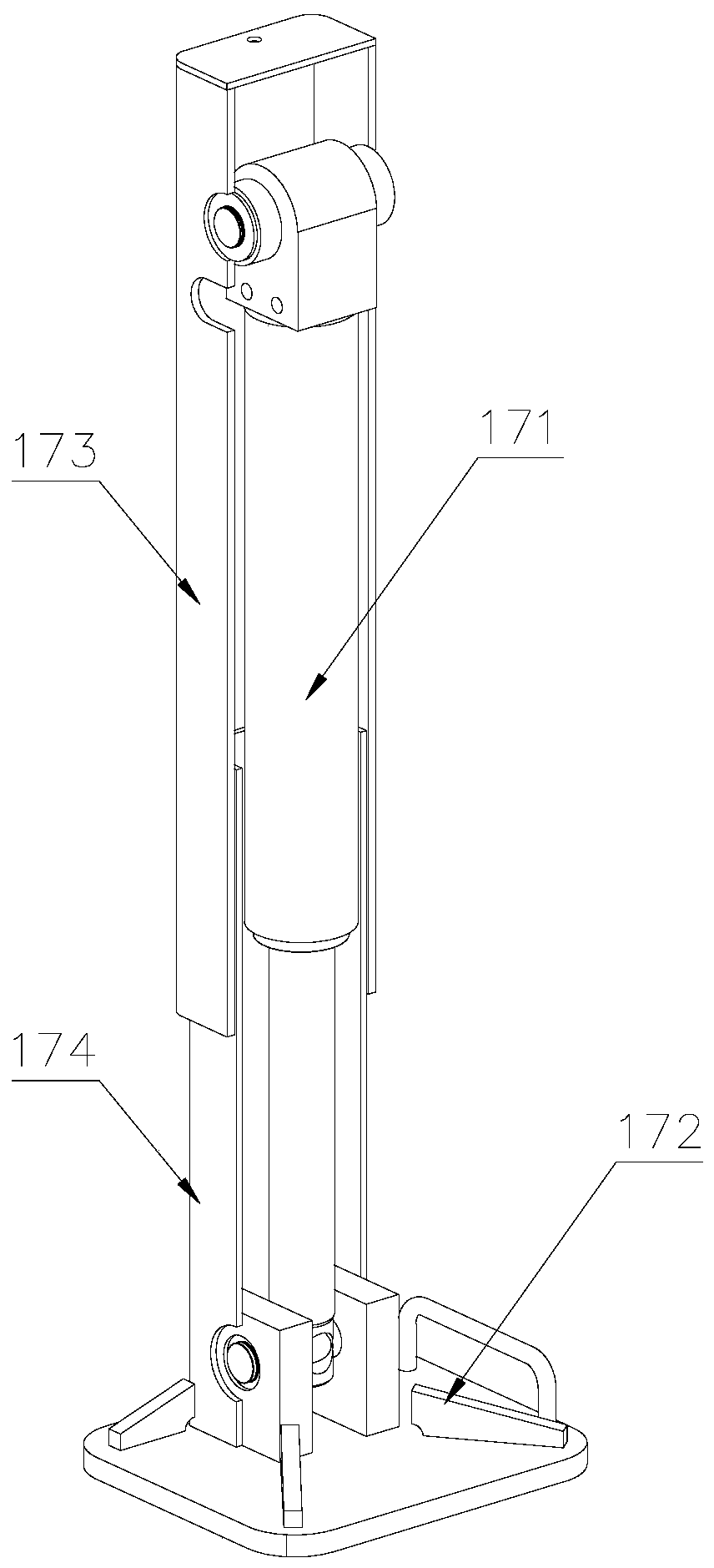

Bed exchanging device for visceral injury patient

The invention provides a bed exchanging device for a visceral injury patient. The bed exchanging device for the visceral injury patient comprises a support mechanism, a walking mechanism installed onthe support mechanism, a lifting mechanism installed on the walking mechanism, a crane mechanism installed on the lifting mechanism, a balance mechanism which is installed on the lifting mechanism andused for matching with the crane mechanism, a driving mechanism which is installed on the support mechanism and matched with the walking mechanism, and a control mechanism which is installed on the driving mechanism and used for controlling the lifting mechanism and the balance mechanism to be operated. The bed exchanging device is capable of directly fixing and tensioning a bed mat, lifting thebed mat and the patient on the bed mat through the lifting mechanism, keeping the stability of the lifting mechanism through the balance mechanism, translating the bed mat to a sickbed to be placed through the walking mechanism, reducing the labor intensity of medical workers while the patient is transferred from the sickbed, and reducing the discomfort of the patient because of the unfulfillmentof the strength and the cooperation of operators in a transferring process.

Owner:张桂华

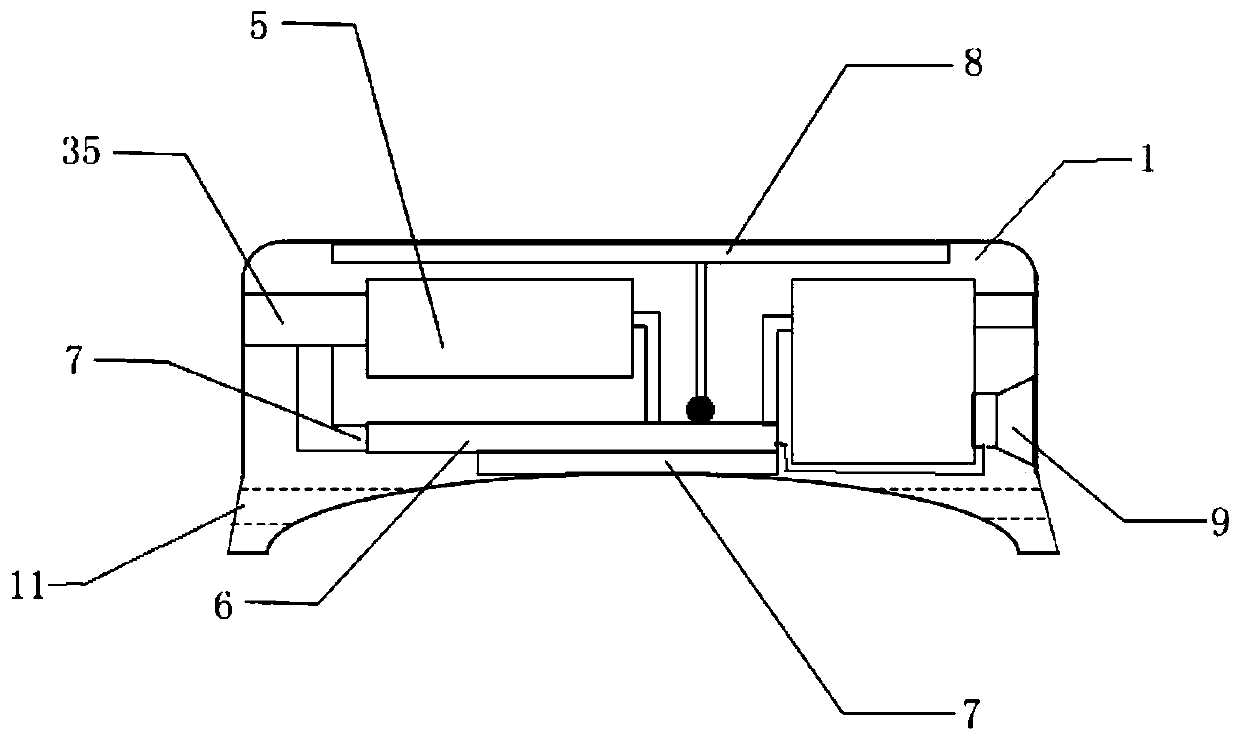

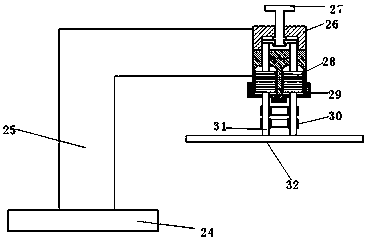

Intermittent air-compression treatment device for hemangioma

ActiveCN109730741AFirmly connectedGuaranteed compression effectTourniquetsAgainst vector-borne diseasesAir compressionEngineering

The invention discloses an intermittent air-compression treatment device for a hemangioma. The intermittent air-compression treatment device comprises a bandage, a support, a motor, a rotary shaft, discs, a receding groove, a connecting plate, a sliding pin, an oval pillar, a compression plate, a connecting pin, a fixing plate, an air bag, springs and an air cushion. The intermittent air-compression treatment device is ingenious in structure, powerful in function and easy to operate; through the device, the hemangioma of a child patient is in an intermittent air compression state to be subjected to compression treatment, and the compression effect of the child patient with hemangioma is ensured.

Owner:王崇宝

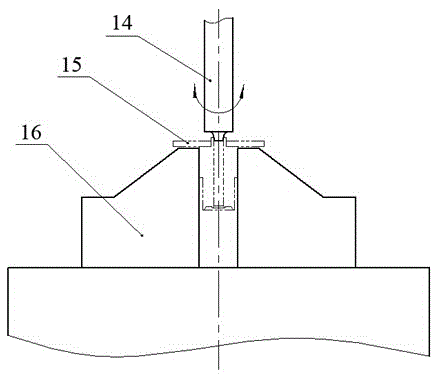

Welding method

ActiveCN107214429AMake sure it is fully clampedSimple structureWelding/cutting auxillary devicesAuxillary welding devicesManipulatorWelding

The invention discloses a welding method. A welding device is used for welding a workpiece; and the welding method comprises the steps that (1) the workpiece is conveyed, wherein a mechanical hand air pressure rod is used for controlling a mechanical hand to grab the workpiece, a motor continuously drives a lead screw to move, a mechanical hand installing base reaches the position above a lower pressing block, and the height of the mechanical hand installing base is larger than that of an upper pressing block; (2) the workpeice is clamped, wherein a raising block extends to the appropriate position so as to enable the height of the lower pressing block to be larger than that of the upper pressing block, the lower pressing block is in contact with the bottom face of the workpeice, the mechanical hand air pressure rod is used for controlling the mechanical hand to release the workpiece, the mechanical hand installing base returns along the original way, a rotating rod rotates to the appropriate angle, and therefore the workpiece can avoid the lower pressing block to downwards move, the raising block contracts back to the original height, a lifting rod rises to the appropriate height and is higher than the workpiece, the rotating rod then rotates to the appropriate angle, the side portion of the workpiece can be just located above the upper pressing block, the air pressure rod is clamped to push a push block, and clamping is carried out through the upper pressing block; and (3) welding is carried out.

Owner:苏州市艾西依钣金制造有限公司

Psychiatric disease abnormity nursing device

ActiveCN112057257AGood demandQuick use requirementsNursing bedsDiseasePhysical medicine and rehabilitation

The invention discloses a psychiatric disease abnormity nursing device. The device comprises a bed body; supporting legs with a supporting function are installed at four corners of the bottom end faceof the bed body; sliding grooves are symmetrically formed in one side of the top end face of the bed body; four sets of rotating shafts arranged in a rectangular array are installed on the other sideof the top end face of the bed body; sliding blocks arranged in a sliding mode are installed in the two sets of sliding grooves; a first arc-shaped frame and a second arc-shaped frame are welded to the sides, close to each other, of the upper end faces of the two sets of sliding blocks respectively; the first arc-shaped frame and the second arc-shaped frame are connected in a clamped mode; and adjusting pressing mechanisms are installed on the first arc-shaped frame and the second arc-shaped frame. According to the psychiatric disease abnormity nursing device, the head can be conveniently placed, the head can be conveniently adjusted to the position above a breathable pad, meanwhile, after nursing is completed, the first arc-shaped frame and the second arc-shaped frame can be rapidly separated from a patient, the device is convenient to use, the circumstance that the head sweats too much during pressing and limiting is avoided, and the device is suitable for patients with different head sizes.

Owner:PEOPLES HOSPITAL OF DEYANG CITY

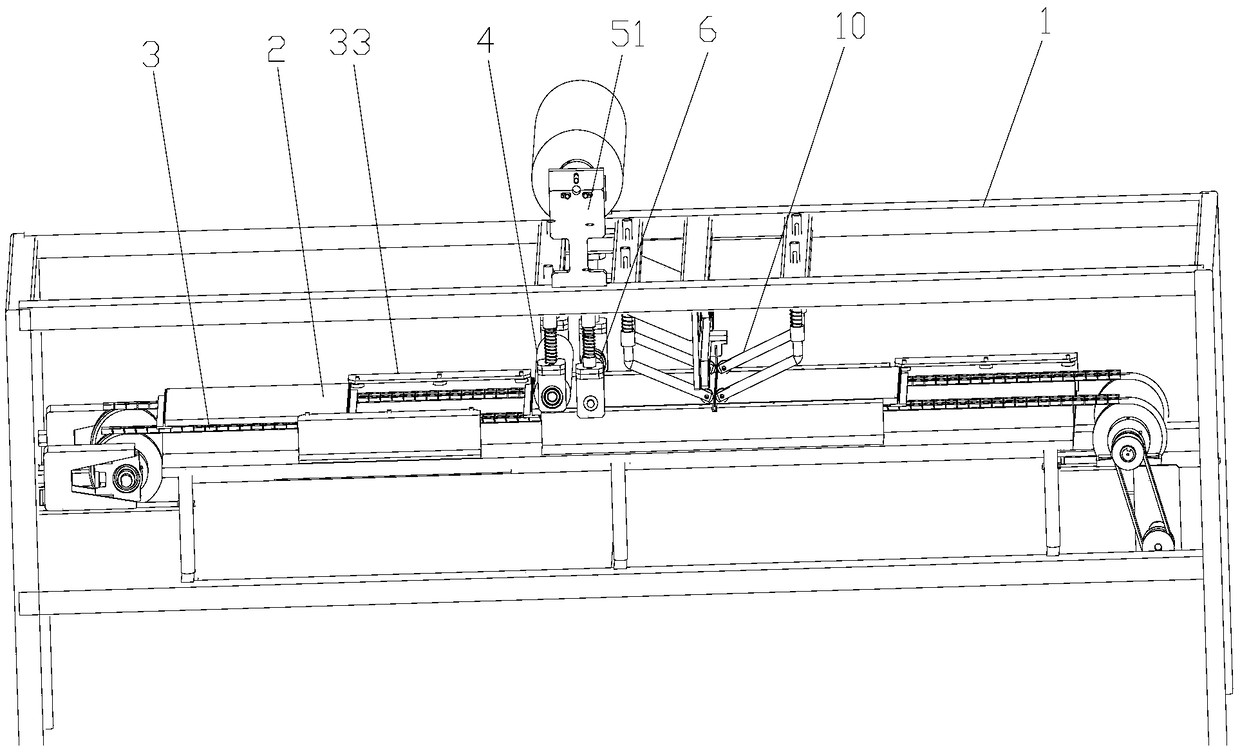

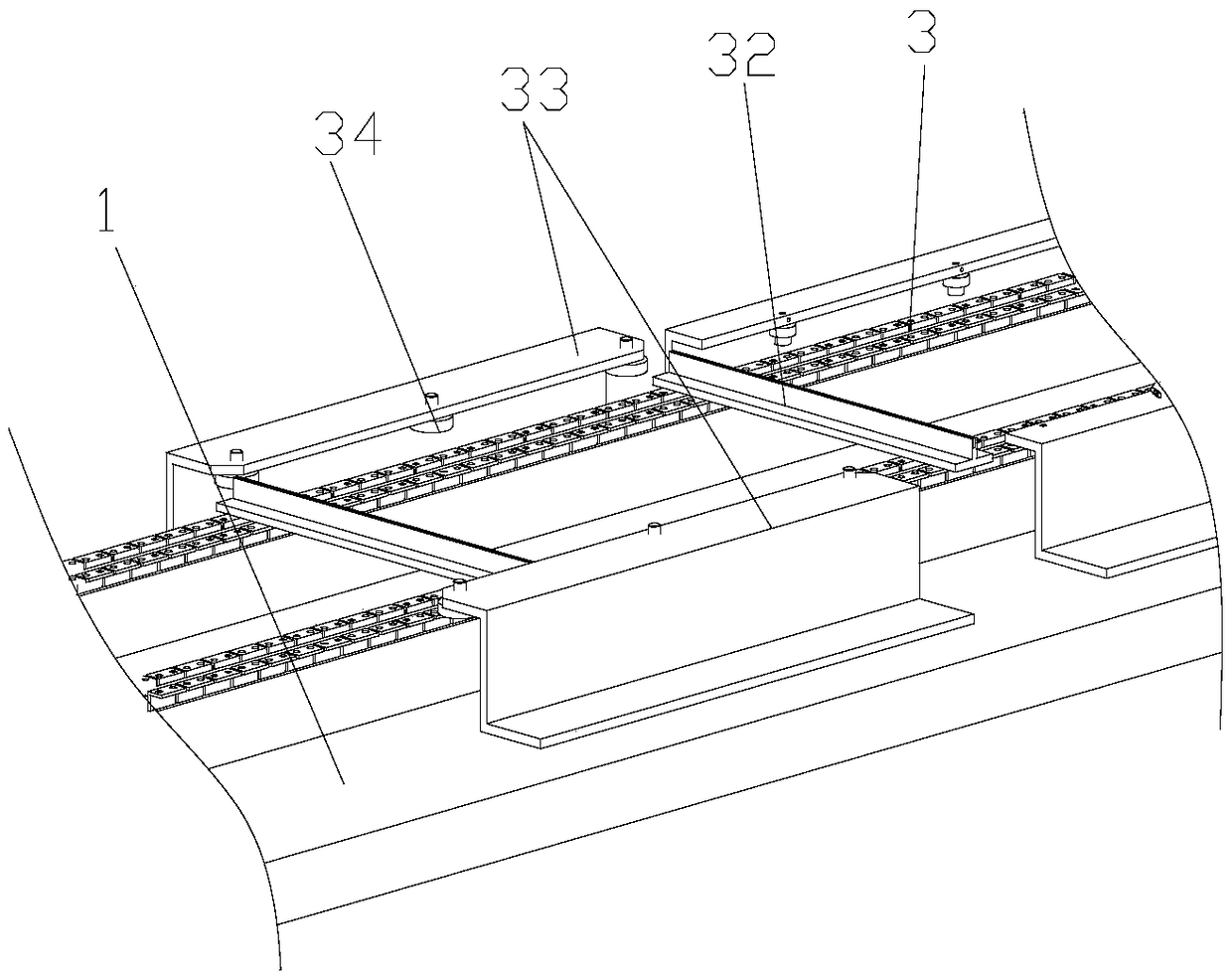

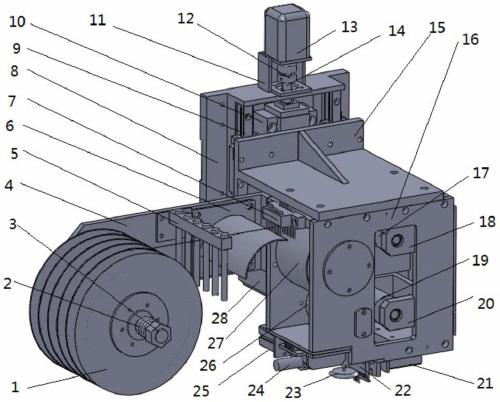

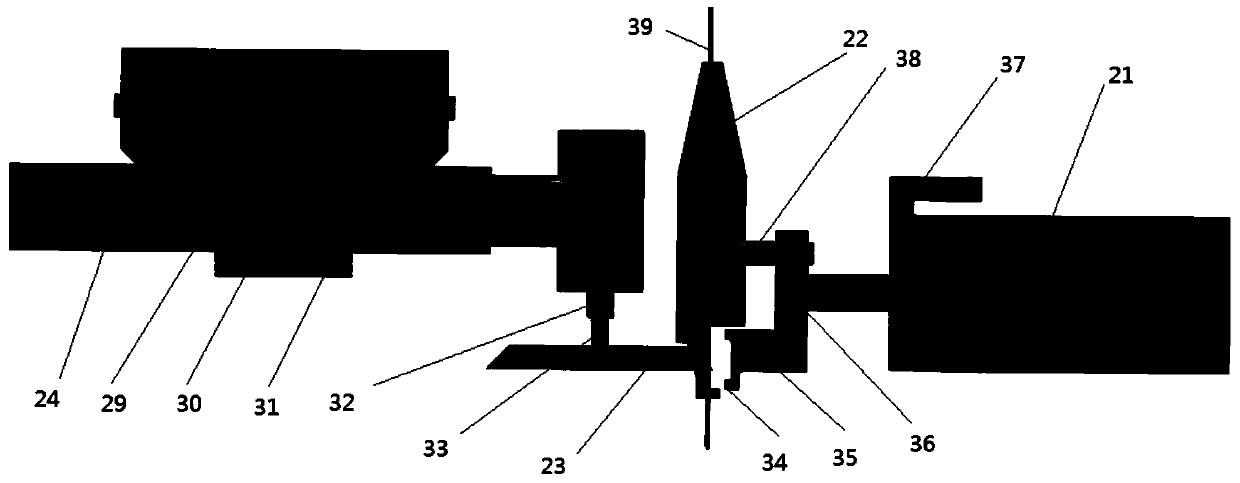

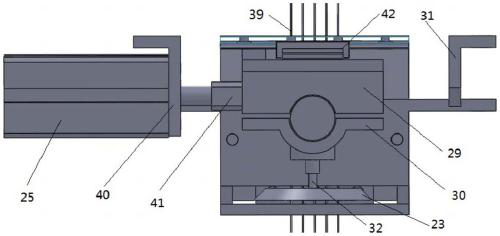

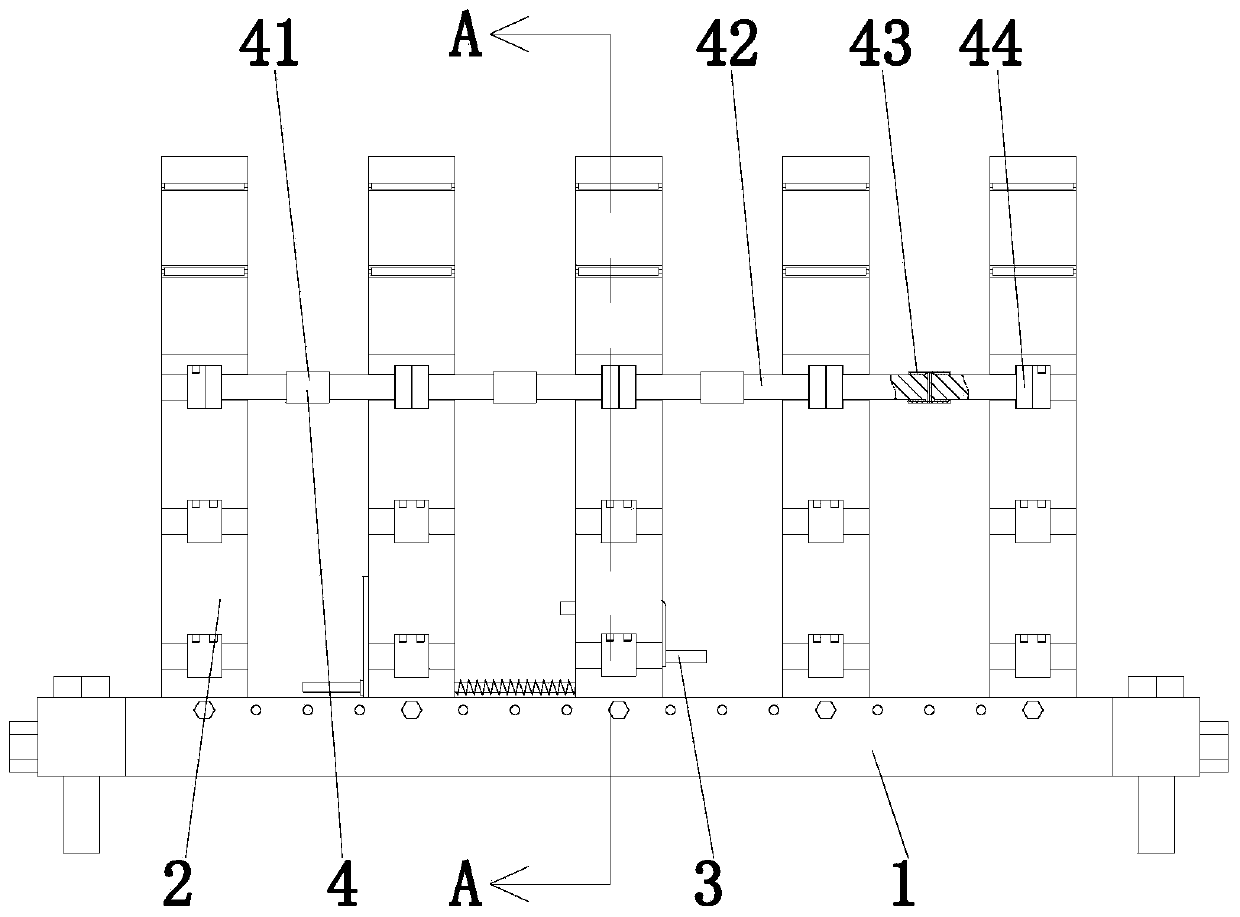

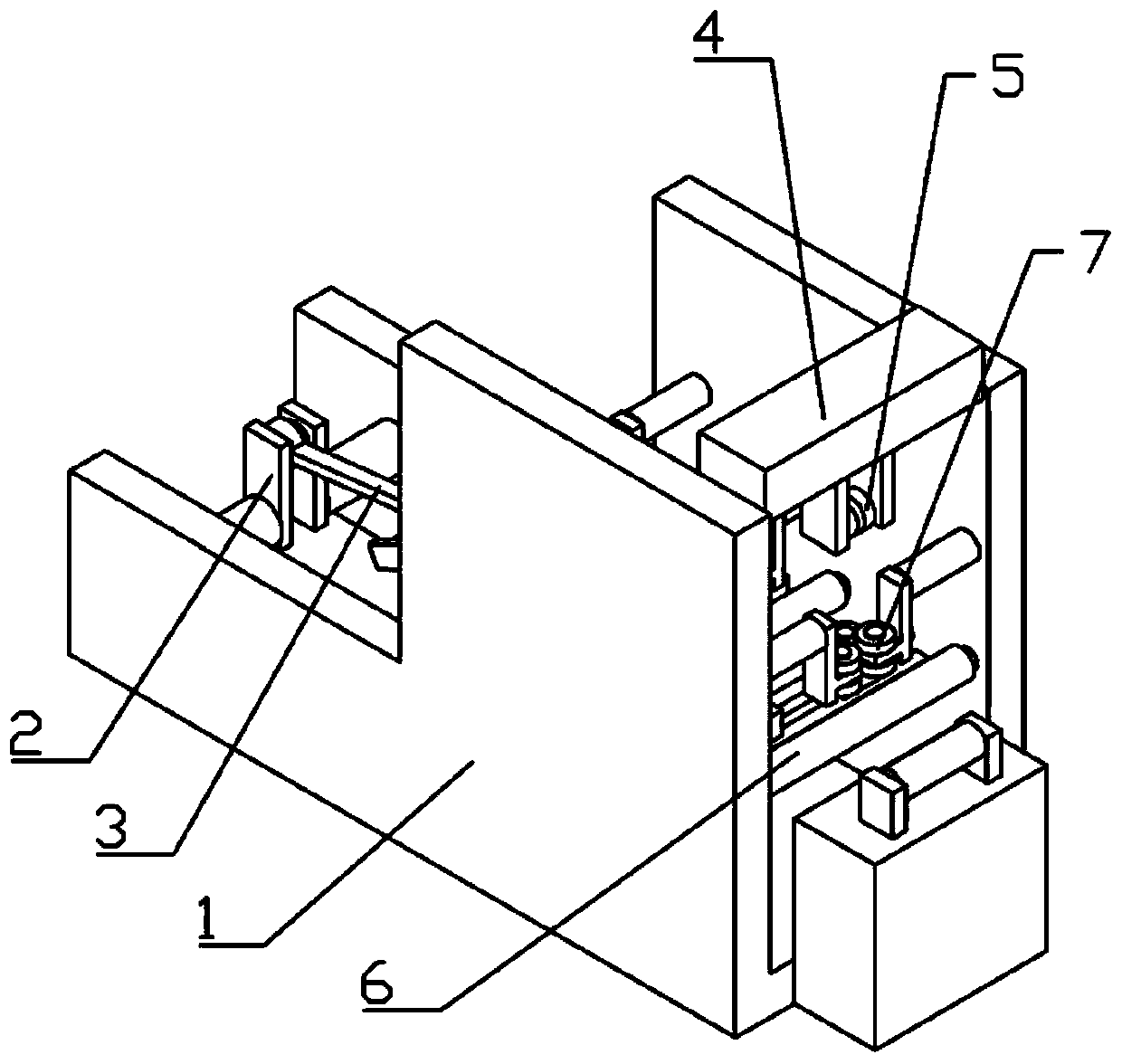

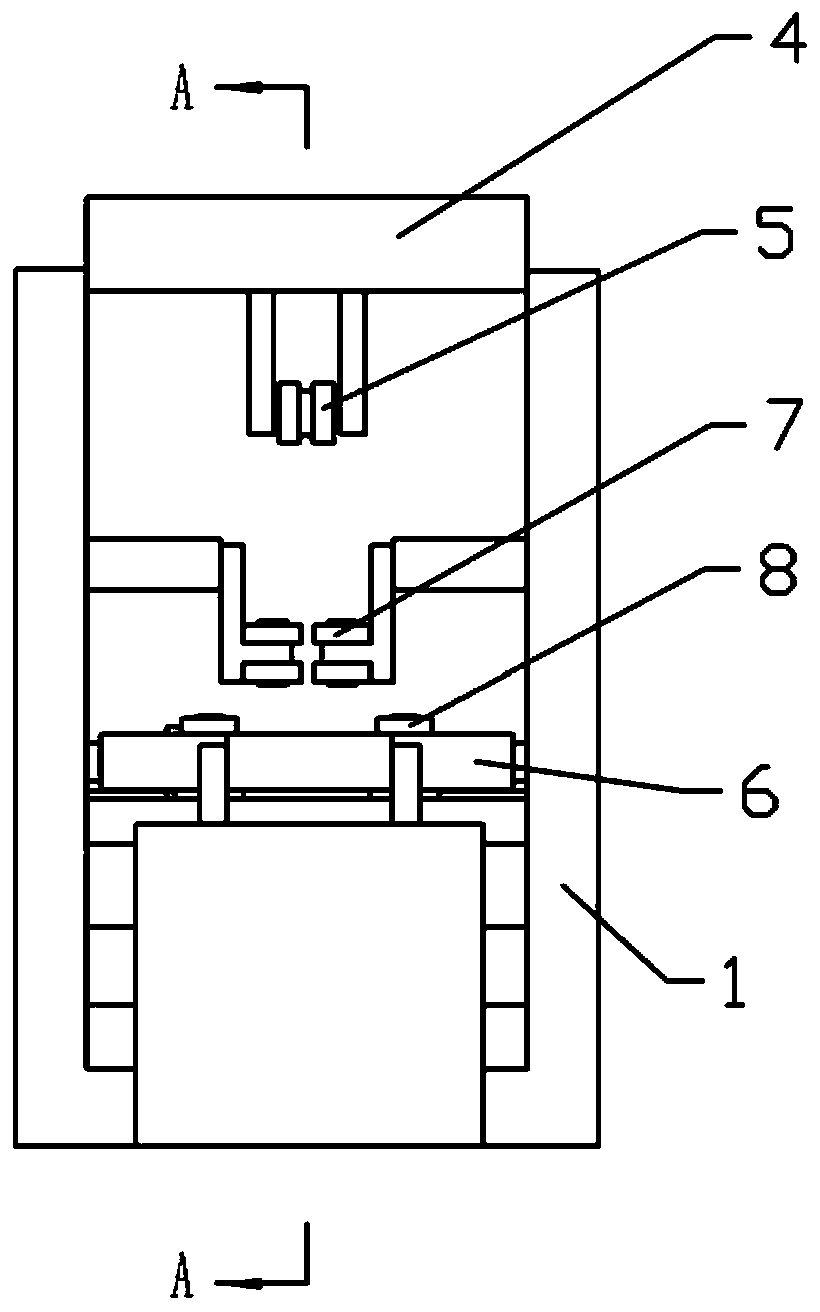

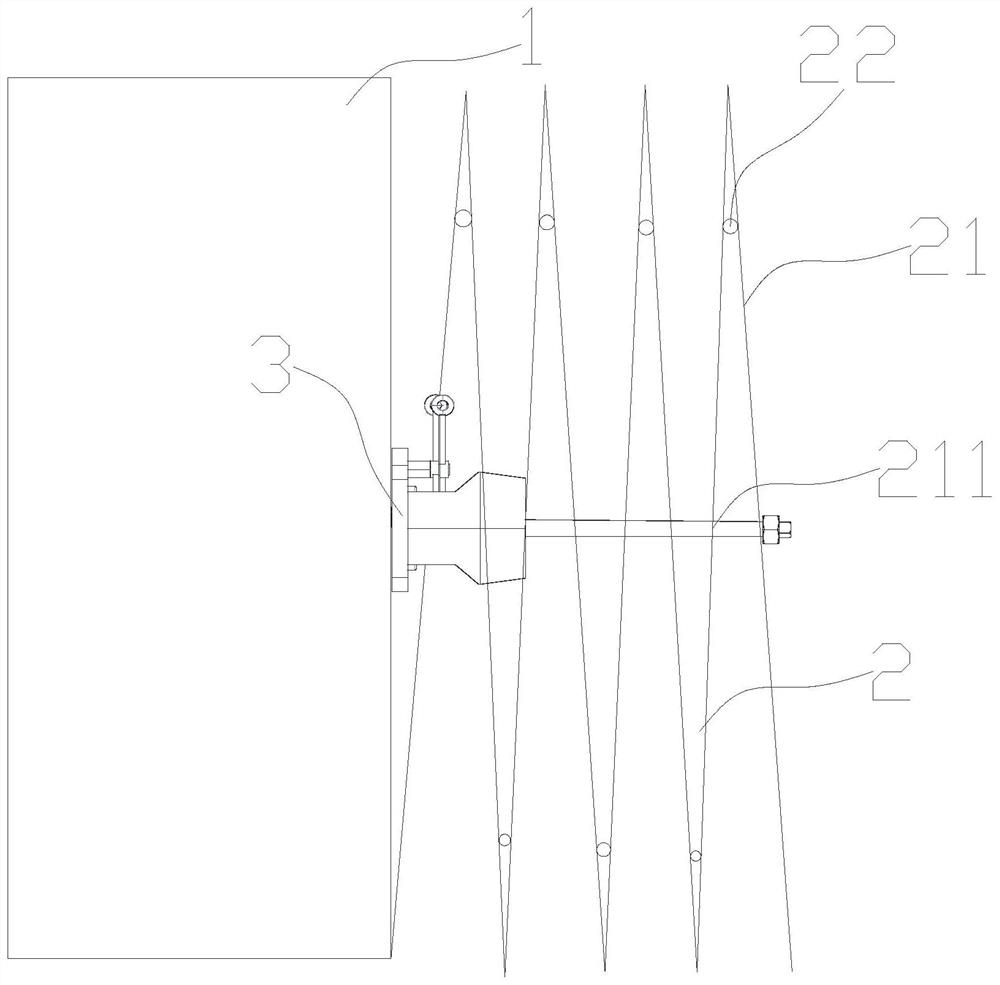

High-reliability and high-efficiency multi-Z-pin pressing-in and cutting-off mechanism

ActiveCN111284045APrecise control of feed displacementPrecise Control of DisplacementGrinding machinesReciprocating motionStructural engineering

The invention discloses a high-reliability and high-efficiency multi-Z-pin pressing-in and cutting-off mechanism. The mechanism can be used for realizing pressing-in and cutting-off of a foam carrierin a Z-pin transition implantation process, and can solve the technical problems of poor implantation precision, low reliability and low efficiency in an existing foam pre-implant preparation equipment technology. The mechanism is characterized in that the pressing-in and cutting-off mechanism can be arranged in a gantry type frame structure, stays at any position in a plane under driving of two vertical feeding mechanisms in the same plane, and is composed of a feeding mechanism, a pressing-in feeding mechanism and a pressing cutting mechanism; and a diamond grinding wheel in the pressing cutting mechanism can cut off multiple Z-pins at the same time in one-time reciprocating motion, and the reliability of cutting-off and pressing-in actions is improved through a pressing device. According to the mechanism, by means of the machining mode that the Z-pins are pressed in the foam carrier in two times through the mechanism, high-reliability and high-efficiency automatic pressing-in and cutting-off for the multiple Z-pins are achieved.

Owner:CHANGCHUN EQUIP TECH RES INST

Novel heat-insulation device for trunks of gardening trees

InactiveCN108849133AConvenient winding workLabor savingPlant protective coveringsInsect catchers and killersDrive wheelElectric machinery

The invention discloses a novel heat-insulation device for trunks of gardening trees. The novel heat-insulation device comprises a frame housing, wherein the frame housing comprises an upper frame anda lower frame, the upper frame is internally provided with three compressing mechanisms abutting against the outer surface of a trunk along its inner wall in an array way, one end of the lower frameis rotatably provided with a roller for a heat-insulation rope to be wound for storage, a driving wheel driven by a first driving motor is hinged to the other end of the lower frame, achieves positionlocking through a limiting mechanism and is compressed with the outer surface of the trunk of a tree, the lower frame is provided with a storage groove communicated with the outside in its circumferential direction, multiple guiding wheels are arranged in the storage groove in an array way, and the upper frame is provided with a horizontal adjusting mechanism. The novel heat-insulation device replaces the manual work of winding straw ropes around the trunk of the tree and achieves automatic winding of the heat-insulation ropes around the trunk of the tree, the working efficiency is effectively improved, the labor intensity of workers is reduced, and the work of winding around trees is quicker and more convenient.

Owner:陈宏涛

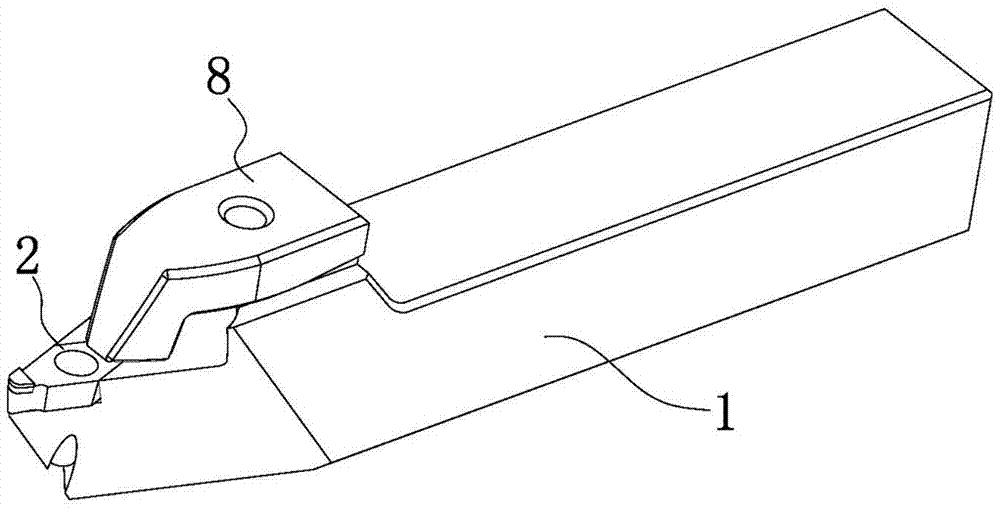

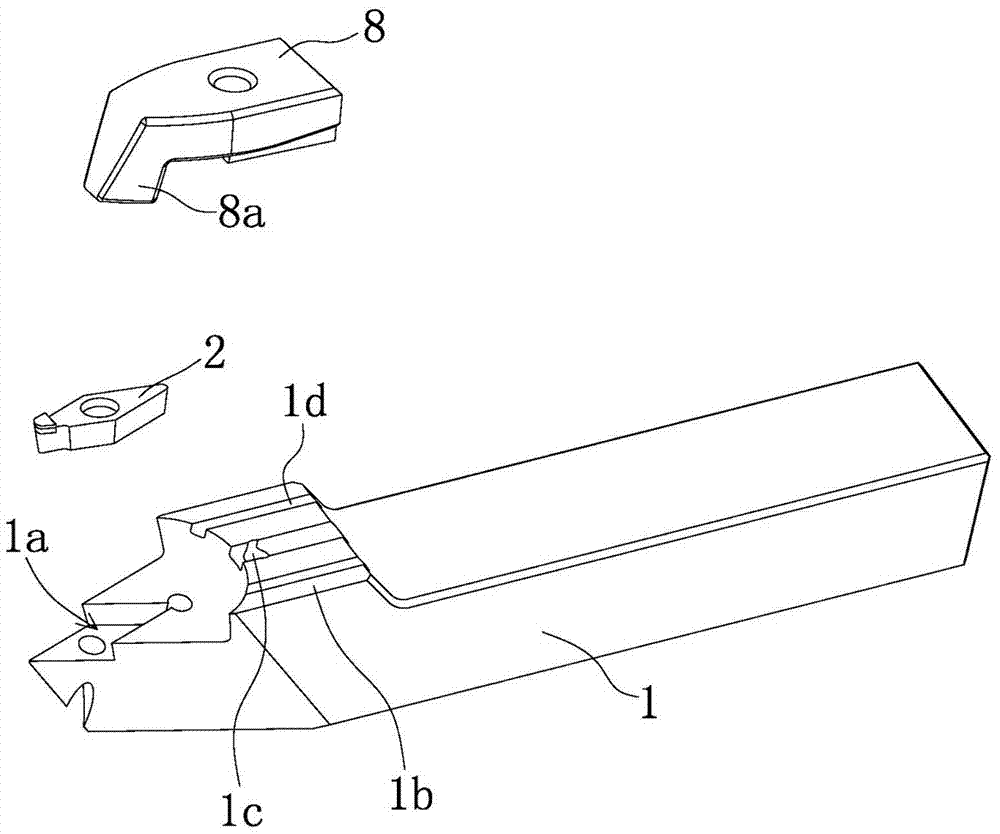

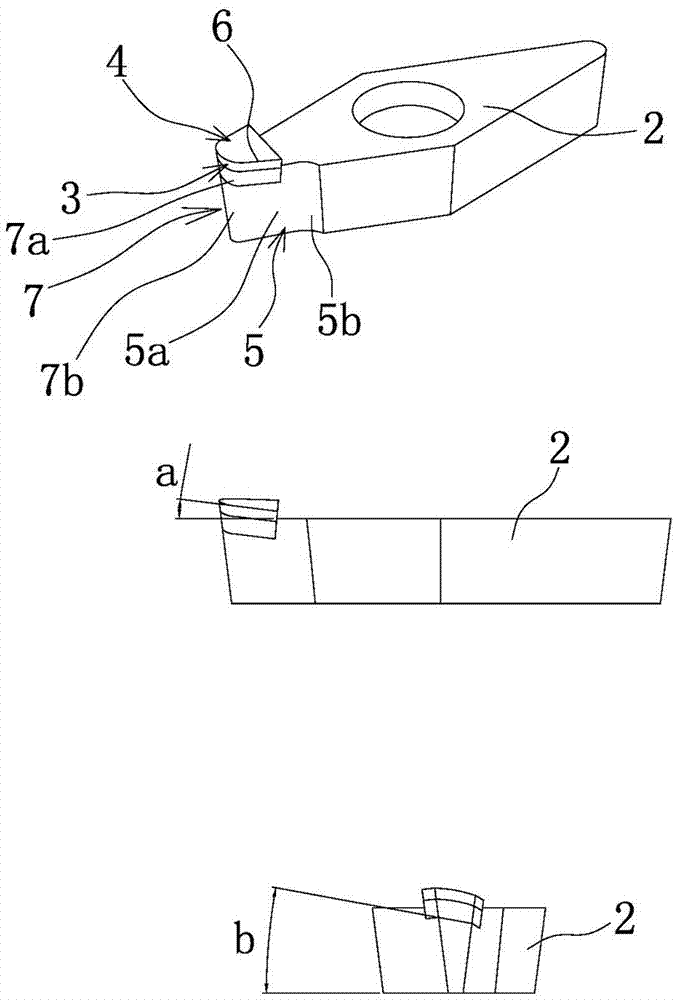

Polycrystalline diamond tool for machining excircles and inner holes of copper materials of all types

ActiveCN107020395AImprove the finishLow manufacturing costCutting insertsWorkpiecesPolycrystalline diamondCopper

The invention provides a polycrystalline diamond tool for machining excircles and inner holes of copper materials of all types, and belongs to the technical field of superhard tools. The polycrystalline diamond tool for machining excircles and inner holes of copper materials of all types solves the problem that polishing on copper materials cannot be omitted with an existing polycrystalline diamond tool. The polycrystalline diamond tool for machining excircles and inner holes of copper materials of all types comprises a tool body and a blade, wherein the cutting edge of the blade is a large fillet, and the radius of the large fillet ranges from 1.0 mm to 1.4 mm; the blade has a dual compound top rake, so that the top rake between the active face and the horizontal plane ranges from 2 degrees to 10 degrees, and the left dip angle b between the active face and the horizontal plane ranges from 5 degrees to 15 degrees; a sideway chip removal guide is arranged on the side face of the blade and comprises a planar chip guiding plane and a cambered chip outlet cambered surface connected with the chip guiding plane, and a wiper is arranged on the edge of the active face of the blade. With the polycrystalline diamond tool for machining excircles and inner holes of copper materials of all types, copper workpieces can be machined without polishing or cooling liquid.

Owner:玉环卡布里尔刀具科技有限公司

Sheet clamping and transporting device

InactiveCN107867546ANo offsetGuaranteed compression effectConveyor partsCouplingArchitectural engineering

The invention discloses a sheet clamping and transporting device and belongs to the field of mechanical transportation equipment. According to the sheet clamping and transporting device, a sliding rail bar and a support plate are arranged on the front surface of a fixed plate; a sliding block is arranged on the sliding rail bar; a rectangular groove is formed in the fixed plate below the sliding rail bar; an L-shaped plate is arranged on the rear surface of the fixed plate; a support I and a support II are arranged on the L-shaped plate; a motor is fixed on the bottom plate of the L-shaped plate; a lead screw is connected between the support I and the support II; the output shaft of the motor is connected with the lead screw through a coupling; a movable seat is arranged on the lead screwin a sleeving manner; a movable plate is arranged on the lower surface of the movable seat; a connecting plate and a vertical rack I are arranged on the movable plate; a vertical rack II is arranged on the support plate; an air cylinder I is fixed on the vertical rack II; and an air cylinder II is fixed on the vertical rack I. The sheet clamping and transporting device is simple in structure and steady in transportation, can transport strip-type sheets, is high in degree of automation and can be widely applied.

Owner:孝昌县睿科智能科技有限公司

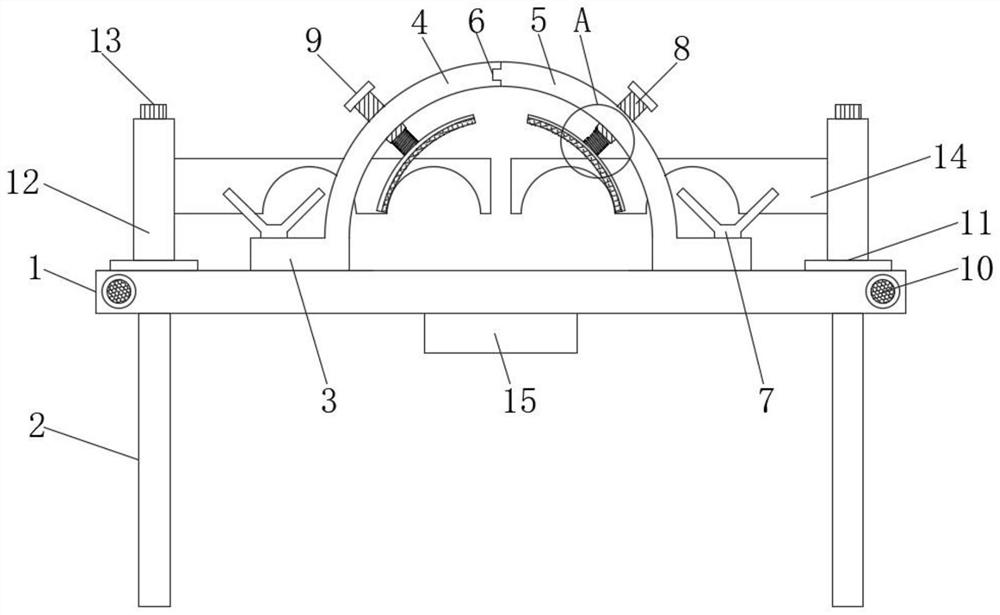

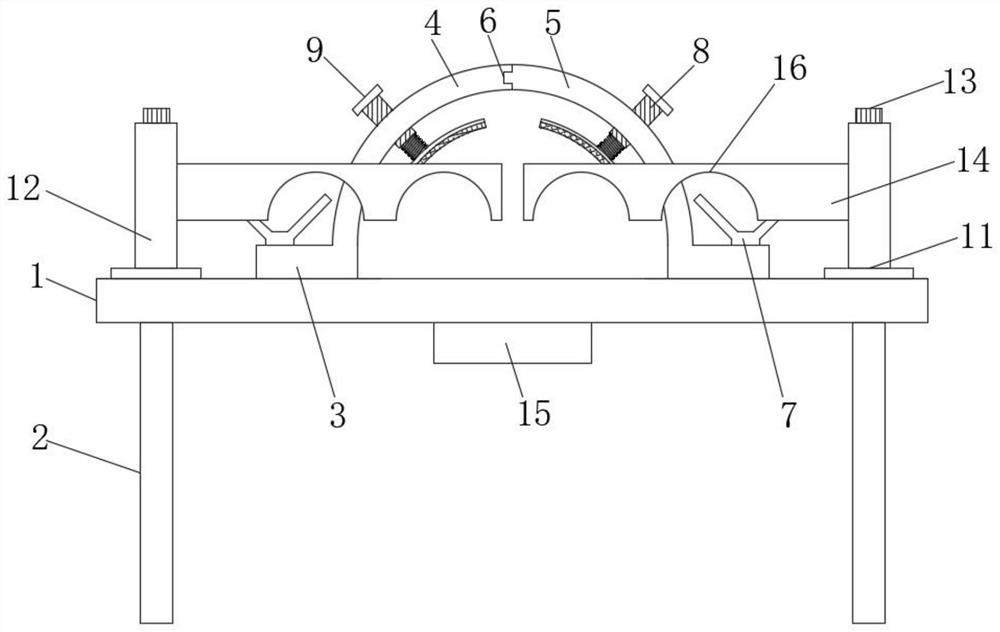

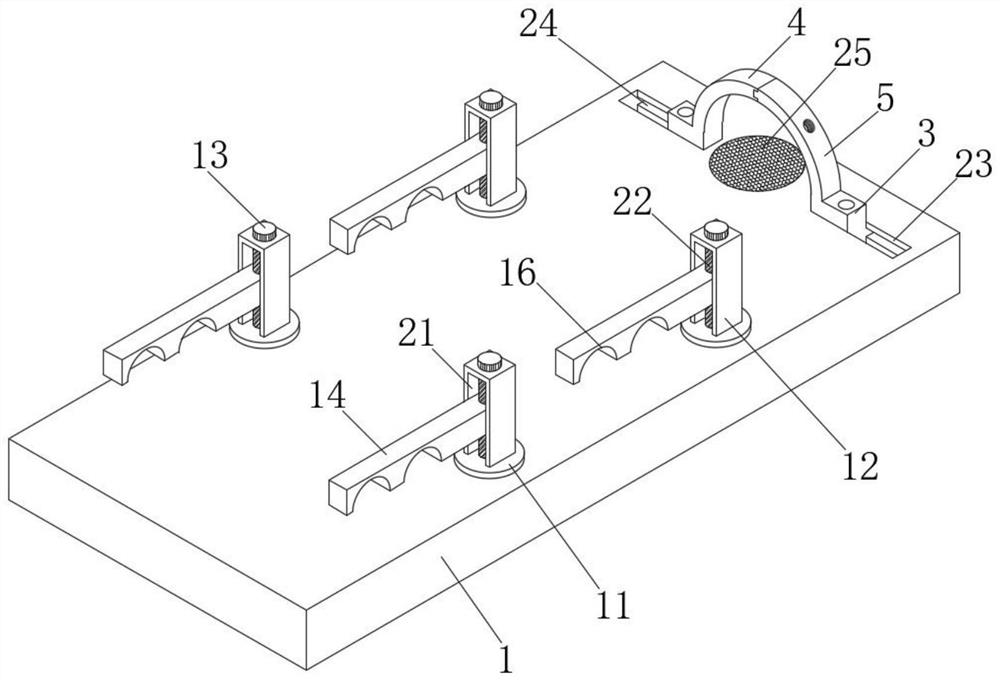

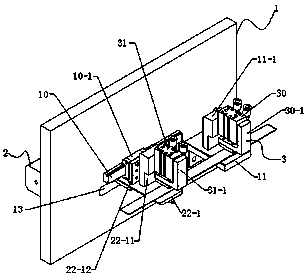

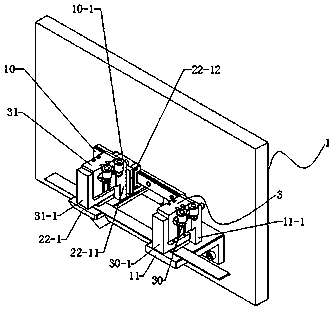

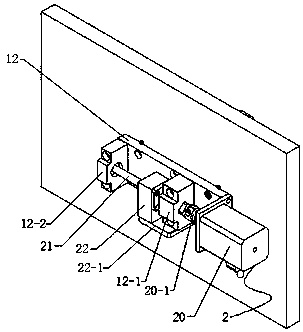

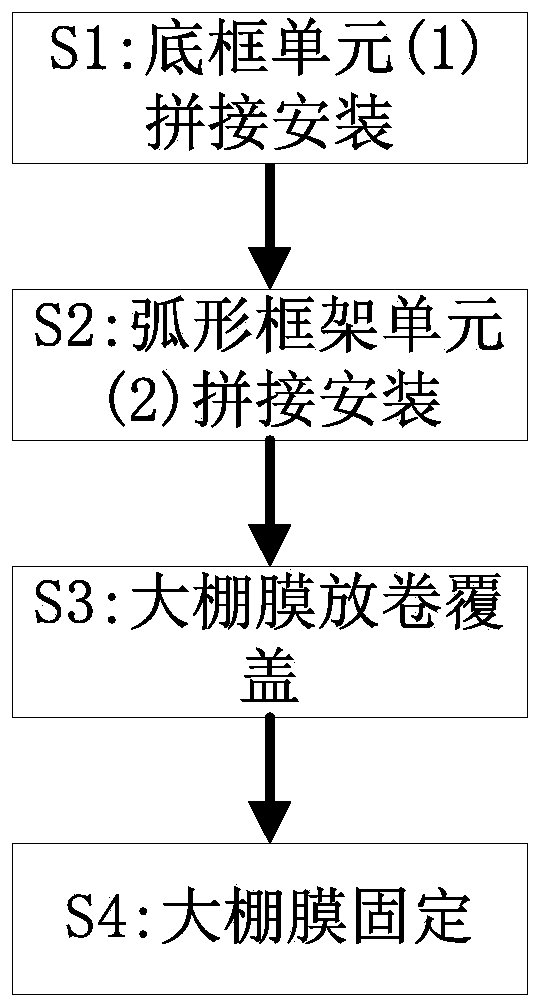

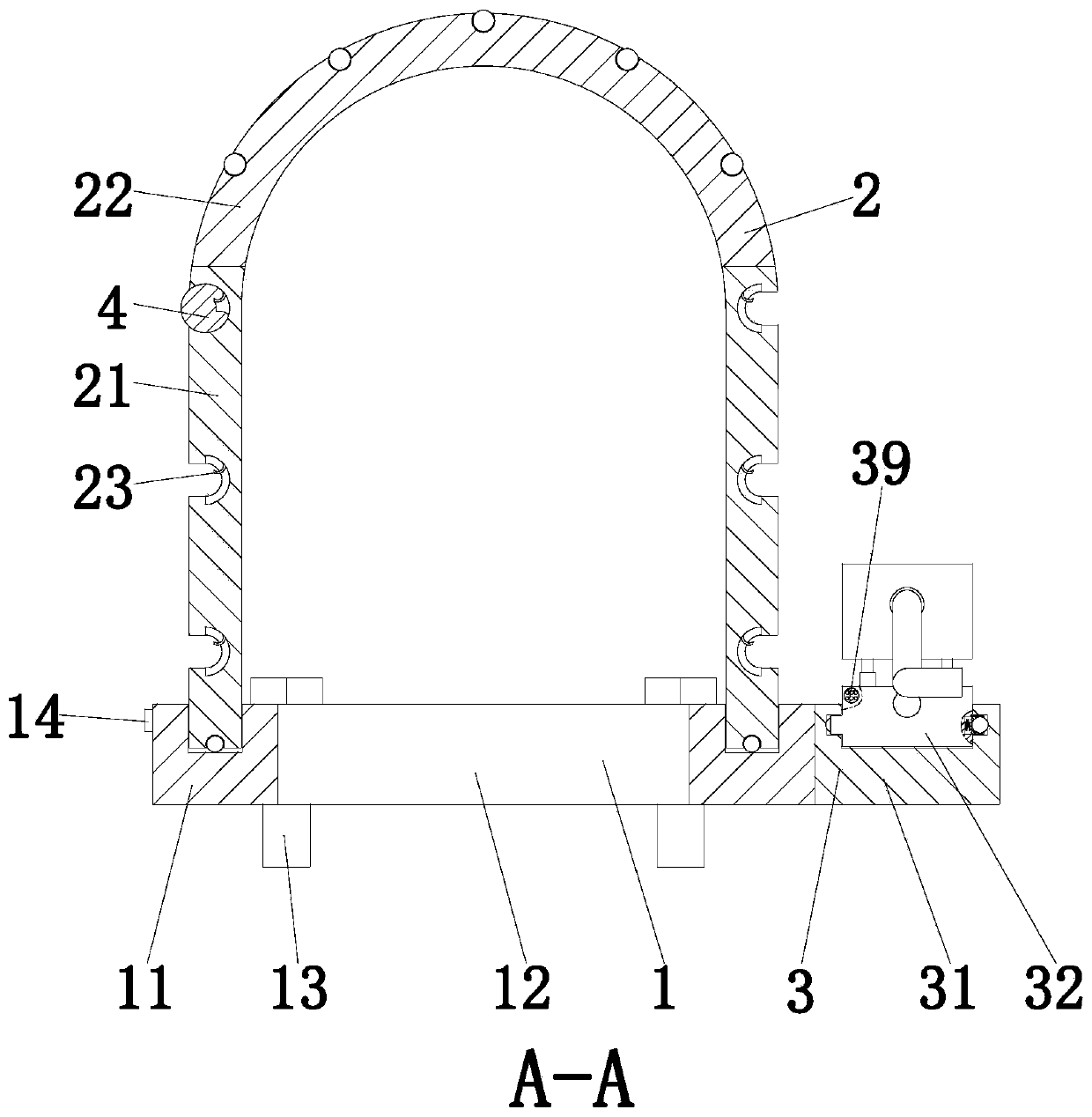

Building method of structural steel frame for agriculture ecologic greenhouse

ActiveCN111527943AGuaranteed compression effectGuaranteed installation qualityClimate change adaptationGreenhouse cultivationEnvironmental resource managementGreenhouse

The invention provides a building method of a structural steel frame for an agriculture ecologic greenhouse. Through cooperation of a bottom frame unit, a curved frame unit, a film placing unit and alimiting unit, building of the structural steel frame for an agriculture ecologic greenhouse can be completed. According to the building method, the difficult problems that at current, in the buildingand using process of a greenhouse framework, a plastic film is paved on the greenhouse framework, the plastic film easily causes friction with the framework to enable the plastic film to be broken, after the plastic film is used, the inner temperature of the greenhouse can be influenced, the plastic film and the greenhouse framework are fixed in a fixing manner of tying down with a rope, the manner of tying down with a rope is not firm, the greenhouse film and the greenhouse framework are loose, and the greenhouse film is easy to come off and break due to strong wind, are solved

Owner:新疆科创天达农业工程有限公司

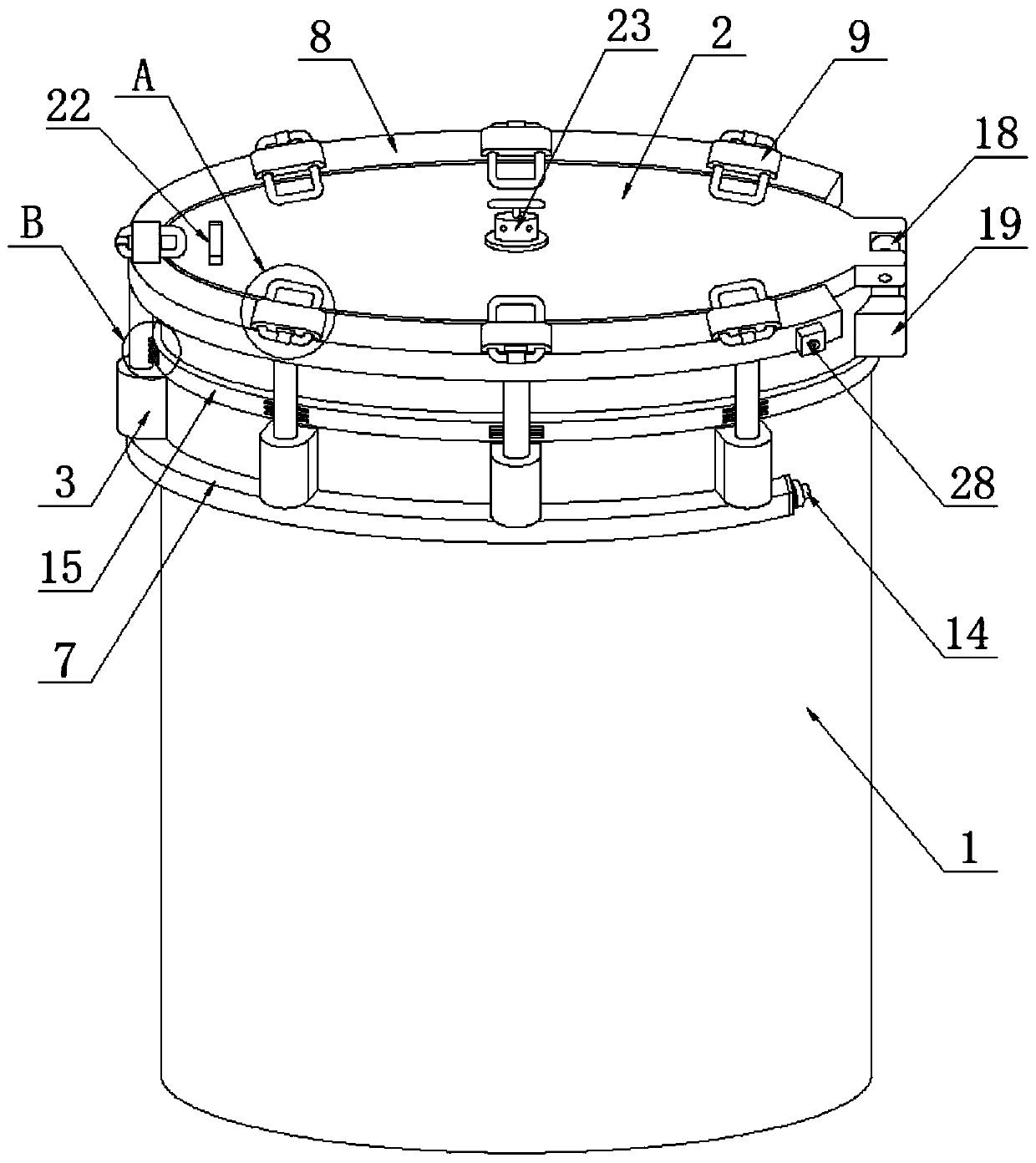

Cylinder cover locking mechanism for vertical pressure container

The invention discloses a cylinder cover locking mechanism for a vertical pressure container. The cylinder cover locking mechanism includes a cylinder body and a cylinder cover, the bottom of the cylinder cover abuts against the top of the cylinder body, a piston cylinder is fixedly connected to the top of the outer side of the cylinder body, a first piston is slidably connected to the inside of the piston cylinder, a pull rod is fixedly connected to the top of the first piston, the top end of the pull rod penetrates through the top of the piston cylinder and extends to the outside of the piston cylinder, and a pre-compression spring is arranged at the position, located inside the piston cylinder, of the surface of the pull rod in a sleeving manner. The cylinder cover locking mechanism relates to the technical field of vertical pressure vessels. By means of the cylinder cover locking mechanism for the vertical pressure container, the pull rod is arranged to downwards pull a pressure ring, the rectangular pressure ring downwards presses the cylinder cover, and therefore the better sealing effect is achieved; and the pull-down action of the pull rod is realized through cooperation ofthe pre-compression spring and a ring pipe, the rectangular pressure ring can be controlled to pop up and retract back through cooperation of a permanent magnet coil and an electromagnet, operation is convenient and quick to realized, and manpower is saved.

Owner:合肥化机装备制造有限公司

Highway crossing support frame for power grid construction

ActiveCN110518492AAvoid bendingEnsure traffic safetyApparatus for overhead lines/cablesHydraulic cylinderVehicle frame

The invention discloses a highway crossing support frame for power grid construction. One side of the upper part of a frame is provided with a flat plate. A bottom plate is arranged on the upper partof the flat plate. One side of the bottom plate is provided with a coaming plate. First support rods are movably installed at the two ends of the coaming plate through hinges. One end of a second hydraulic cylinder is movably connected with a connecting rod, and the other end of the second hydraulic cylinder is movably connected with the first support rods through a hinge head. A second support rod is movably connected with a first connecting plate. One end of a third hydraulic cylinder is movably connected with the first support rods through the hinge head, and the other end of the third hydraulic cylinder is movably connected with the second support rod through the hinge head. The first support frame and the second support frame are arranged on the vehicle body. The second hydraulic cylinder is utilized to support the first support frame and the third hydraulic cylinder is utilized to support the second support frame in use so that the erection of the support frame is quickly and efficiently completed, the efficiency of cable construction is improved, the stability of the support frame is enhanced and the personal safety of construction personnel and highway colleagues is guaranteed.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Rear oil cap molding technology and drilling tool used in technology

InactiveCN108723701AReduce manufacturing costImprove yieldPositioning apparatusMetal-working holdersThermodynamicsLeak testing

The invention belongs to the technical field of rear oil cap production and manufacture, and relates to a rear oil cap molding technology and a drilling tool used in the technology. The rear oil cap molding technology comprises the following steps of, S1, feeding; S2, blanking; S3, drawing; S4, edge modifying; S5, hole drilling; S6, tapping; and S7, leak testing. According to the rear oil cap molding technology, production cost of the rear oil cap is reduced, rejection rate in the production process of the rear oil cap is reduced, and production efficiency of the rear oil cap is improved.

Owner:合肥信和机械科技有限公司

Fixing device for spot welding of circuit board

ActiveCN110153521AEasy to fixSmooth rotationWelding/cutting auxillary devicesAuxillary welding devicesFixed frameSpot welding

The invention discloses a fixing device for spot welding of a circuit board. The fixing device comprises a fixing frame, a bottom plate, a base, a fixing seat, a spot welding gun assembly, a workbenchfor fixing the circuit board, an adjusting and supporting assembly and a clamping and fixing assembly arranged on the workbench for clamping the circuit board. The fixing device is simple in structure and convenient to use; the circuit board can be conveniently fixed by adopting multiple compression ways, the effect of compression is good, the compression area is large, the situation that the circuit board is damaged due to excessive compression force can be prevented, meanwhile, the compression effect can be guaranteed by adopting the multiple compression ways; and in addition, during welding, the workbench can be conveniently rotated to achieve angular deflection, therefore, a optimal welding angle can be selected for welding, and the reliability of the circuit board is guaranteed.

Owner:YANCHENG DLD WELDING SCI & TECH

Steel assemblage clamping device

ActiveCN111151949AImprove production efficiencySimple structureWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention belongs to the technical field of auxiliary equipment for profile steel manufacturing and particularly discloses a steel assemblage clamping device. The steel assemblage clamping devicecomprises a support; a plurality of supporting rollers which are arranged transversely are rotationally connected to the support; the tops of all the supporting rollers are located on the same plane;a first positioning wheel set and a second positioning wheel set are rotationally connected to the support; the rotation axis of the first positioning wheel set is parallel to that of the second positioning wheel set; a tight pressing wheel is further disposed above the supporting wheels, and the axis of the tight pressing wheel is parallel to the axes of the supporting rollers; and a feeding mechanism is disposed on the support. By means of the scheme, the problem that in the prior art, welding is inconvenient due to complicated positioning operation during profile steel manufacturing is solved.

Owner:重庆实创钢结构有限公司

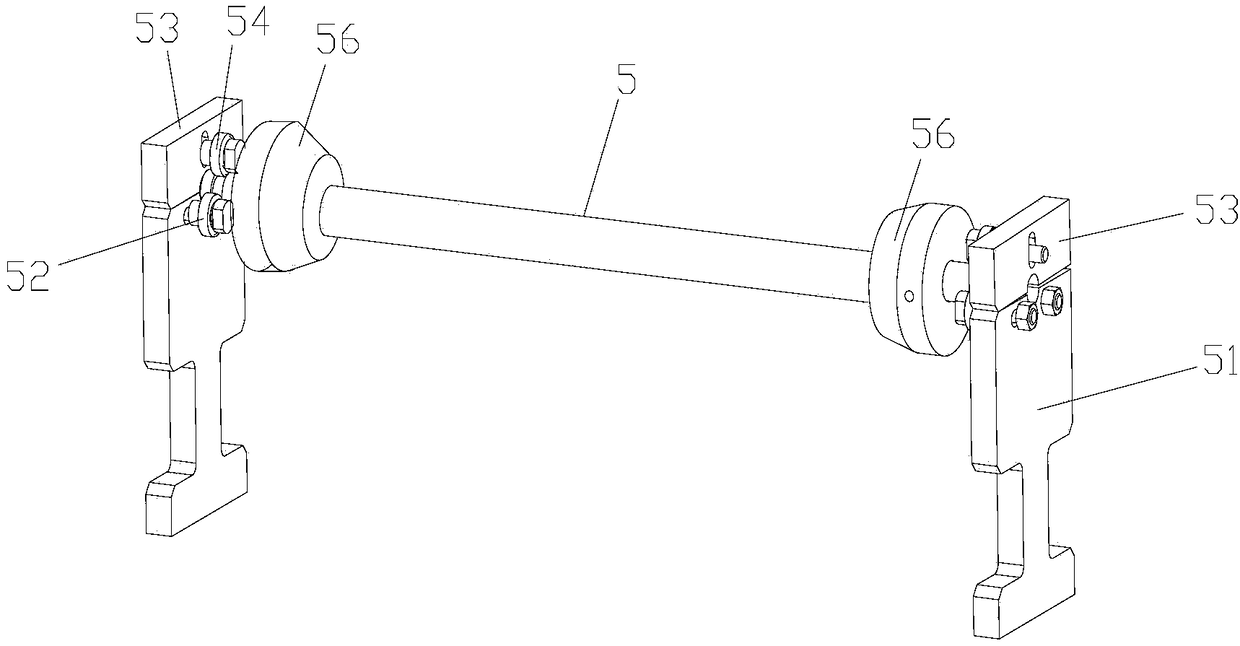

Roller device

ActiveCN108435844AGuaranteed CylindricalGuaranteed compression effectWelding/cutting auxillary devicesAuxillary welding devicesCompressed airEngineering

The invention belongs to the technical field of vehicle fittings, and in particular, discloses a roller device. The roller device comprises a base bracket, a connecting shaft, a cover body, a cylinderexpansion mechanism, a plate body pressing mechanism, and an outer cylinder with a feed port; the cylinder expansion mechanism comprises expansion plates, sliding pieces, a pushing piece and a firstdriving piece; multiple sliding pieces and expansion plates are provided; clamping ports are formed in one sides of the expansion plates opposite to the feed port; slide ways are symmetrically formedin the expansion plates on the two sides of the clamping ports; first clamping pieces are sealed and slidingly connected into the two slide ways; one ends of the slide ways communicate with the clamping ports, and the other ends of the slide ways communicate with compressed air sources; the plate body pressing mechanism comprises multiple slide bases; second clamping pieces are sealed and slidingly connected into the slide bases; and the upper parts of the slide bases communicate with the compressed air sources. The roller device needs no manual operation, and is high in production efficiency.

Owner:安徽航嘉汽车零部件制造有限公司

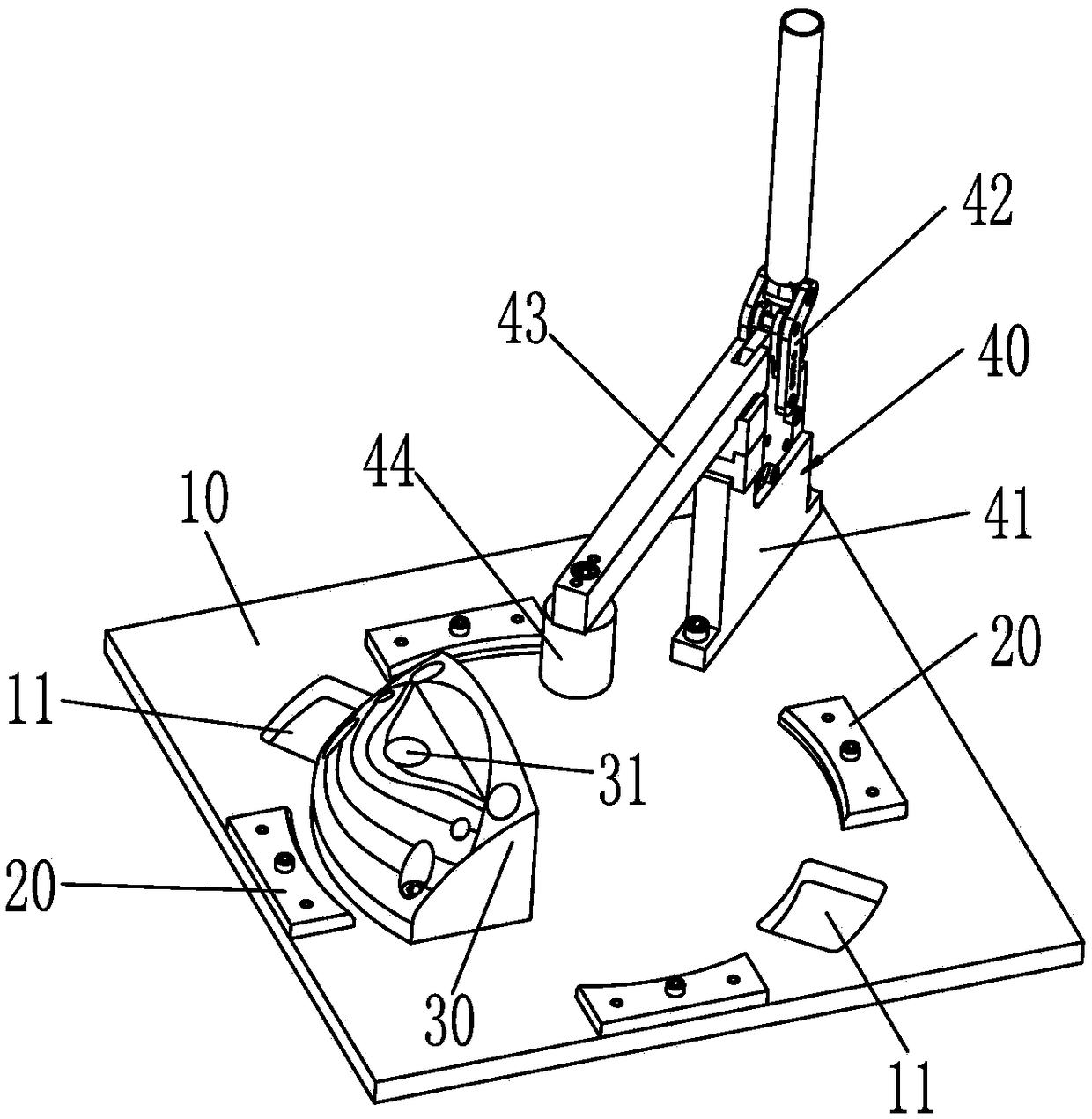

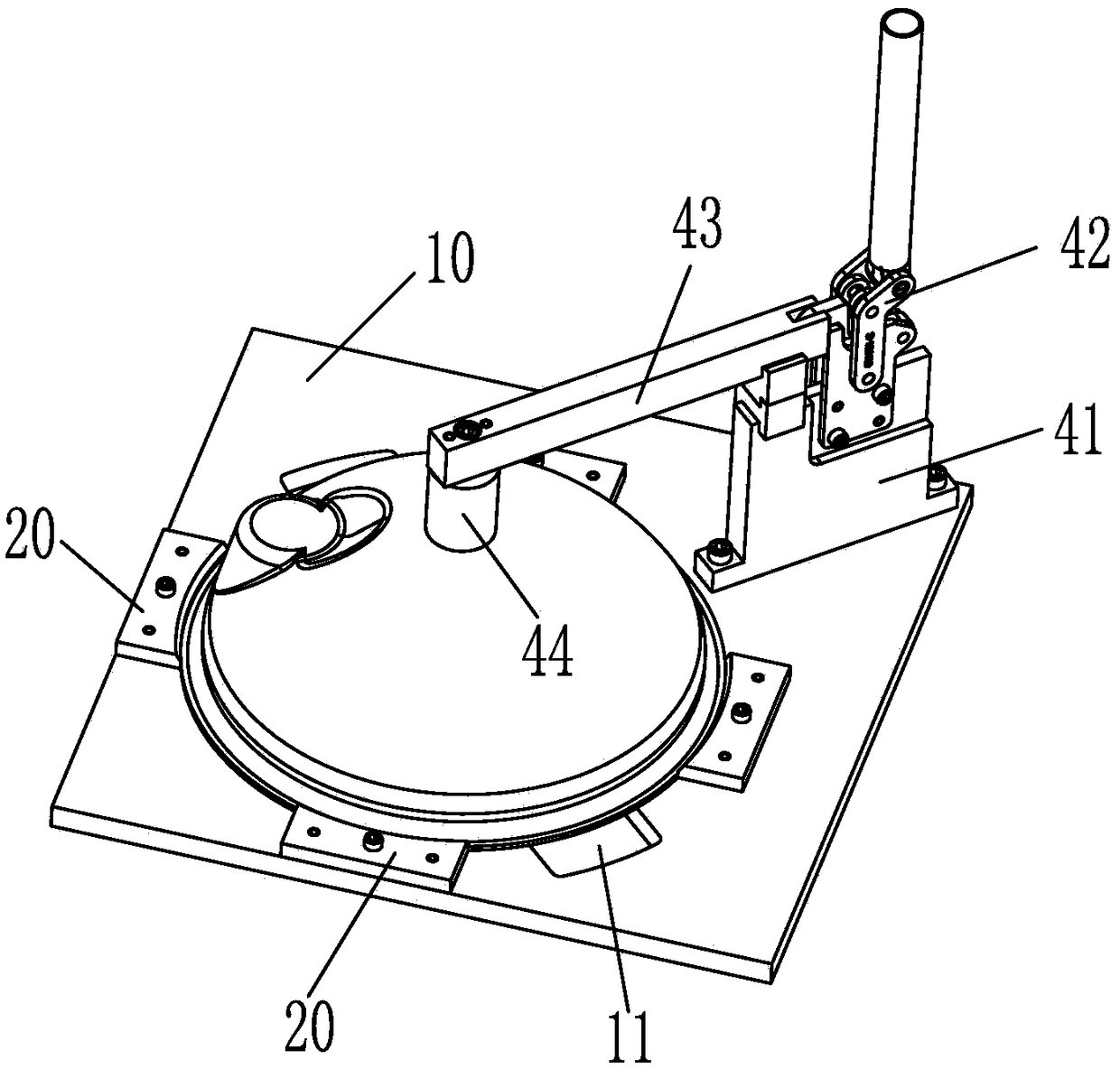

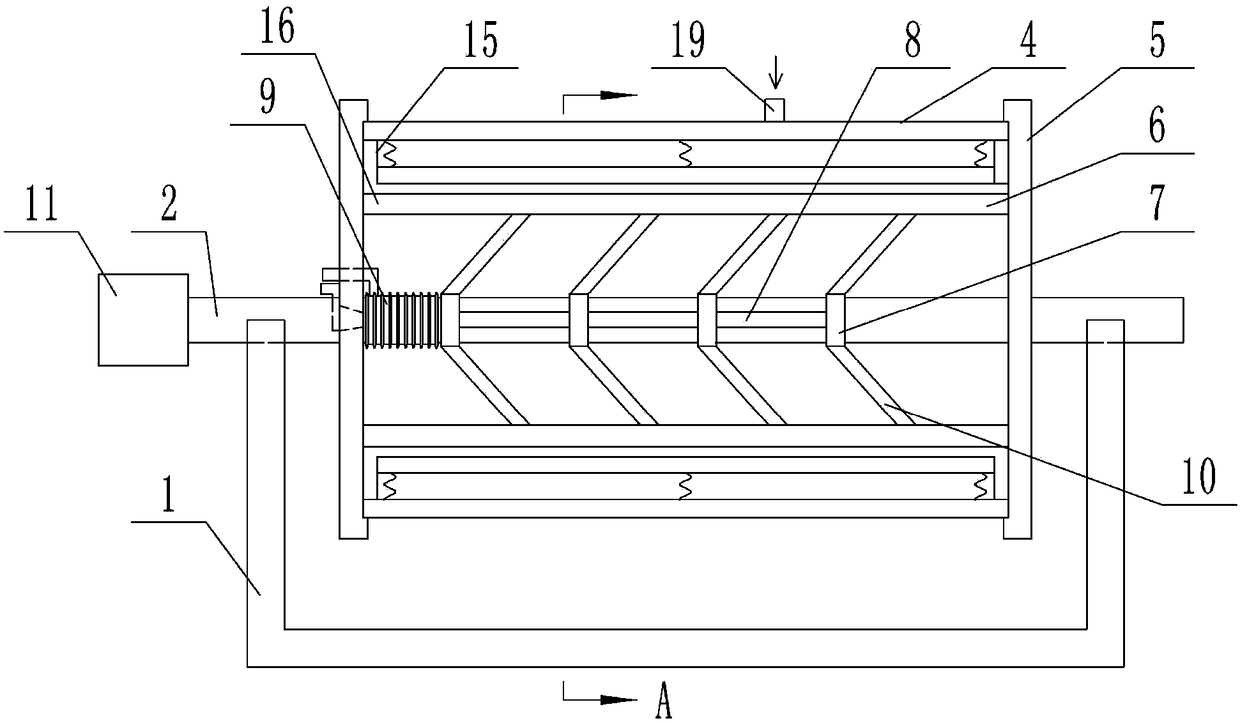

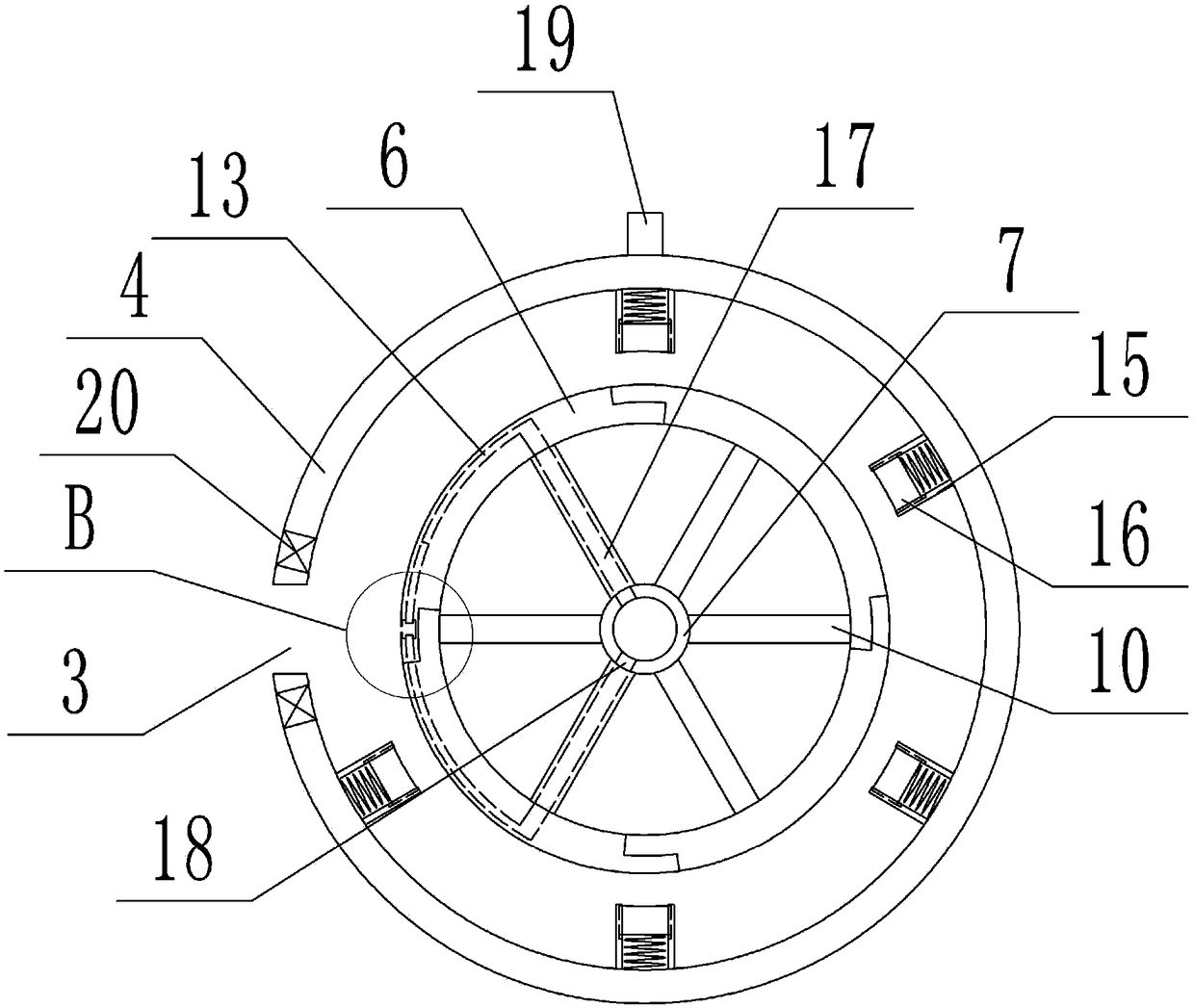

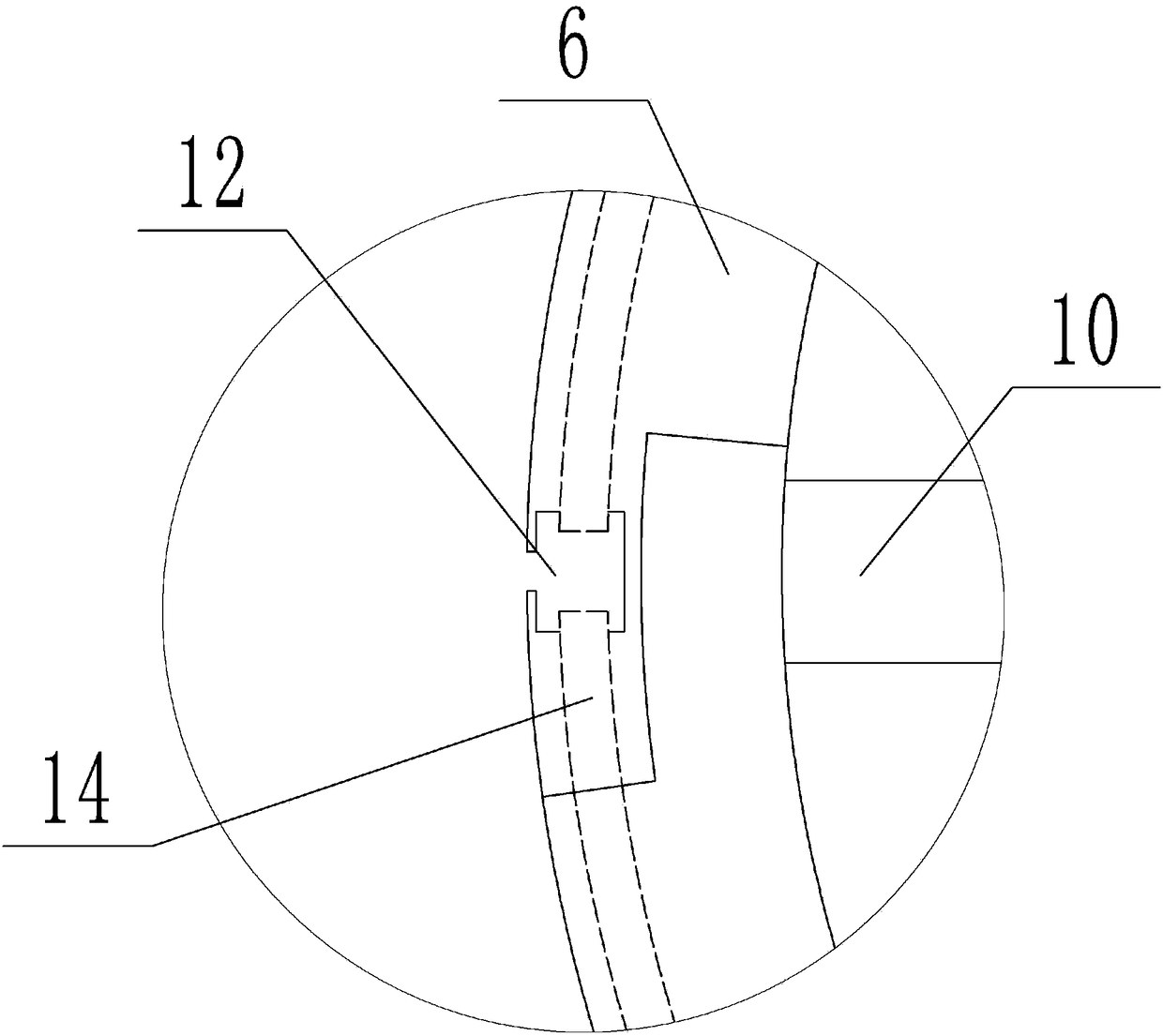

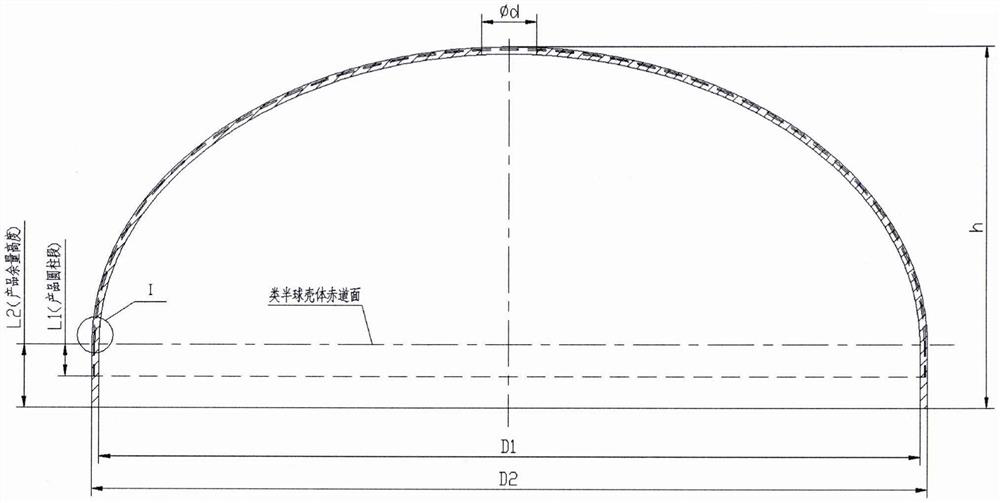

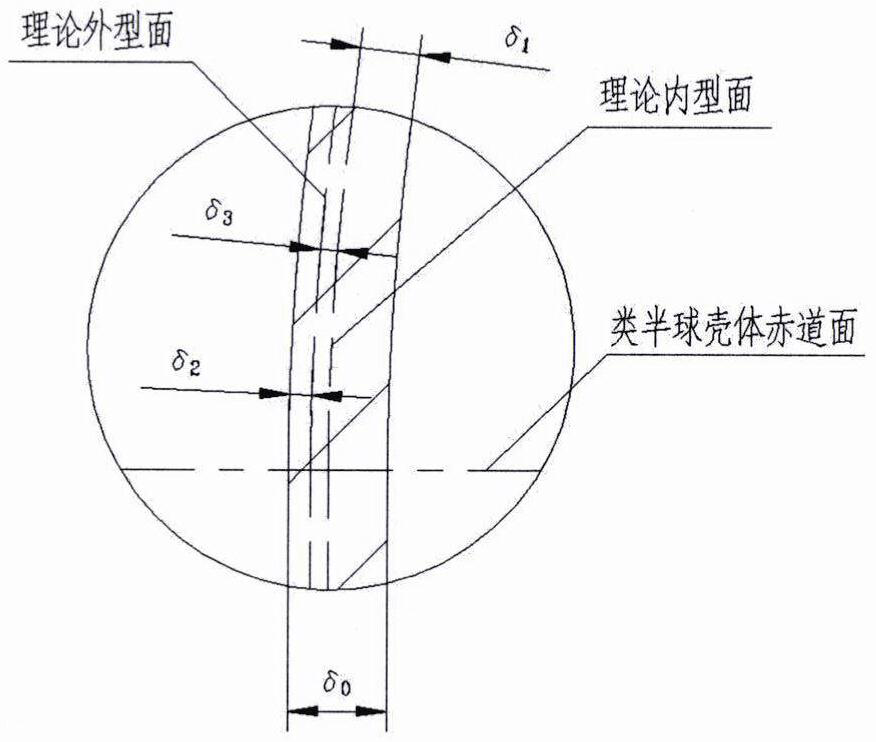

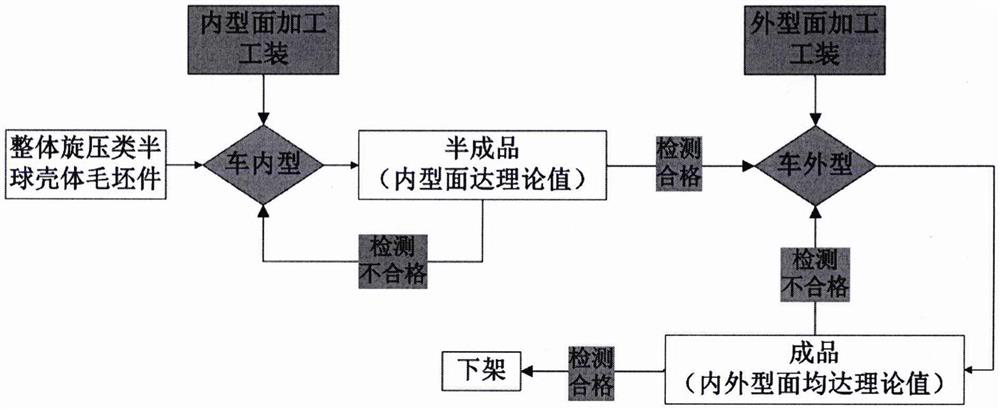

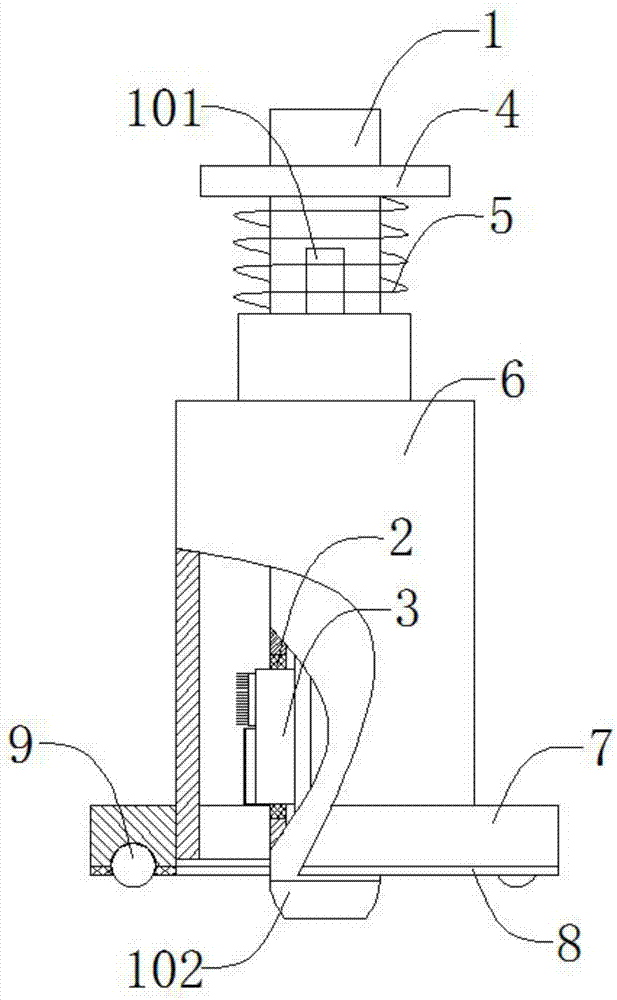

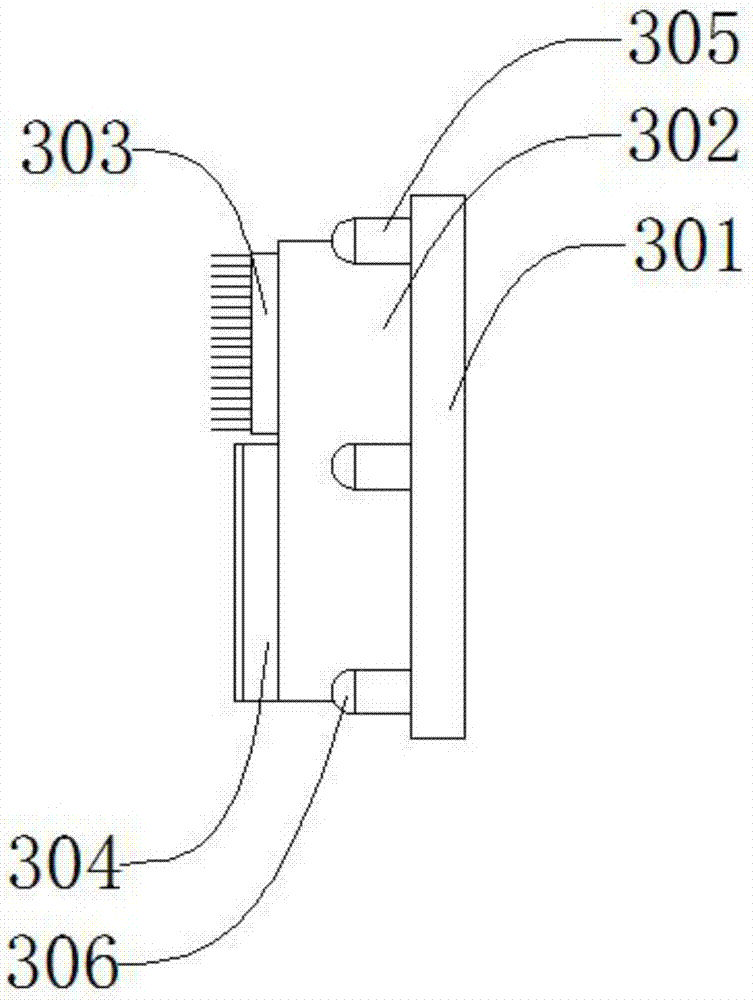

Machining device for inner molded surfaces of integral spinning hemisphere-like shells

ActiveCN112405044ARealize integrated batch manufacturingImprove machine efficiencyPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to the technical field of precision machining of inner molded surfaces of integral spinning-formed hemisphere-like shells, in particular to a machining device for inner molded surfaces of integral spinning hemisphere-like shells. The machining device comprises a flexible supporting mechanism, a vice clamping and shape correcting mechanism, an upper pressing plate assembly anda bottom pressing plate assembly; the flexible supporting mechanism comprises a tool base; a groove used for containing the hemisphere-like shell is formed in the tool base in a concave mode; the vice clamping and shape correcting mechanism comprises a plurality of clamping and shape correcting assemblies; the upper pressing plate assembly comprises a plurality of upper pressing plate units; allthe upper pressing plate units and the clamping and shape correcting assemblies are distributed around the end surface of the tool base in a staggered mode in the circumferential direction; the bottompressing plate assembly comprises a vertical base in the center of the bottom of the groove; and a bottom pressing plate is installed on the vertical base in a threaded mode. According to the machining device, end sockets of the hemisphere-like shells are integrally and accurately positioned and clamped, inner molded surface machining is finally completed, the hemisphere-like shell end socket machining efficiency is improved, and integral batch manufacturing of the end sockets of the hemisphere-like shells is achieved.

Owner:CAPITAL AEROSPACE MACHINERY

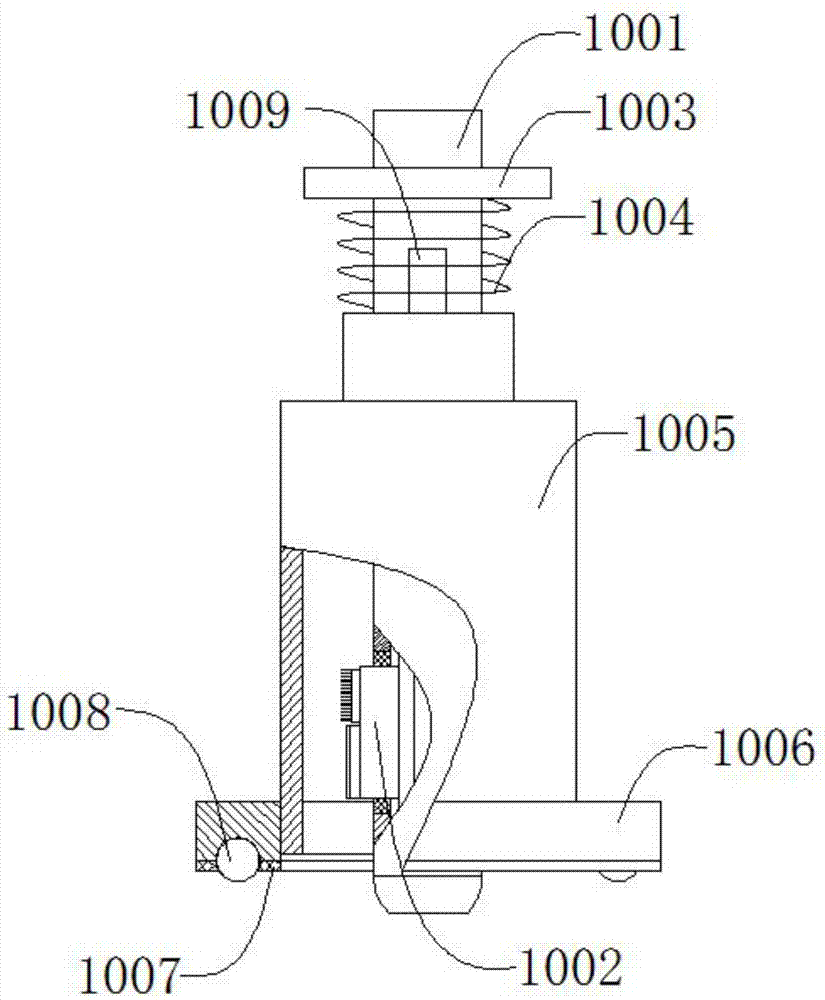

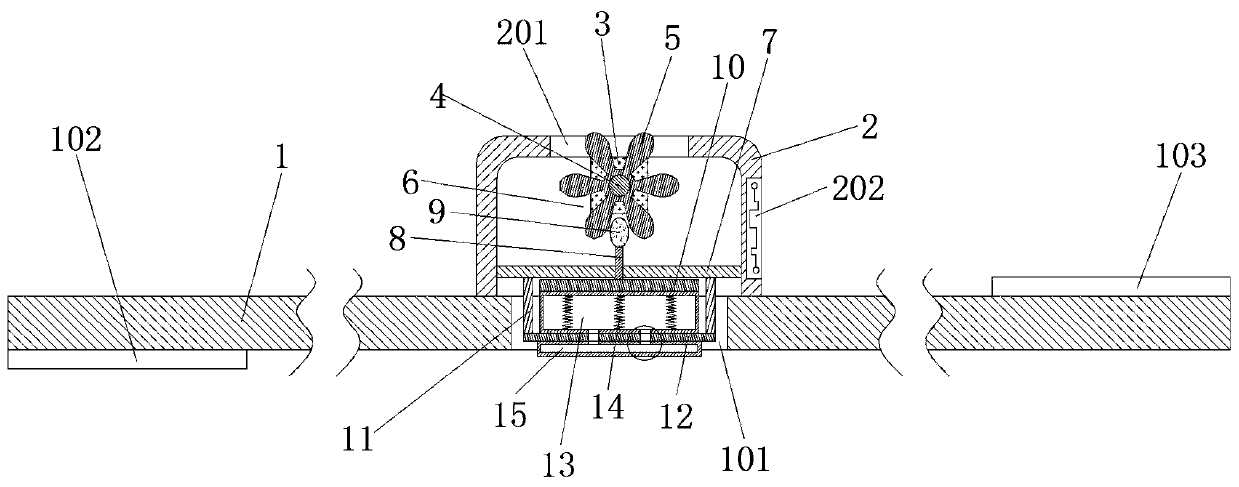

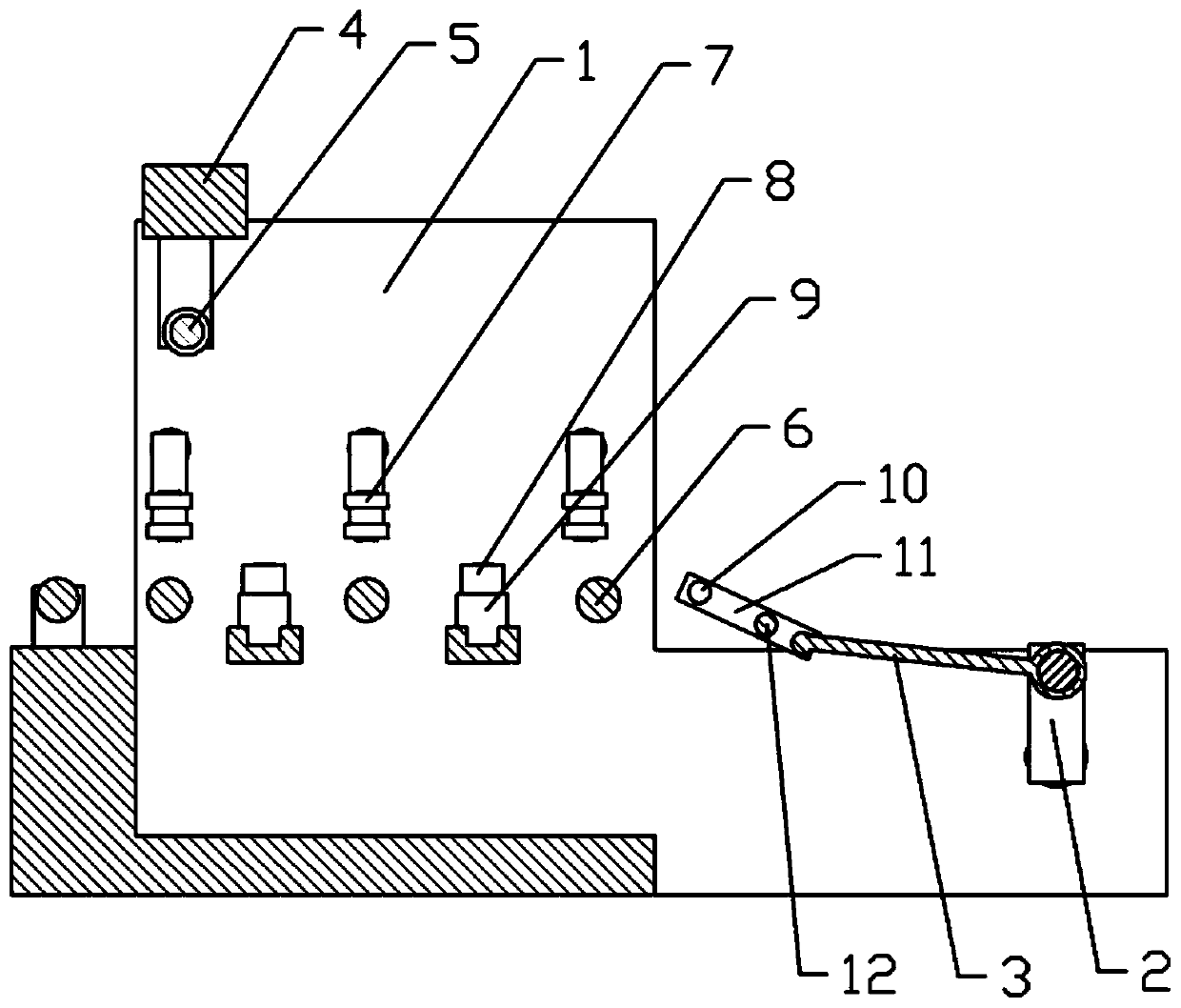

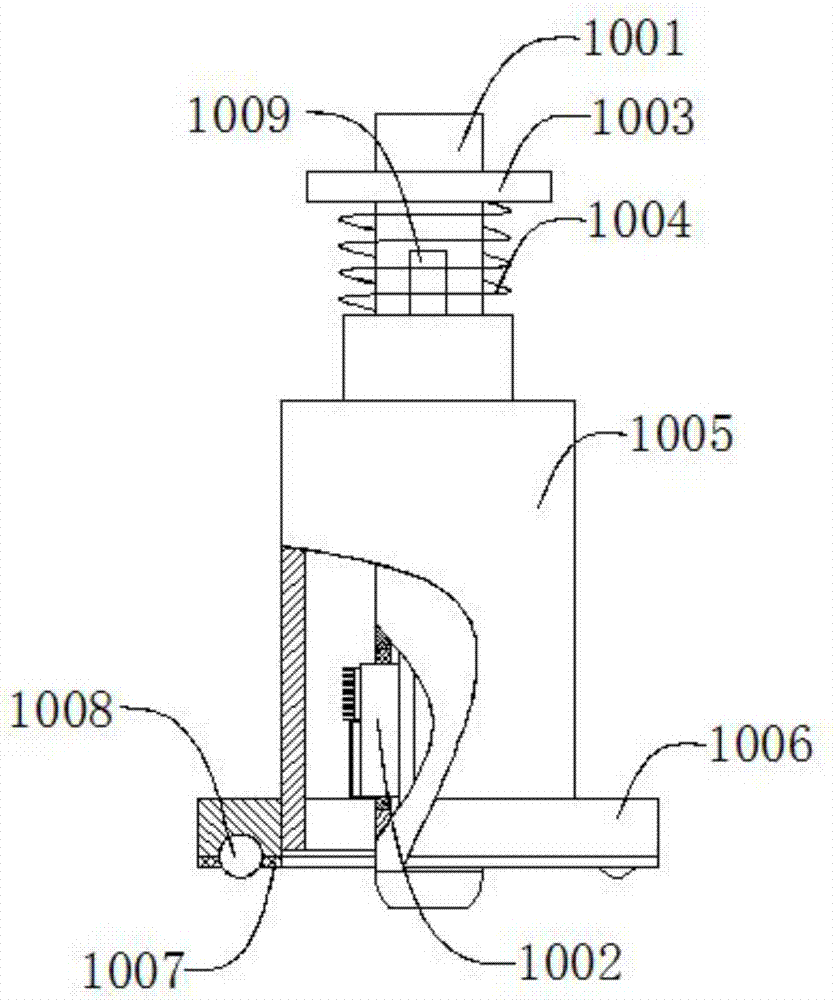

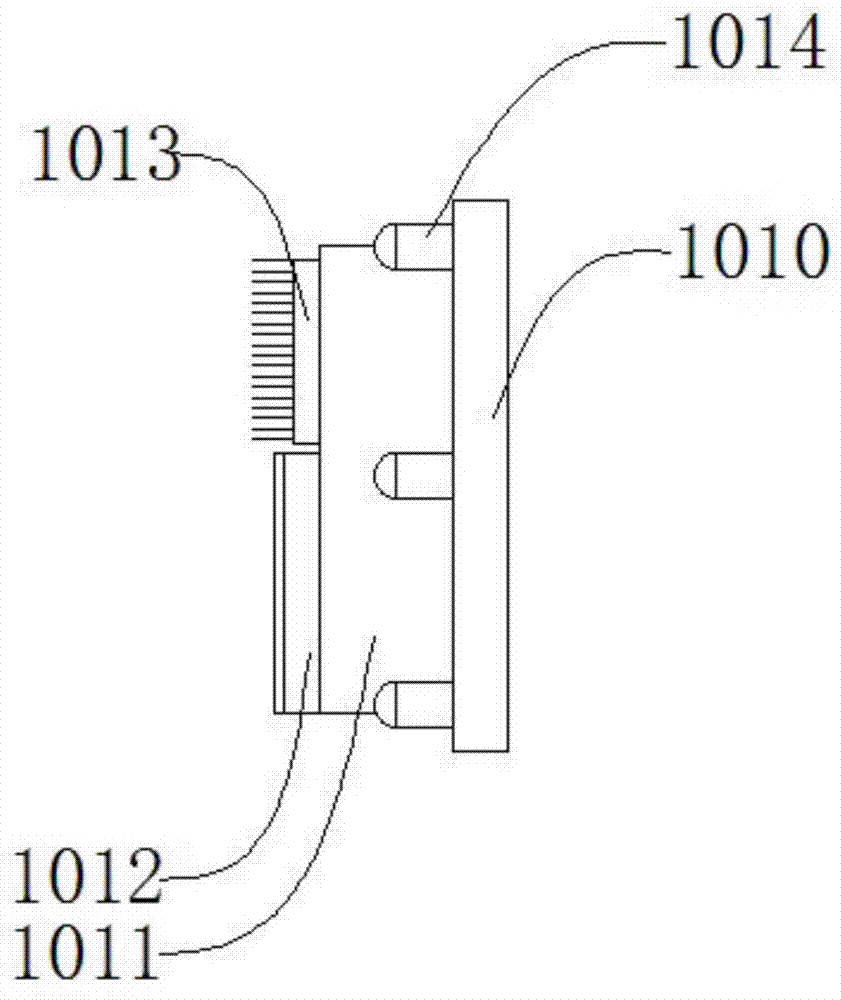

Pre-press type PCB hole slag removing drill bit

InactiveCN107442820AImprove yieldAvoid destructionTransportation and packagingPrinted circuit manufactureTool bitEngineering

The invention discloses a pre-press type PCB hole slag removing drill bit. The pre-press type PCB hole slag removing drill bit comprises a hollow casing pipe, two limiting sleeves symmetrically arranged along the hollow casing pipe, a drilling tool mechanism, an adjusting block, a spring, a pressing sleeve, a pressing ring, a baffle and a steel ball. The hollow casing pipe is inserted in a PCB hole which is about to be subjected to slag removal, the spring is compressed, accordingly, the pressing sleeve is reversely acted, the steel ball makes contact with a PCB, then, the hollow casing pipe rotates, the drilling tool mechanism slowly stretches out under the action of centrifugal force and damping action of an elastic column, a tool bit arranged on the drilling tool mechanism crushes and removes attached slag in the hole, a brush sweeps the hole wall machined through the tool bit, and accordingly slag is removed; and meanwhile, the steel ball rolls between the pressing ring and the baffle, and a pressing effect is kept accordingly. The device is simple in structure, the slag and scraps attached to the inner wall of the PCB hole can be effectively removed, environment friendliness is achieved, and the removal effect is good; and meanwhile, automatic pre-pressing can be conducted, hole wall damage caused by deformation of the PCB is prevented, and the yield of the PCB is increased.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

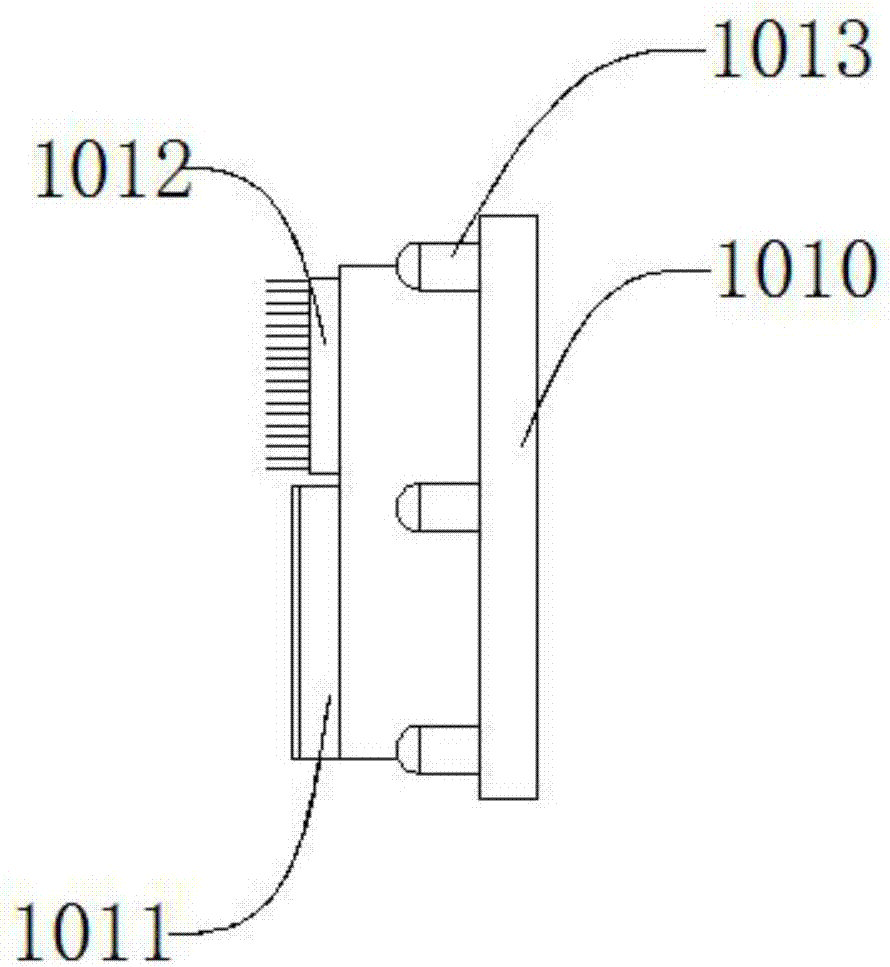

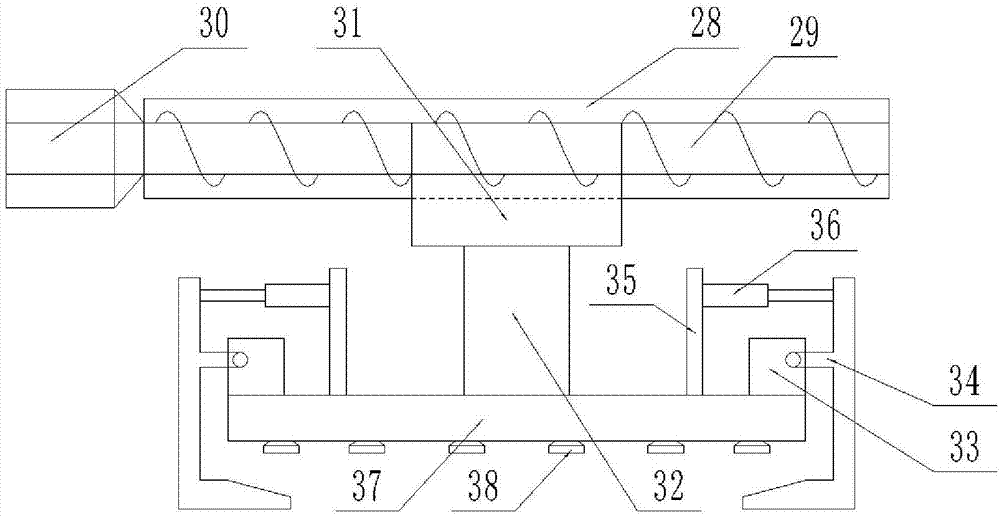

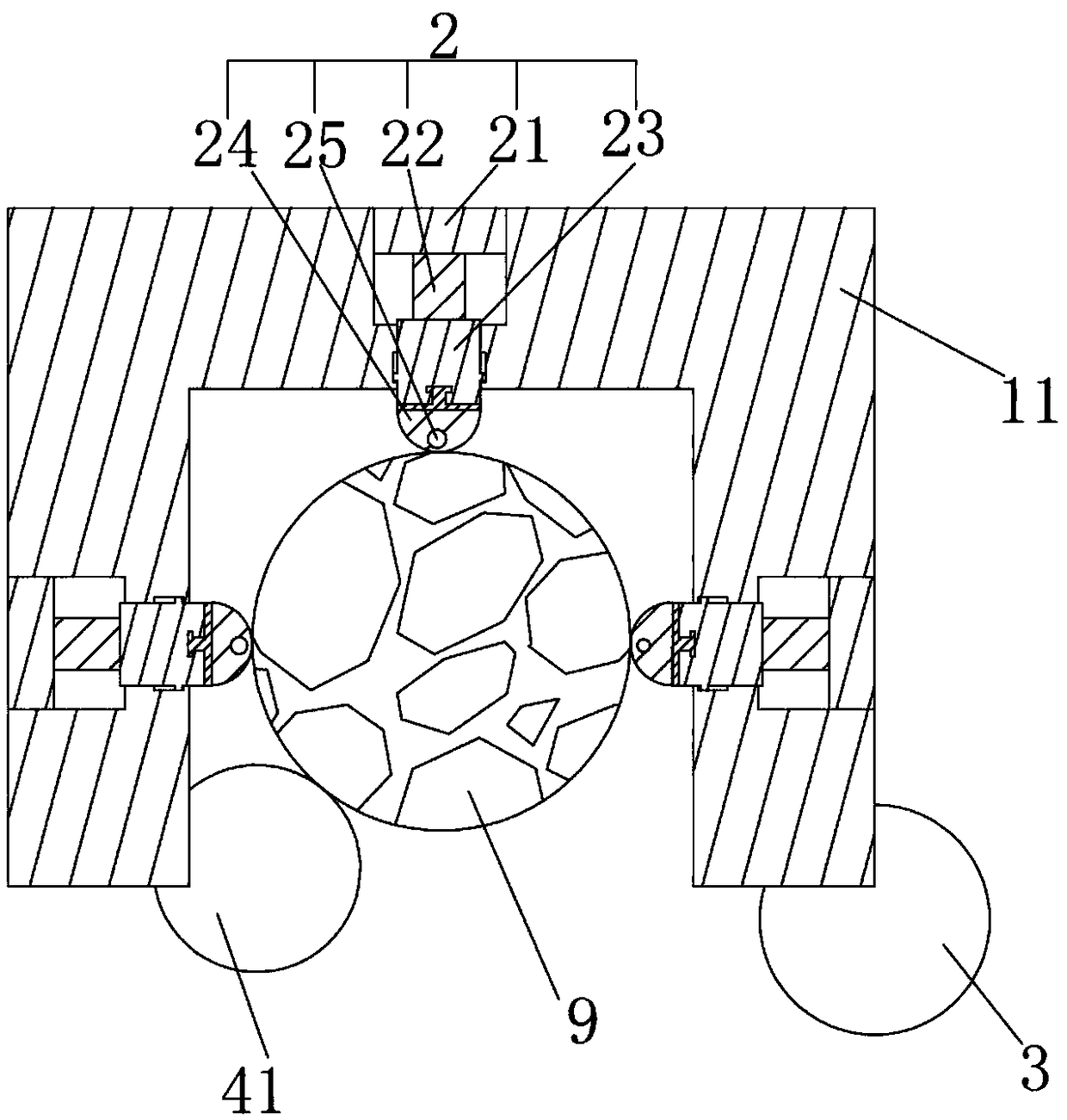

Prepressing type PCB hole residue removal device

ActiveCN107497736AImprove yieldAvoid secondary pollutionDirt cleaningCleaning using toolsTool bitElectric machinery

The invention discloses a prepressing type PCB hole residue removal device. The prepressing type PCB hole residue removal device comprises a rack, a placement mold, an air cylinder, guide rods symmetrically arranged along the air cylinder, an upper supporting board, a lower supporting board, a speed adjusting motor, an air bellow, a chuck and a prepressing drilling tool mechanism. A PCB to be subjected to residue clearing is placed in the placement mold, the air cylinder pushes the upper supporting board to move downwards, and therefore the prepressing drilling tool mechanism is pushed to move downwards to tightly press the PCB; then the speed adjusting motor works, tool bits arranged on drilling tool mechanism bodies smash and remove residues attached in a hole, brushes sweep the hole wall machined by the tool bits, and therefore the residues are removed; and an air pipe carries out extraction in the air bellow to form negative pressure, and free waste chips pass through a hollow sleeve pipe and a chip outlet hole in sequence to enter the air bellow and then are discharged by the air pipe. The device is simple in structure, and residues and chips attached to the inner wall of the hole of the PCB can be effectively removed; environment friendliness is achieved, and the free waste chips can be collected to prevent secondary contamination of the waste chips; and meanwhile, prepressing can be carried out automatically, hole wall damage caused by PCB deformation can be avoided, and the yield of the PCB can be increased.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

Inflatable press mounting head of cloth

InactiveCN110834354ARealize damage-free compressionGuaranteed compression effectMetal working apparatusEngineeringMechanical engineering

The invention discloses an inflatable press mounting head of cloth. The inflatable press mounting head includes a fixed plate, the lower end of the fixed plate is provided with two pressing blocks, the fixed plate and the pressing blocks are enclosed to form an assembly groove, the assembly groove is internally provided with an elevation type elevating adjusting plate, the lower end of the elevating adjusting plate is provided with an air bag, and the air bag extends out of the lower end of the assembly groove; the inner sides of the pressing blocks are provided with guide grooves for guiding,and the elevating adjusting plate slides along the guide grooves; and the air bag and the elevating adjusting plate are enclosed to form a gas storage cavity, and the air bag is in a circular arc shape. According to the inflatable press mounting head, the gas storage cavity is formed by enclosing the air bag and the elevating adjusting plate, through deformation of the air bag, a way of elastic progressive compaction of the cloth can be provided, injury-free compaction of the cloth is realized, magnetic adsorption is achieved through a magnetic strip in a mounting hole, the way of elastic compaction of the cloth can be provided, the compaction effect is ensured, and meanwhile compaction marks in mechanical compaction are effectively reduced.

Owner:天津汇来制衣有限公司

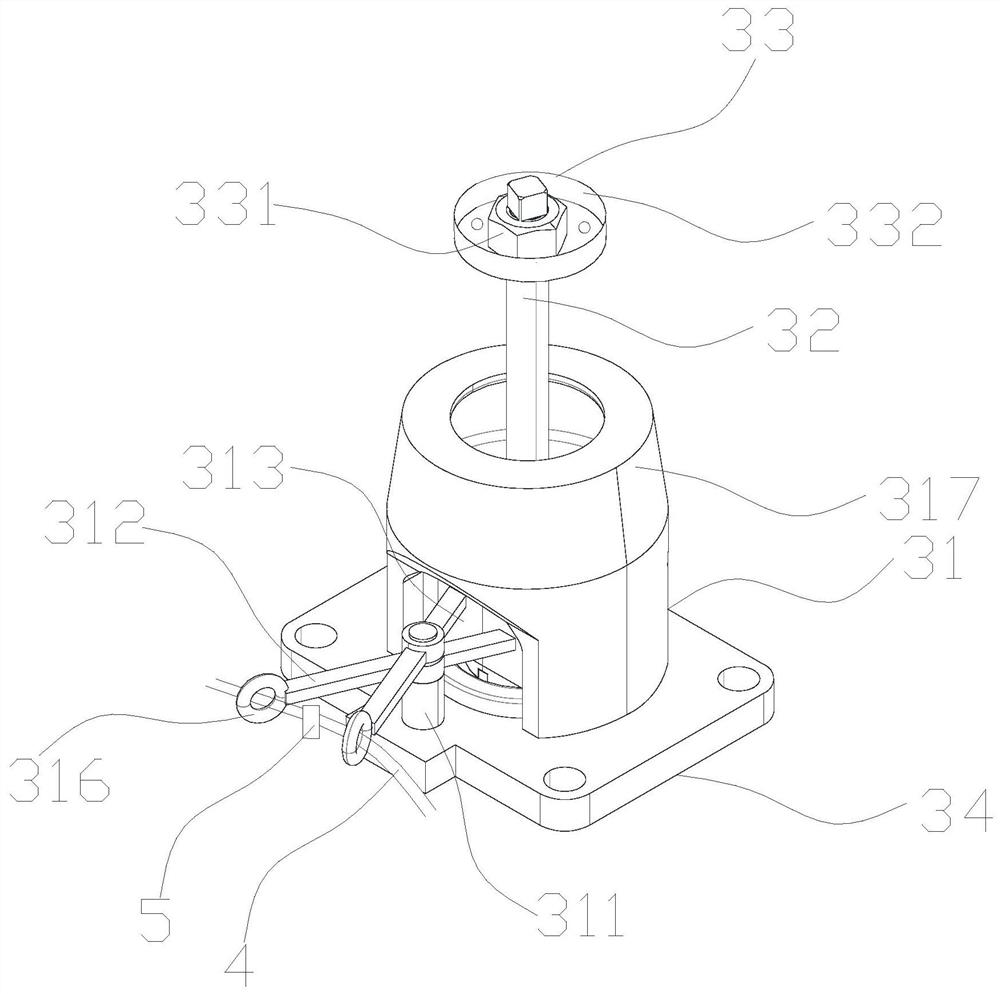

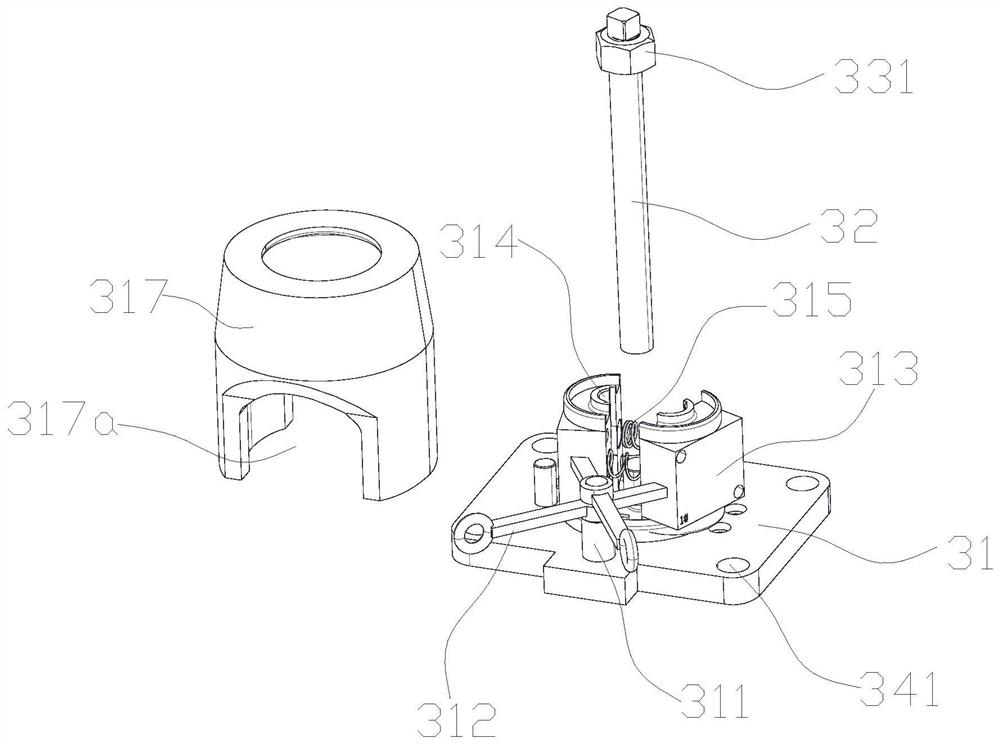

Pressing and releasing device of folding type solar wing

ActiveCN113212810AAddress the impactSolve the dangerCosmonautic vehiclesCosmonautic power supply systemsEngineeringMechanical engineering

The invention relates to a pressing and releasing device of a folding solar wing, one end of the pressing and releasing device is fixed on a satellite body, the other end of the pressing and releasing device is connected with a solar wing base plate, the pressing and releasing device comprises a pressing rod and a connecting structure, one end of the pressing rod is provided with a limiting part, the other end of the pressing rod is connected with the connecting structure, and the pressing rod penetrates through the solar wing base plate; the solar wing base plate is contracted between the limiting part and the connecting structure, the connecting structure is used for fixing the pressing rod, and the connecting structure can release the pressing rod so that the pressing rod can be separated from the connecting structure. According to the device, the solar wing base plates are pressed and fixed after being folded in the mode that the pressing rods penetrate through folding solar wing base plate blocks, the multiple folding solar wing base plates can be synchronously pressed, the pressing effect of the folding solar wing base plates is guaranteed, when the multiple pressing devices are arranged on the solar wing base plates, all the pressing devices can be synchronously released, and effects of synchronously tightening a plurality of folding type solar wing base plates and synchronously releasing a plurality of pressing points are achieved.

Owner:北京吾天科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com