Machining device for inner molded surfaces of integral spinning hemisphere-like shells

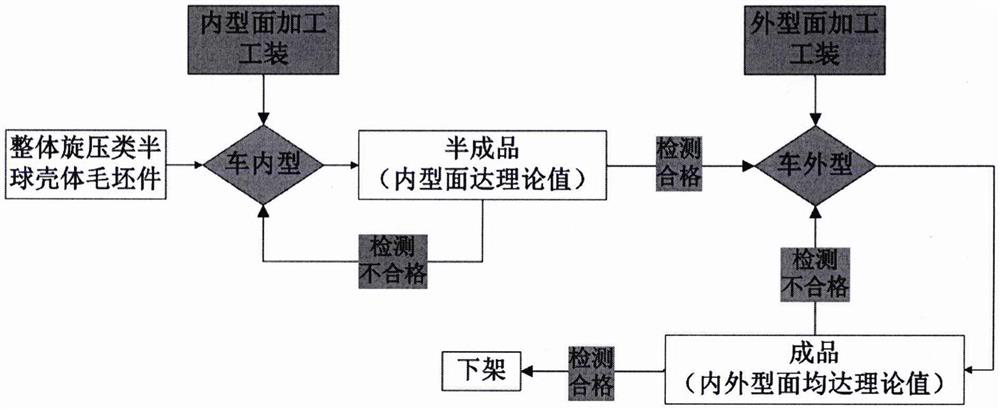

A technology of inner surface and adding devices, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to achieve calibration, low processing accuracy, low positioning and clamping accuracy of hemispherical shell heads, etc. problems, to achieve the effect of ensuring product processing quality and processing accuracy stability, improving machining efficiency, and fast product fixing and clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

[0036] refer to Figure 4 to Figure 11 The shown integral spinning type hemispherical shell internal surface machining device includes a flexible supporting mechanism 1, a vise clamping and correcting mechanism 2, an upper pressing plate assembly 3 and a bottom pressing plate assembly 4, and the flexible supporting mechanism 1 Including a tooling base 11, the tooling base 11 is concaved with a groove for accommodating a hemispherical shell, and the vise clamping and correcting mechanism 2 includes several fixedly mounted The clamping correction assembly on the top of the tooling base 11, the upper pressing plate assembly 3 includes several upper pressing plate units fixedly installed on the top of the tooling base 11 with equiangular differences around the circumferential direction of the groove end surface, all the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com