Full-automatic laser welder

A laser welding machine, fully automatic technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of laser welding focal length, workpiece performance influence, laser welding instant Problems such as high temperature, to achieve the effect of broad application range and prospects, good welding consistency, high welding efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The fully automatic laser welding machine according to the present invention will be described in detail below with reference to the accompanying drawings.

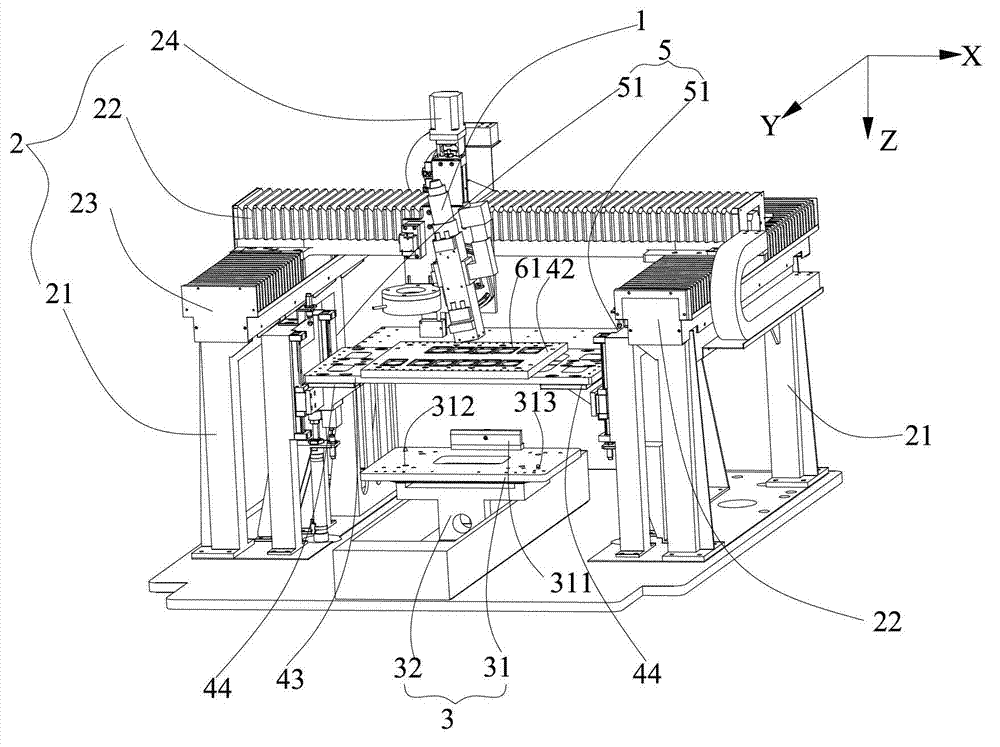

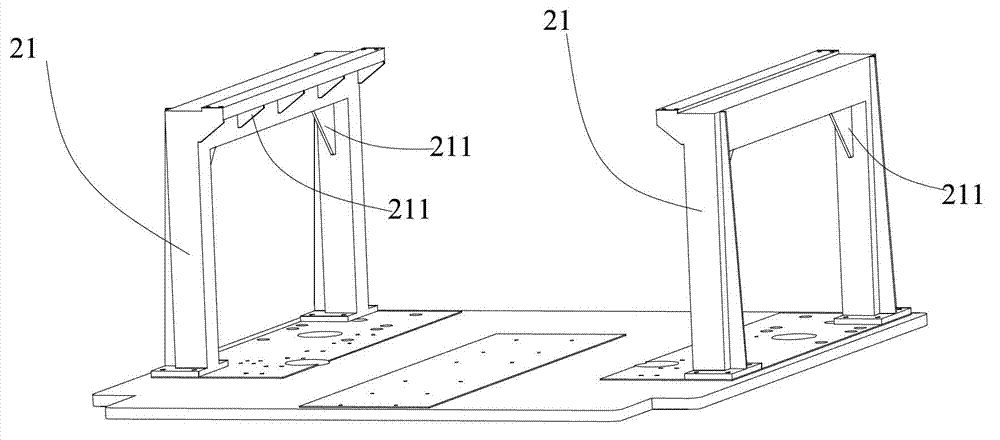

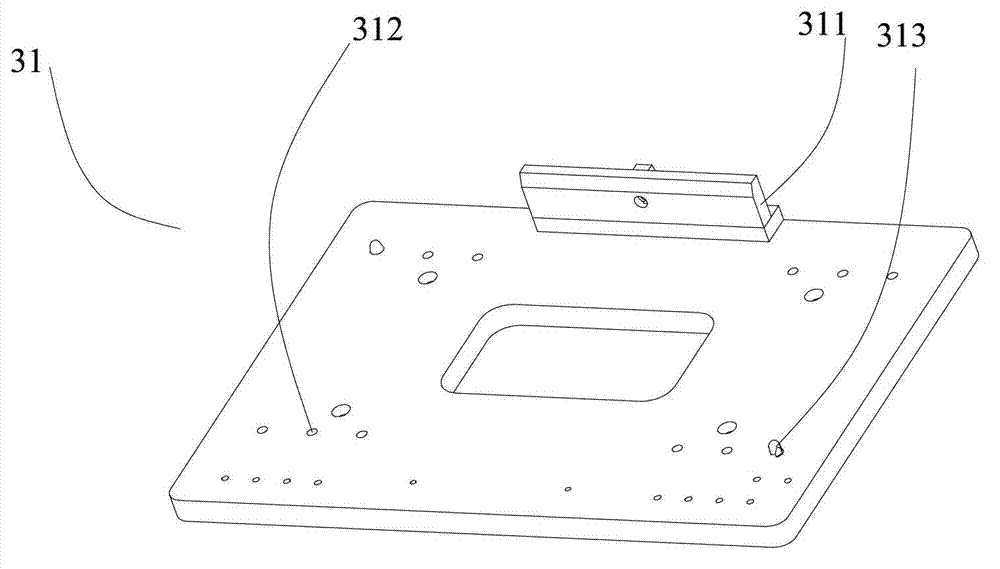

[0060] like figure 1 , Figure 4-12 As shown, the fully automatic laser welding machine according to the present invention includes: a laser head 1; a laser head servo mechanism 2, including driving the laser head 1 to move in three-dimensional space; and a loading and unloading mechanism 3, supporting and positioning the workpiece 8 to be welded and The adapter piece 9 drives the workpiece 8 and the adapter piece 9 to move repeatedly in the space below the laser head 1; the pressing mechanism 4; and the transmission mechanism 5. The pressing mechanism 4 includes: a plurality of pressing blocks 41 , and each pressing block 41 has a channel 414 through which the laser light emitted by the laser head 1 passes; and a pressing block bracket 42 elastically connected to each pressing block 41 . The transmission mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com