Inflatable press mounting head of cloth

An inflatable, press-fitting head technology, applied in metal processing and other directions, can solve the problem of no cloth, and achieve the effect of less imprinting and guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

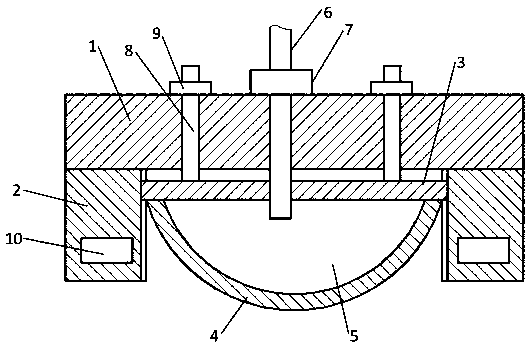

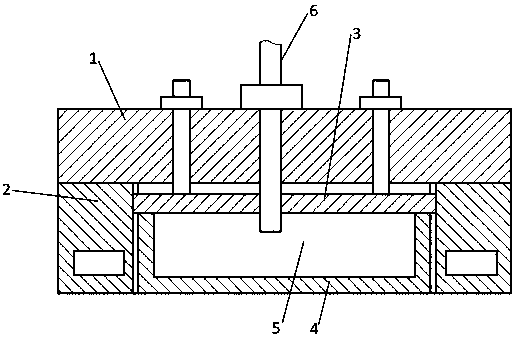

[0024] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0025] Such as Figure 1~2 As shown, an inflatable press head for cloth includes a fixed plate 1, and two pressing blocks 2 are arranged at the lower end of the fixed plate 1, and the fixing plate 1 and the pressing blocks 2 are enclosed to form an assembly groove, and the assembly A lift-type lifting adjustment plate 3 is arranged in the groove, and an air bag 4 is arranged at the lower end of the lifting adjustment plate 3, and the air bag 4 sticks out from the lower end of the assembly groove.

[0026] The upper end of the fixed plate 1 is connected with the telescopic end of the telescopic cylinder, and the fixed plate 1 is driven by the telescopic cylinder.

[0027] The fixing method between the two pressure blocks 2 and the fixing plate 1 is one of welding, riveting or bolting.

[0028] A guide groove 11 for guiding is formed on the inner side of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com