Prepressing type PCB hole residue removal device

A PCB board and pre-pressing technology, applied in the field of mechanical devices, can solve the problems of secondary pollution of waste chips, long reaction time, low efficiency, etc., so as to improve the yield rate of PCB boards, prevent secondary pollution, and prevent hole wall damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

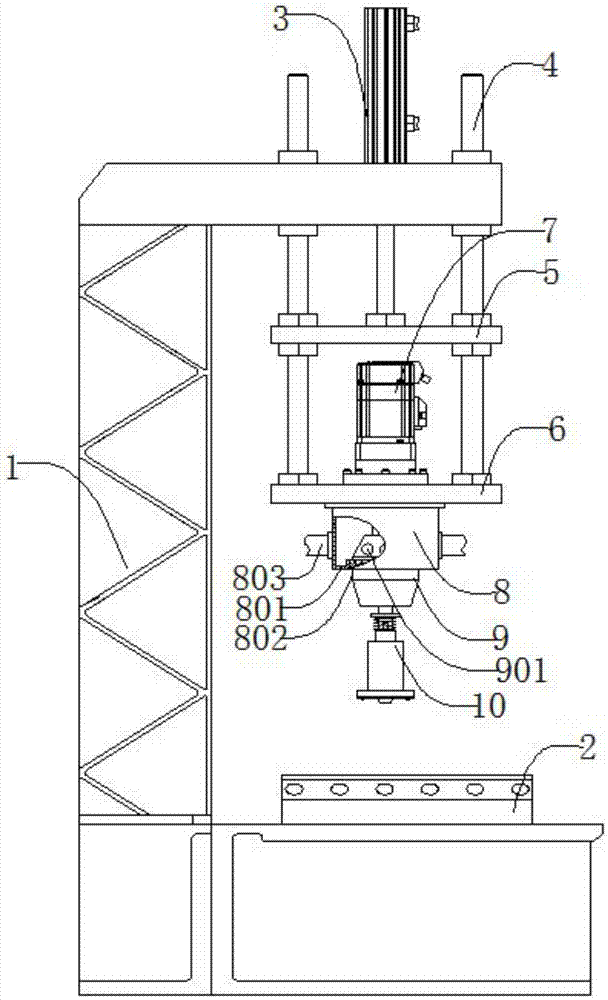

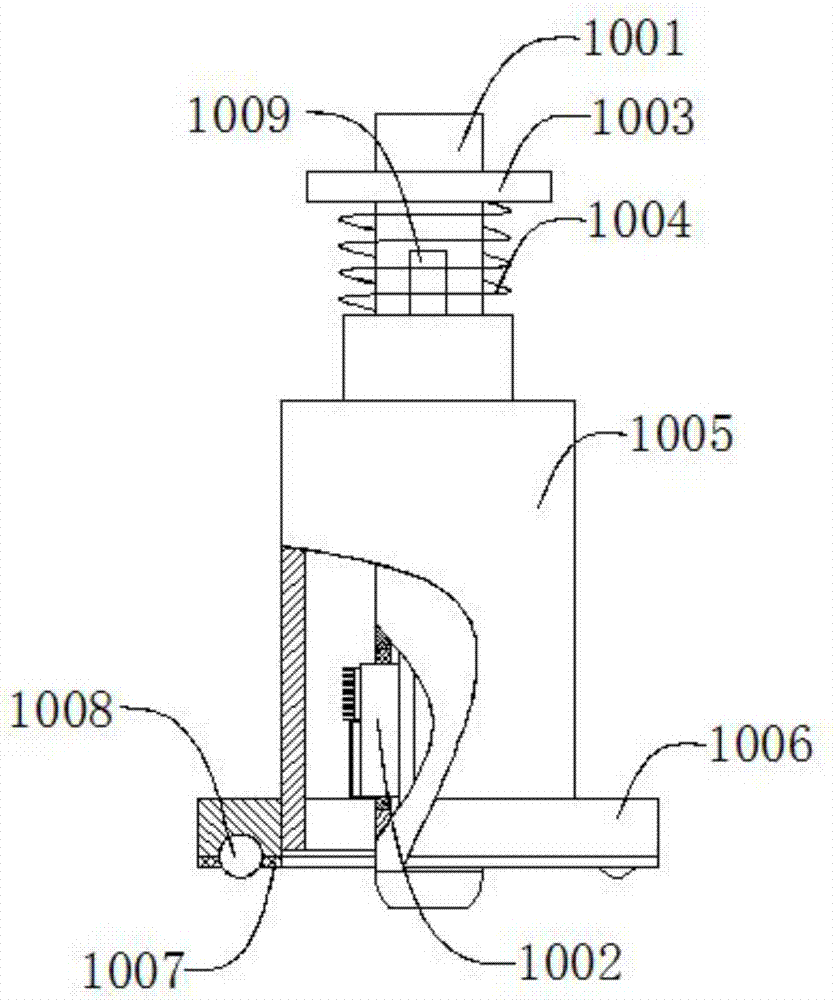

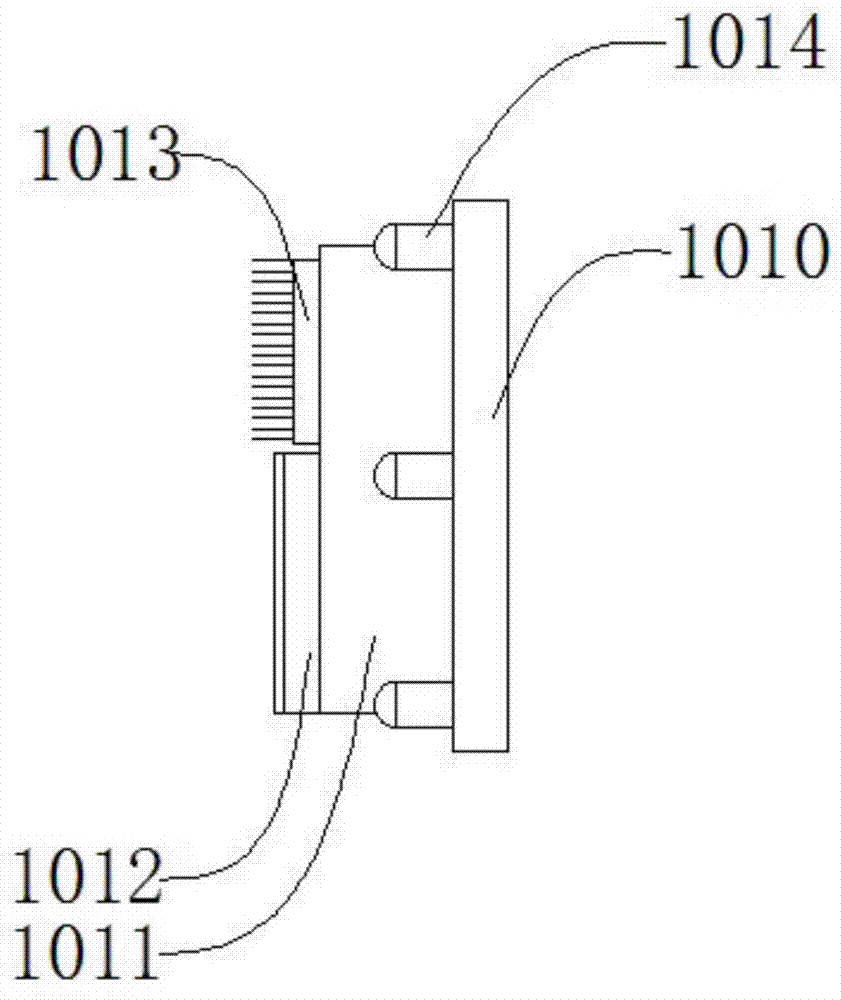

[0035] like figure 1 , figure 2 , image 3As shown, a pre-pressed PCB board hole slag removal device includes a frame 1, a placement mold 2, a cylinder 3, a guide rod 4 arranged symmetrically along the cylinder 3, an upper pallet 5, a lower pallet 6, an adjustment Speed motor 7, bellows 8, collet 9, pre-pressing drill mechanism 10, described placement mold 2 is positioned at frame 1 lower end, described placement mold 2 is connected with frame 1 screw thread, and described cylinder 3 is positioned at machine The upper end of the frame 1, the cylinder 3 is threadedly connected with the frame 1, the guide rod 4 runs through the frame 1, the guide rod 4 is connected with the frame 1 with a gap, and the upper supporting plate 5 is located on the cylinder 3 The lower end is penetrated by the guide rod 4, the upper supporting plate 5 is threadedly connected with the cylinder 3 and connected with the guide rod 4, the lower supporting plate 6 is located at the lower end of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com