Patents

Literature

42results about How to "Good welding consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

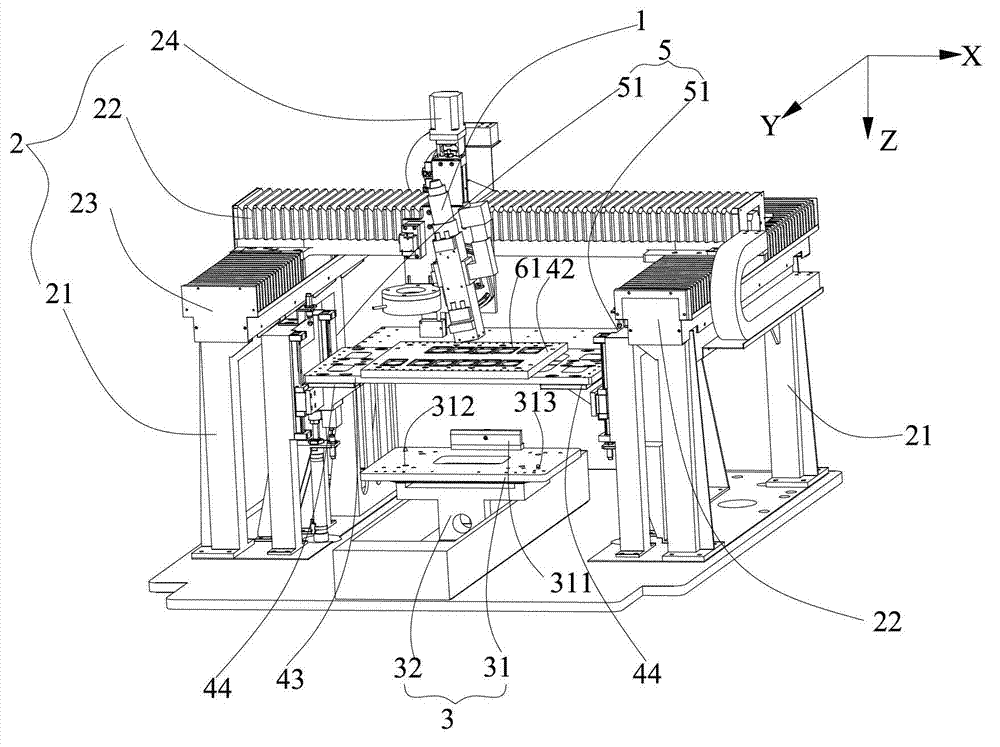

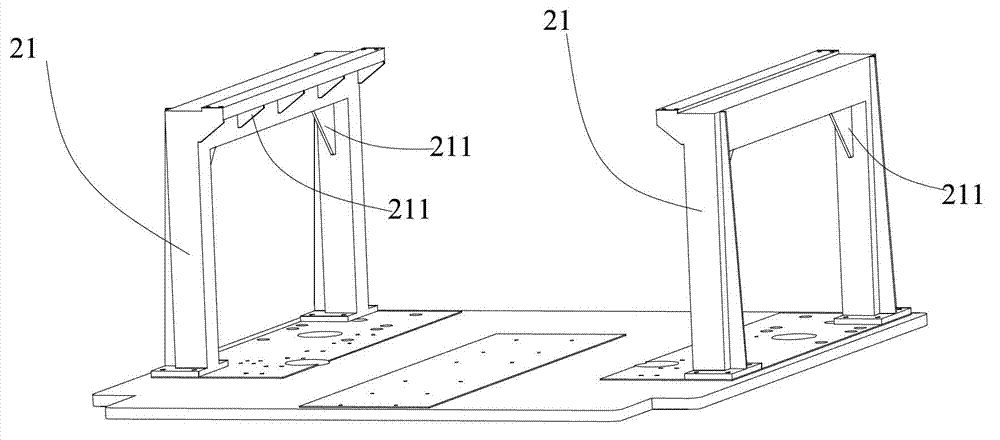

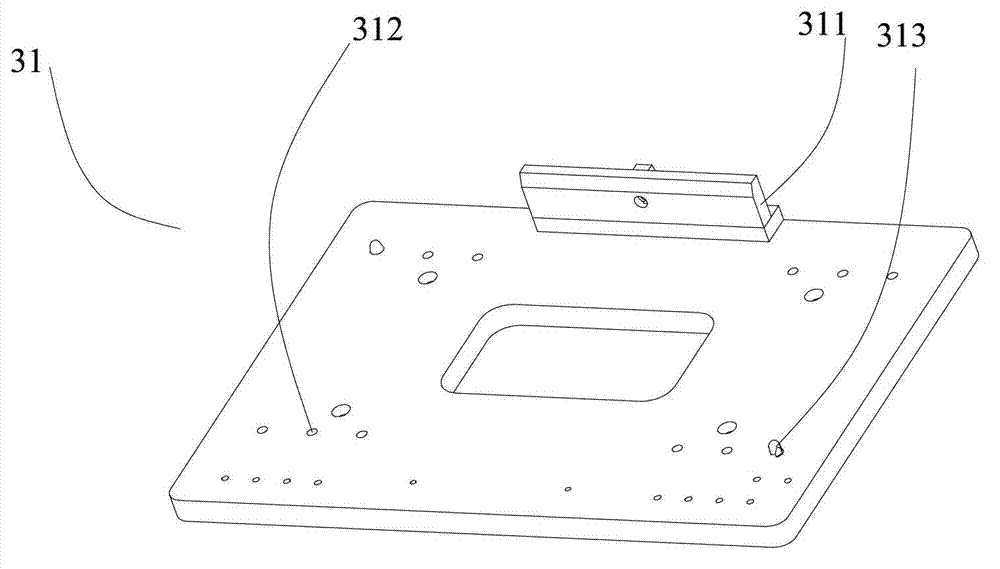

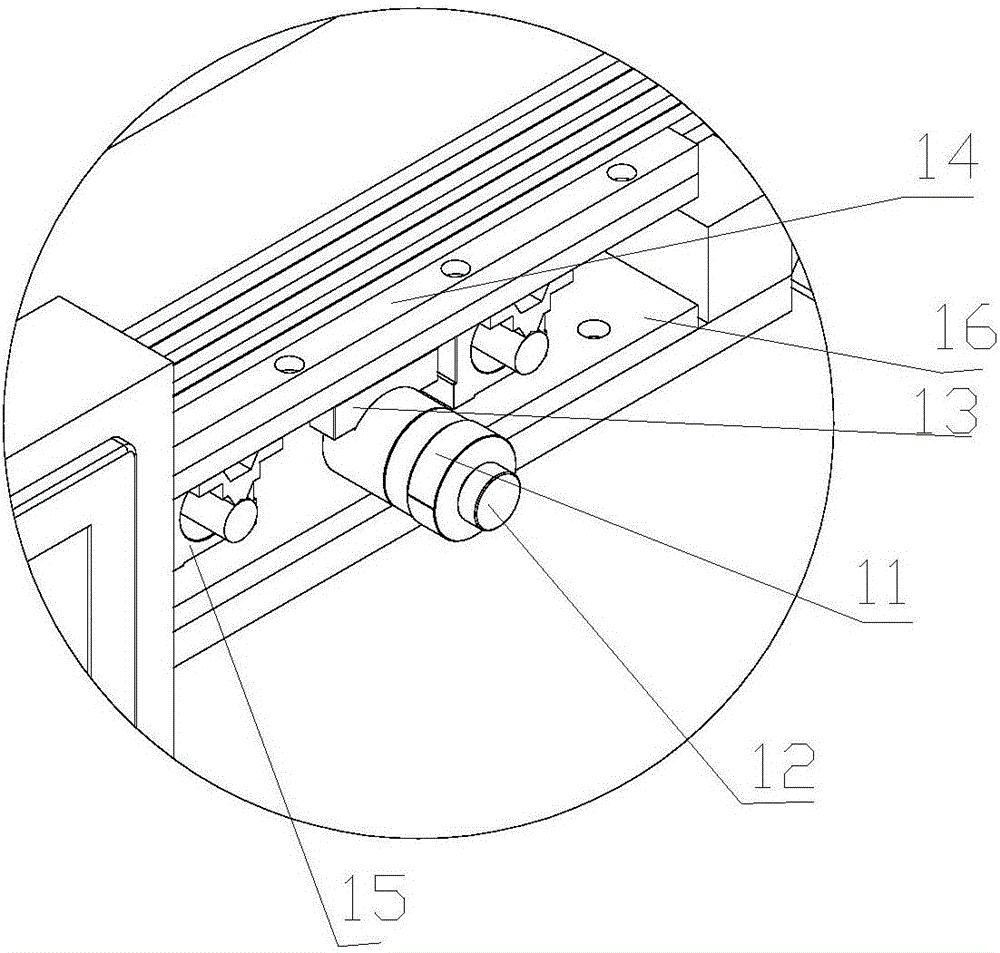

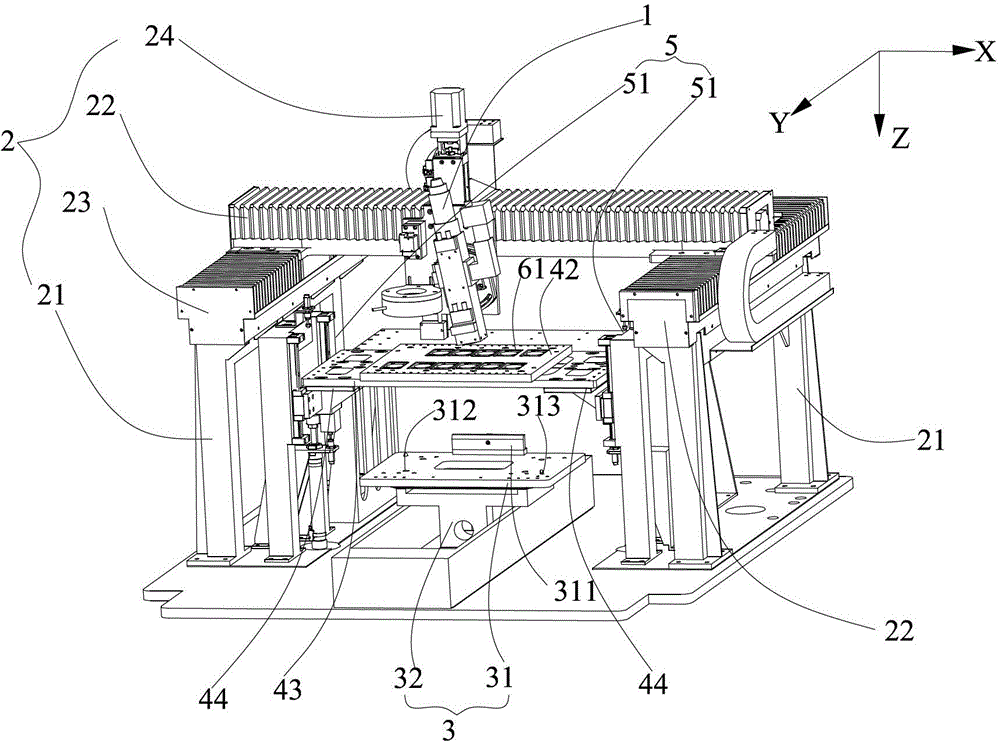

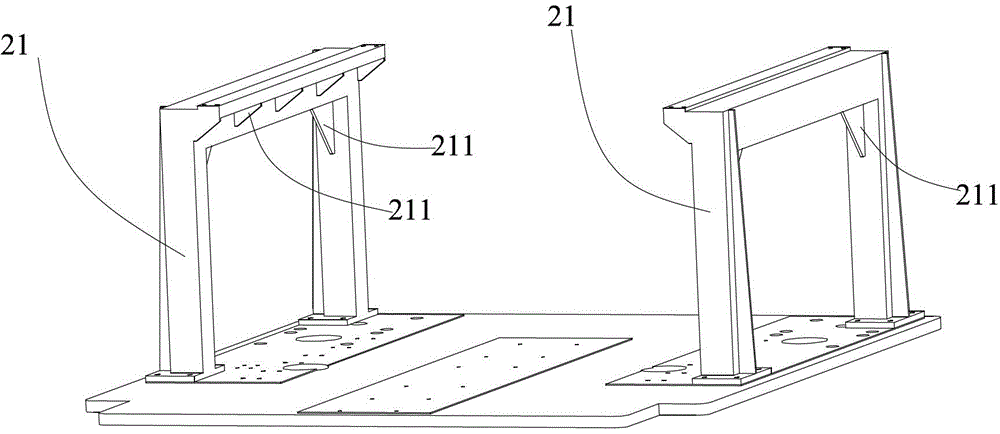

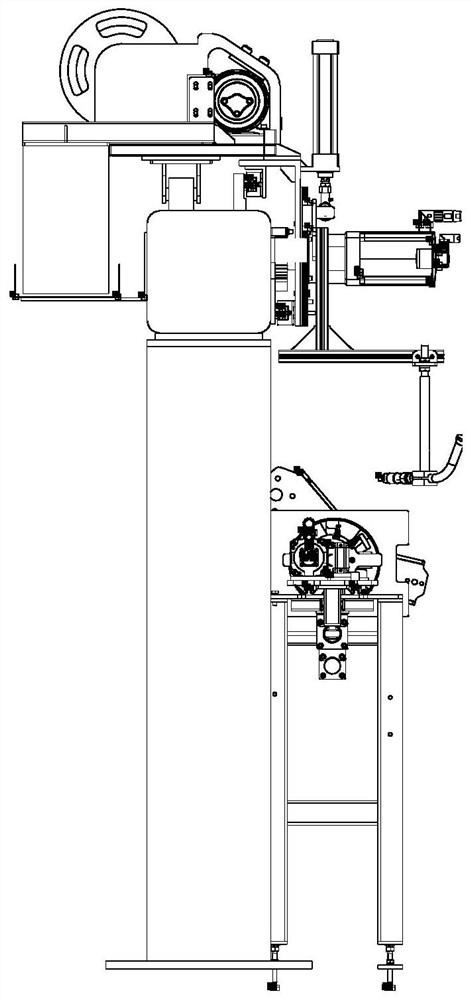

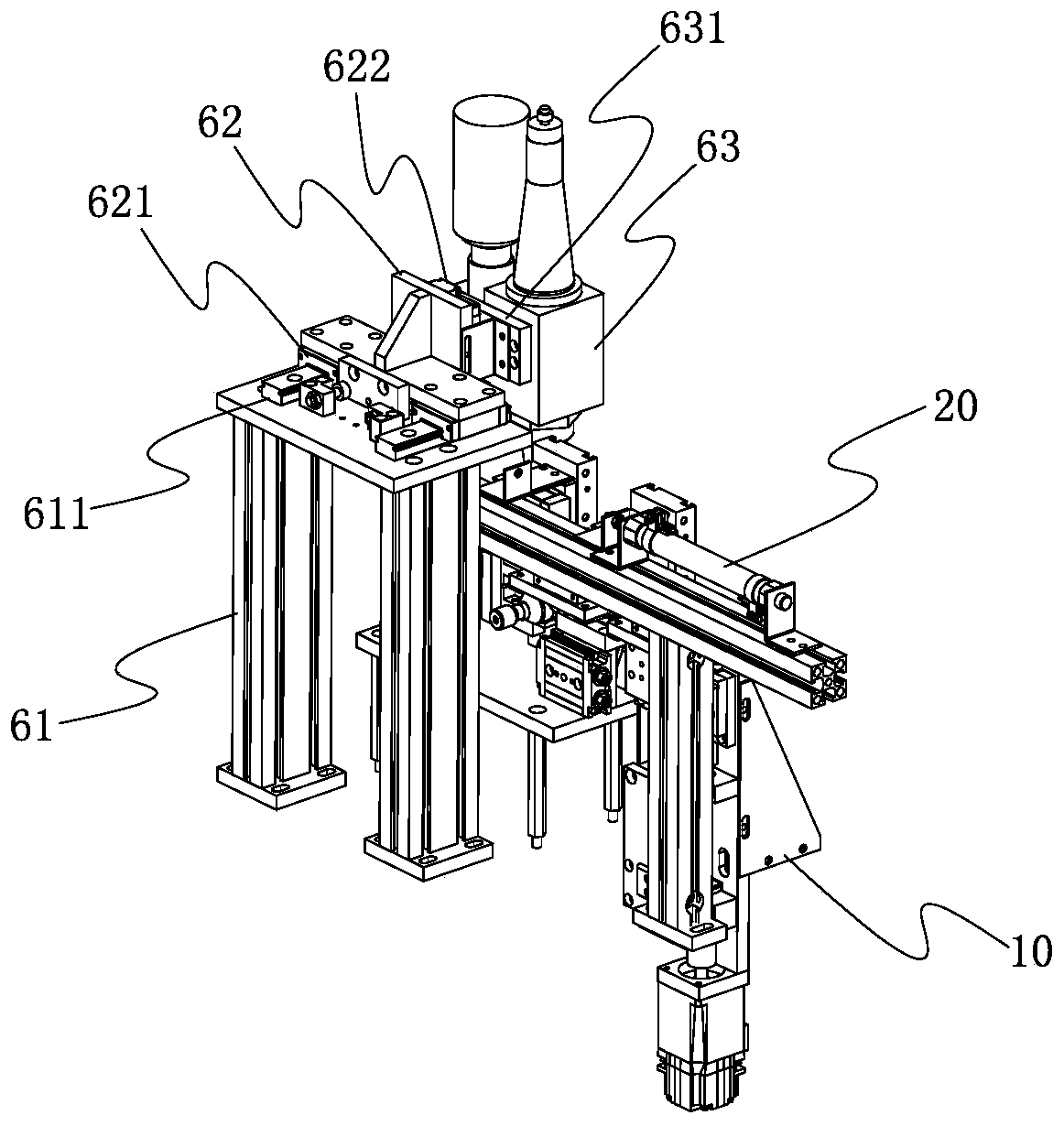

Full-automatic laser welder

ActiveCN103240527AGuaranteed compression effectSolving Automatic Laser Welding ProblemsLaser beam welding apparatusPortal frameLaser

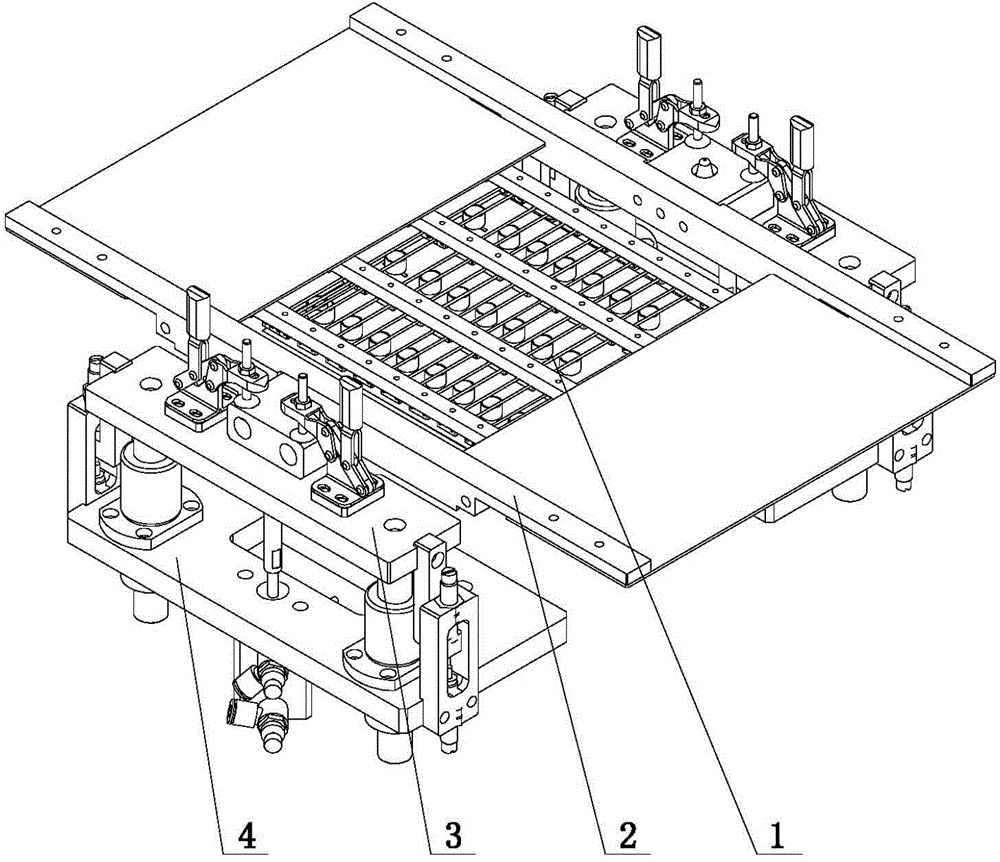

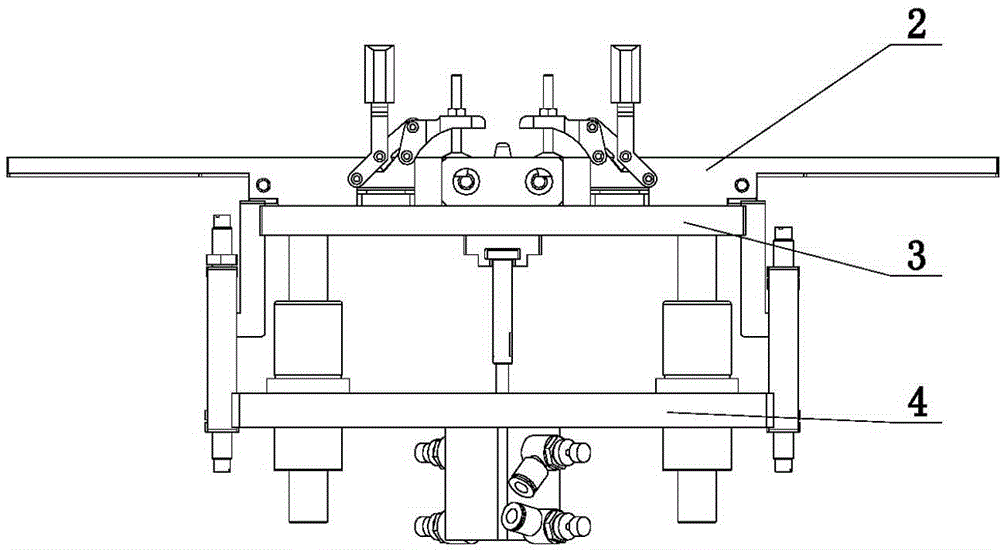

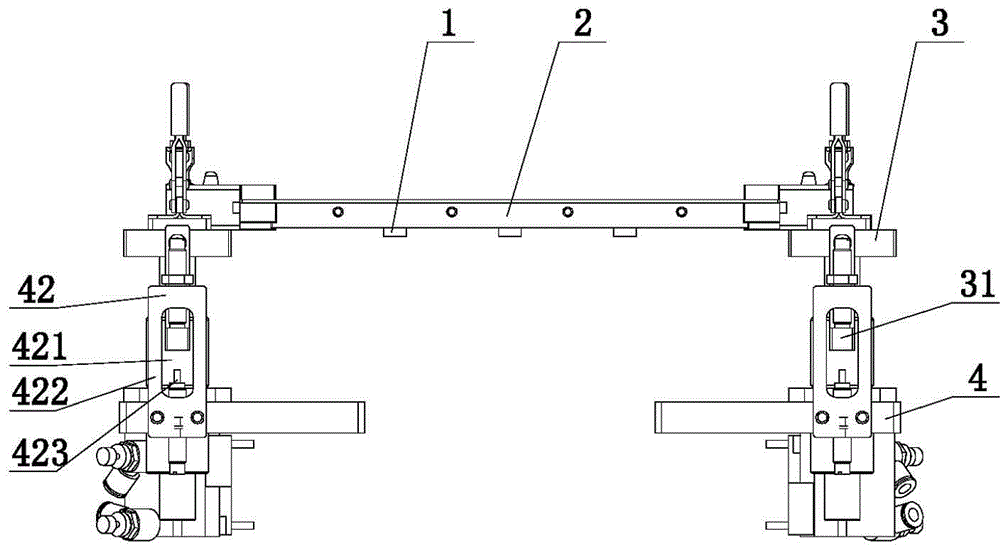

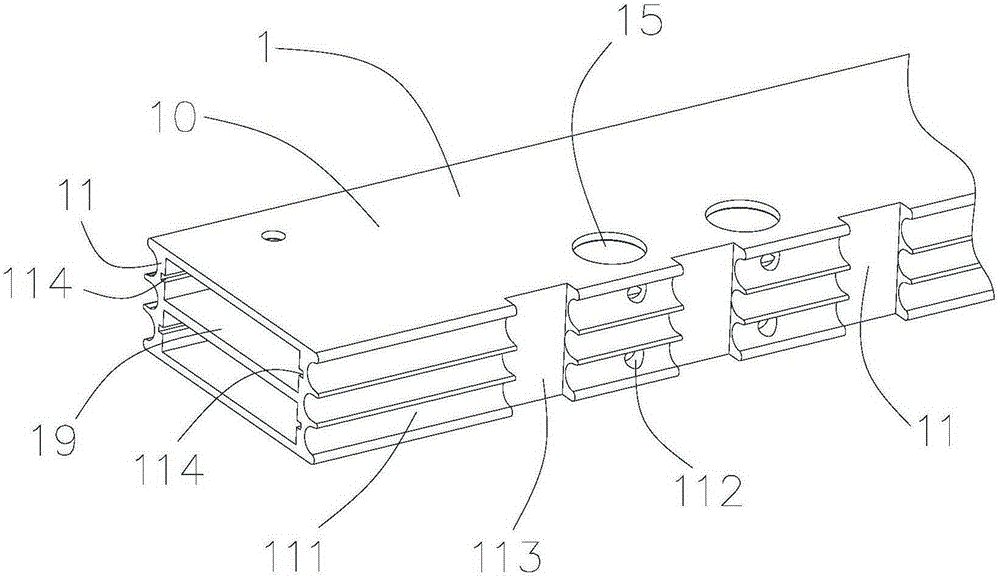

The invention provides a full-automatic laser welder comprising a laser head, a laser head servo mechanism, a feeding and discharging device, a pressing mechanism and a transmission mechanism. The pressing mechanism comprises a plurality of pressing blocks and a pressing block support, wherein each pressing block is provided with a passage for laser emitted by the laser head to pass; and the pressing block support is elastically connected with each pressing block. The transmission mechanism is connected to the pressing block support to drive the pressing block support to move vertically so as to press or separate from corresponding connecting pieces. The laser head servo mechanism can further comprise two portal frames which are bilaterally and symmetrically arranged relative to the feeding and discharging mechanism along the X-direction, and each portable frame is provided with reinforcing ribs. The transmission mechanism can comprise a pair of transmission components which is bilaterally and symmetrically arranged relative to the feeding and discharging mechanism. The full-automatic laser welder can further comprise a gas cooling mechanism, a welding positioning unit and a controller. Therefore, pressing effects of welding spots of workpieces at different heights are guaranteed, welding temperature is lowered effectively, stability of a welding process is guaranteed, and welding optimal rate and efficiency are quite high.

Owner:CONTEMPORARY AMPEREX TECH CO

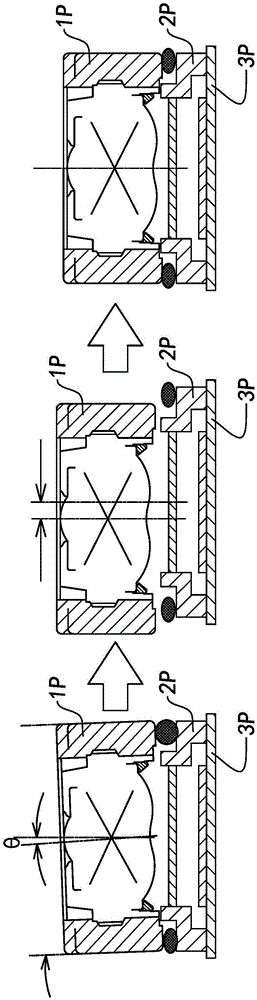

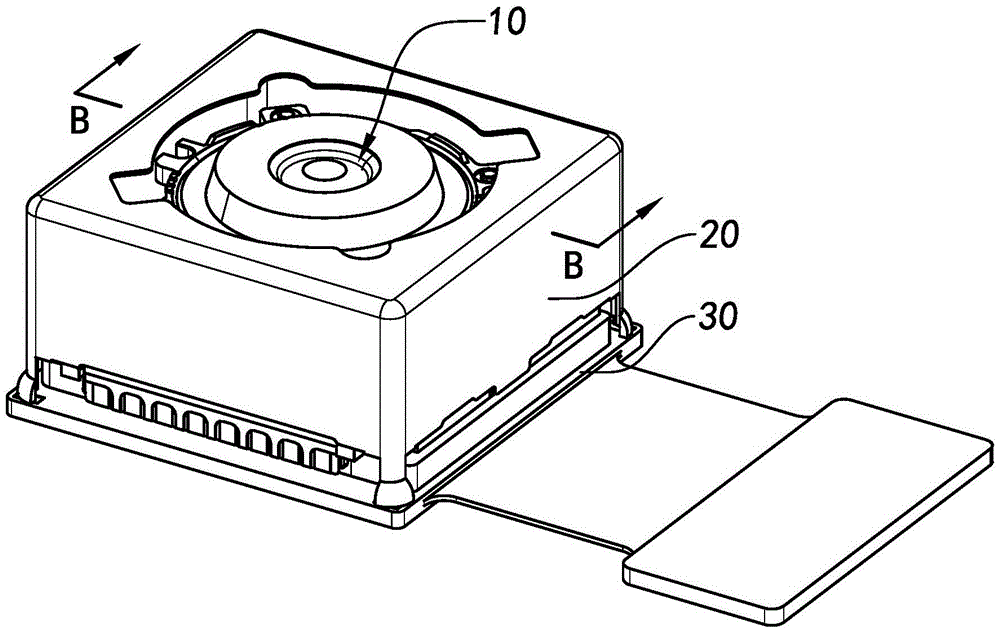

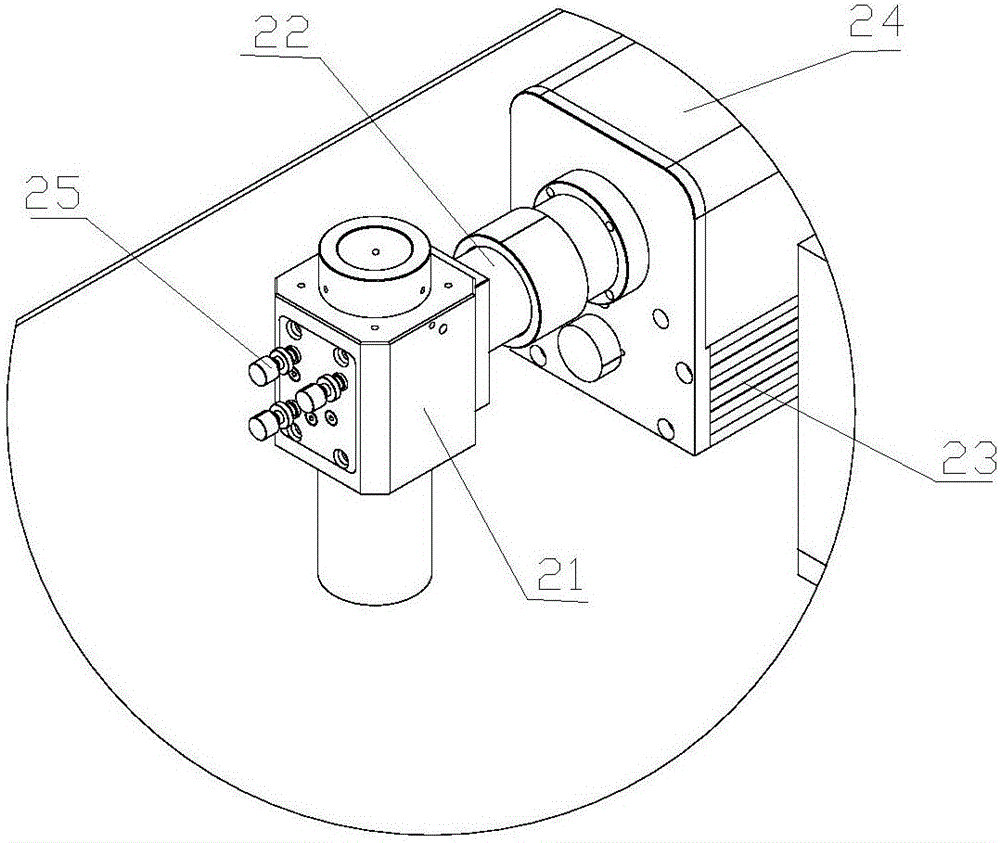

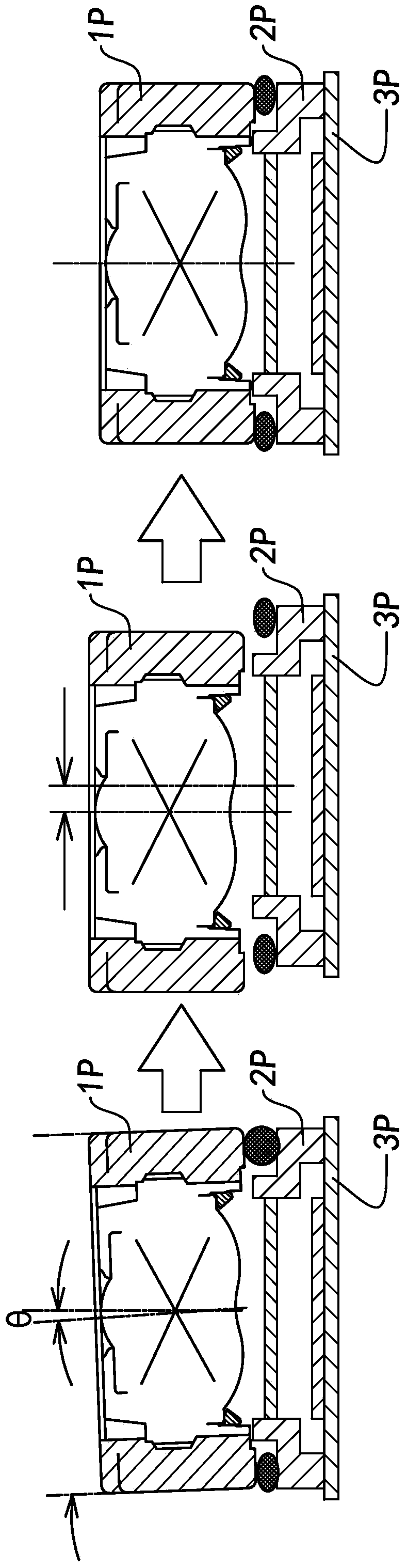

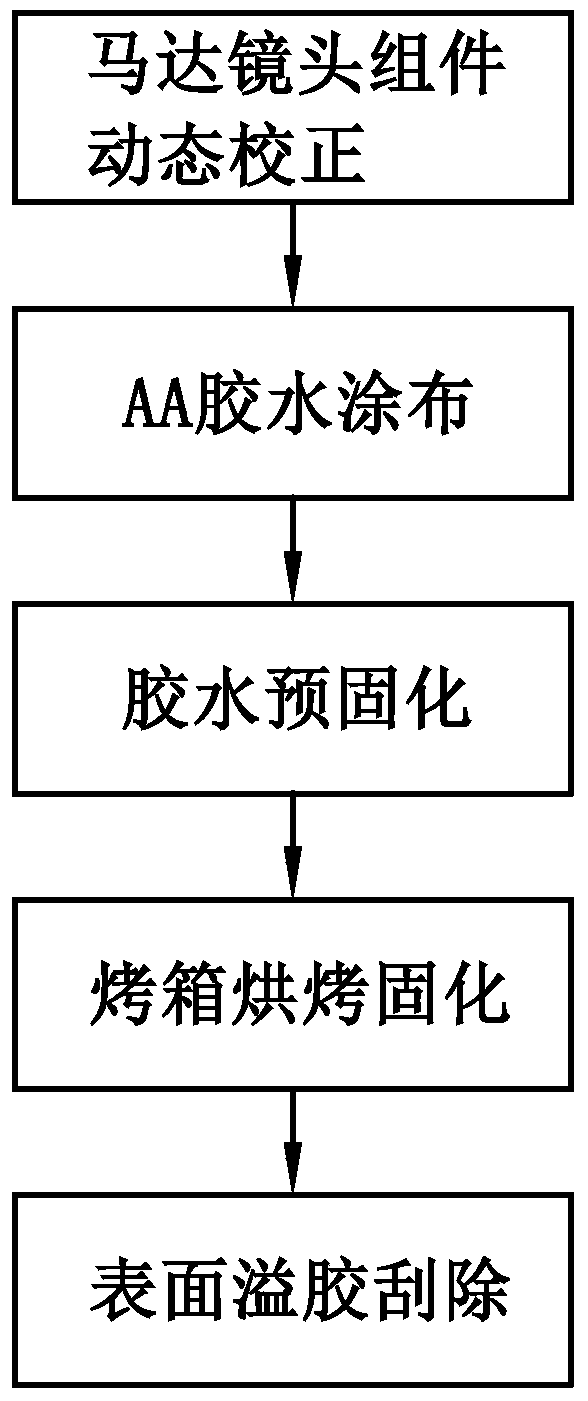

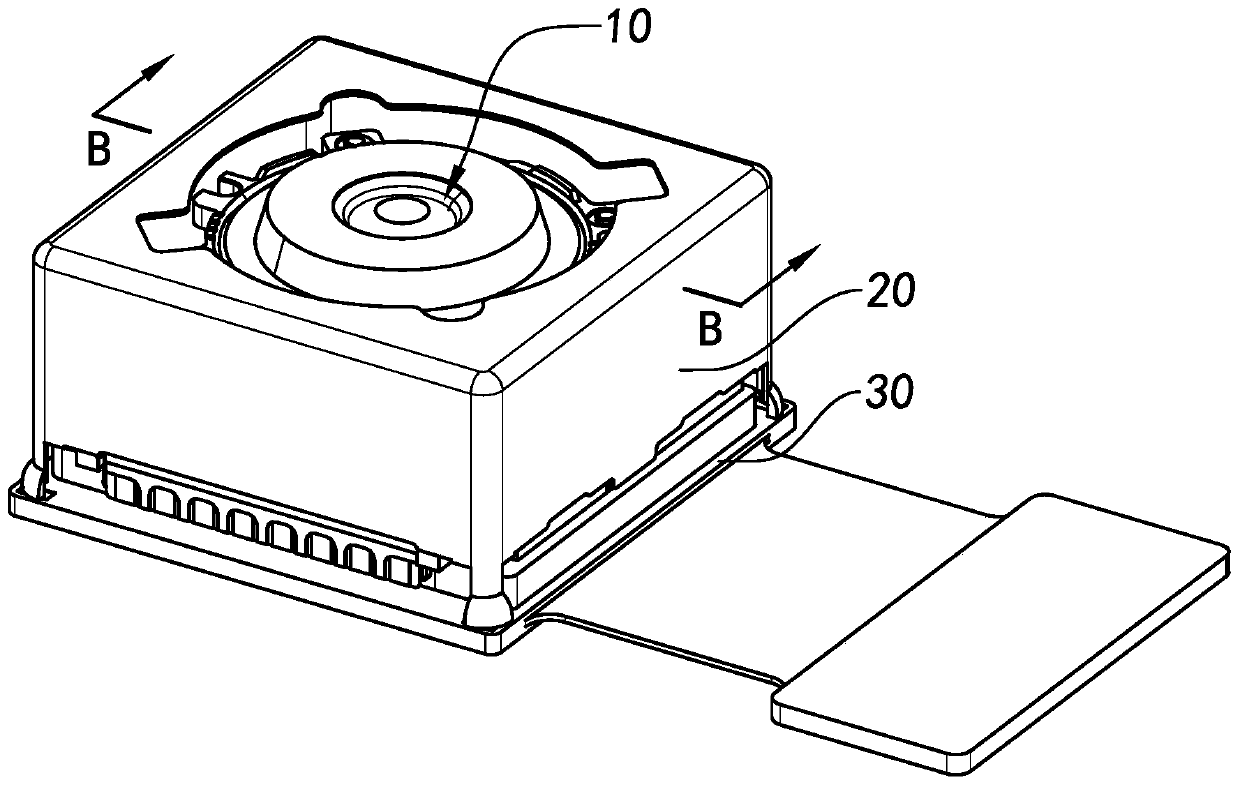

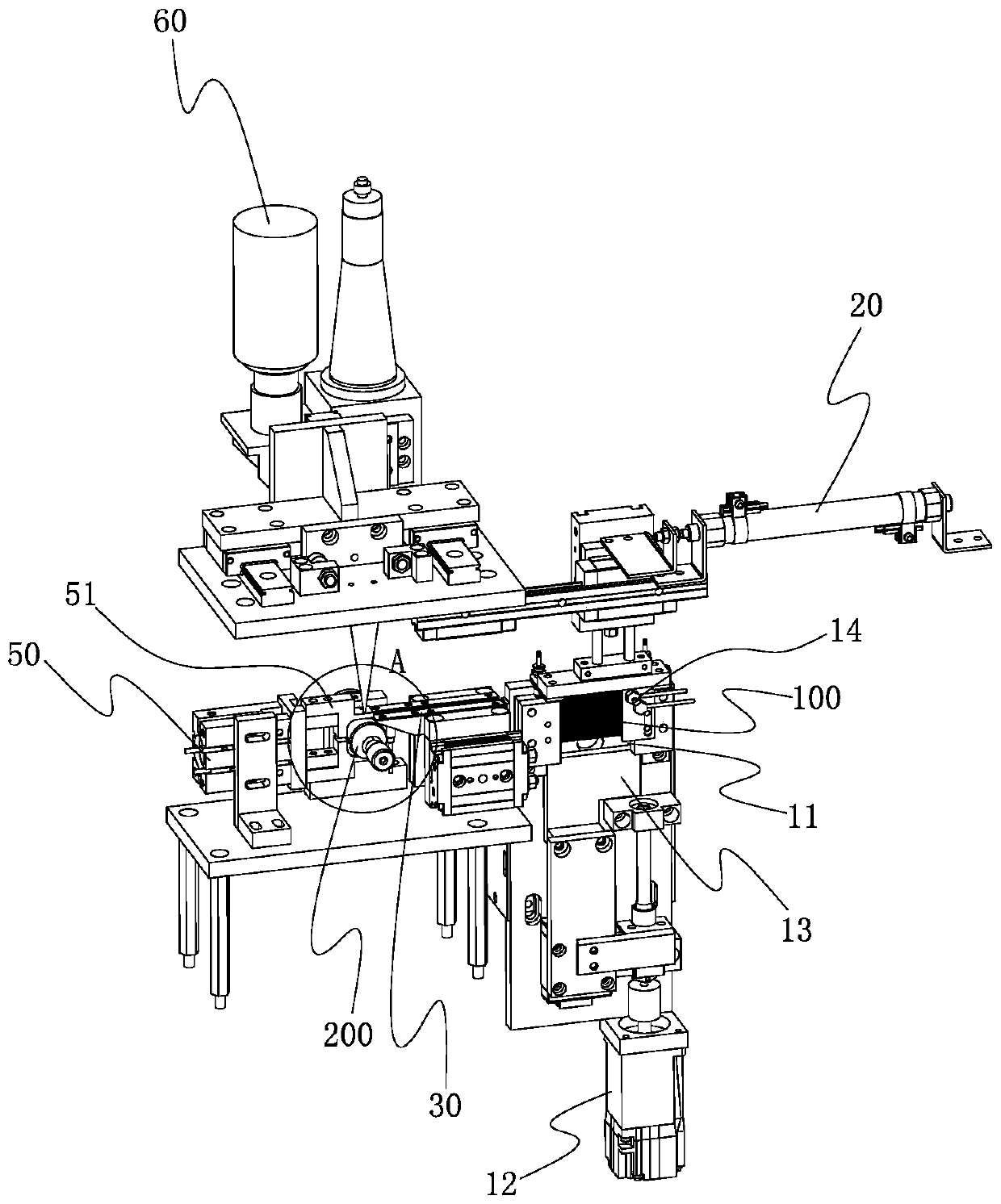

Camera module group, structure thereof, and assembly method thereof

ActiveCN106817515AImprove Design FeasibilityFast productionTelevision system detailsColor television detailsCamera moduleComputer science

The invention discloses a camera module group, a structure thereof, and an assembly method thereof. The camera module group comprises a first motor lens member and a circuit module. The motor lens member is located at a front side of the circuit module, so as to enable the light passing through the motor lens member to reach the circuit module. Moreover, the motor lens member is welded to the circuit module. The assembly method of the camera module group comprises the steps: (A), dynamically adjusting the motor lens member; (B), welding the motor lens member to the circuit module.

Owner:NINGBO SUNNY OPOTECH CO LTD

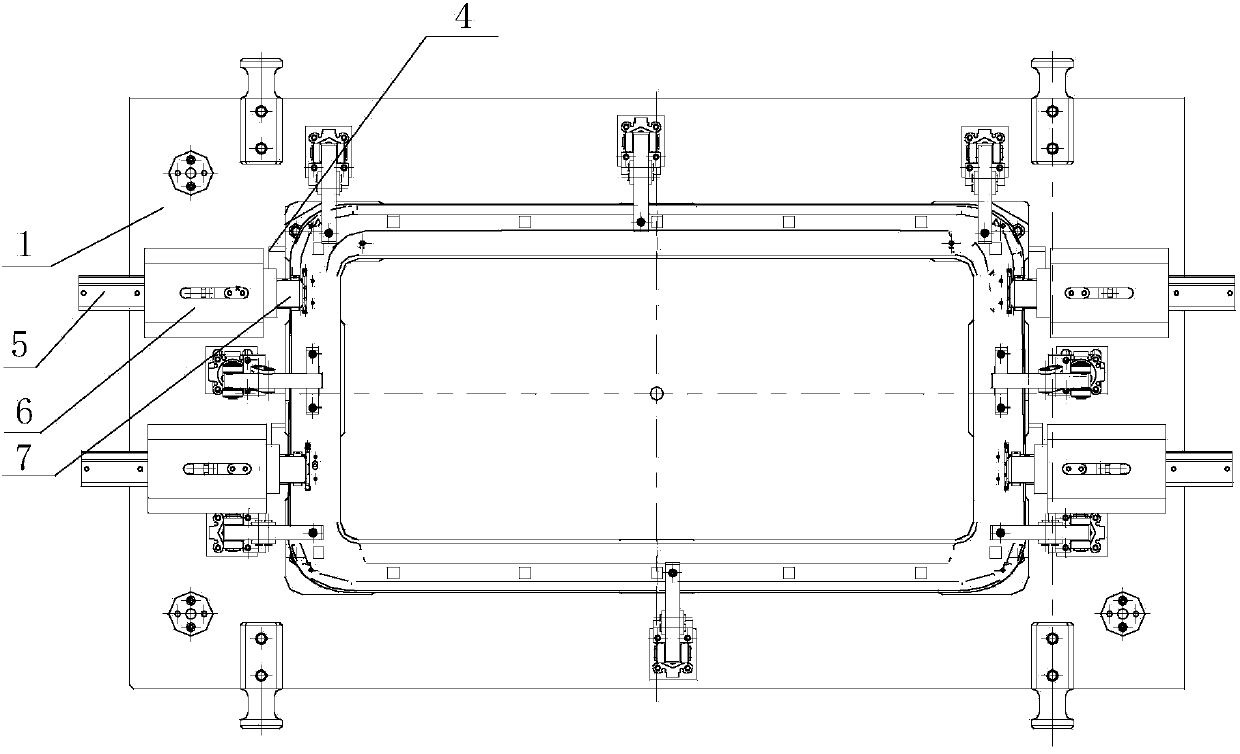

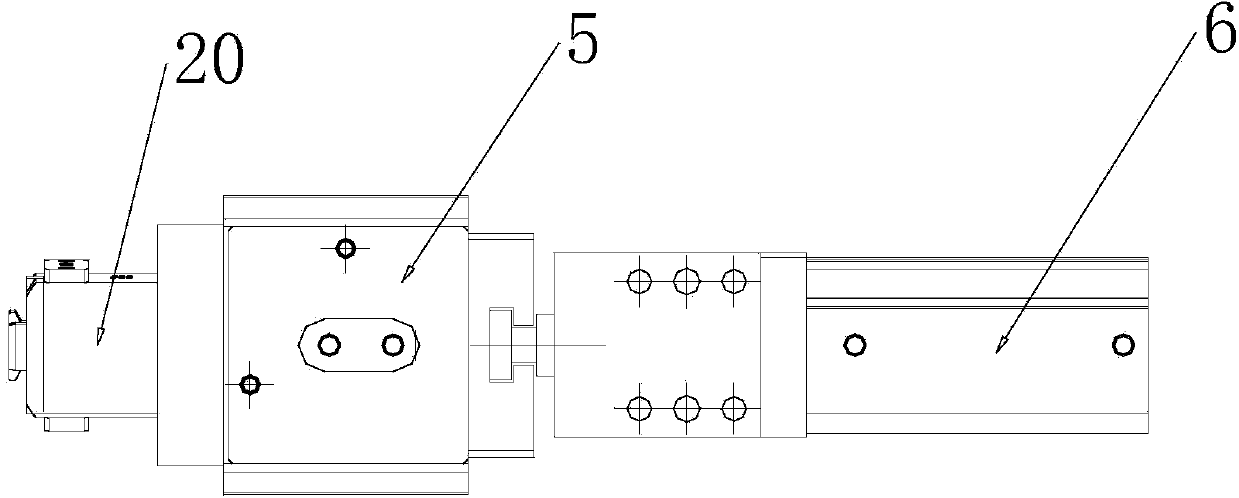

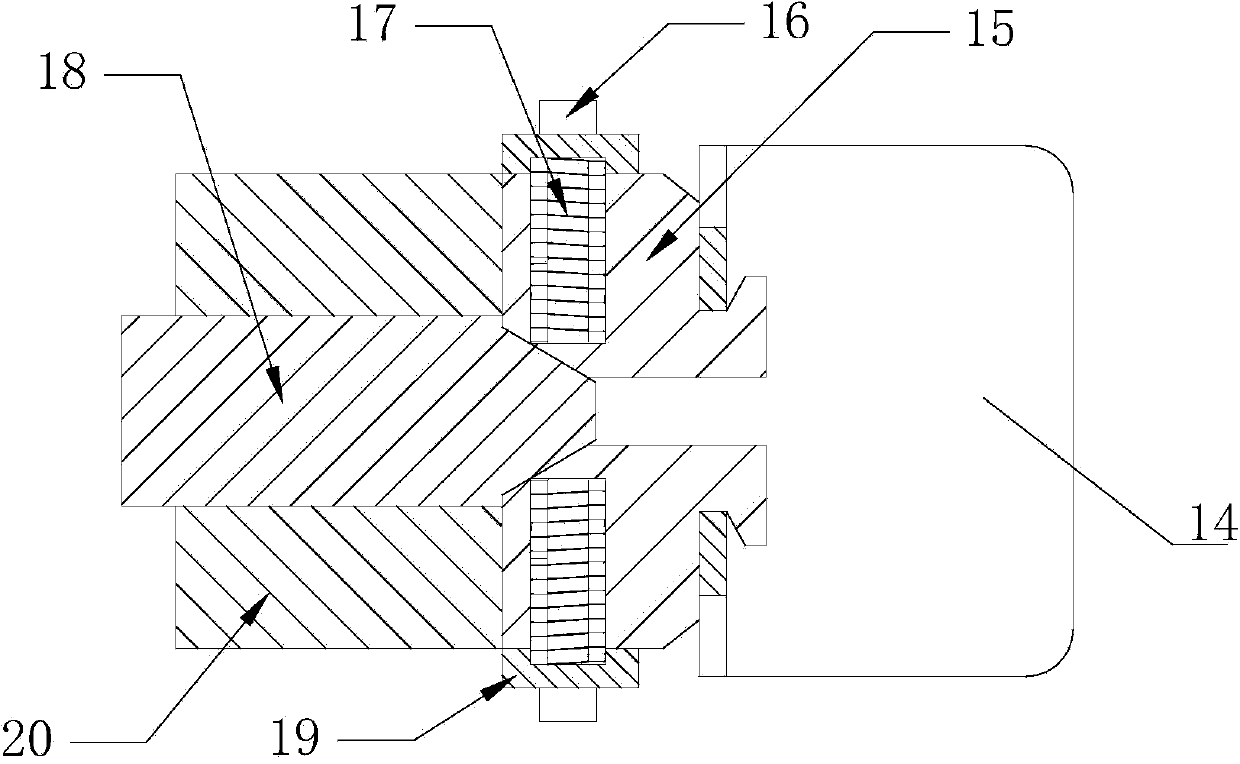

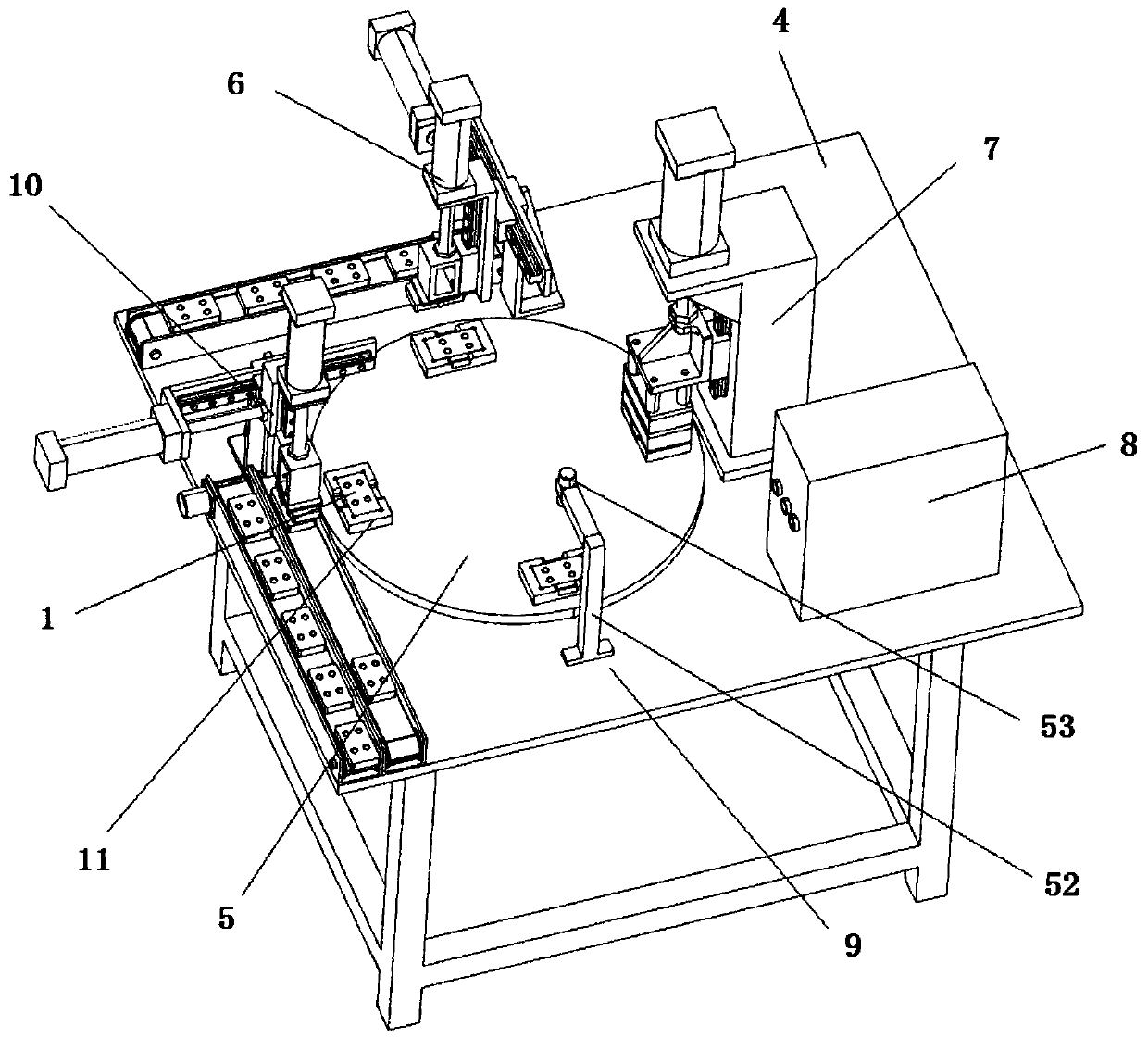

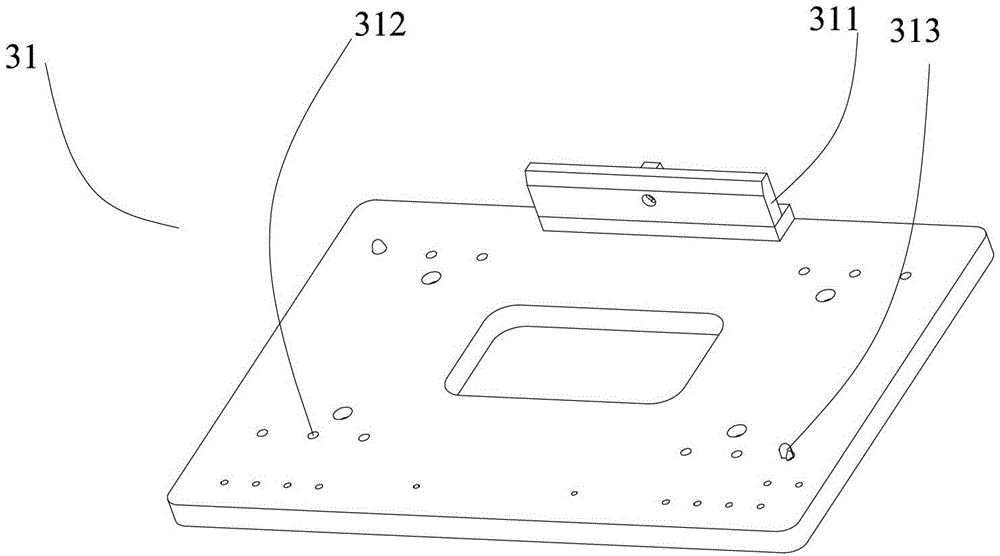

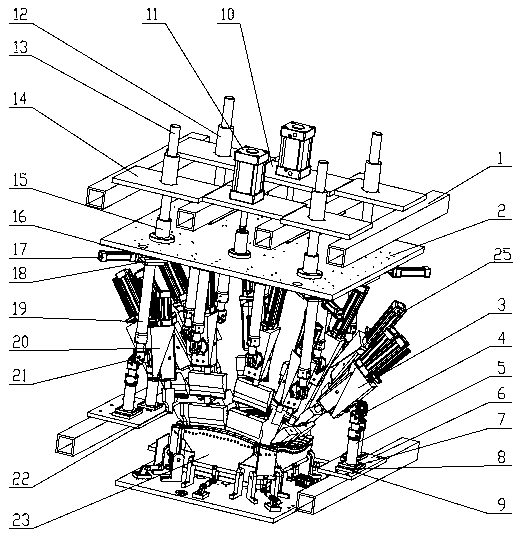

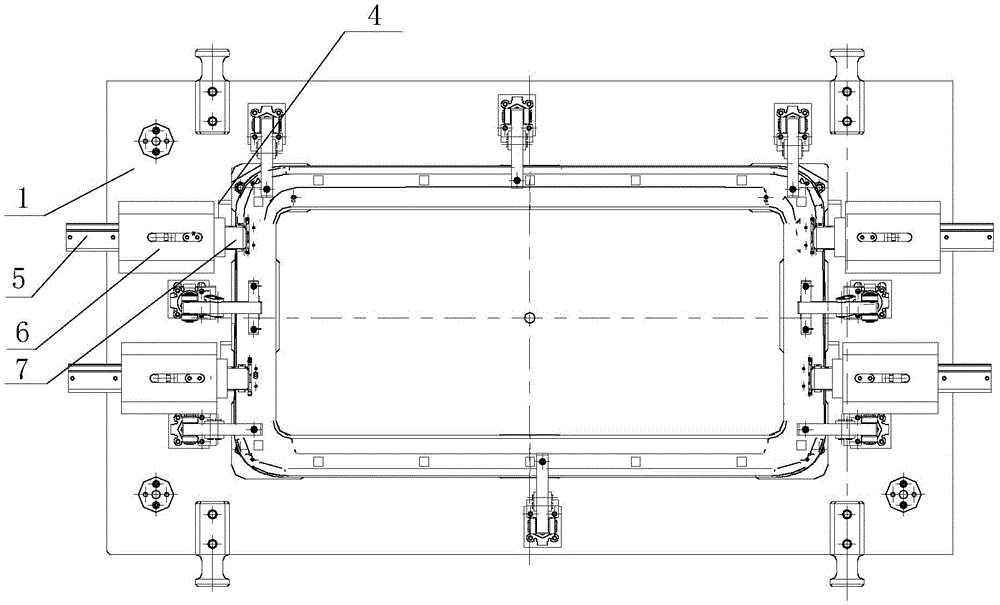

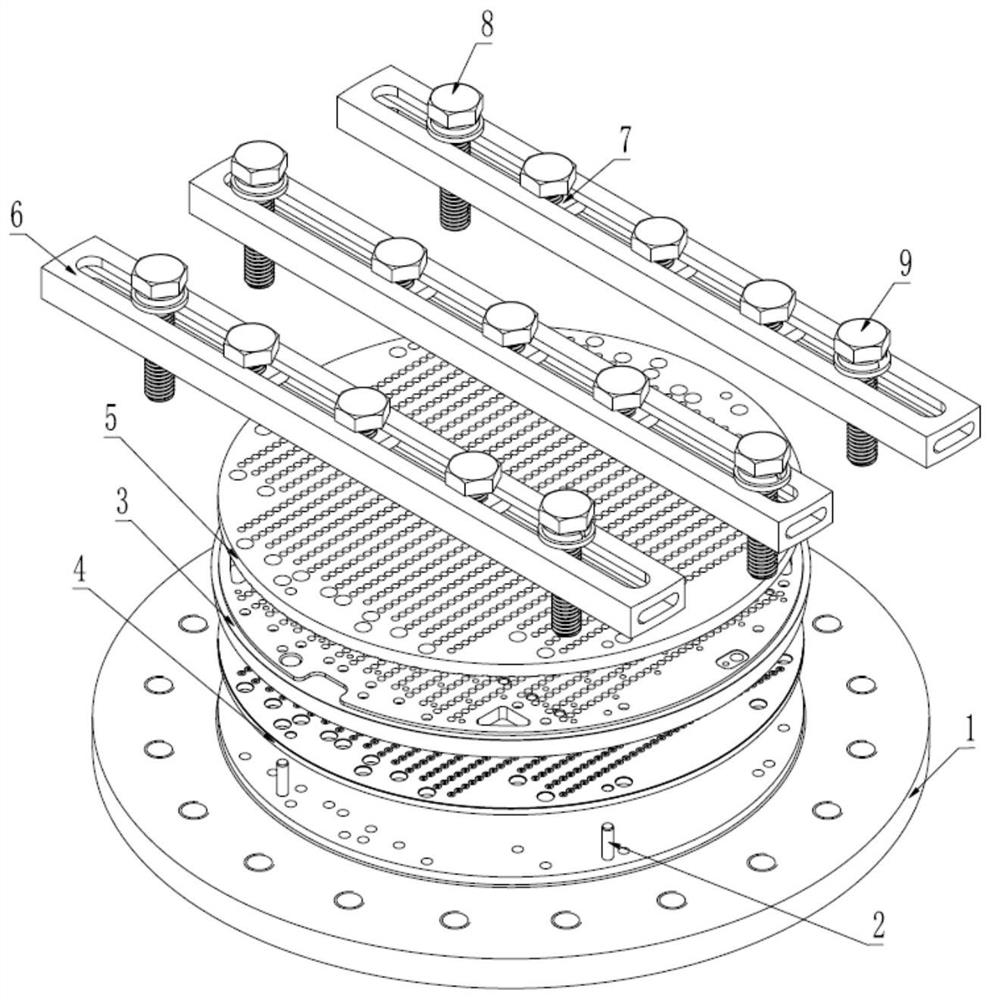

Car lock lug welding fixture

InactiveCN104191141ARealize clamping positioningSolve the positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention relates to the field of automobile manufacturing devices, in particular to a car lock lug welding fixture. By the car lock lug welding fixture, the problem that an existing lock lug welding fixture is insufficient of space for arrangement is solved. A plurality of positioning seats (4) are arranged on a rectangular welding fixture platform (1), a lug clamping unit is arranged on each positioning seat (4), each lug clamping unit comprises a lug clamping cylinder (5), a lug positioning cylinder (6) and a wedge mechanism (7), each lug positioning cylinder (6) is connected with the corresponding wedge mechanism (7) and drives the same to move horizontally, and wedges (18) can be driven to move by being connected with the corresponding lug clamping cylinders (5). The car lock lug welding fixture is used for welding automotive lugs.

Owner:HARBIN INST OF TECH

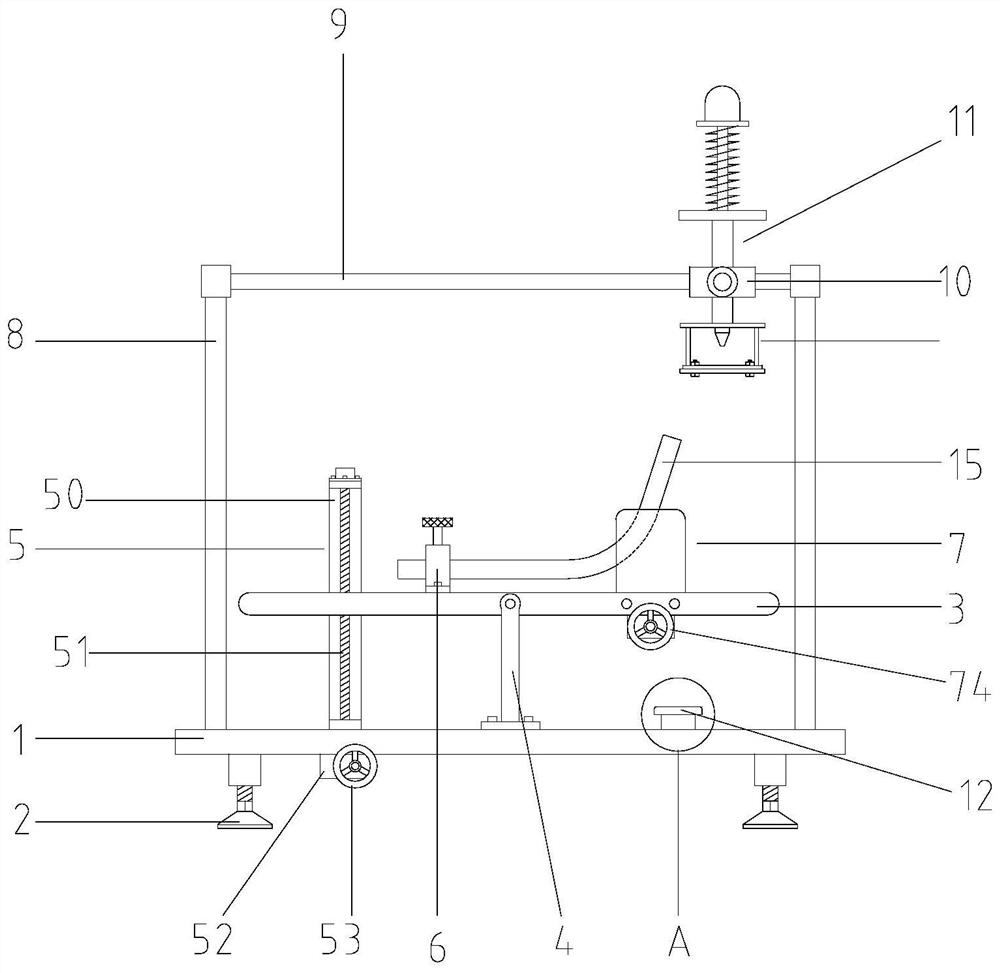

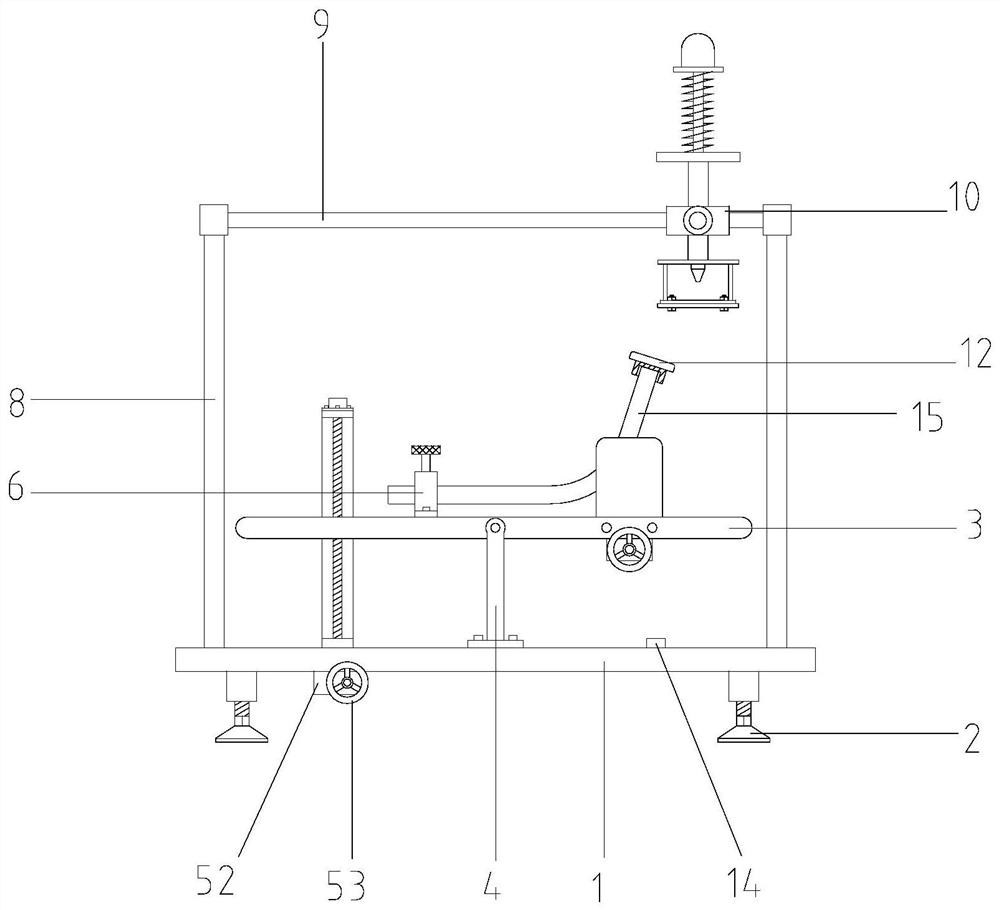

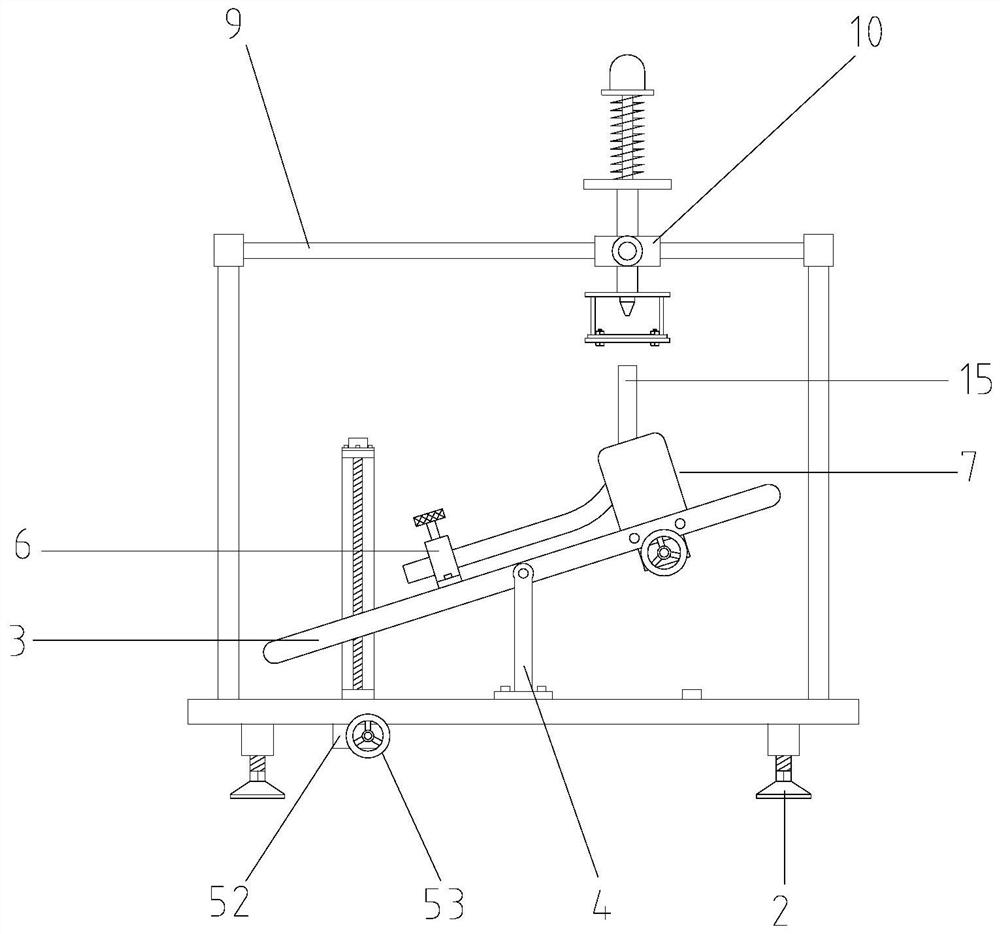

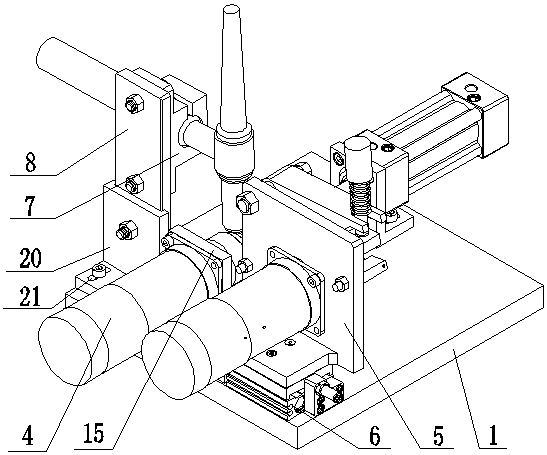

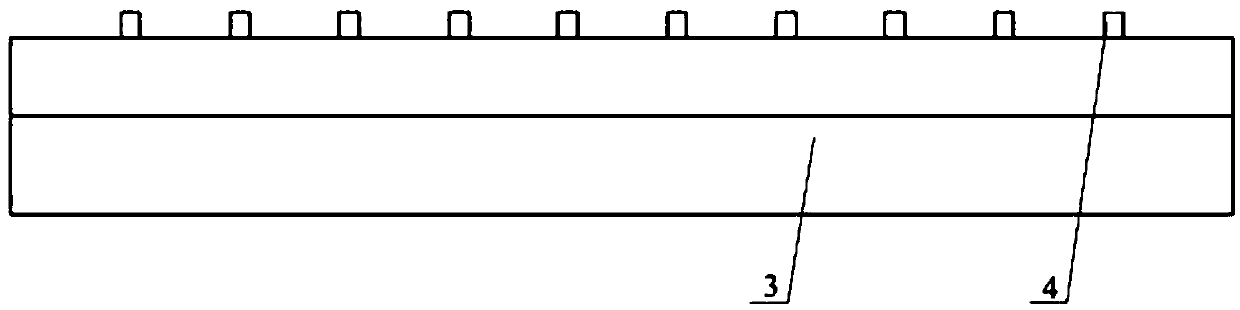

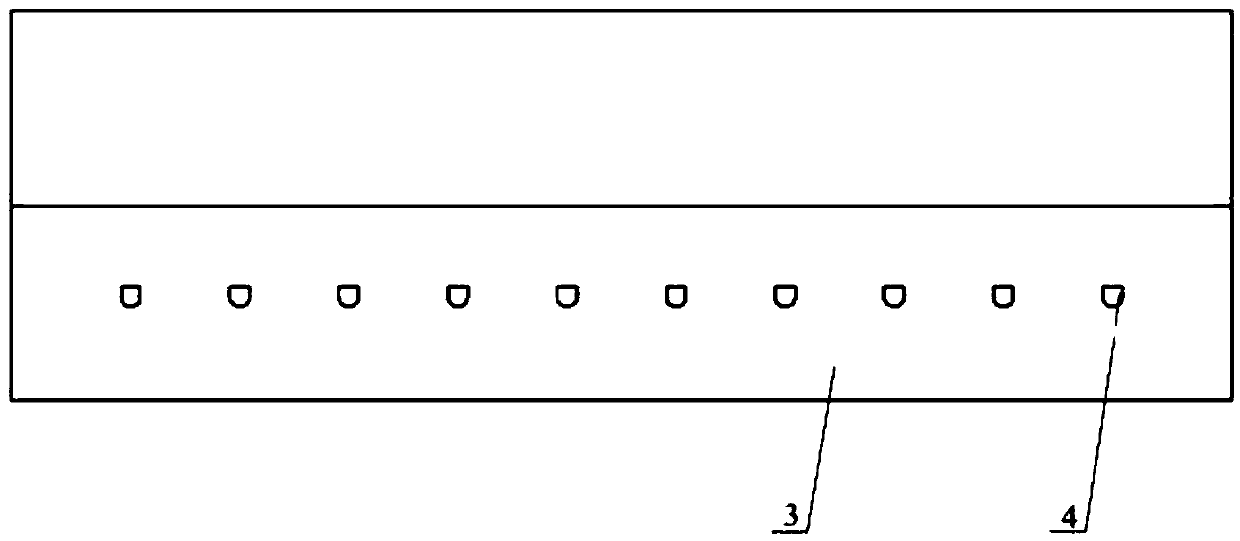

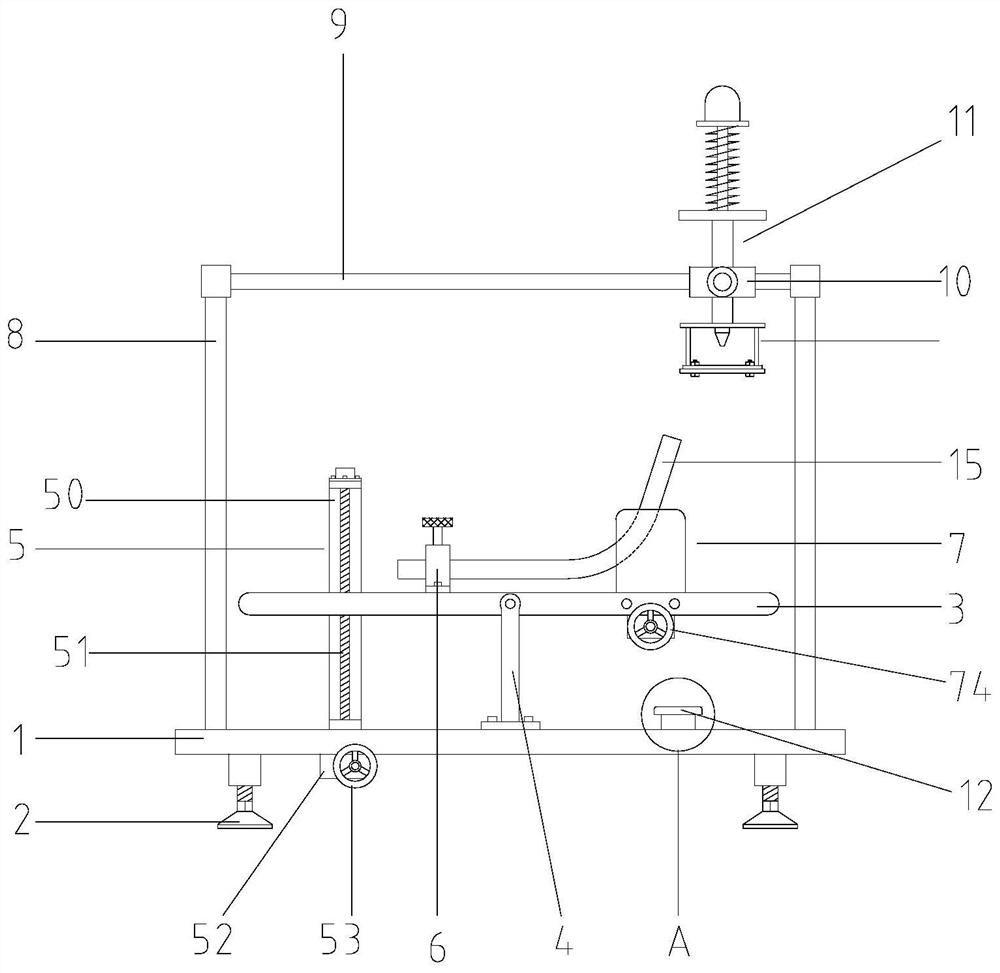

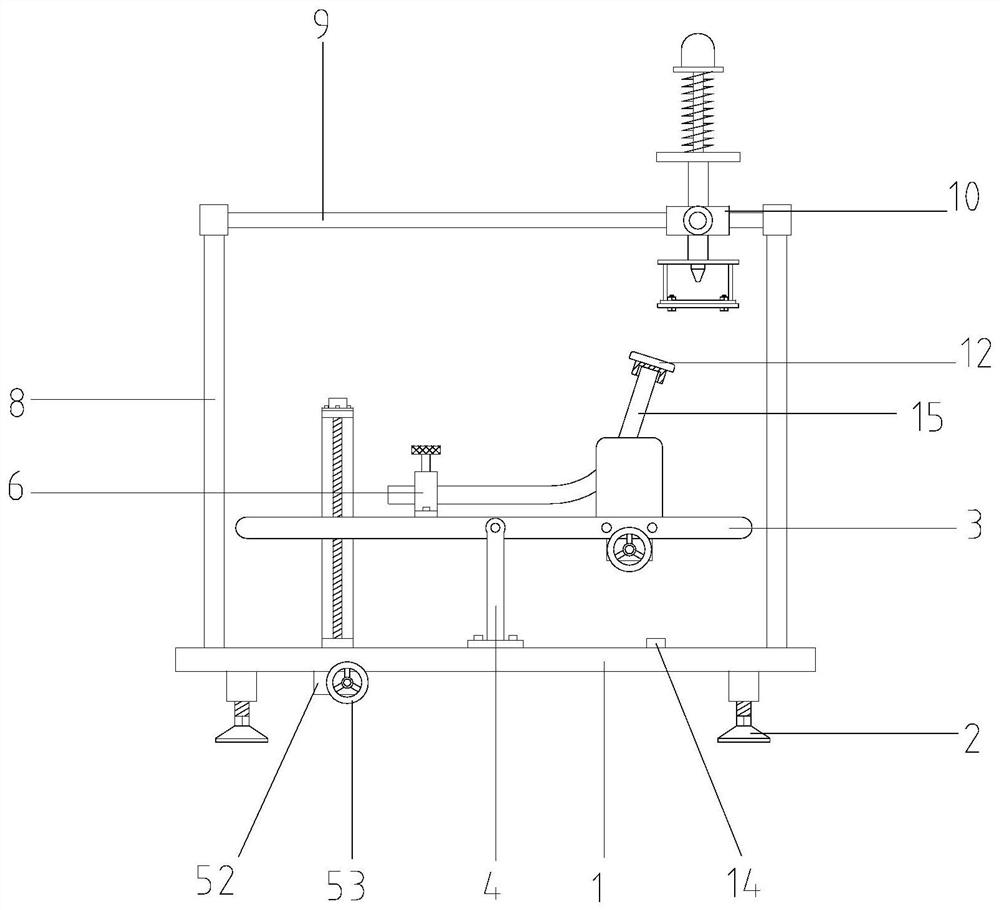

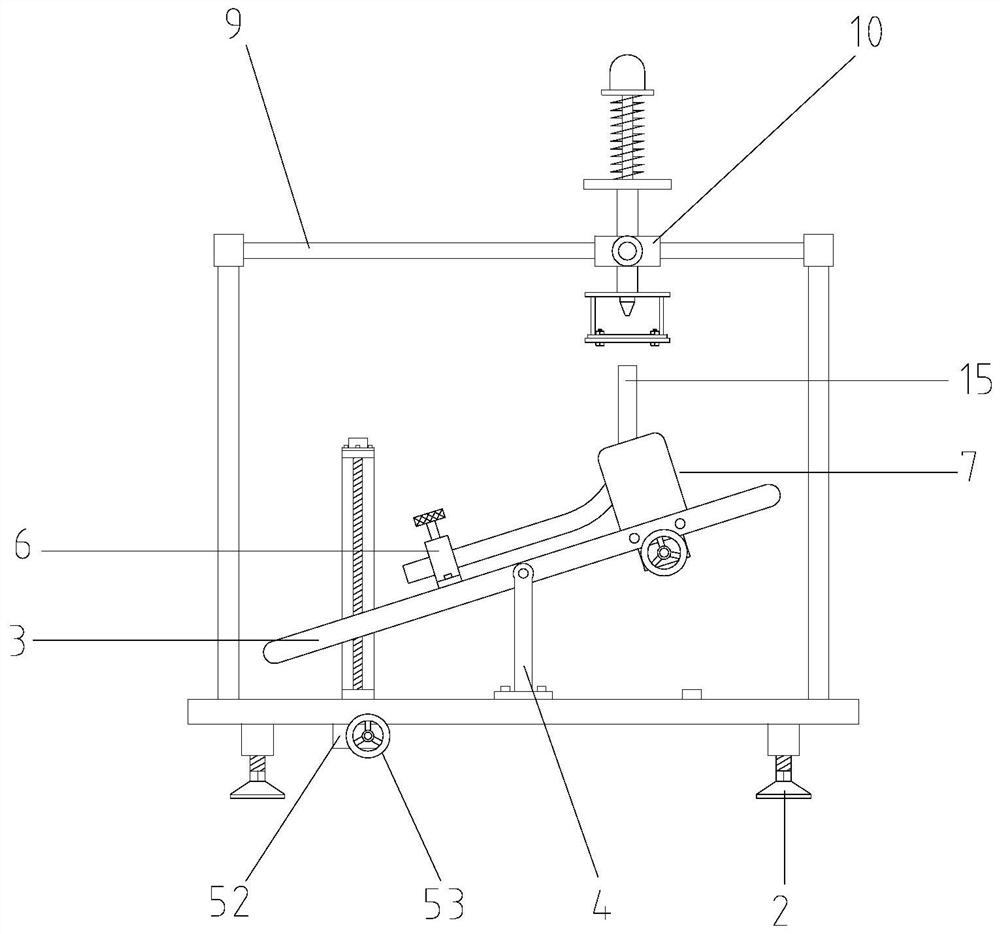

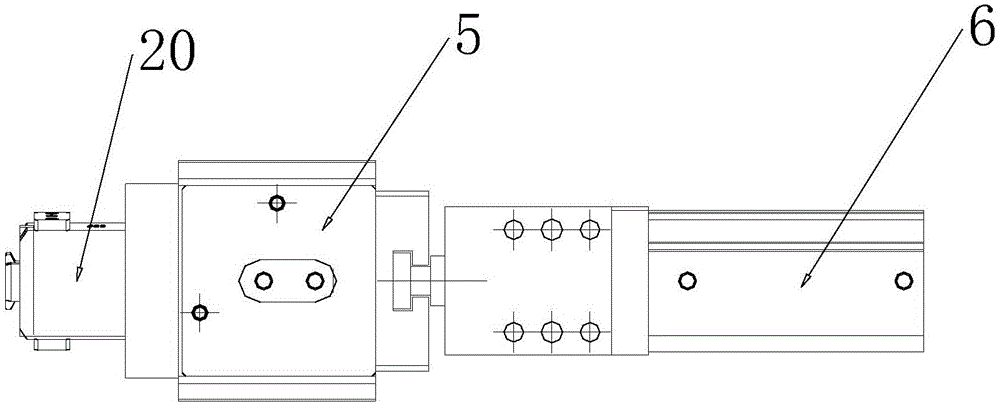

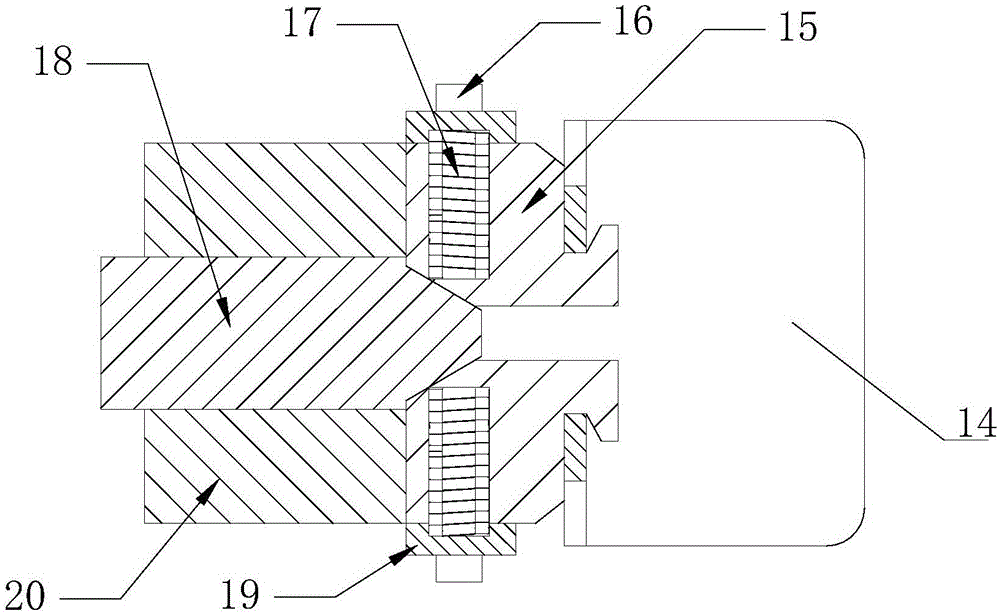

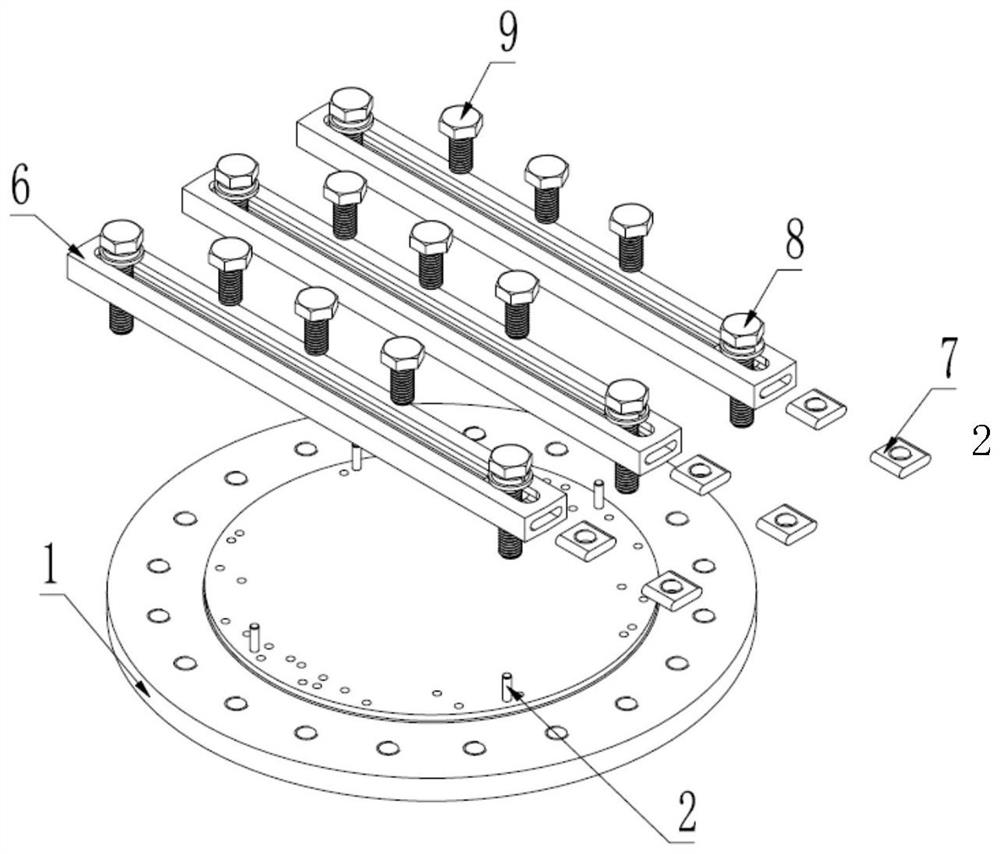

Non-standard bent pipe and flange welding positioning tool

ActiveCN112077509AGood welding consistencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsFlange

The invention relates to the technical field of tool clamps, and discloses a non-standard bent pipe and flange welding positioning tool. The non-standard bent pipe and flange welding positioning toolcomprises a bottom plate, wherein a plurality of height-adjustable supporting legs are arranged at the bottom of the bottom plate, a bent pipe positioning plate distributed in parallel is arranged above the top face of the bottom plate, supporting columns are arranged at the two sides of the middle of the bent pipe positioning plate, and the lower ends of the supporting columns are fixedly connected with the bottom plate. The upper ends of the supporting columns are rotationally connected with the bent pipe positioning plate, an angle adjusting mechanism used for adjusting the angle of the bent pipe positioning plate is arranged between the left end of the bent pipe positioning plate and the bottom plate, and a bent pipe clamping mechanism and a bent pipe centering mechanism are arranged on the bent pipe positioning plate. Supports are arranged at the two ends of the bottom plate, sliding rods parallel to the bottom plate are arranged between the upper ends of the supports, a sliding base is arranged between the sliding rods, and a flange positioning adjusting mechanism is arranged on the sliding base; and a level gauge is further arranged on the bottom plate. According to the non-standard bent pipe and flange welding positioning tool, the high-precision positioning of a flange and a bent pipe can be achieved, it is guaranteed that the welding consistency of the flange and thebent pipe is good, and the welding quality is high.

Owner:QUZHOU COLLEGE OF TECH

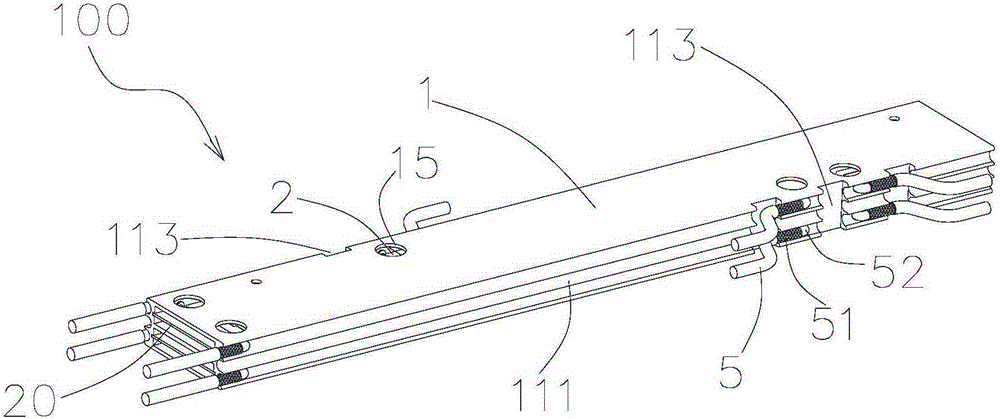

Elastic press-holding mechanism

ActiveCN105665867ASimple structureImprove job stabilitySoldering auxillary devicesEngineeringSolar cell

The invention belongs to the field of production equipment for solar cell modules, and particularly relates to an elastic press-holding mechanism of a welding workstation of a solar cell piece infrared welding machine. The elastic press-holding mechanism provided by the invention is compact in structure, high in strength, gentle in acting force and long in service life and comprises an installation support provided with elastic pressing pins. The elastic press-holding mechanism is characterized in that lifting bases are arranged at the two ends of the installation support correspondingly, and the two lifting bases are connected with a lifting driving device.

Owner:YINGKOU JINCHEN MACHINERY

Cavity of microwave communication device and microwave communication device

ActiveCN105244566APrecise positioningEasy to weldWaveguide type devicesMicrowaveElectrical conductor

The invention discloses a cavity of a microwave communication device. At least one of two transverse ends of the cavity is open; the cavity comprises a bottom wall, a pair of side walls extending upwards on two sides in the longitudinal direction of the bottom wall and a top wall spanning the pair of side walls; the top wall, the bottom wall and the pair of side walls jointly define a cavity for accommodating a microwave communication circuit and a medium; a wiring groove for paving an outer conductor of a cable therein is formed in at least one side wall, a yielding hole which penetrates through the side wall of the cavity and allows an inner conductor of the cable and the medium to pass is formed in the wiring groove, and the cavity is provided with a heat resistant slot for cutting off the wiring groove in at least one of the left and right sides of the yielding hole. The cavity facilitates positioning and welding of the cable, and ensures high welding quality and good consistency. The invention further discloses a microwave communication device adopting the cavity.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

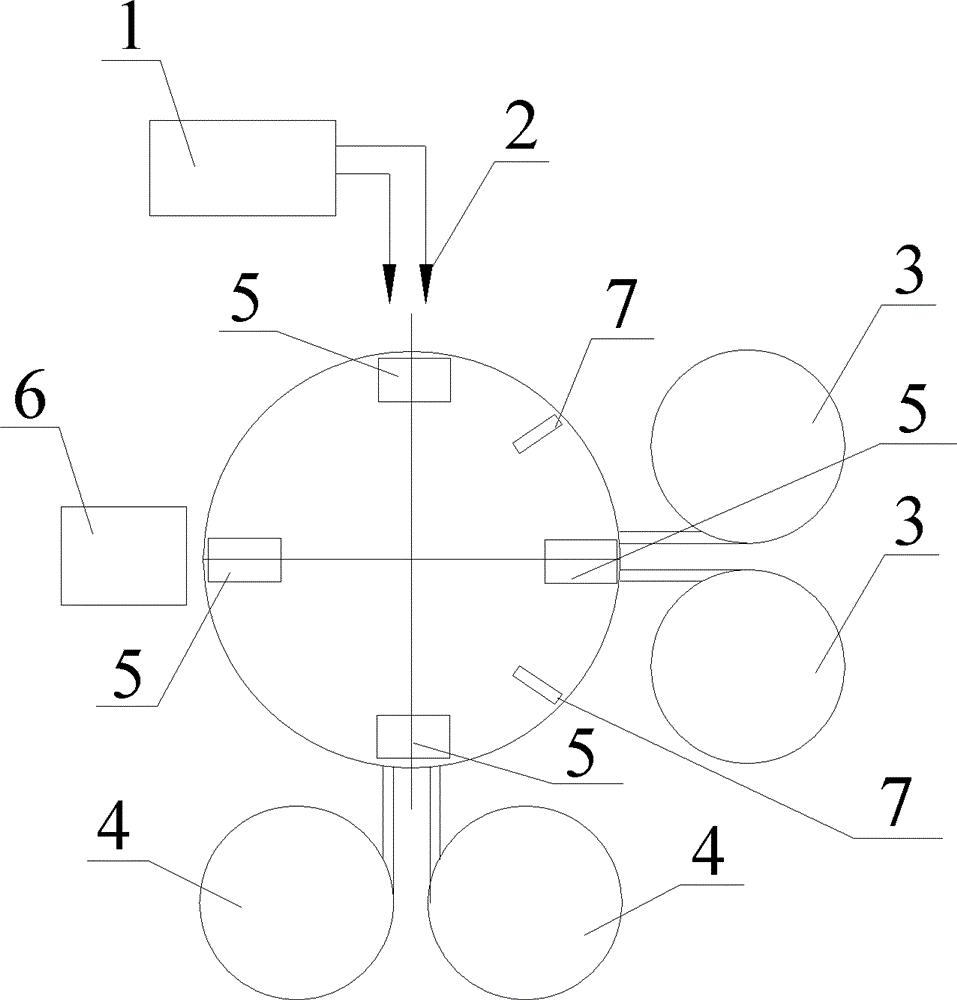

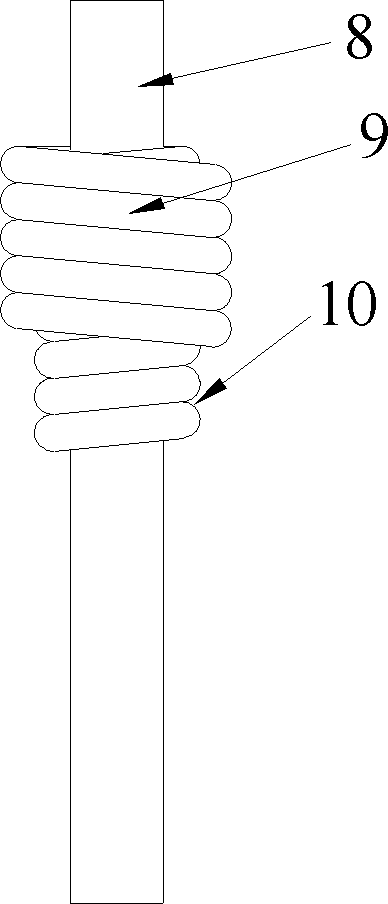

Method and device for soldering tin by induction heating of magnetism collecting rod

PendingCN110039142AGood welding consistencyIncrease productivitySoldering apparatusMetal working apparatusHigh frequency powerEngineering

The invention relates to a method and device for soldering tin by induction heating of a magnetism collecting rod, and relates to the field of electronic appliances and electromechanical industries which requires a soldering technology. The defects of a conventional technology using soldering iron for soldering tin are overcome, a high-frequency power supply is adopted to provide a high-frequencyworking power supply for an induction coil to generate a high-frequency alternating magnetic field inside the induction coil, the magnetism collecting rod is used to transfer energy of the high-frequency alternating magnetic field inside the induction coil to a soldering position and a soldered tin wire, and with the adoption of an electromagnetic principle, heat energy generated by eddy current formed on the metal surface by magnetic lines is used to weld. Compared with the prior art, the method and the device have the following advantages that 1, the welding consistency is better; 2, the production efficiency is improved; 3, energy is transferred in a more concentrated manner; 4, more energy is saved; and 5, a high-frequency welding process has no consumables, but soldering with a soldering bit needs to frequently replace a soldering iron nozzle, so that the production cost is reduced more with the high-frequency welding process.

Owner:深圳市双建科技有限公司

Flange automatic welding device of transformer oil conservator

ActiveCN103286424AReduce labor intensityEnsure uniformityWelding/cutting auxillary devicesElectrode supporting devicesTransformer oilIndustrial engineering

Owner:SHENDA ELECTRIC GROUP

Full-automatic welding device of magnetic inductor

PendingCN111361162ARealize automatic feeding processRealize automatic weldingSortingControl engineeringInductor

The invention relates to a full-automatic welding device of a magnetic inductor. The full-automatic welding device comprises a rack, wherein a rotary positioning disc, an automatic feeding mechanism,an automatic welding mechanism, a workbin control mechanism, an automatic detecting mechanism and an automatic discharging mechanism are arranged on the rack; the automatic feeding mechanism, the automatic welding mechanism, the automatic detecting mechanism and the automatic discharging mechanism are sequentially arranged around the rotary positioning disc; and workpiece positioning clamps in one-to-one correspondence with the automatic feeding mechanism, the automatic welding mechanism, the automatic detecting mechanism and the automatic discharging mechanism are arranged on the rotary positioning disc. The workpiece positioning clamps on the rotary positioning disc as processing stations to be in one-to-one correspondence with the automatic feeding mechanism, the automatic welding mechanism, the automatic detecting mechanism and the automatic discharging mechanism are utilized, so that the full-automatic welding device realizes unified and continuous operation of automatic feeding,automatic welding, automatic detection and automatic discharging, realizes replacement of manual operation through full automation, and greatly improves the assembling efficiency.

Owner:HUIZHOU JIAHONGCHANG MAGNET PROD

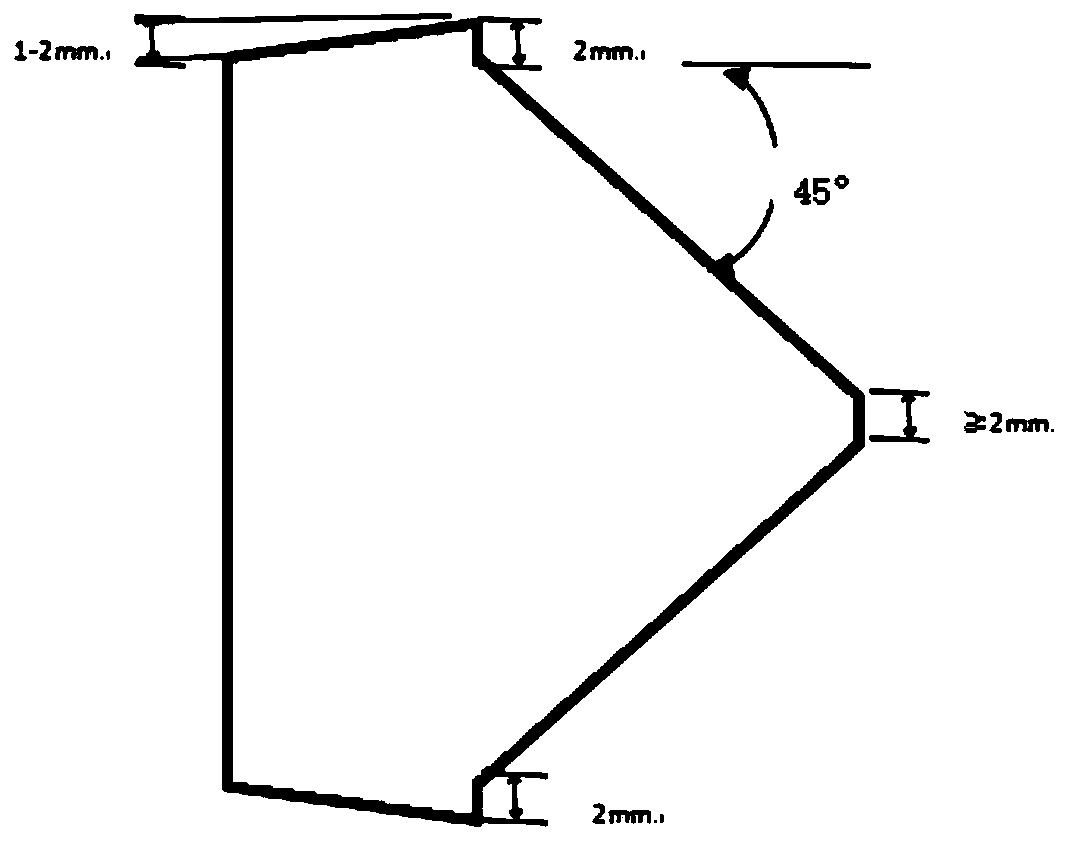

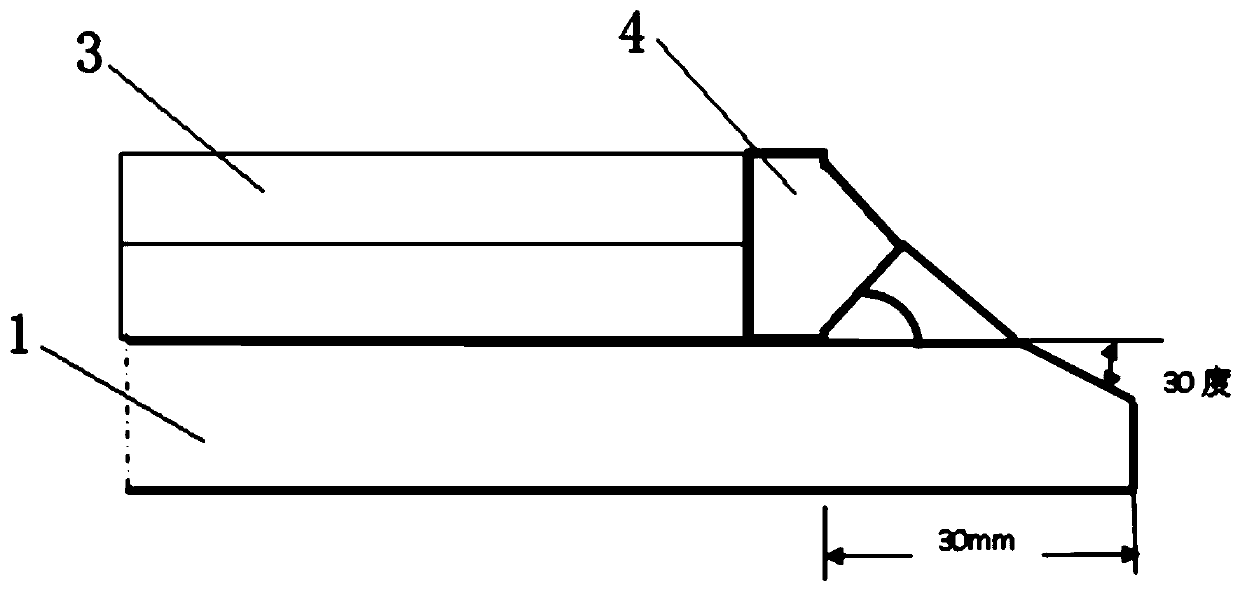

Symmetrical-hot-rolled composite plate blank and seal welding method thereof

ActiveCN111299974ALower manufacturing requirementsReduce manufacturing difficultyLayered productsArc welding apparatusIsosceles trapezoidStructural engineering

The invention relates to a symmetrical-hot-rolled composite plate blank and a seal welding method thereof. An enclosure frame comprises two parts, the first part forms the inner side of the enclosureframe, and the cross section of the first part is an isosceles trapezoid; the second part forms the outer side of the enclosure frame, the cross section of the second part is trapezoidal, and the length of the lower bottom edge of the second part is smaller than the length of the lower bottom edge of the first part; a groove is formed in the side, close to the enclosure frame, of the end of an upper base material; a special groove structure is formed through the innovative enclosure frame structure design, and the seal welding process is innovatively divided into two welding process flows; automatic welding equipment such as an arc welding robot or a special machine is adopted, and laser weld joint tracking and self-adaptive welding equipment is configured; a horizontal position welding mode is adopted, a high-penetration welding process is adopted for a root welding bead, and a high-deposition-rate welding process is adopted for a filling welding bead; and compared with the prior art,high-quality, high-efficiency and low-cost seal welding is realized through unique methods such as enclosure frame structure design, groove structure design, two-step welding process flow, welding process optimization and automatic welding equipment.

Owner:科斯焊接技术(无锡)有限公司

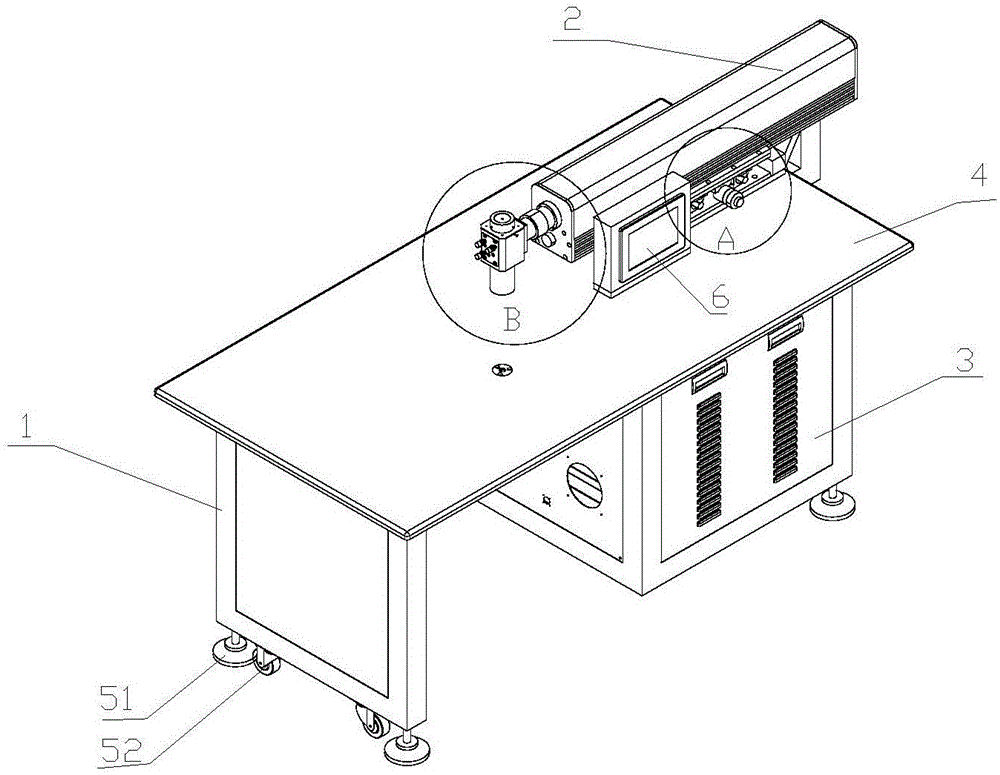

Integrated type laser welding machine

InactiveCN106735896ASimple structureIngenious designLaser beam welding apparatusIntegrated designEngineering

The invention discloses an integrated type laser welding machine comprising an integrated machine frame, a laser welding device, a machine cabinet and a work panel. The laser welding device is connected to the top end of the integrated machine frame through a movement adjusting device. The machine cabinet is fixedly installed at the lower end of the integrated machine frame in an embedded manner. The work panel is fixedly connected to the middle portion of the integrated machine frame. A control unit is arranged in the machine cabinet and connected with a monitoring display terminal. The monitoring display terminal is fixedly arranged at the top end of the integrated machine frame. The laser welding device comprises a laser device, a transmitting optical fiber, a focus lens and a laser head, wherein the laser device, the transmitting optical fiber, the focus lens and the laser head are sequentially connected. According to the integrated type laser welding machine, the overall stability of the welding device is greatly improved in the welding process through integrated design, the welding efficiency and the quality of products are improved, the rejection ratio of the products is lowered, and the production cost is reduced.

Owner:深圳市耐恩科技有限公司

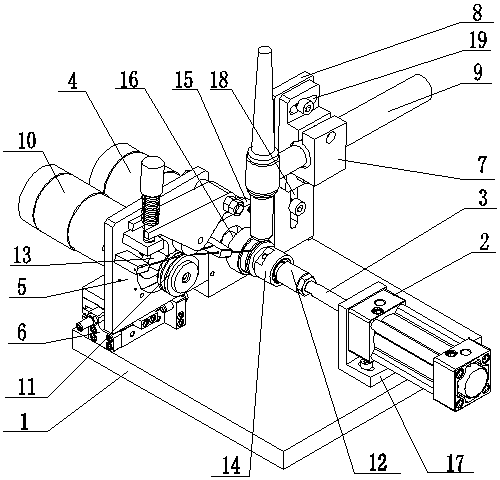

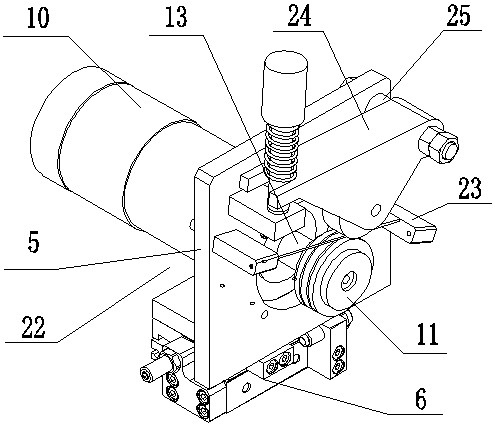

Rotary body part automatic argon arc welding device

ActiveCN108274098AGood welding consistencyEasy to controlWelding accessoriesElectric controlAir cylinder Press

The invention discloses a rotary body part automatic argon arc welding device. The welding device is composed of a mechanical part, an electric control part and a pneumatic control part, and mainly comprises an electrode holder, an electrode holder clamp, a wire feeder, a rotary servo motor, a wire feeding servo motor, a telescopic air cylinder, a sliding table air cylinder and the like. During work, the telescopic air cylinder presses and positions a workpiece needing to be welded, then an argon switch works, the sliding table air cylinder moves forwards to enable a welding wire and the workpiece to be welded, meanwhile, the rotary servo motor and the wire feeding servo motor rotate synchronously, after the rotary servo motor rotates by one circle, the sliding table air cylinder retracts,argon supply is stopped, and welding is completed. The welding device is accurate in control and high in automation degree, and can meet requirements of different welding beads.

Owner:JILIN TEACHERS INST OF ENG & TECH

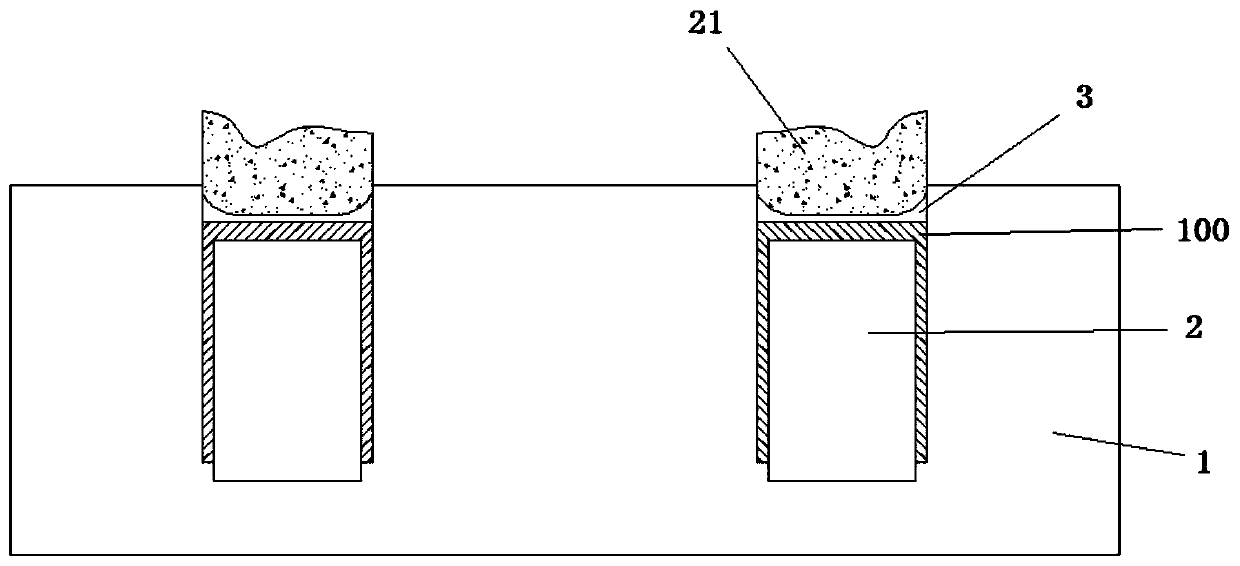

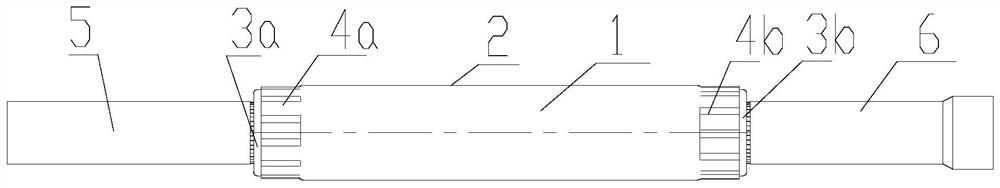

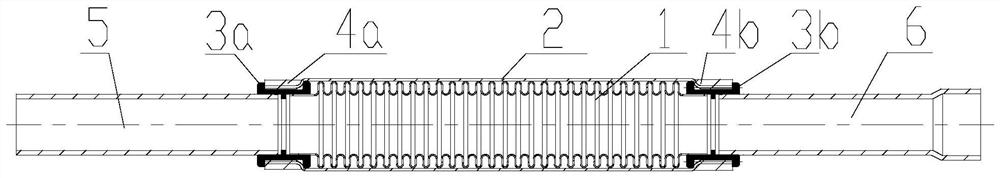

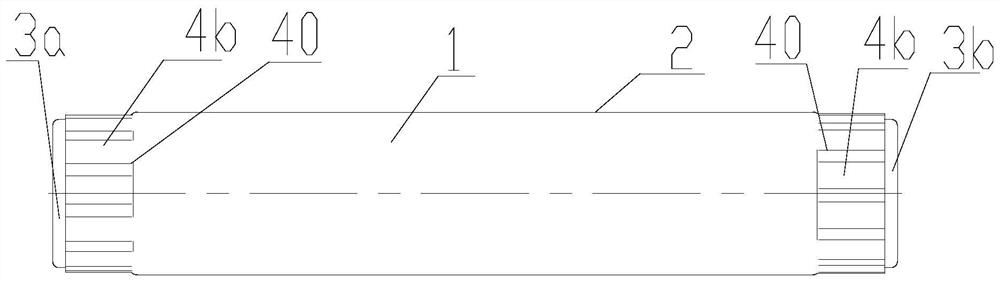

Shock absorbing tube and manufacturing method thereof

ActiveCN108526636BGood welding consistencyImprove connection reliabilitySoldering apparatusPipe fittingEngineering

The invention discloses a method for manufacturing a shock-absorbing tube, which includes: a solder placement process, placing the solder in the placement part of the inner cavity of the adapter; a pipe assembly process, installing the bellows and the adapter on the corresponding side of the adapter The fitting part of the adapter, so that the inner cavity of the adapter communicates with the inner cavity of the bellows and the inner cavity of the connecting pipe, and after fixing or limiting the bellows, the adapter and the connecting pipe, the pipe fitting assembly is obtained; component welding process , the pipe fitting assembly of the external pipe is welded in a furnace to obtain the main body of the shock absorbing pipe. The invention also provides an integrally welded shock absorbing tube, which has better welding consistency and can improve the reliability of component connection.

Owner:XINCHANG COUNTY SITONG ELECTRICAL CO LTD

Welding assembly process of regulator of automotive generator

ActiveCN103442522AReduce investmentSimple processPrinted circuit assemblingElectrical componentsSolder ballEngineering

The invention discloses a welding assembly process of a regulator of an automotive generator. According to the welding assembly process of the regulator of the automotive generator, the purposes of welding an IC, welding a PCB and a support, welding an externally-connected electronic material and solidifying cooling gel and combination gel are achieved through a one-time reflow oven. The welding assembly process of the regulator of the automotive generator has the advantages of simplifying working procedures, reducing investment of personnel and equipment, improving welding quality and being free of solder balls.

Owner:JIANGSU YUNYI ELECTRIC

Full-automatic laser welder

ActiveCN103240527BGuaranteed compression effectSolving Automatic Laser Welding ProblemsLaser beam welding apparatusEngineeringPortal frame

The invention provides a full-automatic laser welder comprising a laser head, a laser head servo mechanism, a feeding and discharging device, a pressing mechanism and a transmission mechanism. The pressing mechanism comprises a plurality of pressing blocks and a pressing block support, wherein each pressing block is provided with a passage for laser emitted by the laser head to pass; and the pressing block support is elastically connected with each pressing block. The transmission mechanism is connected to the pressing block support to drive the pressing block support to move vertically so as to press or separate from corresponding connecting pieces. The laser head servo mechanism can further comprise two portal frames which are bilaterally and symmetrically arranged relative to the feeding and discharging mechanism along the X-direction, and each portable frame is provided with reinforcing ribs. The transmission mechanism can comprise a pair of transmission components which is bilaterally and symmetrically arranged relative to the feeding and discharging mechanism. The full-automatic laser welder can further comprise a gas cooling mechanism, a welding positioning unit and a controller. Therefore, pressing effects of welding spots of workpieces at different heights are guaranteed, welding temperature is lowered effectively, stability of a welding process is guaranteed, and welding optimal rate and efficiency are quite high.

Owner:CONTEMPORARY AMPEREX TECH CO

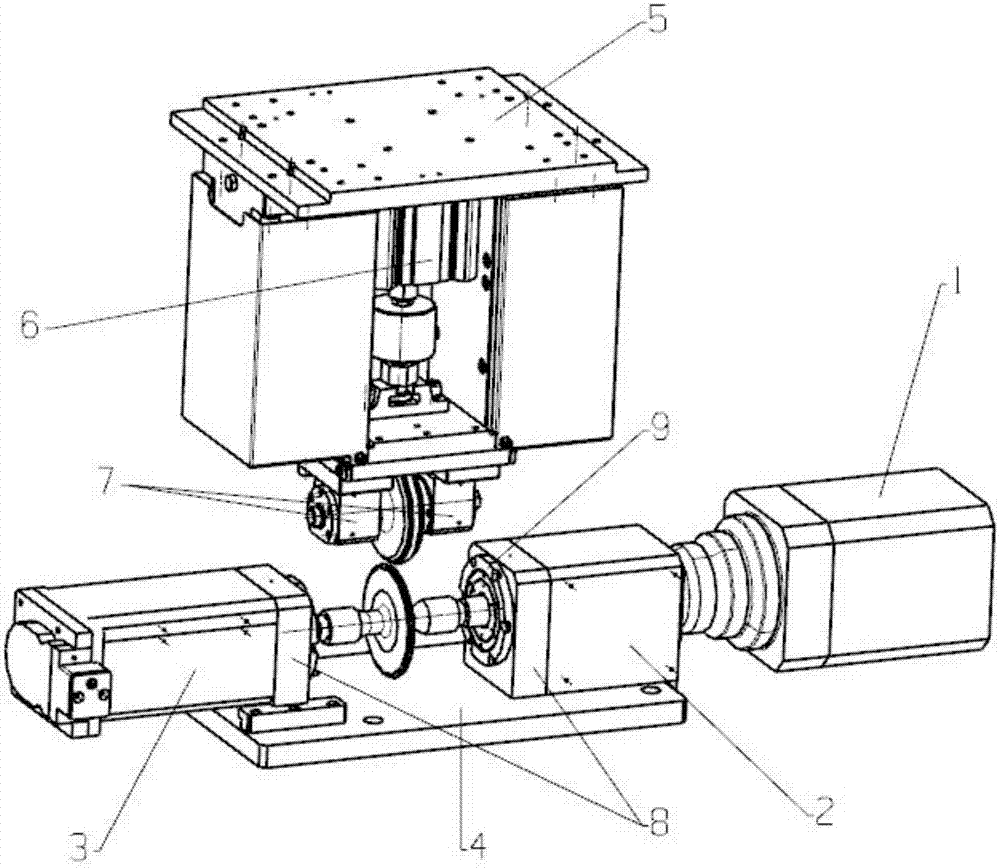

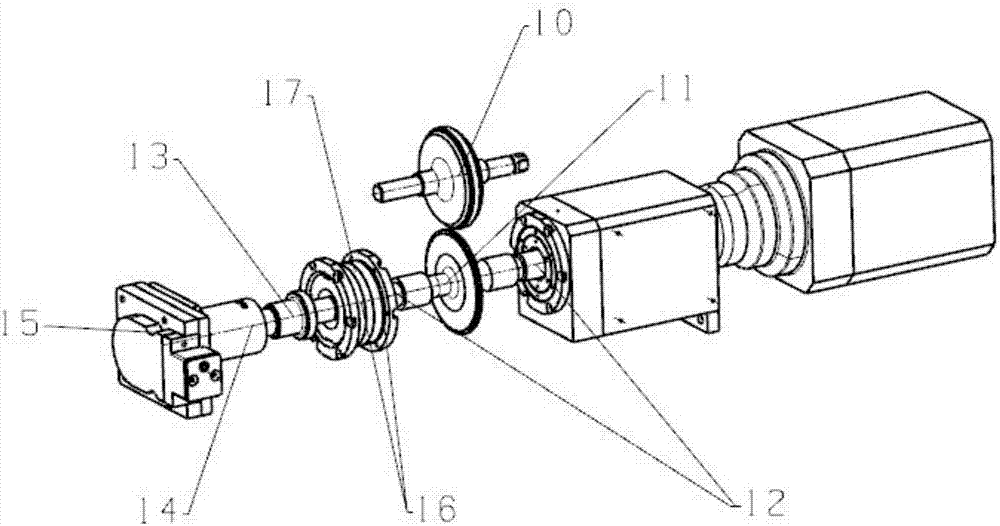

Ultrasonic rolling welding device based on full-wave welding head

InactiveCN107498174AImprove rigidityGood welding consistencyNon-electric welding apparatusFull waveEngineering

The invention discloses an ultrasonic rolling welding device based on a full-wave welding head. The provided ultrasonic rolling welding device based on the full-wave welding head is designed on the basis of the full-wave welding head, the rigidity of the welding head is good, coaxiality and circle run-out are easy to control, stress is uniform, and welding consistency is good. According to the provided ultrasonic rolling welding device, an amplitude modulation device with any magnification times can be arranged according to needs, and accordingly welding requirements for different products can be met. The provided ultrasonic rolling welding device can achieve the high-speed product rolling welding process without moving along with a mechanical automatic device during welding, the welding speed can reach 100 m / min, the welding precision is good, and stability is high.

Owner:SBT ULTRASONIC TECH CO LTD

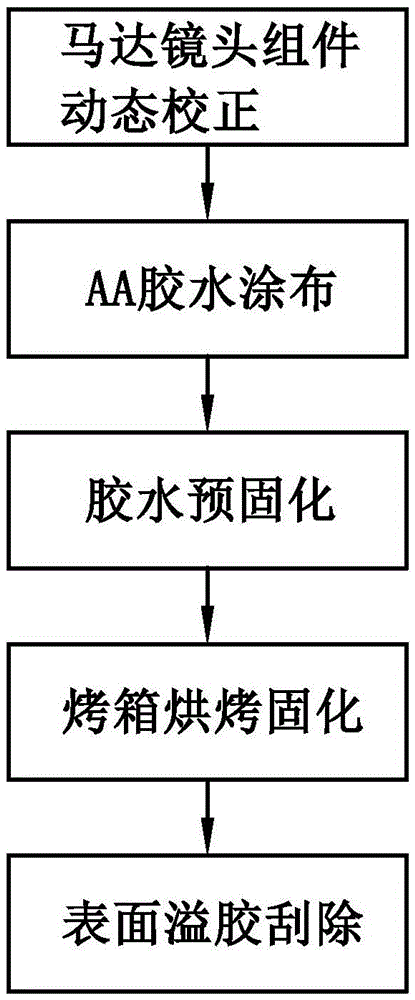

Camera module and its structure and assembly method

ActiveCN106817515BImprove Design FeasibilityFast productionTelevision system detailsColor television detailsEngineeringCamera module

A camera module and its structure and assembly method, wherein the camera module includes a motor lens component and a circuit assembly; the motor lens component is located on the front side of the circuit assembly, so that the light passing through the motor lens component reaches The circuit assembly, and the motor lens component is welded to the circuit assembly. The camera module assembly method includes the steps of: (A) dynamically adjusting a motor lens component; (B) welding the motor lens component to a circuit assembly.

Owner:NINGBO SUNNY OPOTECH CO LTD

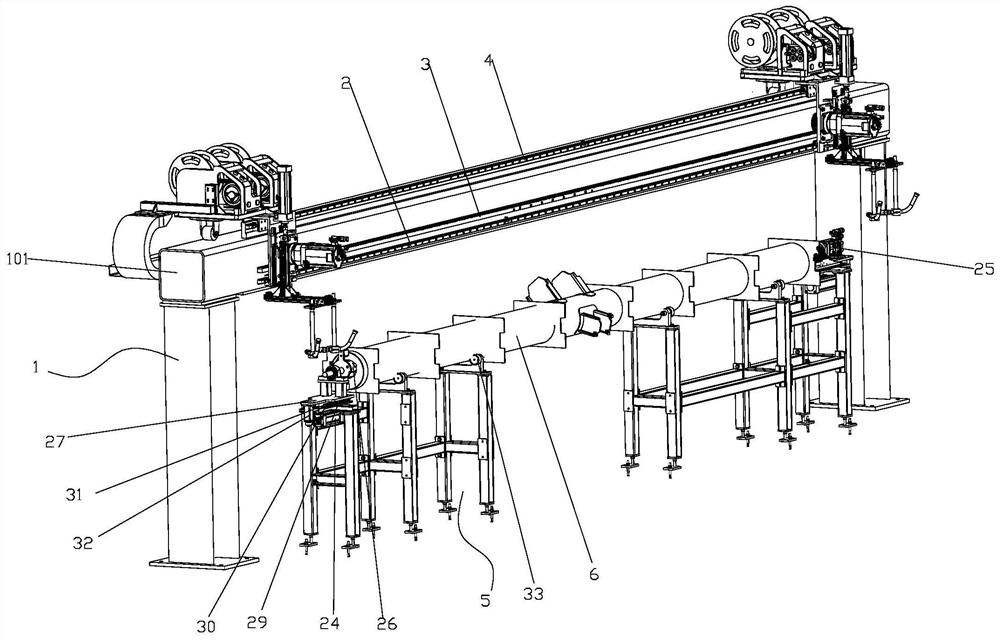

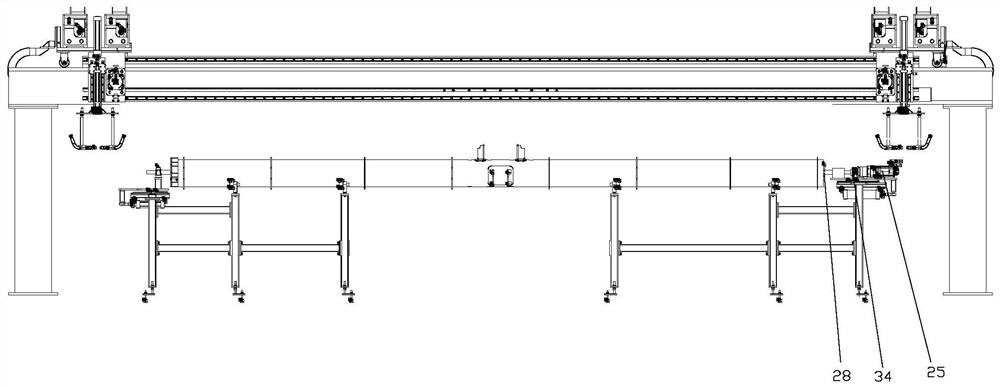

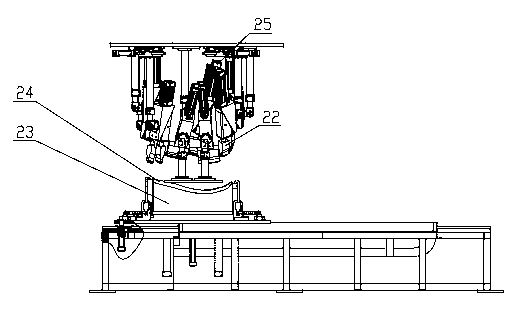

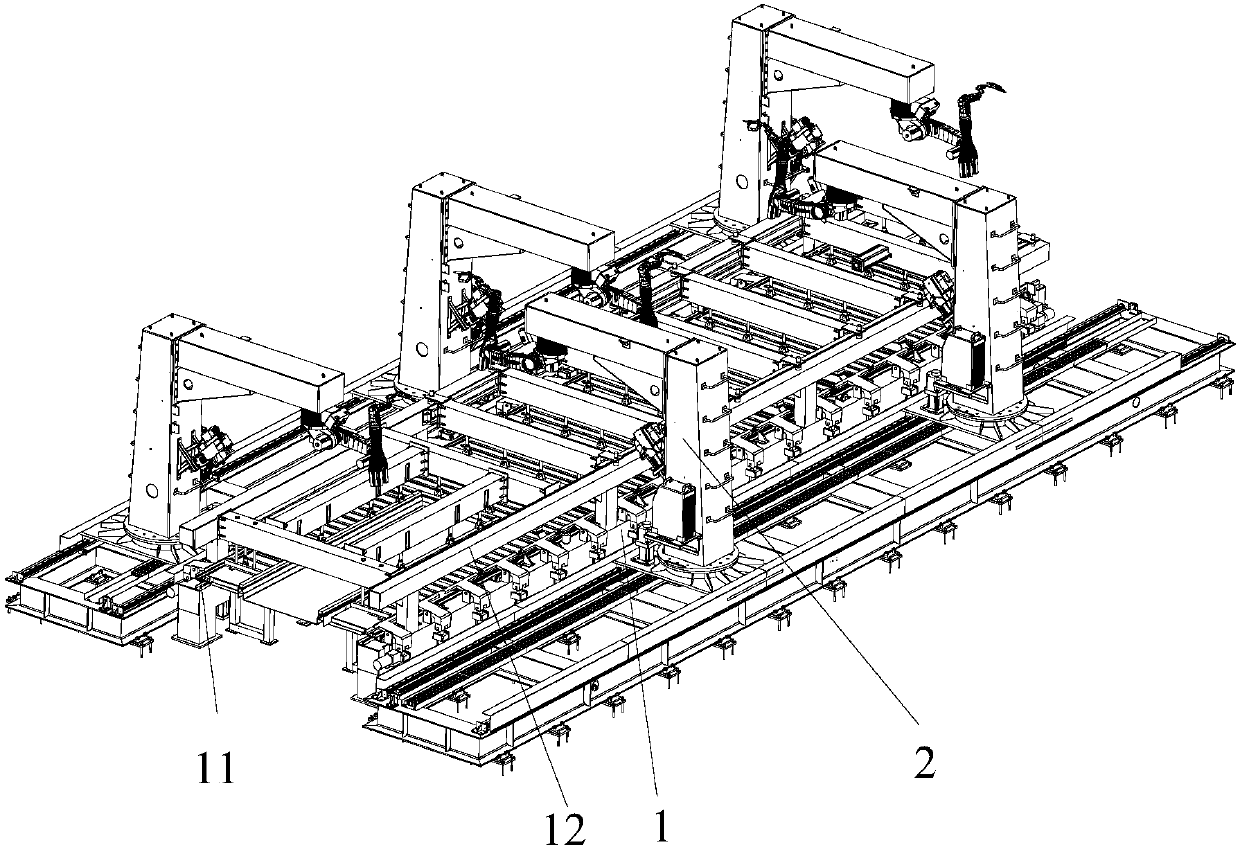

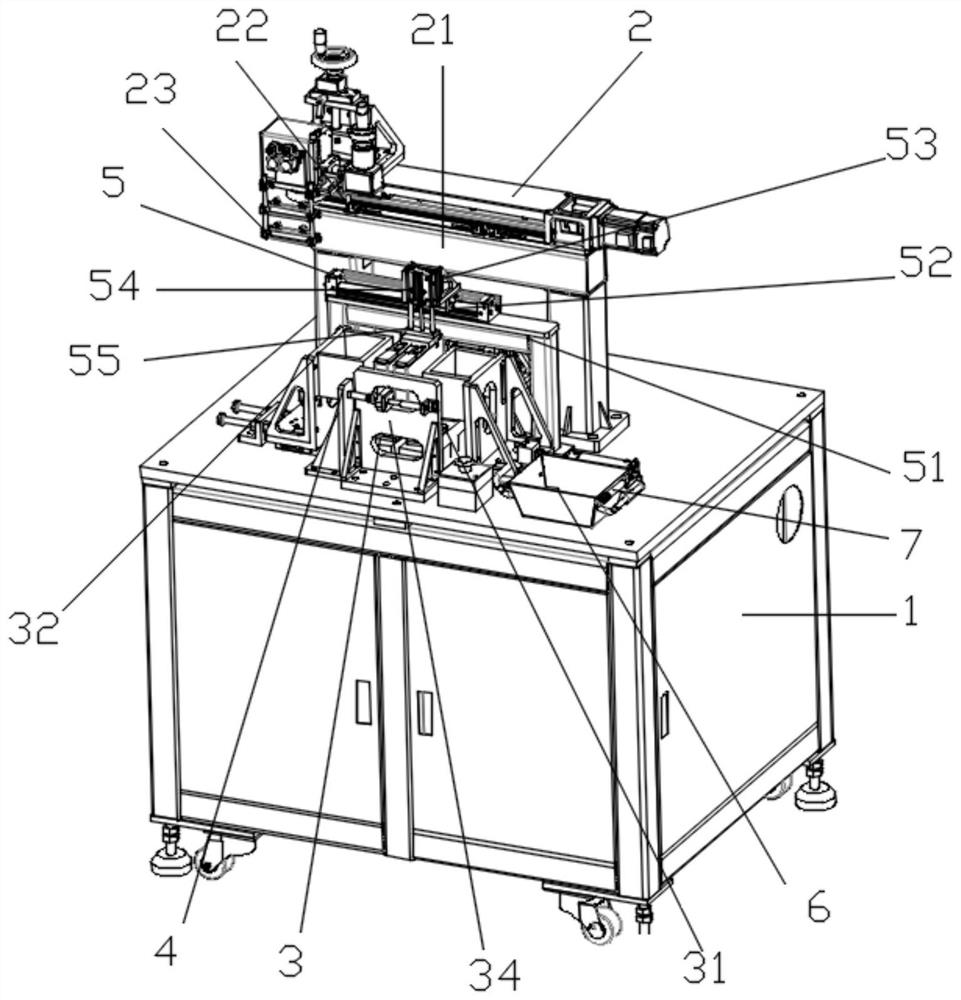

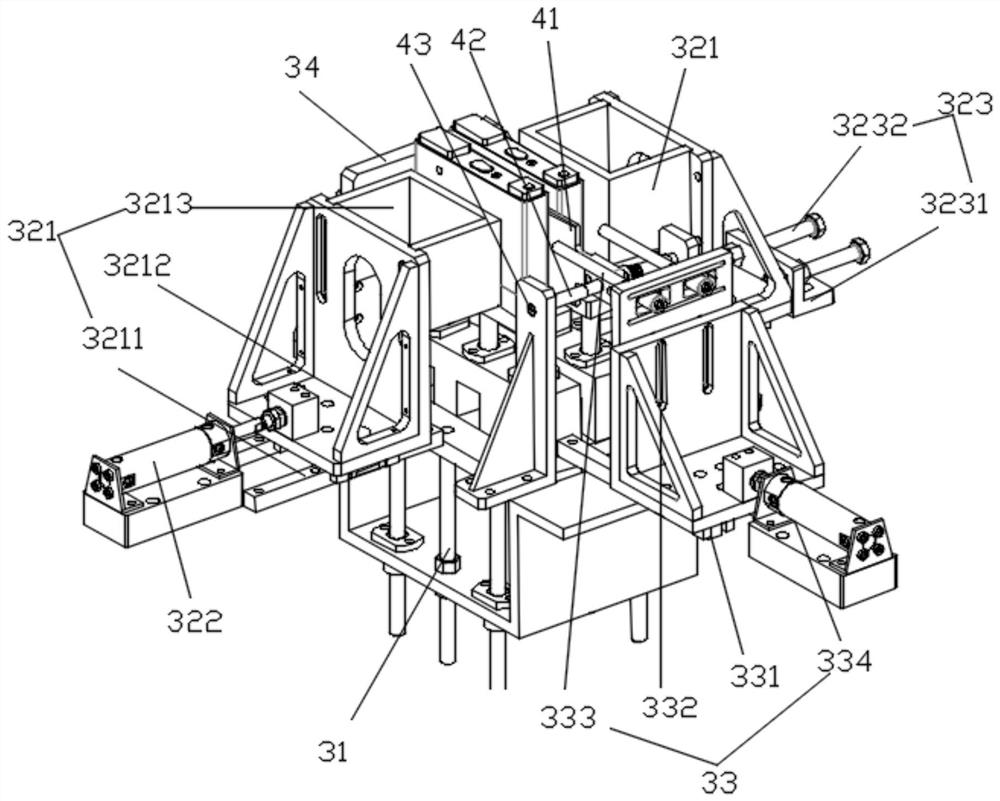

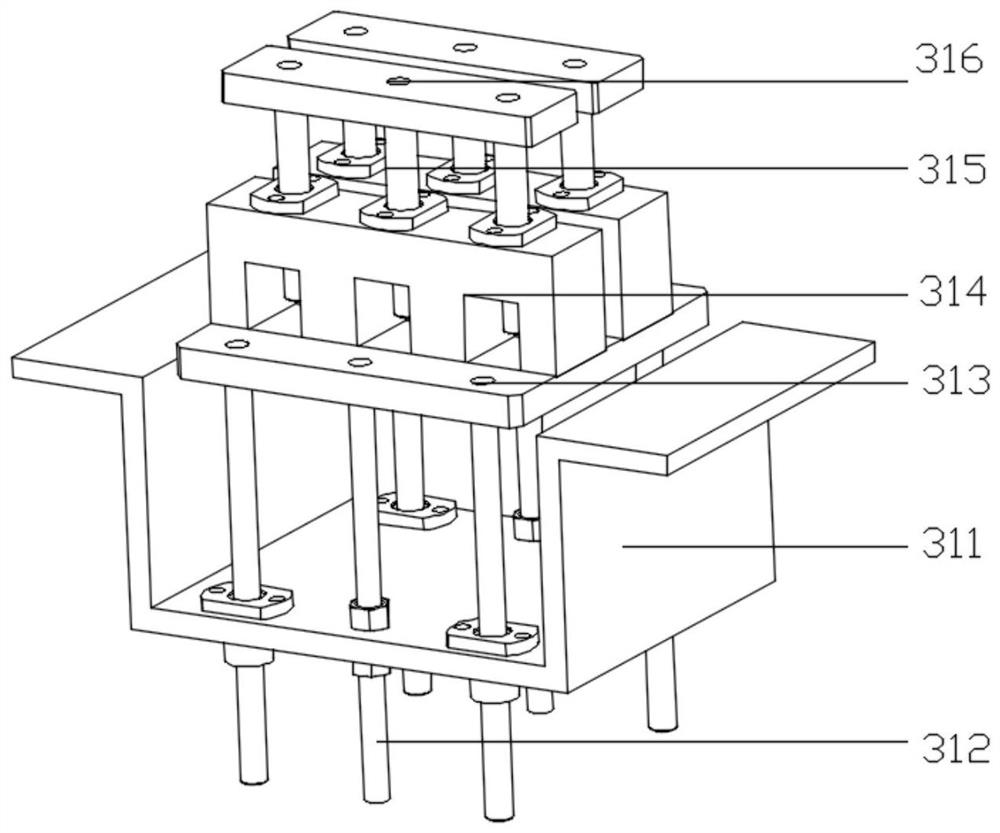

Special double-head automatic welding machine for welding strut beams of heliostat support main beam

PendingCN112427846ARealize automatic welding processShorten welding timeWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The embodiment of the invention provides a special double-head automatic welding machine for welding strut beams of a heliostat support main beam. The machine comprises a gantry frame, welding gun clamping fixing devices, welding gun lifting devices, wire feeder fixing devices and rotary position-changing mechanisms, wherein a guide rail and a rack are arranged on the side face of a main crossbeamof the gantry frame, a first guide rail is arranged at the top of the main crossbeam, the welding gun lifting devices are mounted on the main crossbeam of the gantry frame, the wire feeder fixing devices are mounted on the gantry frame, the top of each welding gun lifting device is fixed to the corresponding wire feeder fixing device, each welding gun clamping fixing device is mounted at the bottom of the corresponding welding gun lifting device, two fixing frames are arranged at the two sides of the gantry frame, a workpiece is placed on the two fixing frames, and the rotary position-changing mechanisms are mounted on the two fixing frames and are connected with the two ends of the workpiece. On the basis of guaranteeing the welding quality, the welding speed is increased, and the laborintensity of workers is reduced.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

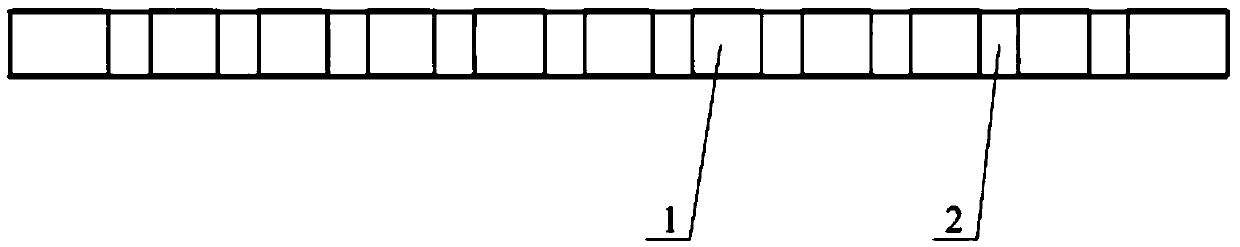

NTC temperature sensor insert production device and method

ActiveCN106092364BGuaranteed unityImprove pass rateThermometers using electric/magnetic elementsUsing electrical meansWire rodIndustrial engineering

The invention discloses an NTC temperature sensor insert plate production apparatus and belongs to the field of electronic sensor production. The NTC temperature sensor insert plate production apparatus comprises a fixing plate, a wire rod and core positioning tool and a wire rod and core shaping tool. The fixing plate is provided with a plurality of grooves in an interval manner. The wire rod and core positioning tool is provided with a plurality of bosses corresponding to the grooves. Two opposite angels of each boss are arranged in a chamfering manner. The width of each boss equals to the space between two cores of the same wire rod. The wire rod and core shaping tool is provided with open grooves. The top of each groove is arranged in a V-shaped manner. The width of each open groove equals to or is larger than the space between two cores of the same wire rod. The temperature sensor production is updated from previous one-by-one manual welding to equipment entire-frame welding, so that welding time and welding temperature are unified, and the product production efficiency is effectively improved. The welding speed is fast, the welding process is precisely controlled and the welding consistency is good, so that the qualified rate of finished products is greatly improved. The invention also discloses an NTC temperature sensor insert plate production method.

Owner:句容市双诚电子有限公司

A non-standard elbow flange welding positioning tool

ActiveCN112077509BGood welding consistencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The invention relates to the technical field of tooling and fixtures, and discloses a non-standard elbow flange welding positioning tool, which includes a bottom plate, a number of height-adjustable support feet are provided at the bottom of the bottom plate, and parallel distributed elbows are arranged above the top surface of the bottom plate. Positioning plate, the middle sides of the elbow positioning plate are provided with support columns, the lower end of the support column is fixedly connected with the bottom plate, the upper end of the support column is rotationally connected with the elbow positioning plate, and there is a set between the left end of the elbow positioning plate and the bottom plate An angle adjustment mechanism for adjusting the angle of the elbow positioning plate. The elbow positioning plate is equipped with an elbow clamping mechanism and an elbow centering mechanism; there are brackets at both ends of the bottom plate, and a slide parallel to the bottom plate is provided between the upper ends of the brackets. A sliding seat is provided between the sliding rods, and a flange positioning adjustment mechanism is provided on the sliding seat; a level is also provided on the bottom plate. The invention can realize the high-precision positioning of the flange and the bent pipe, and ensure good welding consistency and high welding quality of the flange and the bent pipe.

Owner:QUZHOU COLLEGE OF TECH

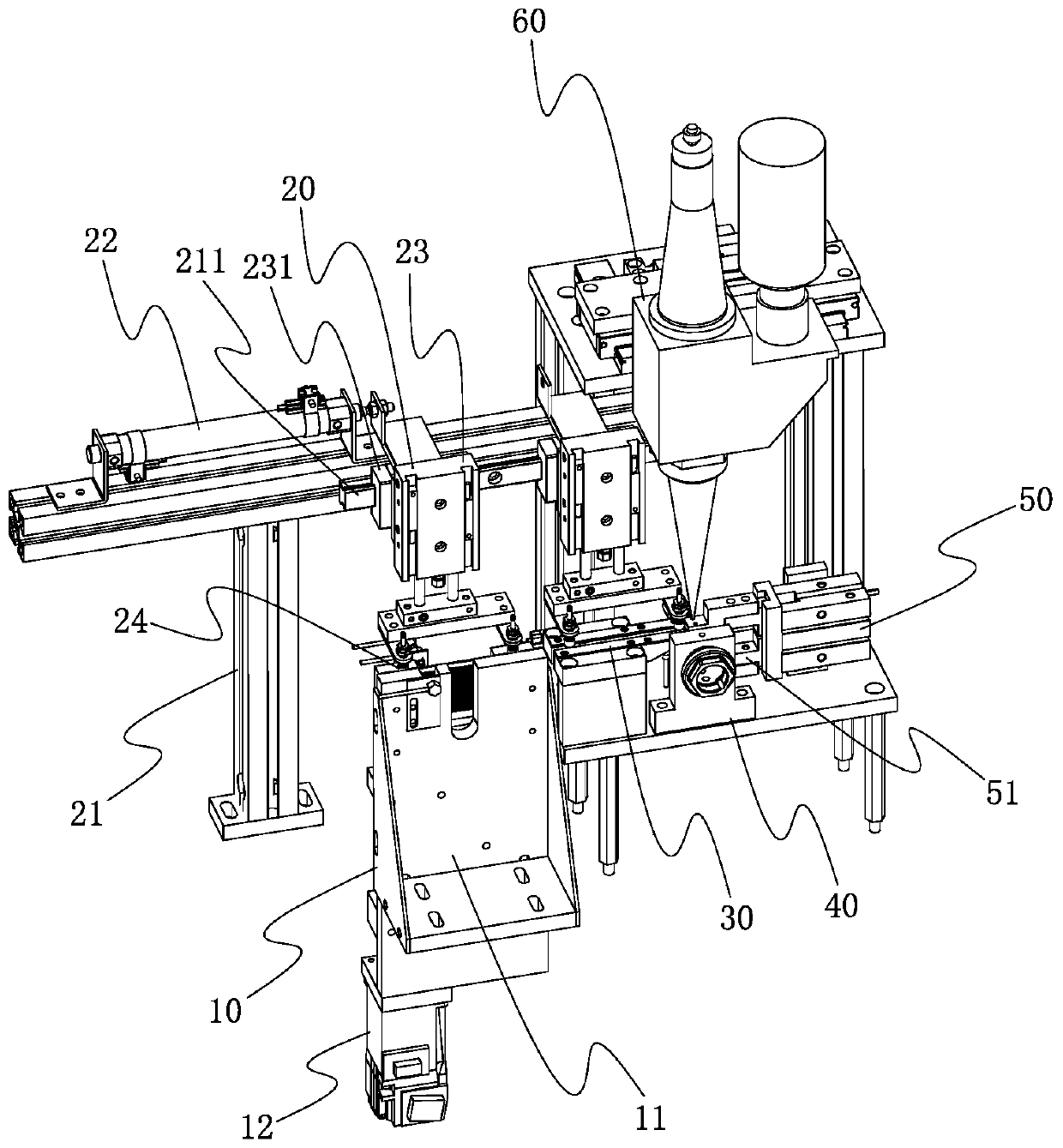

Precision bolt filter screen welding device

PendingCN111015000AImprove welding qualityGood welding consistencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringManufacturing engineering

The invention discloses a precision bolt filter screen welding device. The precision bolt filter screen welding device comprises a loading assembly, a transfer assembly, a guide unit, a precision boltpositioning unit, a fixing unit, a welding assembly and a precision bolt clamping rotating unit, wherein a stock bin is arranged at one side of the loading assembly; a jacking gas cylinder is arranged below the stock bin; the output end of the jacking gas cylinder is connected with a jacking plate; the jacking plate is at least partially positioned in the stock bin; the transfer assembly comprises a first fixed frame, a transfer gas cylinder arranged on the first fixed frame, a lifting gas cylinder connected to the output end of the transfer gas cylinder and an adsorption unit arranged at theoutput end of the lifting gas cylinder; the fixing unit is provided with two clamping parts which get close to each other or get away from each other relatively; arc-shaped clamping holes are formedin opposite sides of tail ends of the two clamping parts; and two welding holes are formed in the tail ends of the clamping parts in a spaced mode. The precision bolt filter screen welding device canautomatically weld a filter screen to the peripheral surface of a precision bolt, is high in welding quality, is good in welding consistency, and is high in welding efficiency.

Owner:浙江宇钻精密元件有限公司

3D (three-dimensional) wrapping cloth welding mechanism of seat back wrapping machine

ActiveCN102551393BAccurately meet welding requirementsMeet welding requirementsUpholstery manufactureStoolsEngineeringSlide plate

Owner:无锡研中科技有限公司

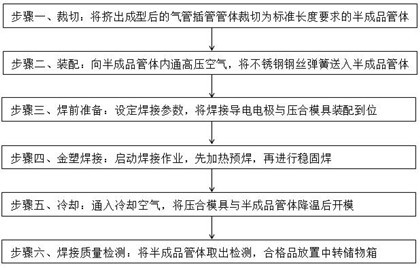

A manufacturing process of gold-plastic welded steel wire reinforced endotracheal intubation tube

The invention discloses a manufacturing process of a metal-plastic welded steel wire reinforced tracheal intubation tube. The manufacturing process is as follows: Step 1, cutting a semi-finished tube body; Step 2, passing a stainless steel wire spring to the semi-finished tube body Inside; step 3, set the welding parameters of the welding equipment, contact the welding conductive electrode with the ends of the stainless steel wire spring at both ends, and install the semi-finished pipe body equipped with the stainless steel wire spring in the pressing mold; step 4, start welding Equipment, first perform heating pre-welding, and then perform stable welding. After completion, turn off the welding equipment; step five, cooling: after the welding operation is completed, use compressed cold air to cool the semi-finished pipe body and the pressing mold; step six, welding quality inspection . Through the manufacturing process disclosed by the present invention, the stainless steel wire spring and the tube body of the trachea intubation can be quickly welded together, and the cost is significantly reduced compared with the traditional inner dipping process, and it has the advantages of high pass rate, low energy consumption, clean and environment-friendly.

Owner:HENAN TUOREN MEDICAL DEVICE GRP

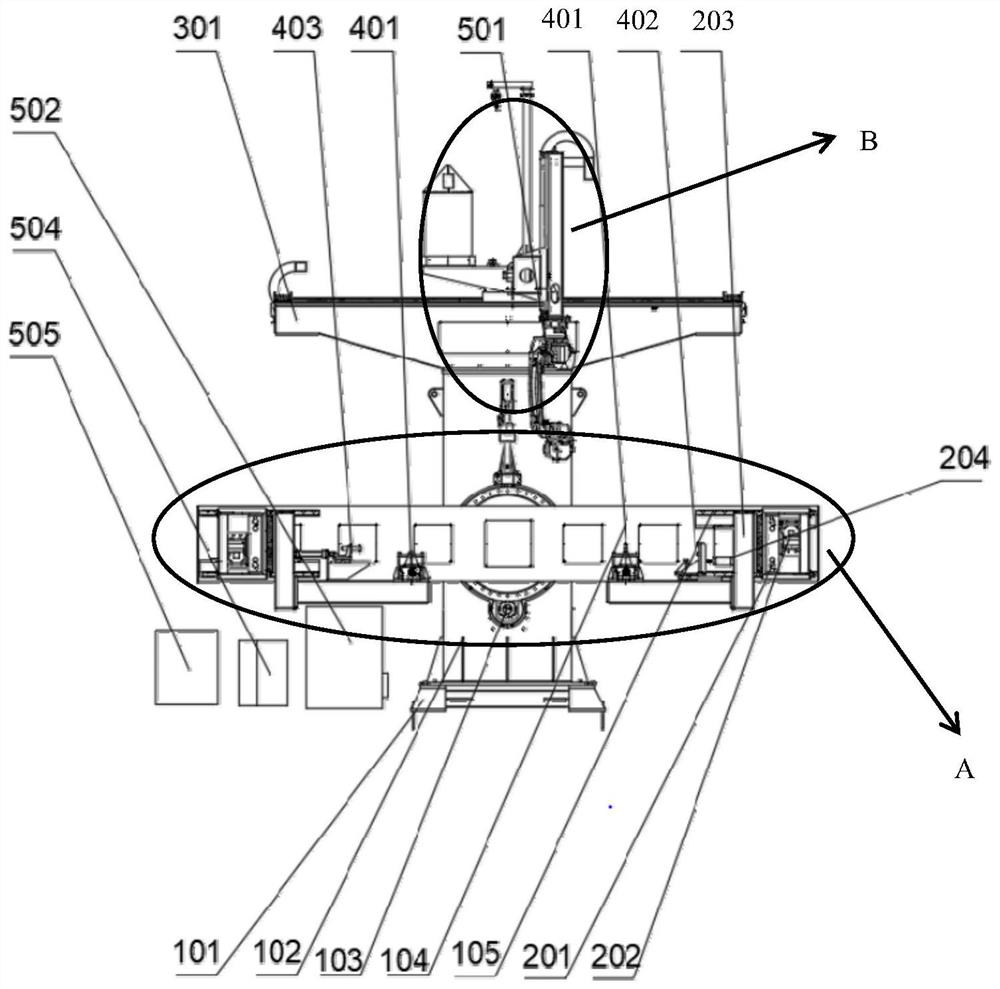

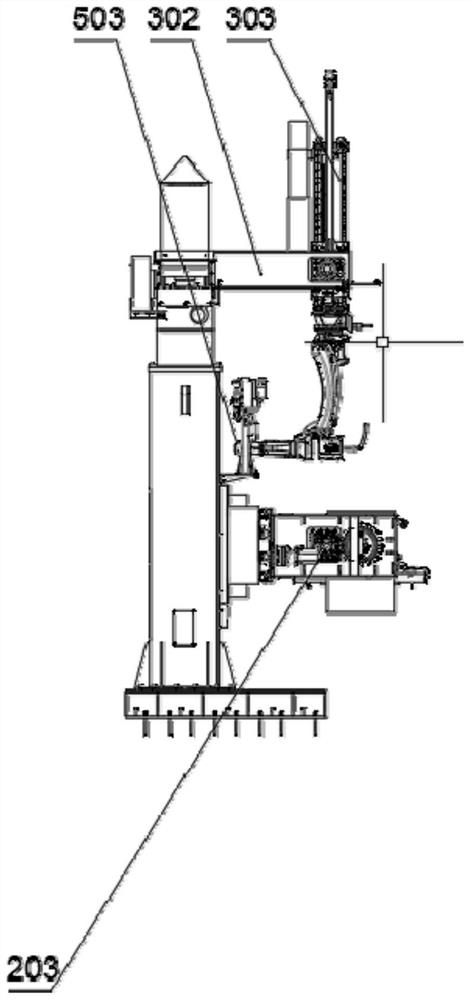

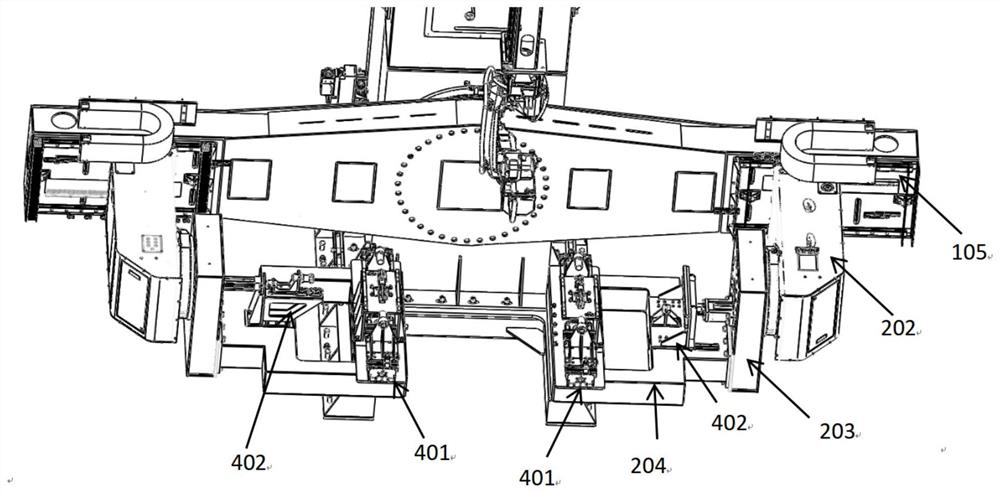

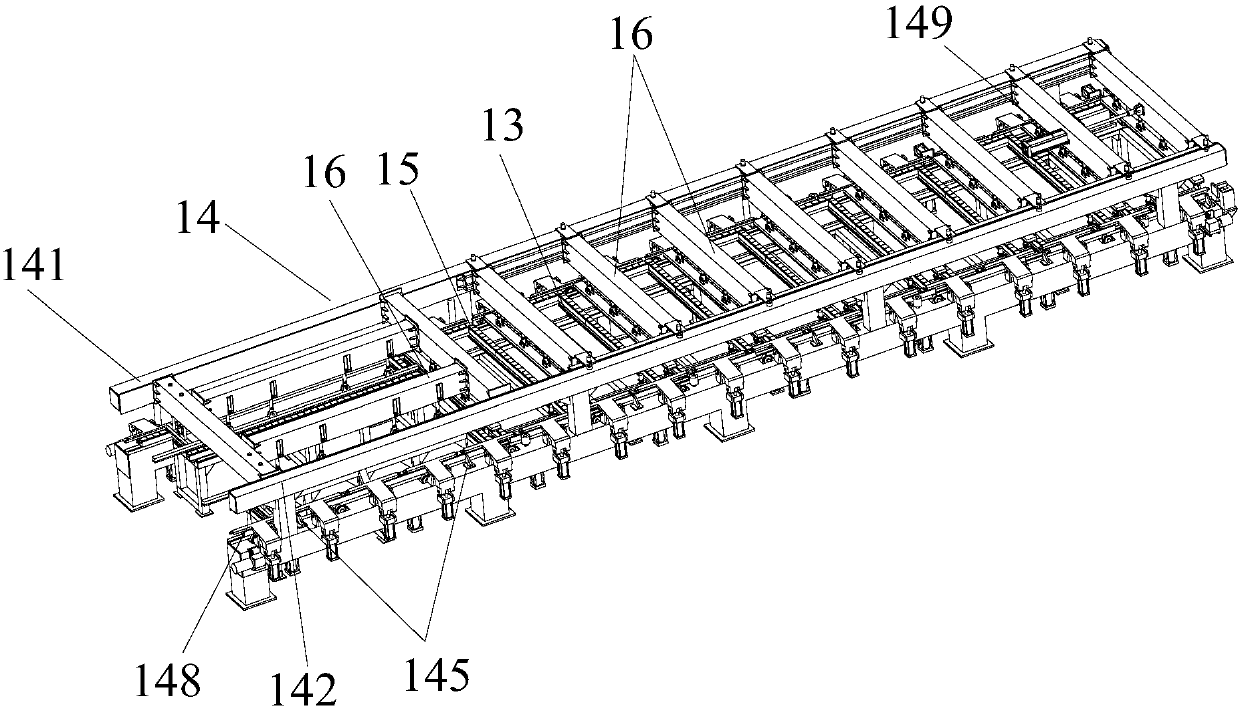

Flexible automatic welding system for track beam structural member

ActiveCN114289920AResolve continuitySolve the problem that different models need to configure special equipmentWelding/cutting auxillary devicesAuxillary welding devicesVertical planeCentre of rotation

According to the flexible automatic welding system for the crawler belt beam structural part, a crawler belt beam is clamped through a positioning clamping mechanism, meanwhile, the center line of the crawler belt beam coincides with that of a clamp, and positioning in the length direction of the crawler belt beam is completed. Then the track beam structural part is adjusted to rotate in the horizontal plane along the center axis of the track beam structural part through the rotating displacement mechanism, the track beam structural part is made to rotate in the vertical plane with the displacement machine body as the rotating center through the main displacement mechanism, and the position of a welding gun is moved through the truss mechanism while rotation is conducted; movement of the welding gun is matched with rotation of the track beam, and the flexible and automatic welding process of the track beam is achieved. Flexible automatic welding of engineering machinery track beams of various models is achieved, the problems that in a traditional production process, key welding seams cannot be continuously welded, and special equipment needs to be arranged for different models are solved, and the automatic flexible welding device has the advantages of being high in automation and flexibility degree, high in production efficiency and good in welding quality and consistency.

Owner:无锡恒久安泰智能制造有限公司

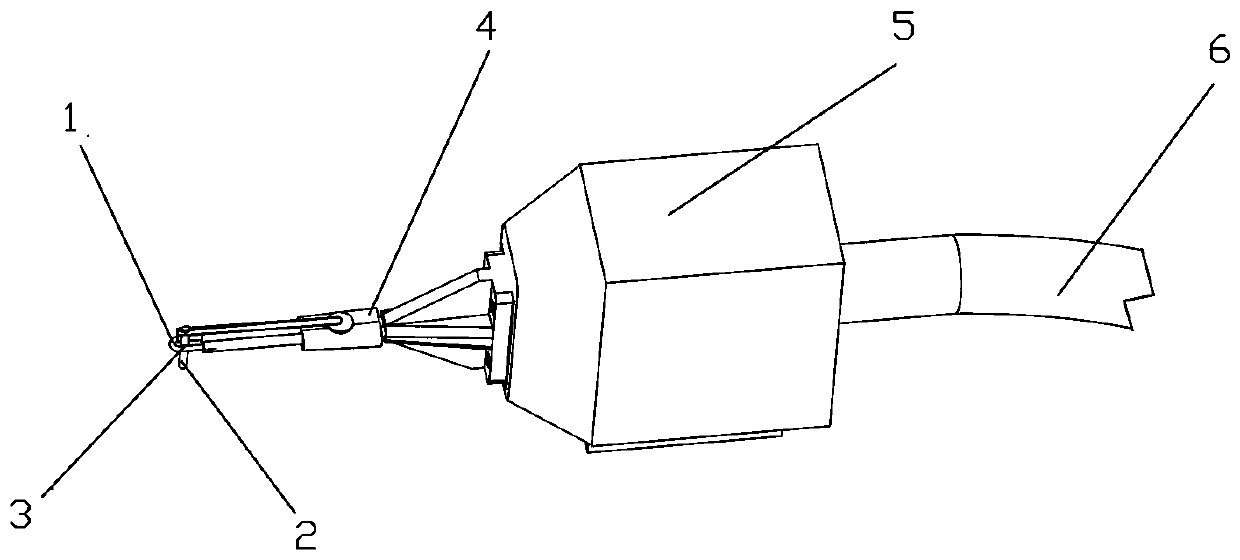

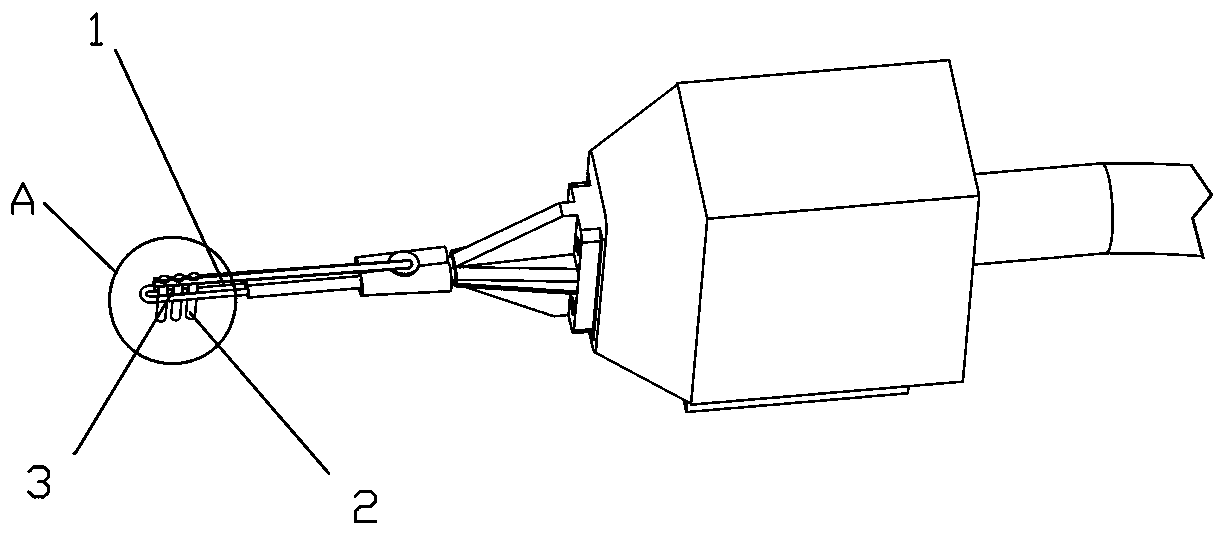

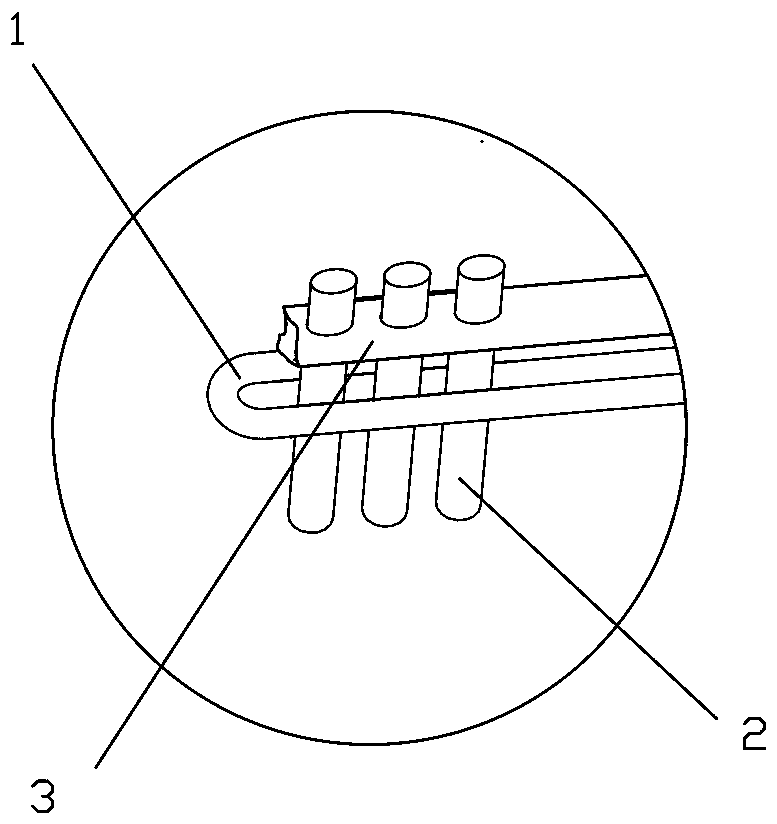

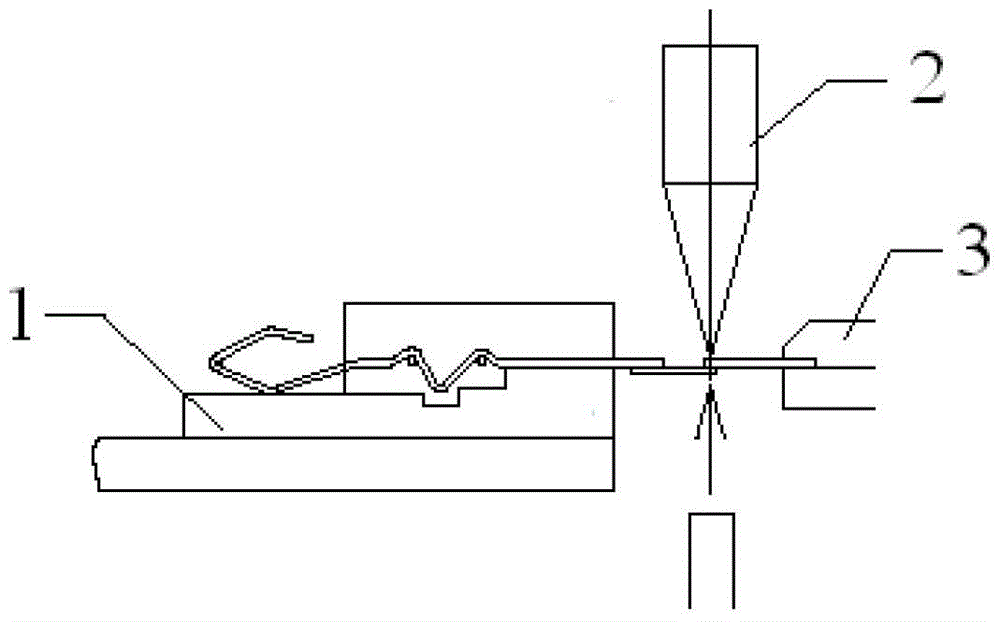

A method for manufacturing an electrode assembly for an automotive metal halide lamp

ActiveCN104139243BMake sure not to be piercedControl laser energy stabilityLaser beam welding apparatusMetal-halide lampEngineering

The invention relates to a production method of an electrode component for an automotive metal halide lamp. A tungsten wire tool is used for clamping a tungsten wire to be processed; a molybdenum chip fixture is used for fixing a molybdenum chip to be processed; and after the position, to be processed, of the tungsten wire is precisely controlled, a laser generated by a laser generator is output through a laser emitting head to perform the welding connection for the tungsten wire and the molybdenum chip. Compared with the prior art, a product, produced by the production method, has the advantages of good welding consistency, quality guarantee and large improvement of welding efficiency.

Owner:上海亚尔精密零件制造有限公司

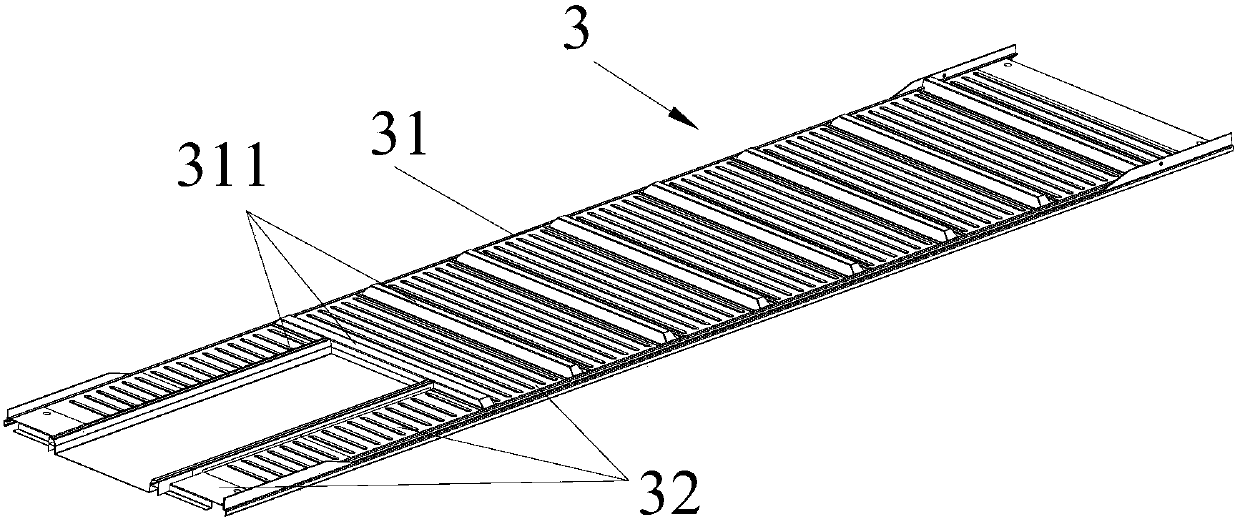

Workpiece thin plate welding processing system and processing method

ActiveCN106112339BRealize automatic transportationAccurate welding positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining system

Owner:CHANGSHA CTR ROBOTICS

Laser welding method of high-strength gas discharge electrode

ActiveCN103286448BControl laser energy stabilityGood welding consistencyLaser beam welding apparatusHydrogenHigh intensity

The invention relates to a laser welding method of a high-strength gas discharge electrode. A mandril and an electrode spring enter a fixture through a blanking mechanism respectively and the electrode spring is clamped on the mandril, the mandril and the electrode spring are placed at a laser generator and are welded through laser, and the electrode spring is fixed on the mandril, so that the high-strength gas discharge electrode is obtained, and automatic blanking is performed after inspection. Compared with the prior art, the laser energy can be stably controlled, the product welding consistency is good, the quality is guaranteed, the product consistency is guaranteed to the greatest extent, and two articles are molten mutually after welding, so that the product strength after hydrogen burning is better.

Owner:上海亚尔精密零件制造有限公司

An automobile lock lug welding fixture

InactiveCN104191141BRealize clamping positioningSolve the positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

Owner:HARBIN INST OF TECH

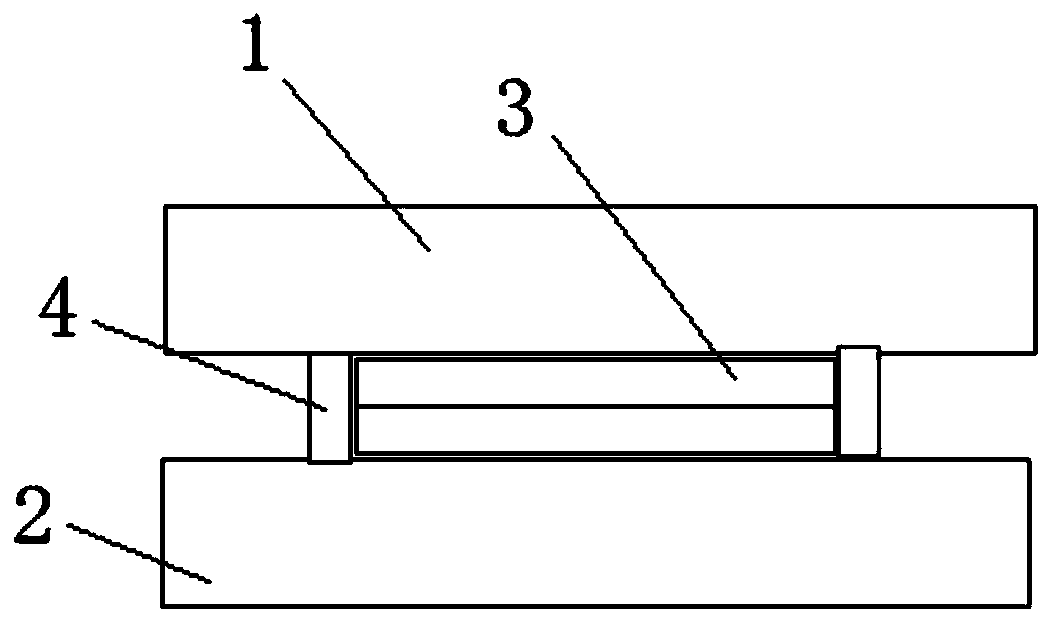

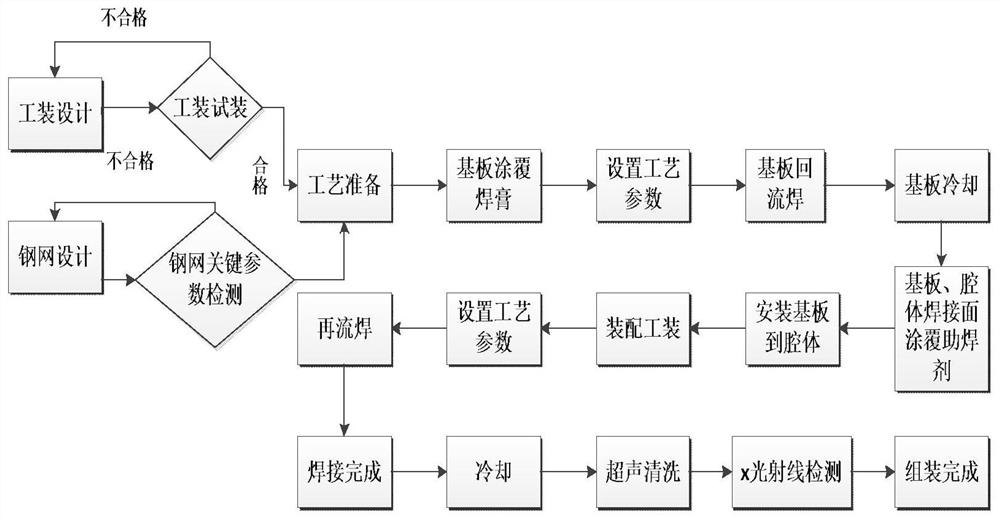

Process method for assembling PCB substrate antenna and carrier structural member

ActiveCN114094348AStable jobEfficient process achievabilityAntenna arrays manufactureMicrostrip array antennaEngineering

The invention discloses a process method for assembling a micro-strip array antenna PCB substrate antenna 4 and a carrier structural member, and aims to provide a process method capable of improving the welding yield of a PCB substrate antenna and a carrier and reducing the voidage. According to the technical scheme, the method comprises the steps that a solder coating tool and a welding tool which are matched with a printed circuit board (PCB) substrate antenna in shape are prepared, solder is applied to the welding face of the PCB substrate antenna through the solder coating tool, reflowing solder paste on a heating plate is placed after the solder is controlled, the PCB substrate antenna is cooled, and solder fixing is completed; the printed board PCB substrate antenna and the carrier structural member are fixed through a welding tool; and the PCB substrate antenna and the carrier structural member which are provided with the tool are put into a reflow soldering furnace together, and the PCB substrate antenna and the carrier structural member are finally fixed together through reflow soldering, thereby completing the welding assembly of the PCB substrate antenna and the carrier structural member.

Owner:10TH RES INST OF CETC

Adjustable battery sealing and welding equipment

InactiveCN112207437AAchieve weldingEliminate height differenceLaser beam welding apparatusStructural engineeringBattery cell

The invention discloses adjustable battery sealing and welding equipment. The equipment comprises an operation table, a welding device and an adjustable clamp device, wherein the adjustable clamp device comprises a lower floating assembly, a first extrusion assembly, a second extrusion assembly and a fixing plate, and the first extrusion assembly comprises a pair of extrusion frames; the pair of extrusion frames are arranged on the two opposite sides of the lower floating assembly respectively; a first driving piece connected with one extrusion frame is fixedly connected to the operation table, and a limiting piece used for limiting the other extrusion frame is fixedly connected to the operation table; and the second extrusion assembly is used for extruding one end of a to-be-welded battery in the thickness direction towards the direction of the fixing plate. According to the adjustable battery sealing and welding equipment provided by the invention, the to-be-welded battery is supported through the lower floating assembly, an aluminum sheet is adsorbed through a pen-shaped adsorber and then placed on the to-be-welded battery, transverse fixing of the to-be-welded battery is completed through the first extrusion assembly and the second extrusion assembly, and the to-be-welded battery is welded through the welding device.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com