Process method for assembling PCB substrate antenna and carrier structural member

An assembly process and structural part technology, which is applied in the manufacture of antenna array devices, antennas, antenna arrays, etc., can solve the problems of difficult production, low assembly yield, and high assembly difficulty, and achieve the improvement of radiation efficiency and operating frequency. , Improve the electrical performance index, the effect of good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

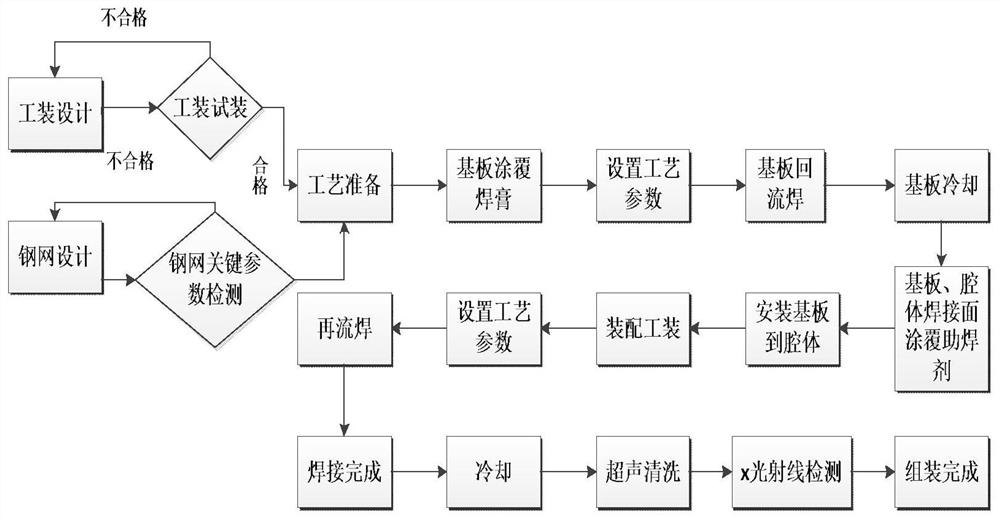

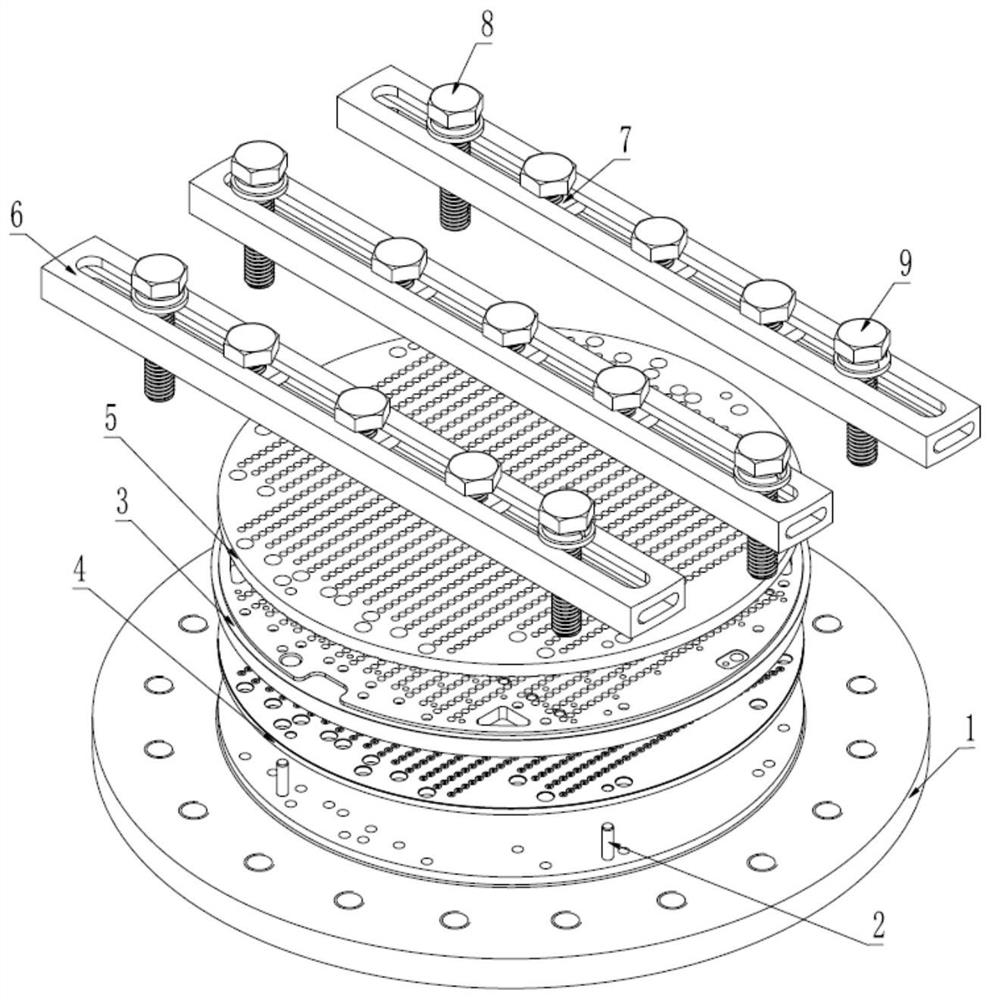

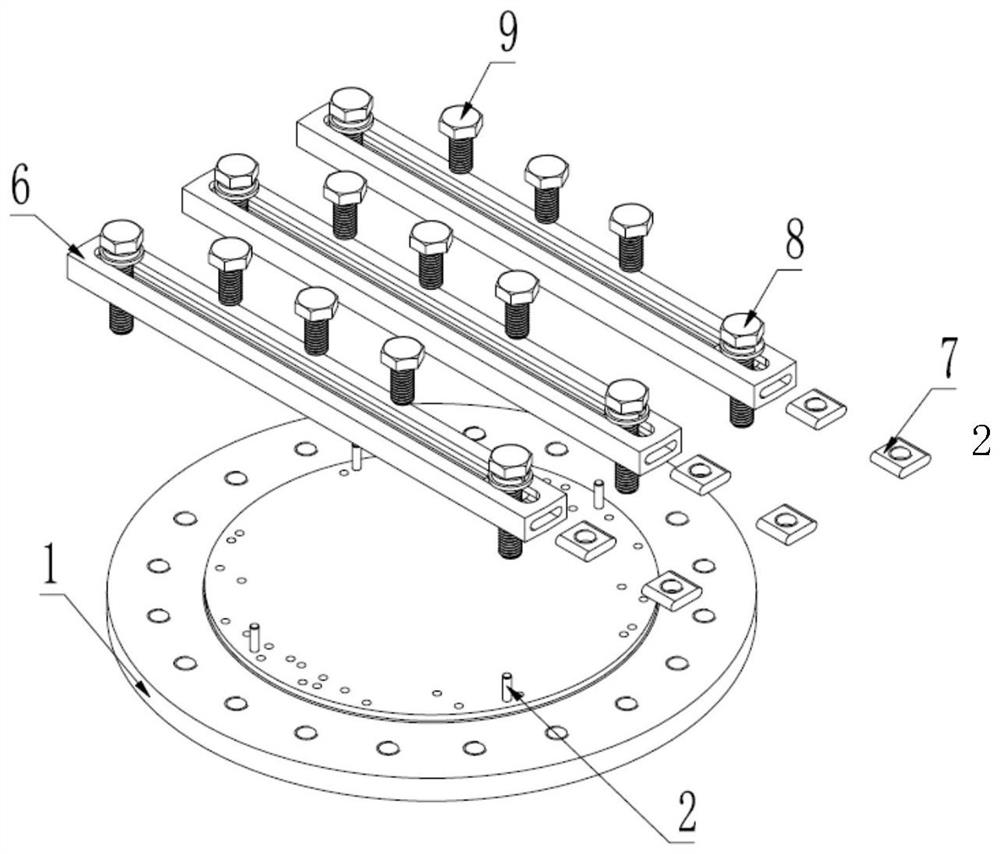

[0027] refer to figure 1 , figure 2 . According to the present invention, for the antenna array module composed of the carrier structure 3, the KA frequency band PCB substrate antenna 4, the fur button assembly, the metal cover plate, etc., a solder coating tool for matching the external dimensions of the PCB substrate antenna 4 is prepared And welding tooling, apply solder paste on the welding area at the bottom of PCB substrate antenna 4 through solder coating tooling, because the welding density is too high, first use solder coating tooling to apply solder to the soldering surface of PCB substrate antenna 4, and then place it on the heating plate for reflow Solder paste on the PCB substrate antenna 4, cool the PCB substrate antenna 4, and complete the solder fixation on the PCB substrate antenna 4; apply flux to the welding surface of the PCB substrate antenna 4 and carrier structure 3 that has been coated with solder, and install the PCB substrate Antenna 4 to carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com