Patents

Literature

228results about How to "Improve welding yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

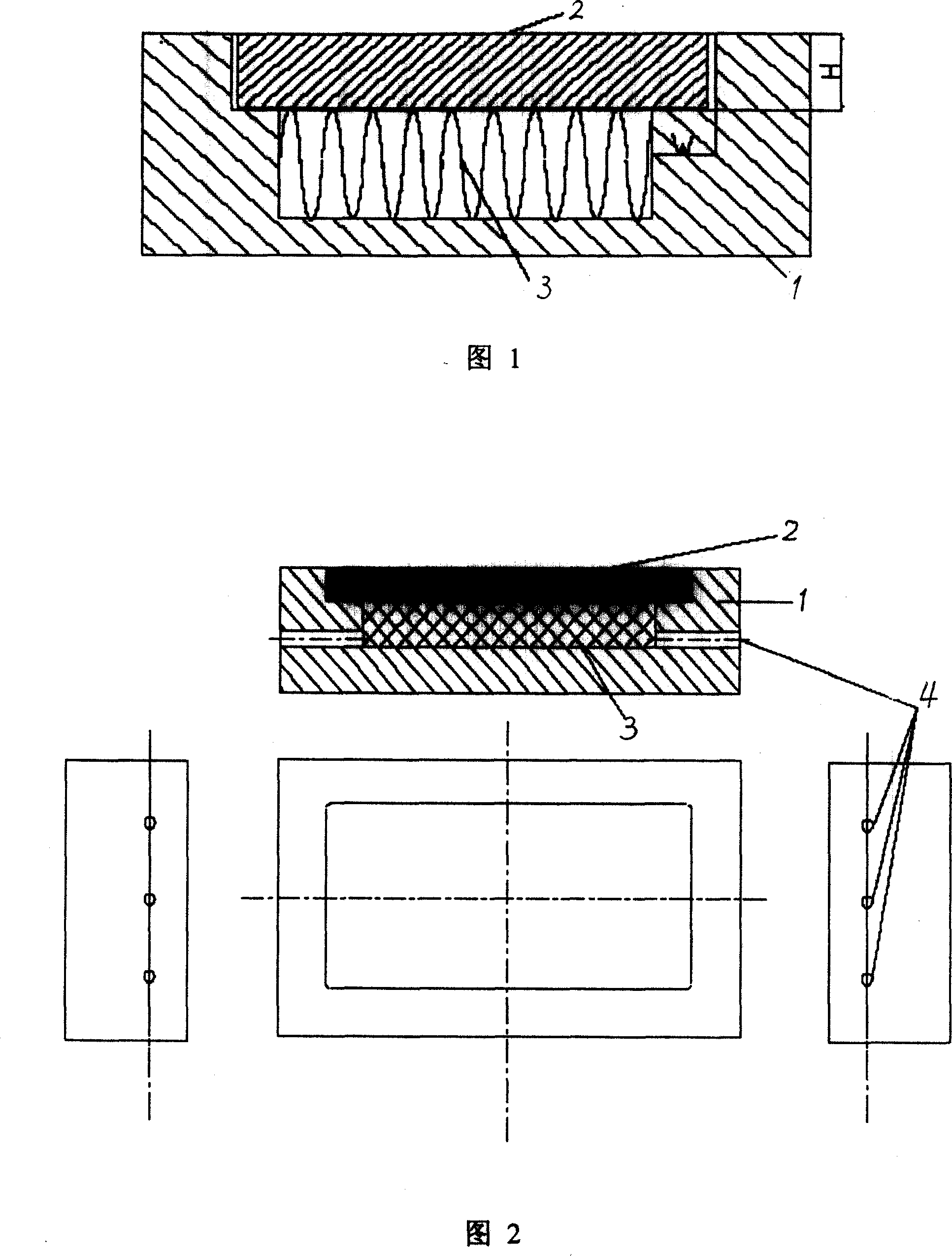

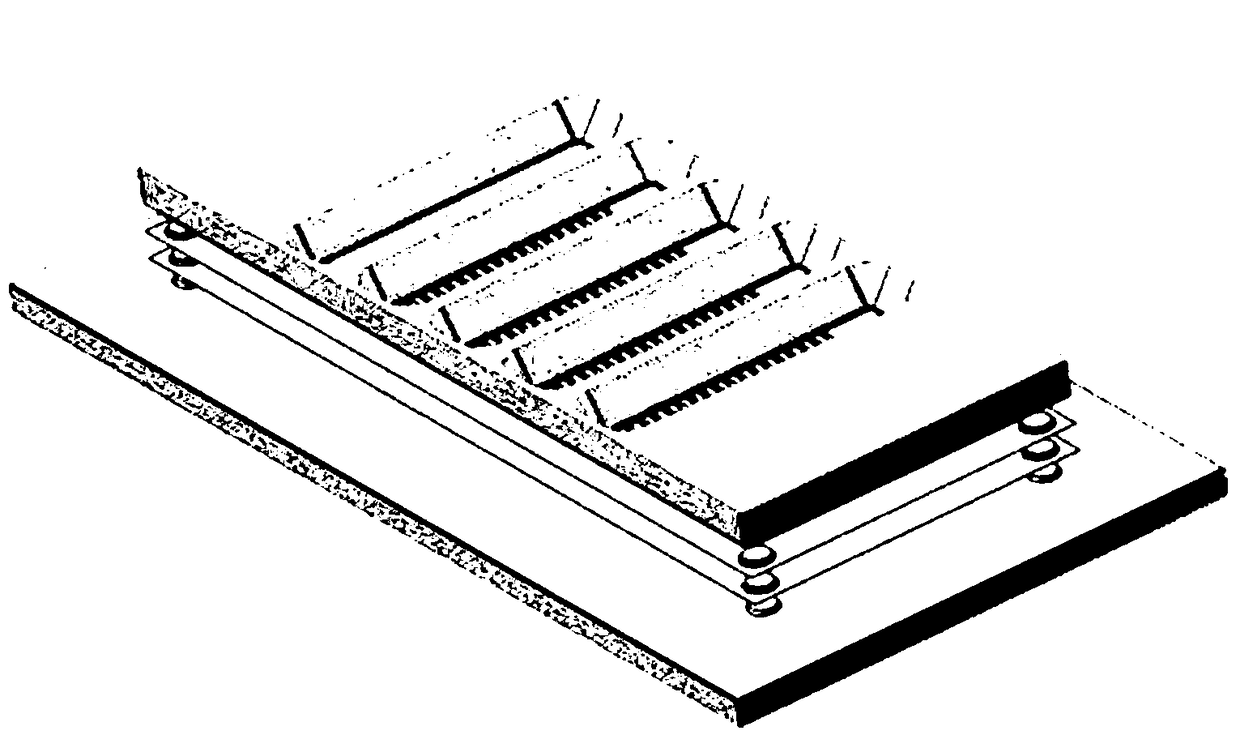

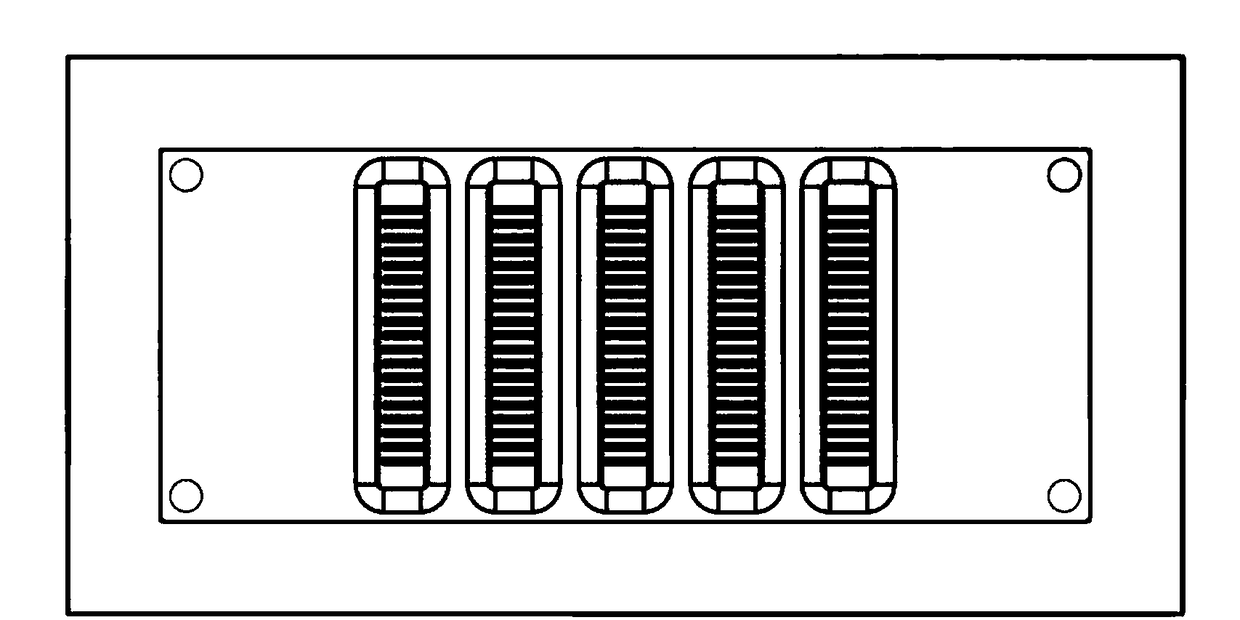

Air cold plate sealing forming technology of aluminum alloy

InactiveCN101007381AGuaranteed tightness requirementsLeakage and scrap rate is highWelding/cutting media/materialsMilling equipment detailsCold plateNitrogen gas

A aluminum alloy air-cooled freezing-plate sealing shaping process includes the following steps: 1. processing the appearance of freezing-plate, dissipating heat fins and cover plate parts according to structure design, the structure design of freezing-plate is flush type cavity structure, the two ends of freezing-plate shell is equipped with 2-3 soldering fabrication holes with diameter of 2-3mm; 2. welding the dissipating heat fins and freezing-plate shell, cover plate through the soldering method in nitrogen protection furnace; 3. milling out printed circuit board slots on the freezing-plate shell; welding the cover plate and shell vertical soldering seam through stirring friction welding; 5. mechanical processing the appearance and two end ventilators of freezing-plate according to the drawings requirements, processing the soldering fabrication holes into two end ventilators. The aluminum alloy freezing-plate using the art method of combination of soldering and stirring friction welding in the invention increases the resistant finely processed capacity of brazing seam surface, ensures the hermeticity requirement after finely process aluminum alloy freezing-plate and increases the welding yield rate of electronic structure cabinet.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

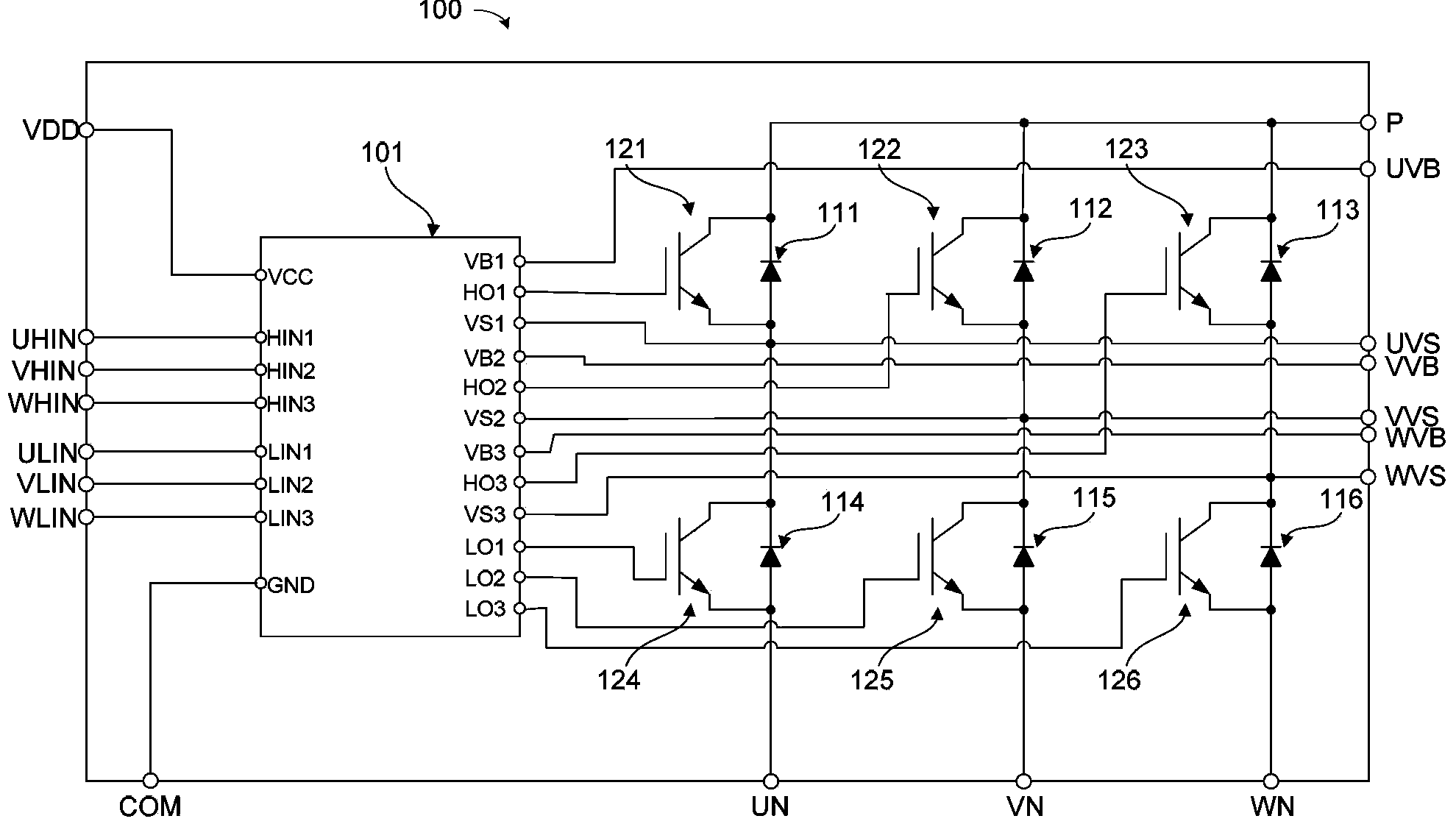

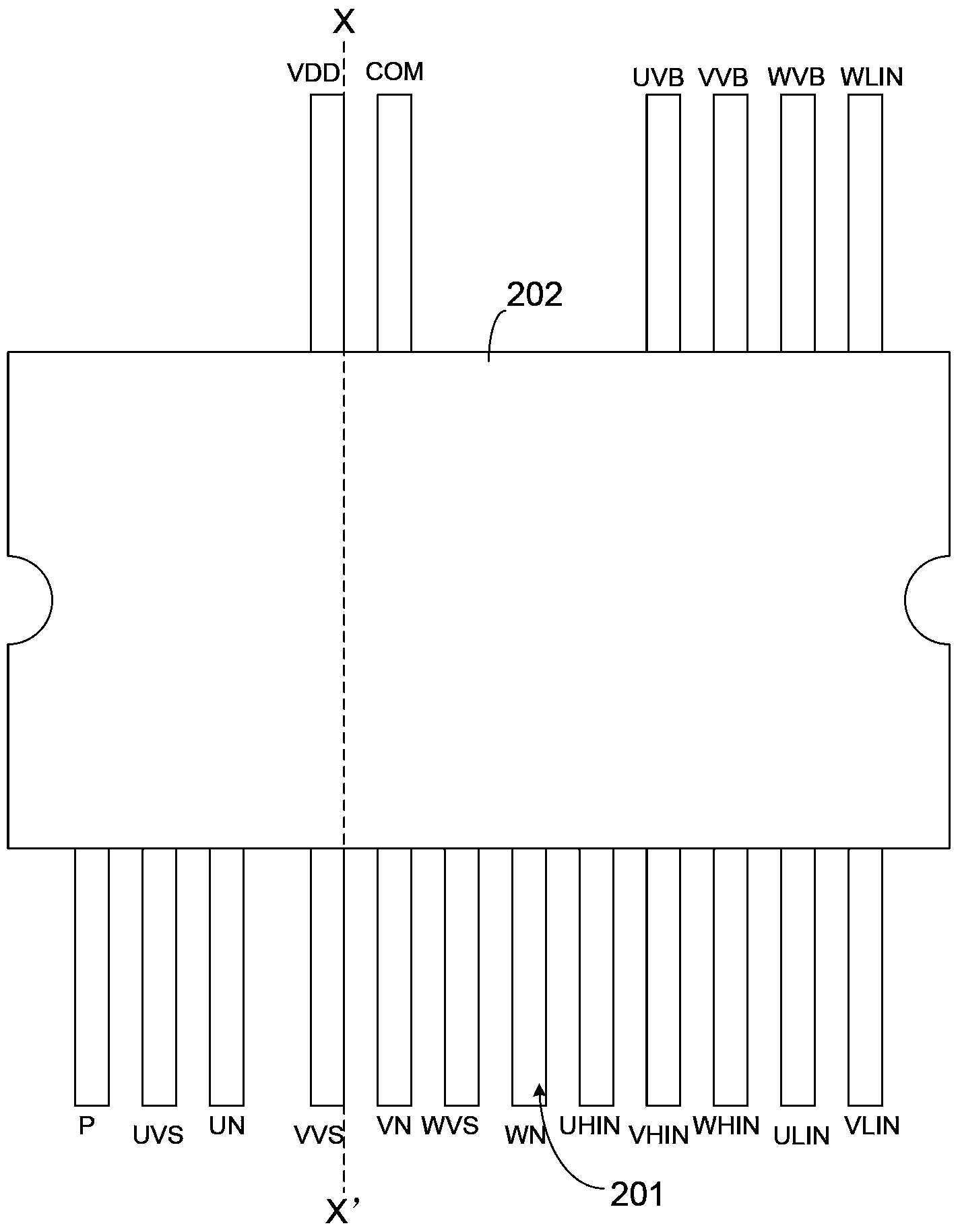

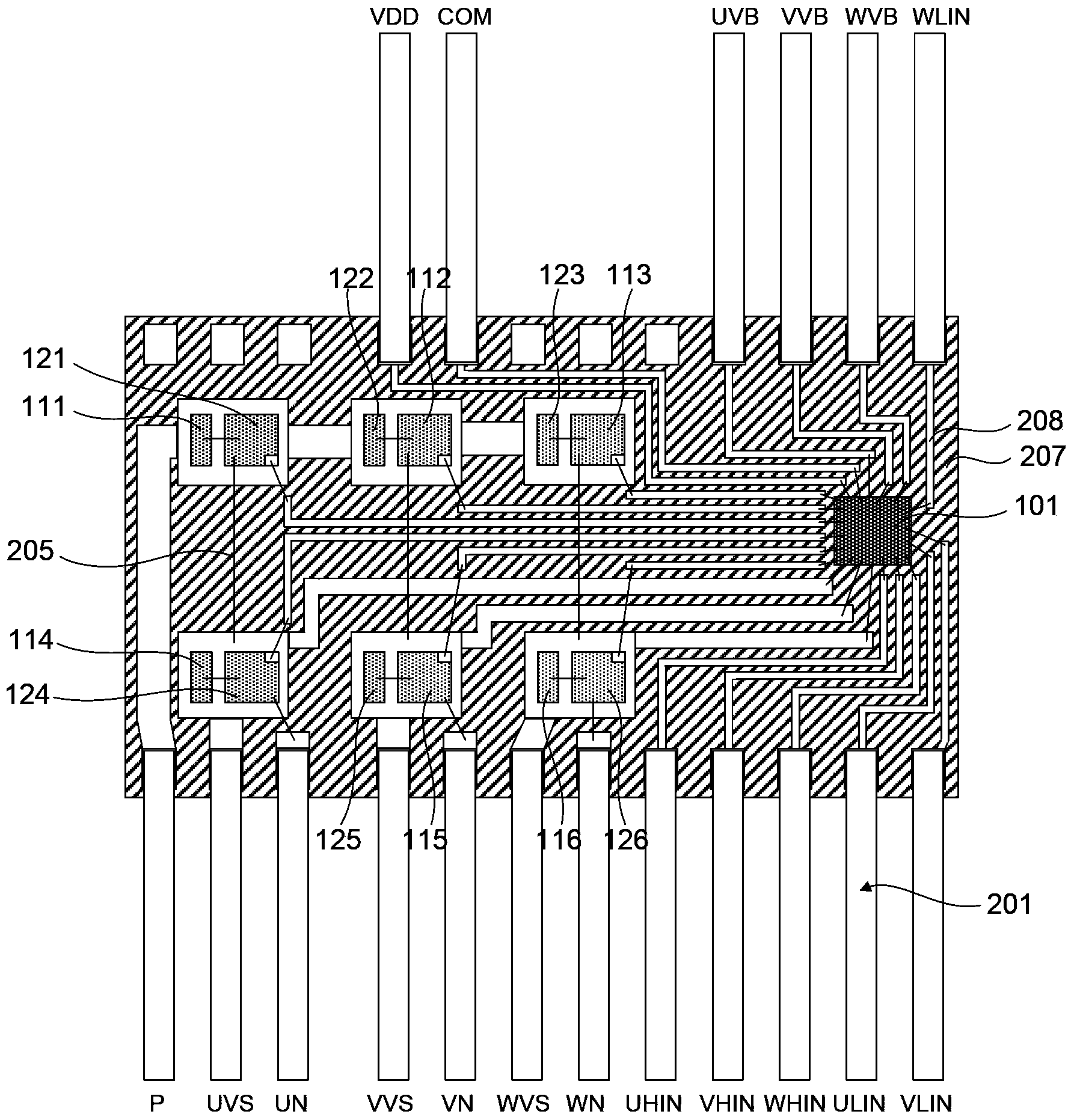

Intelligent power module and manufacturing method thereof

ActiveCN104112740AGuaranteed samenessReduce areaSolid-state devicesSemiconductor/solid-state device manufacturingElectricityComputer module

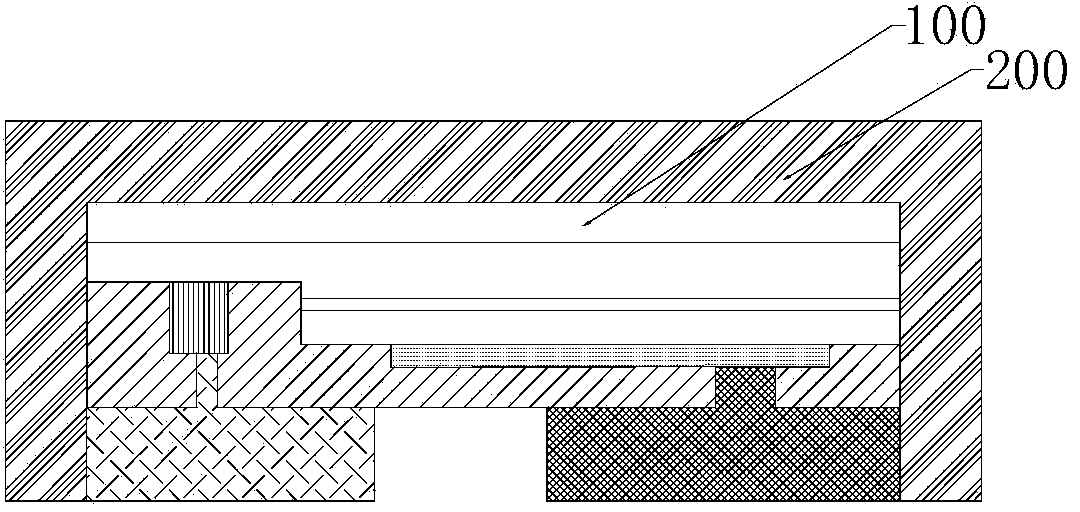

The invention is suitable for the technology of electronic devices, and provides an intelligent power module and a manufacturing method thereof. The intelligent power module comprises a metal substrate of which one surface is covered with an insulating layer; a circuit wiring layer which is formed on the surface of the insulating layer; multiple IGBT tubes which are arranged on the preset positions of the circuit wiring layer; gate electrode drive tubes which are identical with the IGBT tubes in number, wherein each gate electrode drive tube respectively acts as a drive circuit for the corresponding IGBT tube, and the drive end of each gate electrode drive tube is the same with wiring length of gate electrode electric connection of the IGBT tubes; and a metal wire which is connected between the circuit wiring layer, the IGBT tubes and the gate electrode drive tubes so that a preset circuit is formed. Wiring from the gate electrode drive tubes to the IGBT tube gate electrodes is ensured to be identical so that dynamic characteristics of the IGBT tubes are enabled to be identical without additional arrangement of wiring of the intelligent power module.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

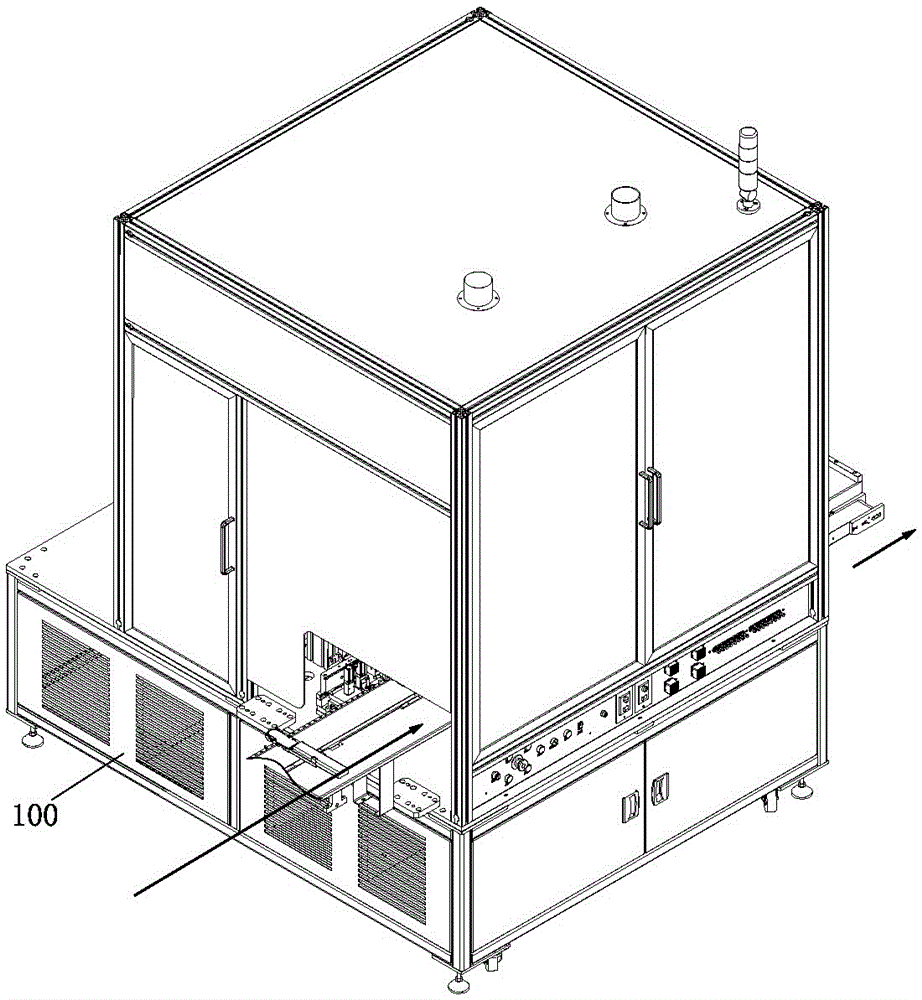

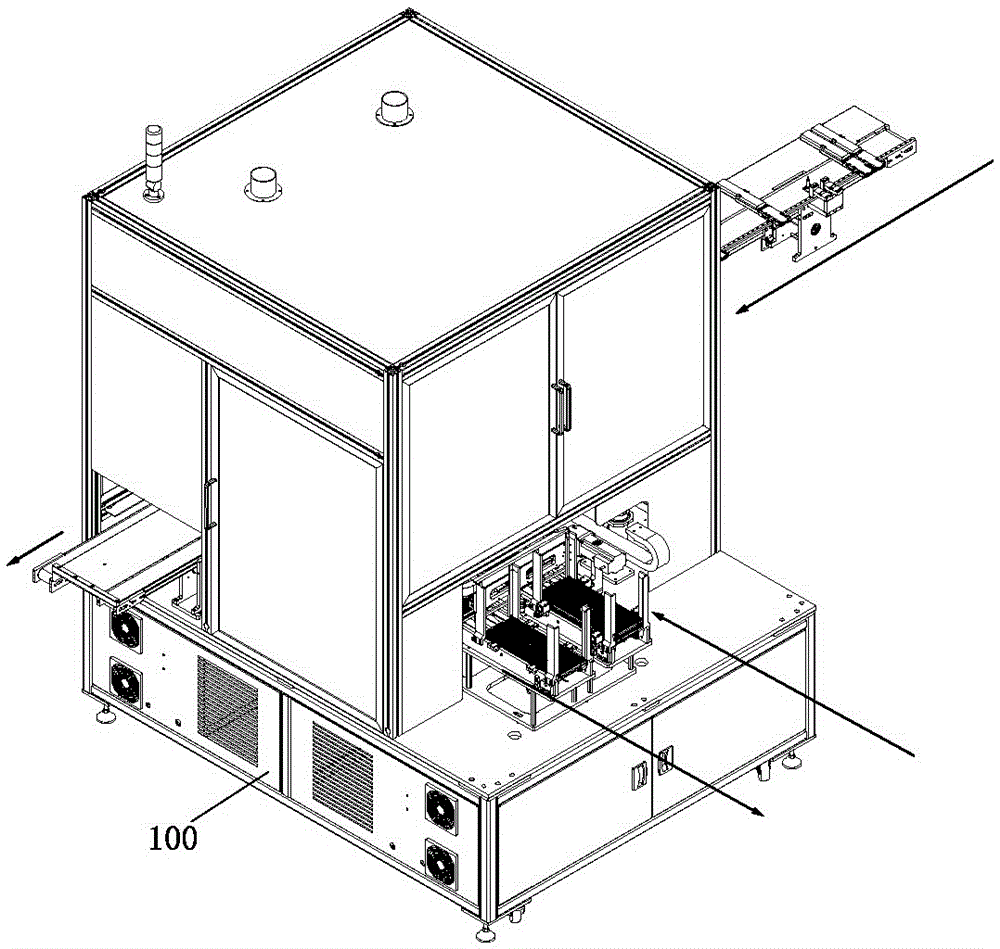

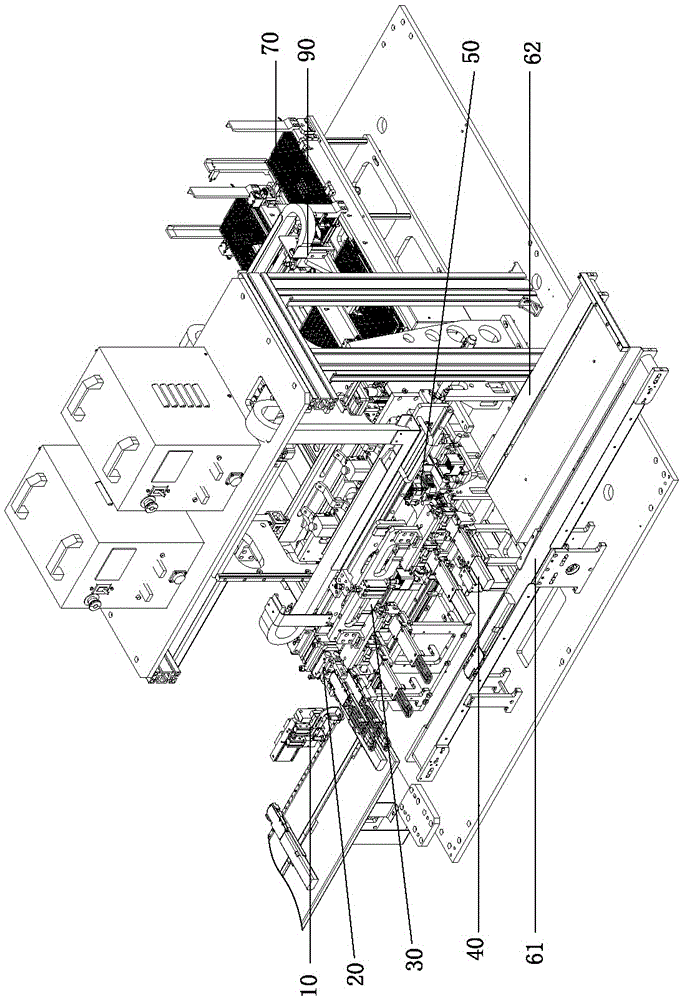

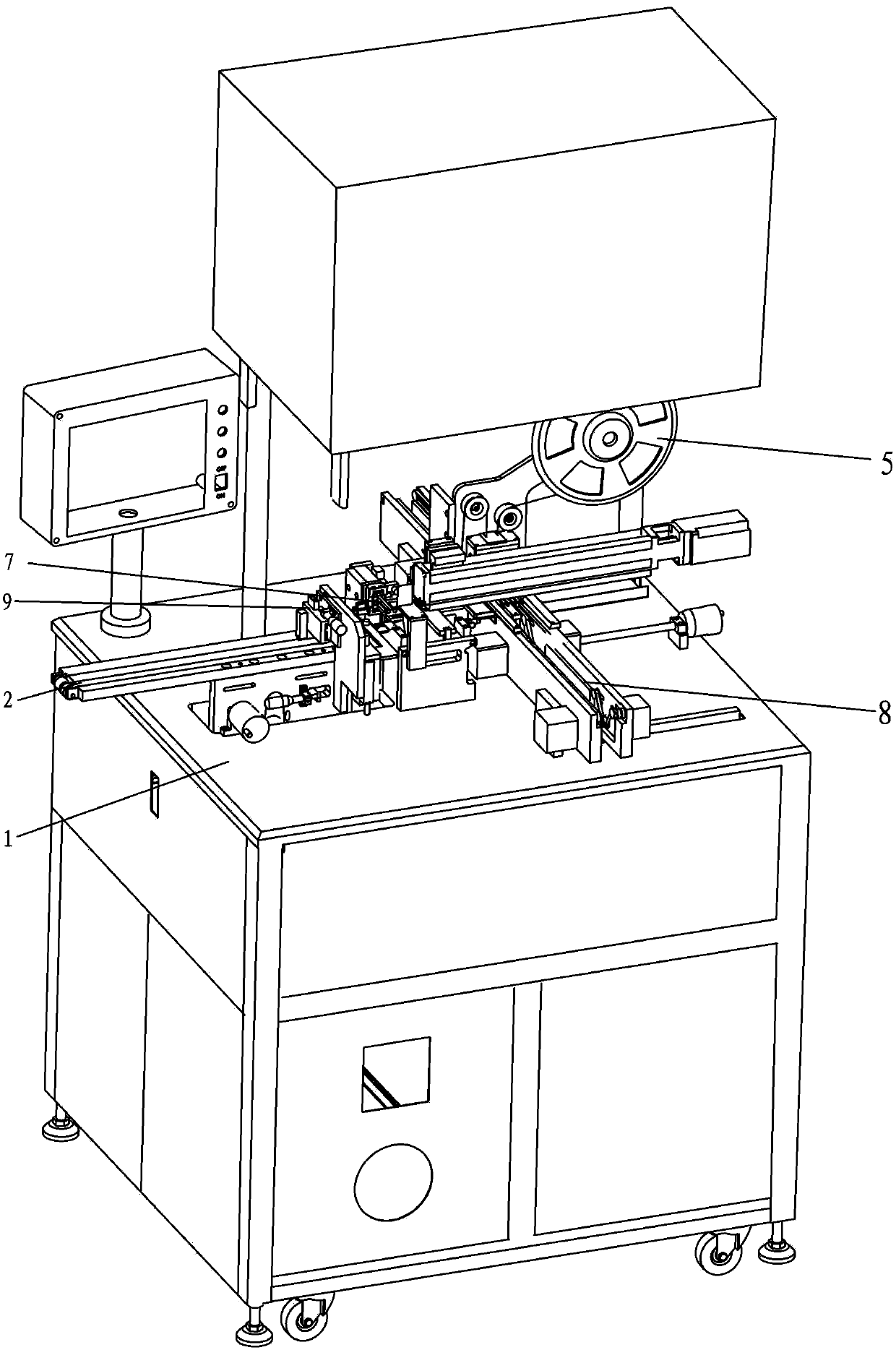

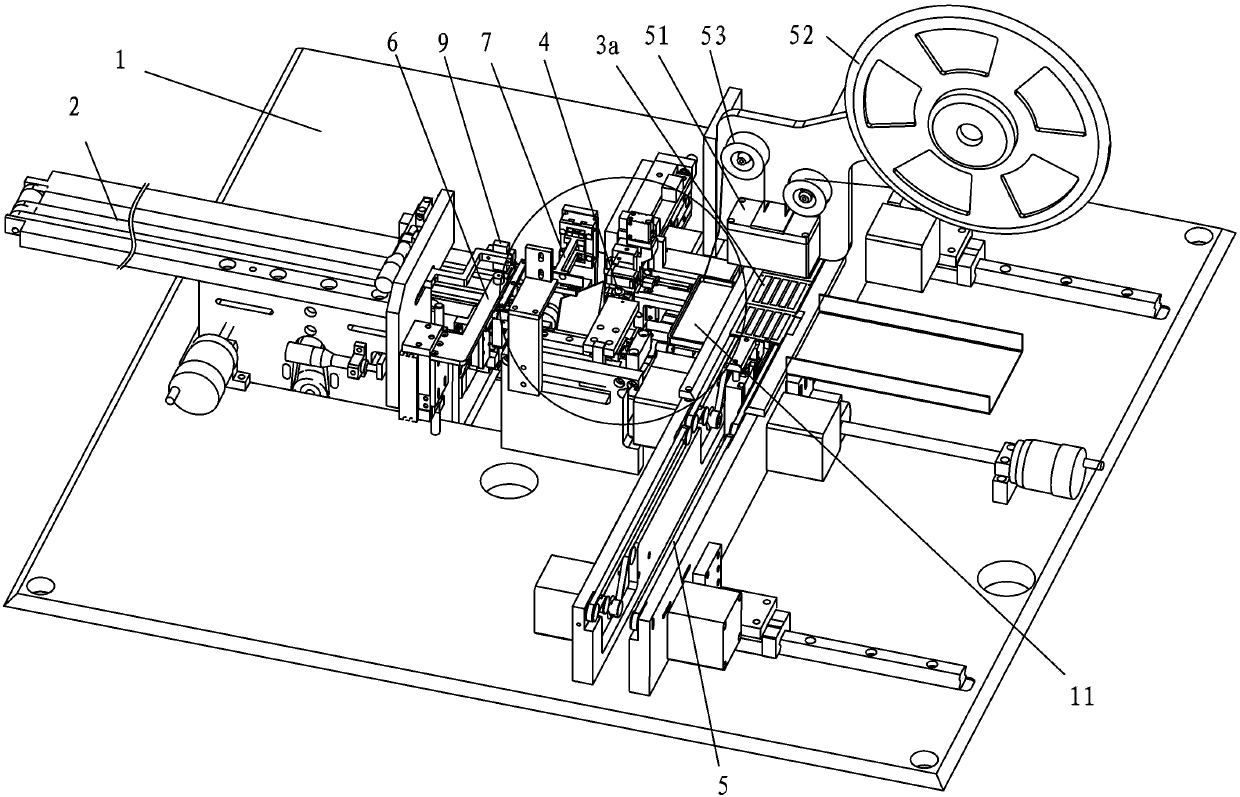

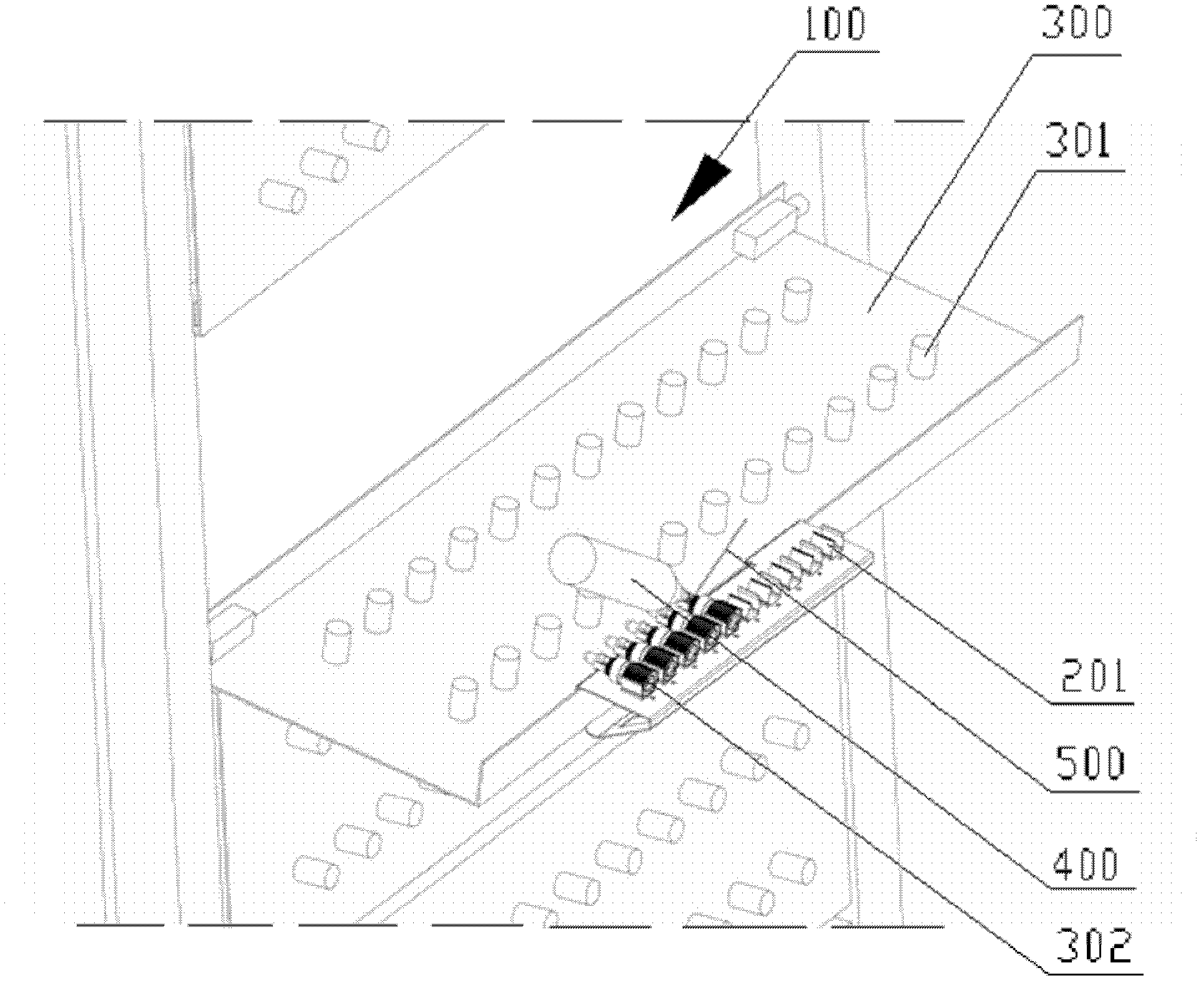

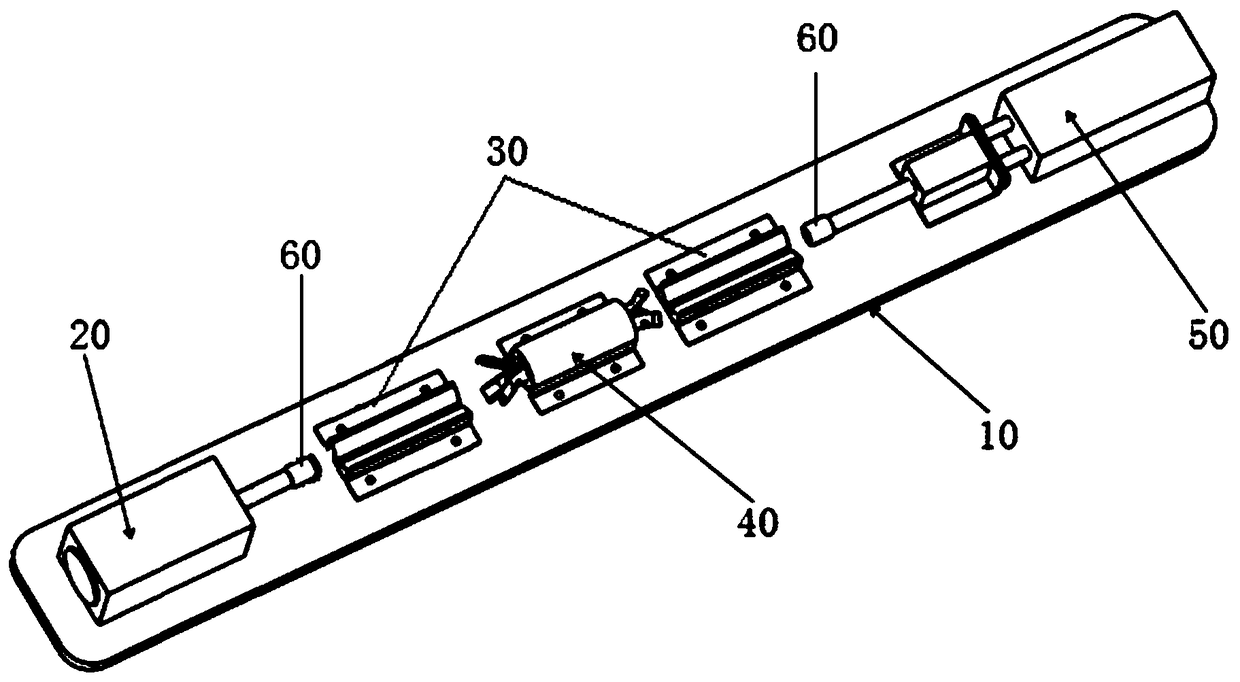

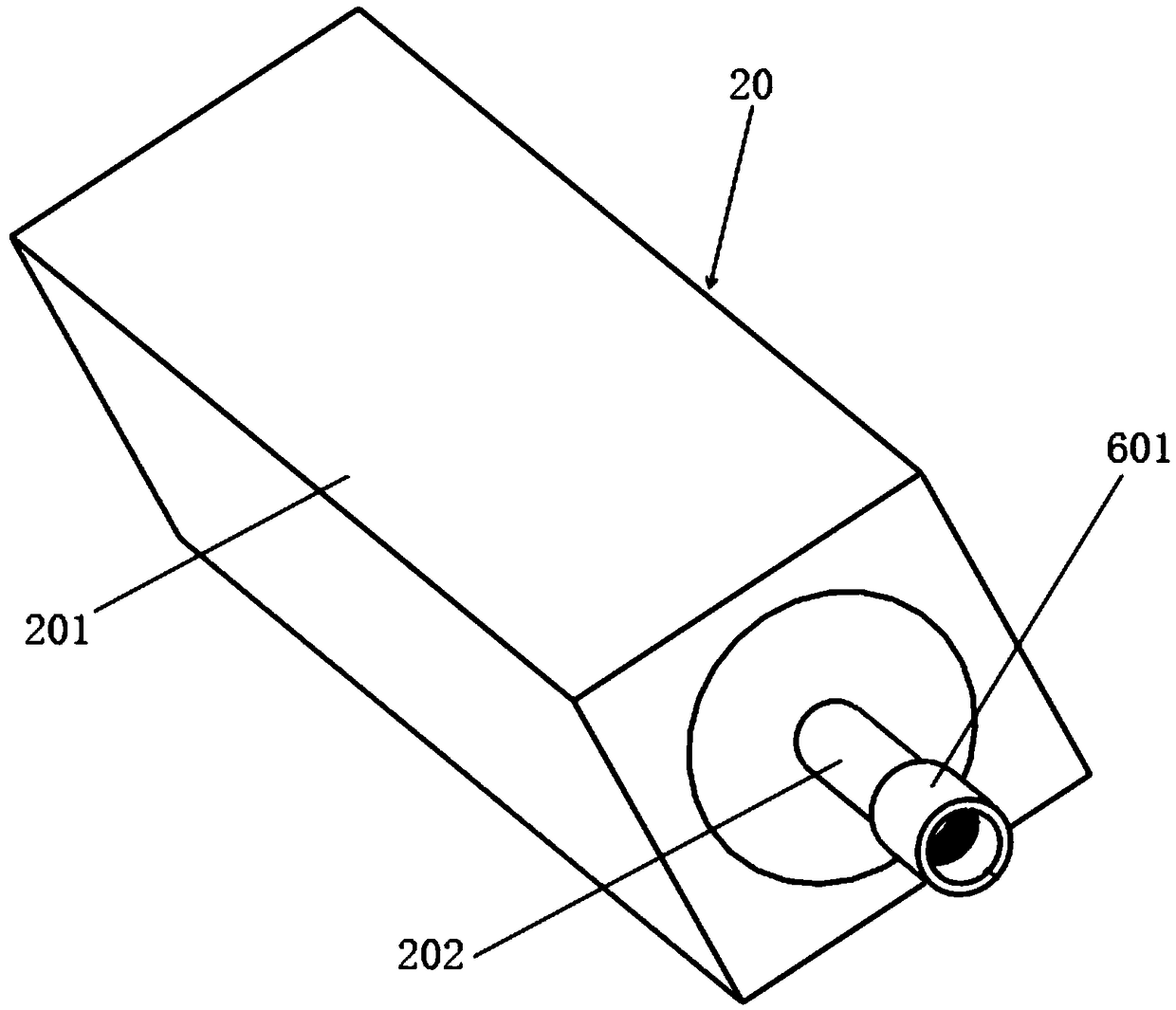

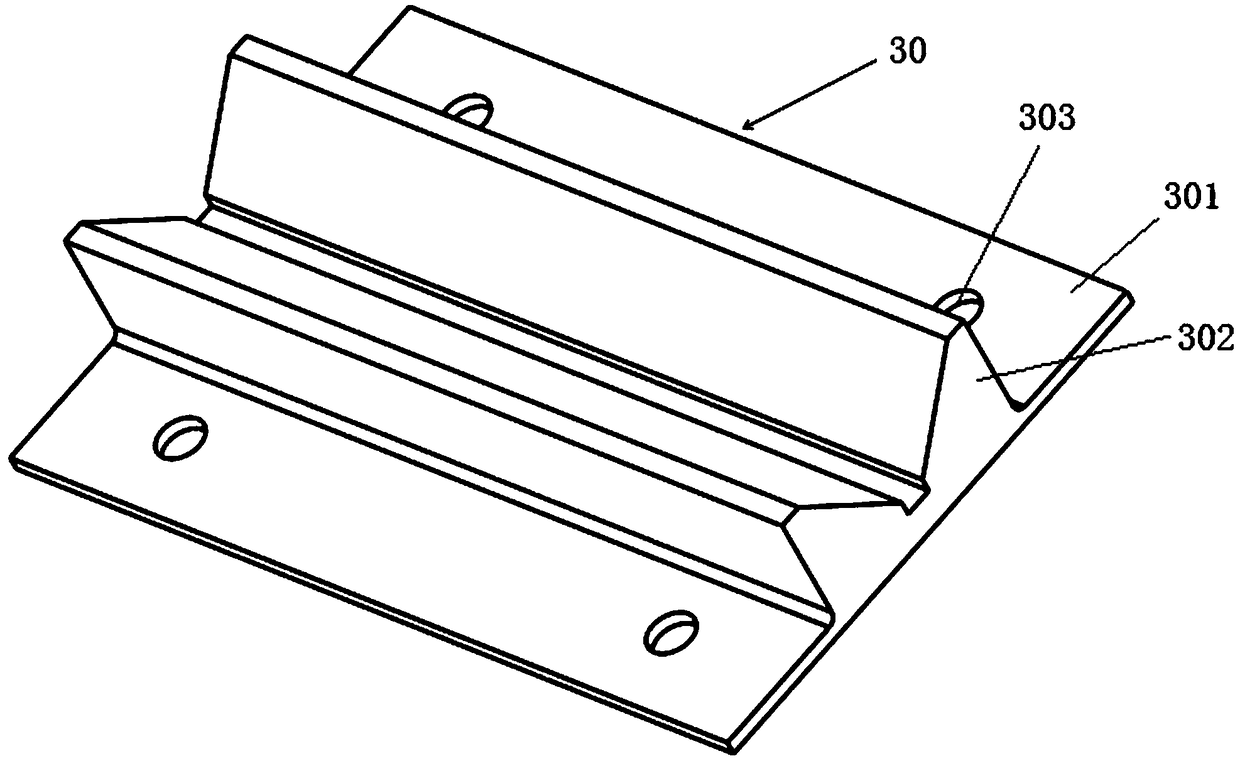

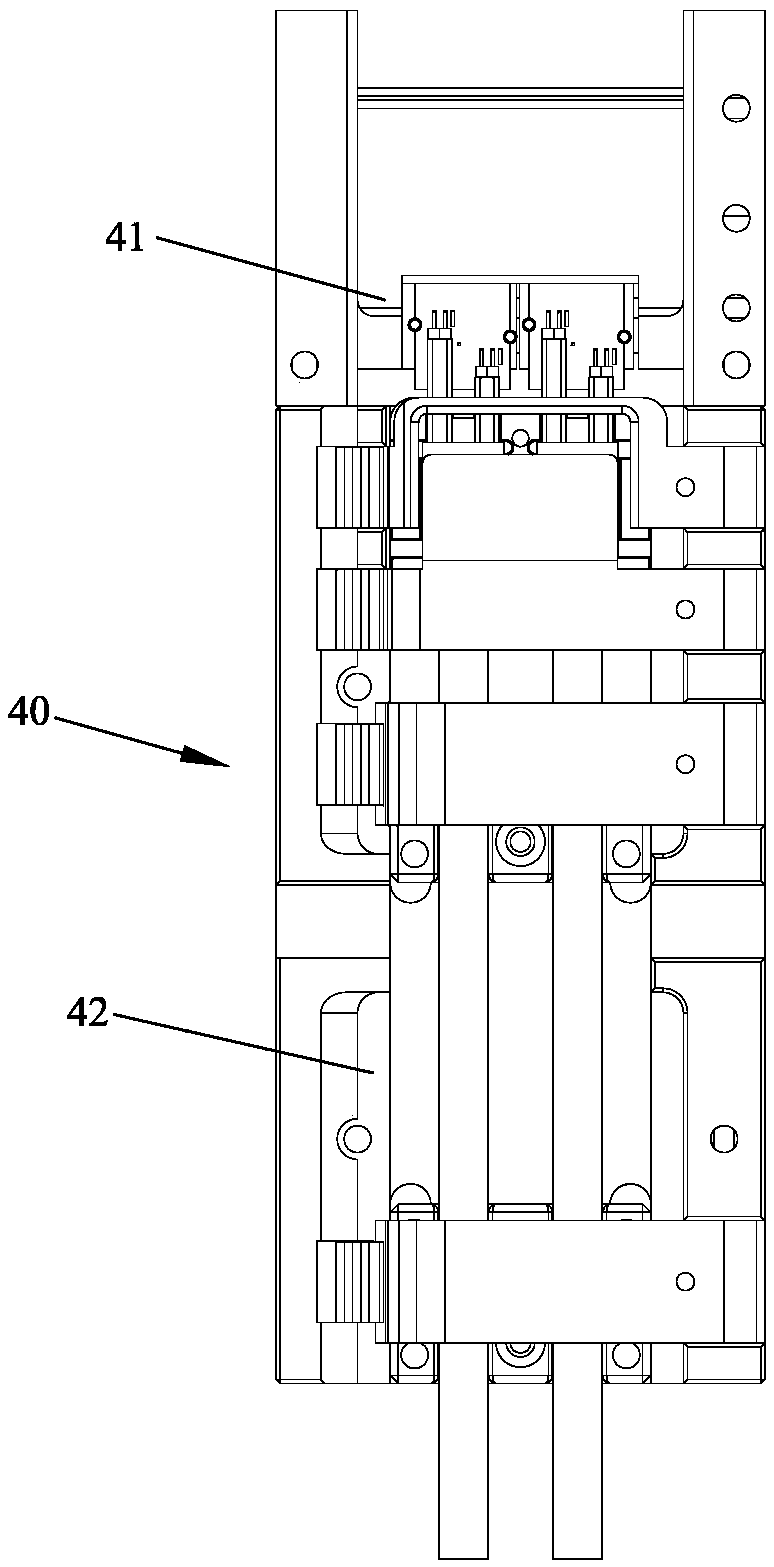

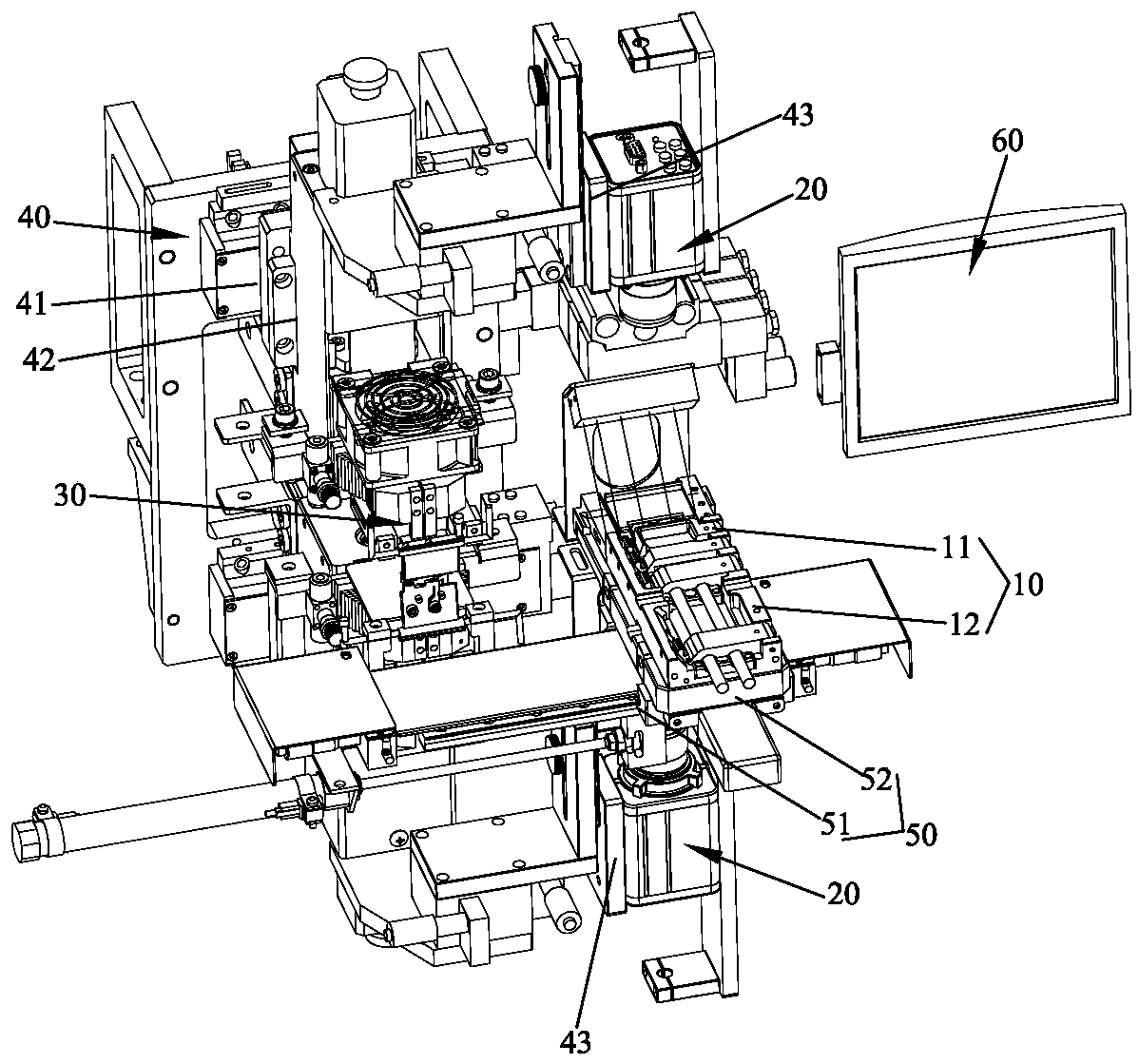

Connector core wire automatic welding device and welding method therefor

InactiveCN105470775AIngeniously realize fully automatic assembly and weldingReduce fatigueLine/current collector detailsCharge and dischargeElectrical and Electronics engineering

The present invention discloses a connector core wire automatic welding device and a welding method therefor. The device comprises a rack, an X-axis operating line arranged on the rack and a Y-axis operating line arranged on the rack; according to a process sequence, the X-axis operating line is sequentially provided with a fixture conveying module, an overturning and positioning module, a fixture shifting module, a fixture positioning module, a welding module, a fixture reflowing module, and a fixture discharging module; according to a process sequence, the Y-axis operating line is sequentially provided with a connector feeding module, a connector shifting module, and a tray unloading module; and the Y-axis operating line includes first and second Y-axis operating lines which are parallel to each other and charge and discharge materials through branch pipes. According to the device, the core wire and connector feeding and the combination welding at the welding module are realized through the X-axis operating line and the Y-axis operating line; an empty tray from which all connectors are taken out is output by the second Y-axis operating line; a fixture is automatically discharged by the fixture discharging module; and full-automatic assembling and welding of connectors and core wires are ingeniously realized, thereby greatly improving the welding efficiency and reducing the machining costs.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

White LED chip and manufacturing method thereof

ActiveCN104022207AImprove luminous efficiencyAvoid pollutionSemiconductor devicesEngineeringElectrode

The invention discloses a white LED chip and a manufacturing method thereof. The white LED chip comprises a mount type LED chip. A pre-molded optical conversion layer slice for light color conversion is mounted on an epitaxial substrate layer of the mount type LED chip. A light reflecting walls for light leakage at side surfaces of the LED chip closely surrounds the periphery of the mount type LED chip. The light reflecting wall is connected with the optical conversion layer slice. The manufacturing method of the while LED chip comprises the following steps: (1) manufacturing the light reflecting wall on the surface of the optical conversion layer slice, wherein the light reflecting wall is provided with a plurality of LED chip mounting chambers on the surface of the optical conversion layer slice; and (2) mounting the mount type LED chip in the LED mount chamber, and cutting the mount type LED chip to a single white LED chip which is provided with an optical conversion layer on the upper part and is provided with the light reflecting wall at the periphery. The white LED chip can improve light emitting efficiency of the white LED chip and furthermore can prevent bottom electrode pollution of the LED chip according to the prior art. Furthermore the white LED chip has advantages of easy production and high yield of the product.

Owner:APT ELECTRONICS

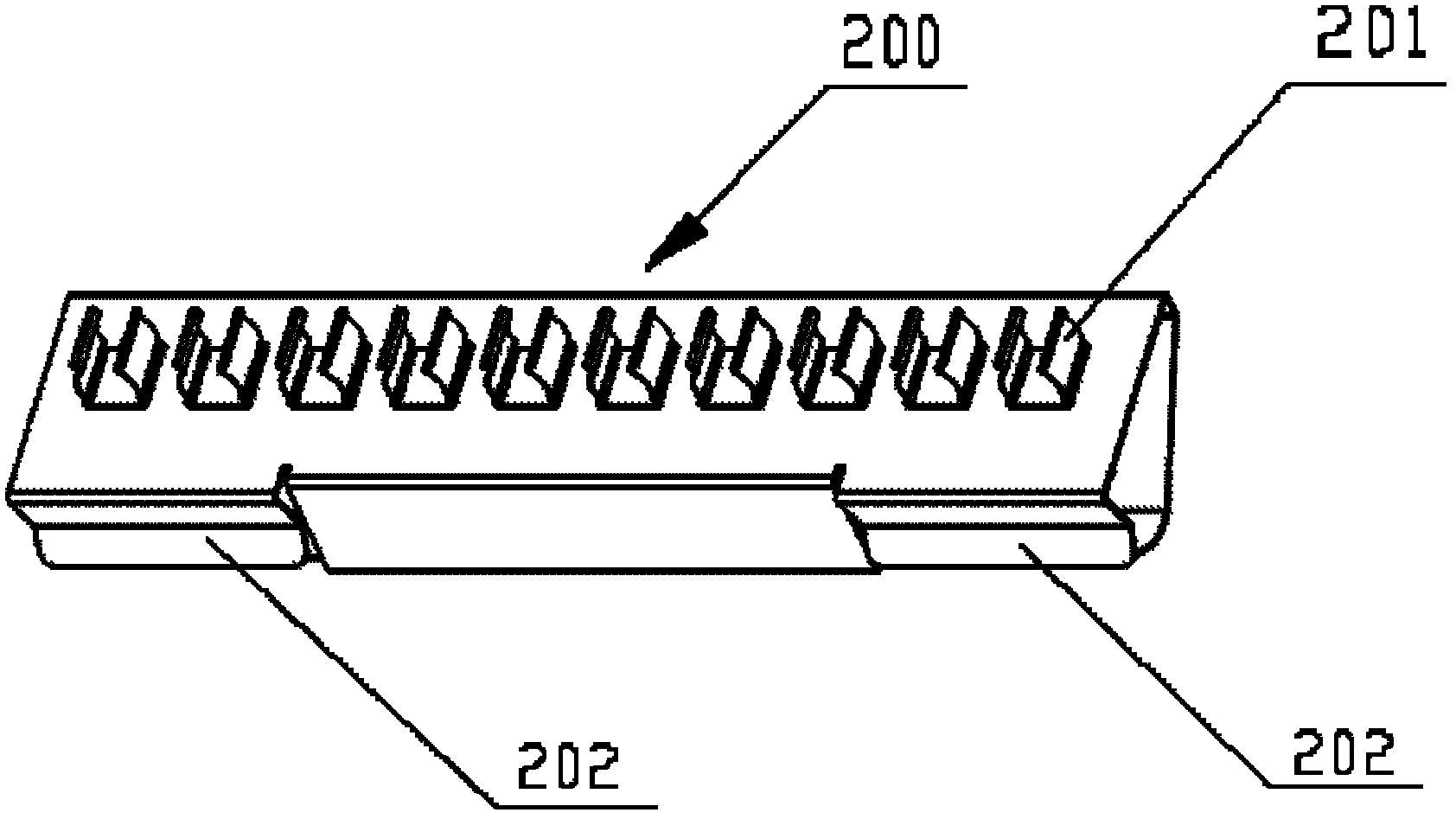

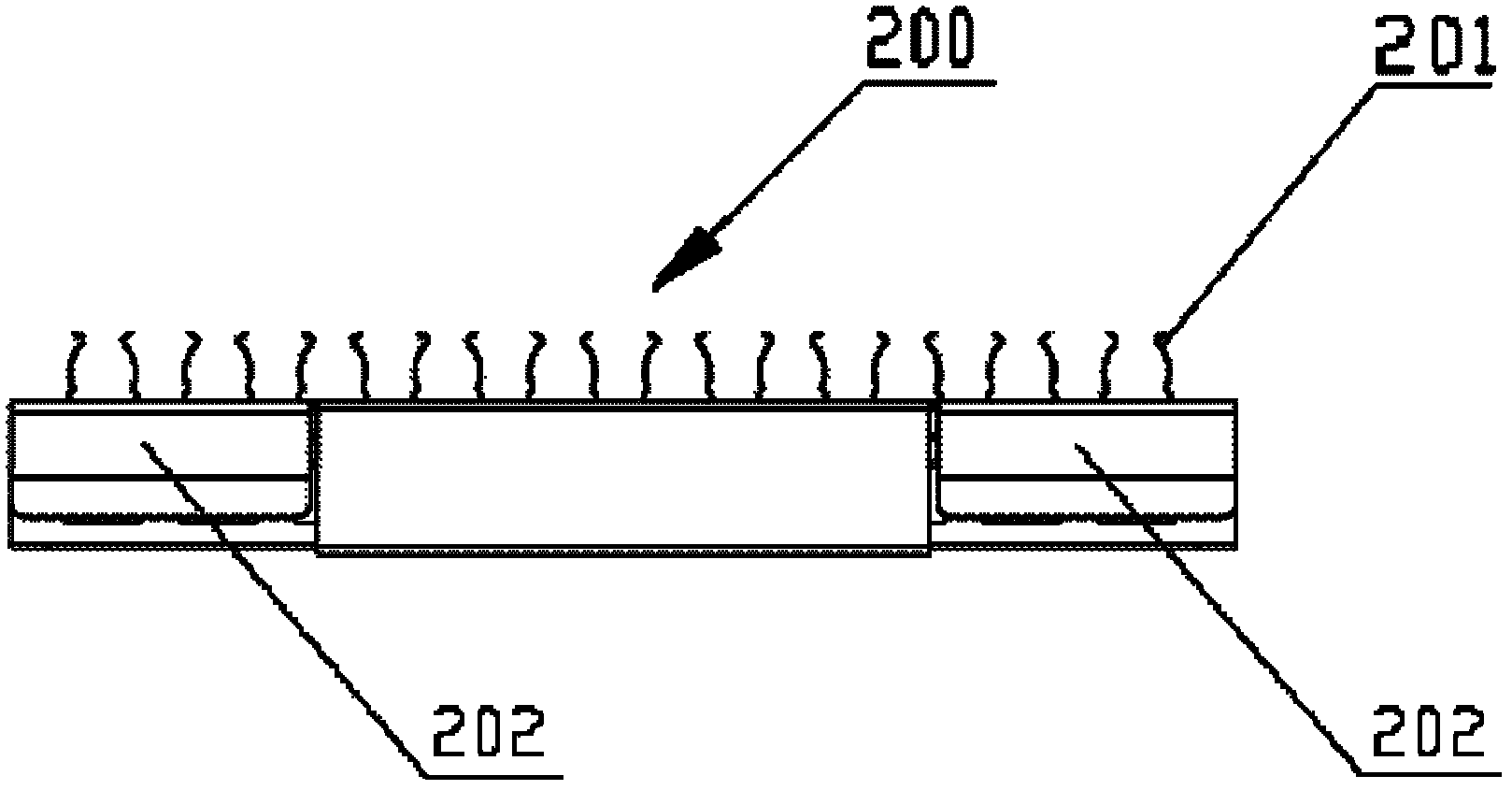

Automatic cell welding machine for small solar component

ActiveCN103386555AEasy to operateIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesIndustrial AccidentCell separation

The invention discloses an automatic cell welding machine for a small solar component. The automatic cell welding machine comprises a conveyor belt and a cell separation mechanism, which are sequentially connected along the feeding direction of a solar cell component. The automatic cell welding machine also comprises a welding strip conveying mechanism, a first suction mechanical hand, a welding mechanism, a second suction mechanical hand and a placement output mechanism. According to the automatic cell welding machine for the small solar component, the solar cell component is separated into independent solar cells through the cell separation mechanism, and a welding strip is welded on the back surfaces of the solar cells through the welding mechanism to connect electrodes of circuits in the solar cells. A staggered cell separation mode is adopted, so that the automatic cell welding machine is easy to operate, the production efficiency and the welding yield can also be improved, the labor intensity can be reduced, and the problems of high breaking rate of manual cell separation of the conventional small cell component, high pseudo welding rate and high component damage rate of the small component and high industrial accident rate are solved.

Owner:WINCHANCE TECH

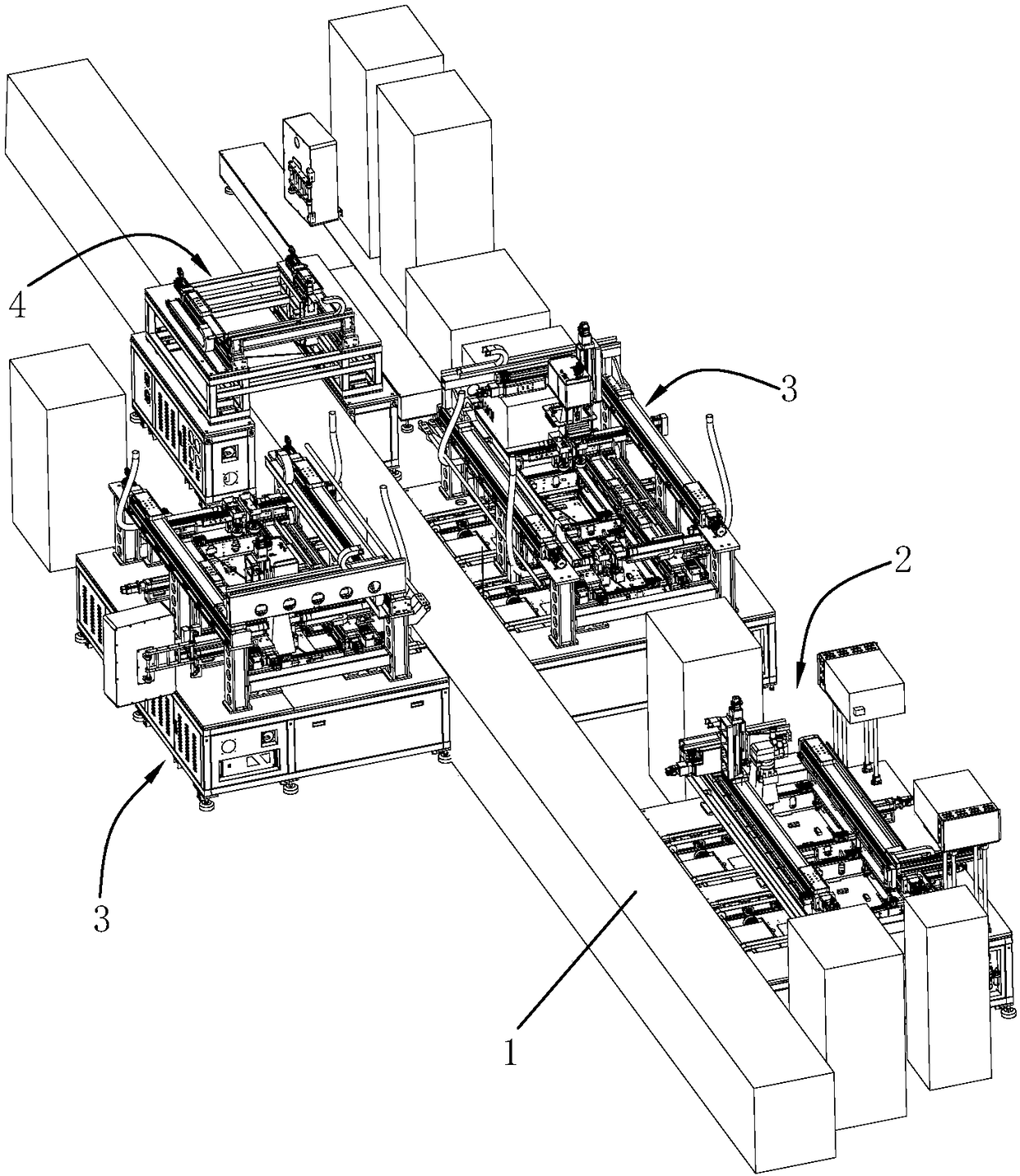

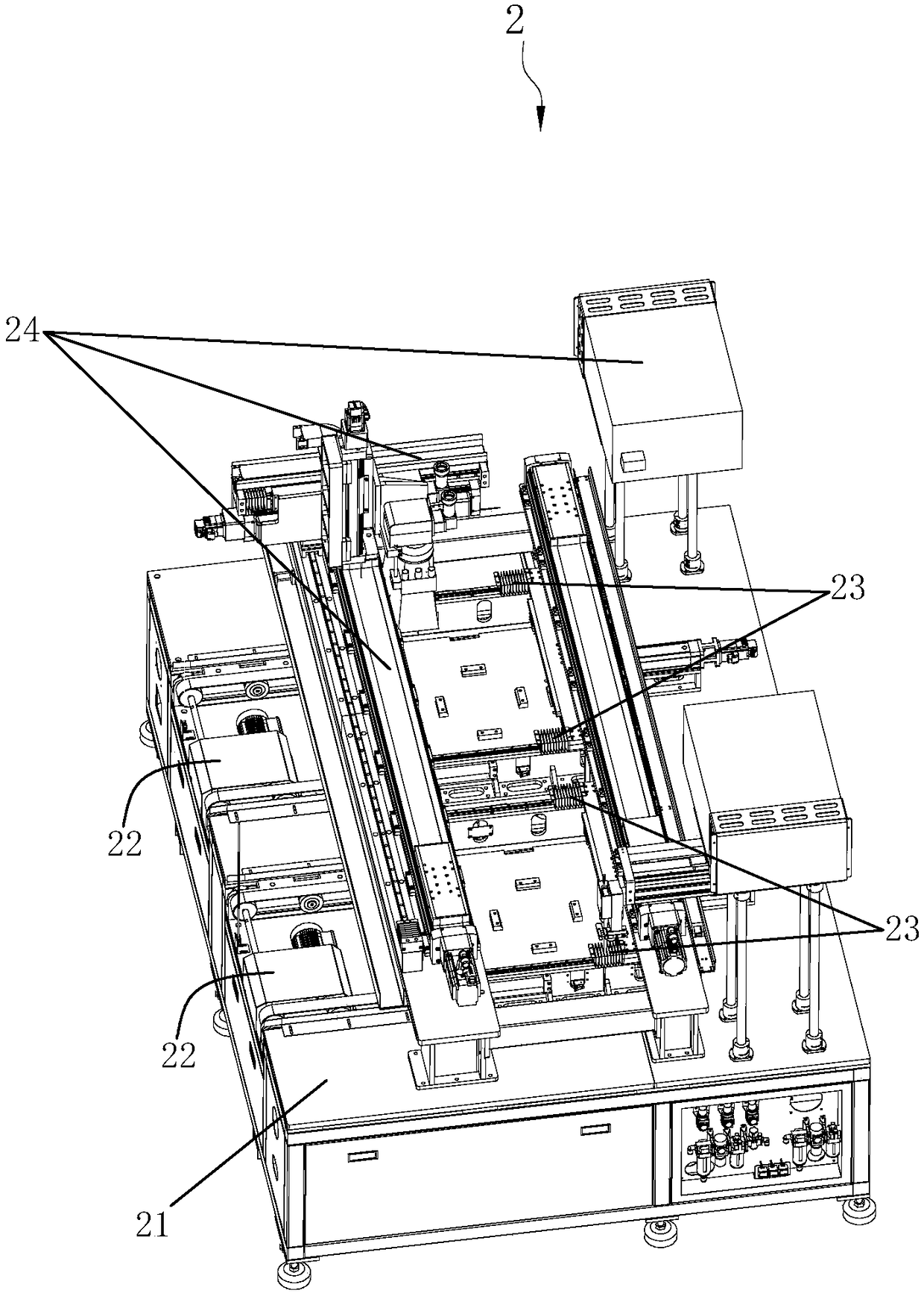

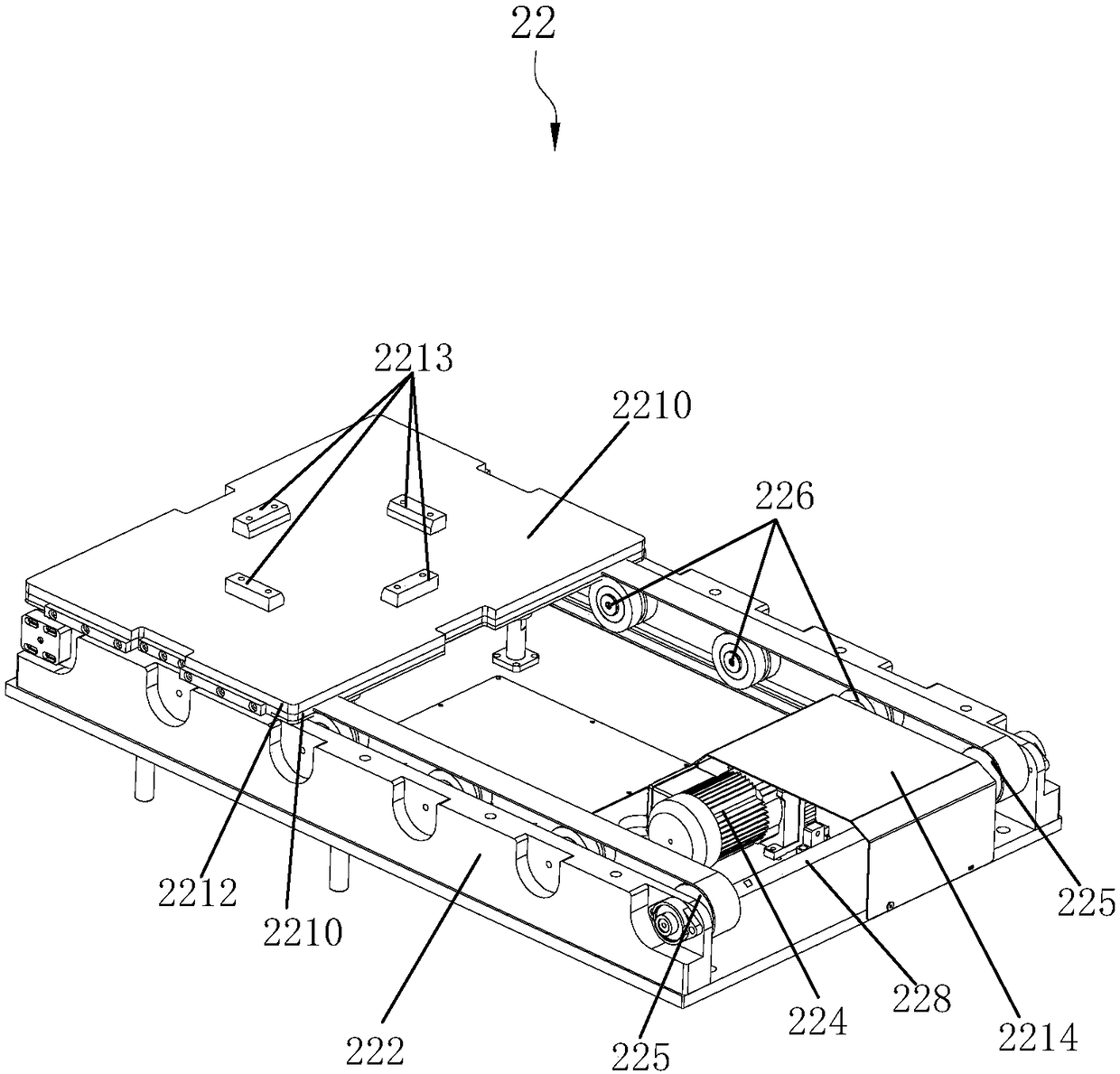

Automatic welding work station of battery module

PendingCN108539243AHighly integratedImprove cleanlinessFinal product manufactureCylindrical casing cells/batteryAssembly lineWorkstation

The invention discloses an automatic welding work station of a battery module. The automatic welding work station comprises an assembly line for conveying a battery module to be welded, and a laser washing device, at least one laser welding device and an after-welding detection device which are arranged in sequence along an operation direction of the assembly line, wherein the laser washing deviceis arranged beside the assembly line and is located at an entrance of the assembly line; the laser washing device is used for carrying out laser washing on the battery module to be welded; the laserwelding devices are symmetrically arranged at two sides of the assembly line, are located between the laser washing device and the after-welding detection device and are used for welding a battery cell electrode column on the battery module and a module bus bar; the after-welding detection device is arranged at two sides of the assembly line and is located at one end far away from the laser washing device; the after-welding detection device is used for detecting whether the quality is qualified or not after welding is finished. Compared with traditional module welding equipment, the automaticwelding work station has the characteristics of relatively high automation degree, working efficiency, welding yield and the like.

Owner:UNITED WINNERS LASER CO LTD

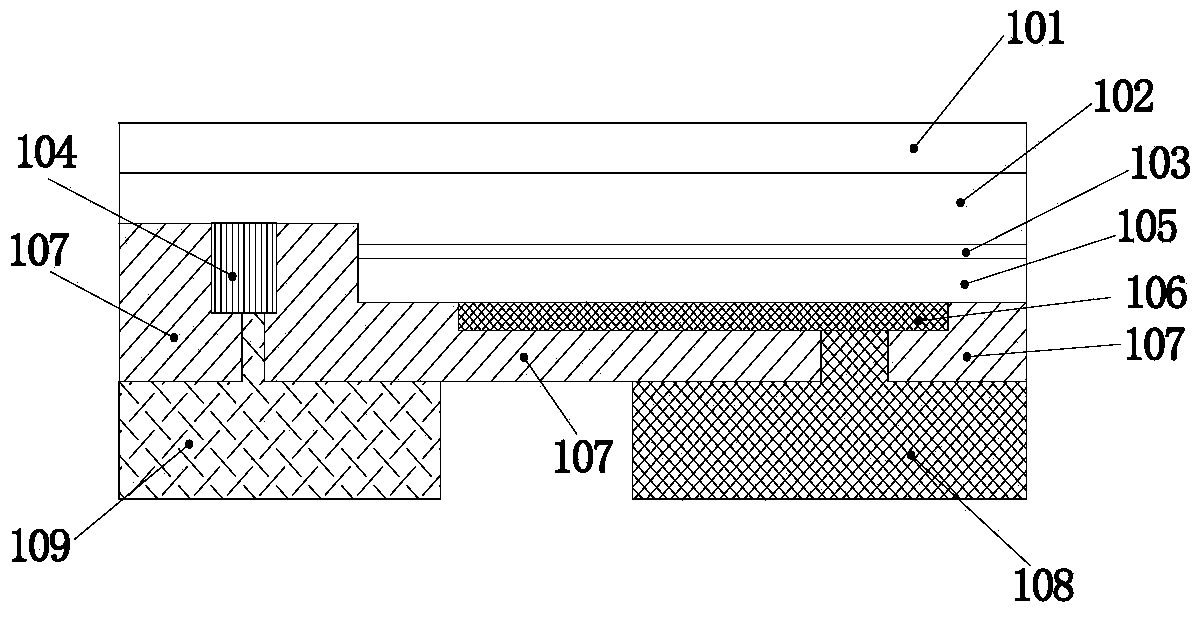

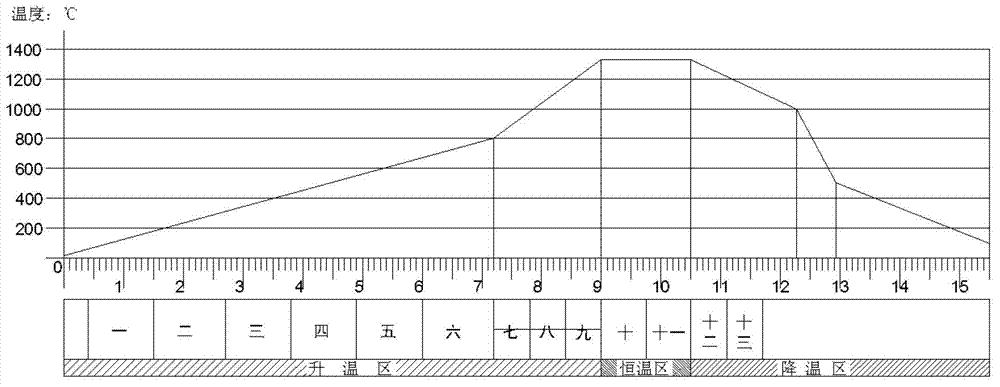

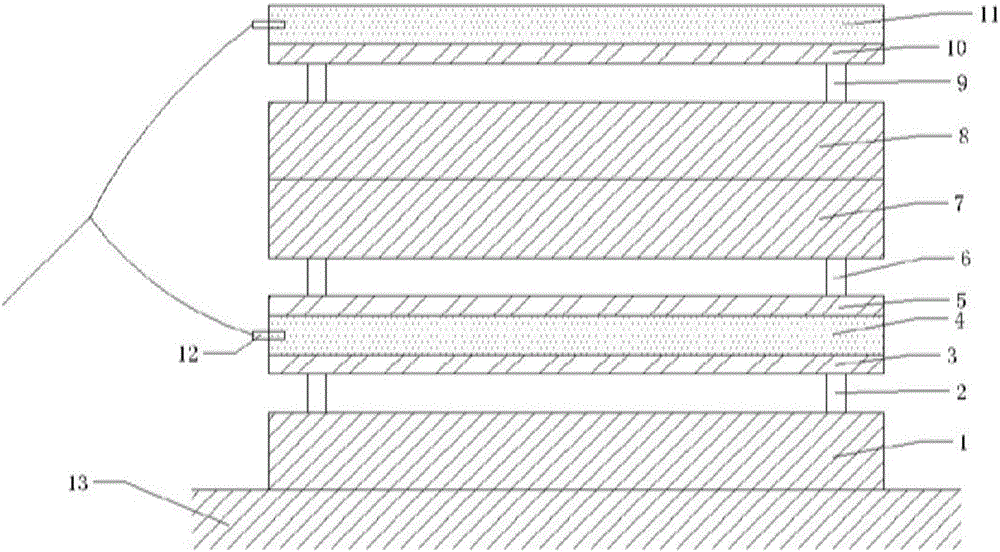

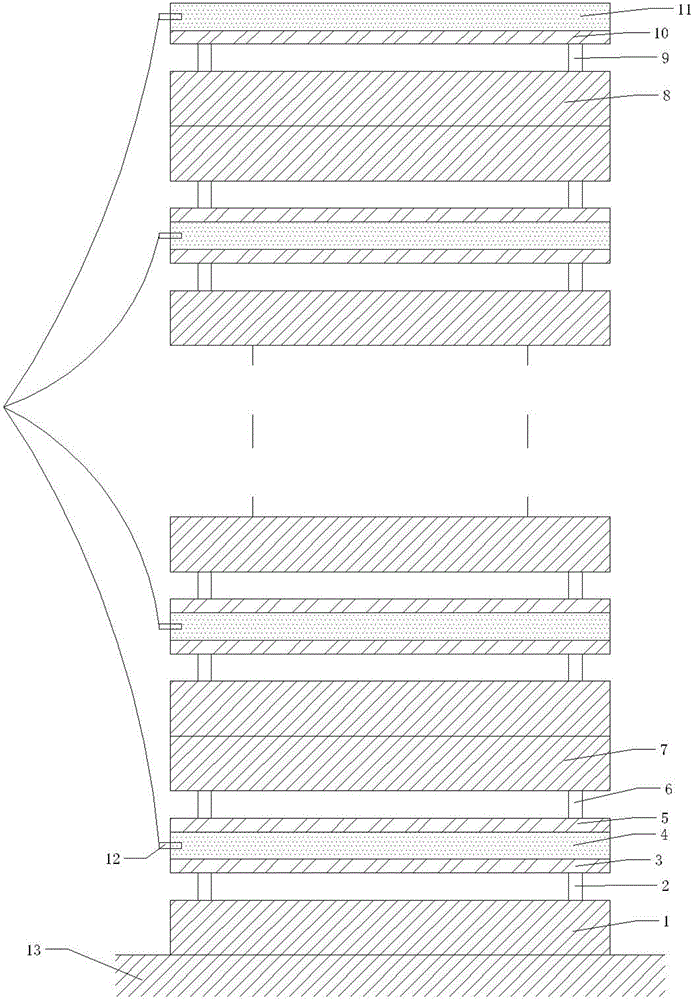

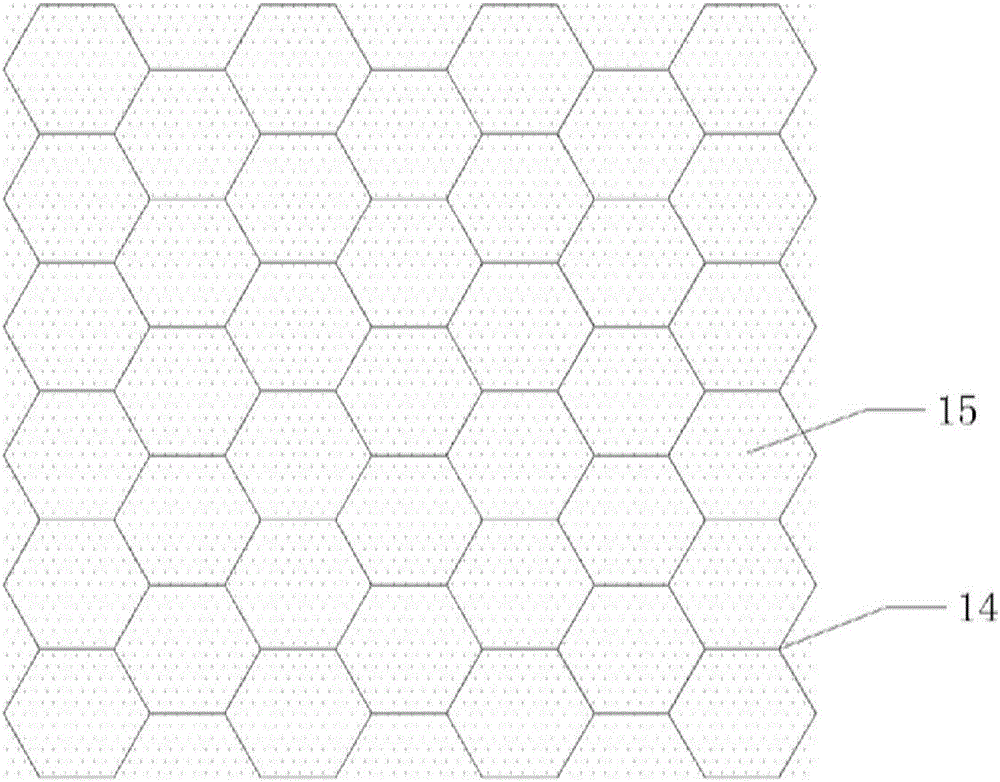

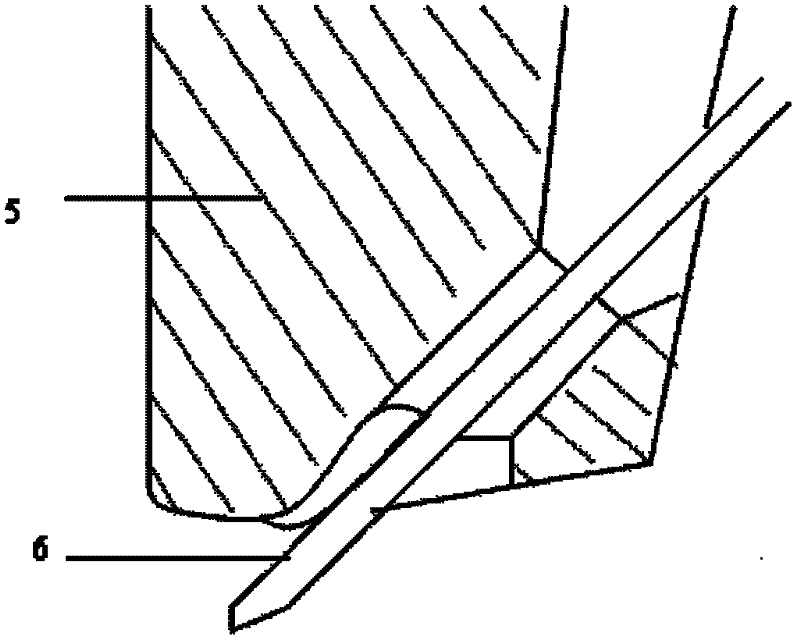

Preparation method of high temperature resistant packaging framework of silicon carbide diode

ActiveCN105118790AImprove welding yieldImprove production yieldSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor device fabricationDiode

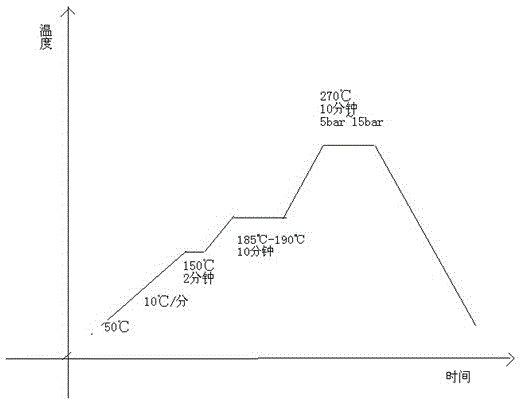

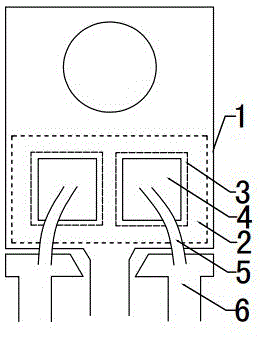

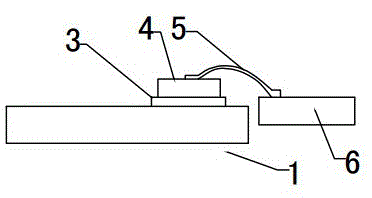

A preparation method of a high temperature resistant packaging framework of a silicon carbide diode belongs to the field of manufacture equipment for a semiconductor device. The preparation method is characterized by comprising the following low temperature sintering steps of: putting a framework main body (1) into a vacuum welding furnace, silicon carbide crystal grains (4) adhering to the framework main body by a nano-silver paste; vacuumizing the vacuum welding furnace to 50-55 mbar and then filling with nitrogen; heating the vacuum welding furnace at a speed of a speed of 10-12 DEG C / min to 150-155 DEG C and keeping the temperature for 2-4 min; and then continuously heating the vacuum welding furnace to 185-190 DEG C and keeping the temperature for 8-12 min; heating the vacuum welding furnace again to 270-275 DEG C; vacuumizing the vacuum welding furnace and filling with nitrogen to 5 bar-15 bar and keeping the pressure for 10-15 min to ensure a bonding strength; and then carrying out cooling, and finishing the welding of the silicon carbide crystal grains (4) and the framework main body (1). According to the invention, two weld zones (a cooling zone and a heating zone) are matched with special temperature curves, and a certain of pressure is added in a welding process. The welding time is shortened, and the production efficiency is improved.

Owner:淄博美林电子有限公司

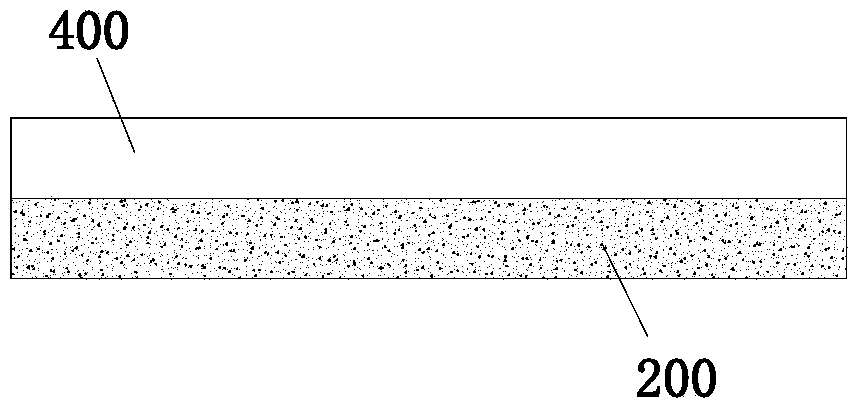

White-light LED chip and manufacturing method for white-light LED chip

ActiveCN104167482AAvoid pollutionImprove welding yieldSemiconductor devicesSurface mountingEngineering

The invention discloses a white-light LED chip and a manufacturing method for the white-light LED chip. The white-light LED chip comprises a surface-mount type LED chip body and a light conversion layer which is used for converting light colors and formed in a prefabricated mode. The manufacturing method for the white-light LED chip includes the following steps: manufacturing the light conversion layer which is used for converting the light colors and formed in the prefabricated mode, arranging one or more installation cavities, where the LED chip bodies are installed, in the surface of the light conversion layer, arranging the LED chip bodies into the installation cavities in a surface-mount mode, and cutting the light conversion layer to form the single while-light LED chips with each installation cavity where the corresponding LED chip body is installed as the unit. By means of the white-light LED chip and the manufacturing method, the light emitting efficiency of the while-light LED chip can be improved, pollution to an electrode at the bottom of an LED chip body in an existing method can be avoided, and the white-light LED chip has the advantages of being easy to produce and manufacture and high in product yield.

Owner:APT ELECTRONICS

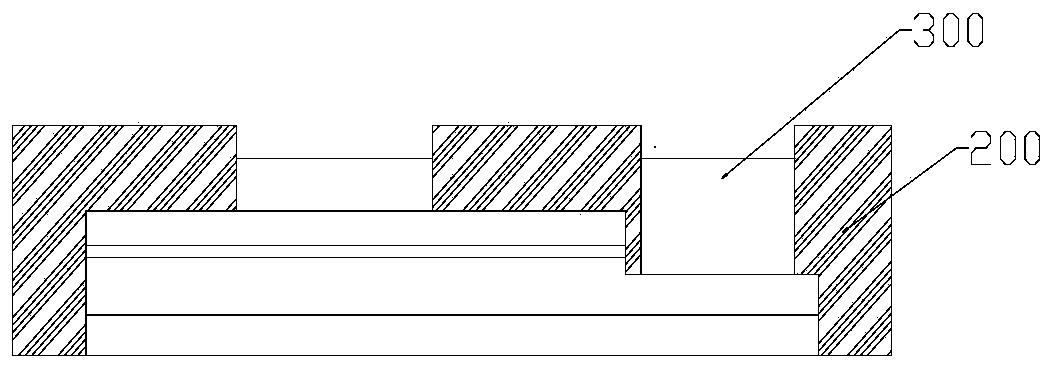

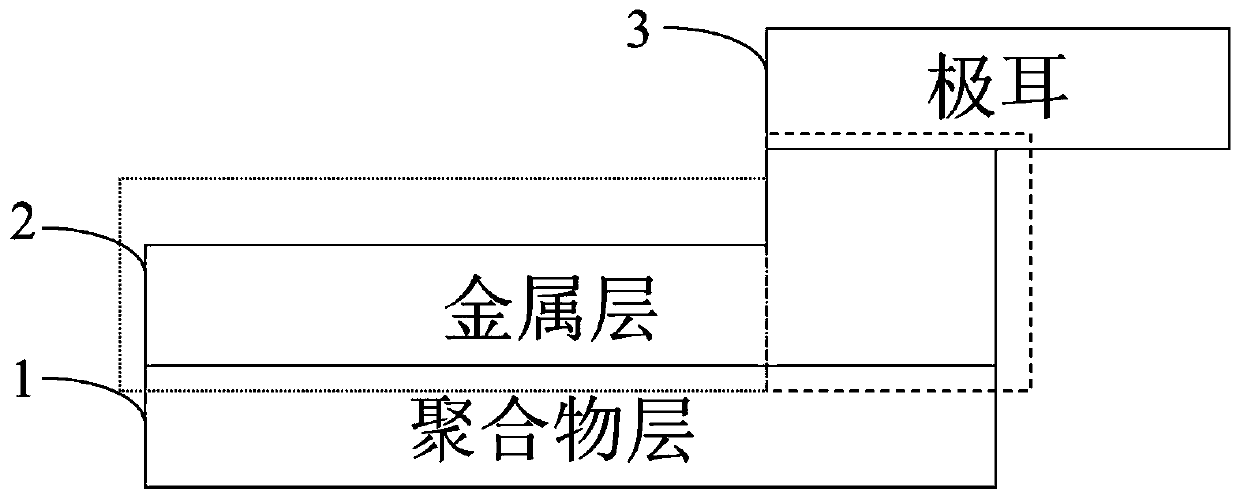

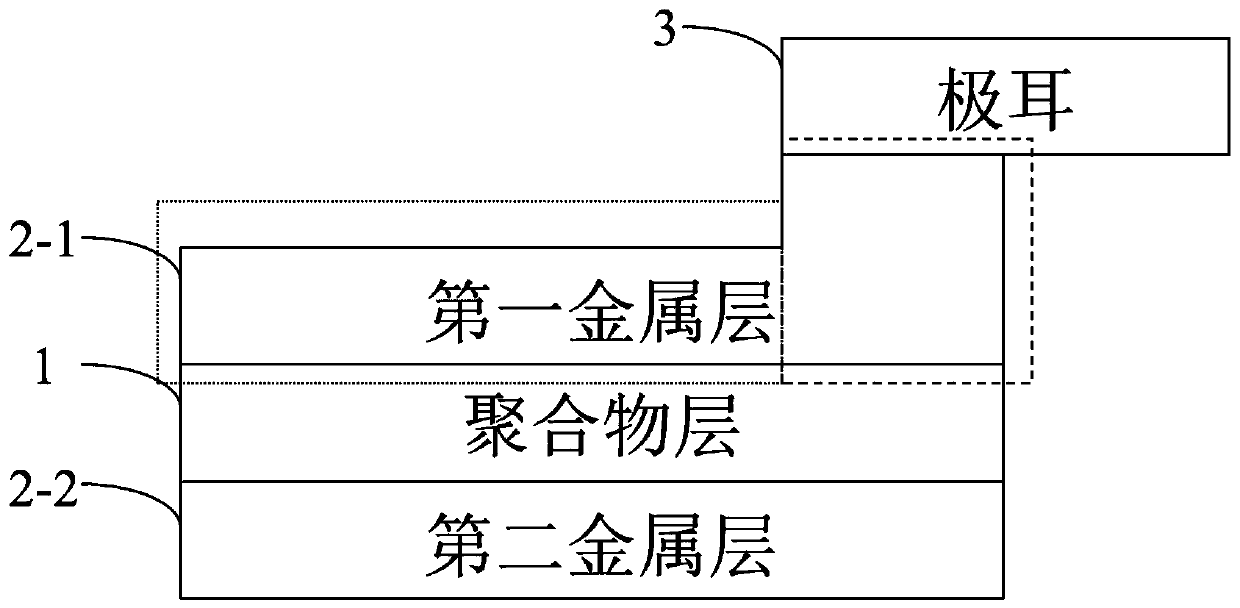

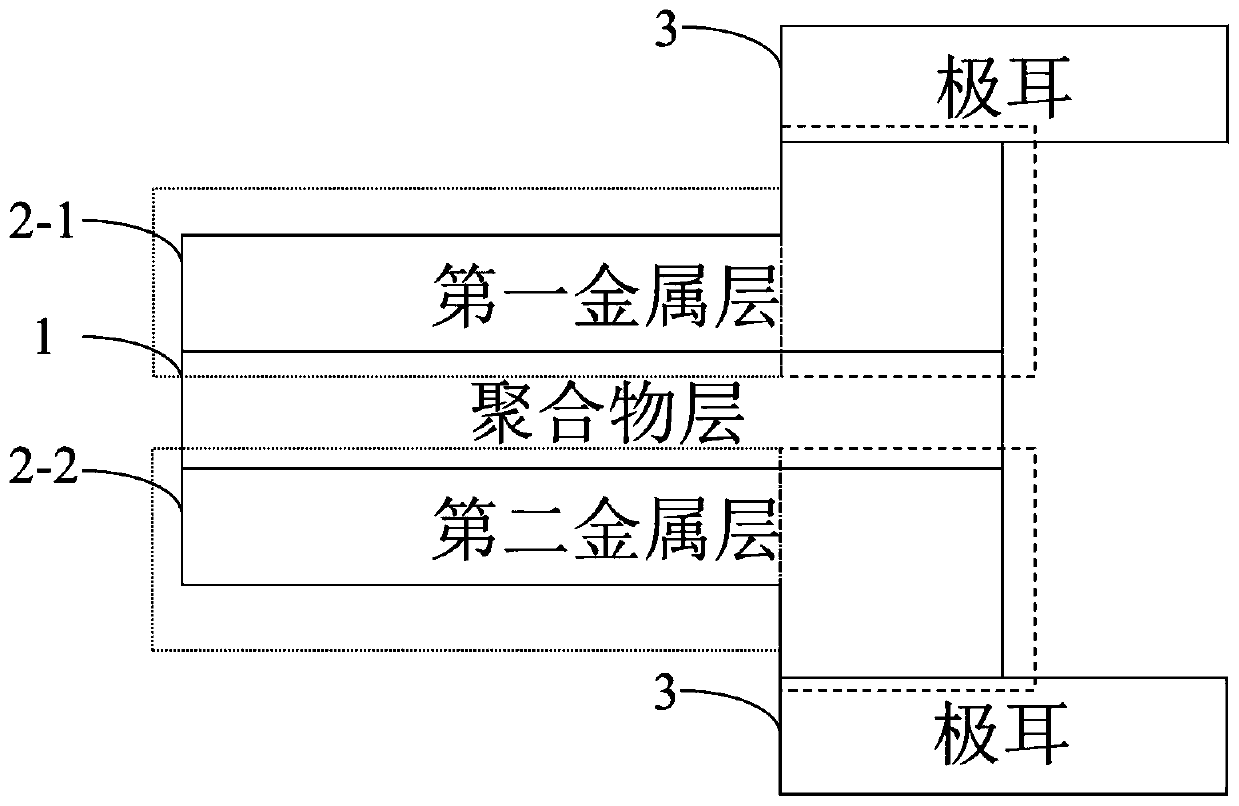

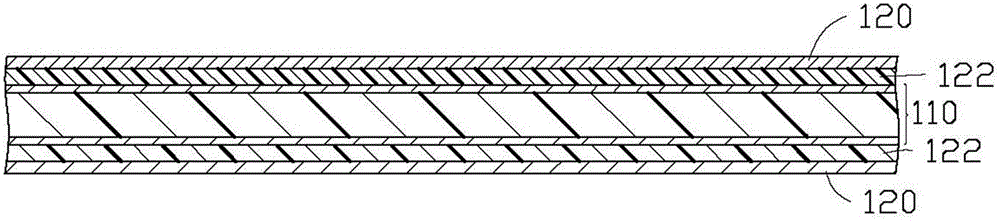

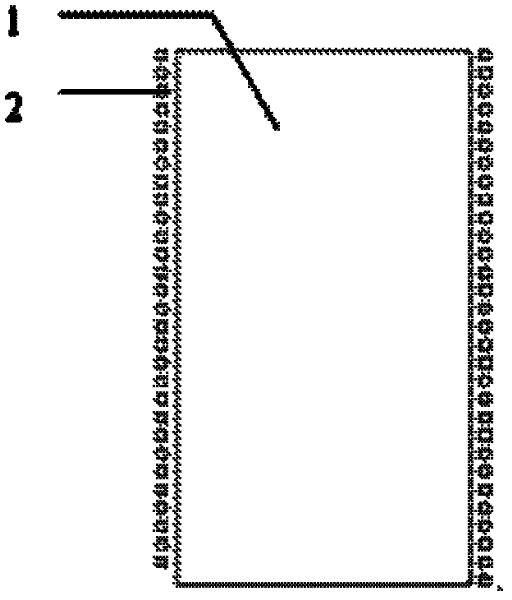

Current collector and application thereof

PendingCN111509233AImprove welding strengthReduce contact resistanceElectrode carriers/collectorsSecondary cellsContact impedanceEngineering

The invention provides a current collector and application thereof. The first aspect of the invention provides a current collector. The current collector comprises M metal layers and N polymer layers,the metal layers and the polymer layers are stacked, L metal layers comprise tab connecting areas and non-tab connecting areas, the thickness of the tab connecting areas is greater than that of the non-tab connecting areas, and M is greater than or equal to 1, N is greater than or equal to 1, L is greater than or equal to 1, and M is greater than or equal to L. According to the current collectorprovided by the invention, the tab connecting areas for connecting the tab on the metal layer is thickened, so that the welding strength of the tab is effectively improved, the binding force of the tab and the current collector is improved, the contact impedance of the tab connecting region is reduced, and the connecting yield of the tab and the metal layer is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

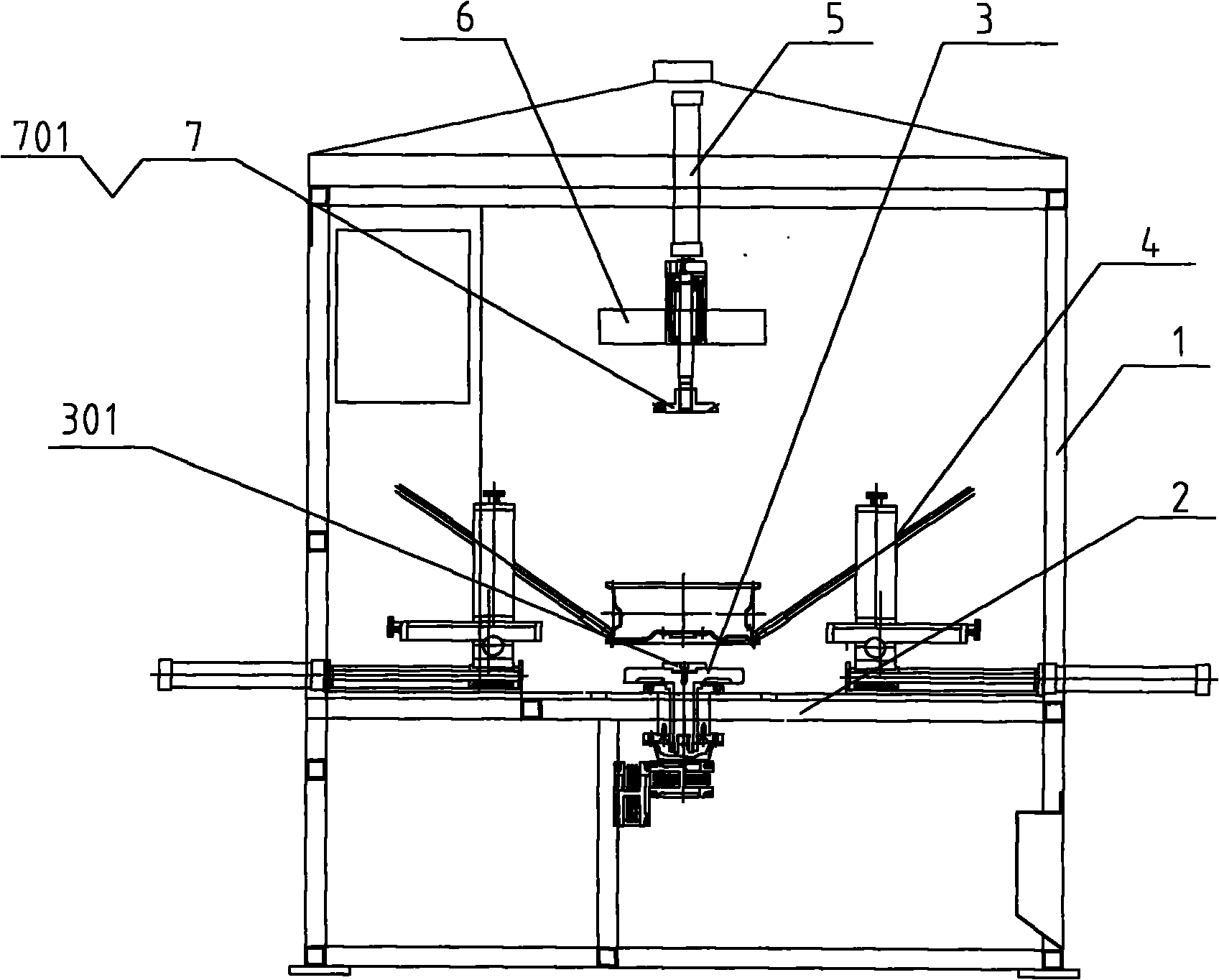

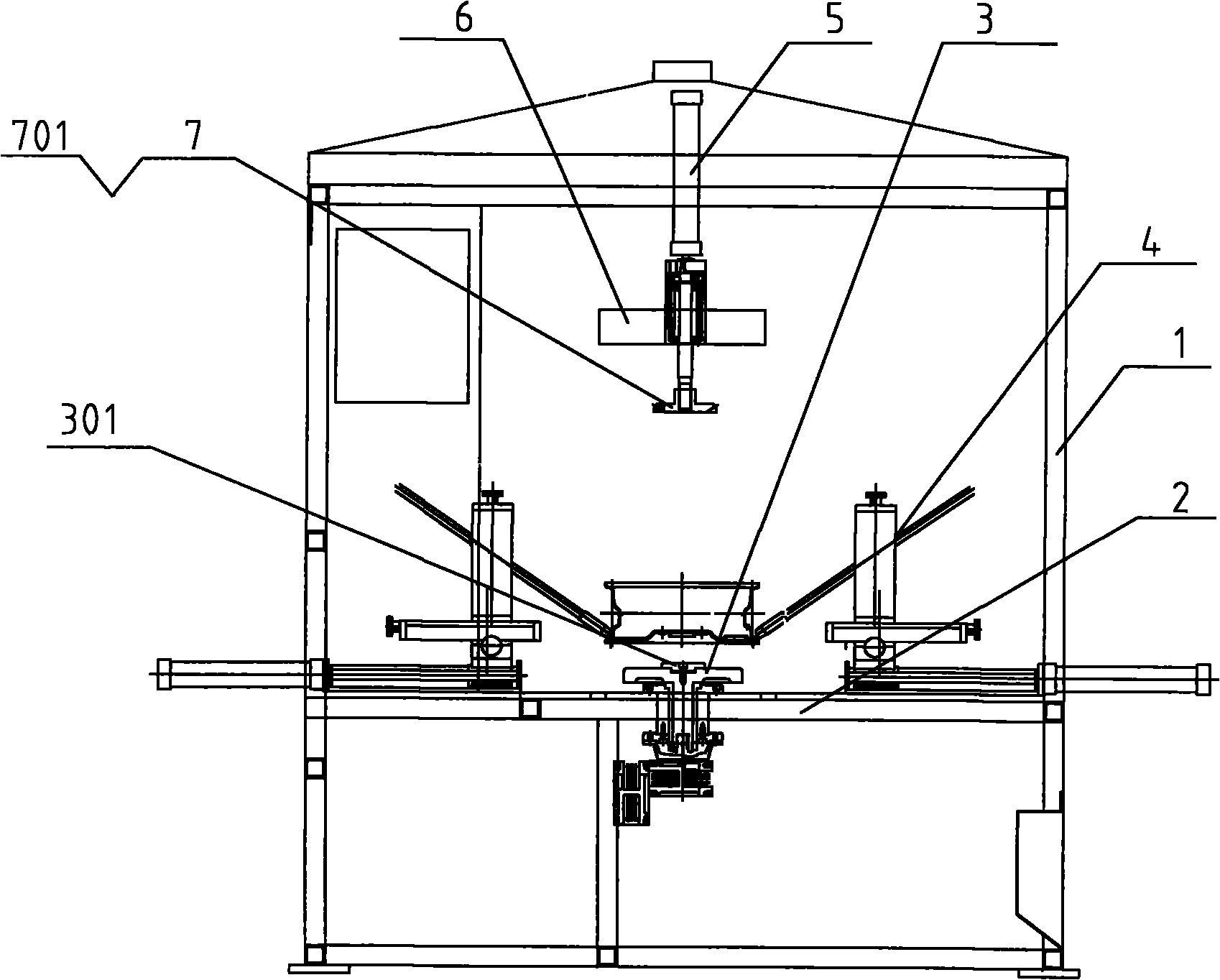

Circular seam welder for automobile wheels

InactiveCN102380723ANot easy to twist and deformImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a circular seam welder for automobile wheels. The circular seam welder comprises a welder body, a workbench arranged in the welder body, a rotatable workpiece clamping device arranged on the workbench and at least two welding guns, wherein the welding guns are uniformly arranged on the workbench around workpieces. Because the at least two welding guns are arranged, the welding efficiency is greatly improved. In addition, due to the introduction of a workpiece compacting and swelling component, the deformation of the wheels in the welding process is also greatly reduced, and the welding effect is also remarkably improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

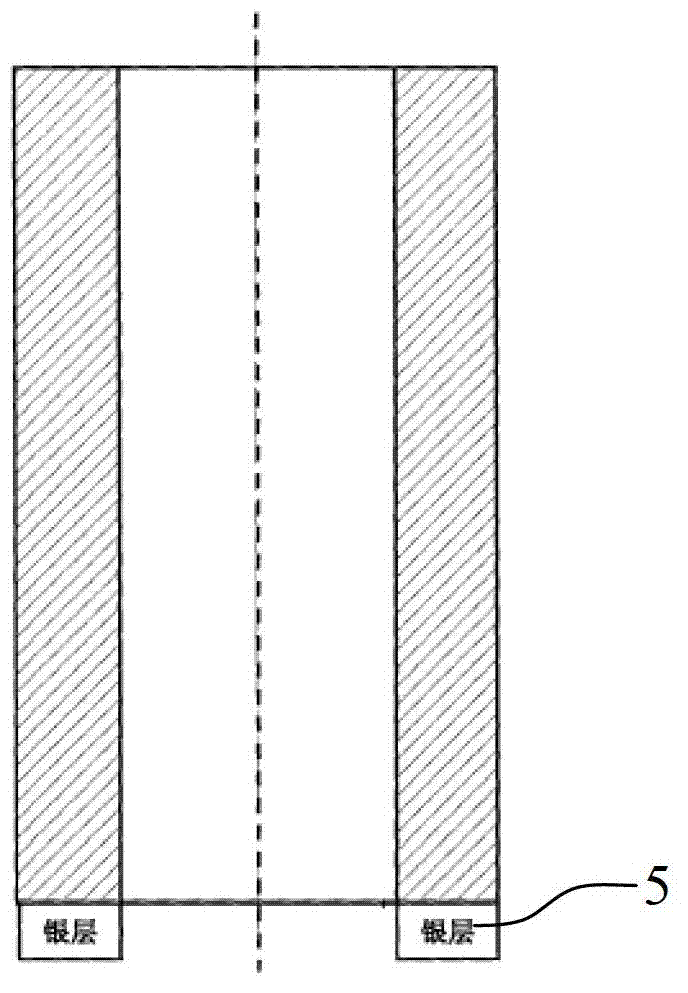

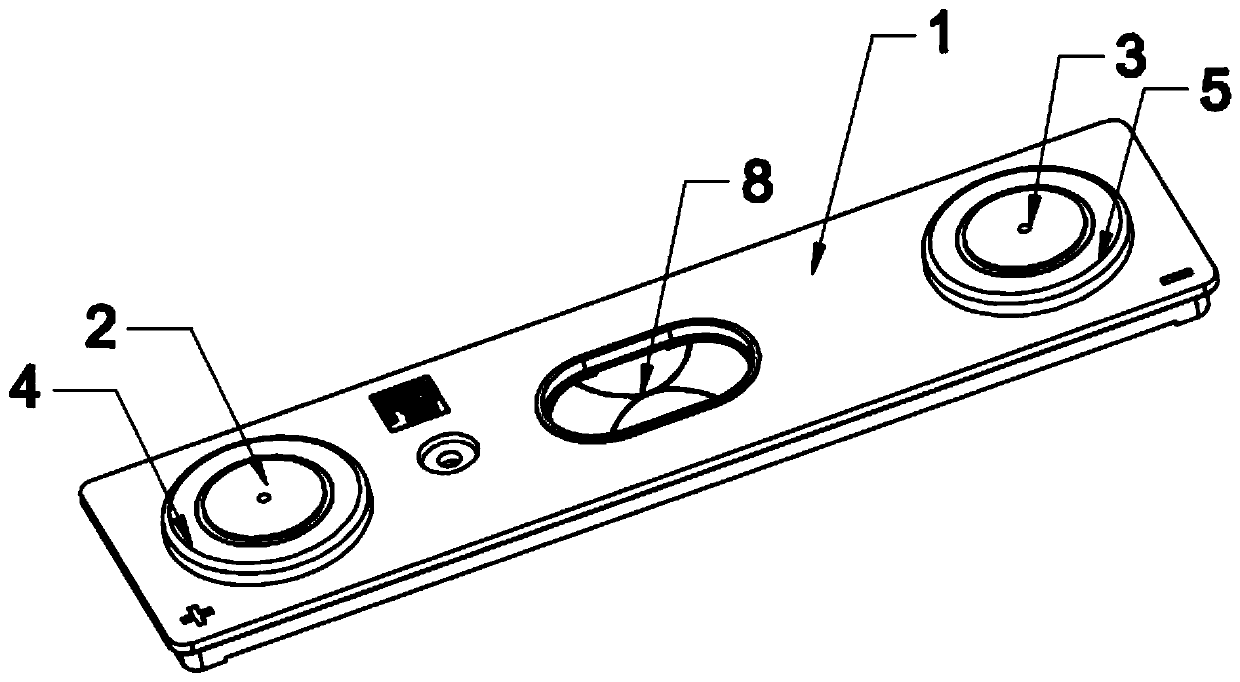

Novel medium cavity filter with cavity

ActiveCN102969549AReduce lossSteep frequency characteristicResonatorsThermal expansionTemperature coefficient

The invention discloses a novel medium cavity filter with a cavity. The novel medium cavity filter comprises the cavity and medium resonators, wherein each medium resonator is a cylinder with a through hole and is prepared from the following components according to mass percent: 29%-32% of calcium carbonate with purity of 97.5%, 9%-11% of aluminum oxide with purity of 97.5%, 21%-25% of neodymium oxide with purity of 99.5%, and 35%-38% of titanium dioxide with purity of 99.6%; a silver layer is coated at one end of each medium resonator, and the other end of the medium resonator is welded inside the cavity; the cavity is prepared from the following components according to mass percent: 95%-96% of aluminum oxide, 2%-3% of calcium carbonate, 0.8%-1.5% of lanthanum oxide, and 0.2%-0.5% of samarium oxide; and the dielectric constant of the cavity is 9.5. The medium cavity filter disclosed by the invention is high in Q value, small in size and adjustable in temperature coefficient, and can ensure high reliability of a product structure and good consistency of thermal expansion coefficients of the cavity and the medium resonators.

Owner:江苏灿勤科技股份有限公司

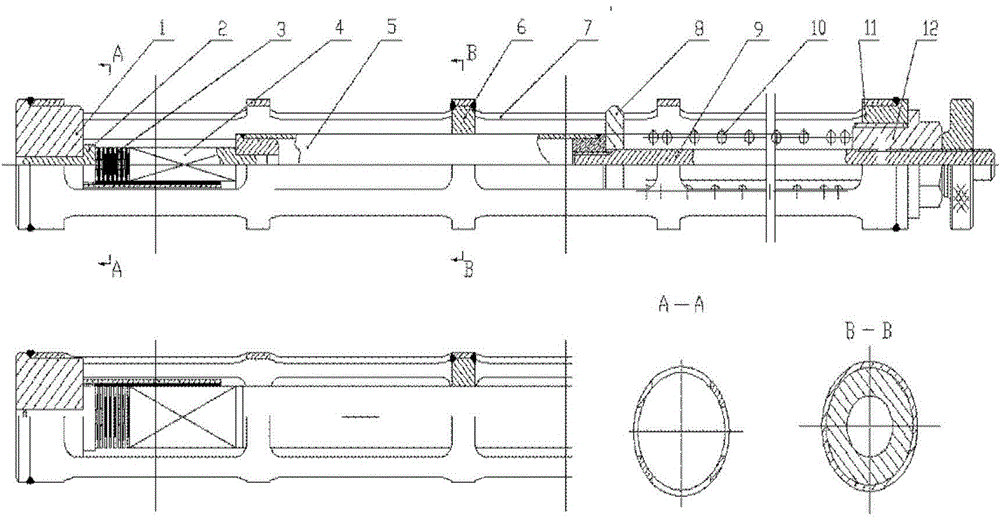

Assistant tool for welding terminal

InactiveCN102509992AAvoid WeldingAvoid wasting resourcesLine/current collector detailsState of artEngineering

The invention discloses an assistant tool for welding a terminal. The assistant tool is used for assisting welding of a cable and the terminal (302) at a panel (300) of a coaxial connector. The assistant tool for welding the terminal is provided with a bearing surface for fixing the terminal (302) and a connection piece in detachable connection with the panel (300) of the coaxial connector. According to the assistant tool for welding the terminal, provided by the invention, the terminal can be fixed at the panel (300) of the coaxial connector, so that after the cable passes through the terminal, the cable is not needed to be fixed manually and an operator can hold soldering iron with one hand and hold the solder wire with the other hand to weld. Therefore, because the terminal and the cable are fixed by the assistant tool for welding, the operator can performs the welding operation more stably. Compared with the prior art, the assistant tool for welding the terminal can effectively avoid insufficient welding so as to improve the welding efficiency and yield as well as avoid wasting of resources.

Owner:HUAWEI TECH CO LTD

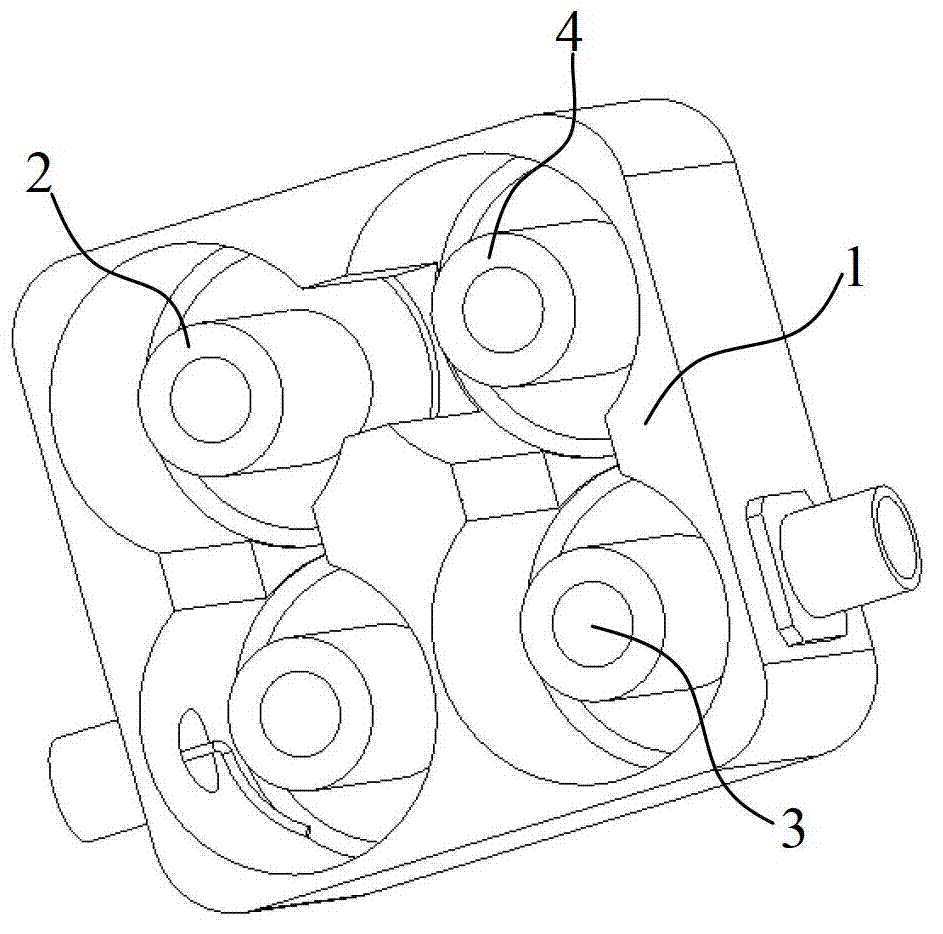

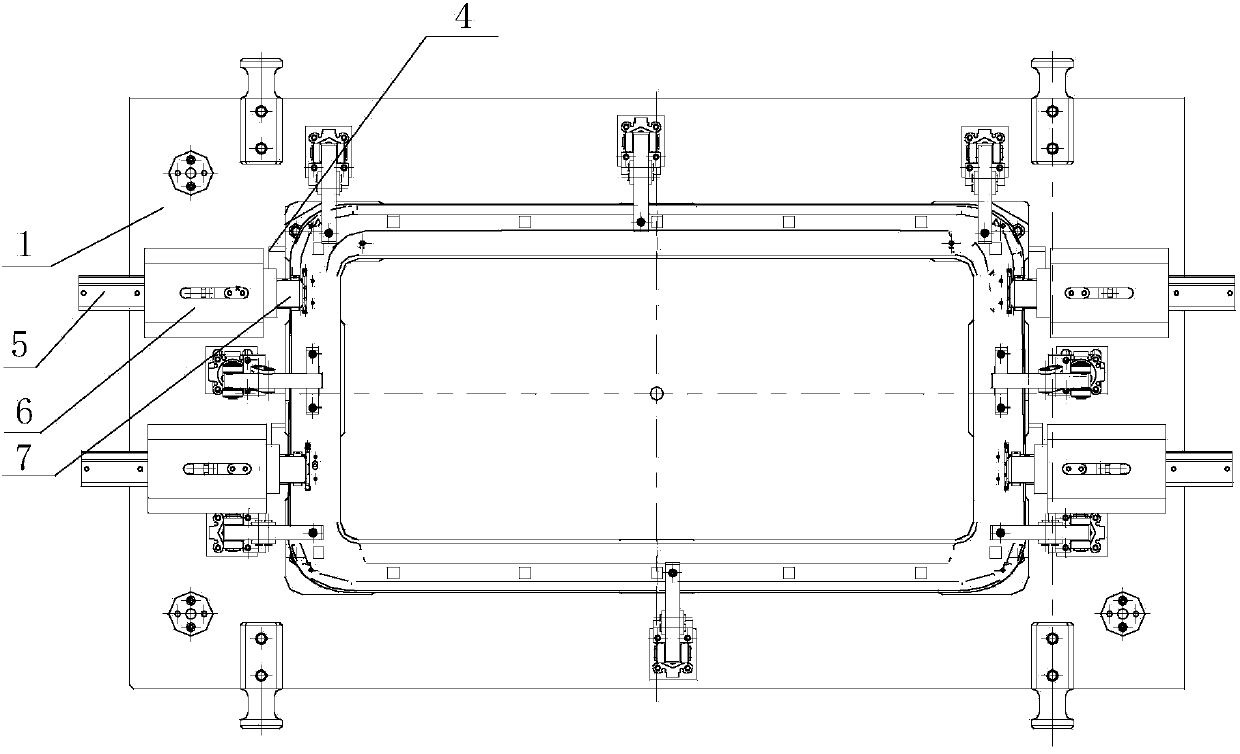

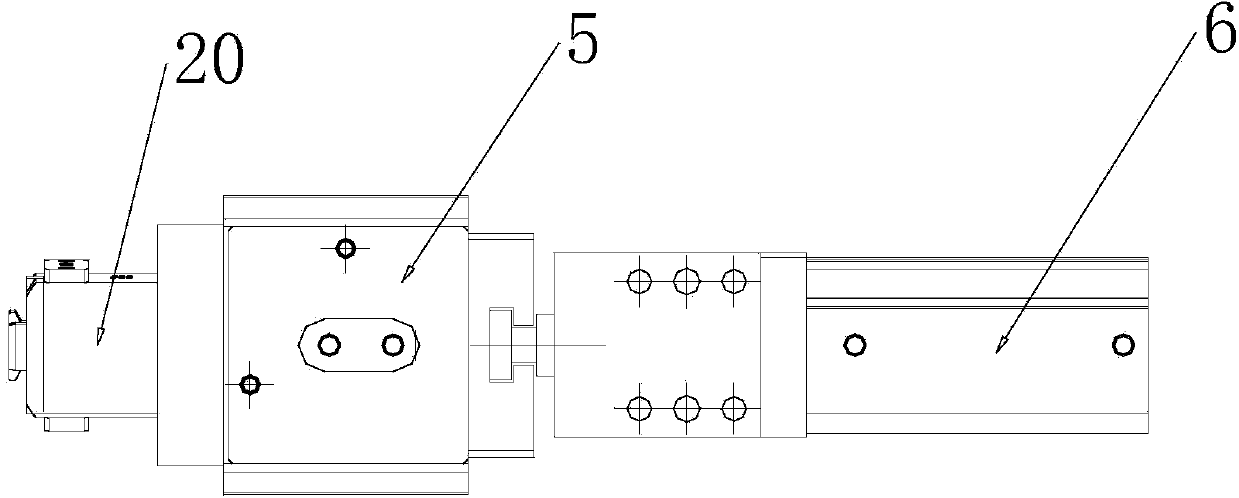

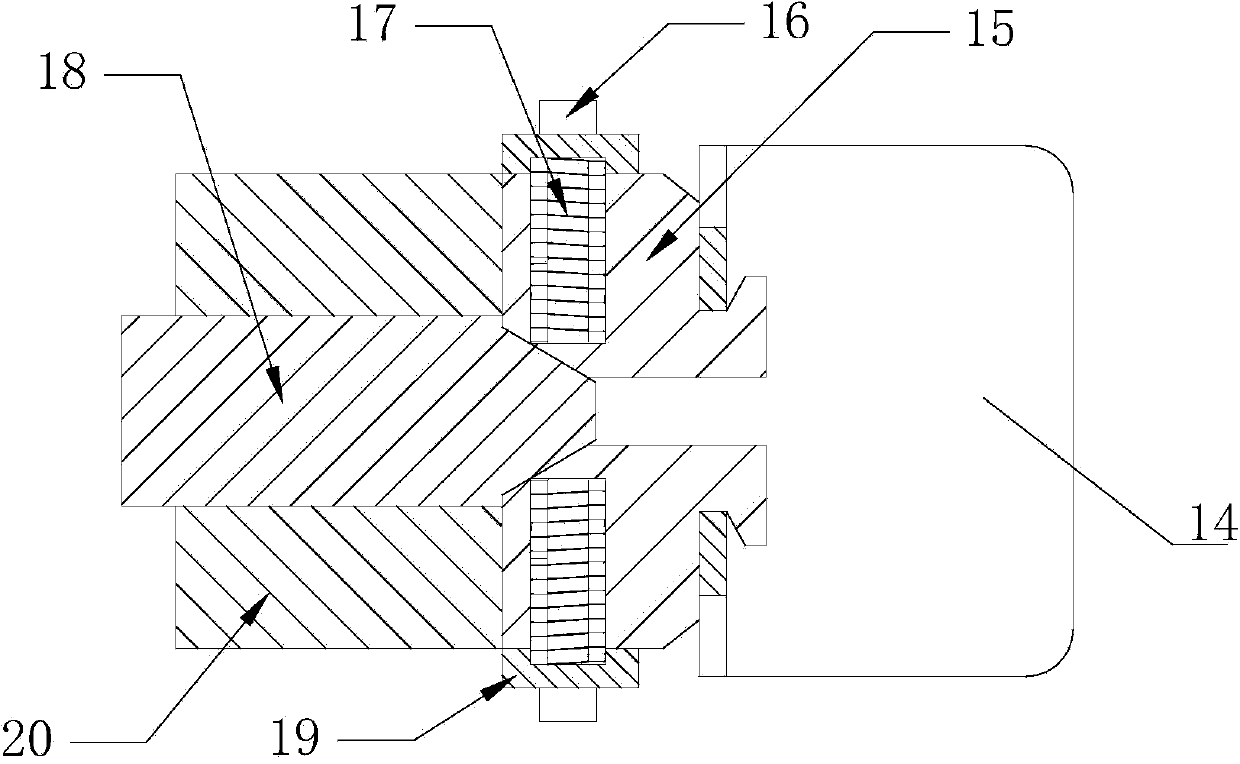

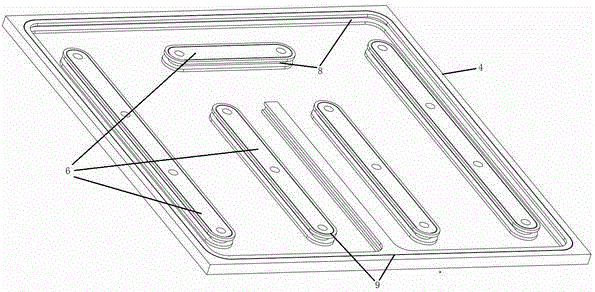

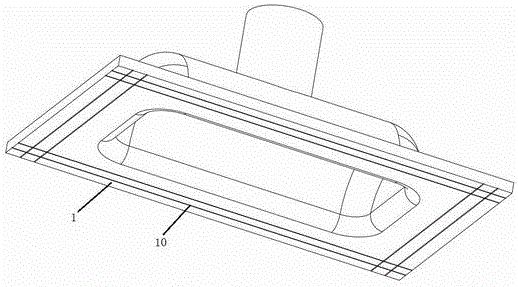

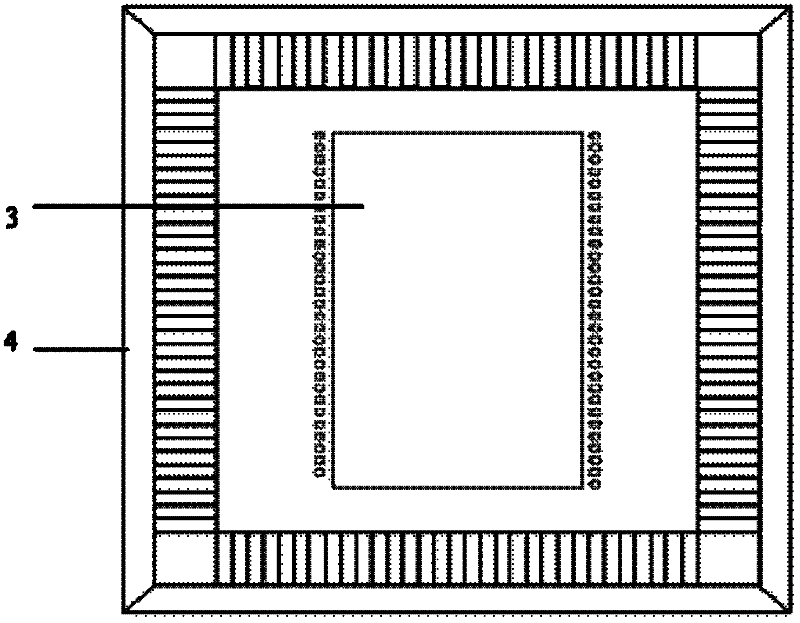

Car lock lug welding fixture

InactiveCN104191141ARealize clamping positioningSolve the positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention relates to the field of automobile manufacturing devices, in particular to a car lock lug welding fixture. By the car lock lug welding fixture, the problem that an existing lock lug welding fixture is insufficient of space for arrangement is solved. A plurality of positioning seats (4) are arranged on a rectangular welding fixture platform (1), a lug clamping unit is arranged on each positioning seat (4), each lug clamping unit comprises a lug clamping cylinder (5), a lug positioning cylinder (6) and a wedge mechanism (7), each lug positioning cylinder (6) is connected with the corresponding wedge mechanism (7) and drives the same to move horizontally, and wedges (18) can be driven to move by being connected with the corresponding lug clamping cylinders (5). The car lock lug welding fixture is used for welding automotive lugs.

Owner:HARBIN INST OF TECH

Automobile air conditioner compressor hollow piston and production method thereof

ActiveCN104805339AHigh tensile strengthHigh yield strengthPositive displacement pump componentsPositive-displacement liquid enginesPorosityWeld seam

The invention discloses an automobile air conditioner compressor hollow piston, which comprises aluminum alloy prepared from the following ingredients in percentage by weight: 11 to 13 percent of Si, 3.5 to 4.5 percent of Cu, 0.2 to 0.5 percent of Mg, 0.8 to 1.5 percent of Ni, 0.1 to 0.3 percent of Cr, 0.1 to 0.3 percent of C, 0 to 0.1 percent of Mn, 0 to 0.5 percent of Zn, 0 to 0.15 percent of Ti, 0.1 to 0.3 percent of RE and the balance Al. The invention also provides a production method of the automobile air conditioner compressor hollow piston. Through the selection and the control on elements in the aluminum alloy for the hollow piston, the intensity and the hardness of the piston are improved; through further improvement on the laser welding process, the welding seam fine porosity rate is reduced, the welding tension is enhanced, and the welding quality is improved, so the use performance of the hollow piston is improved, and the service life of the hollow piston is prolonged.

Owner:SHANDONG HUICHUAN AUTO PARTS

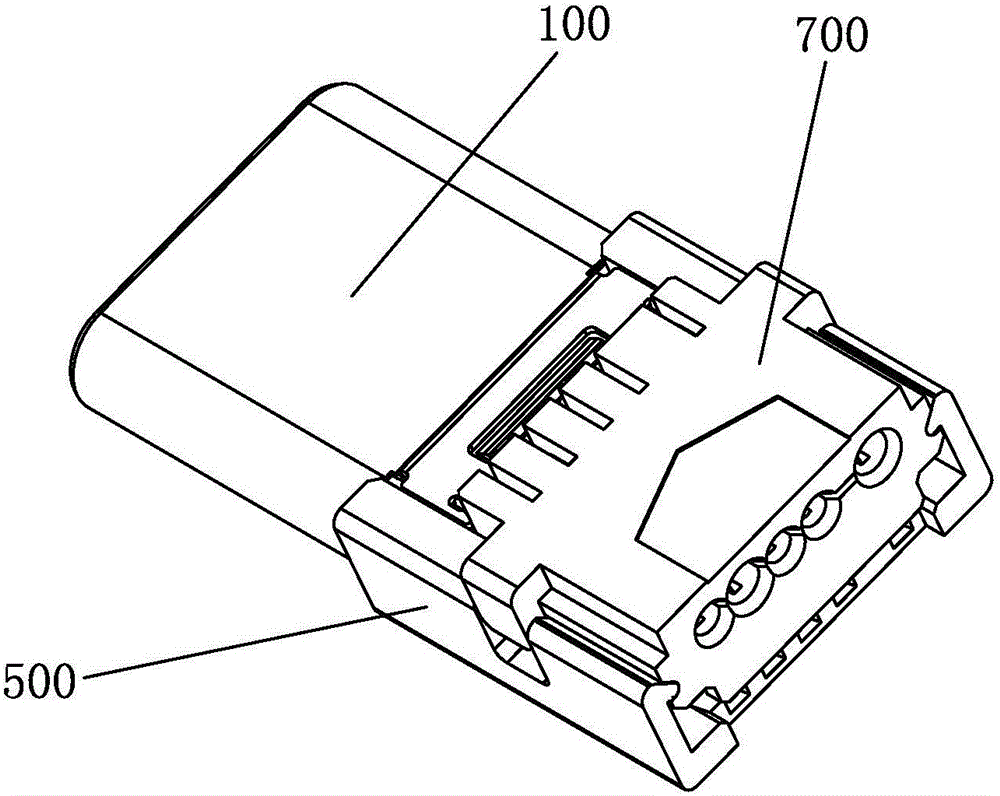

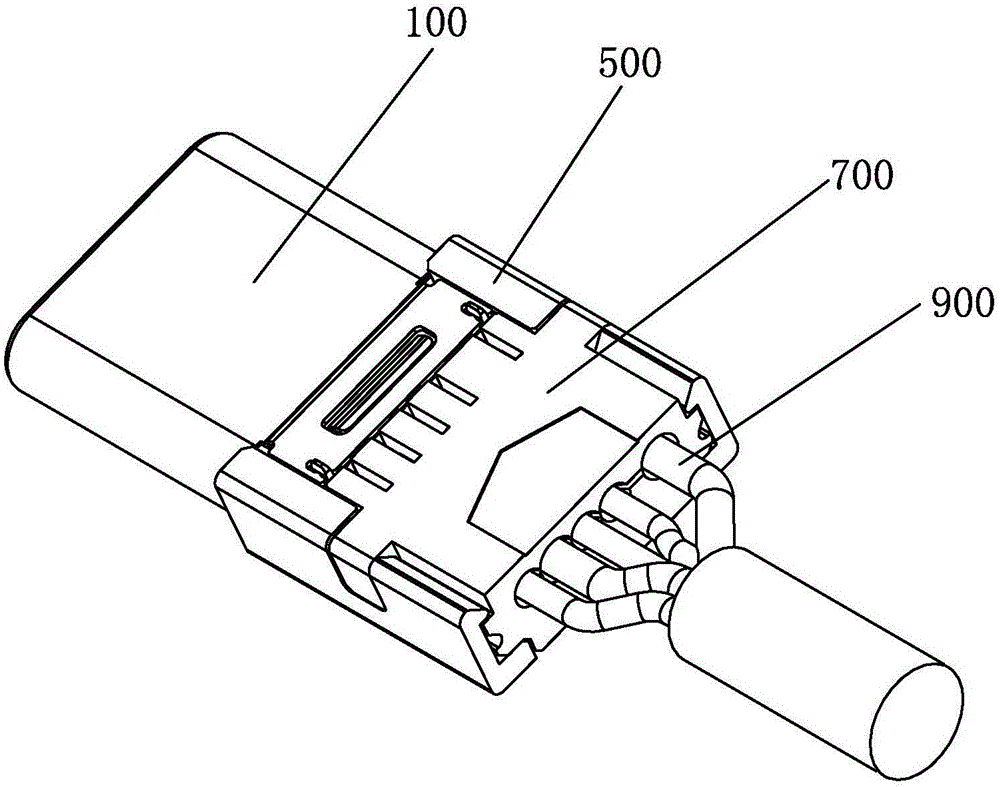

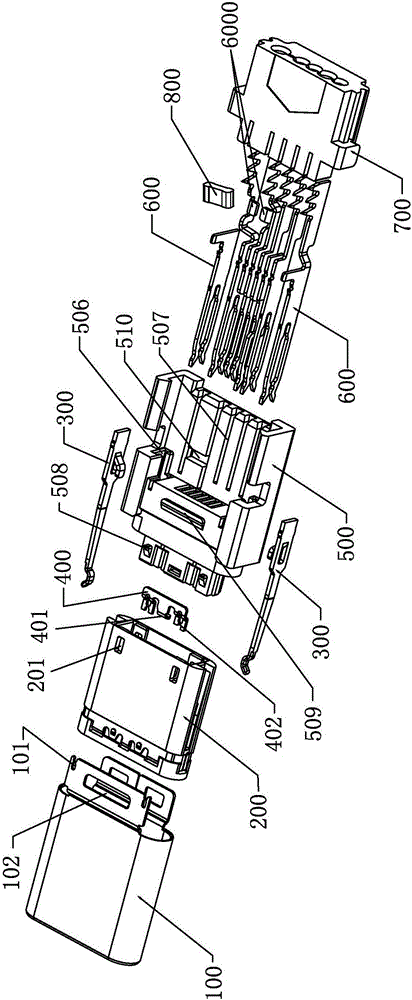

USB TYPE-C puncture-type connector and processing method therefor

InactiveCN105762570ASimple processing technologyLow costSoldered/welded conductive connectionsCoupling device detailsEngineeringUSB

The invention is suitable for the technical field of connectors, and provides a USB TYPE-C puncture-type connector and a processing method therefor. The connector comprises an iron housing, a connection rubber core, a main body rubber core, a resistor, and PINs. The PINs are divided into two rows: A and B, wherein a resistor is connected between two PINs in the row A. The connection rubber core is clamped on the main body rubber core. The iron housing is disposed on the main body rubber core, and covers the connection rubber core. The PINs are embedded on the main body rubber core. The two PINs connected with the resistor are respectively provided with a welding piece, and the resistor is fixedly welded on the welding pieces, thereby enabling the resistor and the two PINs to be connected. According to the invention, the connector enables the resistor to be directly welded with the two PINs in a fixed manner to form an electric condition circuit. The connector is simple in processing technology, is low in cost, is high in machining efficiency, is high in welding yield, and is high in application value and market prospect.

Owner:NINGBO BROAD TELECOMM

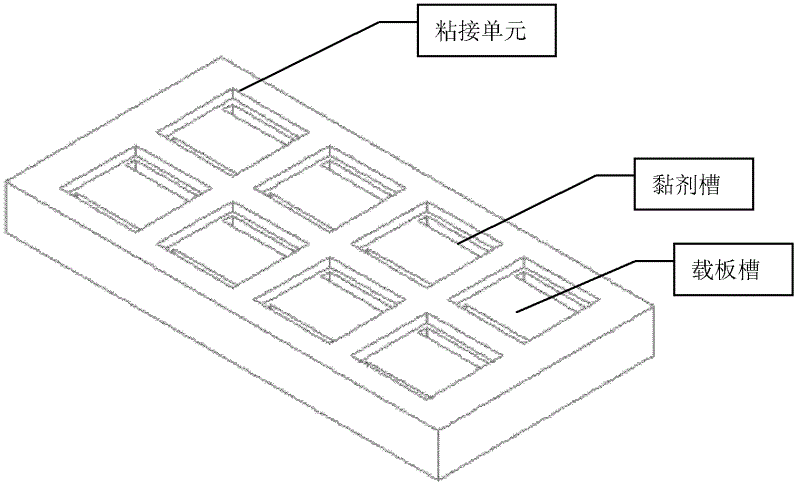

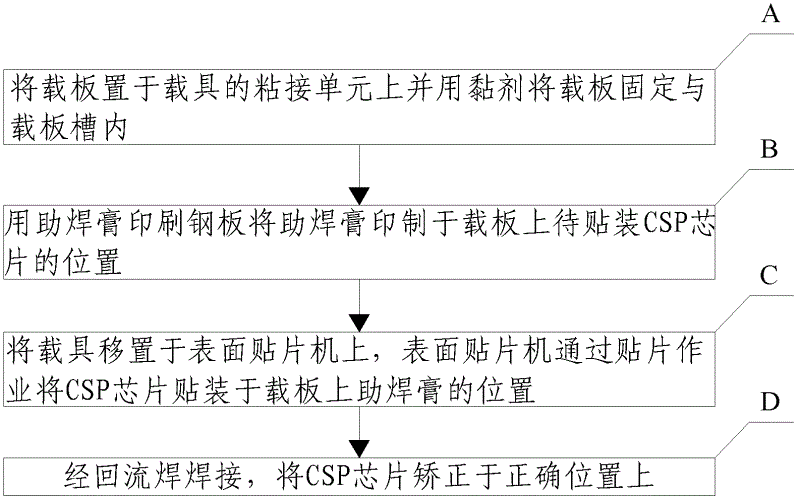

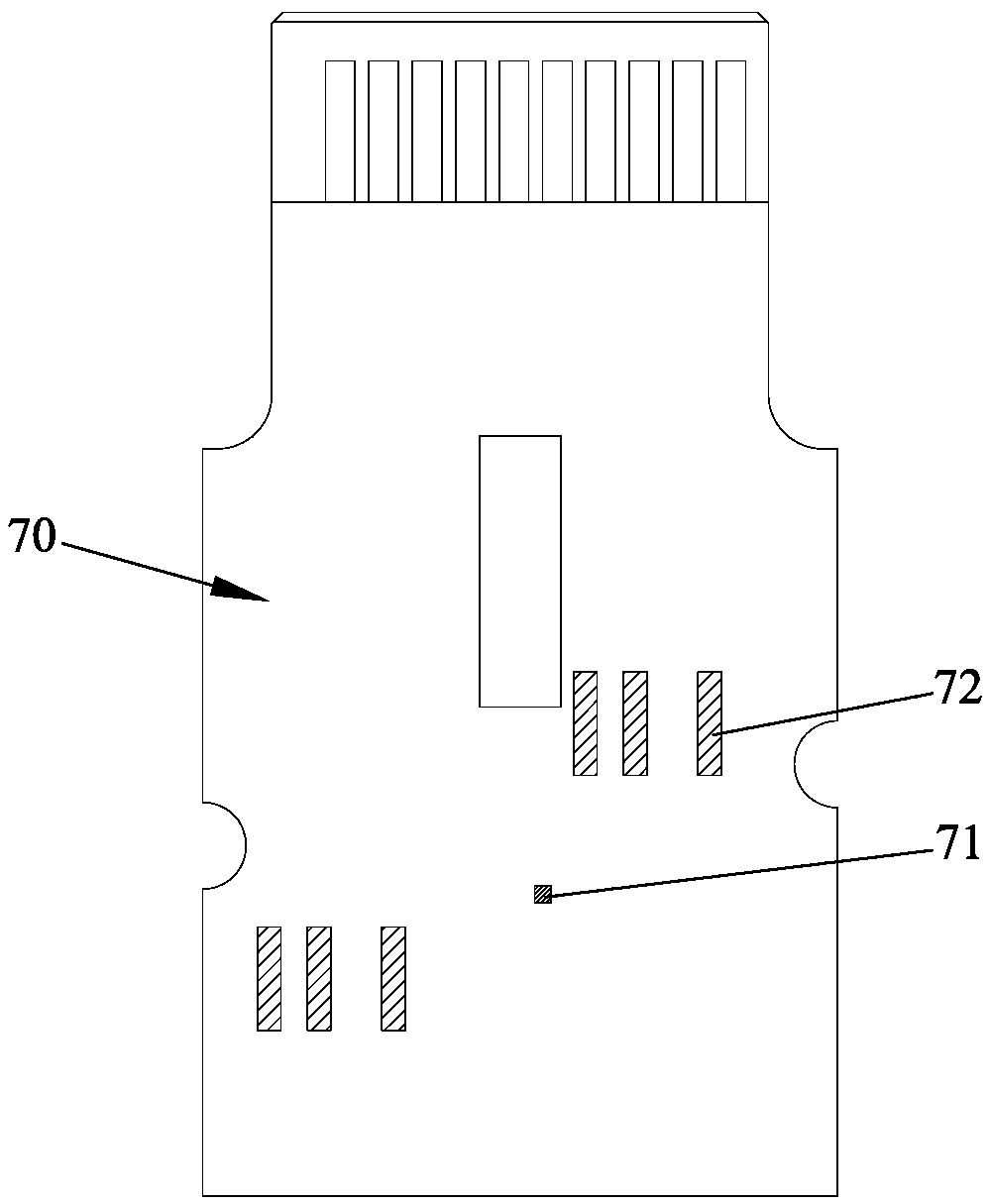

Chip scale package (CSP) chip mounting loading device and mounting method

ActiveCN102623371AQuick assemblyOptimize mass production processPrinted circuit assemblingSemiconductor/solid-state device manufacturingAdhesiveSurface mounting

The invention discloses a chip scale package (CSP) chip mounting supporting device and a mounting method, and relates to the technical field of semiconductor assembly. The supporting device is provided with a plurality of adhesive units, and the adhesive units comprise supporting plate grooves for placing supporting plates to be mounted and adhesive grooves located on the edges of the grooves of the supporting plates to be mounted and used for placing adhesive for adhering with the supporting plates to be mounted. CSP chips are mounted on the chip supporting plates by using a traditional surface mounting technology (SMT) surface mounting device, and no semiconductor level special assembly device is needed, so that investment cost of the device is reduced. The CSP chip mounting supporting device achieves multi-chip layout arrangement of the supporting plates, optimizes mass production processes of CSP chip mounting, reduces part accumulative errors, simultaneously can assemble the CSP chips effectively and rapidly, and improves welding yield and rolled yield of products.

Owner:SUZHOU ETRON TECH CO LTD

Self-restrained explosive welding device with high energy utilization rate

PendingCN106735836AImprove energy utilizationReduce usageNon-electric welding apparatusNoise pollutionHigh energy

The invention discloses a self-restrained explosive welding device with a high energy utilization rate. The device comprises one or more double-side explosive welding combinations and a single-side welding combination. When explosives blast, the whole device is in a self-restrained state, movement of all composite plates is limited mutually, the hot potato that composite plates fly apart during double-side explosive compositing is perfectly solved, and the safety of field operation is improved. Compared with traditional explosive welding method, explosive energy utilization is more reasonable, the explosive using amount is greatly reduced, the cost is reduced, meanwhile, shockwave energy transmitted to air is reduced, and the noise pollution is remarkably reduced. In addition, the designed device can composite the multiple composite plates on one foundation at a time, and the explosive field can be saved, and the working efficiency can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

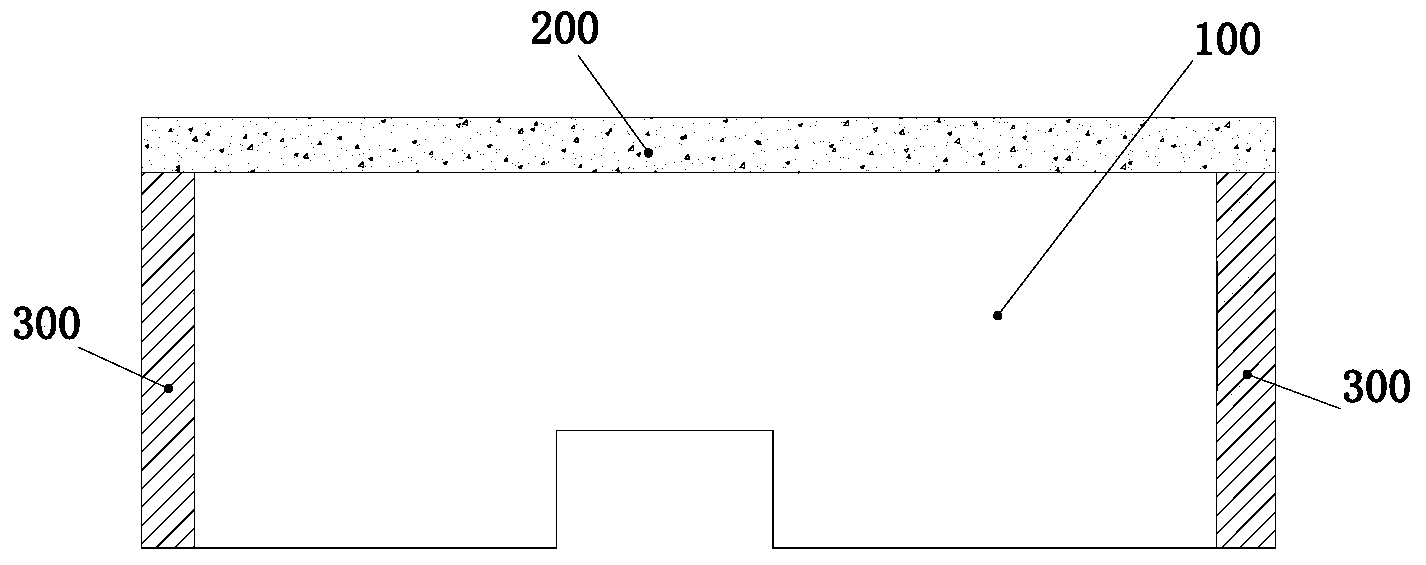

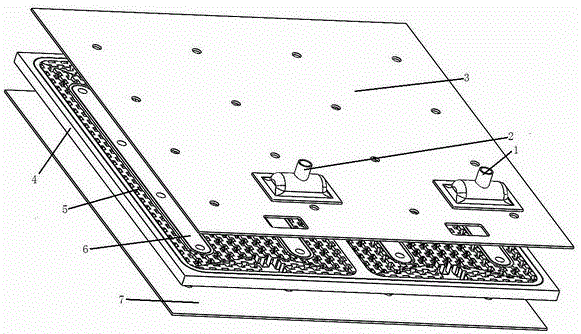

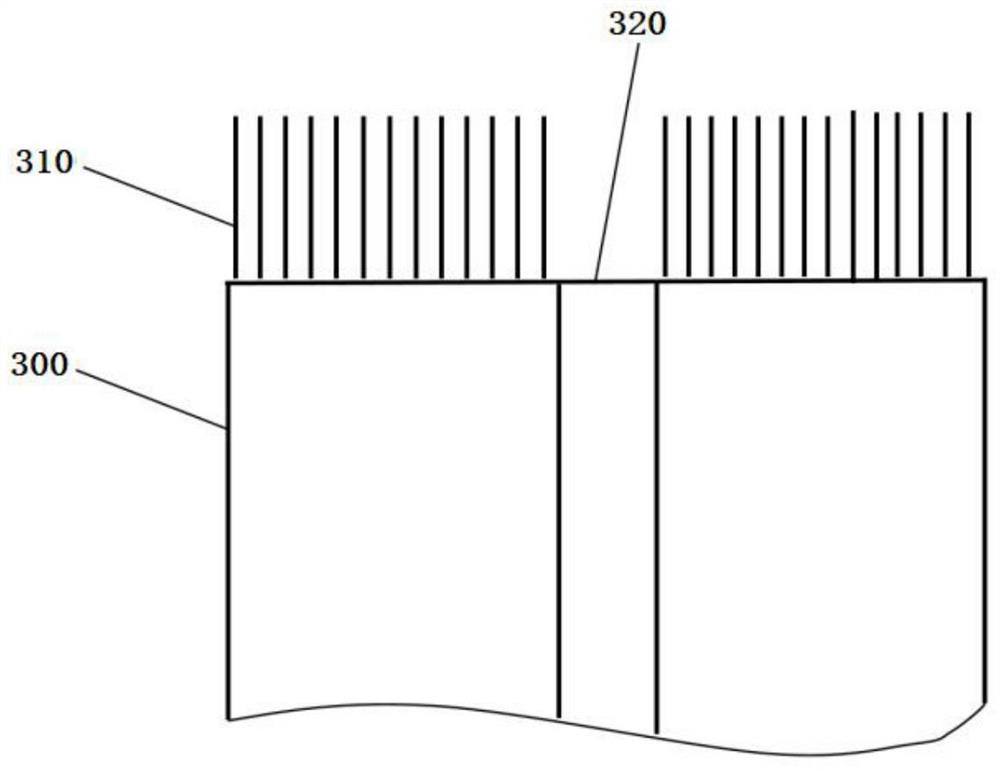

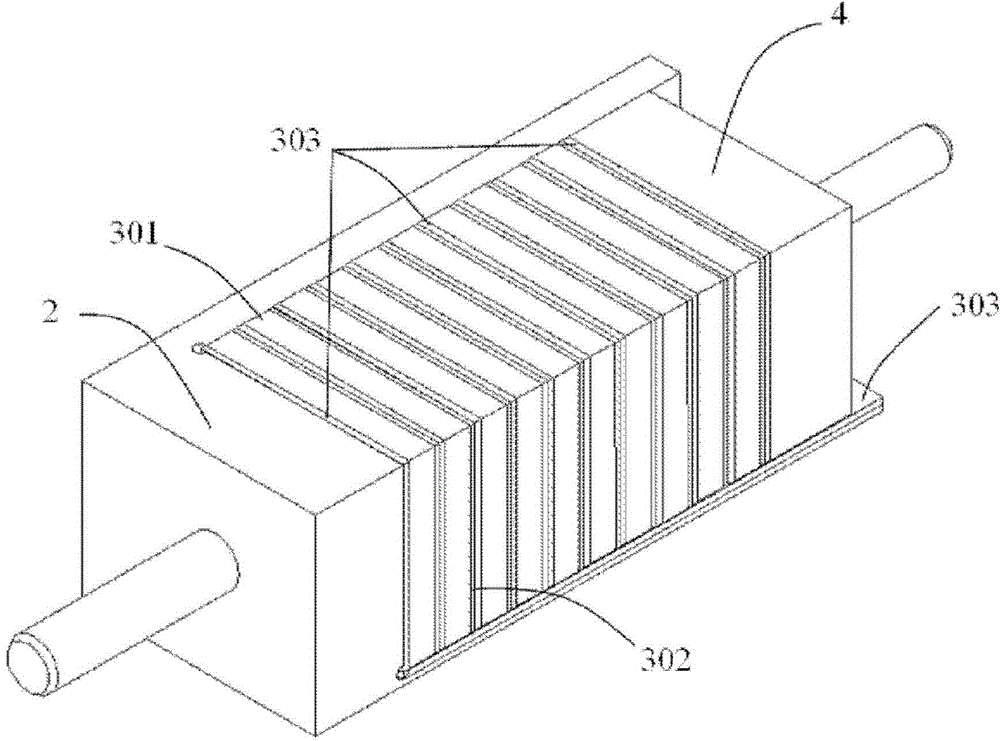

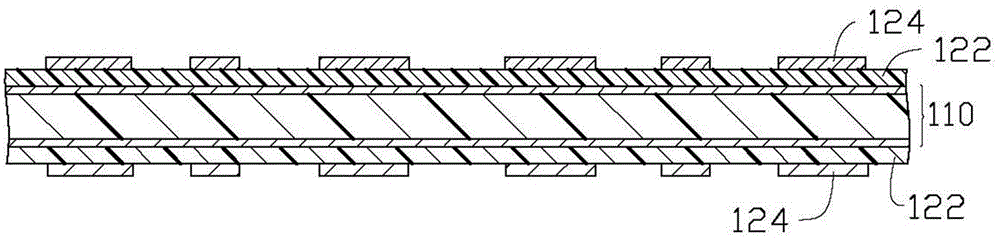

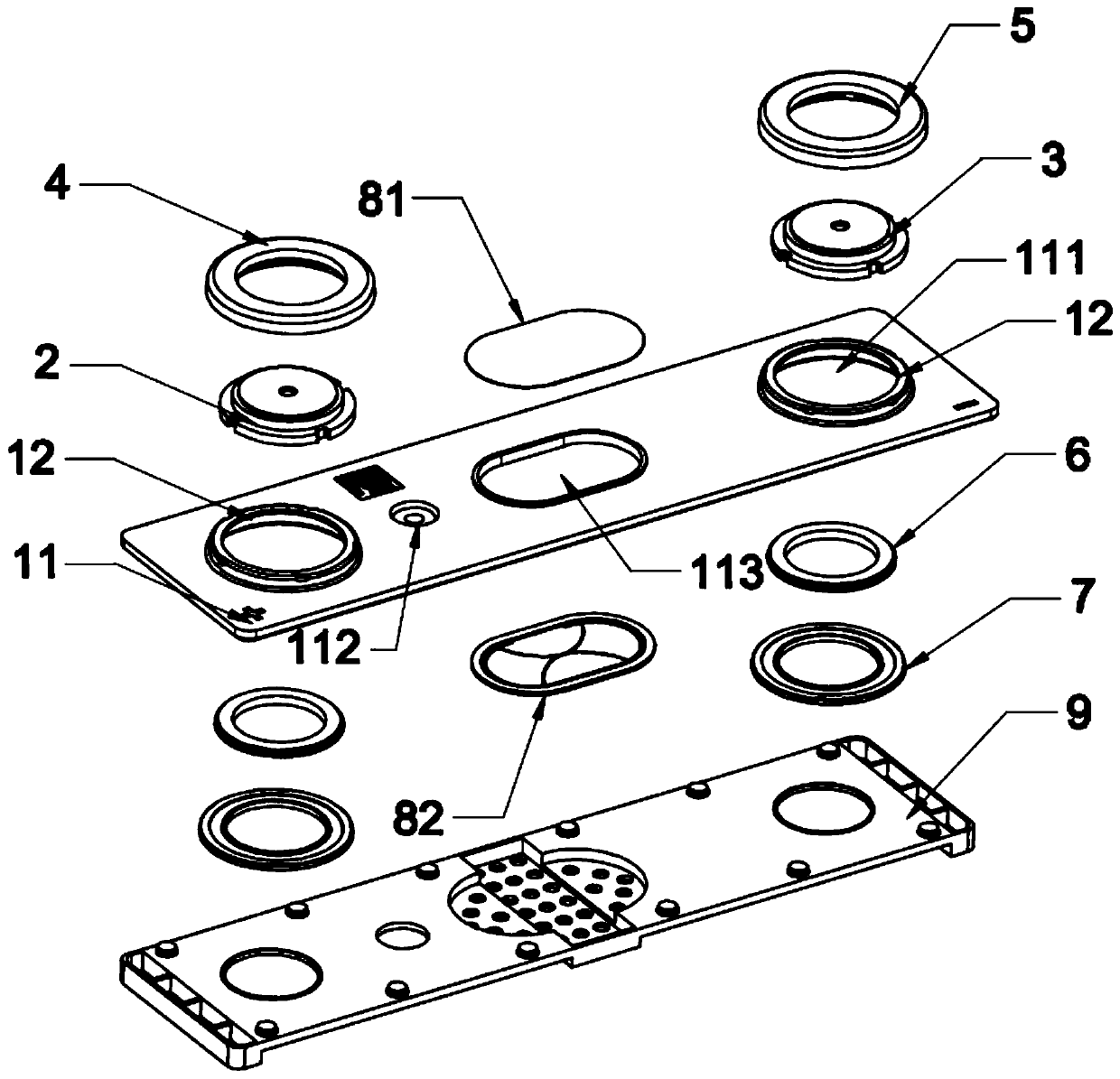

Liquid-cooling cold plate

ActiveCN105682431AImprove temperature uniformityReduce flow dead zoneCooling/ventilation/heating modificationsEngineeringCold plate

The invention discloses a liquid-cooling cold plate, which comprises a liquid inlet connector, a liquid outlet connector, an upper cover plate, frame strip seal, fins, pad blocks and a bottom board, wherein the pad blocks and the fins are arranged in the frame strip seal; the upper cover plate and the bottom board are connected to the two sides of frame strip seal through vacuum brazing to form a sealed heat exchange cavity; the two sides of the pad blocks are connected with the upper cover plate and the bottom board through vacuum brazing respectively; the liquid inlet connector and the liquid outlet connector are connected with the upper cover plate through vacuum brazing; and the inner side surface of the frame strip seal or / and the outer side surfaces of the pad blocks contacted with a heat exchange medium are respectively provided with a groove. The liquid-cooling cold plate is simple in structure, low in cost, high in heat exchange efficiency, good in brazing process, high in welding finished product rate, more beautiful in appearance, small in flow dead zone and good in temperature uniformity.

Owner:XINXIANG TEMEITE HEAT TRASFER EQUIP CO LTD

Flattening method for all-tab cylindrical battery

ActiveCN114361555AExhaust in good conditionIncreasing the thicknessFinal product manufactureSecondary cells manufactureEngineeringMechanical engineering

The invention belongs to the technical field of batteries, and discloses a full-tab cylindrical battery rubbing method and a full-tab cylindrical battery. The method comprises the following steps: rotating to a first position from the outer ring of a battery cell kneading plane to the center direction by using a first kneading wheel; and the second rubbing wheel rotates to a second position from the center of the battery cell rubbing plane to the outer ring direction, and the path through which the first rubbing wheel passes and the path through which the second rubbing wheel passes do not coincide. According to the method, under the condition that the tab foil is not increased, the thickness of the rubbing plane of the welding area of the collector plate is effectively increased, the thickness of the non-welding area is reduced, the welding yield of the collector plate is improved, the infiltration rate of electrolyte is improved, and the problem that the rubbing plane blocks the center hole is solved.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

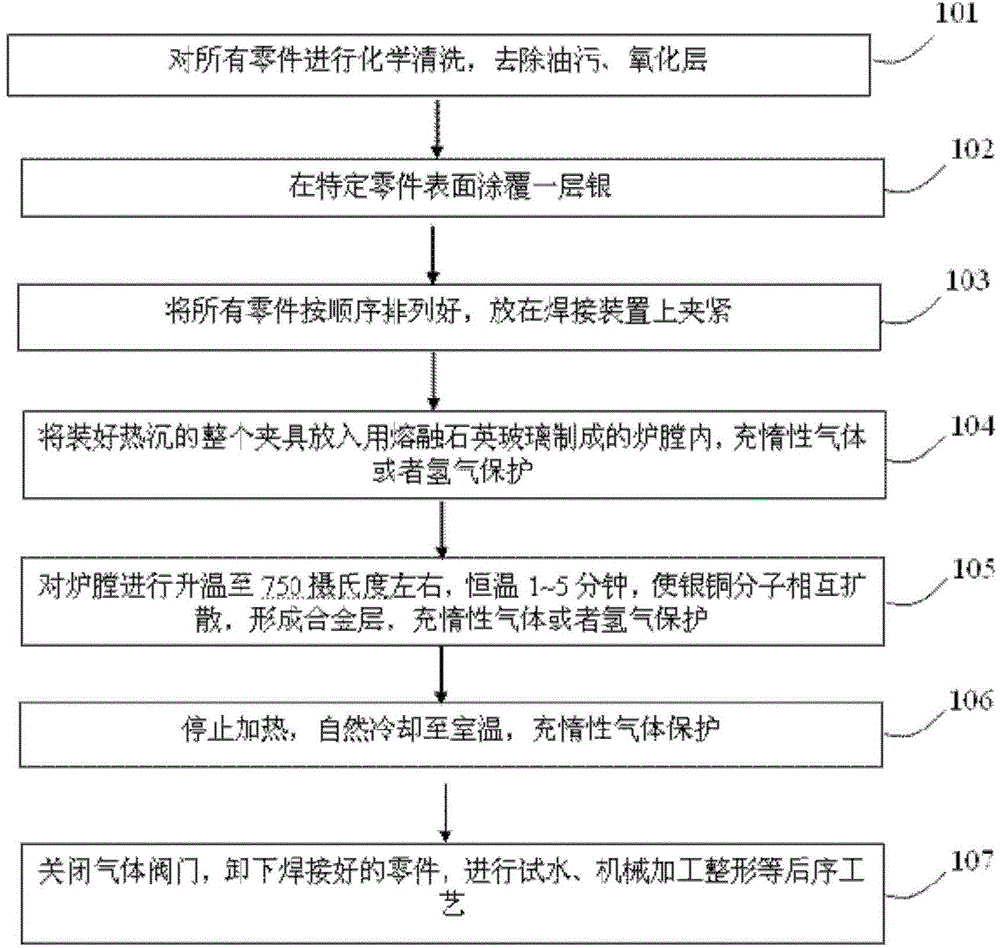

Silver copper diffusion welding method and device

InactiveCN104874932AAvoid heat sinkPrevent oxidationWelding/cutting auxillary devicesAuxillary welding devicesWater basedEngineering

The invention provides a novel silver copper diffusion welding method and a welding device used by same. The method and the welding device can integrally weld a plurality of thin plates or micro radiating graphics by a heat sink manner, have the advantages of being simple in method, high in welding yield, good in welding quality and good in reliability, and are mainly applied to water-based heat sink in refrigerating of a power type electronic element, a laser or an optical gain medium and mass production of bases.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Rotary welding positioning device of lithium ion cylindrical battery cover plate

ActiveCN108637478APrecise positioningImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusLithiumElectrical battery

The invention provides a rotary welding positioning device of a lithium ion cylindrical battery cover plate. The rotary welding positioning device comprises a base, and a front clamping piece, a positioning assembly and a rear clamping piece are fixedly arranged on the central axis of the base in sequence, wherein the positioning assembly comprises an outer cylinder, at least two positioning plates are arranged inside the outer cylinder along the axial direction of the outer cylinder, and the back face of the positioning plate is fixedly connected with a cylinder wall of the outer cylinder through a spring; the positioning plate comprises a positioning plate body which the front surface is in an inwards-concave shape, the two ends of the positioning plate body are correspondingly connectedwith arc-shaped end plates extending towards the cylinder wall direction of the outer cylinder, and all the end plates are located outside the outer cylinder to form an outer trumpet shape; and a fixing part is fixedly arranged at the inner concave part of the positioning plate body, the fixing part comprises a hoop and a connecting rod, and freely-rotating balls are sleeved with the hoop. According to the device, the cylindrical battery with different diameters can be positioned in a floating mode, the rotating center of the cylindrical battery can be accurately positioned, so that the welding quality is improved; and a laser welding area is provided with a welding dust removal interface, so that the environmental pollution is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

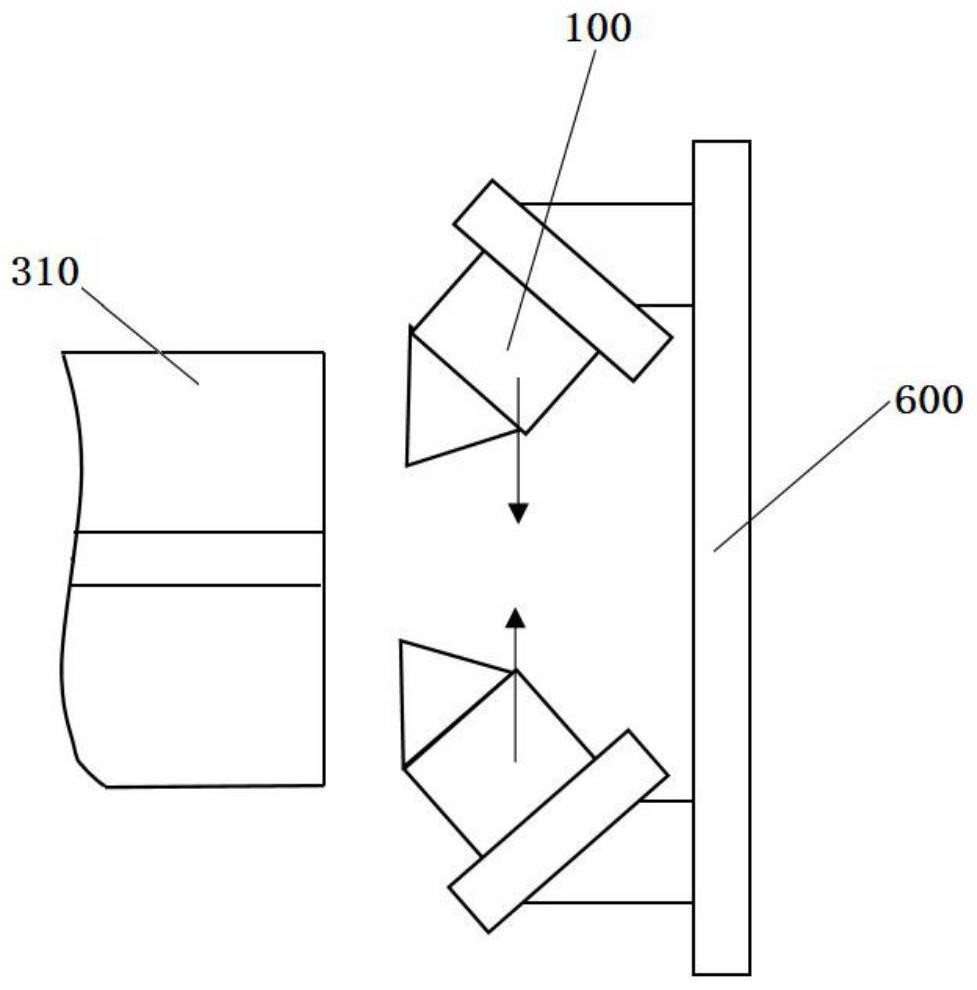

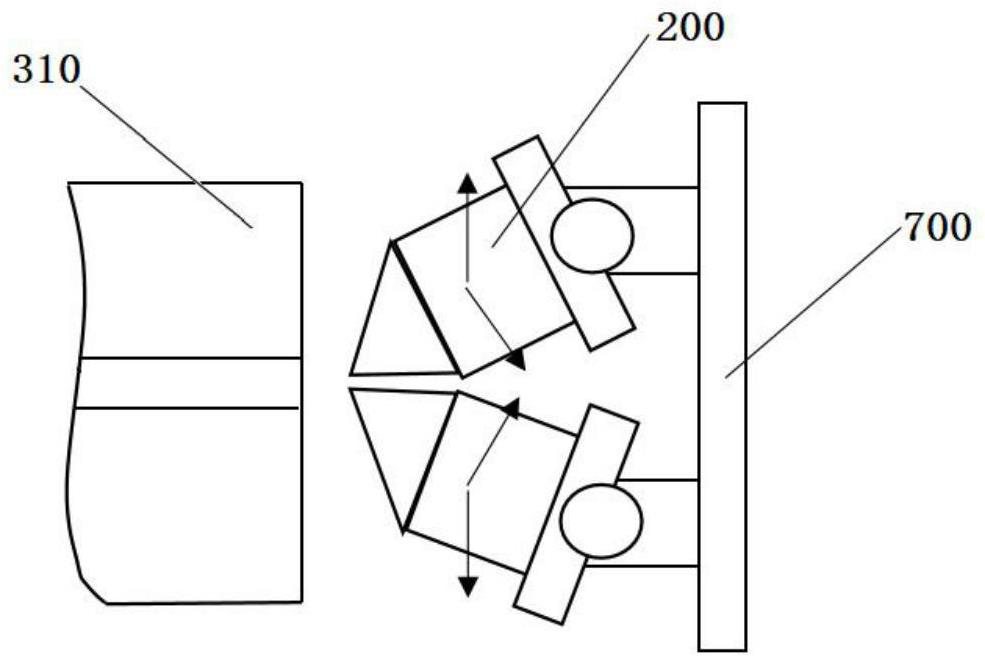

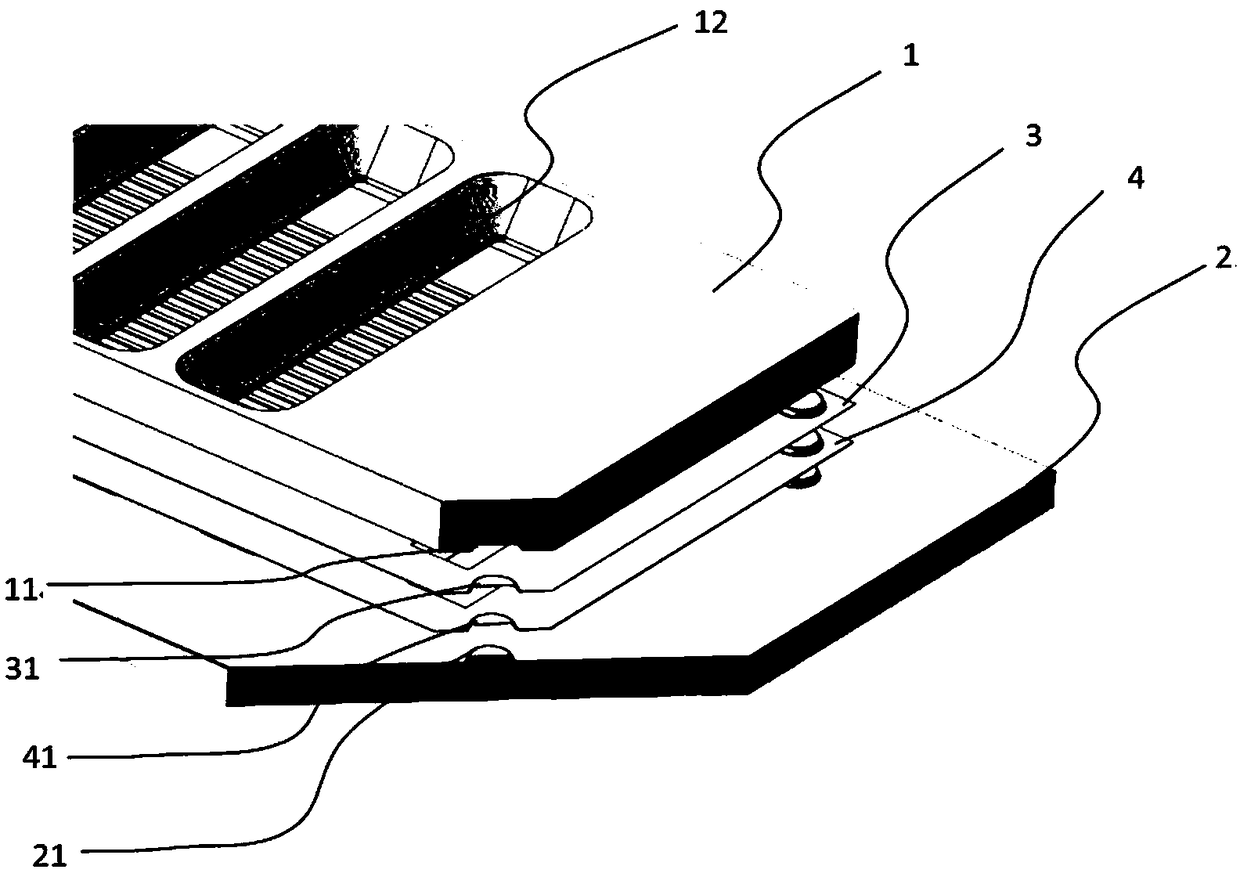

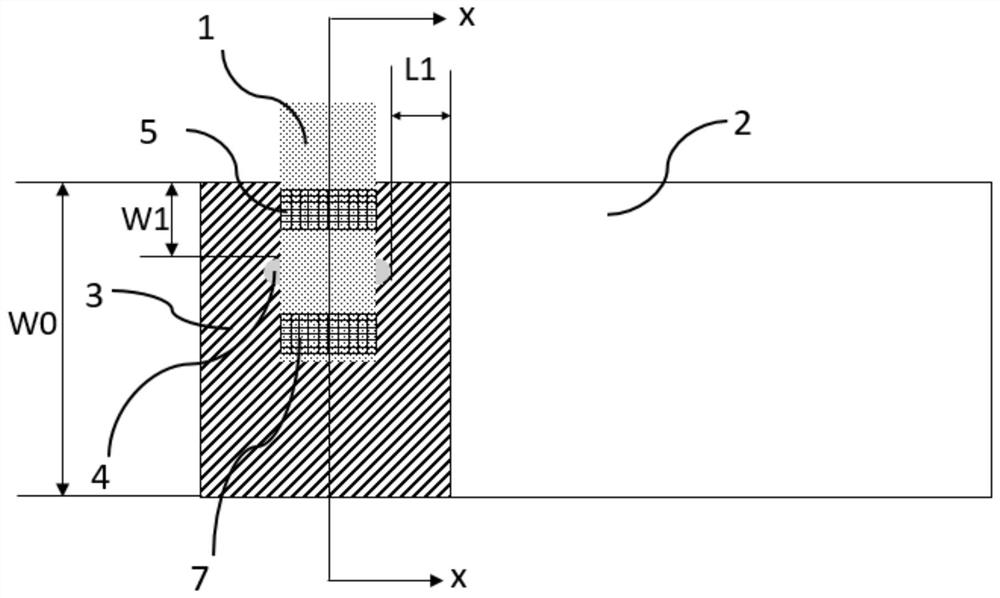

Laser welding method for active region of metal bipolar plate

ActiveCN108115277AImprove efficiencyReduce scrap rateCell component detailsLaser beam welding apparatusHydrogen fuel cellWaste product

The invention relates to a laser welding method for an active region of a metal bipolar plate. After the metal bipolar plate is positioned, a welding region of the active region of the bipolar plate is welded by laser from a laser source. The bipolar plate is positioned by a bipolar plate laser positioning clamp, corresponding embedded positioning points are arranged on the bipolar plate and the positioning clamp, and welding holes for welding the bipolar plate are formed in the positioning clamp; the welding region of the bipolar plate is welded by the laser from the laser source through thewelding holes. The active region of the bipolar plate is creatively welded by adopting a welding technology, and the bipolar plate in the active region fully fits, and has no clamping deformation andstress deformation and other problems after welding; meanwhile, the waste product rate is low, and the power generation efficiency of a hydrogen fuel cell is also improved. By using the method provided by the invention, the active region is firstly welded, which is convenient to detect whether the bipolar plate is dislocated and deformed, and then a sealing region is welded. The test shows that the welding yield rate of the bipolar plate can be increased by 15% and the overall performance of the bipolar plate can be increased by 20%.

Owner:湖南振邦氢能科技有限公司

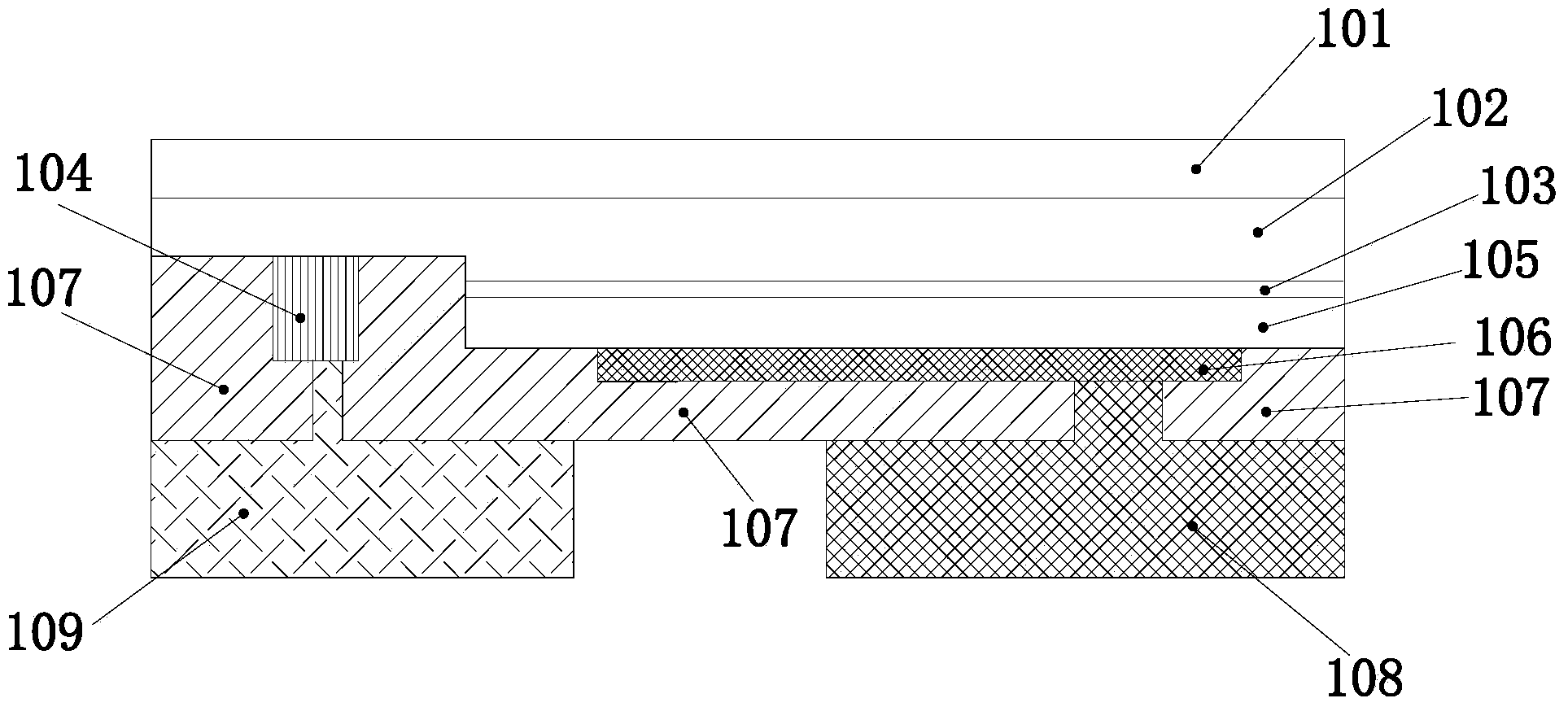

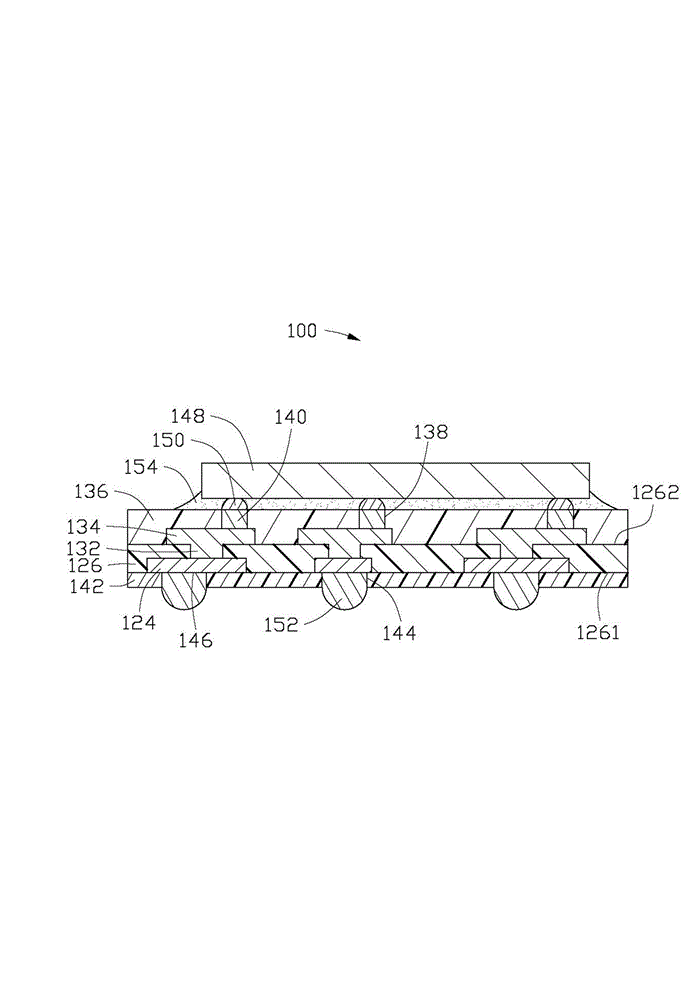

Chip packaging structure and manufacture method thereof, and chip packaging substrate

InactiveCN105097558AImprove welding yieldLess prone to empty weldingSemiconductor/solid-state device detailsSolid-state devicesDielectric layerElectroplating

A manufacturing method of a chip packaging structure comprises the steps that a loading plate is provided, a first conductive line layer, a first dielectric layer and a second conductive line layer are successively formed at one side at least of the loading plate, and the first conductive line layer is connected with the second conductive line layer via first conductive poles; a second dielectric layer is formed at one side, far from the loading plate, of the second conductive line layer, openings of the second dielectric layer are formed in the second conductive dielectric layer, and form second conductive poles via electroplating, the second conductive line layer is electrically connected with the second conductive poles, and the surfaces, far from the first dielectric layer, of the second conductive poles are approximately leveled with the surface, far from the first dielectric layer, of the second dielectric layer; and the loading plate is removed, and a chip is welded to form the chip packaging structure. The invention also relates to a chip packaging substrate and structure.

Owner:QI DING TECHNOLOGY QINHUANGDAO CO LTD +1

Packaging method of chip of phase change memory

ActiveCN102446781AMaintain cleanlinessImprove welding speed and yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPhase-change material

The invention discloses a packaging method of a chip of a phase change memory. The method comprises: a chip that needs to be packaged is fixed in a packaging shell; an ultrasonic bonding technology is utilized to enable electrodes of the chip and pins of the shell to be connected one by one; and then, a shielding cover is used to enable the chip to be isolated from the outside world. According to the invention, because ultrasonic bonding does not need a critical bonding temperature, packaging on a chip can be carried out at a normal temperature, so that there is no influence on a characteristic of the chip itself of the phase change memory. When bonding is carried out, no current is added and no fusing is carried out; there is no effect on physical and mechanical performances of materials; no compound is formed to influence the performance of the chip; the cleanness of the chip can be maintained; and packaging can be directly carried out without tedious cleaning processing, so that testing demands of good stability, high precision and good repeatability can be met.

Owner:HUAZHONG UNIV OF SCI & TECH

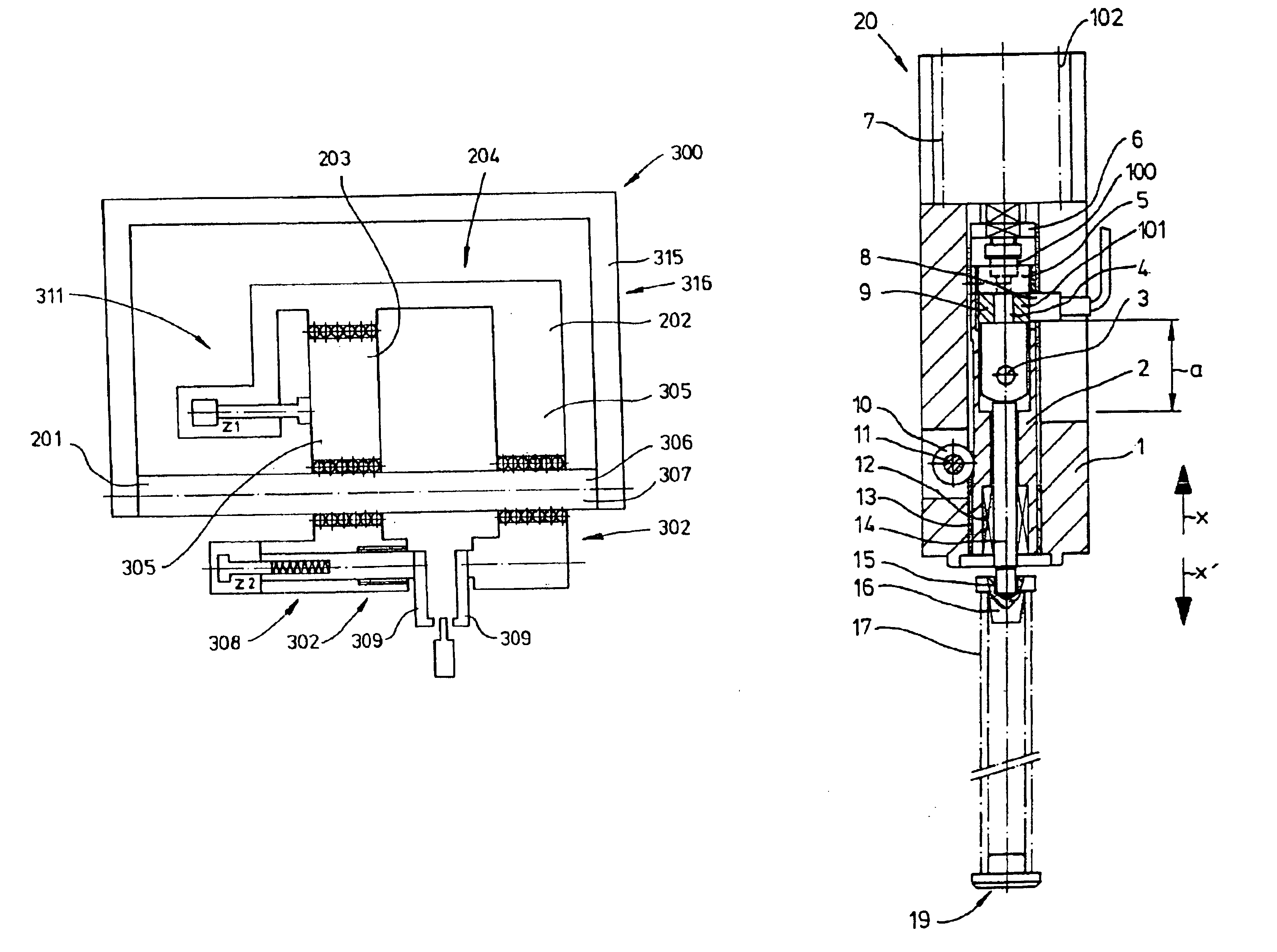

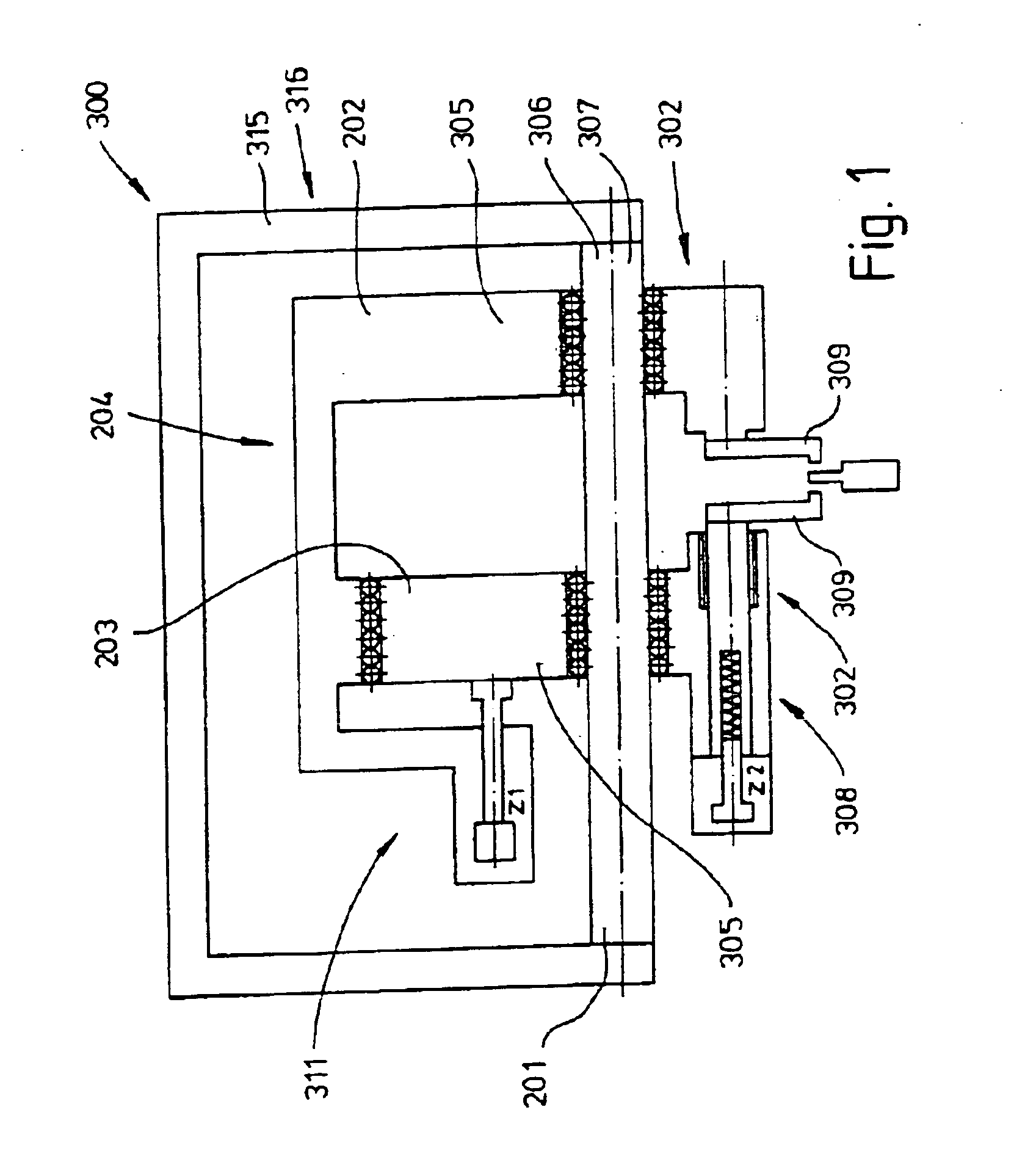

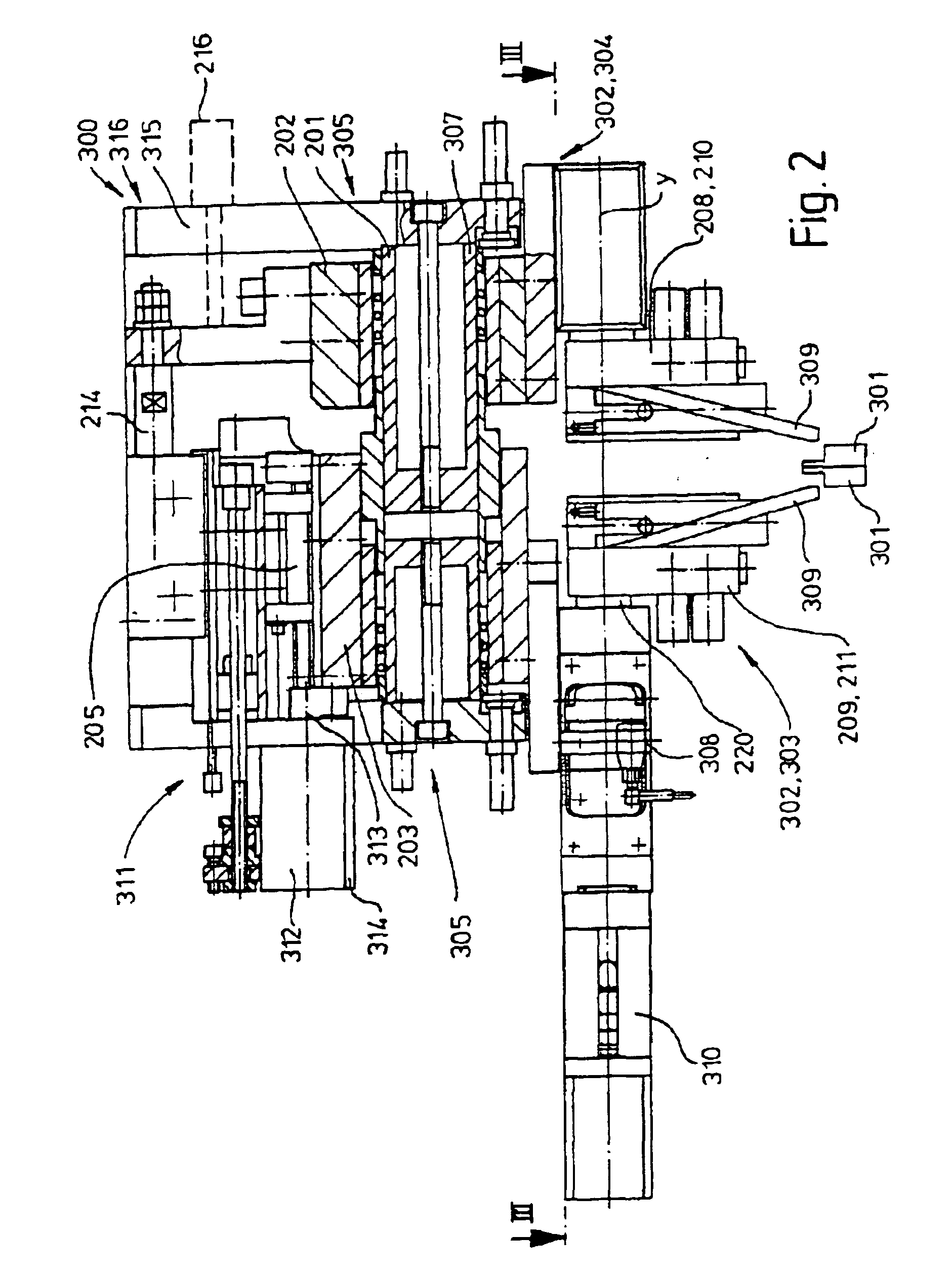

Welding head

InactiveUS6911615B2Uniform loadSlow motionResistance electrode holdersElectric discharge heatingElectrical resistance and conductanceDrive shaft

A welding head for connecting weld members by resistance welding includes an infeed cylinder having a piston rod, an electrode movable via the cylinder; and a sensor arranged between the piston rod of the infeed cylinder and a readjusting spring for the rapid readjustment of the electrode. The sensor is clamped in place between contact means in a sleeve-shaped or tubular drive shaft mounted in a housing.

Owner:KOMBI TEC

Method for solving welding deviation and welding equipment thereof

PendingCN111468869AHigh positive rateImprove welding yieldWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWeld zone

The invention discloses a method for solving welding deviation and welding equipment thereof. The method comprises the steps of employing a CCD device to shoot a workpiece image, and judging a position deviation value between an actual workpiece image and a standard workpiece image; if no position deviation exists, starting welding; and if the position deviation exists, compensating the position deviation value by moving a welding head or a workpiece fixing device, and then starting the welding. Therefore, the problem that deviation exists between a welding area of the workpiece and the welding head due to the fact that positioning is conducted through appearance of the workpiece traditionally can be effectively eradicated; and a high aligning rate of workpiece welding can be ensured, so that the welding yield of the workpiece is further improved.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

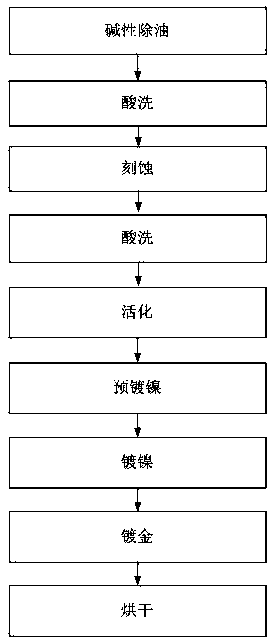

Method for improving welding performance of copper surface heat sink for packaging shell after gold plating

The invention discloses a method for improving the welding performance of a copper surface heat sink for a packaging shell after gold plating. The method comprises the following steps of putting the shell into an alkaline oil removal solution to be cleaned; putting the shell into a pickling solution for cleaning; putting the shell into an etching solution for treatment; putting the shell into a pickling solution for cleaning; putting the shell into an activation solution for pre-plating activation; electroplating a layer of thin nickel on the surface of the shell; electroplating a layer of thick nickel on the surface of the shell; electroplating a layer of thick gold on the surface of the shell; and carrying out high-temperature drying treatment on the washed shell by using a high-temperature blast drying box. According to the invention, etching before plating is carried out on the copper surface heat sink for the packaging shell, etching liquid is corroded along a grain boundary, so that a lattice pattern shape is formed on the copper surface, and after nickel plating and gold plating are subsequently carried out on the basis, the welding performance and the welding yield of the surface of the copper surface heat sink are greatly improved; the etching solution corrodes along the grain boundary, other areas of the copper surface and other materials of the shell are not damaged,and the etching time range is large.

Owner:CETC GUOJI SOUTHERN GRP CO LTD

Battery top cover and power battery

PendingCN110246993ASimple production processSimple manufacturing processSmall-sized cells cases/jacketsVent arrangementsPower batteryPunching

The invention discloses a battery top cover and a power battery. The battery top cover comprises a top cover sheet, a positive pole column, a negative pole column, positive pole conductive upper plastic and negative pole insulating upper plastic. The top cover sheet comprises a sheet-shaped main body and two pole post rings which are formed on the upper end surface of the main body in a protruding manner. Two pole mounting holes are formed in the main body, and a pole ring is arranged at the periphery of each pole mounting hole. The positive pole and the negative pole are respectively arranged in the pole mounting holes in a penetrating manner. The positive pole conductive upper plastic and the negative pole insulating upper plastic are respectively arranged on the pole post rings. Welding aluminum rings are welded to the peripheries of the pole mounting holes in the lower end face of the main body of the top cover sheet through laser respectively. A sealing ring is arranged between each welding aluminum ring and the body. According to the invention, the top cover sheet is manufactured through the integrated punching technology and the upper plastic and the top cover sheet are integrally formed through injection molding, so the production technology can be simplified, and the production cost can be reduced; and the aluminum rings are welded on the back surface, so the positive pole conductive upper plastic / negative pole insulating upper plastic can be prevented from melting and the welding yield is improved.

Owner:武汉阿李智能科技有限公司

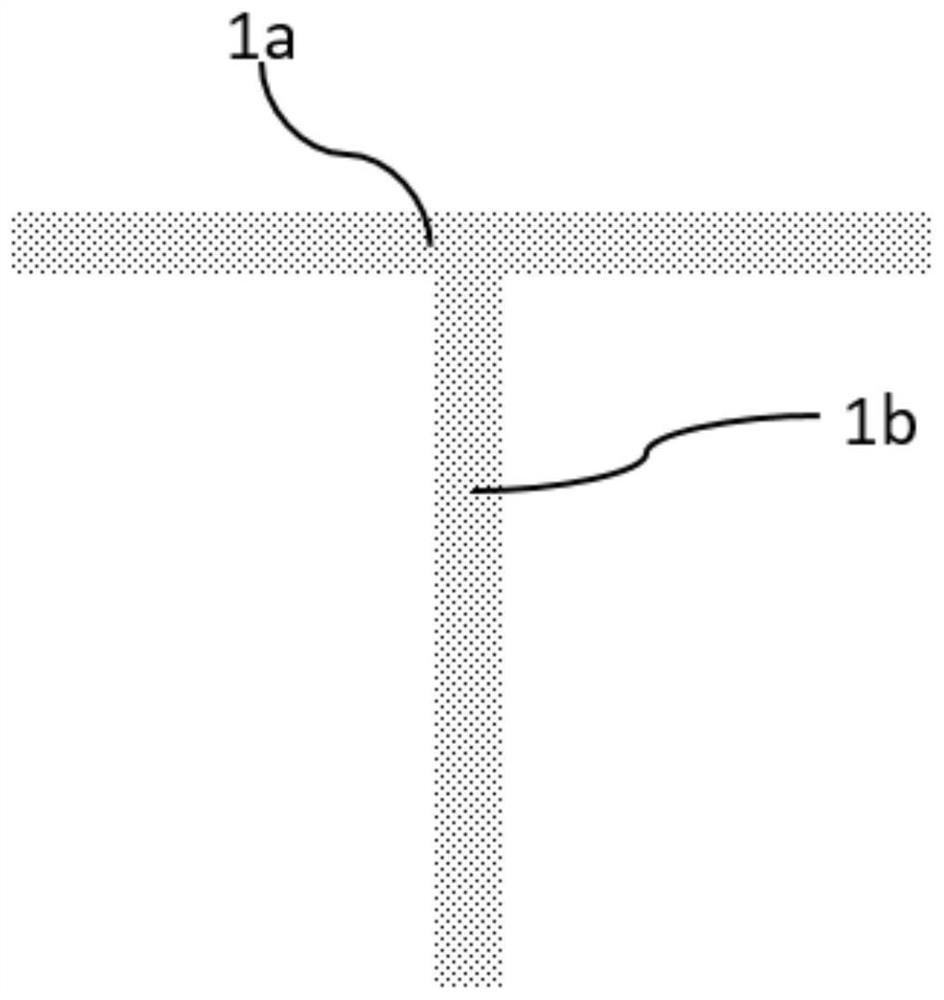

Electrode plate and application thereof

PendingCN113285055AAvoid crackingImprove mass energy densityFinal product manufactureElectrode carriers/collectorsEngineeringLithium-ion battery

The invention provides an electrode plate and an application thereof. A first functional surface of a current collector in the electrode plate comprises a first active layer area and a first tab area, and a second functional surface of the current collector comprises a second active layer area opposite to the first active layer area and a second tab area opposite to the first tab area. The active layer is arranged in the first active layer area and / or the second active layer area; n through holes penetrating to the second tab area are formed in the first tab area, a T-shaped tab passes through the through holes, one end of a first section of the T-shaped tab is connected with the first tab area to form a first connecting area, and the other end of the first section of the T-shaped tab is connected with the first tab area to form a second connecting area; the second section of the T-shaped tab is connected with the second tab area to form a third connecting area, and N is greater than or equal to 1; and the current collector comprises a first conductive layer, an insulating layer and a second conductive layer which are stacked. The lithium ion battery prepared from the electrode plate has relatively high mass energy density and safety performance.

Owner:ZHUHAI COSMX BATTERY CO LTD

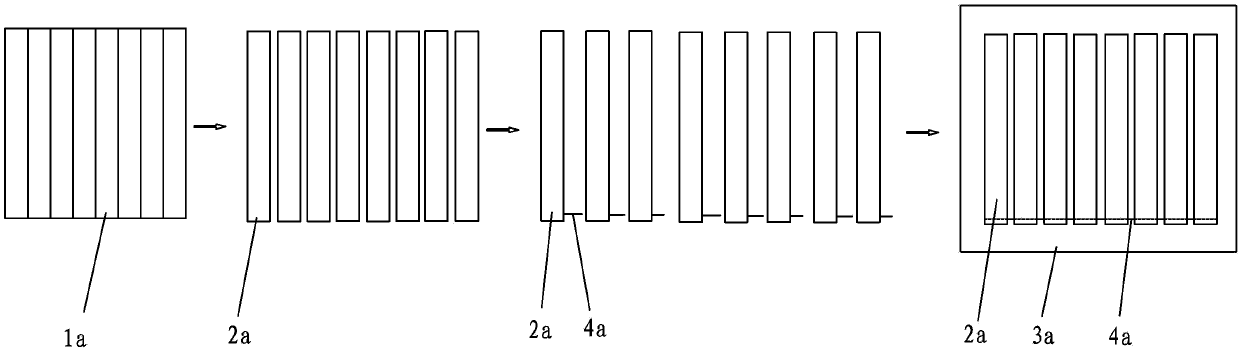

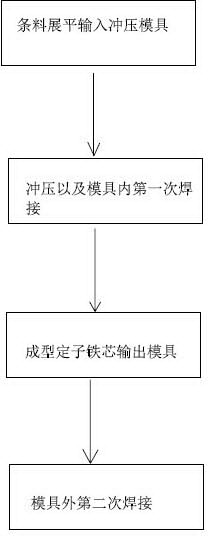

Process for manufacturing straight-bar stator cores

ActiveCN104348312AEasy to separate from each otherReduce processManufacturing stator/rotor bodiesSingle plateEngineering

The invention discloses a process for manufacturing straight-bar stator cores. The process comprises the following steps of stamping a bar material into required stamped plates by using a progressive stamping die, and simultaneously welding the stamped plates into an iron core with certain thickness through laser in the die; welding the rest soldering points on the exterior of the die; finally forming the required products. Pre-welding is realized in the stamping die for the first time, and procedures are effectively reduced; in the stamping procedure, a welding groove gap of the (N+1)th plate is particularly stamped, so that the size of the welding groove of the plate is greater than the size of a welding groove of a conventional stator single plate, and the (N+1)th plate cannot be welded in the welding process in the die, so that stator cores welded in the die can be easily separated from each other, setting on laser welding equipment is not required, the welding yield is greatly improved and the cost is reduced.

Owner:CHANGYING XINZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com