Packaging method of chip of phase change memory

A phase-change memory and packaging method technology, which is applied in the field of phase-change memory chip packaging, can solve problems such as immature chip packaging technology, achieve the effect of improving welding speed and yield, and maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

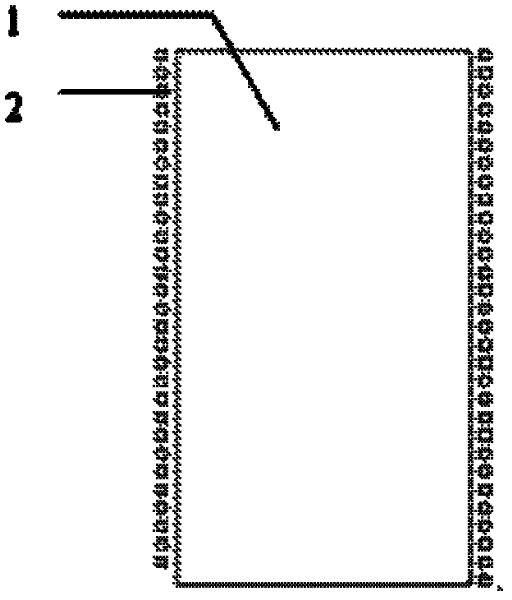

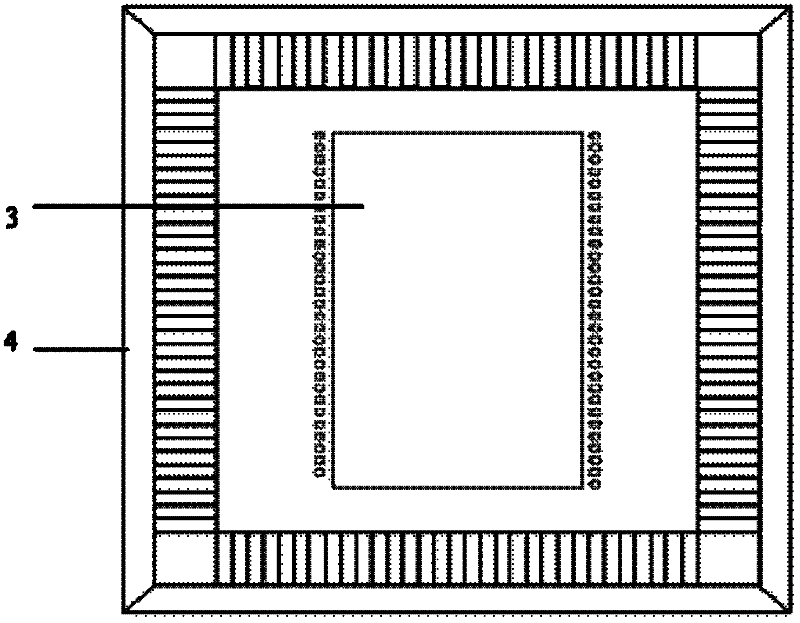

[0019] The packaging method of the phase-change memory chip of the present invention is specifically as follows: firstly, the chip to be packaged is fixed in the packaging tube shell, and then the electrodes of the chip are connected to the pins of the tube shell one by one by ultrasonic bonding technology, and finally the shielding cover is used Isolate it from the outside world.

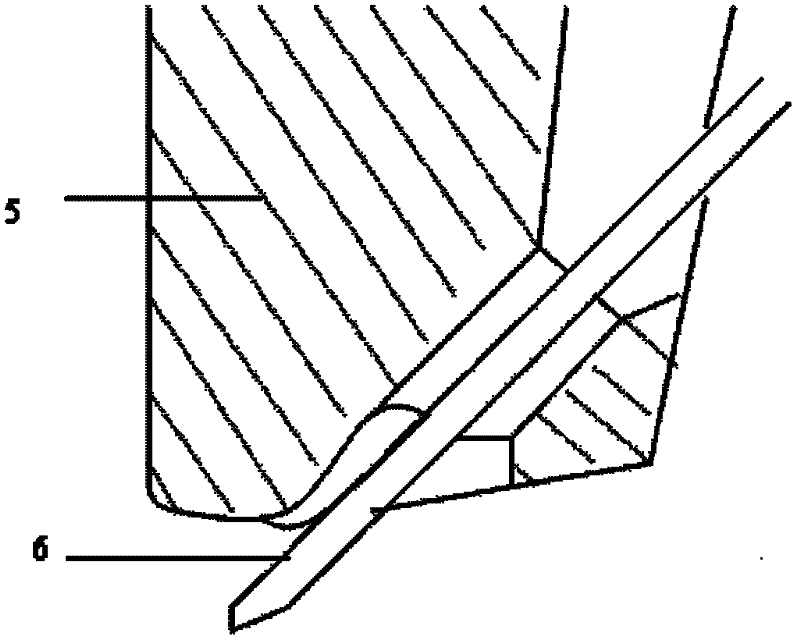

[0020] The specific implementation method of using ultrasonic bonding technology to connect the electrodes of the chip and the pins of the shell one by one is: using a rivet to lead the metal wire to the surface of the electrode of the chip, and driving the rivet to exert pressure on the electrodes through ultrasonic vibration, driving The metal wire rubs against the electrode surface, and the metal wire and the electrode surface produce plastic deformation, and at the same time, the oxide f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Chamfer | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com