Special-shaped glass cutting machine for touch screen production

A touch screen and cutting machine technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of touch screen lack of positioning measures, touch screen position offset, cutting precision reduction, etc., to achieve stable cutting, improve precision, and keep clean degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

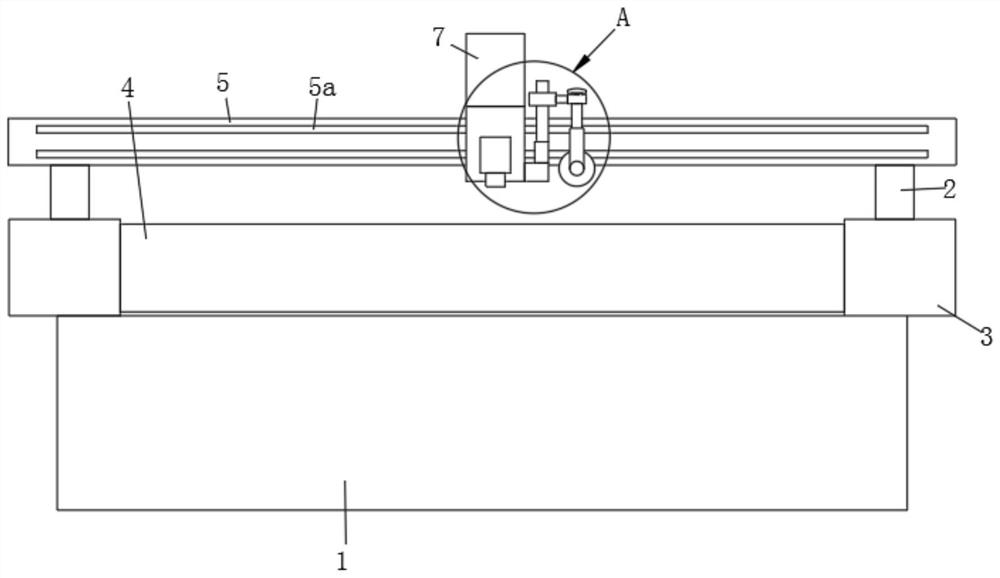

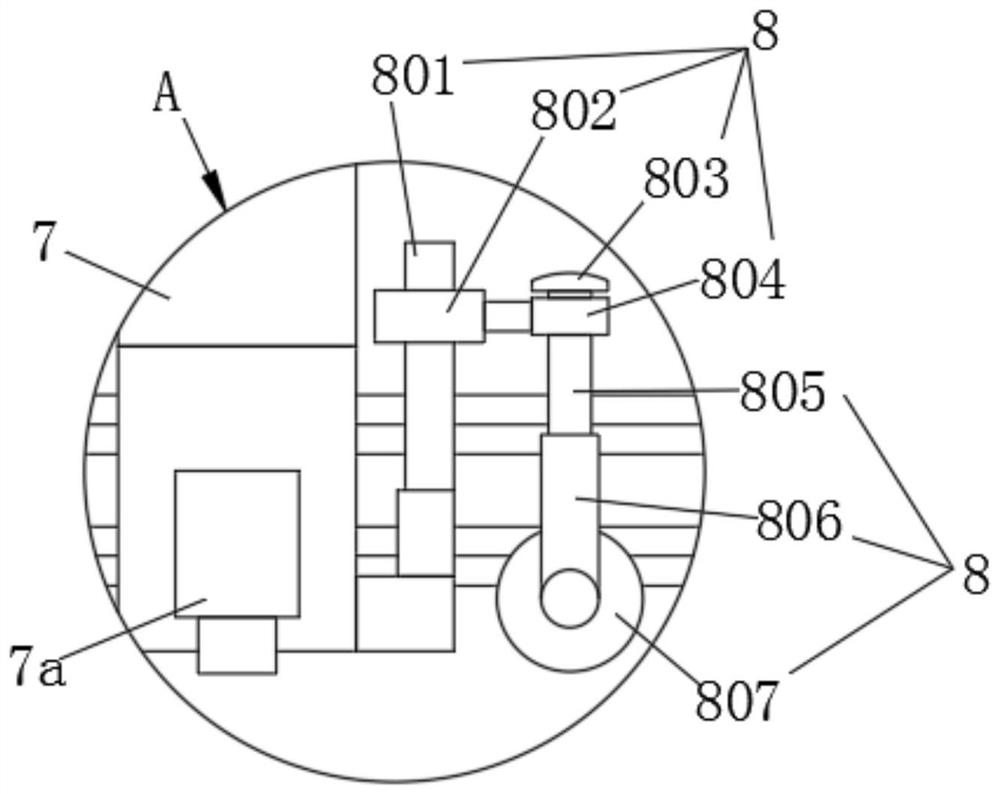

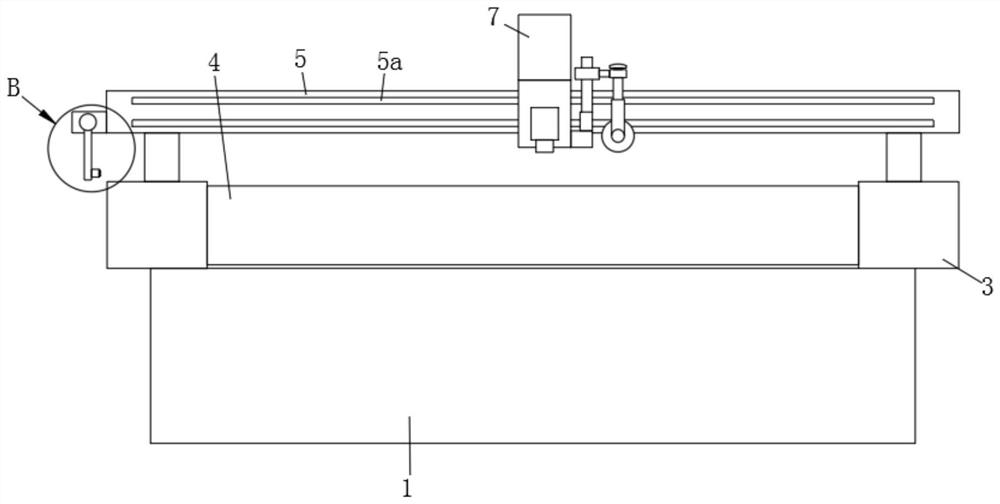

[0039] Such as figure 1 As shown, the present invention provides a special-shaped glass cutting machine for touch screen production, including a support base 1, a movable column 2, a fixed table 3, a transmission platform 4, a traverse seat 5, a cutting seat 7, and a positioning assembly 8.

[0040]A transmission platform 4 is installed on the top of the support base 1 . The transmission platform 4 is fixed with fixed tables 3 symmetrically on both sides along the conveying direction. A movable column 2 sliding along the length direction of the fixed platform 3 is installed on the two fixed platforms 3 . A traversing seat 5 is fixed between the tops of the two movable columns 2 by bolts. A guide rail bar 5a is fixed on the facade of the traversing seat 5 by bolts. The guiding of the guide rail bar 5 a is parallel to the longitudinal direction of the traversing seat 5 .

[0041] The cutting seat 7 is installed on the rail bar 5a. And the cutting seat 7 moves along the guid...

Embodiment 2

[0046] Such as image 3 and Figure 4 As shown, the air blowing assembly 9 includes a main pipe 901 , a connecting block 902 , an air nozzle 903 and a branch pipe 904 . A main pipe 901 is fixed on one end of the traversing base 5 through a connecting block 902 . The manifold 901 communicates with a positive pressure air source. A branch pipe 904 is led out from the main pipe 901 . The end of the branch pipe 904 is clamped with a gas nozzle 903 whose gas flow direction faces the surface of the transmission platform 4 .

[0047] The connecting block 902 is fixed on the end face of the traversing base 5 by bolts. It is convenient to disassemble the connection block 902 and the connected main pipe 901.

[0048] The gas nozzle 903 adopts a porous nozzle structure. Expand the impact range of the airflow and improve the blowing effect.

[0049] When the traversing seat 5 moves, the main pipe 901 moves with the traversing seat, and when the cutting knife 7a cuts and generates d...

Embodiment 3

[0051] Such as Figure 5 and Figure 6 As shown, on the basis of the second embodiment, the other end of the traversing seat 5 is also provided with a cleaning assembly 6 . The cleaning assembly 6 includes a cleaning guide rail 601 , a cleaning guide sleeve 602 , a cleaning cylinder 603 , a cleaning brush 604 and a cleaning bracket 605 . A cleaning bracket 605 is fixed on the fixed platform 3 close to the other end of the traversing seat 5 by bolts. The top end of the cleaning bracket 605 is fixed with a cleaning guide rail 601 arranged above the edge of the transmission platform 4 by bolts. The guiding of the cleaning guide rail 601 is parallel to the conveying direction of the transmission platform 4 . The cleaning guide rail 601 is covered with a cleaning guide sleeve 602 guiding and sliding along the cleaning guide rail 601 . A sweeping brush is installed on the bottom of the cleaning guide sleeve 602 .

[0052] Specifically, the bottom of the cleaning guide sleeve 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com