Collected rubber raw material preprocessing method

A rubber raw material and pretreatment technology, which is applied in the field of rubber processing, can solve the problems of low filtering effect of rubber raw material, less times of rubber raw material filtering, and blockage of filtering structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

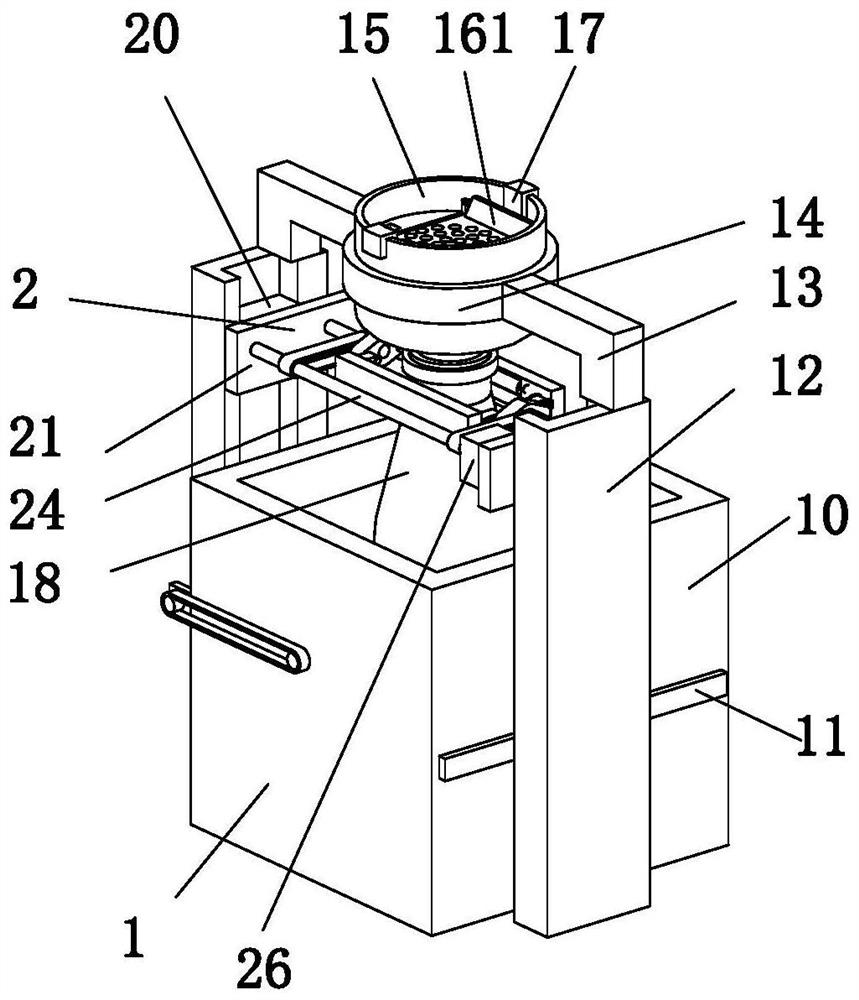

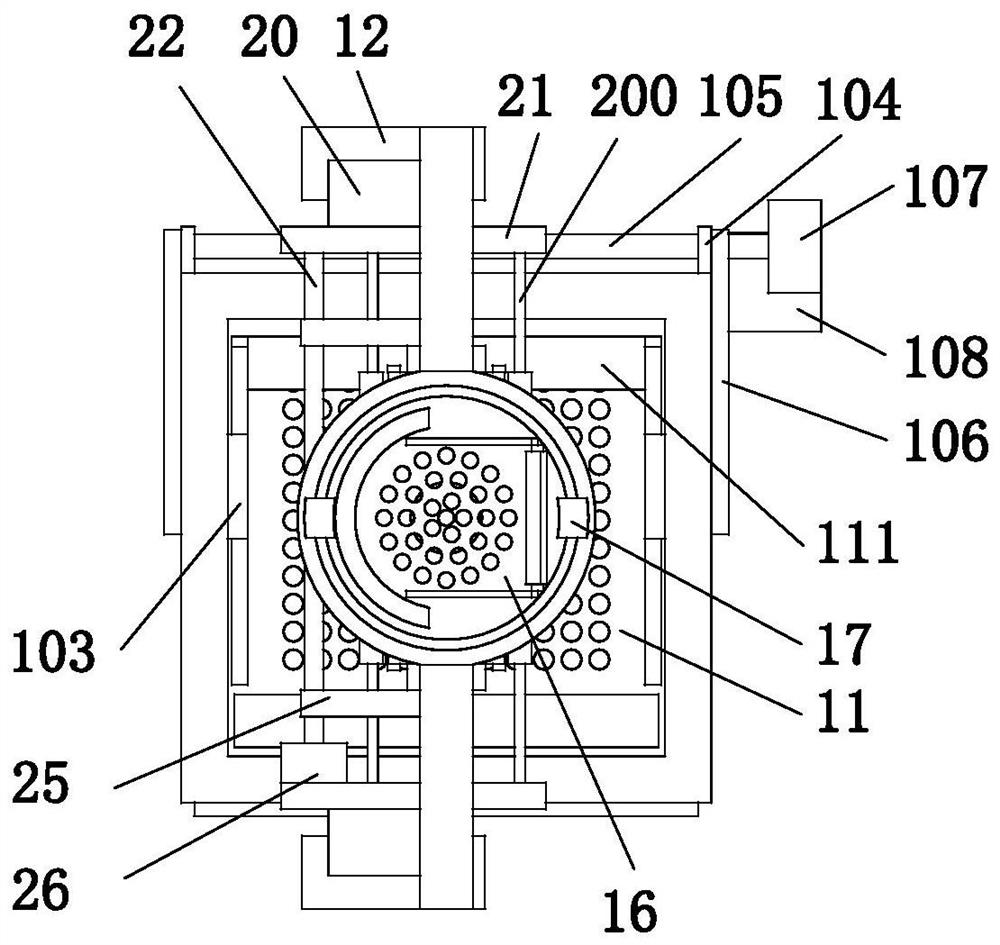

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

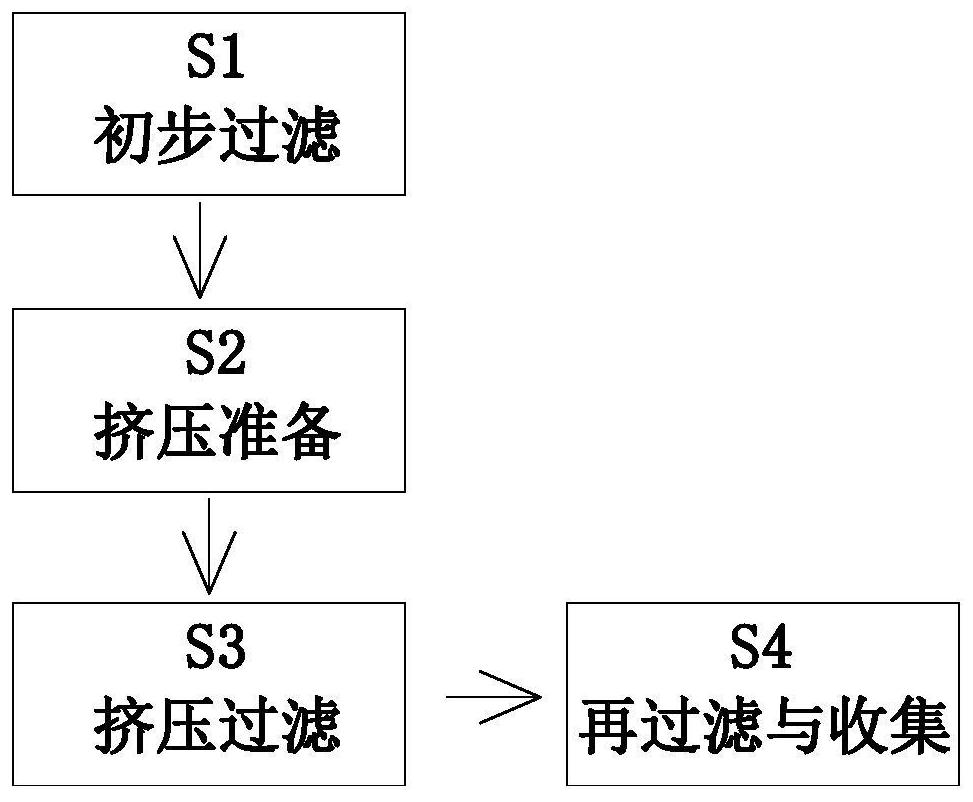

[0039] Such as Figure 1 to Figure 11 As shown, a pretreatment method for rubber raw materials after collection, which uses a pretreatment device for rubber raw materials after collection. The specific pretreatment method when the post-pretreatment device performs pretreatment after collection of rubber raw materials is as follows:

[0040] S1. Preliminary filtration: Pour the rubber raw material into the funnel 15 manually, the rubber raw material flows into the filter cloth bag 18 through the sieve plate 16, the rubber raw material accumulates in the filter cloth bag 18 and performs autonomous slow drip filtration through the filter cloth bag 18, and the sieve Plate 16 carries out the main primary filtration treatment of rubber raw materials; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com