Filter pressing assembly, filter press and filter pressing method

A filter assembly and filter press technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve problems such as low pressure and unsatisfactory effects, and achieve increased strength, faster filtration speed, and improved pressure. The effect of the degree of filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Some embodiments of the present invention will be further introduced below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

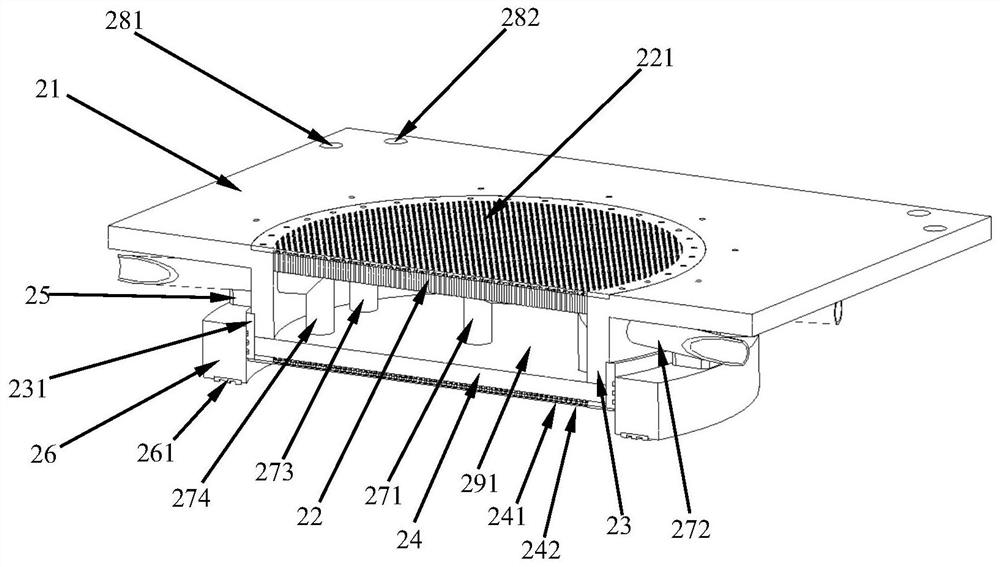

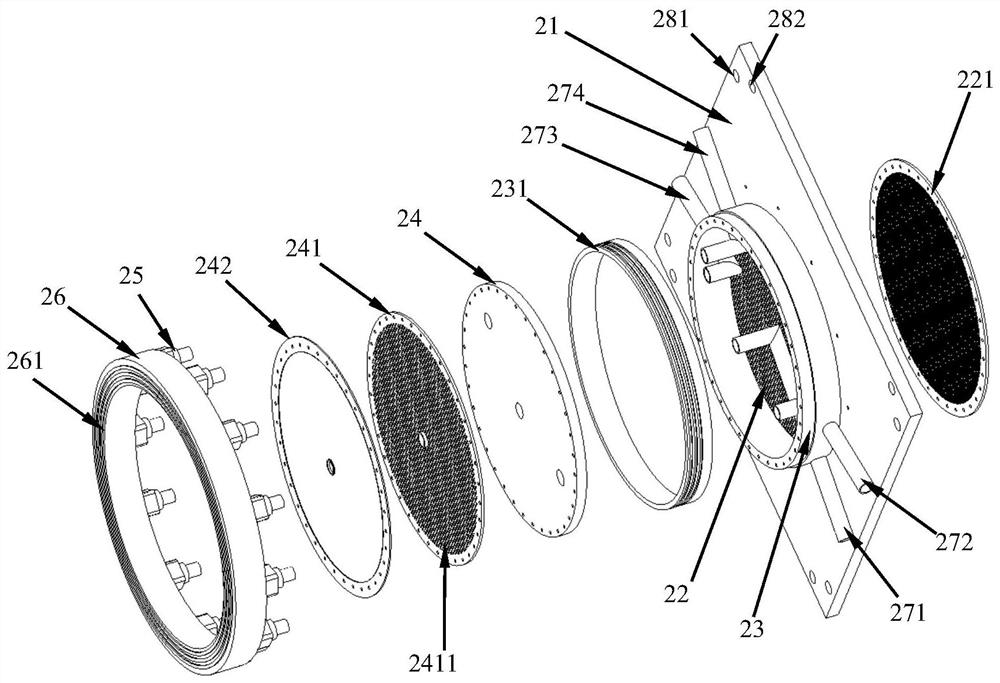

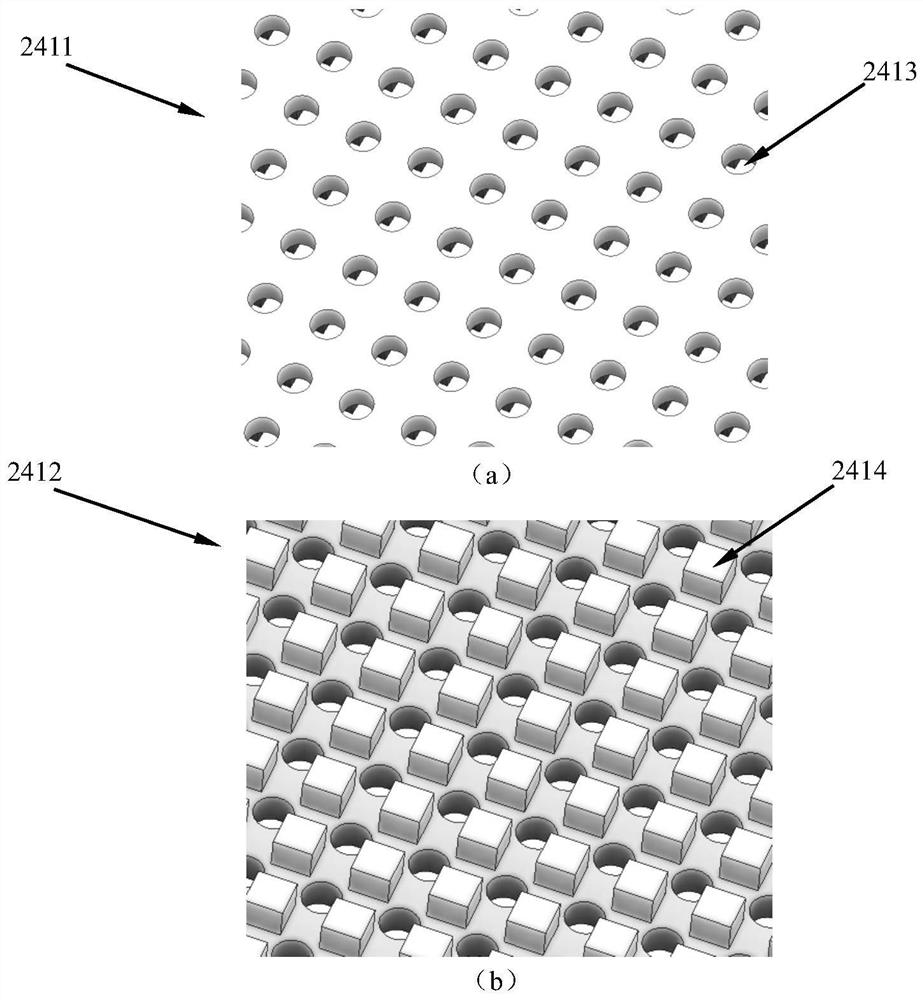

[0036] like Figure 1-7As shown, the press filter assembly of the present invention includes a substrate 21, the middle part of the substrate 21 is provided with a through-hole area 22 formed by one or more through holes penetrating the substrate 21, and the bottom surface of the substrate 21 is provided with a The downwardly extending piston wall 23 of the zone 22 is provided with a piston top plate 24 at the bottom of the piston wall 23, and the piston top plate 24 is provided with a second channel plate 241 so that the groove surface 2412 of the second channel plate 241 is in contact with the piston top plate 24. The lower surface of the second chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com