Patents

Literature

60results about How to "Low fluid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

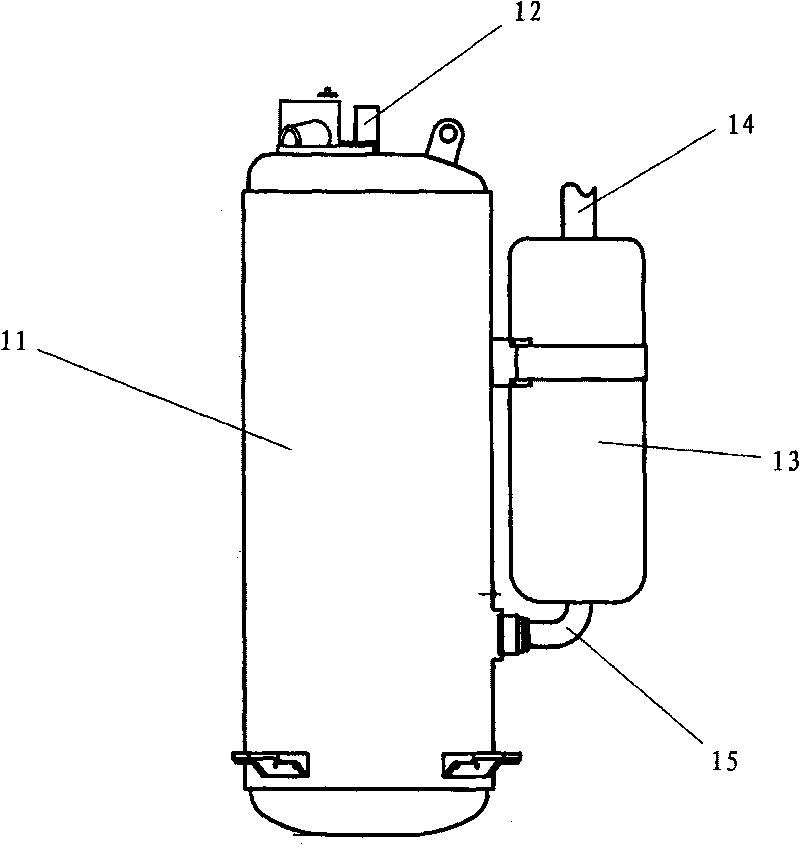

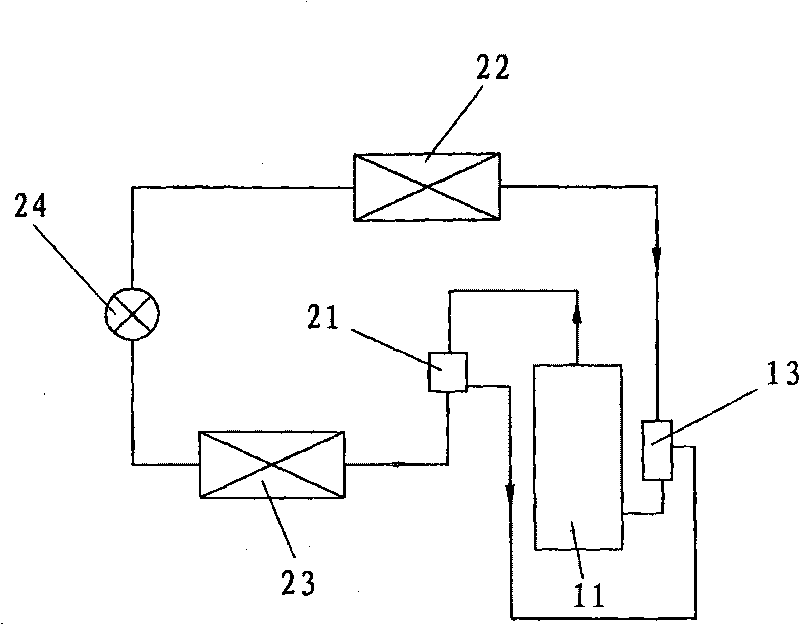

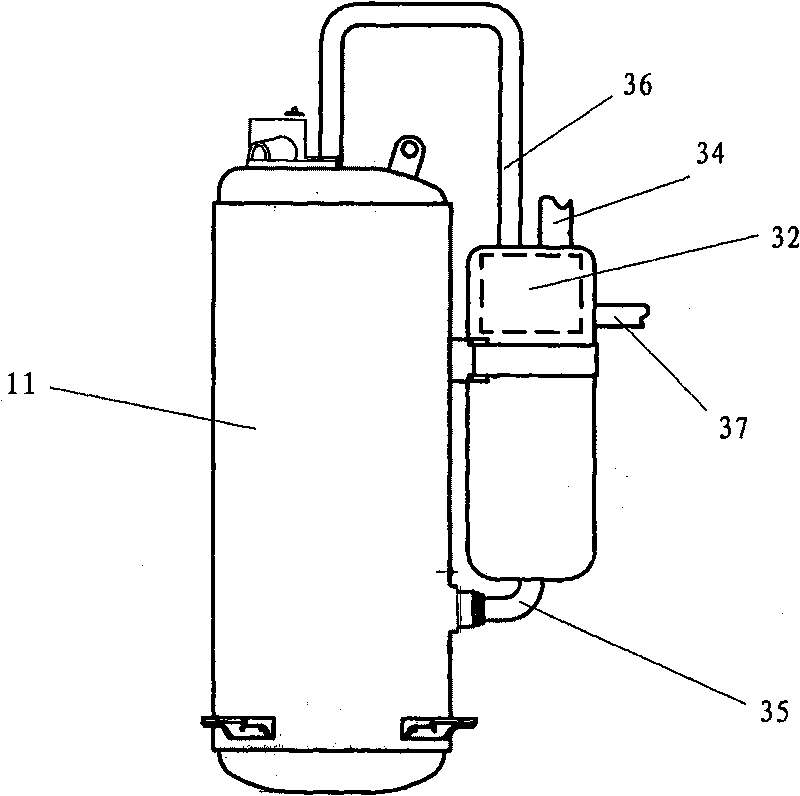

Compact structure of liquid reservoir and oil separator of compressor

ActiveCN101737329AEfficient heat exchangeSmall volumePositive displacement pump componentsPositive-displacement liquid enginesEngineering

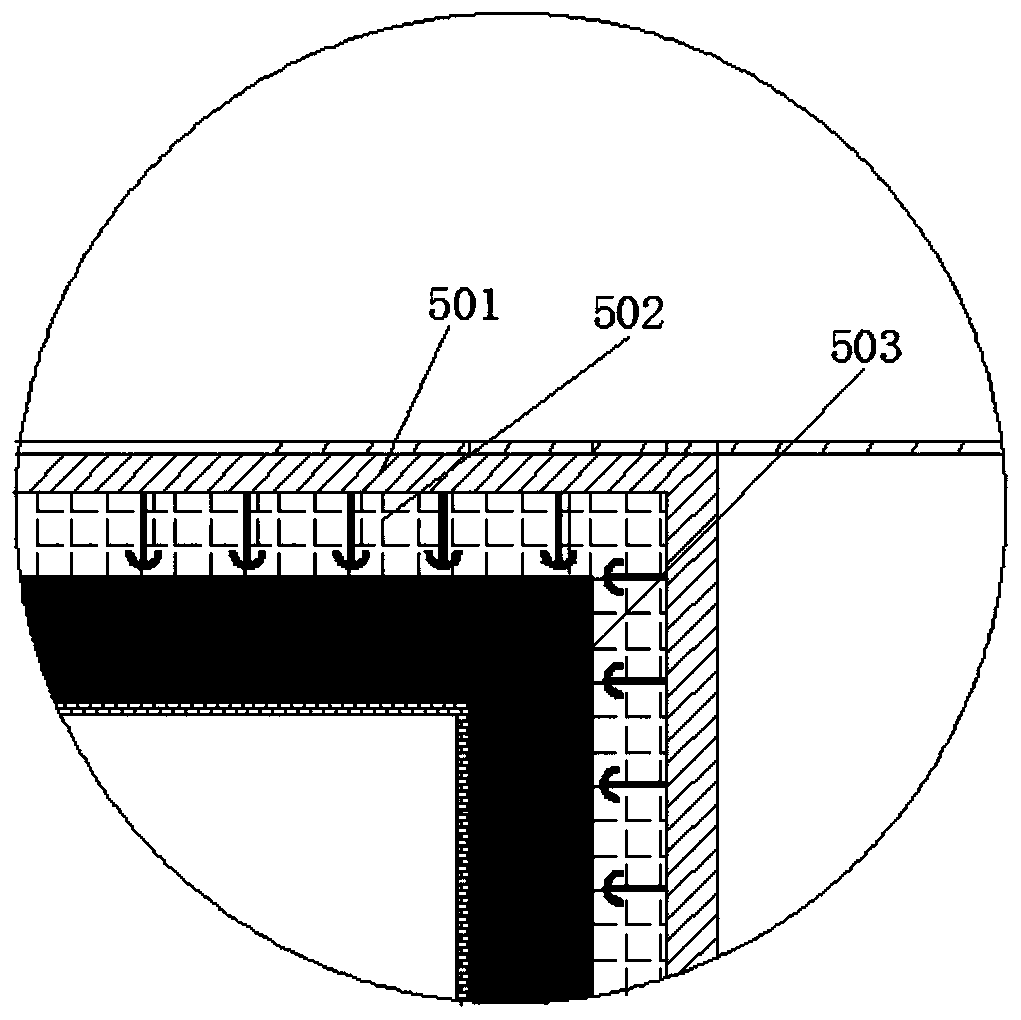

The invention relates to a compact of a liquid reservoir and an oil separator of a compressor, comprising a casing, a high and low pressure partition plate, an air suction inlet pipe, an air suction outlet pipe, an exhaust inlet pipe, an exhaust outlet pipe and a capillary pipe. The compact structure is characterized in that the high and low pressure partition plate divides the cavity in the casing into a liquid storing cavity and an oil separating cavity; fluid in the liquid storing cavity can exchange heat with fluid in the oil separating cavity through the high and low pressure partition plate; the air suction inlet pipe and the air suction outlet pipe extend in and are communicated with the liquid storing cavity; the exhaust inlet pipe and the exhaust outlet pipe extend in and are communicated with the oil separating cavity; and the high and low pressure partition plate is provided with an oil return hole which is communicated with an oil return hole on the air suction outlet pipethrough the capillary pipe, so that the lower part of the oil separating cavity is communicated with the air suction outlet pipe, and the air suction outlet pipe is communicated with the lower part of the liquid storing cavity through the oil return hole on the air suction outlet pipe.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

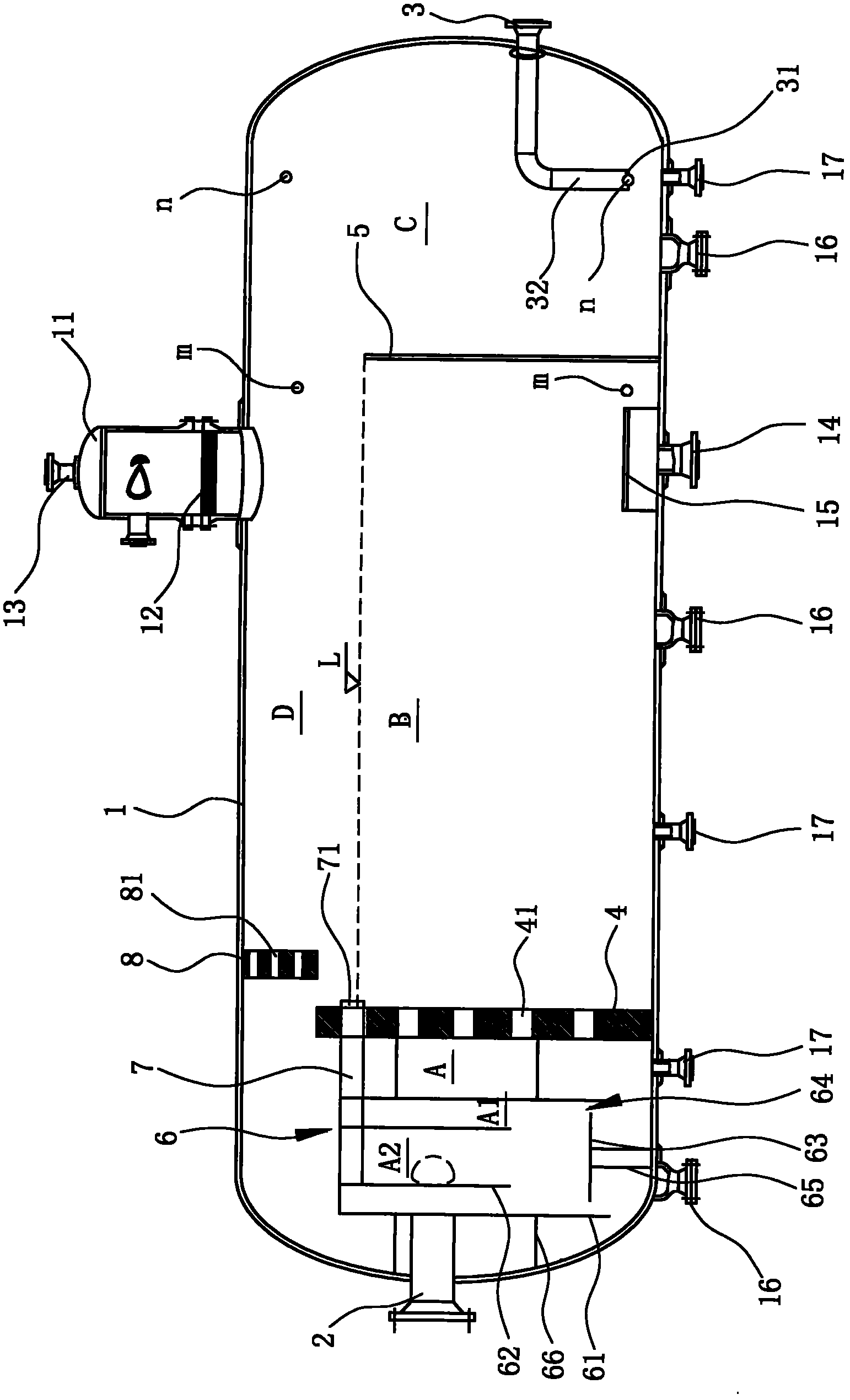

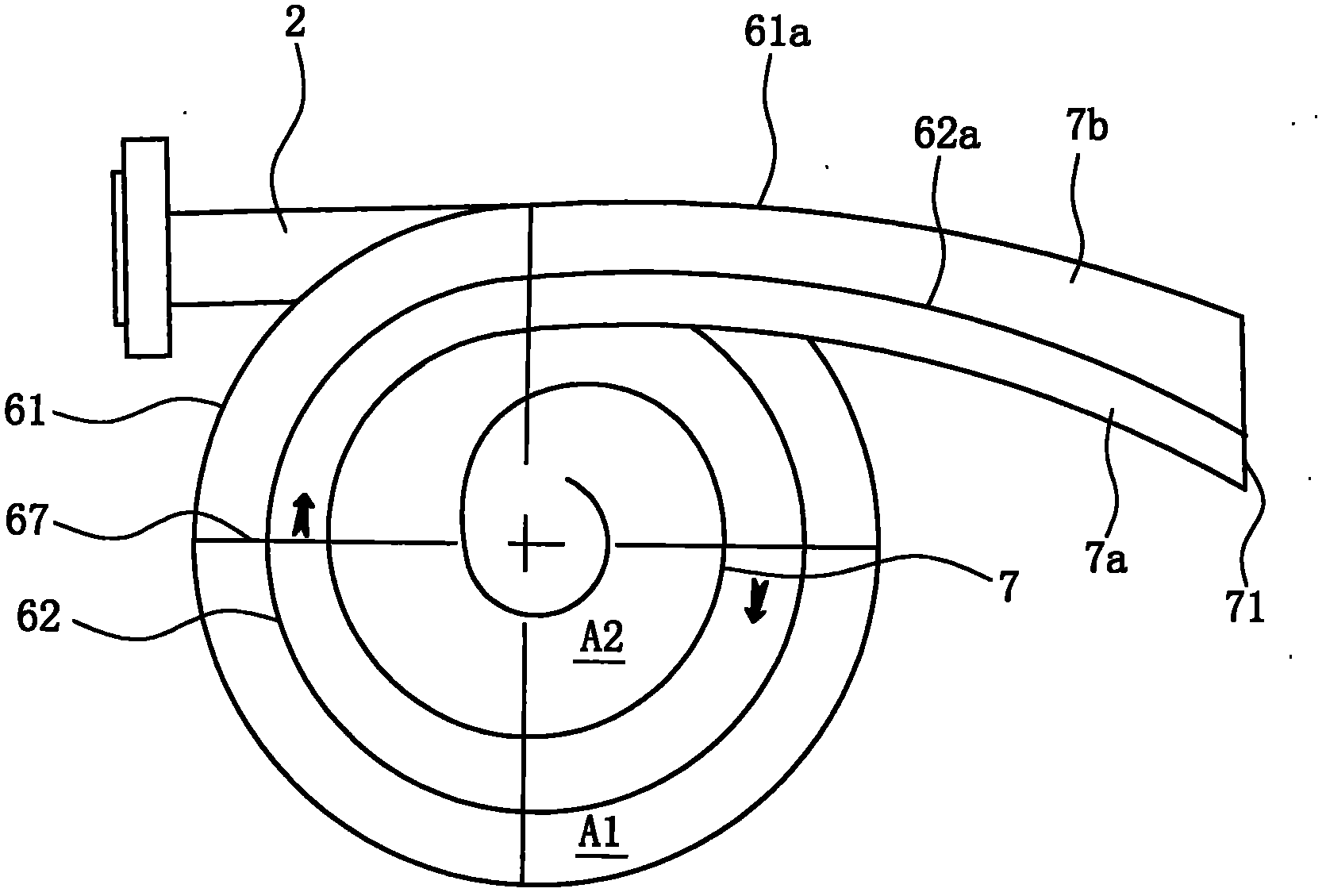

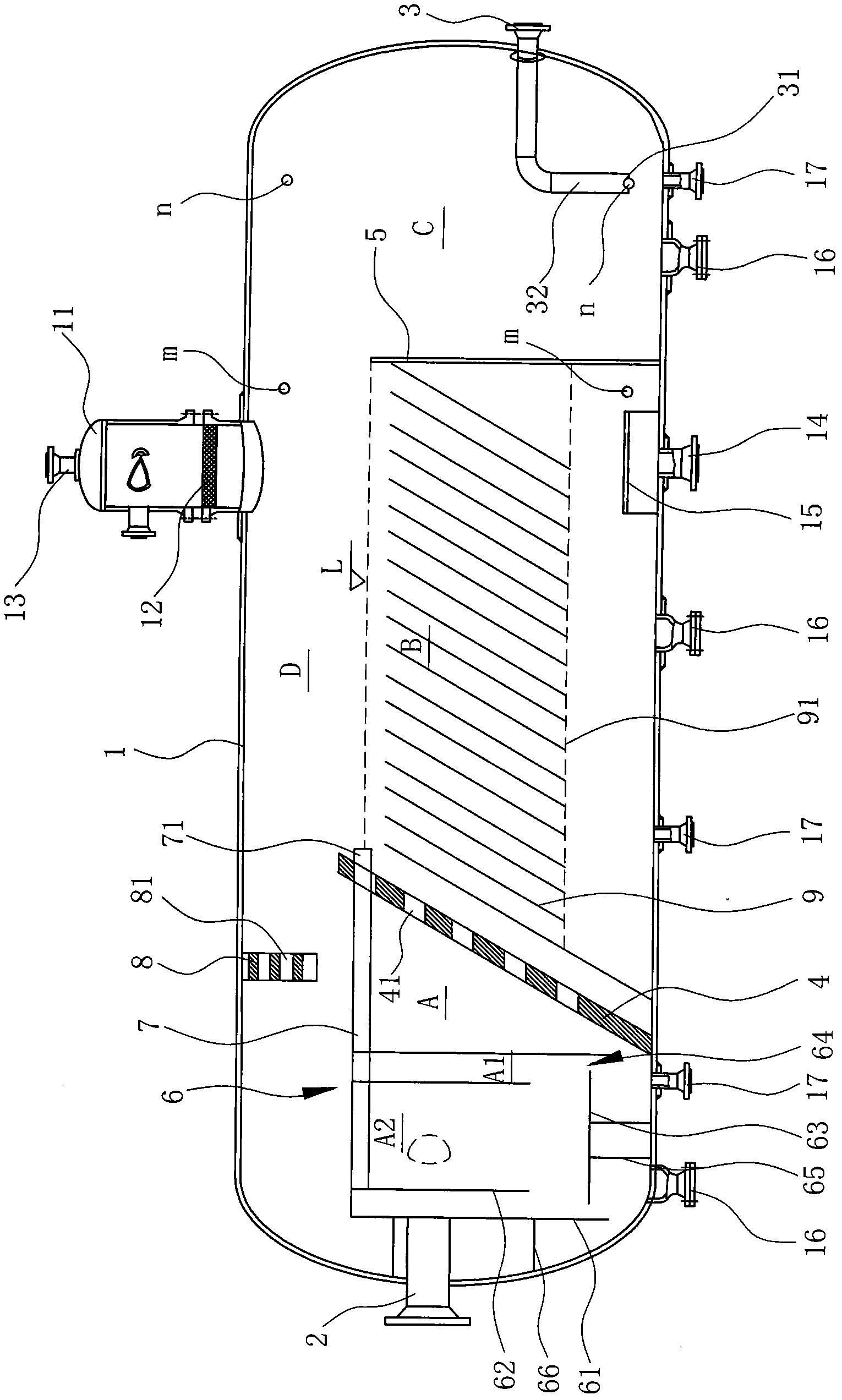

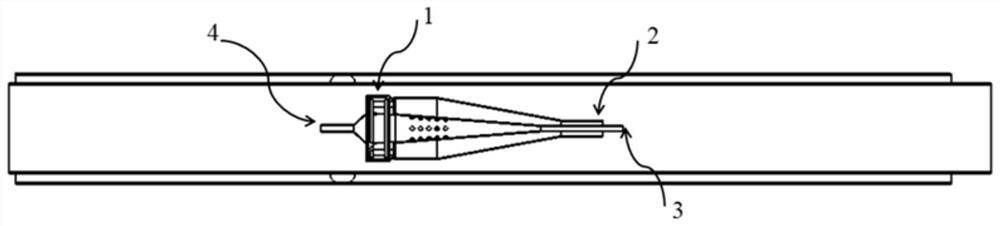

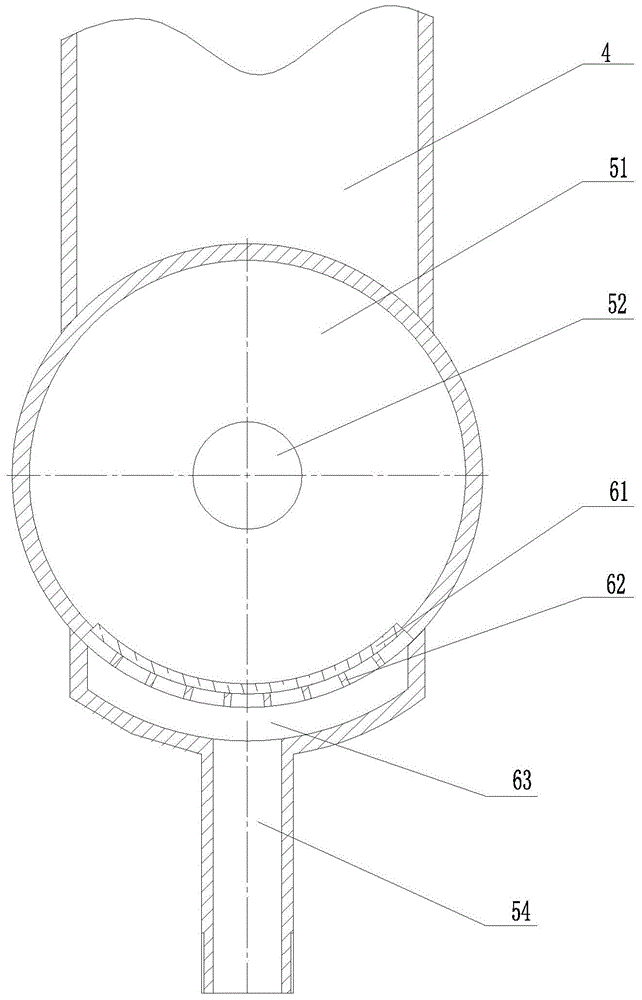

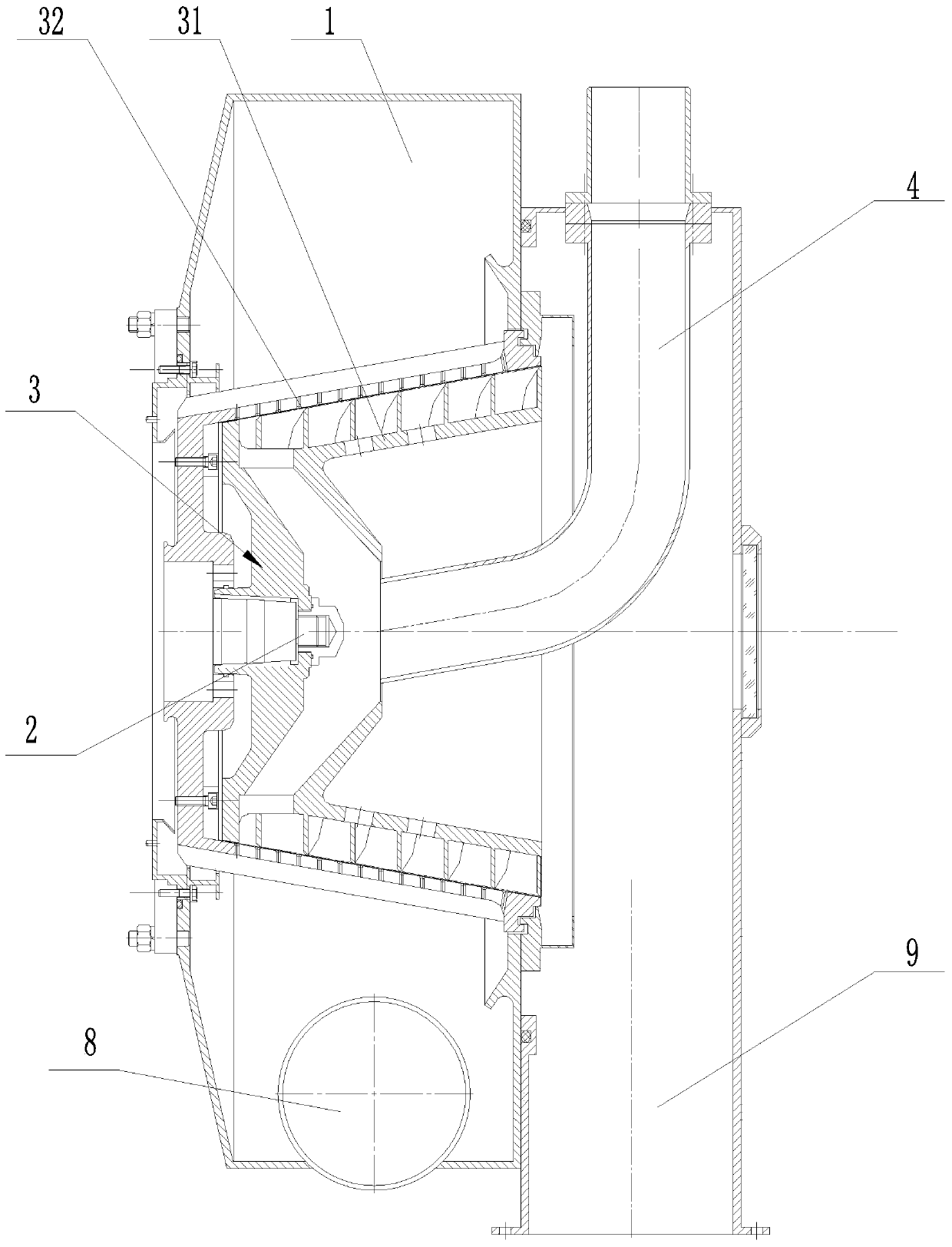

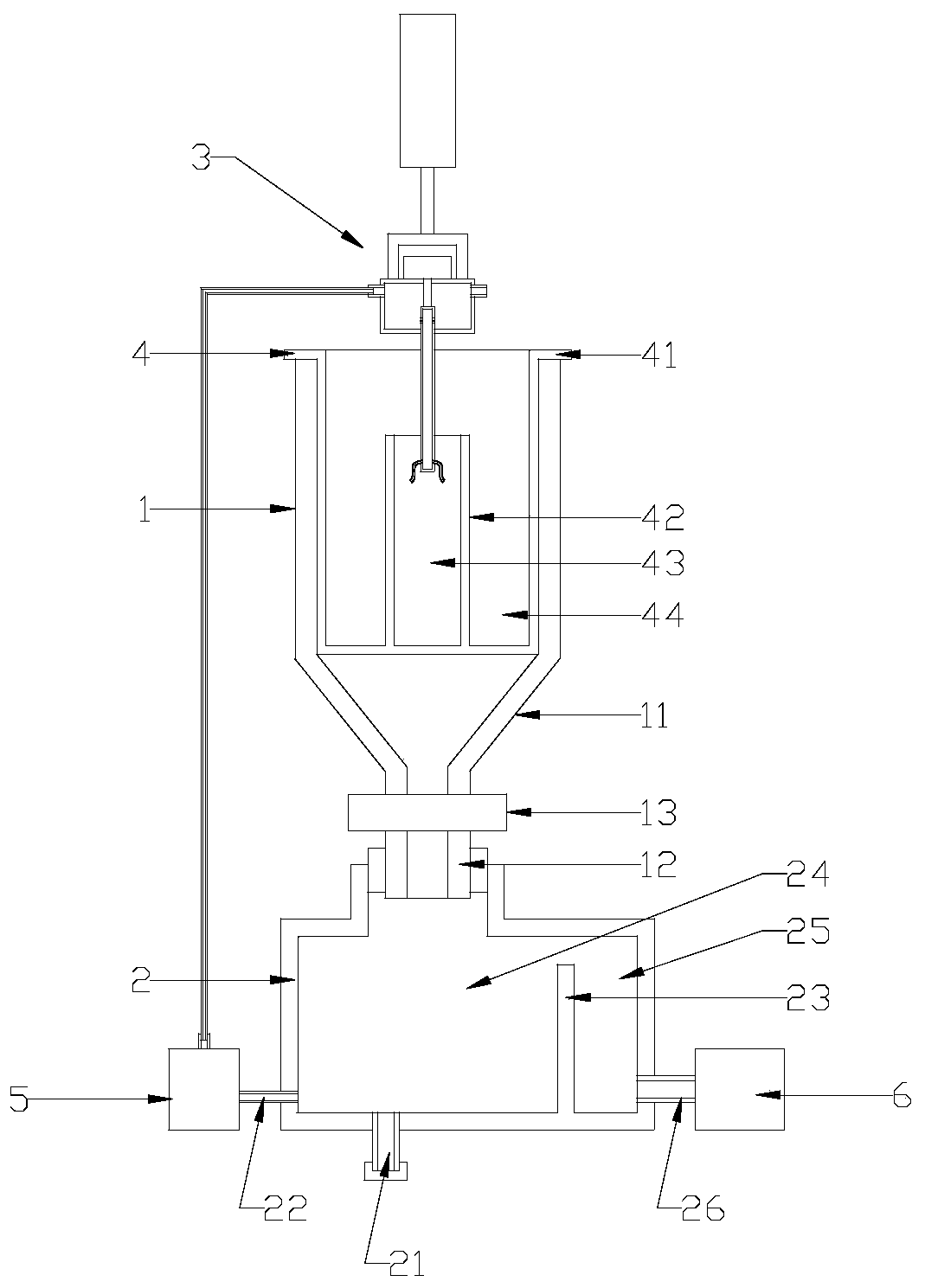

Gas-oil-water three-phase separator

ActiveCN102120103ALabor-saving maintenance workConvenient inspection and maintenance workLiquid degasificationLiquid separationCycloneDraining tube

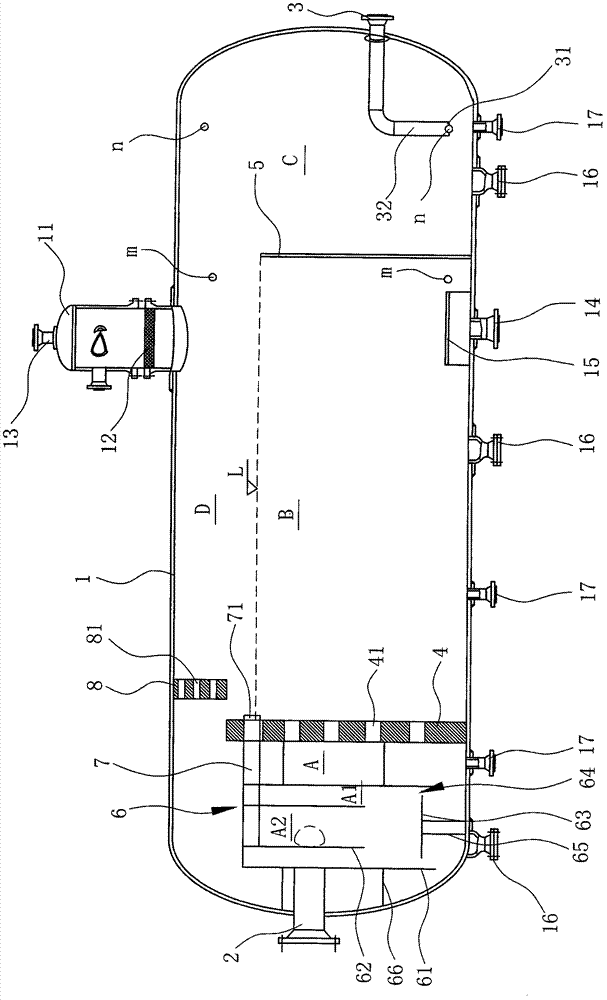

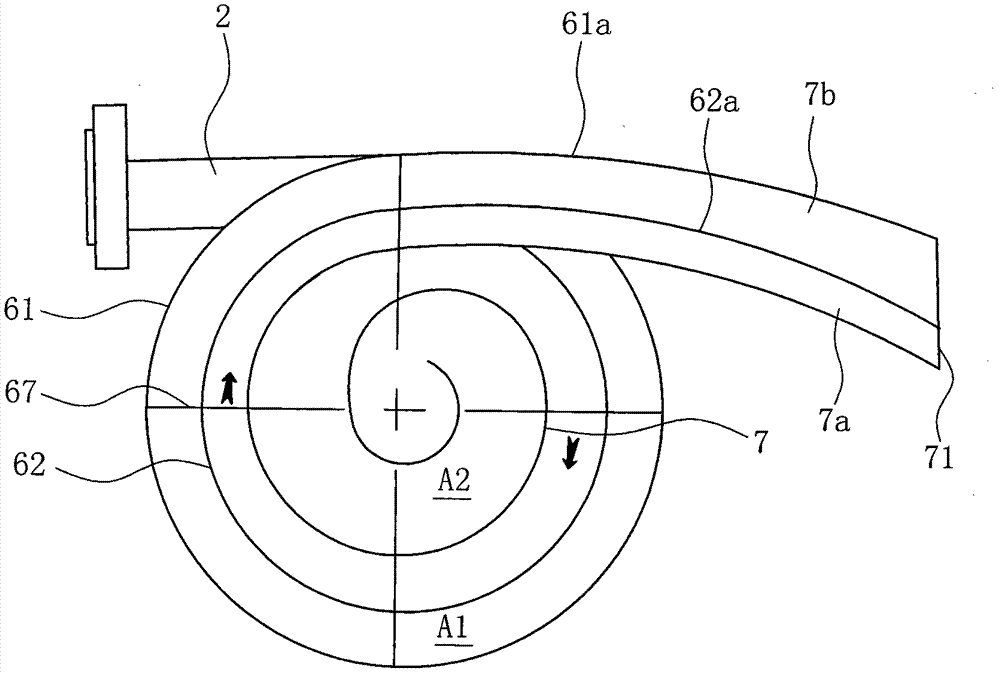

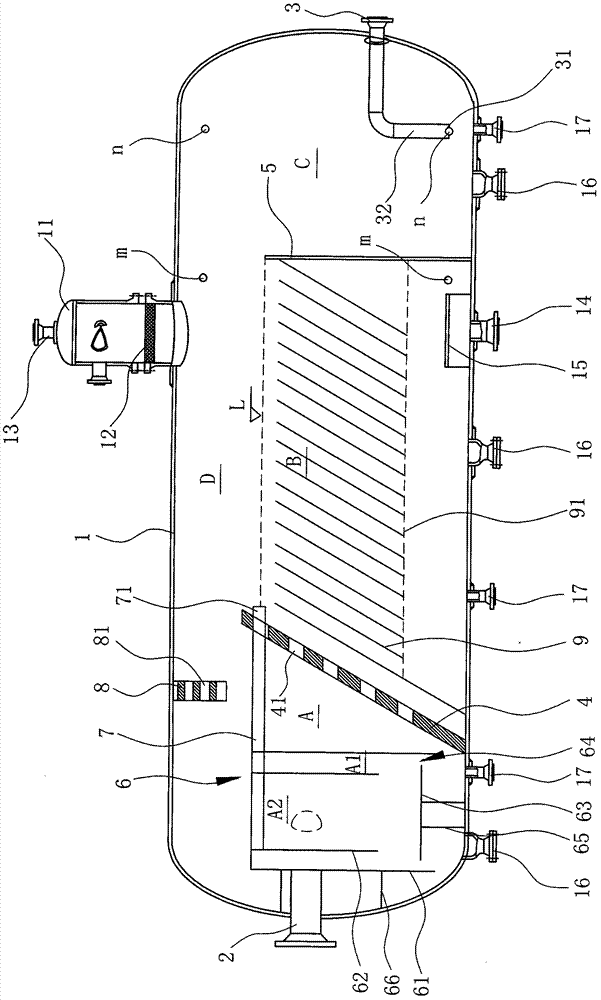

The invention discloses a gas-oil-water three-phase separator which comprises a horizontal tank body (1) and a crude oil input tube (2), wherein a liquid steady flow plate (4) and a baffle (5) are sequentially erected in the tank body (1) from left to right so as to sequentially divide the interior of the tank body (1) into a separating area (A), a liquid collecting area (B) and an oil collectingarea (C); a gas collecting area (D) is arranged above the baffle (5); the bottom of the tank body (1) is provided with a drain tube (14), the top of the tank body (1) is provided with a convex gas collecting bag (11), and the right side end of the tank body (1) is provided with an oil drain tube (3); moreover, a sleeve-type cyclone separator (6) is arranged in the separating area (A) and comprises an outer sleeve (61) and an inner sleeve (62) which are concentrically arranged and parallel and level at the top; a gas-liquid separating area (A1) is arranged between the outer sleeve (61) and theinner sleeve (62); and a gas-water mixing area (A2) is arranged in the inner sleeve (62). Compared with the prior art, the gas-oil-water three-phase separator provided by the invention has the advantages that the repair and maintenance are labor-saving and convenient; for the same crude oil throughput, the volume of the horizontal tank body can be reduced, the gas-oil-water separating efficiency is obviously improved, and the separating effect is more ideal.

Owner:浙江海牛海洋工程有限公司

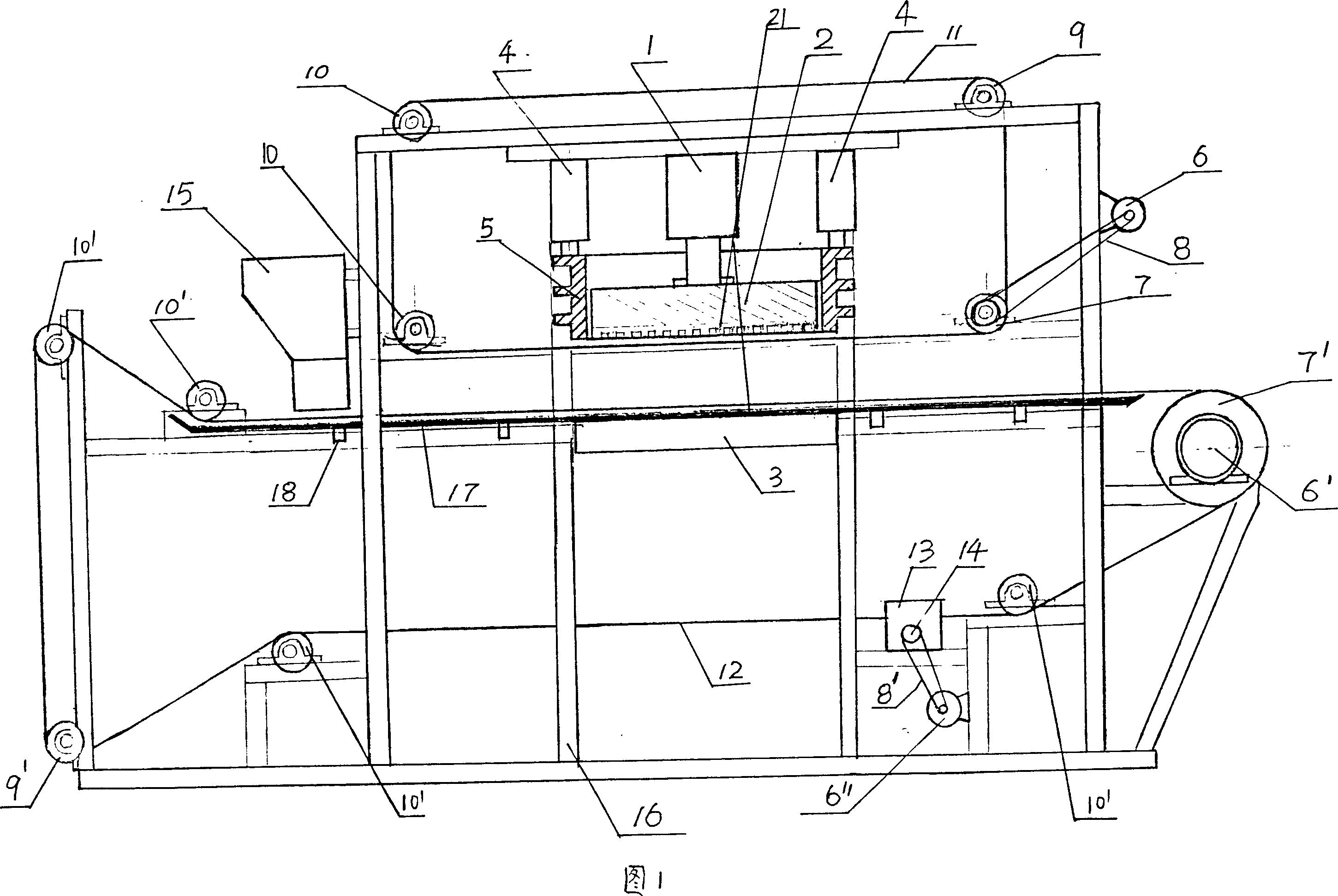

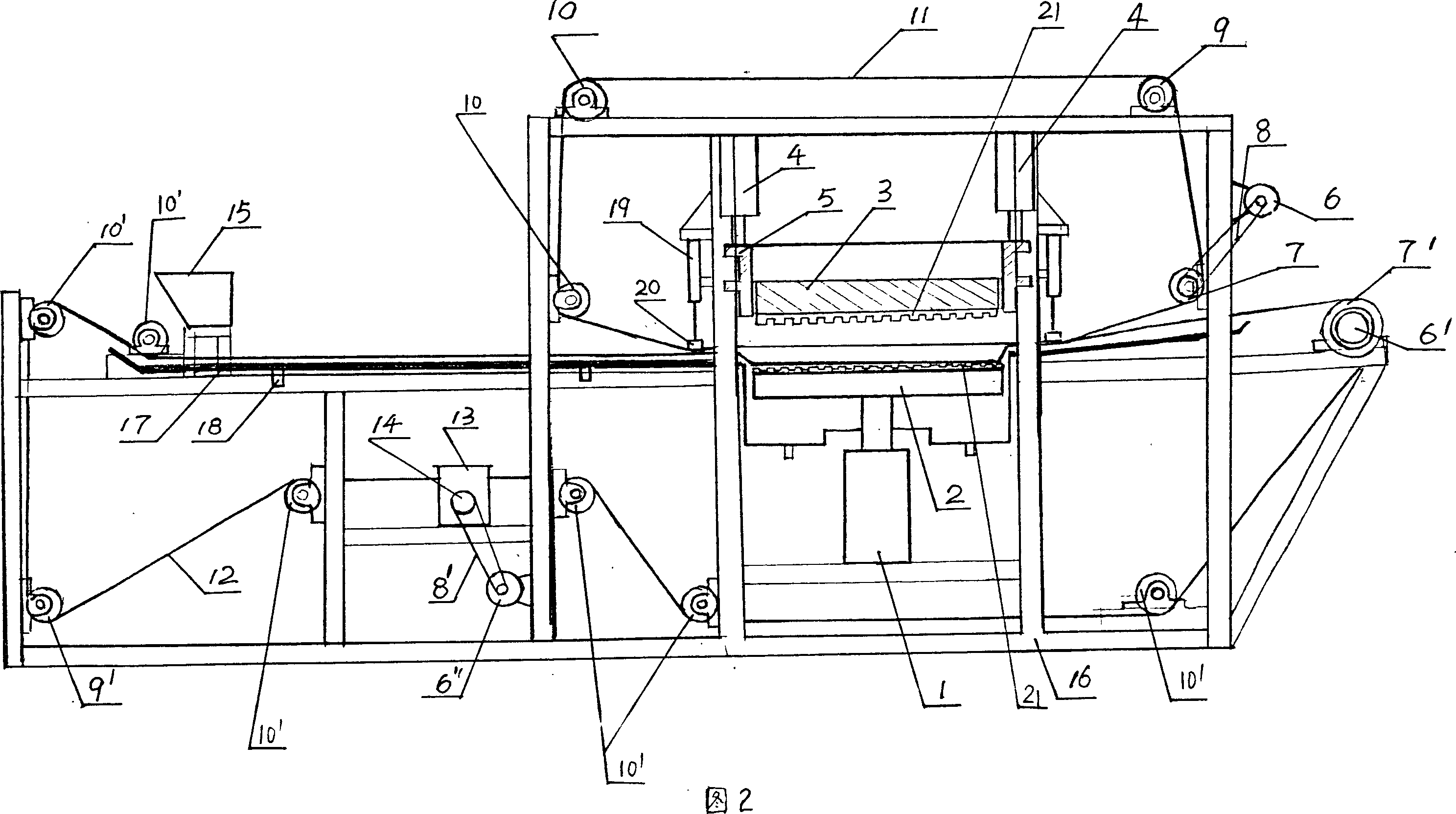

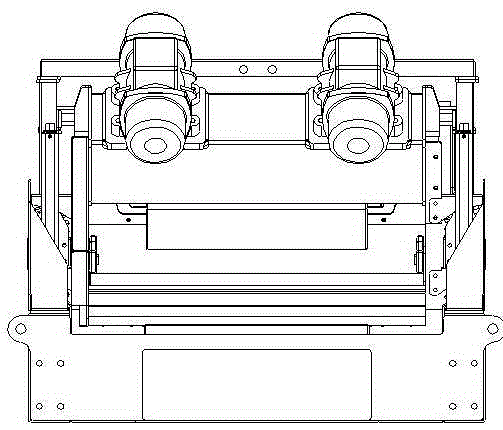

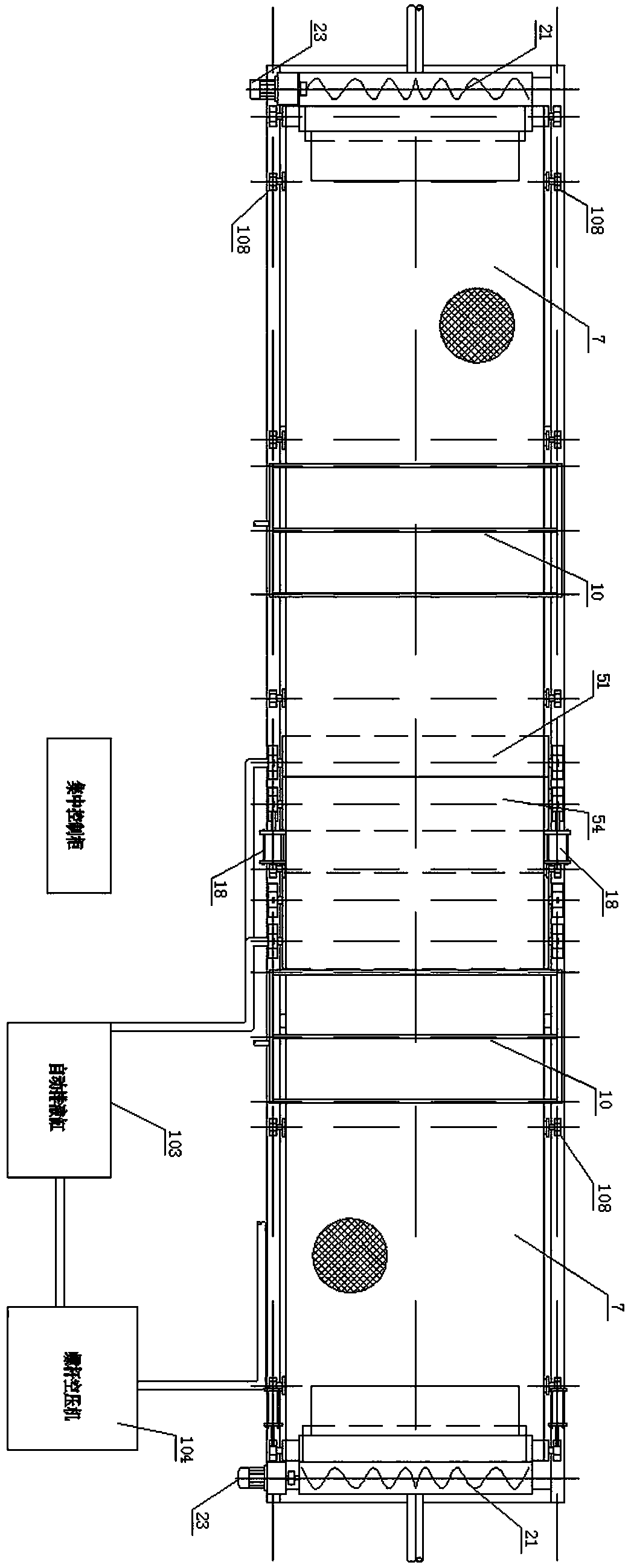

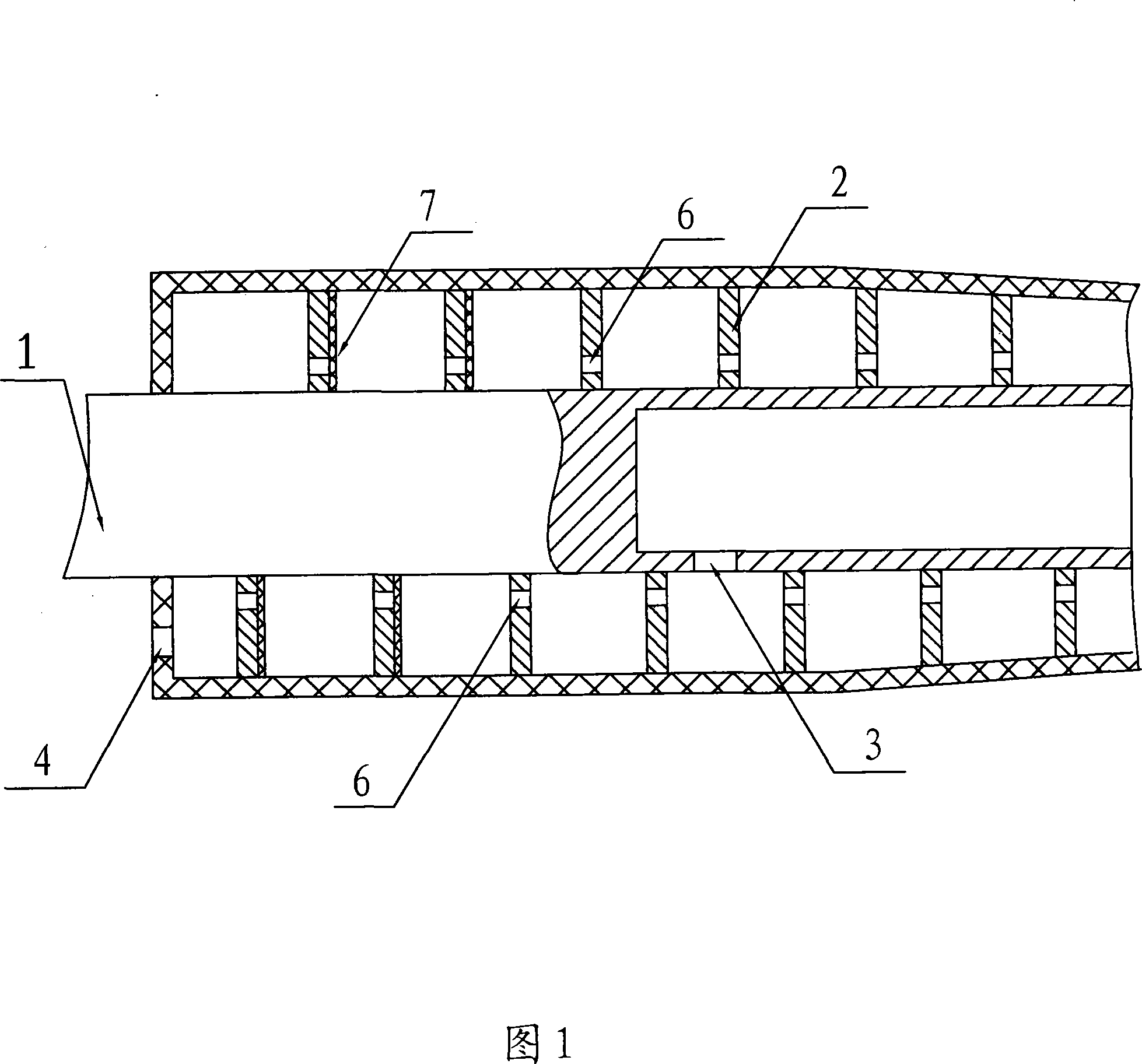

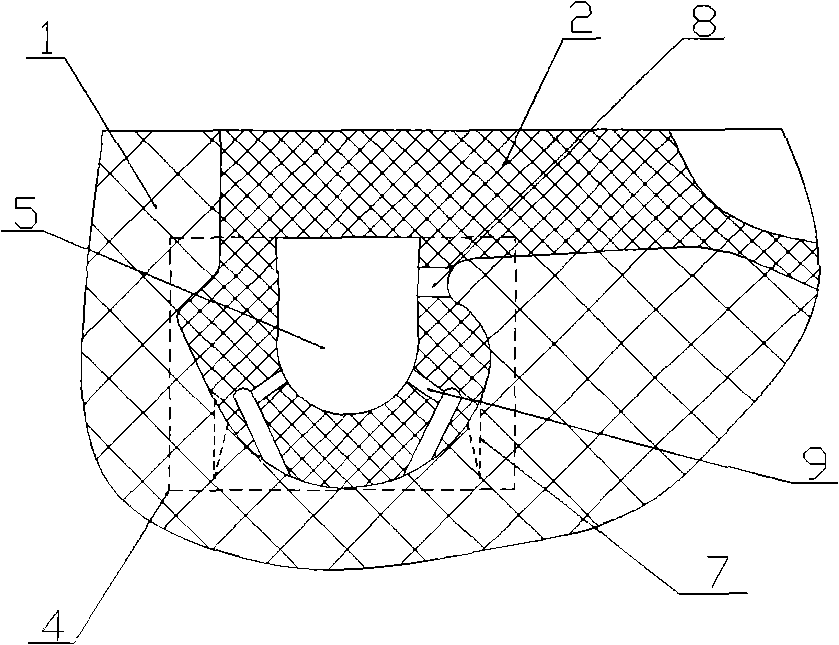

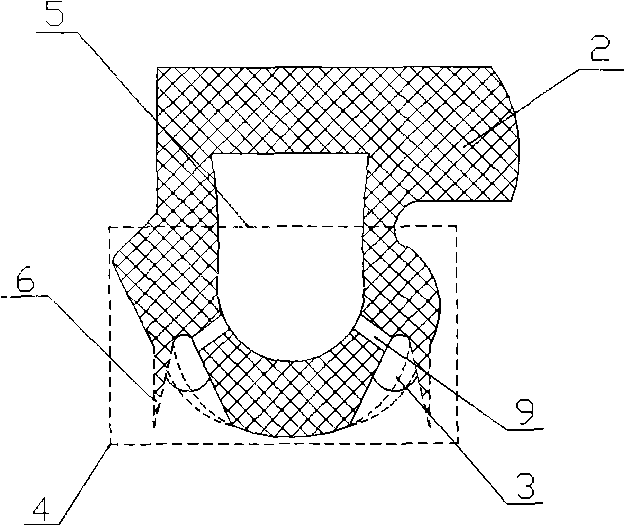

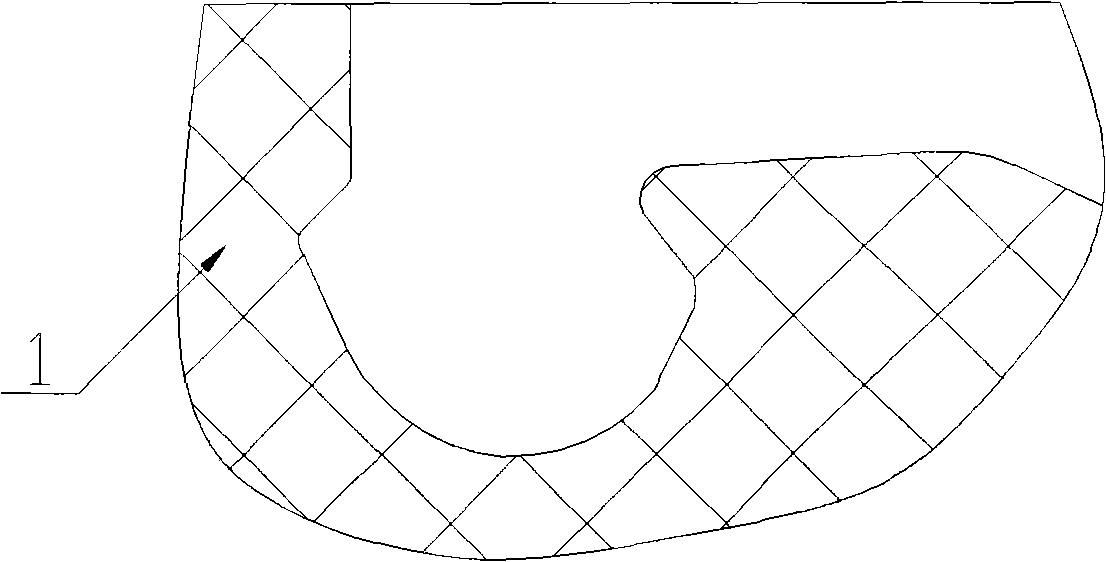

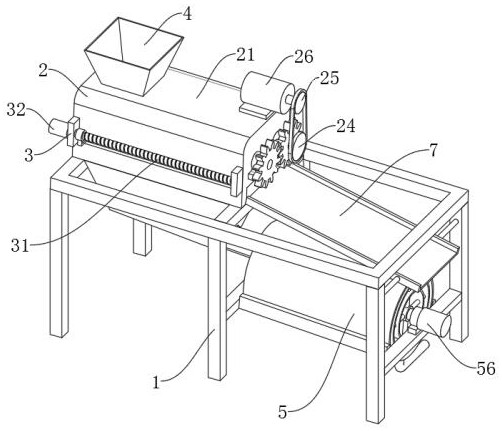

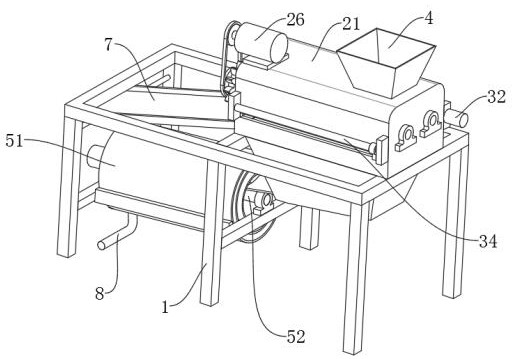

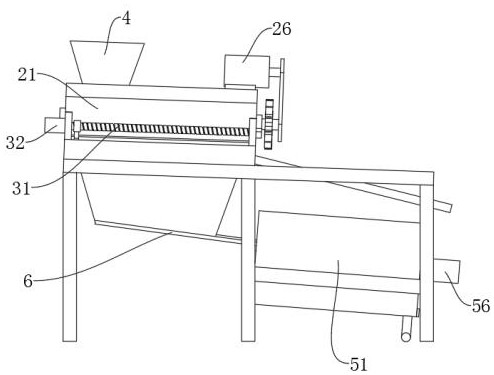

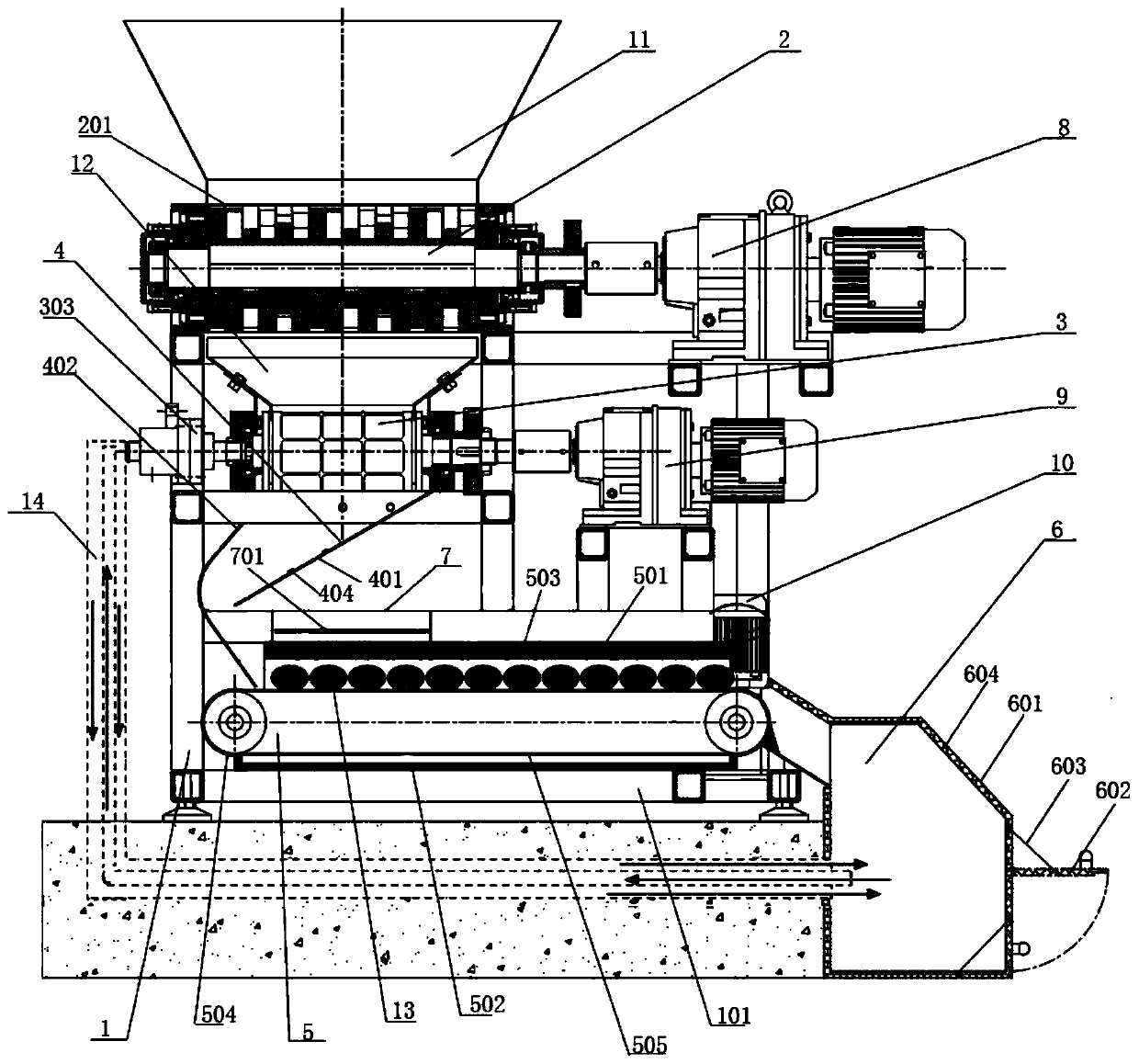

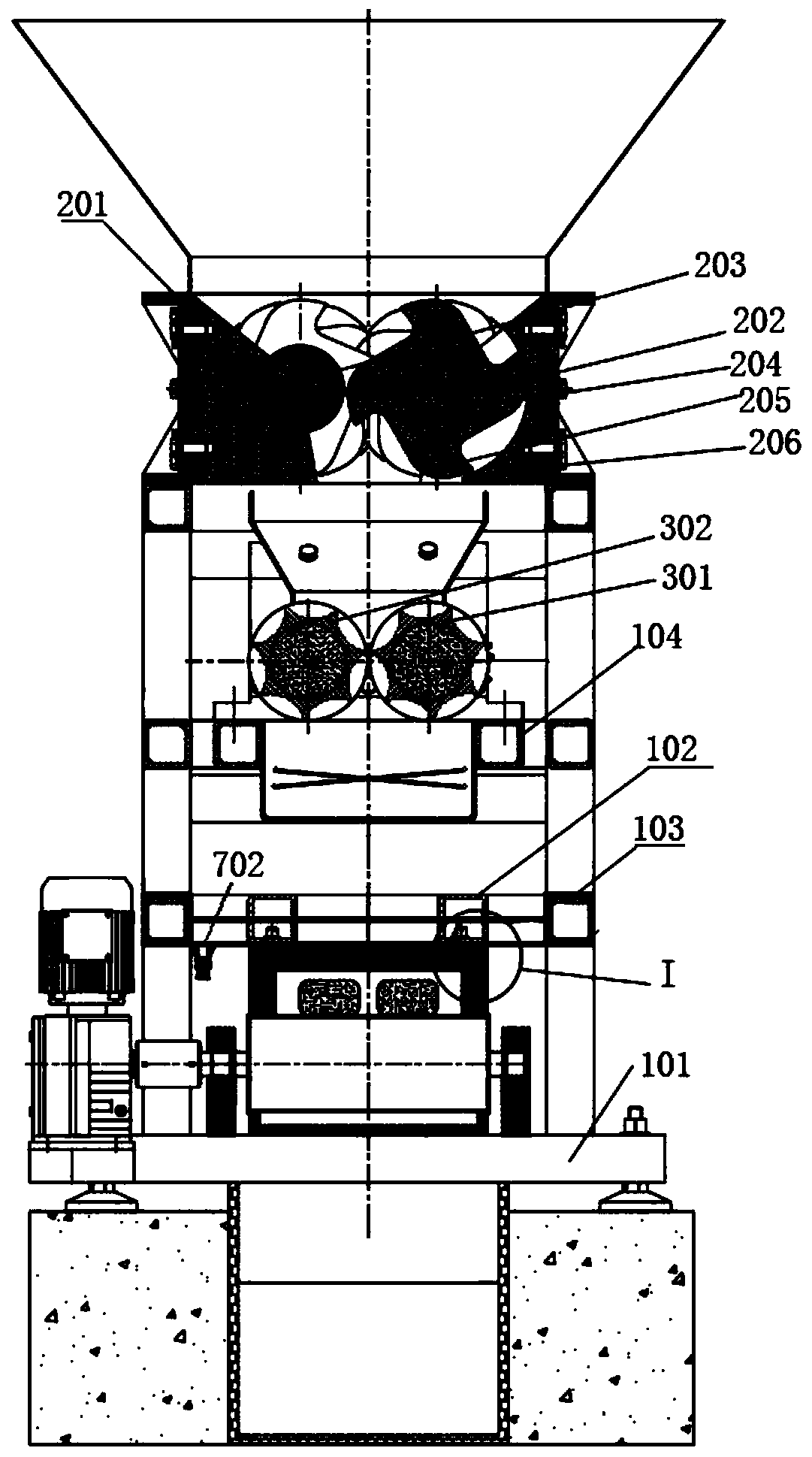

Continuous automatic belt type hydraulic squeezing press

InactiveCN101012997AStrong squeezeImprove applicabilityDrying solid materials without heatDrying machines with progressive movementsContinuous operationDevice form

The invention discloses a continuous automatic band-type hydraulic compressor, comprising a frame (16). The invention is characterized in that the frame (16) is arranged with upper and lower annular filter cloth devices formed by guide roller, expand roller, driving roller and connected upper and lower annular filter cloths and power device. The frame (16) is connected with a material compression sealing device formed by sealing box cylinder (4) and sealing box (5), and a hydraulic compressor formed by a compressing cylinder (1) and a compressing pushing plate (2). The frame (16) is connected with a stop plate (3) relative to the compressing pushing plate (2). The frame (16) is connected with a liquid disc (17) with liquid outlet (18) and a material distributor (15). The invention can realize automatic continuous operation and high compressing speed, with long service life and low cost.

Owner:李连乐

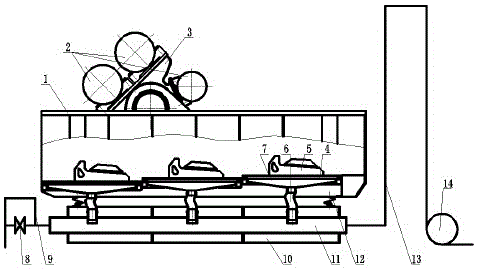

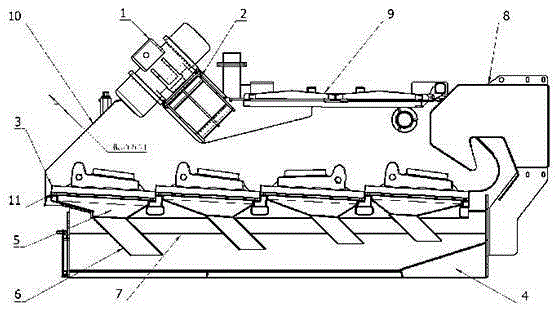

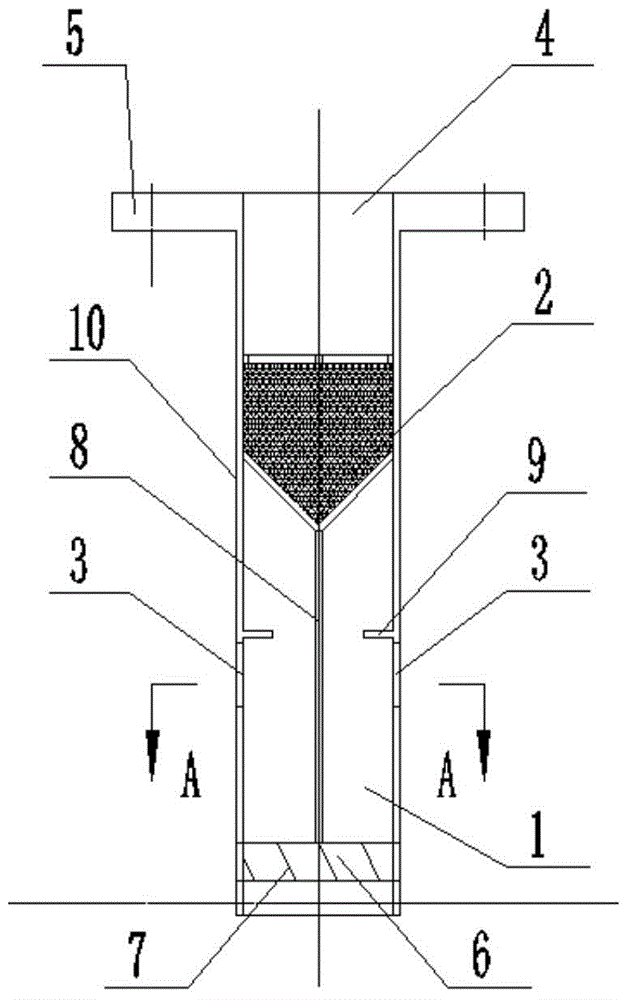

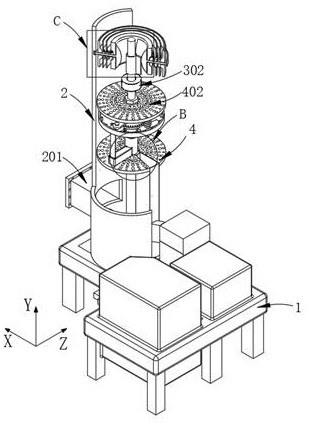

Negative pressure drilling liquid vibration sieve

The invention relates to a negative pressure drilling liquid vibration sieve. The negative pressure drilling liquid vibration sieve mainly comprises a sieve frame, exciting motors, a motor seat, frame sieve meshes, sieve mesh tension wedge blocks, flexible negative pressure tubes, sieve surface lower slurry plates, an effusion emptying valve, a drilling fluid discharging pipeline, a vibration sieve base, a negative pressure main header pipe, damping springs, a negative pressure vertical pipe and a vacuum pump, wherein the sieve surface lower slurry plates are supported on a crossbeam and a side beam of the sieve frame; the frame sieve meshes are mounted on the sieve surface lower slurry plates; the frame sieve meshes and the sieve surface lower slurry plates are fixed to the sieve frame through the sieve mesh tension wedge blocks; the lower part of each sieve surface lower slurry plate is connected to the corresponding flexible negative pressure tube; the lower ends of the flexible negative pressure tubes are inserted into and fixed to the negative pressure main header pipe on the vibration sieve base; when the excitation motors rotate, the sieve frame, the excitation motors, the motor seat, the frame sieve meshes, the sieve mesh tension wedge blocks and the sieve surface lower slurry plates vibrate as a whole. Through the processing of the negative pressure drilling liquid vibration sieve, the liquid content of rock debris is low, the structure is simple, the cost is low, the power consumption is low, and a well drilling solid control system can be simplified.

Owner:SOUTHWEST PETROLEUM UNIV

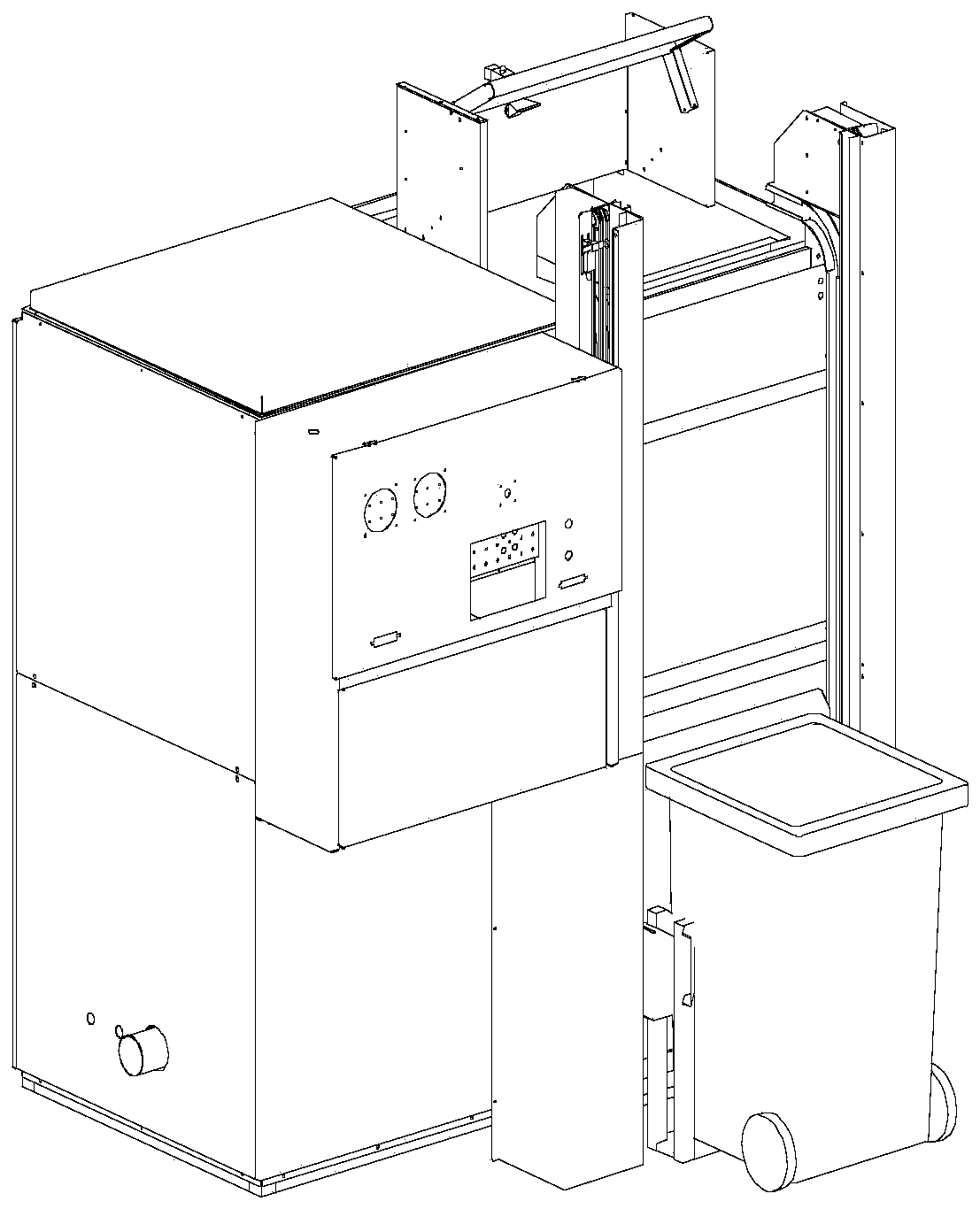

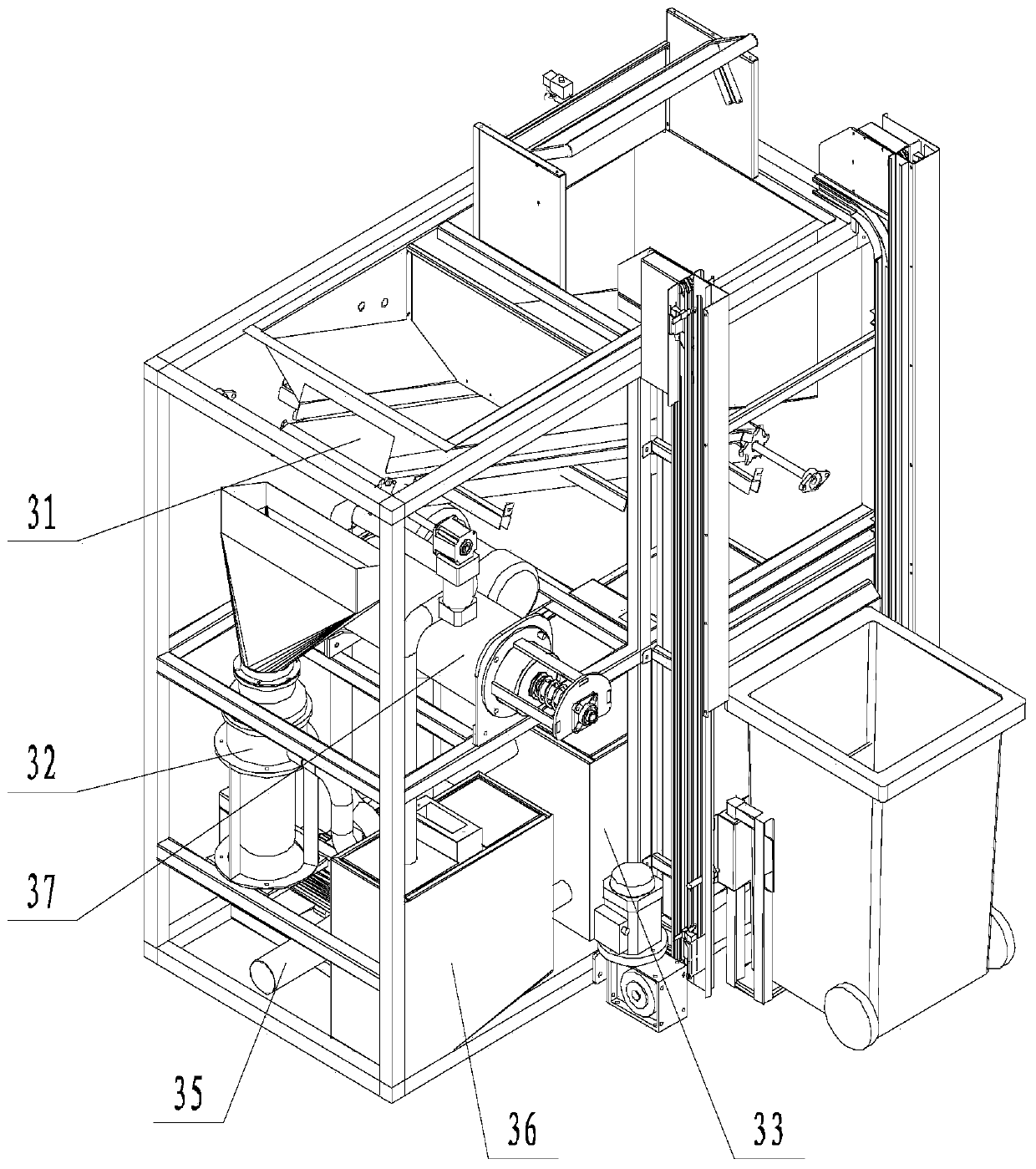

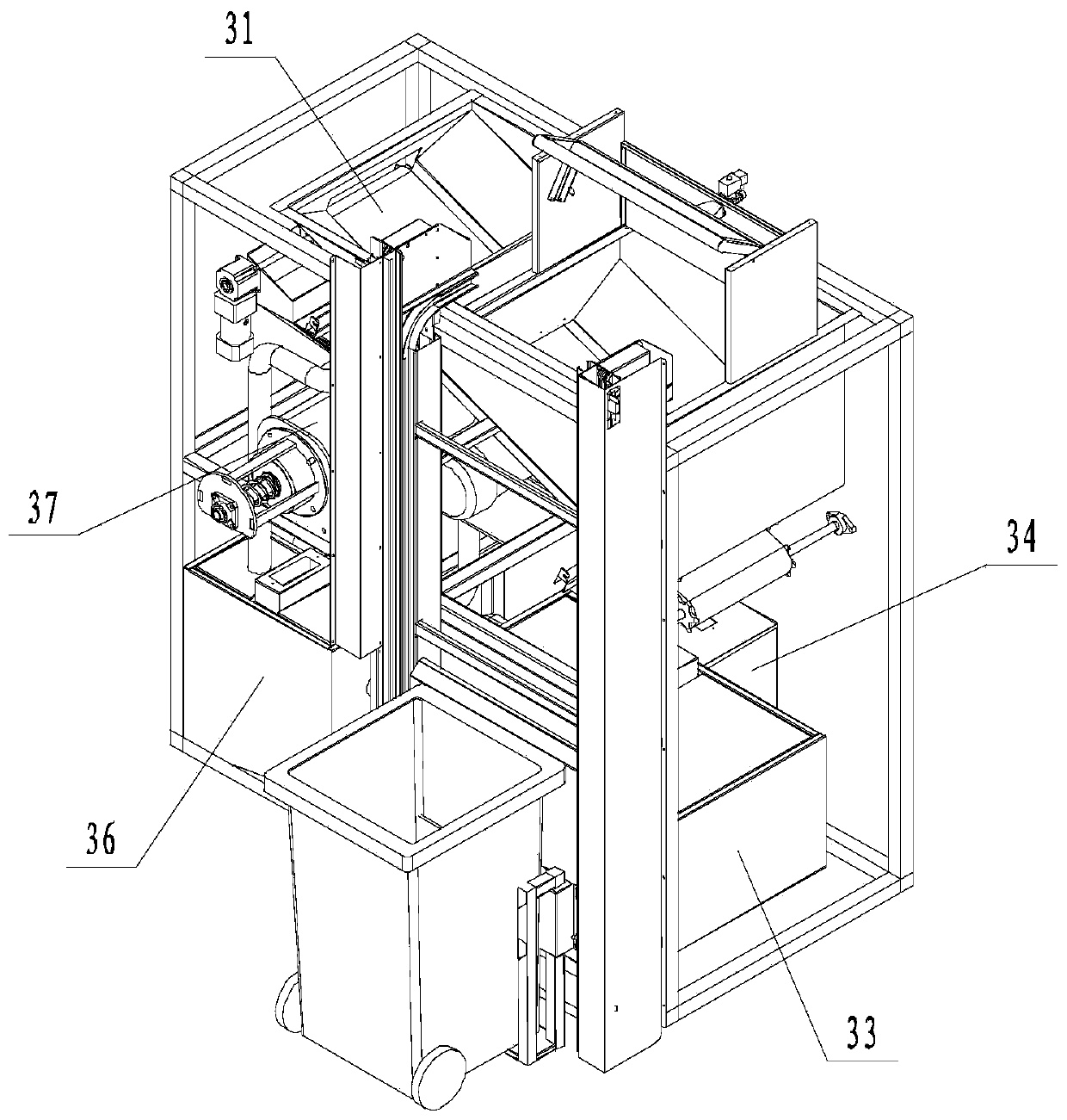

Kitchen waste treatment system and treatment method

PendingCN109834110AFully processedAvoid incomplete treatmentSolid waste disposalLiquid wasteOil separation

The invention discloses a kitchen waste treatment system and treatment method. The kitchen waste treatment system comprises a conveying belt for conveyor kitchen waste from bottom to top, a grinding machine is arranged below the top end of the conveyor belt, an oil separation tank for separating oil and water is arranged below the bottom end of the conveyor belt, the oil separation tank communicates with an oil tank, the oil separated from the oil separation tank entries the oil tank; and the oil tank communicates with a liquid draining tube through a pump; the kitchen waste treatment system further comprises a squeezer for squeezing liquids, the inlet end of the squeezer is a blanking port, the squeezed liquids from the squeezer is discharged from a liquid draining port, and remaining residues are discharged from a residue discharging port; and the discharging end of the grinding machine communicates to a slurry tank, the slurry tank and the oil separation tank communicate to the blanking port of the squeezer through the pump, and the liquid draining port of the squeezer communicates with the liquid draining tube. The kitchen waste treatment system and treatment method are used for solving the problem that the kitchen waste cannot be effectively and automatically treated due to mixing of solids and liquids in the prior art, and purposes of fast treatment of the kitchen waste and separating solid waste and liquid waste in the kitchen waste efficiently are realized.

Owner:SICHUAN HUIDATONG MACHINERY EQUIP MFG

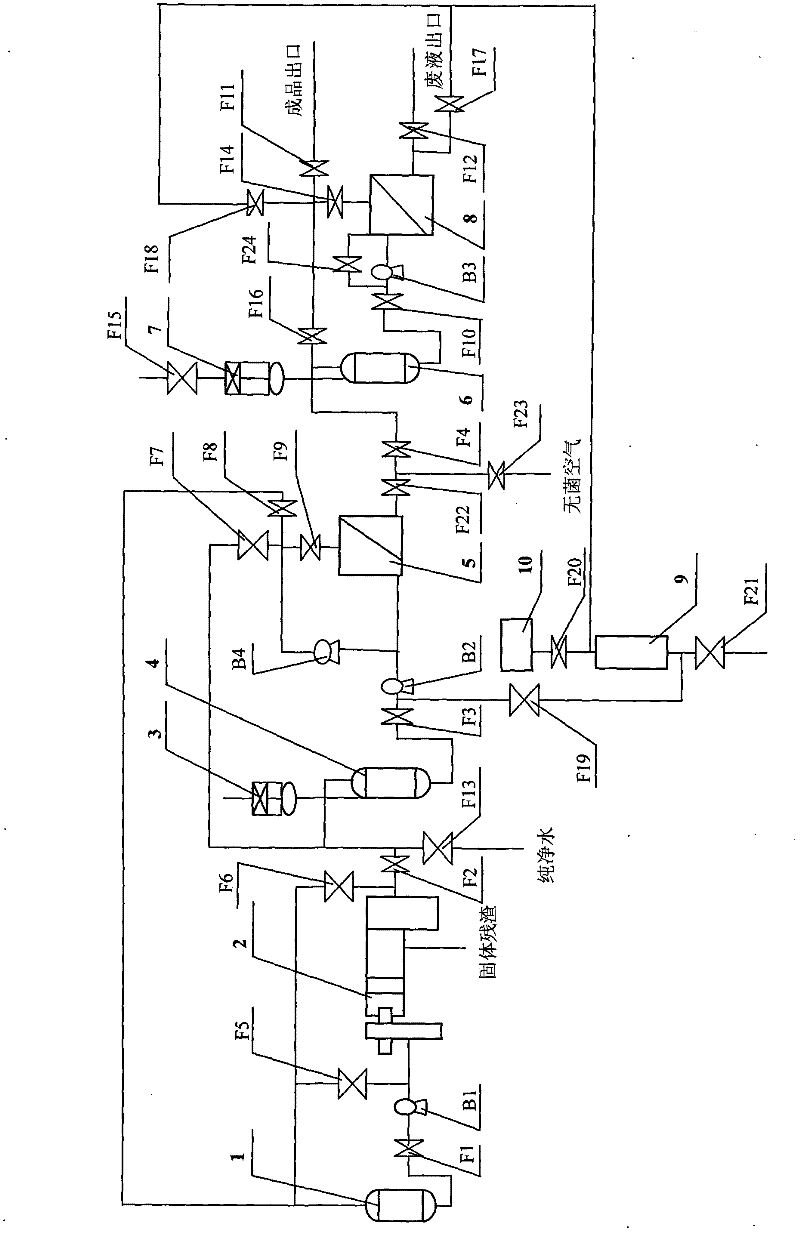

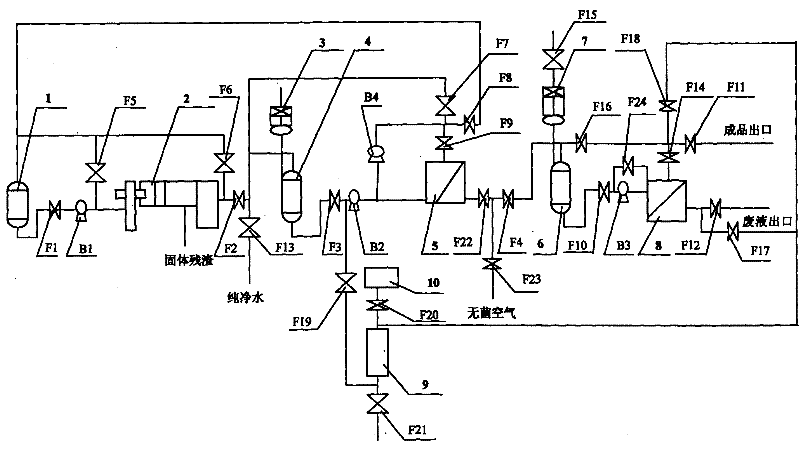

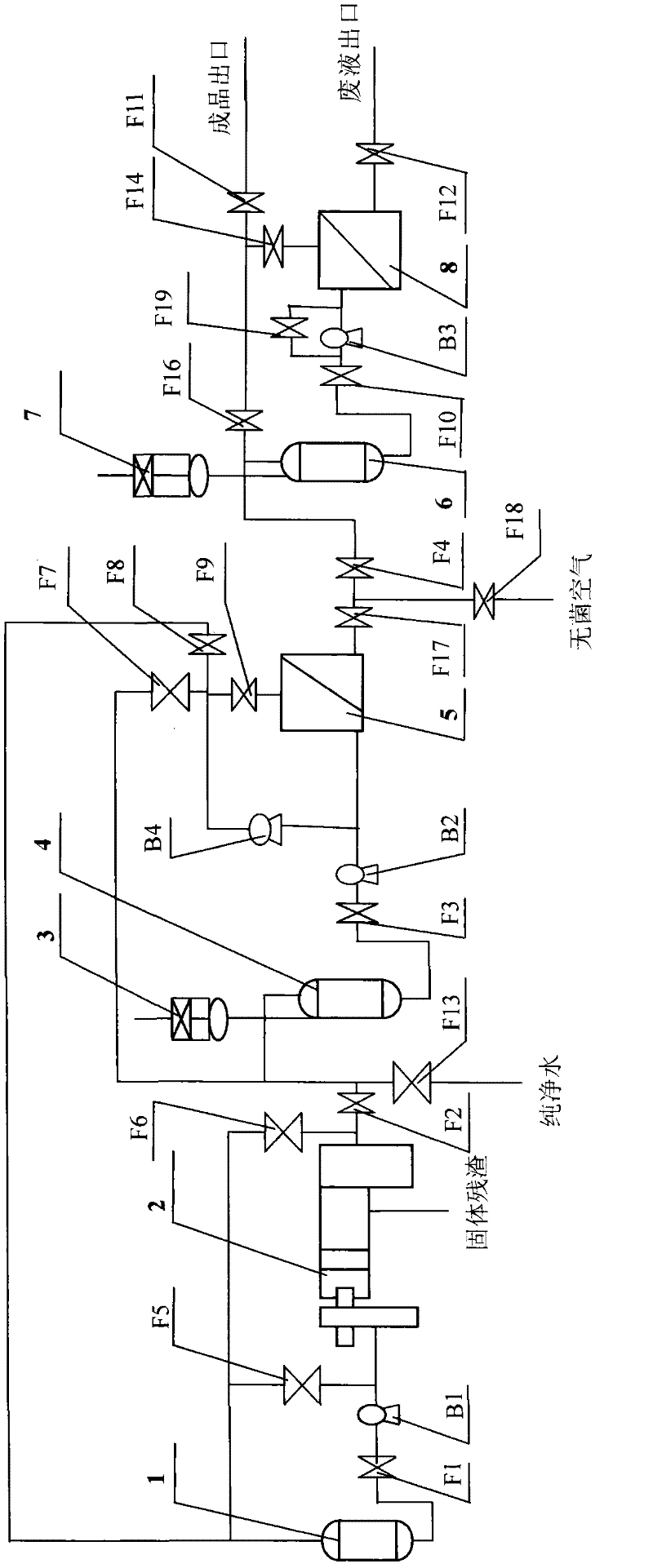

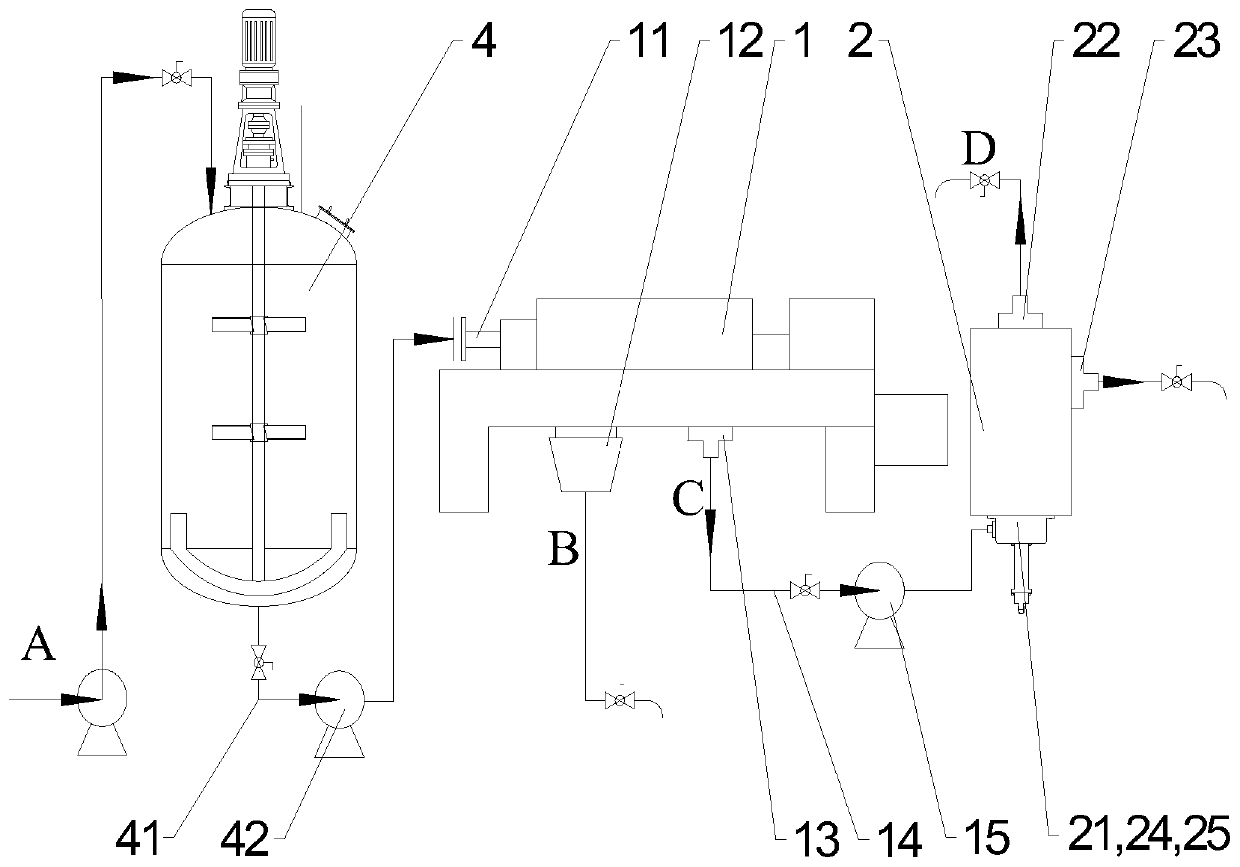

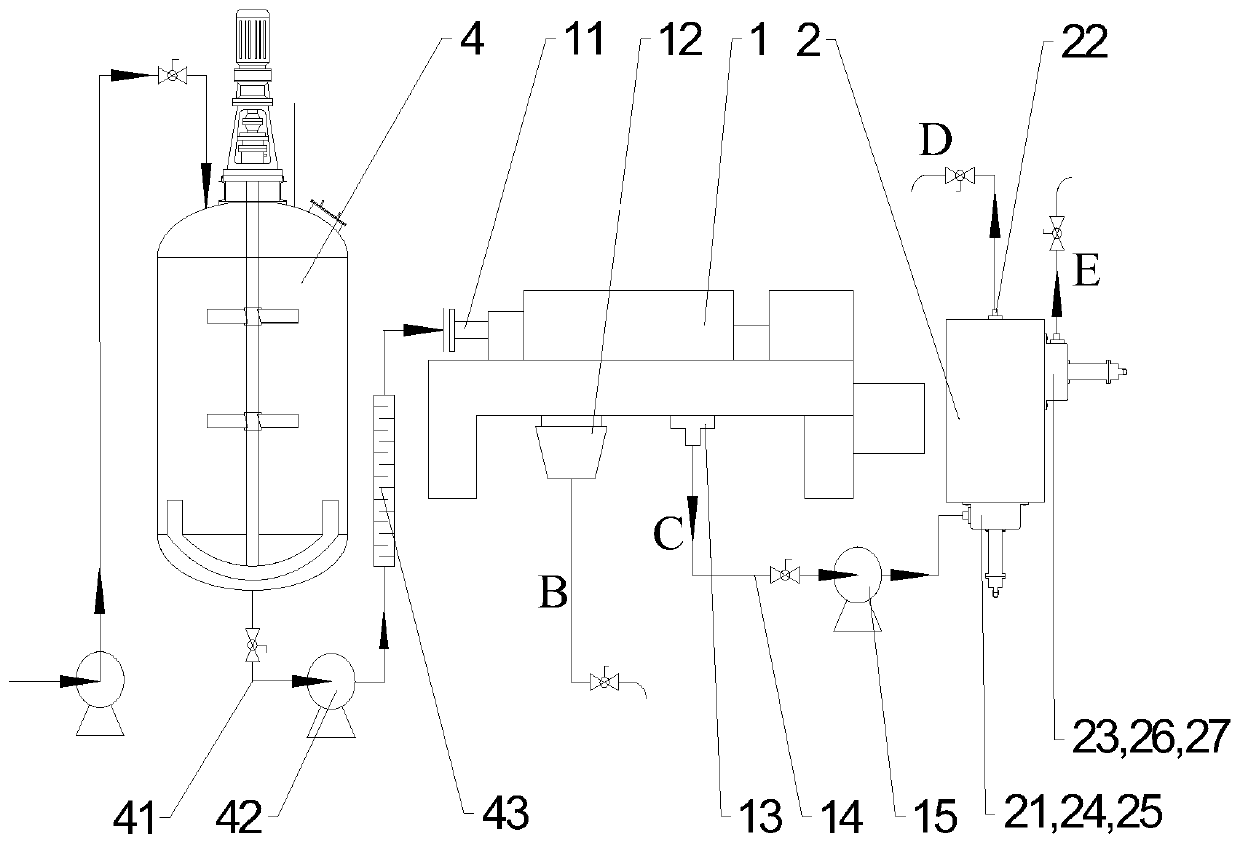

Multifunctional post-extraction production line for enzyme preparation fermentation liquid

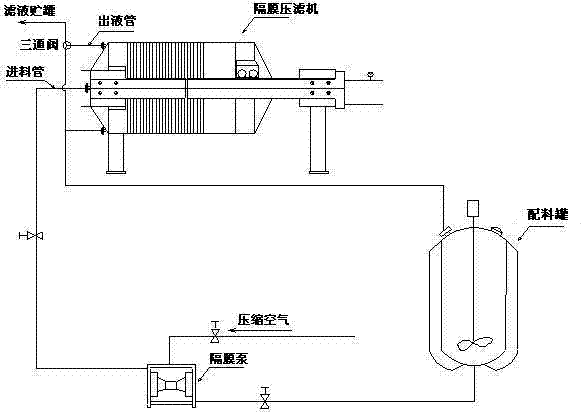

InactiveCN102399687AReduce labor intensityLow moisture content in solidsBiological substance pretreatmentsApparatus sterilizationProduction lineWastewater

The invention discloses a multifunctional post-extraction production line for an enzyme preparation fermentation liquid, and the provided post-extraction production line for an enzyme preparation fermentation liquid has multiple functions of improving enzyme preparation purity, regulating enzyme liquid activity, reducing wastewater discharge, realizing sterile ultrafiltration and condensation, solving a finished product residual liquid, etc. The multifunctional post-extraction production line for an enzyme preparation fermentation liquid in the invention is characterized by making fully use of the advantages of plate and frame filter pressing, tubular membrane microfiltration, and rollup membrane ultrafiltration in solid-liquid separation and liquid-liquid separation respectively. By means of structural design of each operation unit detail and perfect combination, the post-extraction production line of the invention achieves substantial effects in degerming, deslagging, active ingredient purification, sterile condensation, finished product residual liquid recovery, labor intensity reducing, as well as energy saving and emission reduction, etc.

Owner:淮北市三和诺生物工程有限责任公司

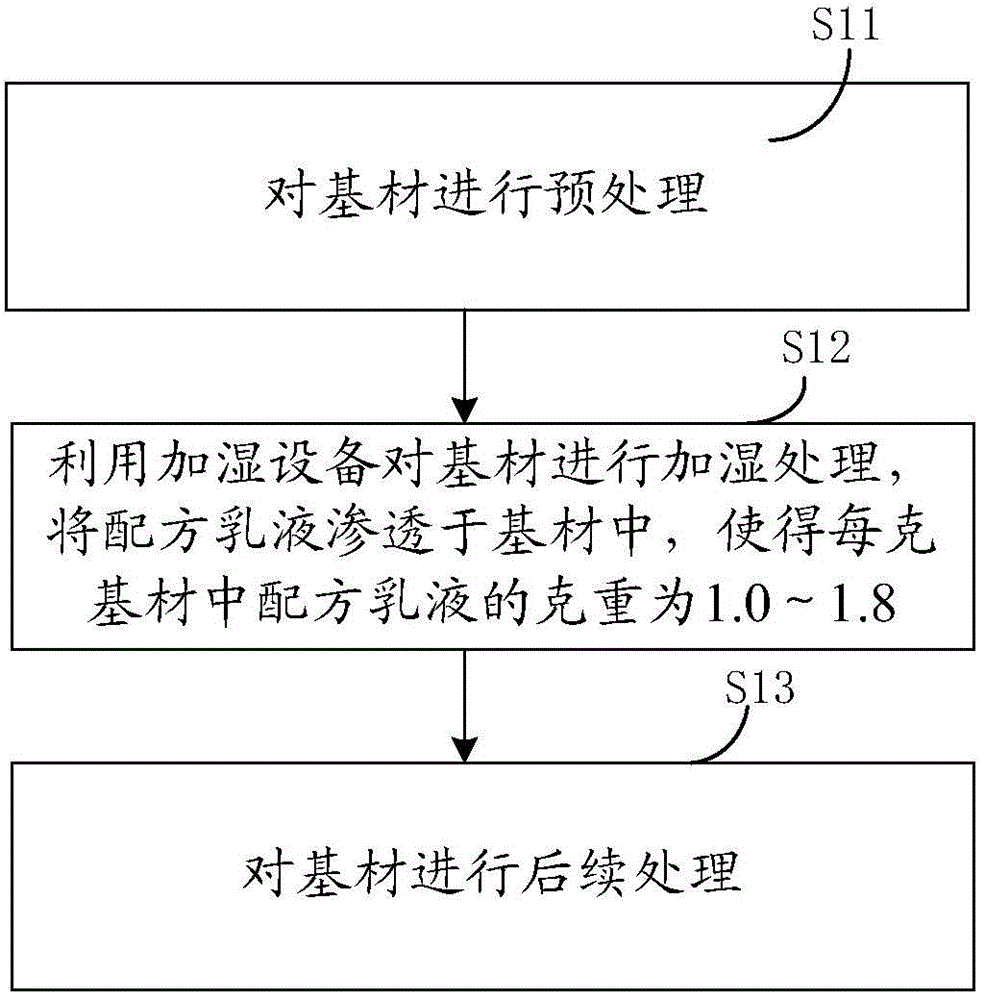

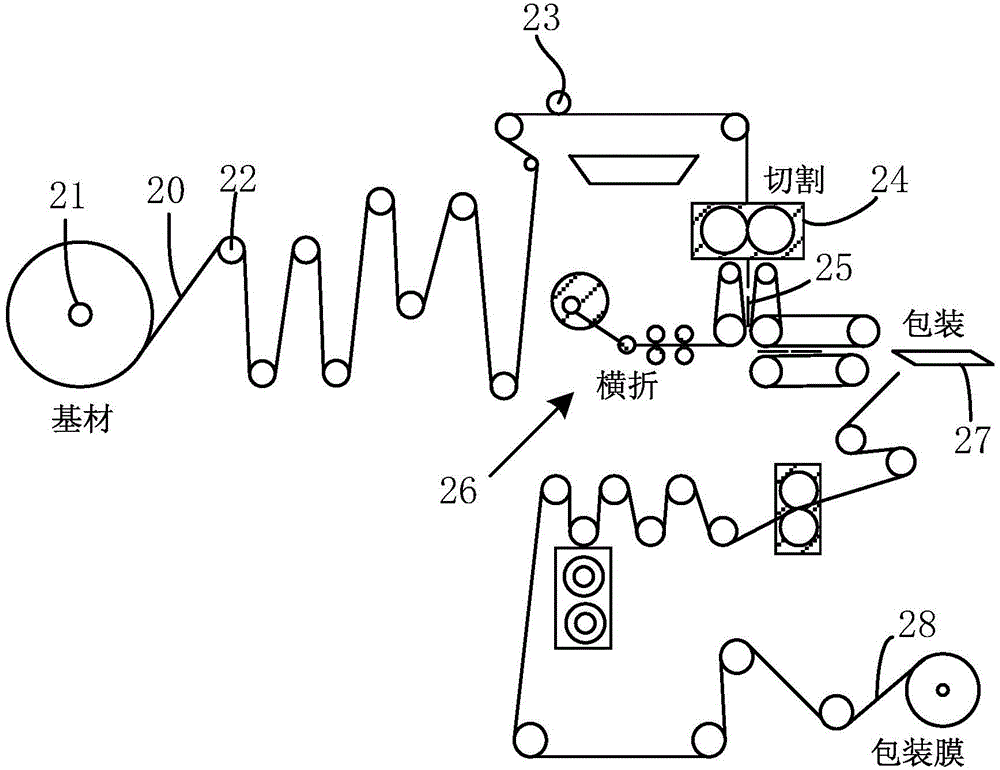

Wet tissue and manufacture method thereof

ActiveCN104921644ALow fluid contentExcellent moist feelingReinforcing agents additionPaper/cardboardEmulsionGram

The invention discloses a wet tissue. The wet tissue comprises a base material and a formula emulsion, the base material is paper, the formula emulsion permeates the base material, and each gram of base material contains 1.0-1.8 grams of the formula emulsion. The invention also discloses a wet tissue manufacture method. Through the above way, after being used, the wet tissue can be degraded easily, when in use, the wet tissue has high wet strength, and normal usage of the wet tissue is not affected.

Owner:GOLD HONG YE PAPER

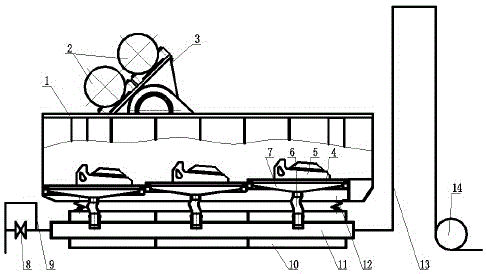

Self-suction negative pressure vibration sieve

InactiveCN105396357ALarge amount of processingLow fluid contentConstructionsSeparation devicesEngineeringPressure - action

A self-suction negative pressure vibration sieve is mainly composed of a sieve box, a vibration motor, a screen, a liquid inlet funnel, a vibration sieve base, a plurality of negative pressure funnels and a negative pressure groove; the screen is fixed on a screen supporting base; the vibration motor is connected with a sieve box side plate frame by a motor base; the negative pressure funnels are arranged at the bottom of the screen and form a sealed cavity with the negative pressure groove on the vibration sieve base through liquid outlets and via a drilling fluid; the liquid inlet funnel is arranged at one side of the vibration sieve base, and an outlet of the liquid inlet funnel is located above the screen. According to the device, the plurality of negative pressure funnels are arranged below the screen, the drilling fluid and rock debris in the drilling fluid are separated in virtue of the negative pressure action, the treatment capacity of the vibration sieve is increased, the liquid content of the rock debris is greatly reduced, the subsequent treatment work intensity and treatment costs are reduced, and the self-suction negative pressure vibration sieve is more environmentally friendly.

Owner:徐小弟

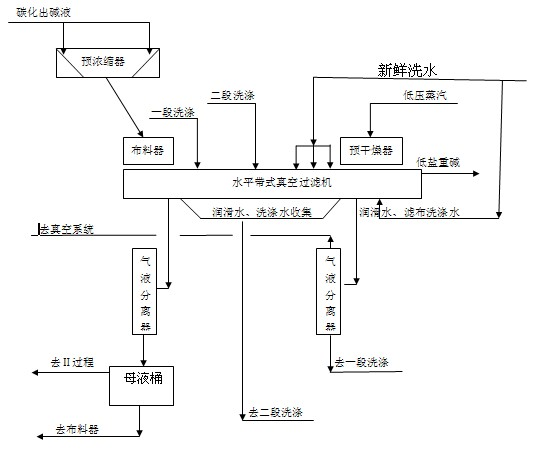

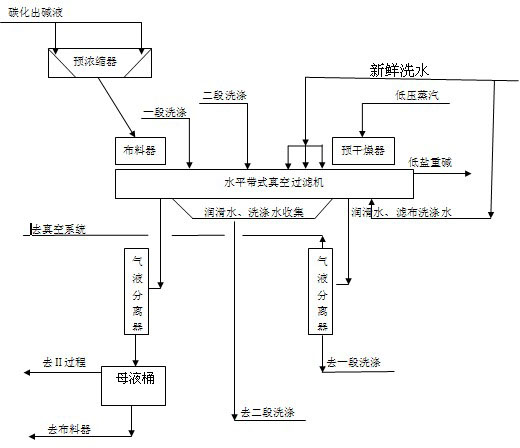

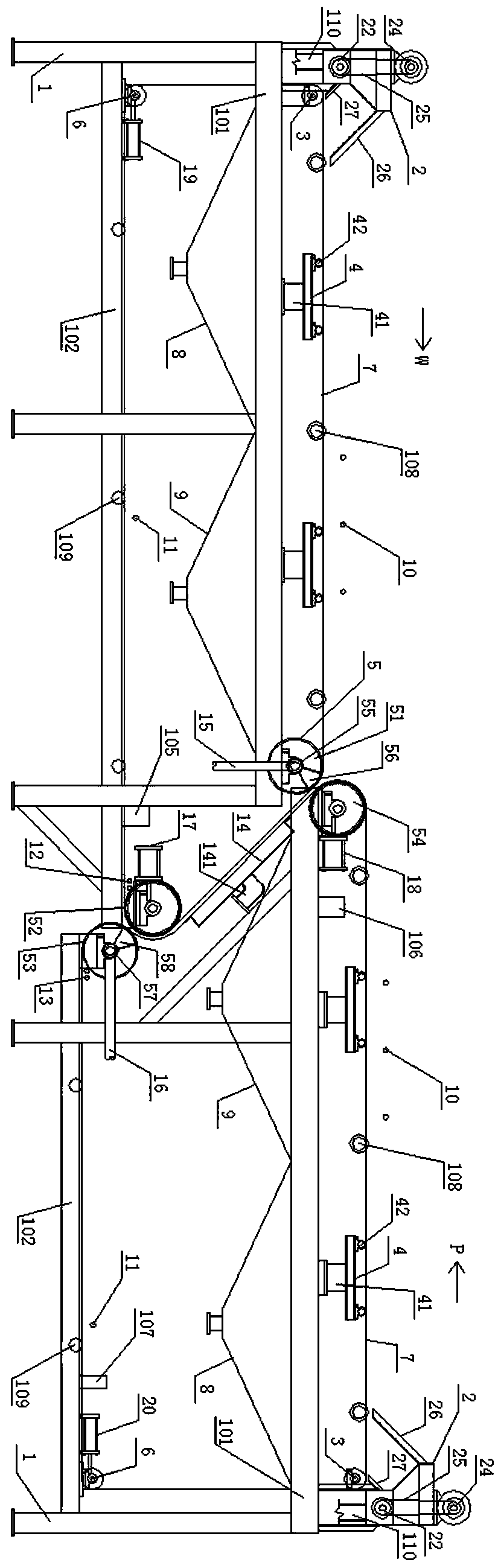

Process method for reinforced alkali-united filtration

ActiveCN102602964AIncrease production capacityLow fluid contentAlkali metal carbonatesSodium bicarbonateFilter media

The invention relates to a process method for reinforced alkali-united filtration. According to the process method, the operation of filtering sodium bicarbonate by applying a horizontal belt type vacuum filtering machine is taken as a basis, and the aim of obtaining a high-quality sodium bicarbonate product with the liquid content below 16 percent and the salt content below 0.2 percent under the condition of 80 percent of the water washing equivalent of a conventional process is realized by pre-concentrating in material feeding and pre-drying before material discharging. According to the process method for the reinforced alkali-united filtration, the research of the technological procedure and equipment is carried out aiming at the characteristic of an alkali-united process and the material property and the filtering performance of a filtering medium. According to the provided novel process method for the reinforced alkali-united filtration, high efficiency, low consumption and clean and civilized production are realized.

Owner:GUANGDONG NANFANG SODA ASH IND

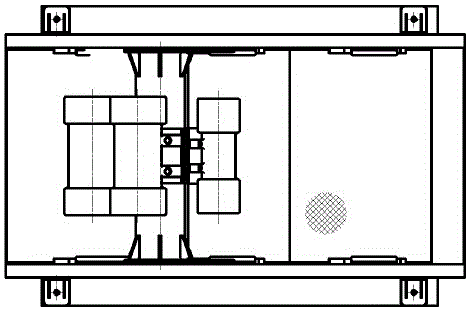

Novel belt type vibratory rolling filtering device

ActiveCN108211478AExtended service lifePrevent extrusionMoving filtering element filtersMechanical engineeringLiquid content

The invention provides a novel belt type vibratory rolling filtering device. The novel belt type vibratory rolling filtering device comprises belt type vibratory rolling filtering machines which are oppositely arranged, wherein each filtering machine comprises a rack; the rack comprises an upper supporting frame and a lower supporting frame; a layering distribution device is arranged at the upstream end of the upper supporting frame; in the material flowing direction, the rack is provided with a guiding roll, a vibrating part, a driving rolling part and a tensioning roll in sequence; a ring-shaped filtering belt is arranged around the guiding roll, the vibrating part, the driving rolling part and the tensioning roll; the left driving rolling part comprises a first extruding and dewateringroller positioned on the upper supporting frame and a second driving electric roller positioned on the lower supporting frame; the right driving rolling part comprises a second extruding and dewatering roller positioned on the lower supporting frame and a first driving electric roller positioned on the upper supporting frame; extruding gaps are respectively formed between the first extruding and dewatering roller and the first driving electric roller, between the two filtering belts surrounding the left driving rolling part and the right driving rolling part and between the second extruding and dewatering roller and the second driving electric roller. The novel belt type vibratory rolling filtering device provided by the invention has the advantages that the liquid content of filter cakesis low and the productivity is improved.

Owner:贾守民 +1

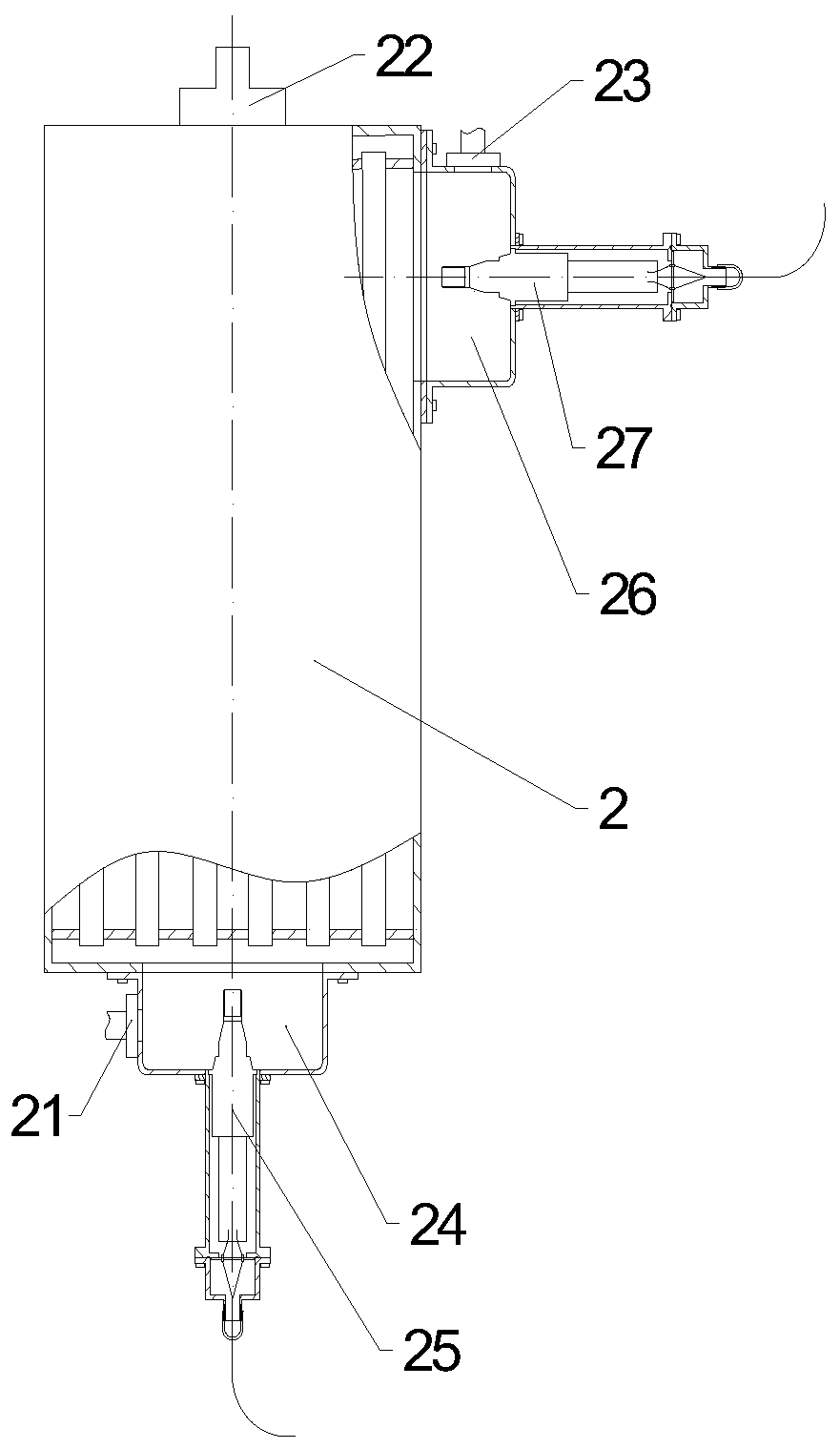

Finished product residual liquid recoverable post-extraction production line of enzyme preparation fermentation liquid

InactiveCN102399685AReduce labor intensityFacilitate solid-liquid separationBiological substance pretreatmentsApparatus sterilizationLiquid wasteSlag

The invention discloses a recovery system for a residual liquid in post-extraction filtering equipment of an enzyme preparation fermentation liquid, and solves the problems of simple and rough process as well as fermentation liquid waste in prior art. The production line of the invention is characterized in that a fermentation liquid storage tank is communicated with a plate and frame filter press, a filter pressing clear liquid storage tank, a microfiltration membrane filter, a storage tank for concentrated solution after microfiltration and ultrafiltration, and an ultrafiltration membrane filter through valves and pumps, and a sterile air branch is disposed at the outlet of the microfiltration membrane filter. The invention comprehensively adopts plate and frame filter pressing, tubularmembrane microfiltration, and rollup membrane ultrafiltration sealed filtering equipment as well as a sterile air residual liquid cleaning facility. By making fully use of the advantages of various equipment, the invention achieves substantial effects in degerming and slag removing, active ingredient purification, finished product residual liquid recovery, labor intensity reducing, as well as energy saving and emission reduction, etc.

Owner:淮北市三和诺生物工程有限责任公司

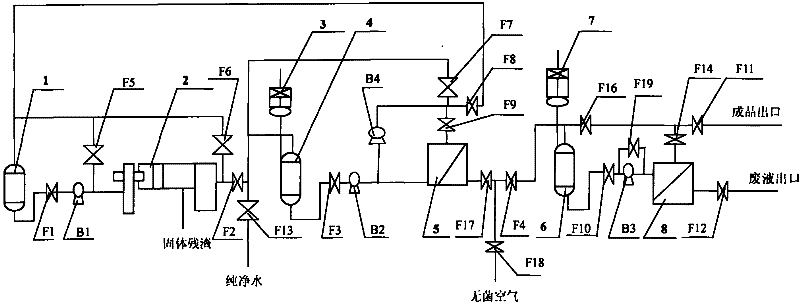

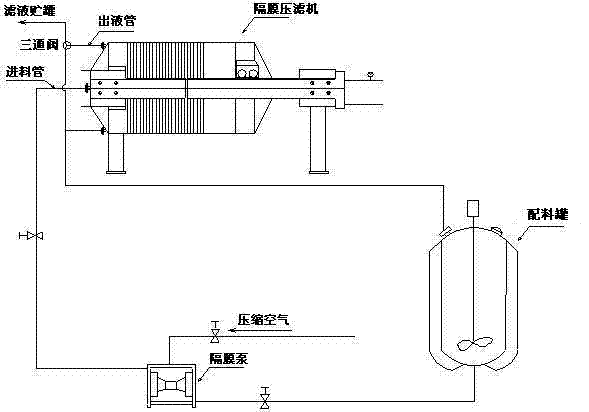

Preparation method of Huoxiangzhengqi Oral Liquid

ActiveCN102258659AHigh recovery rateHigh clarityDigestive systemPharmaceutical delivery mechanismMedicinal herbsBiochemical engineering

The invention discloses a method for preparing ageratum oral liquid. The active ingredients of most of prescription medicinal crops are extracted by using a membrane press filtration, cyclic extraction and separation integrated technology in place of a reflux method, a decoction method and a warm immersion method. A process flow can be simplified, the production period can be greatly shortened, energy can be saved, environmental protection and waste residue utilization can be facilitated, and the recovery rate of the active ingredients can be greatly increased.

Owner:TAIJI GRP CHONGQING FULING PHARM FACTORY CO LTD

Gas-oil-water three-phase separator

ActiveCN102120103BRaise the liquid levelEasy to handleLiquid degasificationLiquid separationCycloneDraining tube

The invention discloses a gas-oil-water three-phase separator which comprises a horizontal tank body (1) and a crude oil input tube (2), wherein a liquid steady flow plate (4) and a baffle (5) are sequentially erected in the tank body (1) from left to right so as to sequentially divide the interior of the tank body (1) into a separating area (A), a liquid collecting area (B) and an oil collecting area (C); a gas collecting area (D) is arranged above the baffle (5); the bottom of the tank body (1) is provided with a drain tube (14), the top of the tank body (1) is provided with a convex gas collecting bag (11), and the right side end of the tank body (1) is provided with an oil drain tube (3); moreover, a sleeve-type cyclone separator (6) is arranged in the separating area (A) and comprises an outer sleeve (61) and an inner sleeve (62) which are concentrically arranged and parallel and level at the top; a gas-liquid separating area (A1) is arranged between the outer sleeve (61) and the inner sleeve (62); and a gas-water mixing area (A2) is arranged in the inner sleeve (62). Compared with the prior art, the gas-oil-water three-phase separator provided by the invention has the advantages that the repair and maintenance are labor-saving and convenient; for the same crude oil throughput, the volume of the horizontal tank body can be reduced, the gas-oil-water separating efficiency is obviously improved, and the separating effect is more ideal.

Owner:浙江海牛海洋工程有限公司

High-efficiency helical material pushing apparatus of horizontal helical centrifuge

An obstruction preventing device of a horizontal spiral centrifuge comprises a feed tube, a main shaft and a frame. The feed tube is fixed on the frame and is mounted in the inner pore of the feeding terminal of the main shaft by an obstruction preventing sleeve. The inner pore of the obstruction preventing sleeve is a screw pore, and the right end thereof is provided with a flare shape. Since the feed tube is fixed on the frame and is mounted in the inner pore of the main shaft by an obstruction preventing sleeve, the solid-liquid mixture in the feeding chamber permeates into the space between the feed tube and the obstruction preventing sleeve during operation, the obstruction preventing sleeve spin with the main shaft to push the solid-liquid mixture permeating into the space between the feed tube and the obstruction preventing sleeve into the feeding chamber, so that permeation of the solid-liquid mixture into the space between the feed tube and the obstruction preventing sleeve is prevented effectively, friction of solid particle in the solid-liquid mixture to the feed tube is reduced, and obstruction between the feed tube and the main shaft is removed. In practical validation, during the centrifuge operation, it is provided with smoothly feeding, without obstruction, and the feed tube is not easily worn.

Owner:JIANGSU HENGLIANG CENTRIFUGE MFG

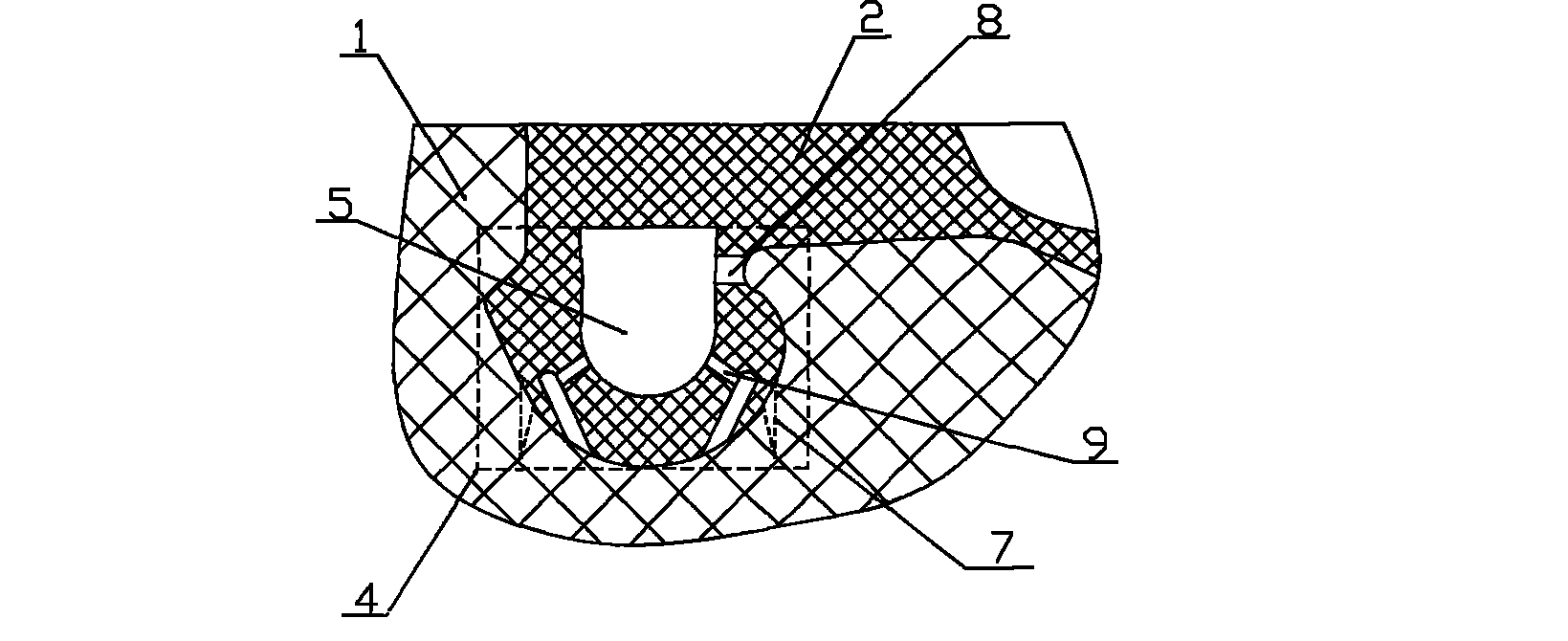

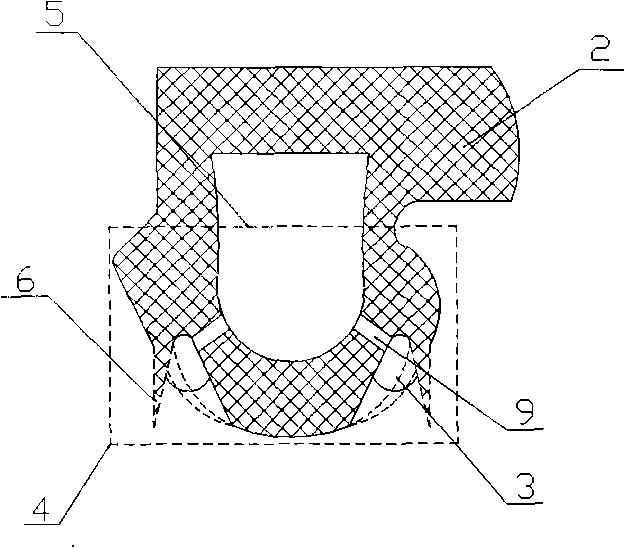

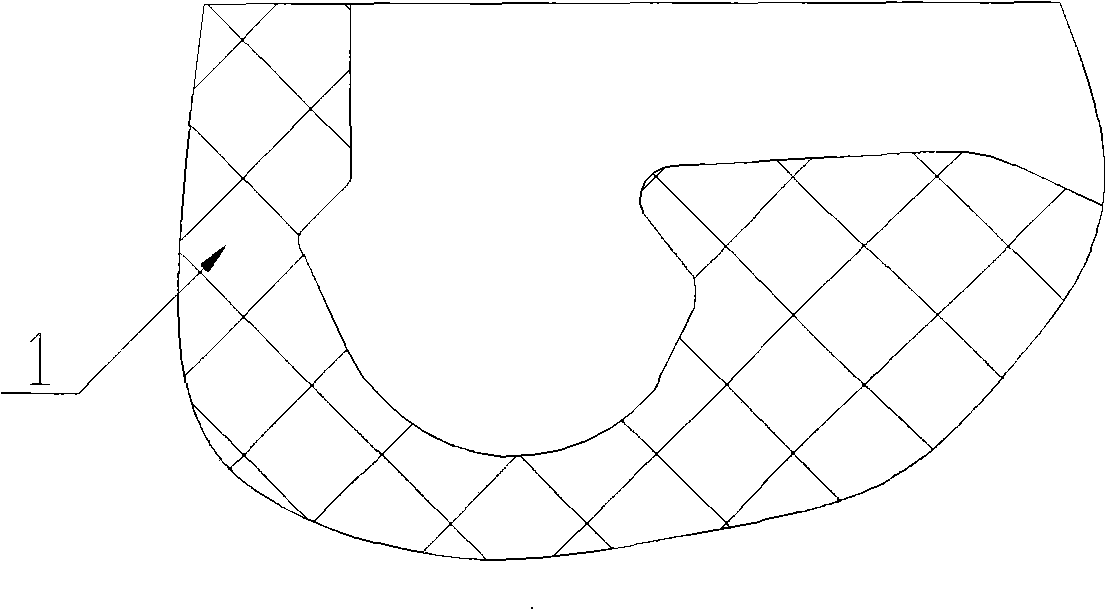

Damp cavity sealed type jogged dissepiment strainer plate and sealing method thereof

ActiveCN101249327AAchieving self-sealingRealize dynamic and static double sealing effectFiltration separationEngineeringHollow core

The invention relates to a chimeric membrane filter plate with the damping sealing performance and a sealing method, a circle line hollow core boss of a membrane embedding part is embedded in a circle line sealing groove in the filter plate and sealed and matched with the circle line groove of the filter plate, one circle or a plurality of circles of lip edges at the bottom of the circle line hollow core boss sleeve in the membrane embedding part are embedded in the filter plate groove, one circle or a plurality of circles of lip edges and the groove surface of the filter plate groove form a self-sealing damping cavity or a linear sealing damping cavity, when the membrane is tympanic, the fluid enters the cavity body of the circle line hollow core boss sleeve by a plurality of fluid inlet holes which are positioned around the root part of the hollow core boss sleeve, the fluid also enters the self-sealing damping cavity of the line sealing damping cavity from a plurality of fluid outlet holes which surround the cavity bottom of the self-sealing damping cavity or the linear sealing damping cavity along with the increase of the pressure of the fluid, the pressure of the fluid is directly acted on the lip edges, so as to force the lip edges and the groove surface of the filter plate groove to form the mandatory surface sealing or linear sealing.

Owner:杭州兴源环保设备有限公司

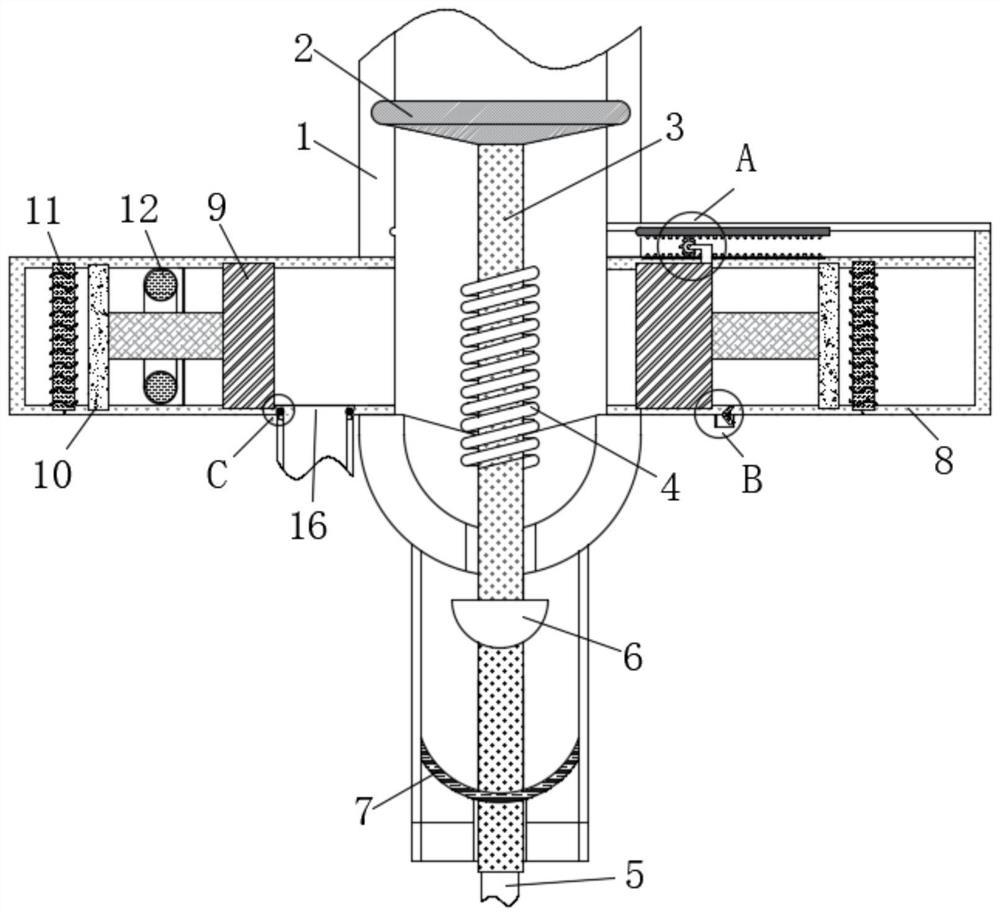

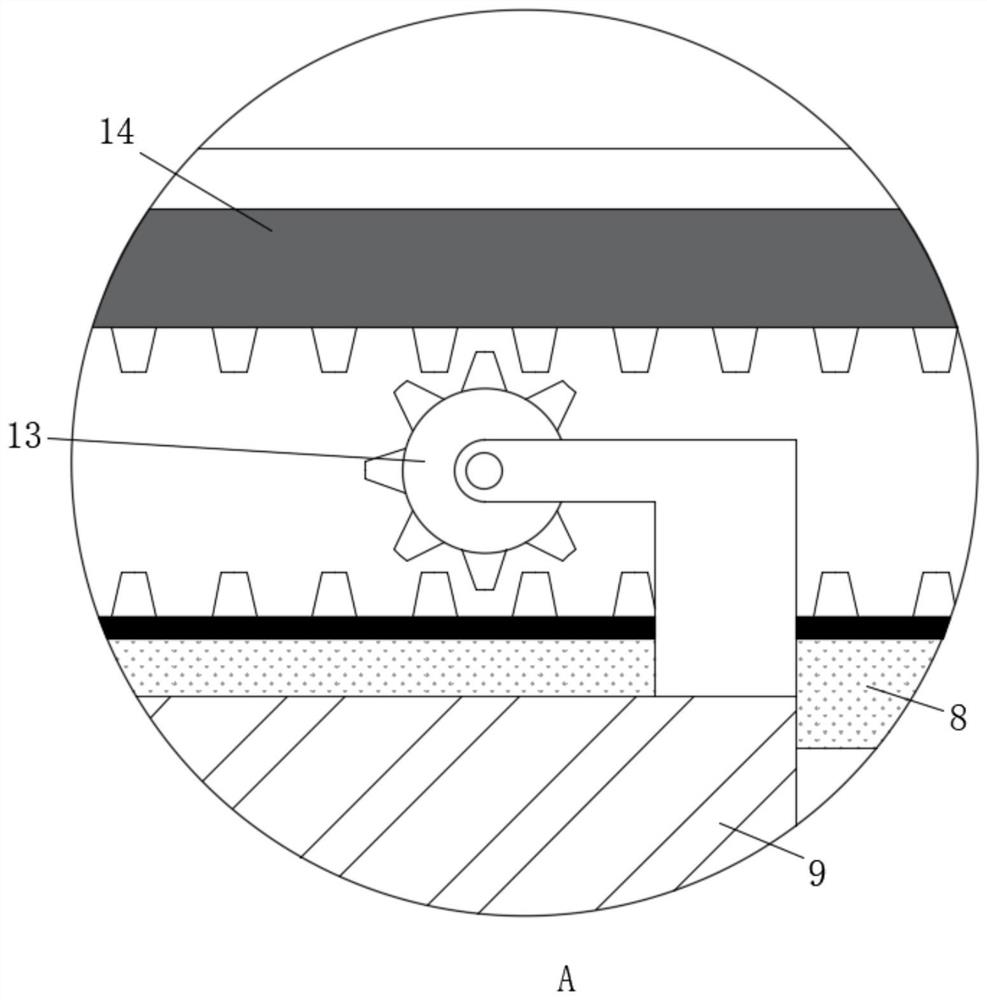

Filtering device for preparing Chinese herbal medicine skin mucous membrane disinfectant

InactiveCN111701334ALow fluid contentEasy extractionSeparation devicesFiltration circuitsBiotechnologyMedicine

The invention discloses a filtering device for preparing a Chinese herbal medicine skin mucous membrane disinfectant. The device comprises a support and a rolling mechanism arranged on the support, afiltering mechanism is arranged on the lower side of the rolling mechanism, a scraping mechanism is arranged on the rolling mechanism, the scraping mechanism is connected with the rolling mechanism, and the filtering mechanism is communicated with the rolling mechanism through a flow guide plate. The rolling mechanism comprises a box body, rollers are arranged on the inner side of the box body ina front-back tangent mode, gears are arranged at one ends of the rollers, a driven belt wheel is arranged on one side of one of the gears, and a driving belt wheel is arranged above the driven belt wheel. Dregs are rolled to remove liquid through the rollers rotating relatively, so that the liquid content of the dregs is reduced, and the extraction amount of liquid medicine is increased. A first annular filter screen and a second annular filter screen with certain inclination are driven by a rotating shaft to rotate to filter liquid medicine, tiny dregs in the liquid medicine are separated quickly, and the filtering efficiency and quality are improved.

Owner:湖南广盛源医药科技有限公司

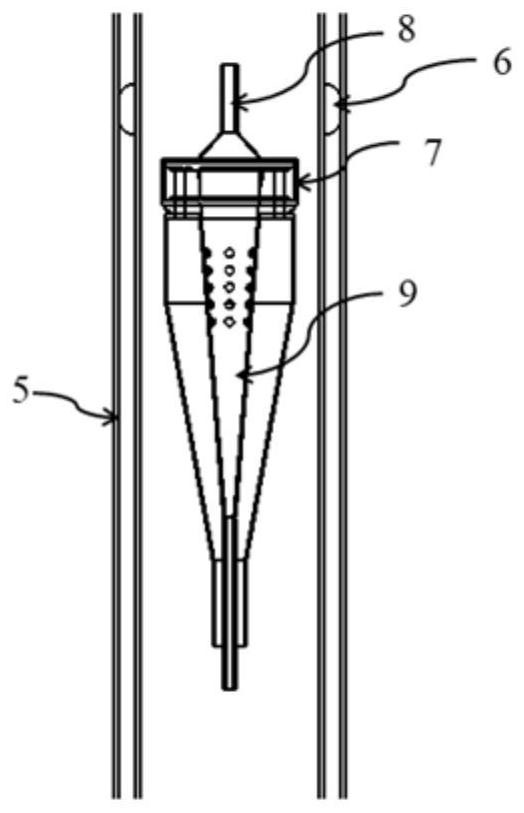

Underground gas-liquid hydrocyclone separation device

The invention discloses an underground gas-liquid hydrocyclone separation device. The hydrocyclone separation device mainly solves the problem that liquid drops are entrained in a gas phase separatedby an existing hydrocyclone separation device. The gas-liquid hydrocyclone separation device is characterized in that the separation device is of a nested pipe type structure, and the two sides of a gas supply sleeve are sealed through gaskets; the gas supply sleeve internally comprises a cylindrical shell and a tangential inlet shell, and the cylindrical shell is used for protecting an internal structure and reducing abrasion and corrosion of the internal structure; the internal structure comprises a tangential inlet disc, an upper hydrocyclone cavity, an internal hydrocyclone device and a gas-liquid separation cavity; after entering a gas supply pipeline, the mixed phase enters the internal hydrocyclone device along a tangential inlet for primary separation, and a gas phase separation cavity is nested in the internal hydrocyclone device to reduce the liquid content of the separated gas phase; and the upper hydrocyclone cavity is formed in the upper portion of the internal hydrocyclone device and is used for carrying out multi-stage separation on the separated gas phase.

Owner:DAQING DONGDA SHENGYUAN TECH DEV CO LTD

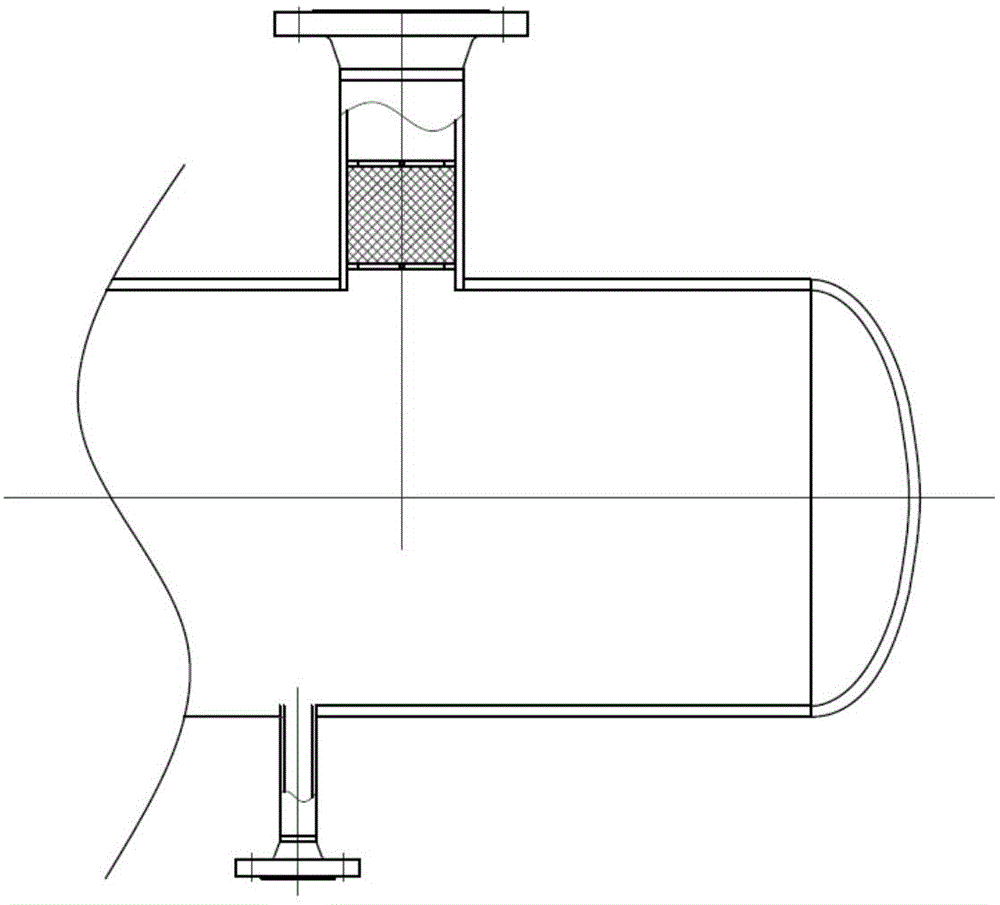

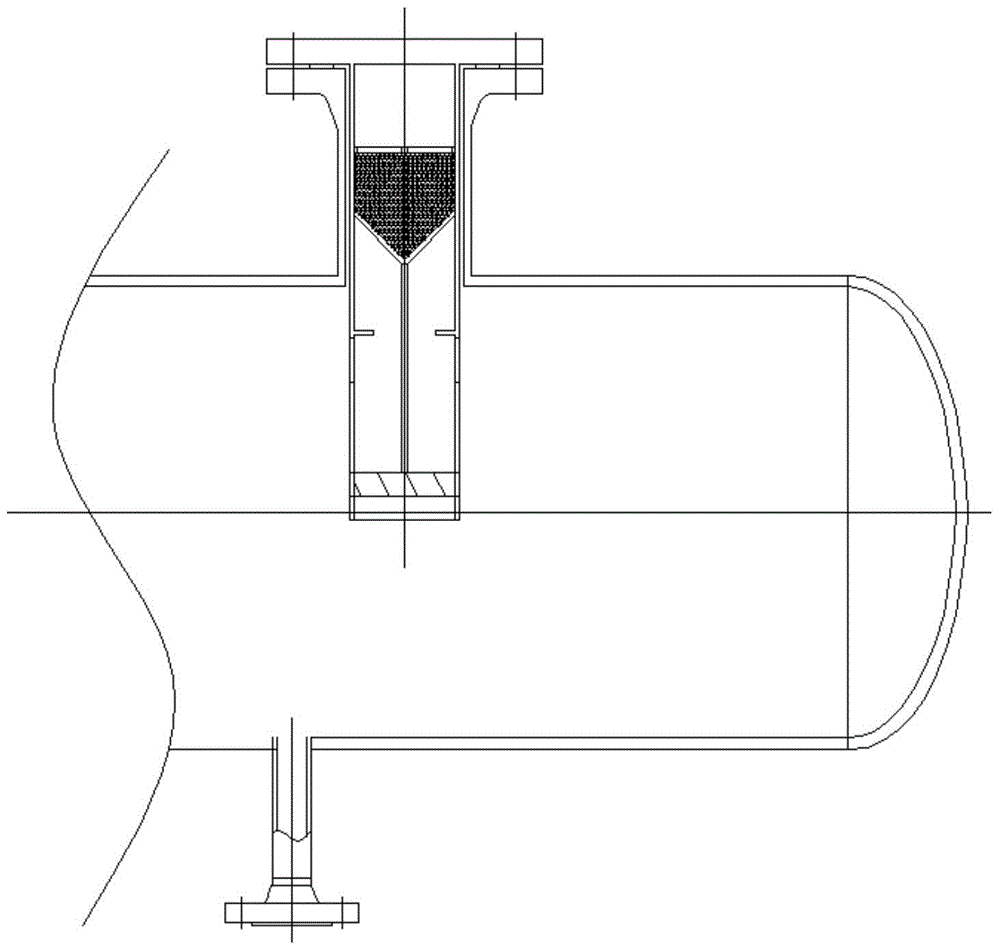

Demister at urea hydrolysis reactor outlet

InactiveCN104096512AIncrease motion track lengthImprove defogging effectCombination devicesFeed devicesCycloneGas phase

The invention discloses a demister at a urea hydrolysis reactor outlet. The demister comprises a barrel as well as a cyclone demisting section and a mesh demisting section which are sequentially arranged in the barrel in a serial connection manner and separated by an annular baffle, wherein the lower end of the barrel extends into the urea hydrolysis reactor outlet, and a gas-phase outlet is formed in the upper end and fixed with the urea hydrolysis reactor outlet; a gas outlet end of the mesh demisting section is communicated with the gas-phase outlet, and a gas inlet end is connected with a gas discharge end of the cyclone demisting section; gas inlets of the cyclone demisting section are arranged on the side wall of the barrel, and a liquid discharge port in the lower end of the cyclone demisting section extends below the liquid level in a urea hydrolysis reactor. According to the demister, two stages of serially connected devices are adopted to perform demisting, the first stage is separation of large liquid drops through cyclone type demisting, and the second stage is separation of small drops through mesh demisting; gas flows from an outlet of the cyclone demisting section enter the mesh demisting section in a rotating flowing manner, so that lengths of the motion traces of the gas flows in the mesh demisting section are increased, the demisting effect of the mesh demisting section is improved, the better comprehensive demisting effect is realized, and the demisting capacity is higher.

Owner:CHINA HUANENG GRP CO LTD +1

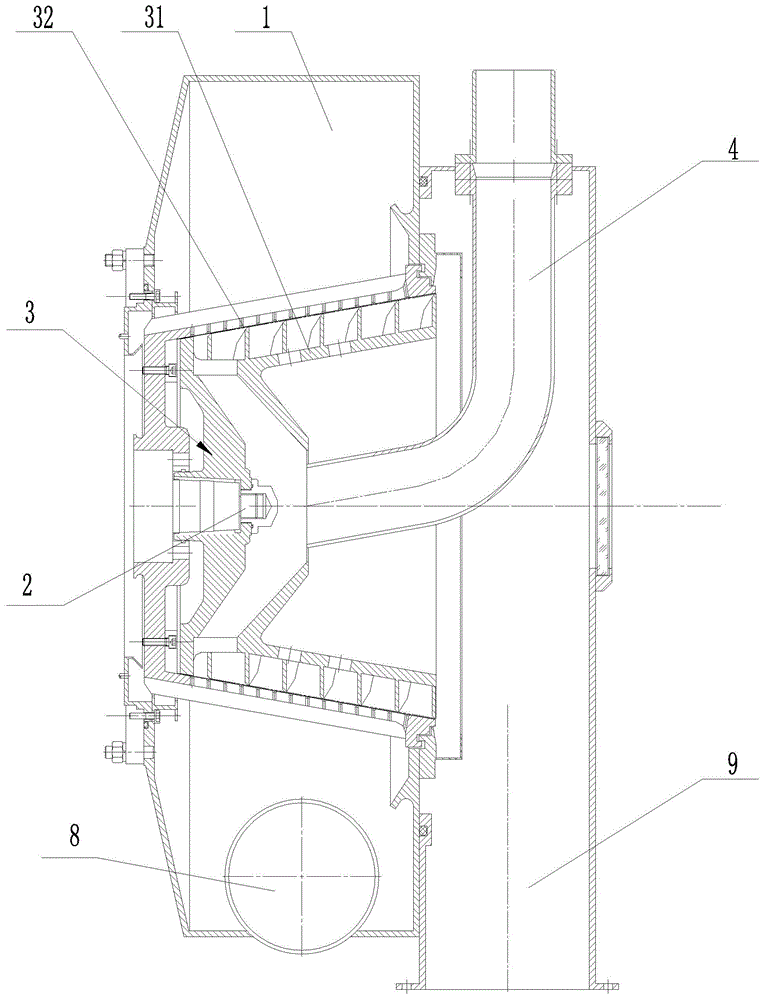

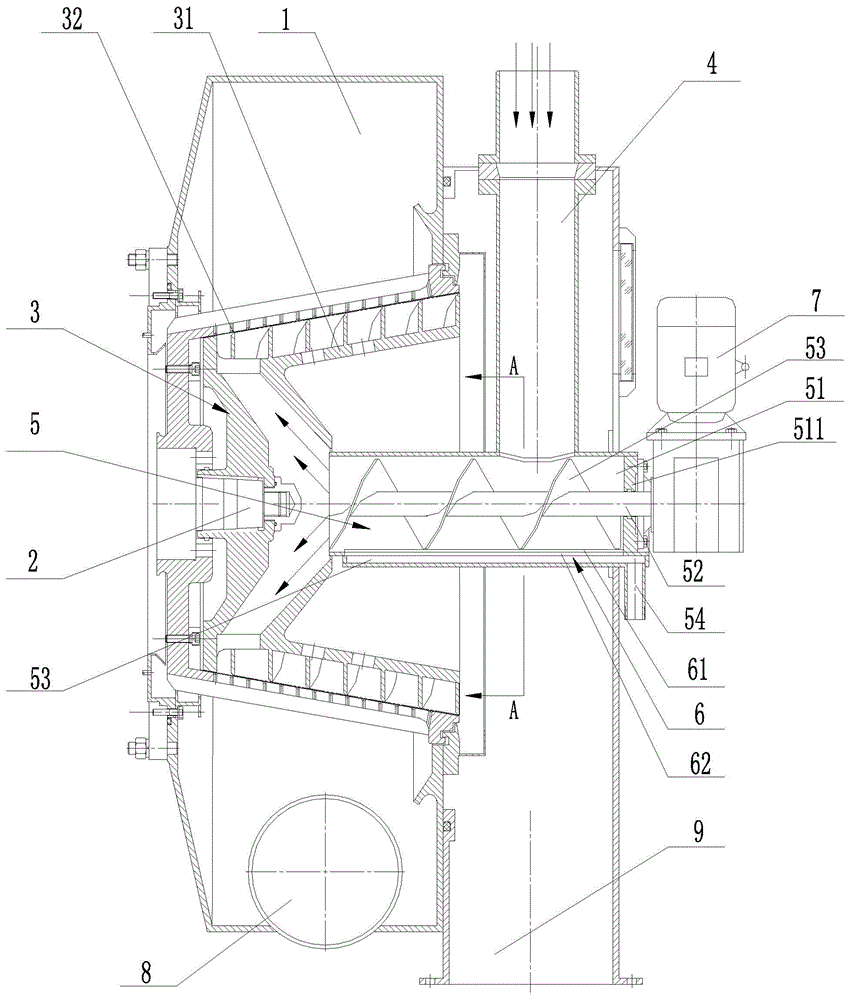

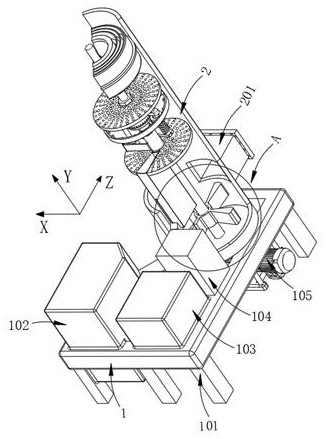

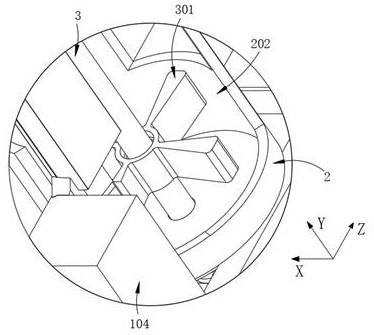

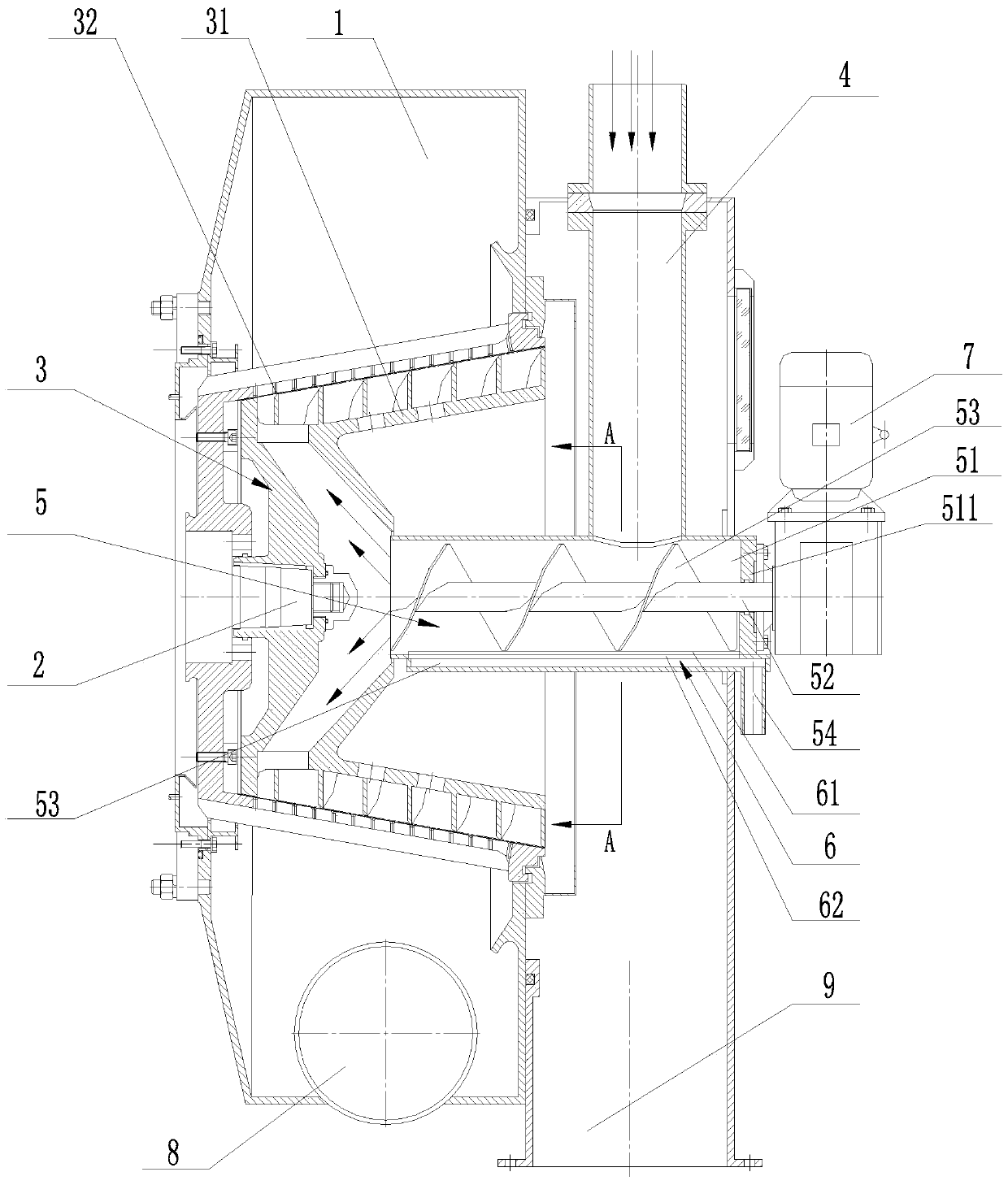

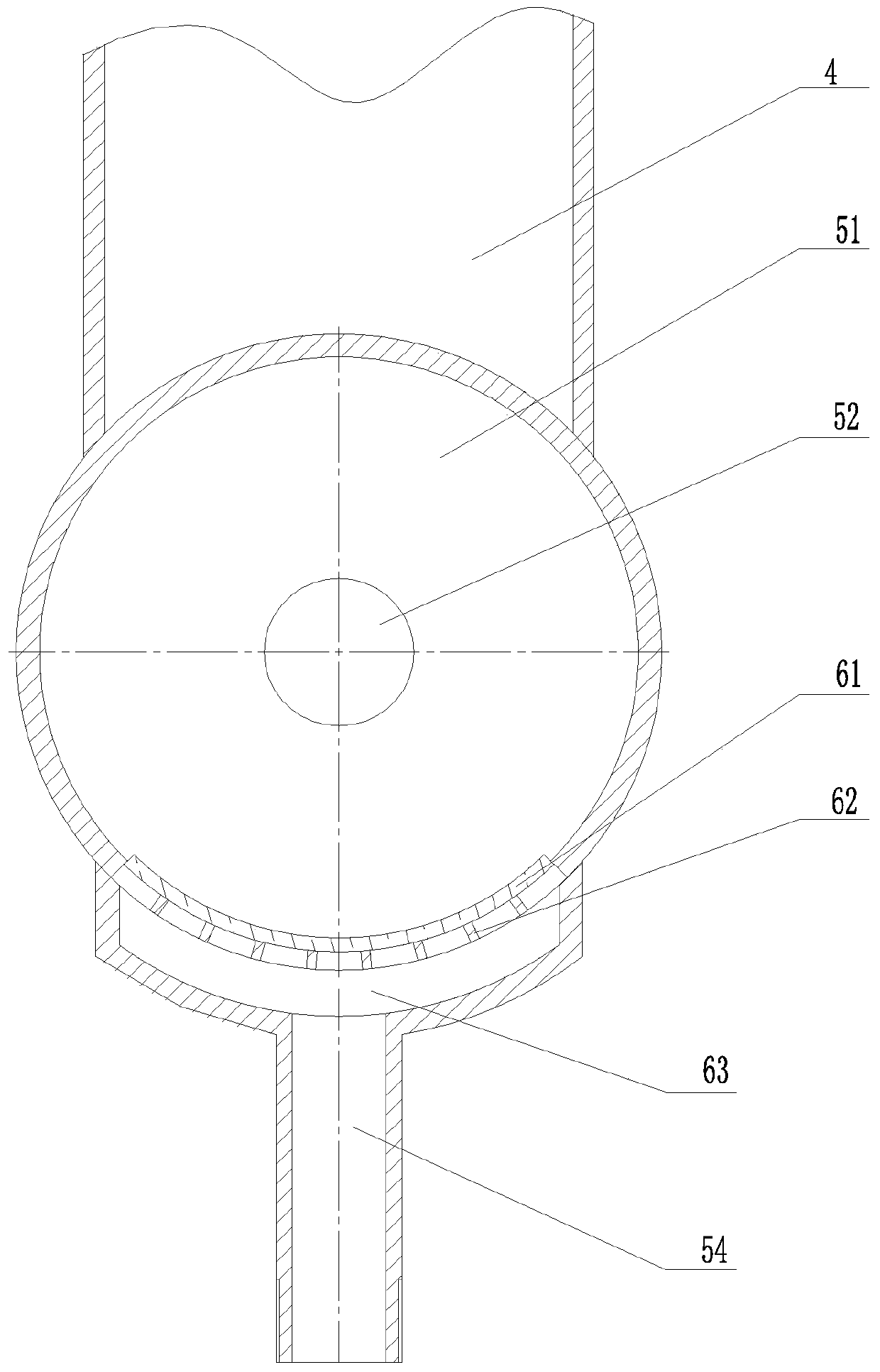

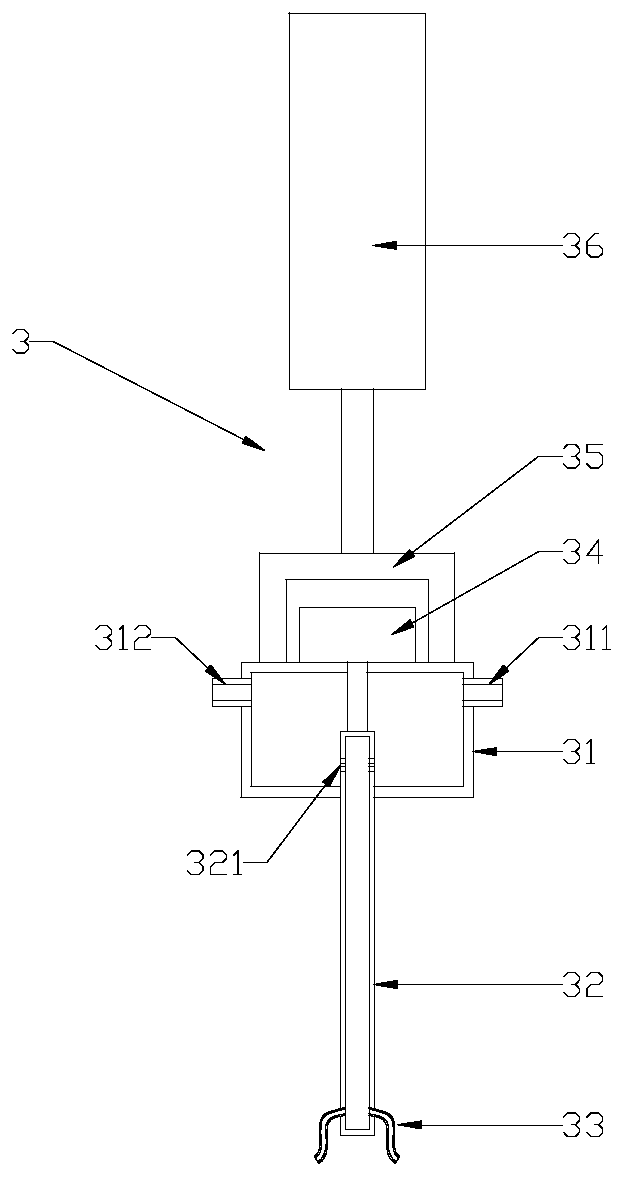

Filtration aiding feeder on horizontal spiral discharge screen centrifuge

ActiveCN104668109ALow fluid contentFacilitate solid-liquid separationRotary centrifugesRotational axisSpiral blade

The invention discloses a filtration aiding feeder on a horizontal spiral discharge screen centrifuge. The centrifuge comprises a shell, a spindle arranged in the shell and a rotary drum sheathed on the spindle, wherein the filtration aiding feeder is arranged on the feeding end of the rotary drum, the filtration aiding feeder comprises a feeding pipe inserted in the shell and a feed screw arranged on the discharge end of the feeding pipe, the feed screw comprises a feeding spiral pipe provided with an inner chamber, a rotating shaft inserted into the feeding spiral pipe and a spiral blade fixedly arranged on the rotating shaft and distributed along the axial direction of the rotating shaft, the front end of the feeding spiral pipe is inserted into the inner chamber of the rotary drum, a feed inlet communicated with the inner chamber of the feeding pipe is formed in the upper pipe wall of the feeding spiral pipe, the filtration aiding feeder further comprises a primary filter device arranged on the inner side of the lower pipe wall of the feeding spiral pipe, and the primary filter device comprises a primary filter screen arranged under the rotating shaft. The filtration aiding feeder has the advantages of simple structure and capabilities of greatly reducing the liquid content of materials entering the rotary drum and greatly improving the solid-liquid separation capacity of the rotary drum.

Owner:JIANGSU PEONY CENTRIFUGE MFG

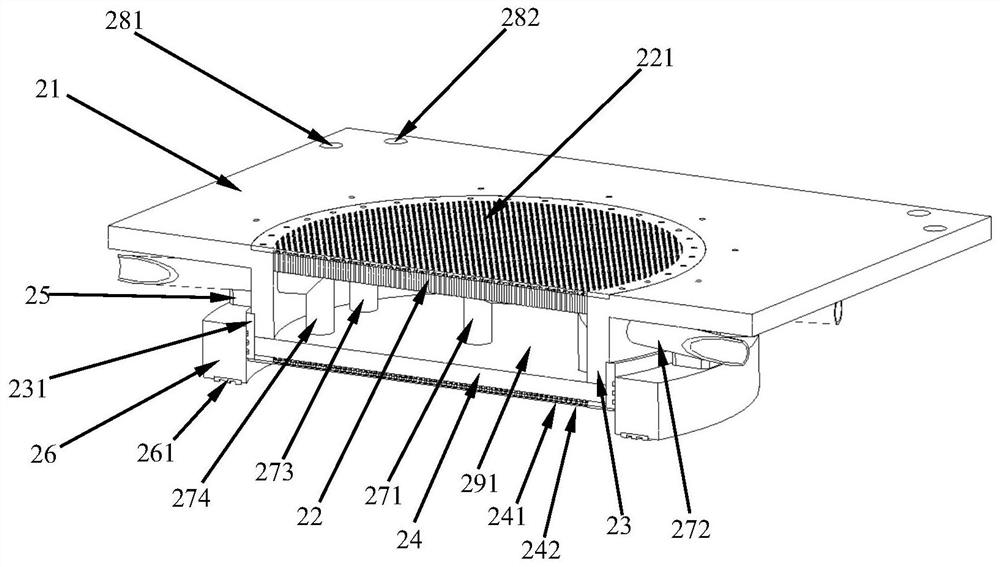

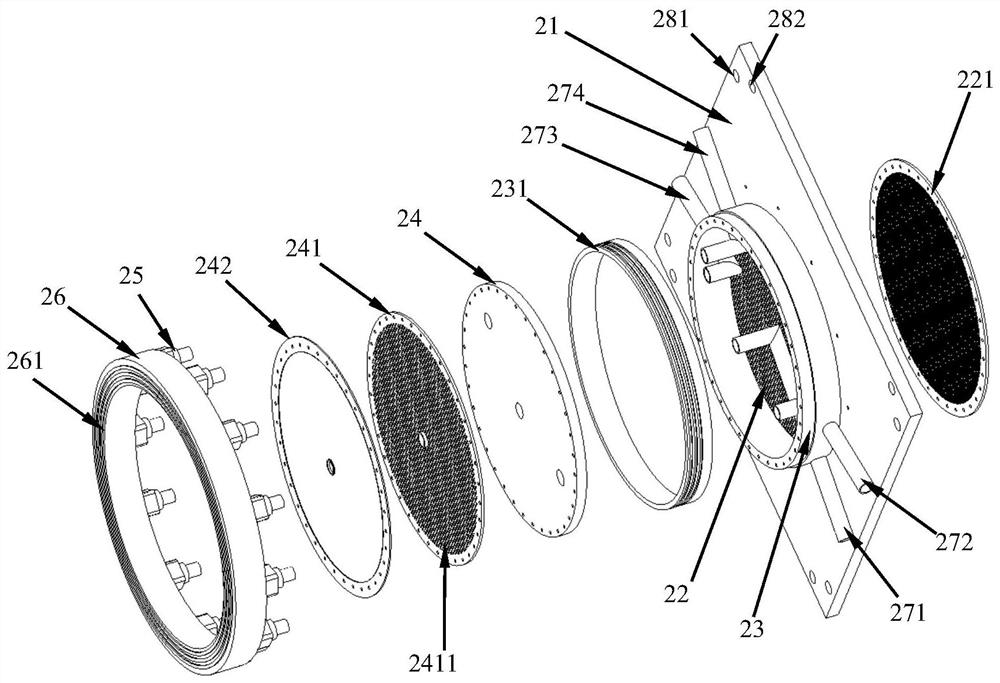

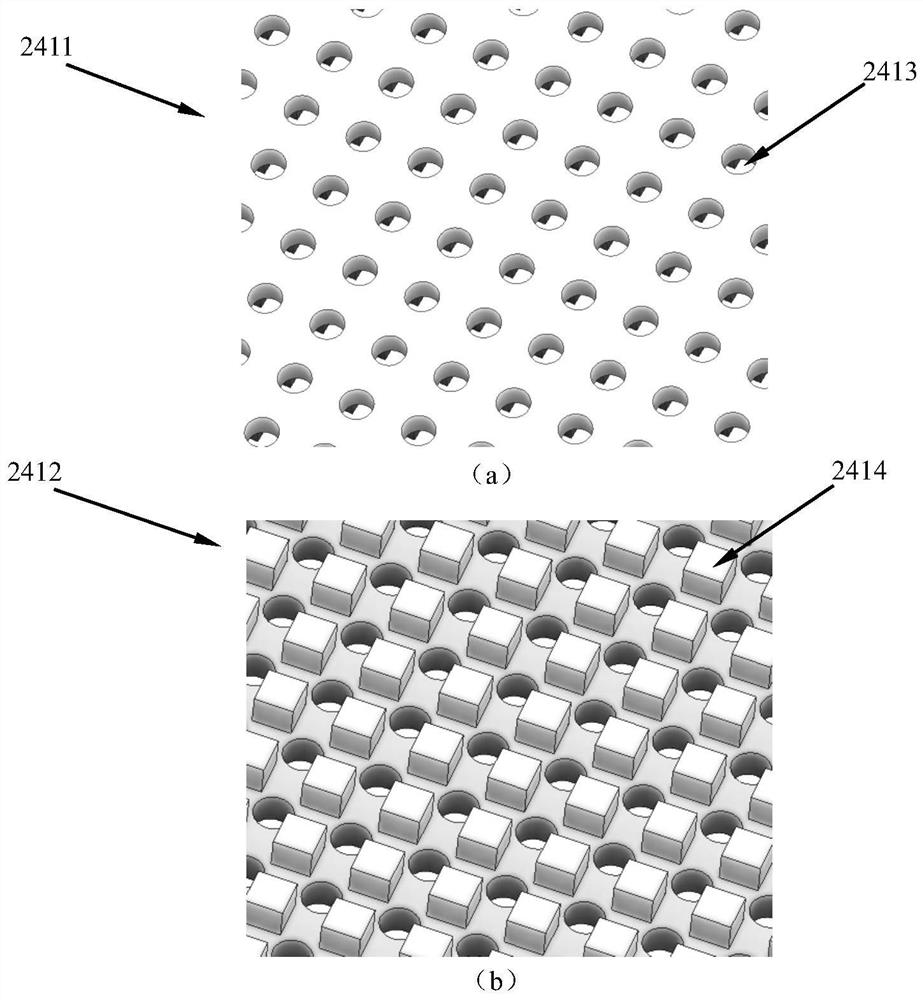

Filter pressing assembly, filter press and filter pressing method

The invention relates to a filter pressing assembly, which comprises a base plate, a through hole area in the middle of the base plate, a piston wall which surrounds the through hole area and extends downwards is arranged on the bottom face of the base plate, and a piston top plate, a channel plate and first filter cloth are sequentially arranged at the bottom end of the piston wall from top to bottom; the piston top plate is provided with a second pipe used for guiding fluid into a groove and a fourth pipe used for discharging the fluid in the groove, the outer surface surrounding the piston wall is sleeved with a piston sleeve, and the lower surface of the first filter cloth and the inner surface of the piston sleeve define a filter pressing cavity, and a first pipe for leading in slurry to be filtered is arranged in the filter pressing cavity. The invention also relates to a filter press comprising the filter pressing assembly and a filter pressing method. The product has the advantages of high operation pressure, high filter pressing speed, low liquid content of a filter cake, reliable structure, convenience in automatic operation and the like, and is particularly suitable for filter pressing of systems difficult to filter, such as activated sludge and pectin.

Owner:金锣水务有限公司

Damp cavity sealed type jogged dissepiment strainer plate and sealing method thereof

ActiveCN101249327BAchieving self-sealingRealize dynamic and static double sealing effectFiltration separationEngineeringHollow core

The invention relates to a chimeric membrane filter plate with the damping sealing performance and a sealing method, a circle line hollow core boss of a membrane embedding part is embedded in a circle line sealing groove in the filter plate and sealed and matched with the circle line groove of the filter plate, one circle or a plurality of circles of lip edges at the bottom of the circle line hollow core boss sleeve in the membrane embedding part are embedded in the filter plate groove, one circle or a plurality of circles of lip edges and the groove surface of the filter plate groove form a self-sealing damping cavity or a linear sealing damping cavity, when the membrane is tympanic, the fluid enters the cavity body of the circle line hollow core boss sleeve by a plurality of fluid inletholes which are positioned around the root part of the hollow core boss sleeve, the fluid also enters the self-sealing damping cavity of the line sealing damping cavity from a plurality of fluid outlet holes which surround the cavity bottom of the self-sealing damping cavity or the linear sealing damping cavity along with the increase of the pressure of the fluid, the pressure of the fluid is directly acted on the lip edges, so as to force the lip edges and the groove surface of the filter plate groove to form the mandatory surface sealing or linear sealing.

Owner:杭州兴源环保设备有限公司

Waste acid and sludge recycling cooperative treatment system

PendingCN114832604AReduce packing cloggingExtend the usage periodDispersed particle separationExhaust fumesProcess engineering

The invention provides waste acid and sludge recycling cooperative treatment equipment. The equipment comprises a supporting unit; the top of the supporting unit is connected with the tower body; the transmission unit is rotationally arranged in the tower body; a transmission unit is arranged in the center of the mass transfer adjusting unit; the demisting unit is arranged at the top end of the mass transfer adjusting unit. Stacked fillers are quantitatively adjusted, so that the fillers at the top can be fully contacted with spraying water under mixing and stirring, the contact area of gas-liquid mass transfer is increased, the fillers at the bottom are pushed and overturned, the blockage of the fillers caused by unidirectional contact is reduced, a small amount of the fillers at the bottom are removed during pushing, and the blockage of the fillers at the bottom is reduced. And the top-layer filler can iterate the bottom-layer filler, so that the stacked filler can comprehensively carry out gas-liquid two-phase mass transfer, and the waste gas purification effect is improved.

Owner:湖州梦源环保科技有限公司

Filter-aid feeder on horizontal screw discharge filter centrifuge

ActiveCN104668109BLow fluid contentFacilitate solid-liquid separationRotary centrifugesHelical bladeFiltration

The invention discloses a filter aid feeder on a horizontal spiral unloading filter centrifuge. The centrifuge includes a casing, a main shaft arranged in the casing, and a rotating drum sleeved on the main shaft. The filter aid feeder is arranged on the feed end of the drum, and the filter feeder includes a feed pipe inserted in the casing, and a feed screw provided on the discharge end of the feed pipe, and the feed screw includes an inner cavity The feeding spiral tube, the rotating shaft inserted in the feeding spiral tube, the spiral blade fixed on the rotating shaft and distributed along its axial direction, the front end of the feeding spiral tube is inserted in the inner cavity of the drum, The upper tube wall of the feeding spiral tube is provided with a feed inlet that communicates with the inner cavity of the feeding tube. The filter aid feeder also includes a primary filter device arranged on the inner side of the lower tube wall of the feeding spiral tube. The primary filter device includes a The primary filter screen under the rotating shaft, the filter feeder has a simple structure, greatly reduces the liquid content of the material entering the drum, and greatly improves the solid-liquid separation capacity of the drum.

Owner:JIANGSU PEONY CENTRIFUGE MFG

Activated carbon cleaning tank

ActiveCN110508267ALow fluid contentSpray evenlyOther chemical processesCombustible gas purificationActivated carbonLiquid waste

The invention discloses an activated carbon cleaning tank, which comprises a tank body, a filtrate tank, a sprayer, a material frame and a pump, the lower side of the tank body is provided with a conical section with a liquid outlet channel which extends into the filtrate tank and is provided with a first electromagnetic valve; the material frame is placed in the tank body; an annular partition net is arranged in the center of the material frame so as to divide the inner cavity into an inner cylinder cavity and an outer ring cavity; the spray head of the sprayer extends into the inner cylindercavity; and the pump is respectively connected with the sprayer and the filtrate tank through hoses. The sprayer is also connected with a washing liquid bottle through a hose; by placing the materialframe filled with activated carbon in the tank body and spraying a cleaning liquid with the sprayer, impurities in the activated carbon are washed away, and waste liquid can be directly subjected toresource treatment or hazardous waste treatment, the activated carbon cleaning tank is convenient and quick; an air cylinder drives a main liquid pipe to move up and down, and a motor drives the mainliquid pipe to rotate at a variable speed, so that an elastic liquid pipe swings up and down telescopically, the outflow direction of a cleaning liquid is continuously changed, and spray dead angles are further reduced.

Owner:浙江威尔森新材料有限公司

Preparation method of high-density lithium iron phosphate cathode material

The invention provides a preparation method of a high-density lithium iron phosphate cathode material, comprising the main steps: mixing reducing iron powder and ferric phosphate according to a certain ratio to obtain a composite iron source; adding deionized water into a ball milling apparatus, adding a lithium source, the composite iron source, a phosphorous source, a carbon source and a surfactant, and performing ball milling to obtain a slurry; injecting the slurry into a diaphragm press filter to carry out solid-liquid separation to obtain a precursor having a solid content of about 85%;drying the precursor in a flash dryer to obtain precursor powder having a liquid content of less than 1%; sintering the precursor powder in a kiln with a protective atmosphere, cooling, and performingjet crushing to obtain lithium iron phosphate powder. The preparation method has the advantages that the method is simple, the cost is low and the finished material has good electrochemical properties.

Owner:江西省金锂科技股份有限公司

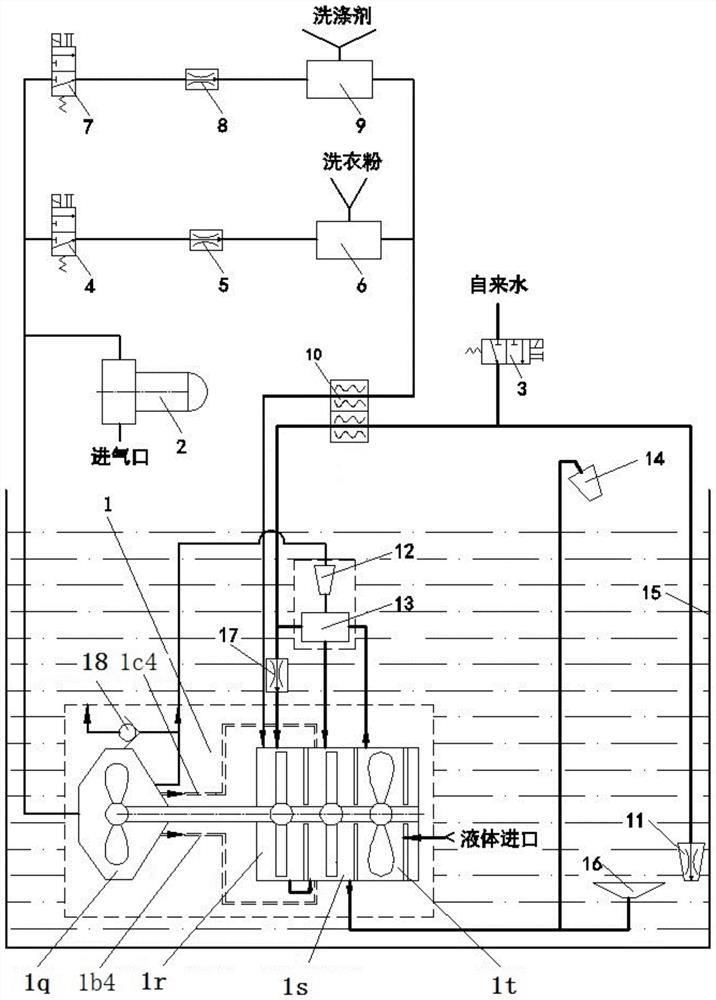

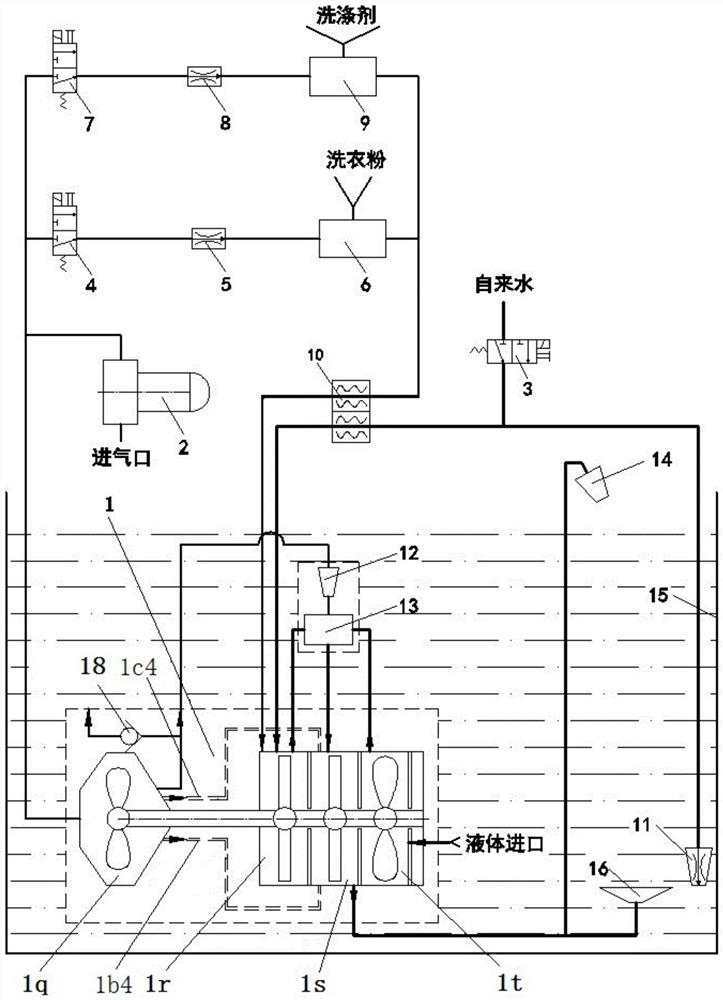

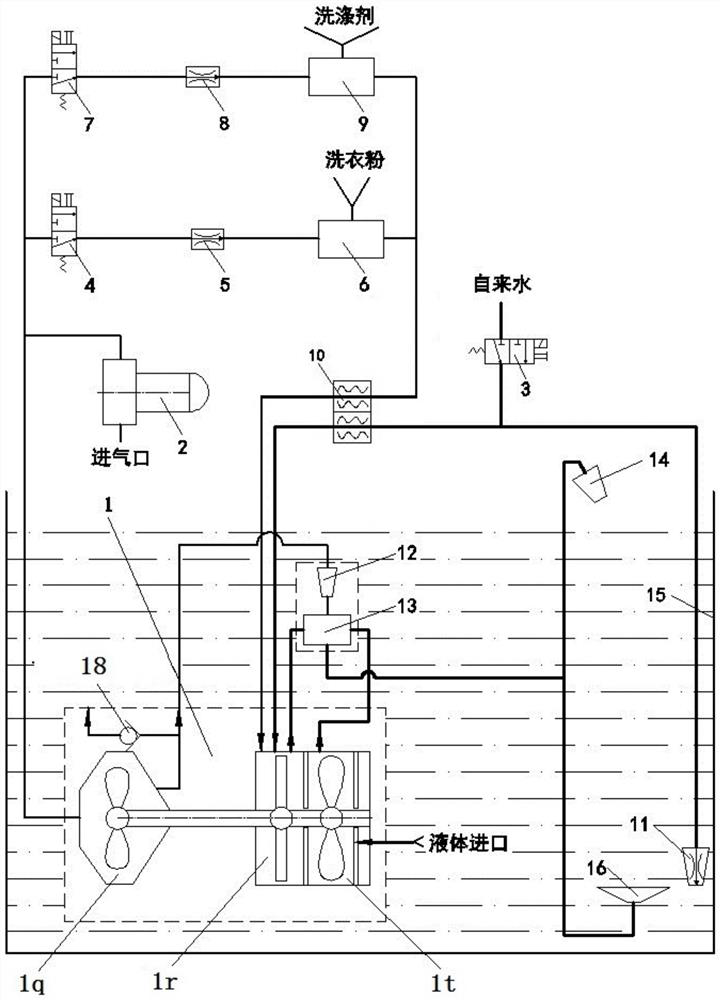

Washing and disinfecting method and washing and disinfecting device for heating air current containing detergent or washing powder and preparing air current into foam flow

ActiveCN111648099AEasy to adjust the densityIncrease elasticityOther washing machinesTextiles and paperLaundry washing machineWastewater

The invention relates to the technical fields of industrial, agricultural, commercial and household washing and cleaning equipment, in particular to a washing and disinfecting method and a washing anddisinfecting device for heating air current containing a detergent or washing powder and preparing the air current into foam flow. The washing and disinfecting method and the washing and disinfectingdevice are suitable for washing equipment such as household washing machines, vegetable washers and dish-washing machines; and the washing and disinfecting device consists of a wind-powered shear mixing type foam fluid generating device, a gas booster pump, a water inlet valve, a quantitative and consistent pneumatic conveying system for the washing powder (a switching valve I, a throttling valveI and pneumatic transmission I for transmitting the washing powder, as well as a switching valve II, a throttling valve II and pneumatic transmission II for transmitting the detergent, a gas-water pipe electric heater, a damping water draining outlet, a reducing pipe, a palisade microporous bubbler, an upper spraying nozzle, a vessel cylinder, a lower spraying nozzle and a throttling water valve.In the washing and disinfecting method and the washing and disinfecting device disclosed by the invention, a material of micronanometer foam flow has good penetrability and dirt portability, so thata good washing effect is realized; and as high dissolved oxygen washing water is produced, the dyeability of fallen dye substance is removed, and the contaminability of wastewater is reduced.

Owner:JIANGNAN UNIV

Dairy farm sewage treatment device and treatment method thereof

PendingCN110342772ARealize solid-liquid separationAchieve the purpose of purificationSludge treatmentWater/sewage treatment with mechanical oscillationsFiltrationWastewater

The invention relates to a dairy farm sewage treatment device and a treatment method thereof. The dairy farm sewage treatment device comprises a solid-liquid separation device, an osmotic membrane filtration device, an ultrasonic sterilization actuator and a waste storage tank; waste in the waste storage tank is conveyed to the solid-liquid separation device for solid-liquid separation, and wastewater mixture separated from the solid-liquid separation is conveyed to the osmotic membrane filtration device for filtration, and clear liquid from the osmotic membrane filtration device can be conveyed to the ultrasonic sterilizer actuator for sterilization; and the dairy farm sewage treatment device realizes the efficient separation and degradation of pollutants, and residual colon bacillus inthe clear liquid is treated through an ultra-high power ultrasonic, the sterilization rate reaches 100%, the whole treatment system is convenient to maintain, the treatment cost is lowered, and the operation and management are simple and convenient.

Owner:江苏连昌环保设备有限公司

Method for manufacturing reusing substances from household kitchen wastes

ActiveCN110560457AImprove exudation rateEasy dischargeFeeding-stuffFood processingMolding machineFlue gas

The invention discloses a method for manufacturing reusing substances from household kitchen wastes. The method comprises the steps of obtaining manufacturing equipment which comprises a crusher, an extrusion molding machine, a discharging guide mechanism, a drying mechanism, a waste heat drying cavity and a waste heat flue gas circulation pipeline, and opening the waste heat flue gas circulationpipeline to introduce hot flue gas into the extrusion molding machine, wherein the waste heat flue gas temperature is 100-200 DEG C, and the preheating time is 5-10 minutes; preheating the extrusion molding machine for 3-5 minutes; turning on a heat radiation source of the drying mechanism, setting the heating temperature of 200-280 DEG C, and preheating a material conveying device of the drying mechanism for 1-3 minutes; mixing the household kitchen wastes and straw powder according to a ratio of 3:1-5:1, adding 3%-6% modified starch, and feeding the mixture into the crusher for crushing; feeding the crushed materials into the extrusion molding machine, keeping extrusion heat conduction for 5 seconds, and performing extrusion molding; placing the extruded materials into the drying mechanism, and controlling the drying time of the materials to be 20 seconds; and conveying the dried materials to the waste heat drying cavity, drying the materials by using the waste heat, and then storingthe materials.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of high-density lithium iron phosphate cathode material

ActiveCN108529584BHigh densityHigh tap densitySecondary cellsPositive electrodesPhosphateActive agent

The invention provides a preparation method of a high-density lithium iron phosphate cathode material, comprising the main steps: mixing reducing iron powder and ferric phosphate according to a certain ratio to obtain a composite iron source; adding deionized water into a ball milling apparatus, adding a lithium source, the composite iron source, a phosphorous source, a carbon source and a surfactant, and performing ball milling to obtain a slurry; injecting the slurry into a diaphragm press filter to carry out solid-liquid separation to obtain a precursor having a solid content of about 85%;drying the precursor in a flash dryer to obtain precursor powder having a liquid content of less than 1%; sintering the precursor powder in a kiln with a protective atmosphere, cooling, and performingjet crushing to obtain lithium iron phosphate powder. The preparation method has the advantages that the method is simple, the cost is low and the finished material has good electrochemical properties.

Owner:江西省金锂科技股份有限公司

Household kitchen garbage treatment device

The invention provides a household kitchen garbage treatment device, and belongs to the technical field of garbage treatment. The household kitchen garbage treatment device comprises a pipe body, wherein a containing plate is slidably connected into the pipe body; a movable rod is connected below the containing plate; a drain pipe is inserted into the movable rod; treatment seats are symmetricallyinserted into the pipe body; movable pieces are slidably connected into the treatment seats; magnetic pieces are connected to the sides, opposite to each other, of the movable pieces; electromagnetscorresponding to the magnetic pieces are arranged on the treatment seats; and an on-off mechanism is arranged in the treatment seat on the right side. According to the household kitchen garbage treatment device, through the mutual connection and combination effects of the containing plate, the electromagnets, the movable pieces, the treatment seats, the drain pipe, a blocking piece and the on-offstructure, garbage and sewage are effectively prevented from dripping into a house and the ground of a path for conveying the garbage to a garbage concentration area, the adverse effect of the garbageon the cleanliness of the house and community environment is reduced, the degree of foul smells generated by rotting of the garbage is relatively reduced due to the fact that the liquid content in the garbage is reduced, and meanwhile, the garbage collection stability is improved.

Owner:陈秀爱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com