Washing and disinfecting method and washing and disinfecting device for heating air current containing detergent or washing powder and preparing air current into foam flow

A disinfection method and detergent technology, which can be used in washing devices, other washing machines, textiles and papermaking, etc., and can solve the problems of energy consumption and slow addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

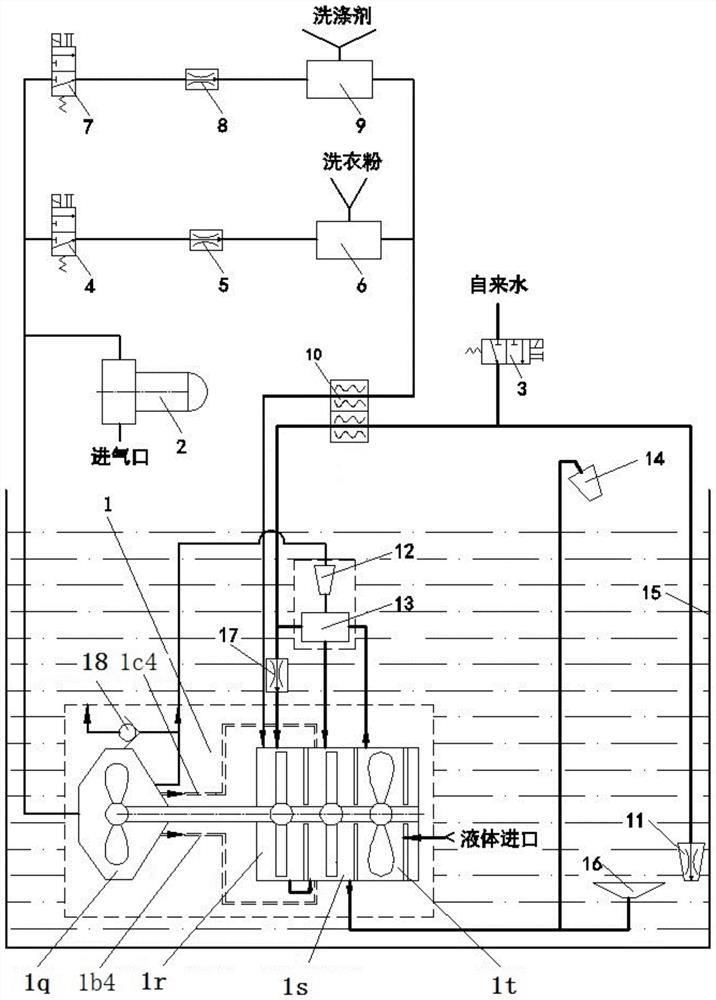

[0072] as attached figure 1 As shown, the washing and disinfection method of detergent or powder mixed with bubble water as foam flow is as follows:

[0073] ① At the beginning of the washing stage, on the control panel, select "detergent" or "washing powder", select the corresponding amount of washing water; press the start button, the water inlet valve 3 is opened for the first time, and the tap water first passes through the microporous bubbler of the fence After 13, it enters the shear mixing chamber 1s of the wind-driven shear-mixing foam fluid generating device 1, the second path passes through the throttling water valve 17, enters the agent powder air-water mixing chamber 1r, and the third path enters the container barrel through the damping water outlet 11 15; the throttling water valve 17 and the damping water outlet 11 have a small damping coefficient, and are used to balance the inlet pressure of the fence micropore bubbler 13, mainly to ensure that gas and tap wate...

Embodiment 2

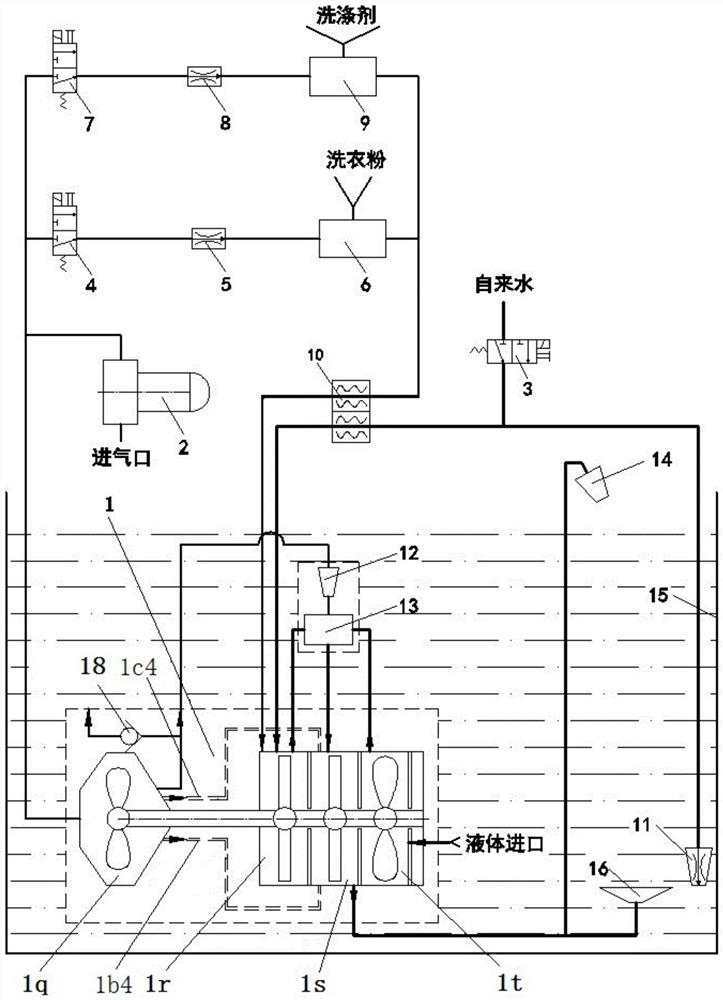

[0095] as attached figure 2 shown, with the attached figure 1 Compared with Embodiment 1, the throttling water valve 17 is removed; in Embodiment 2, the connection relationship between the liquid path and the gas path is:

[0096] The first output of the water inlet valve 3 is connected to the damping water outlet 11, and the tap water of the damping water outlet 11 enters the container barrel 15; the second road is connected to the water inlet of the powder-air-water mixing chamber 1r;

[0097] The main outlet of the gas booster pump 2 is connected to the air cavity 1q of the wind-driven shear-mixing foam fluid generating device 1, and the outlet branches of the gas booster pump 2 are respectively connected to the switch valve 1 4 and the switch valve 2 7; the switch valve 1 4 Connect throttle valve one 5, connect pneumatic conveying one 6, and pneumatic conveying one 6 connect the agent-powder air-water mixing chamber 1r of wind-force shear-mixing foam fluid generating dev...

Embodiment 3

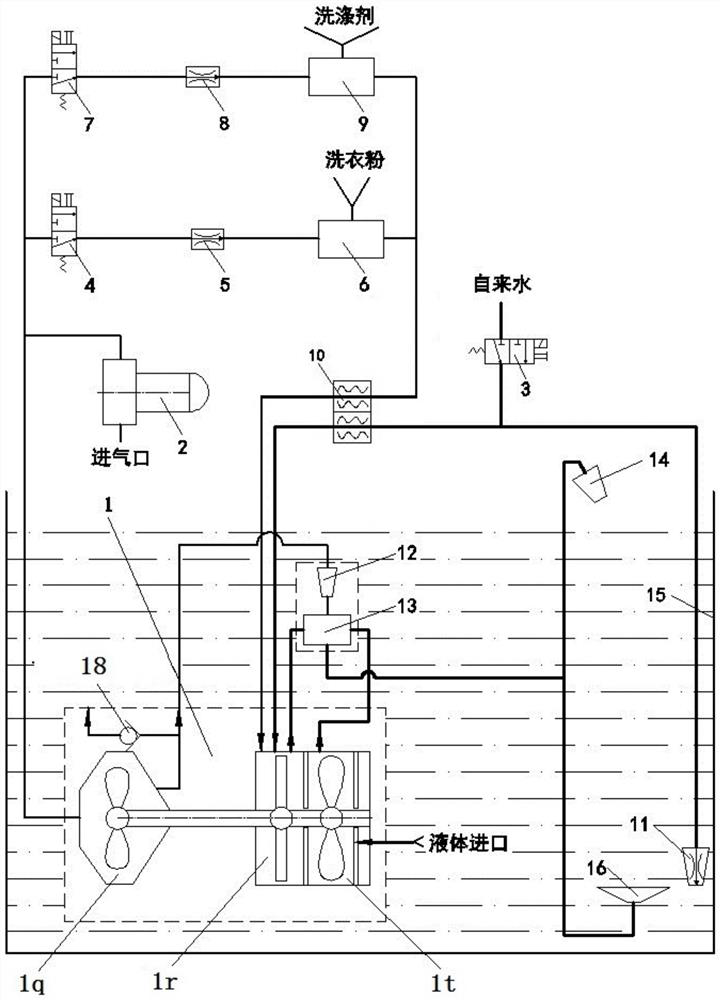

[0101] as attached image 3 shown, with the attached figure 2 Compared with Embodiment 2, the shear mixing chamber 1s and a group of distributed small pores of the wind-driven shear-mixing foam fluid generating device 1 are removed; the connection relationship between the liquid path and the gas path of Embodiment 3 is:

[0102] The first output of the water inlet valve 3 is connected to the damping water outlet 11, and the tap water of the damping water outlet 11 enters the container barrel 15; the second road is connected to the water inlet of the powder-air-water mixing chamber 1r;

[0103] The main outlet of the gas booster pump 2 is connected to the air cavity 1q of the wind-driven shear-mixing foam fluid generating device 1, and the outlet branches of the gas booster pump 2 are respectively connected to the switch valve 1 4 and the switch valve 2 7; the switch valve 1 4 Connect throttle valve one 5, connect pneumatic conveying one 6, and pneumatic conveying one 6 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com